Isosteric Enthalpy Behavior of CO2 Adsorption on Micro-Mesoporous Materials: Carbon Microfibers (CMFs), SBA-15, and Amine-Functionalized SBA-15

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. SBA-15 and SBA-15_APTES Synthesis

2.3. Carbon Microfiber Synthesis

2.4. Characterization Techniques

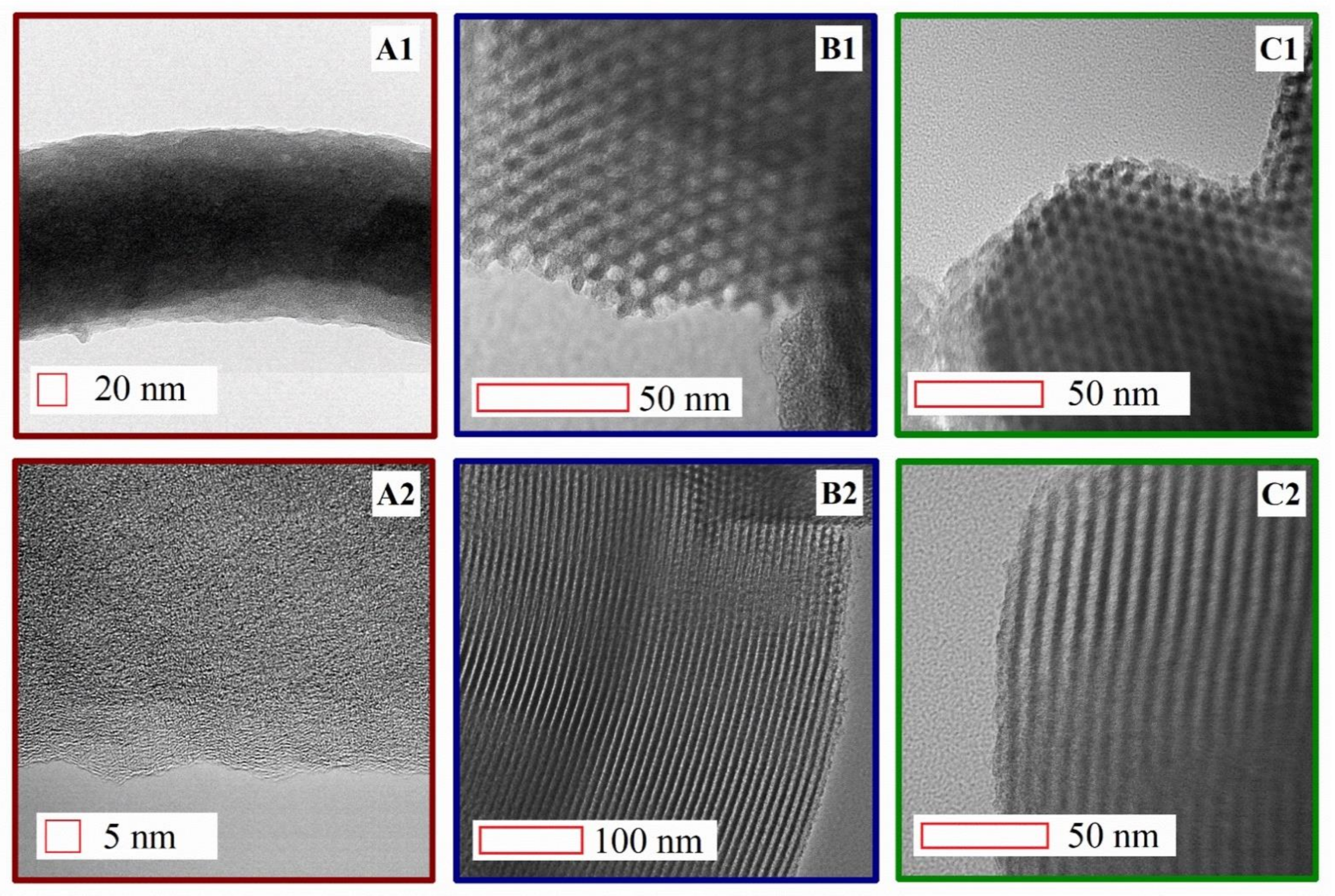

2.4.1. Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM)

