State-of-the-Art Review on Experimental Investigations of Textile-Reinforced Concrete Exposed to High Temperatures

Abstract

:1. Introduction

- Heating at constant load, where the specimens are pre-loaded to a constant stress level before the heating initiates. In this case, the influence of the load level is the decisive parameter.

- Load while heated, where the specimens are first subjected to an increased temperature which remains constant after reaching a target value and then, while being in hot conditions, the mechanical loading initiates. The dominant parameter, in this case, is the target temperature.

- Residual capacity after heating, where the specimens are first exposed to high temperatures and then, after a cooling down phase, they are tested mechanically. The maximum reached temperature and the heating/cooling rates are the dominant parameters in this case.

2. Performance of the Textile-to-Matrix Bond

3. Tensile Performance of the Composite

3.1. Heating at Constant Tensile Load

3.2. Loading at Increased Temperatures or after Cooling Down

3.2.1. Initial Stage

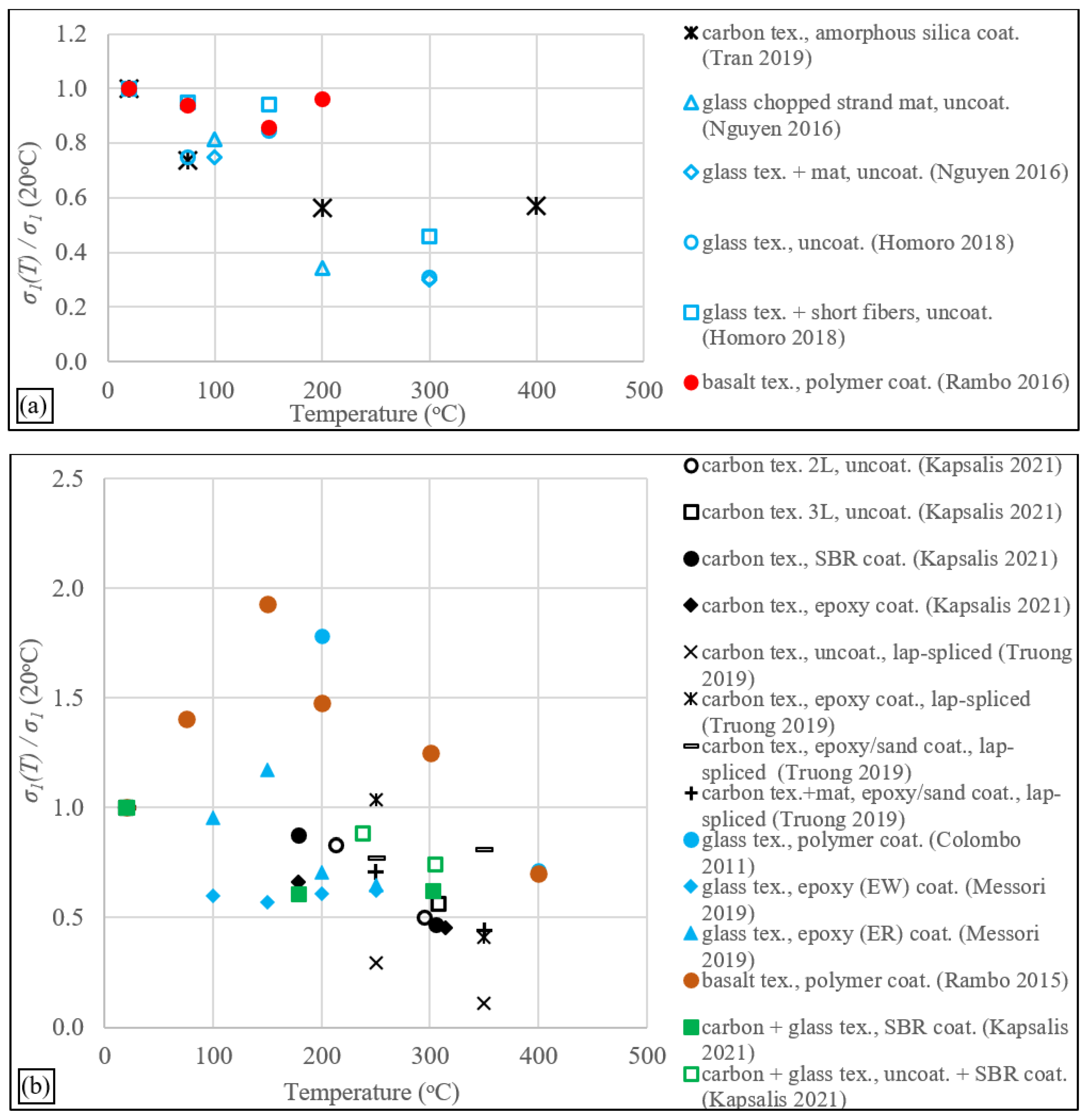

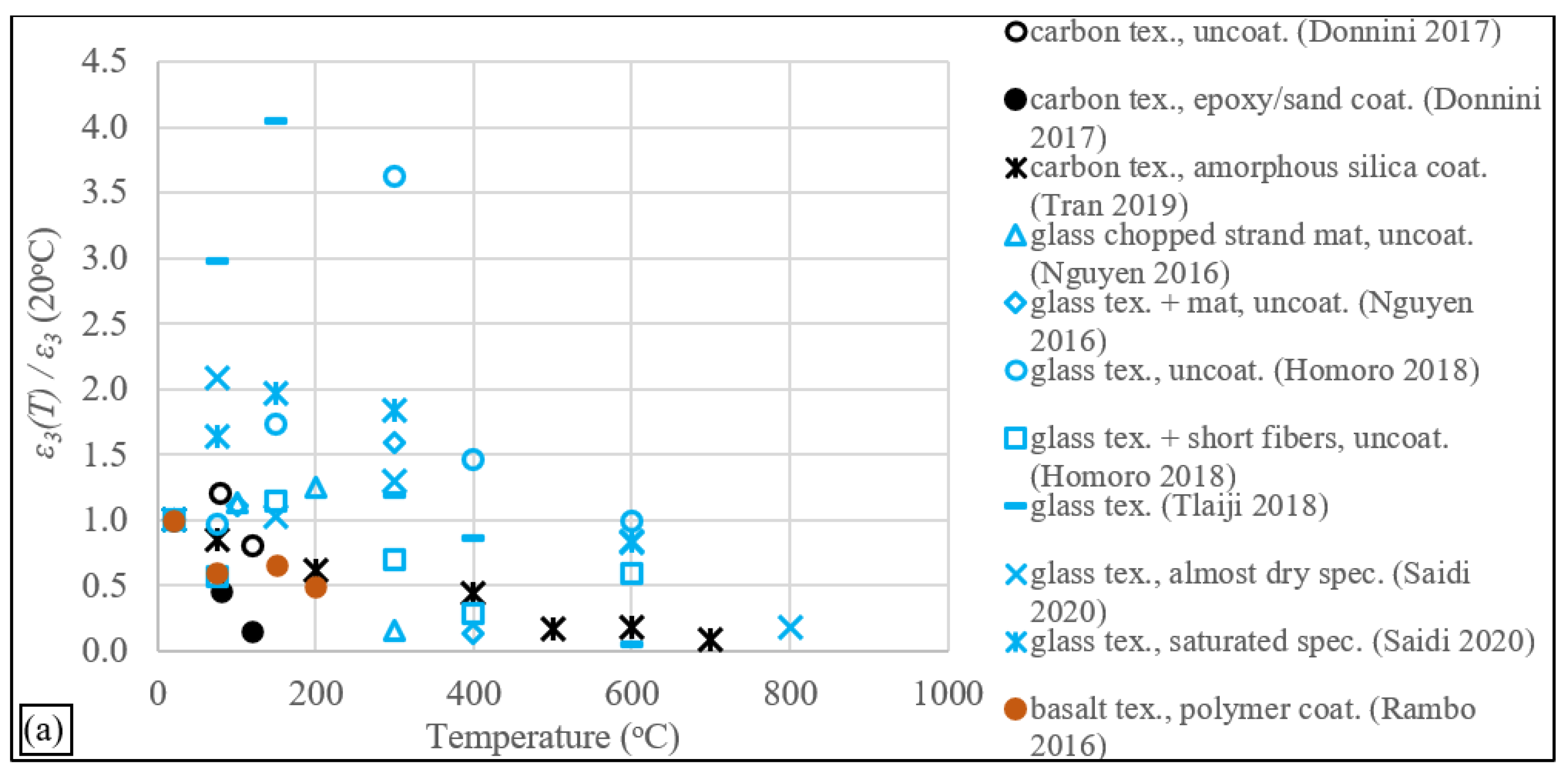

3.2.2. Post-Cracking Stage (Stage III)

4. Flexural Performance of the Composite

5. Conclusions and Knowledge Gaps

Author Contributions

Funding

Conflicts of Interest

References

- Hegger, J.; Will, N.; Bentur, A.; Curbach, M.; Jesse, F.; Mobasher, B.; Peled, A.; Wastiels, J. Composite materials—6.2 Mechanical behaviour of textile reinforced concrete in Textile Reinforced Concrete. In Textile Reinforced Concrete—State-of-the-Art Report of RILEM TC 201-TRC; Brameshuber, W., Ed.; RILEM Publications SARL: Bagneux, France, 2006; pp. 133–186. ISBN 2-912143-99-3. [Google Scholar]

- Papanicolaou, C.G. Applications of textile-reinforced concrete in the precast industry. In Textile Fibre Composites in Civil Engineering; Triantafillou, T.C., Ed.; Woodhead Publishing: Duxford, UK, 2016; pp. 227–244. [Google Scholar]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Hulin, T.; Lauridsen, D.H.; Hodicky, K.; Schmidt, J.W.; Stang, H. Influence of basalt FRP mesh reinforcement on high-performance concrete thin plates at high temperatures. J. Compos. Constr. 2016, 20, 04015034. [Google Scholar] [CrossRef]

- Bisby, L. Fire resistance of textile fiber composites used in civil engineering. In Textile Fibre Composites in Civil Engineering; Triantafillou, T.C., Ed.; Woodhead Publishing: Duxford, UK, 2016; pp. 169–186. [Google Scholar]

- Hegger, J.; Zell, M.; Horstmann, M. Textile reinforced concrete–realization in applications. In Proceedings of the International Fib Symposium: Tailor Made Concrete Structures: New Solutions for Our Society, Amsterdam, The Netherlands, 19–22 May 2008; pp. 357–362. [Google Scholar]

- Zani, G.; Rampini, M.C.; Colombo, M.; di Prisco, M. Fire behavior of sandwich panels for roofing applications. Key Eng. Mater. 2016, 711, 775–782. [Google Scholar] [CrossRef]

- Shen, L.; Wang, J.; Xu, S.; Amoako-Atta, G. Fire Resistance Behavior of Full-scale Self-thermal Insulation Sandwich Walls Made of Textile-reinforced Concrete. Int. J. Heat Technol. 2019, 37, 239–248. [Google Scholar] [CrossRef]

- Bisby, L.; Stratford, T.; Smith, J.; Halpin, S. Comparative performance of fibre reinforced polymer and fibre reinforced cementitious mortar strengthening systems in elevated temperature service environments. In Proceedings of the Structural Faults and Repair 2010 Conference, Edingbrugh, UK, 15–17 June 2010; Engineering Technics Press. [Google Scholar]

- Ehlig, D.; Hothan, S. Reinforced concrete slabs strengthened with textile reinforced concrete subjected to fire. In Proceedings of the 2nd International RILEM Workshop on Concrete Spalling due to Fire Exposure, Delft, The Netherlands, 5–7 October 2011; pp. 419–426. [Google Scholar]

- Bisby, L.; Stratford, T.; Hart, C.; Farren, S. Fire performance of well-anchored TRM, FRCM and FRP flexural strengthening systems. In Proceedings of the 6th International Conference on Advanced Composites in Construction, Belfast, UK, 10–12 September 2013; Network Group for Composites in Construction. [Google Scholar]

- Trapko, T. The effect of high temperature on the performance of CFRP and FRCM confined concrete elements. Comp. B Eng. 2013, 54, 138–145. [Google Scholar] [CrossRef]

- Michels, J.; Zwicky, D.; Scherer, J.; Harmanci, Y.E.; Motavalli, M. Structural strengthening of concrete with fiber reinforced cementitious matrix (FRCM) at ambient and elevated temperature—Recent investigations in Switzerland. Adv. Struct. Eng. 2014, 17, 1785–1799. [Google Scholar] [CrossRef]

- Al-Salloum, Y.A.; Almusallam, T.H.; Elsanadedy, H.M.; Iqbal, R.A. Effect of elevated temperature environments on the residual axial capacity of RC columns strengthened with different techniques. Constr. Build. Mater. 2016, 115, 345–361. [Google Scholar] [CrossRef]

- Tetta, Z.C.; Bournas, D.A. TRM vs. FRP jacketing in shear strengthening of concrete members subjected to high temperatures. Compos. B Eng. 2016, 106, 190–205. [Google Scholar] [CrossRef]

- Ombres, L. Structural performances of thermally conditioned PBO FRCM confined concrete cylinders. Compos. Struct. 2017, 176, 1096–1106. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Karlos, K.; Kefalou, K.; Argyropoulou, E. An innovative structural and energy retrofitting system for URM walls using textile reinforced mortars combined with thermal insulation: Mechanical and fire behavior. Constr. Build. Mater. 2017, 133, 1–13. [Google Scholar] [CrossRef]

- Zhang, J.; Ma, H.; Li, C.; Xu, Q.; Li, W. Experimental study on seismic performance of fire-exposed perforated brick masonry wall. Constr. Build. Mater. 2018, 180, 77–91. [Google Scholar] [CrossRef]

- Cerniauskas, G.; Tetta, Z.; Bournas, D.A.; Bisby, L.A. Concrete confinement with TRM versus FRP jackets at elevated temperatures. Mater. Struct. 2020, 53, 58. [Google Scholar] [CrossRef]

- Ombres, L. Analysis of the bond between fabric reinforced cementitious mortar (FRCM) strengthening systems and concrete. Compos. B Eng. 2015, 69, 418–426. [Google Scholar] [CrossRef]

- Donnini, J.; y Basalo, F.D.C.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Compos. B Eng. 2017, 108, 108–121. [Google Scholar] [CrossRef] [Green Version]

- Maroudas, S.R.; Papanicolaou, C.G. Effect of high temperatures on the TRM-to-masonry bond. Key Eng. Mater. 2017, 747, 533–541. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. Bond between TRM versus FRP composites and concrete at high temperatures. Compos. B Eng. 2017, 127, 150–165. [Google Scholar] [CrossRef]

- Ombres, L.; Iorfida, A.; Mazzuca, S.; Verre, S. Bond analysis of thermally conditioned FRCM-masonry joints. Measurement 2018, 125, 509–515. [Google Scholar] [CrossRef]

- Al-Jaberi, Z.; Myers, J.J.; Chandrashekhara, K. Effect of direct service temperature exposure on the bond behavior between advanced composites and CMU using NSM and EB techniques. Compos. Struct. 2019, 211, 63–75. [Google Scholar] [CrossRef]

- Askouni, P.D.; Papanicolaou, C.G.; Kaffetzakis, M.I. The effect of elevated temperatures on the TRM-to-masonry bond: Comparison of normal weight and lightweight matrices. Appl Sci. 2019, 9, 2156. [Google Scholar] [CrossRef] [Green Version]

- Gao, S.; Zhao, X.; Qiao, J.; Guo, Y.; Hu, G. Study on the bonding properties of Engineered Cementitious Composites (ECC) and existing concrete exposed to high temperature. Constr. Build. Mater. 2019, 196, 330–344. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T. Performance of TRM/TRC systems under elevated temperatures and fire conditions. ACI Spec. Publ. 2021, 345, 32–46. [Google Scholar]

- De Andrade, S.F.; Butler, M.; Hempel, S.; Toledo, F.R.D.; Mechtcherine, V. Effects of elevated temperatures on the interface properties of carbon textile-reinforced concrete. Cem. Concr. Compos. 2014, 48, 26–34. [Google Scholar]

- Liu, S.; Rawat, P.; Chen, Z.; Guo, S.; Shi, C.; Zhu, D. Pullout behaviors of single yarn and textile in cement matrix at elevated temperatures with varying loading speeds. Compos. B Eng. 2020, 199, 108251. [Google Scholar] [CrossRef]

- Rambo, D.A.S.; De Andrade, S.F.; Toledo, F.R.D.; da Fonseca, M.G.O. Effect of elevated temperatures on the mechanical behavior of basalt textile reinforced refractory concrete. Mater. Des. 2015, 65, 24–33. [Google Scholar] [CrossRef]

- Rambo, D.A.S.; De Andrade, S.F.; Toledo, F.R.D.; Ukrainczyk, N.; Koenders, E. Tensile strength of a calcium-aluminate cementitious composite reinforced with basalt textile in a high-temperature environment. Cem. Concr. Compos. 2016, 70, 183–193. [Google Scholar] [CrossRef]

- Ehlig, D.; Jesse, F.; Curbach, M. High temperature tests on textile reinforced concrete (TRC) strain specimens. In Proceedings of the International RILEM Conference on Material Science, Aachen, Germany, 6–8 September 2010; pp. 141–151. [Google Scholar]

- Tran, M.T.; Vu, X.H.; Ferrier, E. Mesoscale experimental investigation of thermomechanical behaviour of the carbon textile reinforced refractory concrete under simultaneous mechanical loading and elevated temperature. Constr. Build. Mater. 2019, 217, 156–171. [Google Scholar] [CrossRef]

- Tlaiji, T.; