The Direct Sandwich Composite Molding (D-SCM) Process: Sandwich Manufacturing and Characterization

Abstract

:1. Introduction

2. The Direct Sandwich Composite Molding (D-SCM) Process Strategy

3. Materials and Methods

3.1. Materials

3.2. Experimental Setup

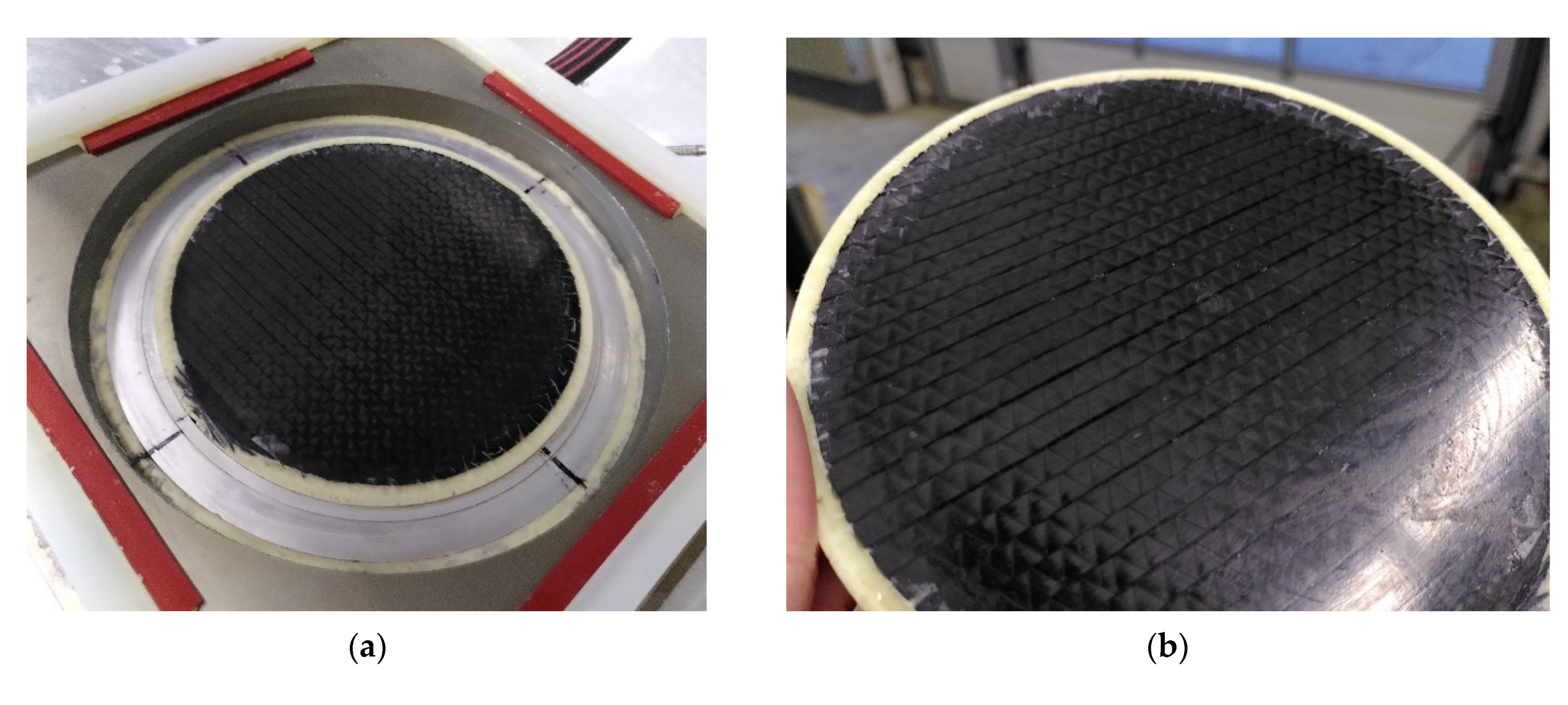

3.3. Sandwich Specimen Manufacturing

3.4. Characterization Methods

3.4.1. Thermogravimetric Analysis of the Face Sheets

- Drying of the specimens for 6 h at 100 °C.

- Pyrolysis of the specimens in nitrogen atmosphere:

- ○

- Heating rate: 2 K/min.

- ○

- Pyrolysis temperature: 430 °C.

- ○

- Pyrolysis duration: 20 h.

3.4.2. Tensile Characterization of the Face Sheets

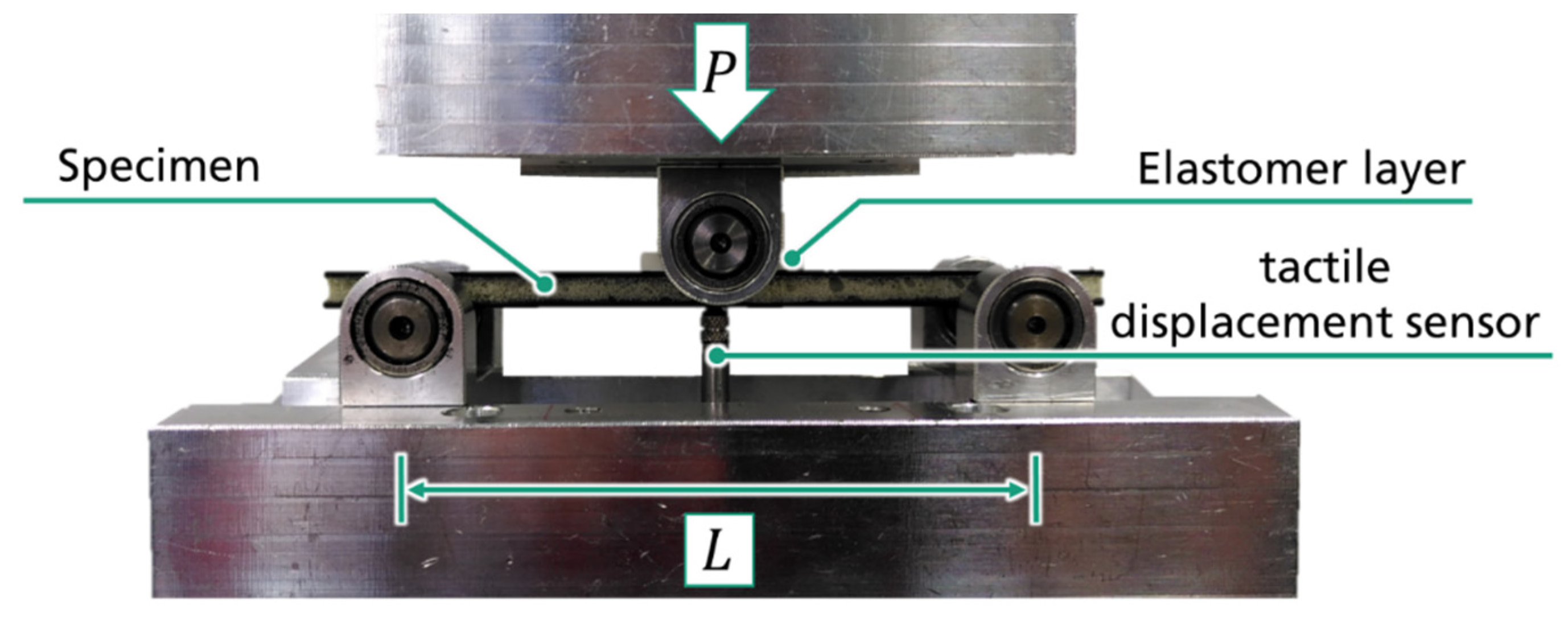

3.4.3. Three-Point Bending Characterization of Sandwich Structure

4. Results

4.1. The D-SCM Manufacturing Process

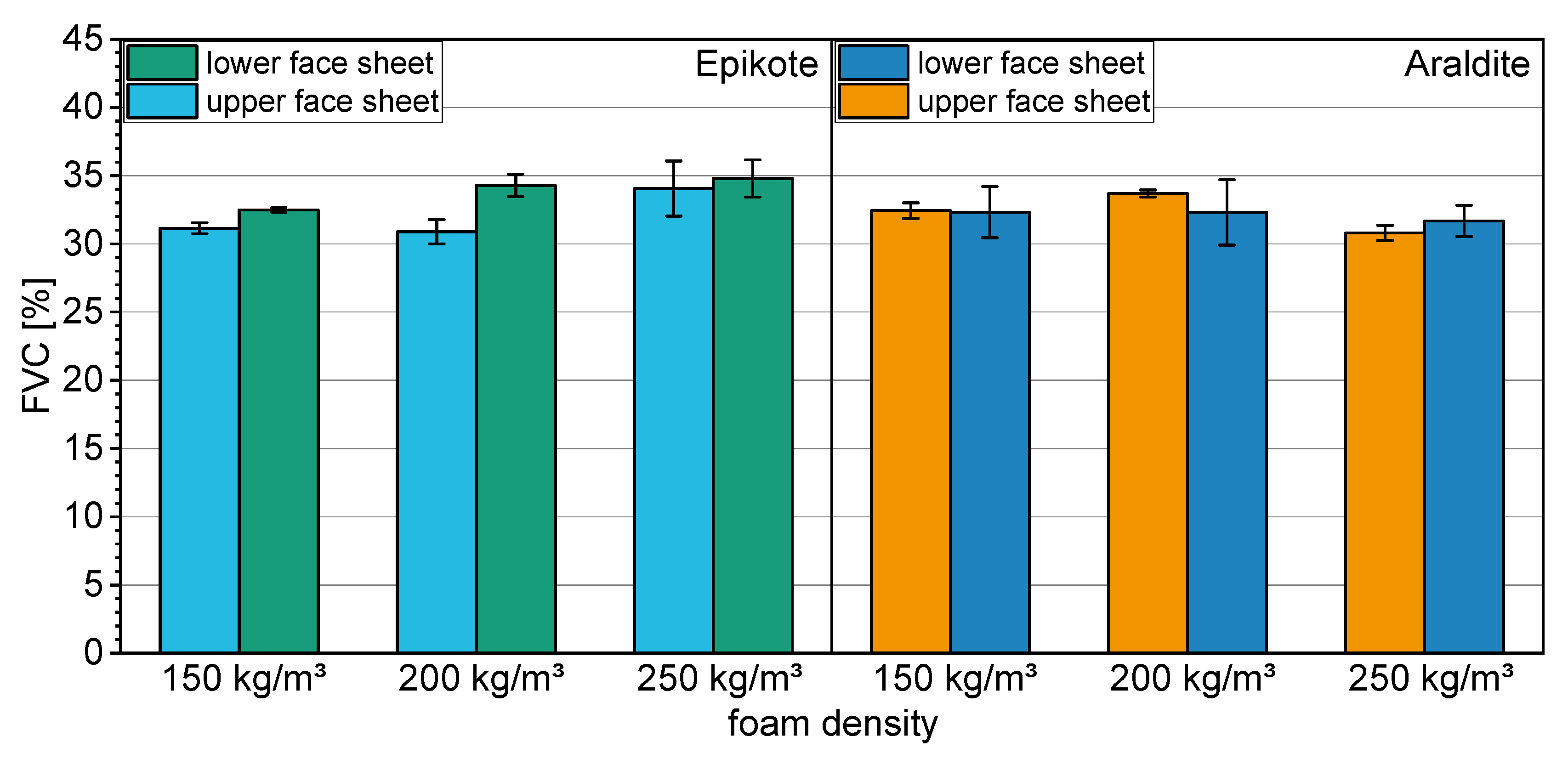

4.2. Fiber Volume Content of the Face Sheets

4.3. Stiffness of the Face Sheets

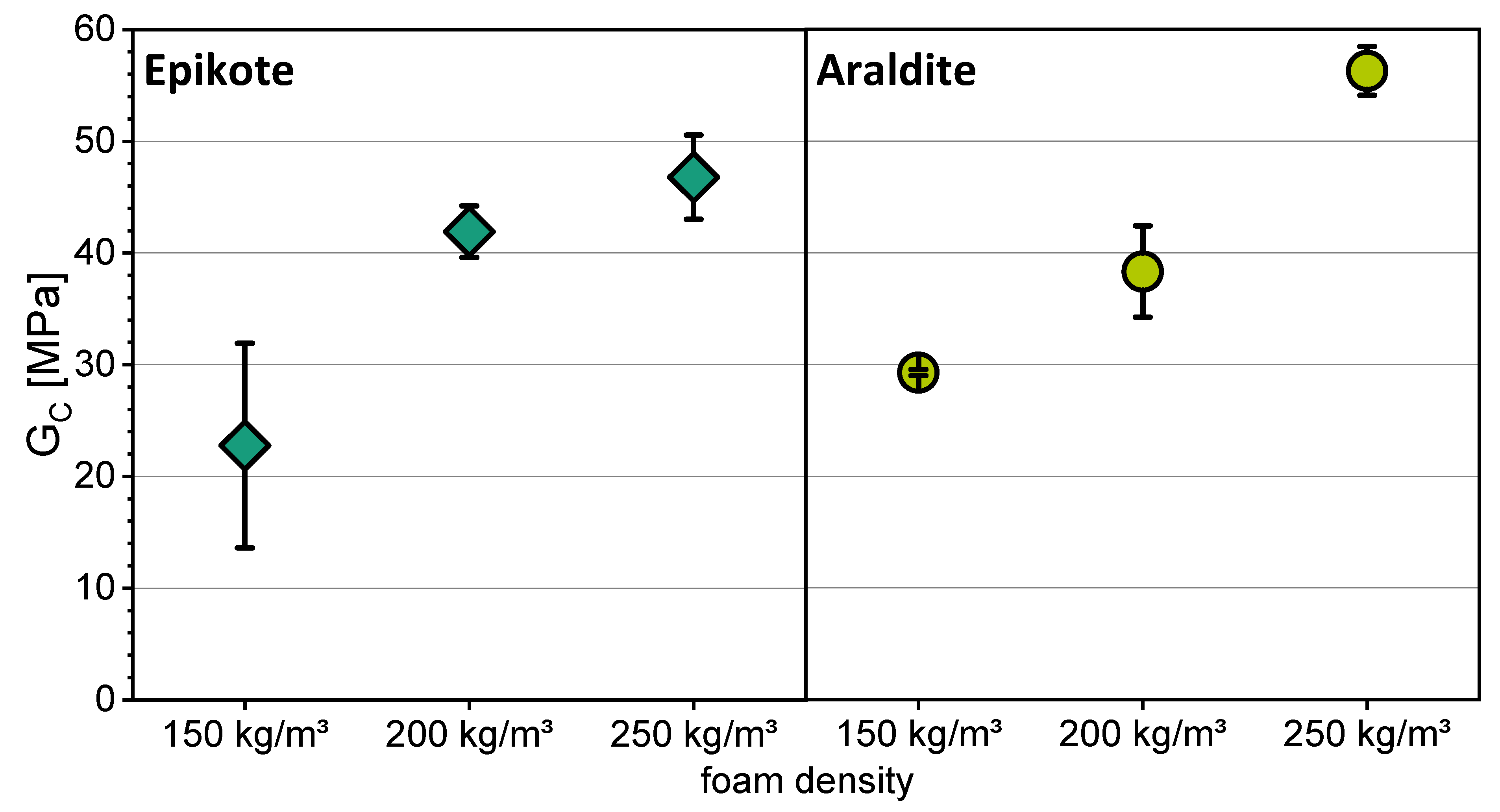

4.4. Three-Point Bending Behavior of the D-SCM Sandwich Structures

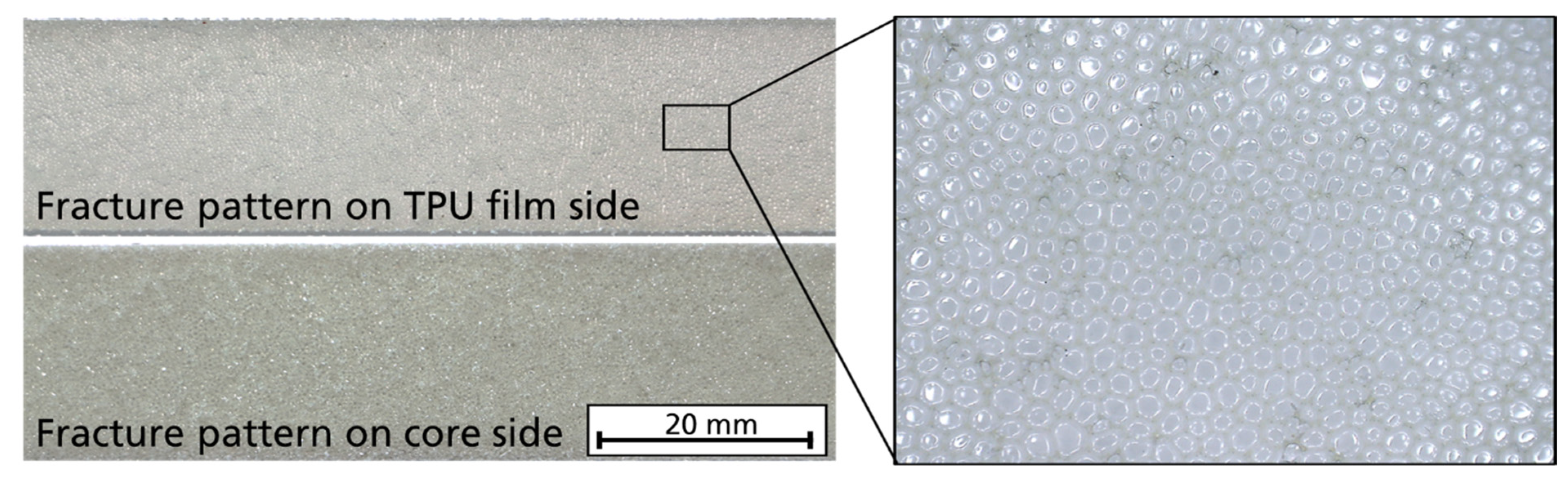

5. Discussion

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Composites Industry Association. Carbon Fiber LCA Data in EcoCalculator: An Essential Extension; Composites Europe: Stuttgart, Germany, 2018. [Google Scholar]

- Vinson, J.R. Sandwich Structures. Appl. Mech. Rev. 2001, 54, 201–214. [Google Scholar] [CrossRef]

- Zenkert, D. An Introduction to Sandwich Structures—Student Edition; Engineering Materials Advisory Services Publishing: Birmingham, UK, 1995; ISBN 978-0947817770. [Google Scholar]

- Zenkert, D.; Nordic Industrial Fund. The Handbook of Sandwich Construction; Engineering Materials Advisory Services Publishing: Birmingham, UK, 1997; ISBN 978-0947817961. [Google Scholar]

- Thomsen, O.T.; Bozhevolnaya, E.; Lyckegaard, A. (Eds.) Sandwich Structures Technology in Commercial Aviation. In Sandwich Structures 7: Advancing with Sandwich Structures and Materials, Proceedings of the 7th International Conference on Sand-wich Structures, Aalborg University, Aalborg, Denmark, 29–31 August 2005; Springer: Dordrecht, The Netherlands, 2005; ISBN 978-1-4020-3444-2. [Google Scholar]

- Gerstenkorn, J. Entwicklung einer Methodik zur Analyse und Vorhersage des Mechanischen Verhaltens Polymerer Hartschäume im RTM-Prozess. Ph.D. Thesis, Karlsruher Institute for Technology, Karlsruhe, Germany, 2021. [Google Scholar]

- Rosenberg, P. Entwicklung einer RTM Prozessvariante zur Kavitätsdruckgeregelten Herstellung von Faserverbundstrukturbauteilen. Ph.D. Thesis, Karlsruher Institute for Technology, Karlsruhe, Germany, 2018. [Google Scholar]

- Seibert, H.F. Applications for PMI foams in aerospace sandwich structures. Reinf. Plast. 2006, 50, 44–48. [Google Scholar] [CrossRef]

- Ware, M. Thermal Expansion Resin Transfer Molding (TERTM)—A Manufacturing Process for RP Sandwich Core Structures. In Proceedings of the 40th Annual Conference, Atlanta, GA, USA, 28 January–1 February 1985; Reinforced Plastics/Composite Institute: New York, NY, USA; The Society of Plastic Industry, Inc.: New York, NY, USA, 1985. [Google Scholar]

- Ware, M. Thermal Expansion Resin Transfer Molding(TERTM)—An Advanced Composite Mass Production Process. In Society of Manufacturing Engineers, Proceedings of the 5th Conference on Composites in Manufacturing, Los Angeles, CA, USA, 13–16 January 1986; Society of Manufacturing Engineers: Southfield, MI, USA.

- Burr, S.T.; Tudor, J.M.; Athreya, S.R.; Parsons, T.J. Expanding Foam Core Prepreg. PCT/US2013/070033, 14 November 2013. [Google Scholar]

- Beukers, A. A new technology for sandwich plates and structures based on the use of in-situ foamable thermoplastic films. In Proceedings of the 37th International SAMPE Symposium and Exhibition, Anaheim, CA, USA, 9–12 March 1992; pp. 172–185. [Google Scholar]

- Hopmann, C.; Karatzias, C.; Böttcher, A. Syntaktische Schäume zur einstufigen Sandwichherstellung von FVK. Lightweight Des. 2016, 9, 44–51. [Google Scholar] [CrossRef]

- Weißenborn, O. Entwicklung eines Neuartigen Imprägnierschäumverfahrens zur Herstellung Komplex Geformter Polyurethan-Sandwichverbundstrukturen. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2020. [Google Scholar]

- Weißenborn, O.; Geller, S.; Jaschinski, J.; Gude, M. Modelling the bending behaviour of novel fibre-reinforced sandwich structures with polyurethane foam core. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012073. [Google Scholar] [CrossRef]

- Hopmann, C.; Wagner, R.; Fischer, K.; Böttcher, A. One Step Production of High-performance Sandwich Components. Cell. Polym. 2018, 36, 135–150. [Google Scholar] [CrossRef]

- Hopmann, C.; Riedel, R.; Karatzias, C. Strukturelle Sandwichbauteile mit prozessintegriert ausgeschäumtem Schaumkern. Fachmag. Für Die Polyurethanindustrie 2015, 91, 11–12. [Google Scholar]

- Behnisch, F.; Lichtner, V.; Henning, F.; Rosenberg, P. Development of a Reactive Polyurethane Foam System for the Direct Sandwich Composite Molding (D-SCM) Process. J. Compos. Sci. 2021, 5, 104. [Google Scholar] [CrossRef]

- ZOLTEK Corporation (Toray Group). ZOLTEK™ PX35 Multi-Directional Fabrics; Technical Datasheet; ZOLTEK Corporation (Toray Group): Bridgeton, MO, USA, 2021. [Google Scholar]

- Hexion™ Inc. Datenblatt EPIKOTE™ Resin Trac 06170; Hexion Inc.: Columbus, OH, USA, 2017. [Google Scholar]

- Huntsman Corporation. Datenblatt Araldite® LY 3031/Aradur® 3032; Huntsman Corporation: The Woodlands, Texas, USA, 2015. [Google Scholar]

- Rühl Puromer GmbH. Datenblatt Rühl Puromer EP 3587/2; Rühl Puromer GmbH: Friedrichsdorf, Germany, 2017. [Google Scholar]

- Bücheler, D.; Kaiser, A.; Henning, F. Using Thermogravimetric Analysis to Determine Carbon Fiber Weight Percentage of Fiber-Reinforced Plastics. Compos. Part B Eng. 2016, 106, 218–223. [Google Scholar] [CrossRef]

- BASF, SE. Elastollan®—Physikalische Eigenschaften. Available online: https://plastics-rubber.basf.com/emea/de/performance_polymers/products/elastollan.html?at_medium=sl&at_campaign=PM_BAW_EMEA_DE_Elastollan_TRA_CROSS&at_term=%2Btpu%20%2Bfolie&at_creation=Search_Google_SERP_Elastollan-General-EMEA-DE&at_platform=google&at_variant=Elastollan-General-EMEA-DE (accessed on 12 December 2021).

- Xiong, J.; Ma, L.; Wu, L.; Liu, J.; Vaziri, A. Mechanical behavior and failure of composite pyramidal truss core sandwich columns. Compos. Part B Eng. 2011, 42, 938–945. [Google Scholar] [CrossRef]

- Wesolowski, M.; Ludewicz, J.; Domski, J.; Zakrzewski, M. Shear properties evaluation of a truss core of sandwich beams. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012085. [Google Scholar] [CrossRef] [Green Version]

- Allen, H.G. Analysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics Division; Elsevier: Oxford, UK, 2013; ISBN 978-1483126623. [Google Scholar]

- Gaugler & Lutz OHG. Produktübersicht: Ihr Starker Partner für den Leicht- und Sandwichbau. June 2019. Available online: https://www.gaugler-lutz.de/fileadmin/user_upload/Unternehmen/Produktuebersicht_LS_DE.pdf (accessed on 12 December 2021).

- Minogue, E. An In-Situ Study of the Nucleation Process of Polyurethane Rigid Foam Formation. Ph.D. Thesis, Dublin City University, Dublin, Ireland, 2000. [Google Scholar]

- Lander, R.; Modro, H.; Hubel, R. Influencing the Cell Structure of Flexible Polyurethane Foams by Additives. In Proceedings of the 2014 Polyurethane Technical Conference, Dallas, TX, USA, 22–24 September 2014; pp. 22–24. [Google Scholar]

| Epoxy System | Foam Core Density | Foam Core Material | Face Sheet Material | Curing Time |

|---|---|---|---|---|

| Araldite | 150 g/L | 10.6 g | 9.5 g | 300 s |

| Araldite | 200 g/L | 14.1 g | 9.5 g | 300 s |

| Araldite | 250 g/L | 17.7 g | 9.5 g | 300 s |

| Epikote | 150 g/L | 10.6 g | 9.5 g | 600 s |

| Epikote | 200 g/L | 14.1 g | 9.5 g | 600 s |

| Epikote | 250 g/L | 17.7 g | 9.5 g | 600 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behnisch, F.; Brütsch, J.; Werner, H.O.; Henning, F. The Direct Sandwich Composite Molding (D-SCM) Process: Sandwich Manufacturing and Characterization. J. Compos. Sci. 2022, 6, 81. https://doi.org/10.3390/jcs6030081

Behnisch F, Brütsch J, Werner HO, Henning F. The Direct Sandwich Composite Molding (D-SCM) Process: Sandwich Manufacturing and Characterization. Journal of Composites Science. 2022; 6(3):81. https://doi.org/10.3390/jcs6030081

Chicago/Turabian StyleBehnisch, Felix, Jonathan Brütsch, Henrik O. Werner, and Frank Henning. 2022. "The Direct Sandwich Composite Molding (D-SCM) Process: Sandwich Manufacturing and Characterization" Journal of Composites Science 6, no. 3: 81. https://doi.org/10.3390/jcs6030081

APA StyleBehnisch, F., Brütsch, J., Werner, H. O., & Henning, F. (2022). The Direct Sandwich Composite Molding (D-SCM) Process: Sandwich Manufacturing and Characterization. Journal of Composites Science, 6(3), 81. https://doi.org/10.3390/jcs6030081