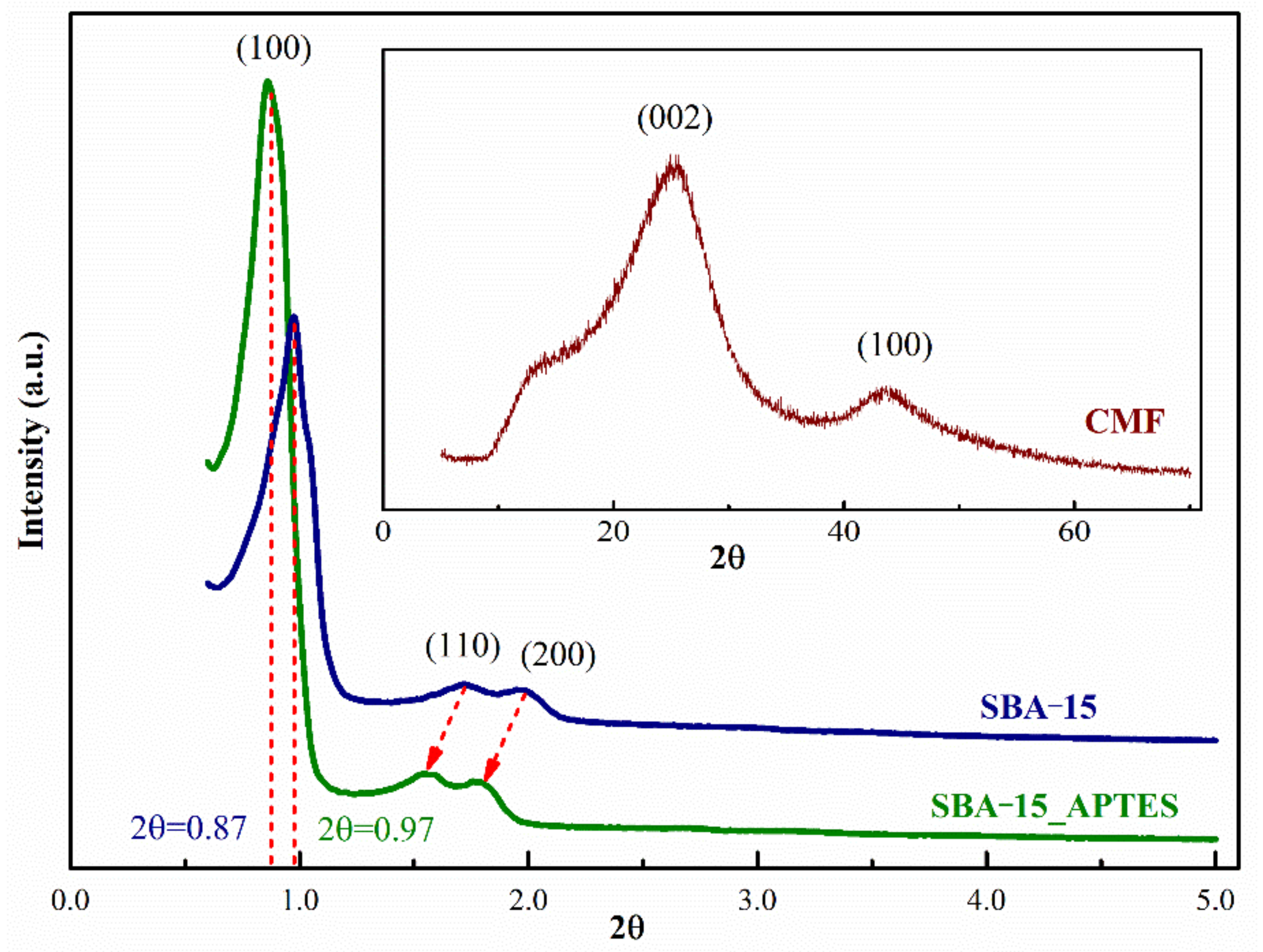

2.4.2. X-ray Diffraction (XRD)

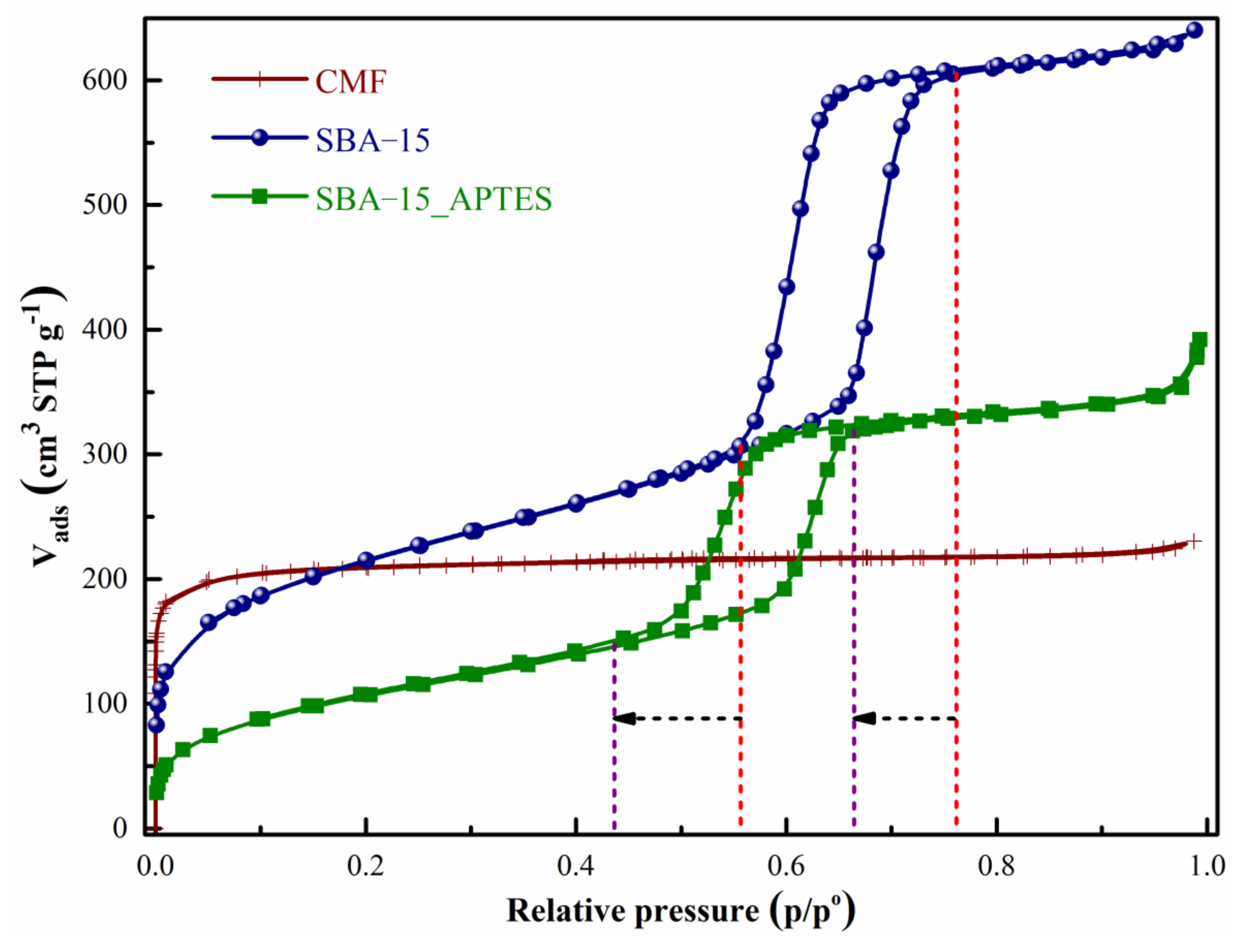

2.4.3. Nitrogen Adsorption/Desorption (77 K)

2.4.4. Nuclear Magnetic Resonance (NMR)

2.4.5. X-ray Photoelectron Spectrometry (XPS)

2.4.6. CO2 Adsorption Measurement (263–303 K)

3. Results and Discussion

4. Conclusions

- (a)

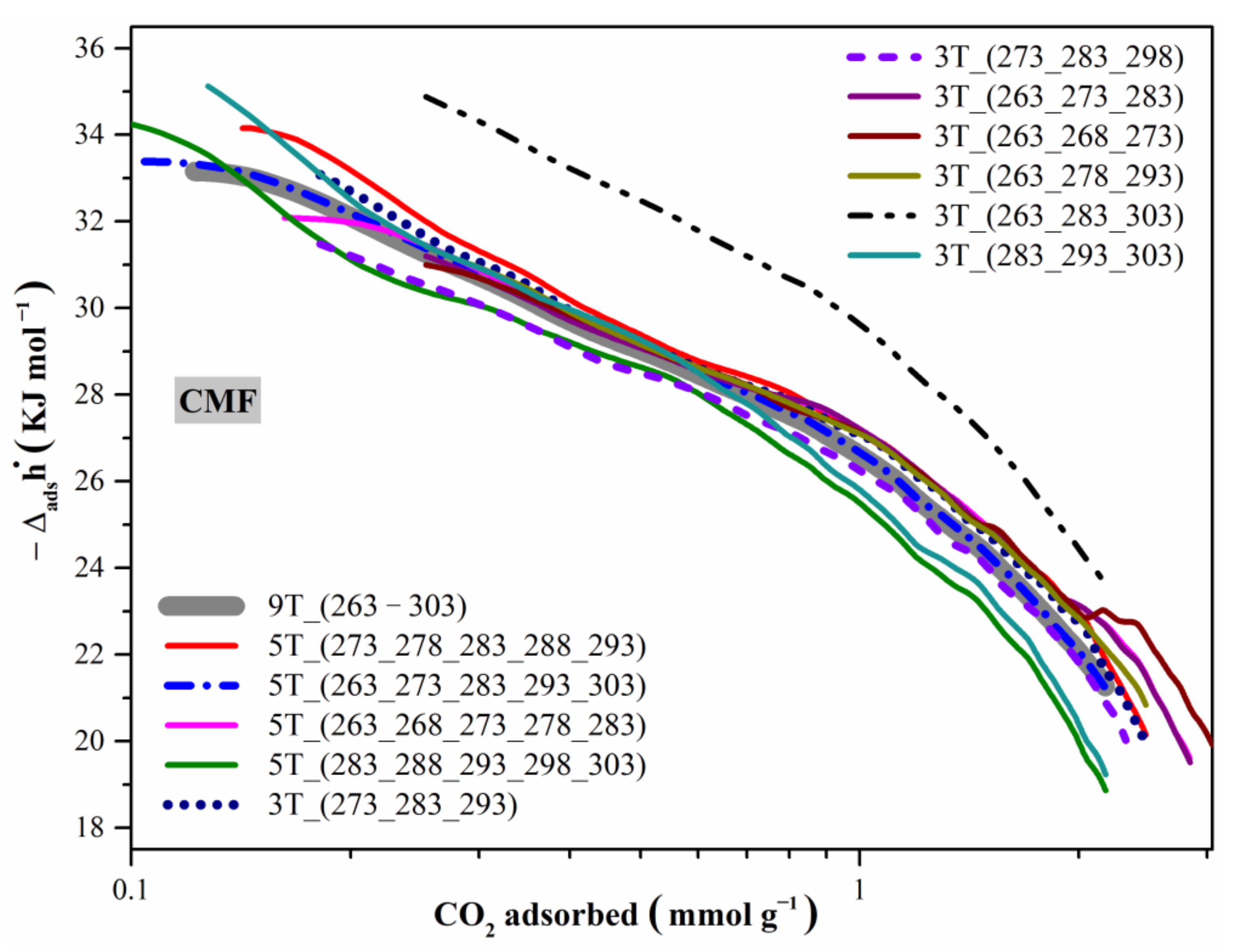

- CMF is a microporous material with a specific surface area of 805 m2 g−1 and a chemical surface with nitrogen and oxygen functional groups, at 298 K and 1 bar; this material adsorbed 2.32 mmol CO2 g−1 with a value of -30 KJ mol−1 (a predominant process of physisorption).

- (b)

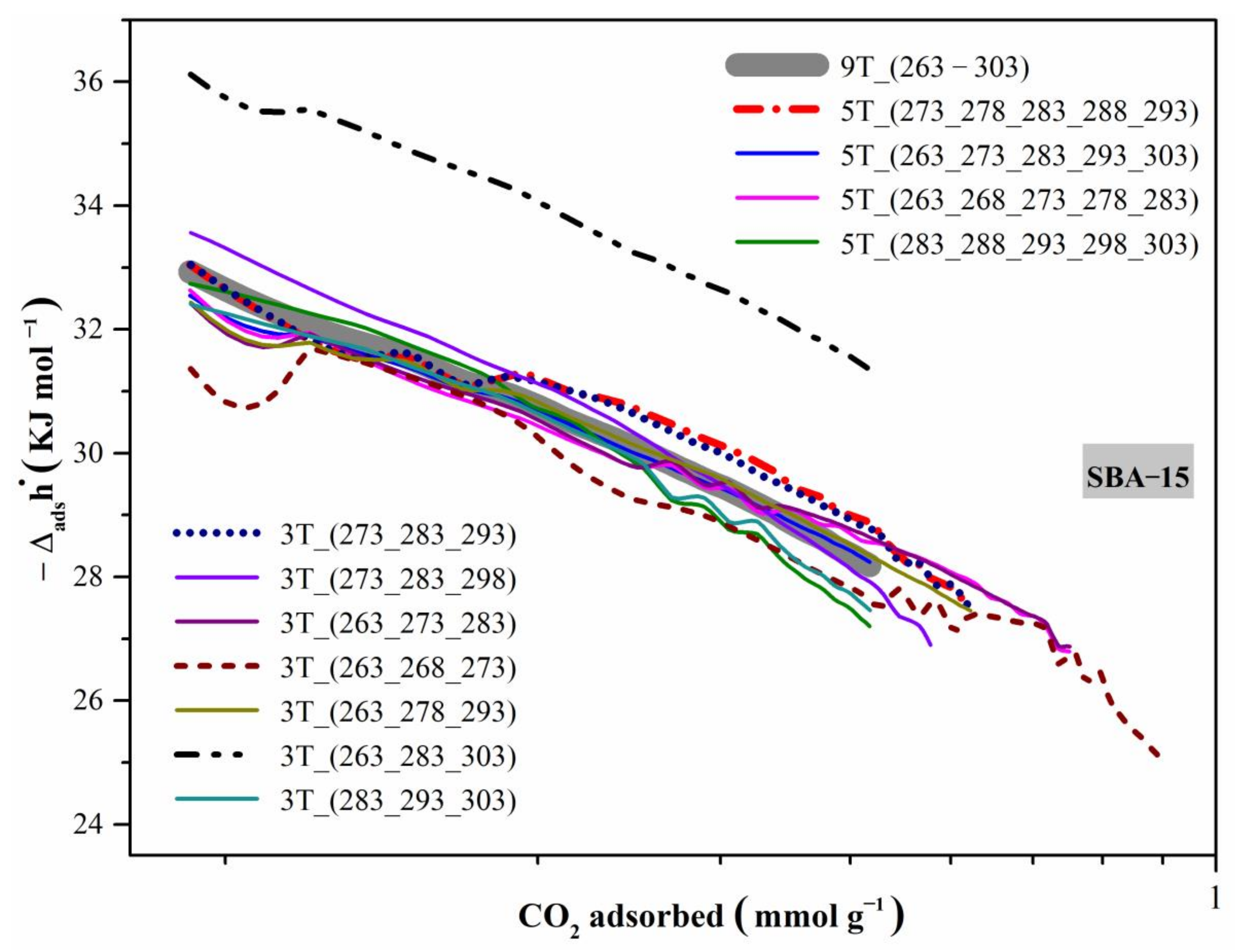

- SBA-15, a mesoporous material with a specific surface area of 735 m2 g−1 and silanol groups in its surface, adsorbed 0.53 mmol CO2 g−1 (at 298 K and 1 bar), about 25% of the total amount adsorbed by CMF, both materials have very similar specific surface areas, this difference could be due to the presence of micropores in CMFs. However, surface chemistry may play a more important role; different nitrogen and oxygen functional groups may have a higher affinity for the CO2 molecule than the silanol groups. The was −29 KJ mol−1, a value almost identical to that for CMFs, where a physisorption process is prevailing.

- (c)

- SBA-15_APTES, a mesoporous material, decreased the specific surface area from 735 m2 g−1 to 389 m2 g−1, which is due to the addition of amine groups by the (3-Aminopropyl)triethoxysilane (APTES) precursor improving CO2 adsorption, rising from 0.53 mmol CO2 g−1 to 1.37 mmol CO2 g−1 (at 298 K and 1 bar); besides, this material has a of −38 KJ mol−1, which means that the surface affinity of SBA-15_APTES with CO2 molecule is stronger compared to CMF and SBA-15. This surface affinity makes it a preferential chemisorption process, resulting in the production of different behaviors.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Przepiórski, J.; Skrodzewicz, M.; Morawski, A. High temperature ammonia treatment of activated carbon for enhancement of CO2 adsorption. Appl. Surf. Sci. 2004, 225, 235–242. [Google Scholar] [CrossRef]

- Douglas, A.; Carter, R.E.; Li, M.; Pint, C.L. Toward Small-Diameter Carbon Nanotubes Synthesized from Captured Carbon Dioxide: Critical Role of Catalyst Coarsening. ACS Appl. Mater. Interfaces 2018, 10, 19010–19018. [Google Scholar] [CrossRef]

- Zeleňák, V.; Badaničová, M.; Halamová, D.; Čejka, J.; Zukal, A.; Murafa, N.; Goerigk, G. Amine-modified ordered mesoporous silica: Effect of pore size on carbon dioxide capture. Chem. Eng. J. 2008, 144, 336–342. [Google Scholar] [CrossRef]

- Boycheva, S.; Zgureva, D.; Lazarova, K.; Babeva, T.; Popov, C.; Lazarova, H.; Popova, M. Progress in the Utilization of Coal Fly Ash by Conversion to Zeolites with Green Energy Applications. Materials 2020, 13, 2014. [Google Scholar] [CrossRef] [PubMed]

- Chaemchuen, S.; Alam Kabir, N.; Zhou, K.; Verpoort, F. Metal–organic frameworks for upgrading biogas via CO2 adsorption to biogas green energy. Chem. Soc. Rev. 2013, 42, 9304–9332. [Google Scholar] [CrossRef] [PubMed]

- Gan, Y.X.; Gan, J.B. Advances in Manufacturing Composite Carbon Nanofiber-Based Aerogels. J. Compos. Sci. 2020, 4, 73. [Google Scholar] [CrossRef]

- Babu, D.J.; Lange, M.; Cherkashinin, G.; Issanin, A.; Staudt, R.; Schneider, J.J. Gas adsorption studies of CO2 and N2 in spatially aligned double-walled carbon nanotube arrays. Carbon 2013, 61, 616–623. [Google Scholar] [CrossRef]

- Liou, T.-H.; Wang, P.-Y. Utilization of rice husk wastes in synthesis of graphene oxide-based carbonaceous nanocomposites. Waste Manag. 2020, 108, 51–61. [Google Scholar] [CrossRef]

- Yan, X.; Komarneni, S.; Yan, Z. CO2 adsorption on Santa Barbara Amorphous-15 (SBA-15) and amine-modified Santa Barbara Amorphous-15 (SBA-15) with and without controlled microporosity. J. Colloid Interface Sci. 2013, 390, 217–224. [Google Scholar] [CrossRef]

- Rao, N.; Wang, M.; Shang, Z.; Hou, Y.; Fan, G.; Li, J. CO2 Adsorption by Amine-Functionalized MCM-41: A Comparison between Impregnation and Grafting Modification Methods. Energy Fuels 2018, 32, 670–677. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Kluwer Academic Publishers: London, UK, 2004; ISBN 1-4020-2302-2. [Google Scholar]

- Rouquerol, F.; Rouquerol, J.; Sing, K.S.W.; Llewellyn, P.; Maurin, G. Adsorption by Powders and Porous Solids: Principles, Methodology and Aplications, 2nd ed.; Elsevier: New York, NY, USA, 2014; ISBN 9780080970356. [Google Scholar]

- Builes, S.; Sandler, S.I.; Xiong, R. Isosteric Heats of Gas and Liquid Adsorption. Langmuir 2013, 29, 10416–10422. [Google Scholar] [CrossRef] [PubMed]

- Nicholson, D.; Quirke, N. The role of isosteric enthalpy of adsorption in micropore characterisation: A simulation study. In Studies in Surface Science and Catalysis; Unger, K.K., Kreysa, G., Baselt, J.P., Eds.; Elsevier Science B.V.: Amsterdam, The Netherlands, 2000; Volume 128, pp. 11–20. ISBN 978-0-444-50259-9. [Google Scholar]

- Sircar, S.; Mohr, R.; Ristic, C.; Rao, M.B. Isosteric Heat of Adsorption: Theory and Experiment. J. Phys. Chem. B 1999, 103, 6539–6546. [Google Scholar] [CrossRef] [PubMed]

- Saha, D.; Grappe, H.A. Adsorption properties of activated carbon fibers. In Activated Carbon Fiber and Textiles; Chen, J.Y., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 143–165. ISBN 978-0-08-100660-3. [Google Scholar]

- Zhao, D.; Feng, J.; Huo, Q.; Melosh, N.; Fredrickson, G.H.; Chmelka, B.F.; Stucky, G.D. Triblock copolymer syntheses of mesoporous silica with seriodic 50 to 300 Angstrom pores. Science 1998, 279, 548–552. [Google Scholar] [CrossRef]

- Ojeda-López, R.; Pérez-Hermosillo, I.J.; Esparza-Schulz, J.M.; Cervantes-Uribe, A.; Domínguez-Ortiz, A. SBA-15 materials: Calcination temperature influence on textural properties and total silanol ratio. Adsorption 2015, 21, 659–669. [Google Scholar] [CrossRef]

- Munguía-Cortés, L.; Pérez-Hermosillo, I.; Ojeda-López, R.; Esparza-Schulz, J.M.; Felipe-Mendoza, C.; Cervantes-Uribe, A.; Domínguez-Ortiz, A. APTES-functionalization of SBA-15 using ethanol or toluene: Textural characterization and sorption performance of carbon dioxide. J. Mex. Chem. Soc. 2017, 61, 273–281. [Google Scholar] [CrossRef]

- Ojeda-López, R.; Esparza-Schulz, J.M.; Pérez-Hermosillo, I.J.; Hernández-Gordillo, A.; Domínguez-Ortiz, A. Improve in CO2 and CH4 Adsorption Capacity on Carbon Microfibers Synthesized by Electrospinning of PAN. Fibers 2019, 7, 81. [Google Scholar] [CrossRef]

- Ladd, M.; Palmer, R. Structure Determination by X-ray Crystallography: Analysis by X-rays and Neutrons, 5th ed.; Springer US: New York, NY, USA, 2013; Volume 35, ISBN 978-1-4614-3954-7. [Google Scholar]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Rouquerol, J.; Llewellyn, P.; Rouquerol, F. Is the BET equation applicable to microporous adsorbents? Stud. Surf. Sci. Catal. 2007, 160, 49–56. [Google Scholar]

- Kim, C.; Park, S.-H.; Cho, J.-I.; Lee, D.-Y.; Park, T.-J.; Lee, W.-J.; Yang, K.-S. Raman spectroscopic evaluation of polyacrylonitrile-based carbon nanofibers prepared by electrospinning. J. Raman Spectrosc. 2004, 35, 928–933. [Google Scholar] [CrossRef]

- Zussman, E.; Chen, X.; Ding, W.; Calabri, L.; Dikin, D.; Quintana, J.; Ruoff, R. Mechanical and structural characterization of electrospun PAN-derived carbon nanofibers. Carbon 2005, 43, 2175–2185. [Google Scholar] [CrossRef]

- Ojeda-López, R.; Ramos-Sánchez, G.; Esparza-Schulz, J.M.; Lartundo, L.; Domínguez-Ortiz, A. On site formation of N-doped carbon nanofibers, an efficient electrocatalyst for fuel cell applications. Int. J. Hydrogen Energy 2017, 42, 30339–30348. [Google Scholar] [CrossRef]

- Kruk, M.; Jaroniec, M.; Sayari, A. Relations between Pore Structure Parameters and Their Implications for Characterization of MCM-41 Using Gas Adsorption and X-ray Diffraction. Chem. Mater. 1999, 11, 492–500. [Google Scholar] [CrossRef]

- Kruk, M.; Jaroniec, M.; Joo, S.H.; Ryoo, R. Characterization of Regular and Plugged SBA-15 Silicas by Using Adsorption and Inverse Carbon Replication and Explanation of the Plug Formation Mechanism. J. Phys. Chem. B 2003, 107, 2205–2213. [Google Scholar] [CrossRef]

- Ide, M.; El-Roz, M.; De Canck, E.; Vicente, A.; Planckaert, T.; Bogaerts, T.; Van Driessche, I.; Lynen, F.; Van Speybroeck, V.; Thybault-Starzyk, F.; et al. Quantification of silanol sites for the most common mesoporous ordered silicas and organosilicas: Total versus accessible silanols. Phys. Chem. Chem. Phys. 2013, 15, 642–650. [Google Scholar] [CrossRef] [PubMed]

- Colilla, M.; Izquierdo-Barba, I.; Sánchez-Salcedo, S.; Fierro, J.L.G.; Hueso, J.L.; Vallet-Regí, M. Synthesis and Characterization of Zwitterionic SBA-15 Nanostructured Materials. Chem. Mater. 2010, 22, 6459–6466. [Google Scholar] [CrossRef]

- Rahman, I.; Jafarzadeh, M.; Sipaut, C. Synthesis of organo-functionalized nanosilica via a co-condensation modification using γ-aminopropyltriethoxysilane (APTES). Ceram. Int. 2009, 35, 1883–1888. [Google Scholar] [CrossRef]

- Chiang, Y.-C.; Lee, S.-T.; Leo, Y.-J.; Tseng, T.-L. Importance of Pore Structure and Surface Chemistry in Carbon Dioxide Adsorption on Electrospun Carbon Nanofibers. Sensors Mater. 2020, 32, 2277. [Google Scholar] [CrossRef]

- Heo, Y.-J.; Zhang, Y.; Rhee, K.Y.; Park, S.-J. Synthesis of PAN/PVDF nanofiber composites-based carbon adsorbents for CO2 capture. Compos. Part B Eng. 2019, 156, 95–99. [Google Scholar] [CrossRef]

- Jeong, D.; Jie, W.; Adelodun, A.A.; Kim, S.; Jo, Y. Electrospun melamine-blended activated carbon nanofibers for enhanced control of indoor CO. J. Appl. Polym. Sci. 2019, 136, 3–10. [Google Scholar] [CrossRef]

- Choma, J.; Stachurska, K.; Marszewski, M.; Jaroniec, M. Equilibrium isotherms and isosteric heat for CO2 adsorption on nanoporous carbons from polymers. Adsorption 2016, 22, 581–588. [Google Scholar] [CrossRef]

- Kamran, U.; Choi, J.R.; Park, S.-J. A Role of Activators for Efficient CO2 Affinity on Polyacrylonitrile-Based Porous Carbon Materials. Front. Chem. 2020, 8, 710–727. [Google Scholar] [CrossRef]

- Li, Y.; Zou, B.; Hu, C.; Cao, M. Nitrogen-doped porous carbon nanofiber webs for efficient CO2 capture and conversion. Carbon 2016, 99, 79–89. [Google Scholar] [CrossRef]

- Králik, M. Adsorption, chemisorption, and catalysis. Chem. Pap. 2014, 68, 1625–1638. [Google Scholar] [CrossRef]

- de Ribeiro, J.; Nunes, E.H.M.; Vasconcelos, D.C.L.; Vasconcelos, W.L.; Nascimento, J.F.; Grava, W.M.; Derks, P.W.J. Role of the type of grafting solvent and its removal process on APTES functionalization onto SBA-15 silica for CO2 adsorption. J. Porous Mater. 2019, 26, 1581–1591. [Google Scholar] [CrossRef]

- Vilarrasa-Garcia, E.; Moya, E.O.; Cecilia, J.; Cavalcante, C.; Jiménez-Jiménez, J.; Azevedo, D.; Rodríguez-Castellón, E. CO2 adsorption on amine modified mesoporous silicas: Effect of the progressive disorder of the honeycomb arrangement. Microporous Mesoporous Mater. 2015, 209, 172–183. [Google Scholar] [CrossRef]

- Cecilia, J.A.; Vilarrasa-García, E.; Morales-Ospino, R.; Bastos-Neto, M.; Azevedo, D.C.S.; Rodríguez-Castellón, E. Insights into CO2 adsorption in amino-functionalized SBA-15 synthesized at different aging temperature. Adsorption 2020, 26, 225–240. [Google Scholar] [CrossRef]

- Medina-Juárez, O.; García-Sánchez, M.Á.; Arellano-Sánchez, U.; Kornhauser-Straus, I.; Rojas-González, F. Optimal Surface Amino-Functionalization Following Thermo-Alkaline Treatment of Nanostructured Silica Adsorbents for Enhanced CO2 Adsorption. Materials 2016, 9, 898. [Google Scholar] [CrossRef]

- Ojeda-López, R.; Aguilar-Huerta, E.; Maia, D.A.S.; Azevedo, D.C.S.; Felipe, C.; Domíngez-Ortiz, A. Tailoring synthesis conditions of carbon microfibers to enhance the microporosity, CO2 and CH4 adsorption by using the response surface methodology. Microporous Mesoporous Mater. 2020, 305, 110333–110341. [Google Scholar] [CrossRef]

| Name | CMF | SBA-15 | SBA-15_APTES |

|---|---|---|---|

| d100 (nm) | --- | 9.097 | 10.142 |

| a0 (nm) | --- | 10.504 | 11.711 |

| tpore (nm) | --- | 3.474 | 5.830 |

| SBET (m2/g) | 805 | 735 | 389 |

| SMICRO (m2/g) | 753.2 | 193.2 | 0 |

| SEXT (m2/g) | 51.9 | 541.8 | 389 |

| VT (cm3/g) | 0.3402 | 0.9336 | 0.5362 |

| VMICRO (cm3/g) | 0.3007 | 0.09422 | 0 |

| % M | 88 | 10 | 0 |

| DPORE_N2 (nm) | 0.78 | 7.03 | 5.88 |

| DPORE_CO2 (nm) | 0.50 | --- | --- |

| 263 K | 268 K | 273 K | 278 K | 283 K | 288 K | 293 K | 298 K | 303 K | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | x | x | x | x | x | x | x | x | x |

| 2 | x | x | x | x | x | ||||

| 3 | x | x | x | x | x | ||||

| 4 | x | x | x | x | x | ||||

| 5 | x | x | x | x | x | ||||

| 6 | x | x | x | ||||||

| 7 | x | x | x | ||||||

| 8 | x | x | x | ||||||

| 9 | x | x | x | ||||||

| 10 | x | x | x | ||||||

| 11 | x | x | x | ||||||

| 12 | x | x | x |

| Adsorbent | Functionalizing Agent | Solvent | SBET (m2 g−1) | Temperature (K) | CO2 Adsorbed (mmol g−1) | REF |

|---|---|---|---|---|---|---|

| SBA-15 | --- | --- | 735 | 298 | 0.53 | This work |

| SBA-15 | APTES 1 | Ethanol | 389 | 298 | 1.37 | This work |

| SBA-15 | --- | --- | 735 | 303 | 0.47 | This work |

| SBA-15 | APTES | Ethanol | 389 | 303 | 1.34 | This work |

| SBA-15 | --- | --- | 572 | 303 | 0.59 | [40] |

| SBA-15 | APTES | Ethanol | 276 | 303 | 0.84 | [40] |

| SBA-15 | APTES | Toluene | 50 | 303 | 1.43 | [40] |

| SBA-15 | APTES | Toluene | 216 | 298 | 2.12 | [41] |

| SBA-15 | PEI 2 | Methanol | 267 | 298 | 1.74 | [41] |

| SBA-15 | APTES | Toluene | 150 | 298 | 1.33 | [42] |

| SBA-15 | PEI | Methanol | 49 | 298 | 1.33 | [42] |

| SBA-15 | --- | --- | 696 | 293 | 1.1 | [43] |

| SBA-15 | APTES | Toluene | 361 | 298 | 1.1 | [43] |

| SBA-15 | --- | --- | 793 | 298 | 0.91 | [20] |

| SBA-15 | APTES | Toluene | 223 | 298 | 1.43 | [20] |

| SBA-15 | APTES | Ethanol | 356 | 298 | 1.40 | [20] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ojeda-López, R.; Domínguez-Ortiz, A.; Felipe, C.; Cervantes-Uribe, A.; Pérez-Hermosillo, I.J.; Esparza-Schulz, J.M. Isosteric Enthalpy Behavior of CO2 Adsorption on Micro-Mesoporous Materials: Carbon Microfibers (CMFs), SBA-15, and Amine-Functionalized SBA-15. J. Compos. Sci. 2021, 5, 102. https://doi.org/10.3390/jcs5040102

Ojeda-López R, Domínguez-Ortiz A, Felipe C, Cervantes-Uribe A, Pérez-Hermosillo IJ, Esparza-Schulz JM. Isosteric Enthalpy Behavior of CO2 Adsorption on Micro-Mesoporous Materials: Carbon Microfibers (CMFs), SBA-15, and Amine-Functionalized SBA-15. Journal of Composites Science. 2021; 5(4):102. https://doi.org/10.3390/jcs5040102

Chicago/Turabian StyleOjeda-López, Reyna, Armando Domínguez-Ortiz, Carlos Felipe, A. Cervantes-Uribe, Isaac J. Pérez-Hermosillo, and J. Marcos Esparza-Schulz. 2021. "Isosteric Enthalpy Behavior of CO2 Adsorption on Micro-Mesoporous Materials: Carbon Microfibers (CMFs), SBA-15, and Amine-Functionalized SBA-15" Journal of Composites Science 5, no. 4: 102. https://doi.org/10.3390/jcs5040102

APA StyleOjeda-López, R., Domínguez-Ortiz, A., Felipe, C., Cervantes-Uribe, A., Pérez-Hermosillo, I. J., & Esparza-Schulz, J. M. (2021). Isosteric Enthalpy Behavior of CO2 Adsorption on Micro-Mesoporous Materials: Carbon Microfibers (CMFs), SBA-15, and Amine-Functionalized SBA-15. Journal of Composites Science, 5(4), 102. https://doi.org/10.3390/jcs5040102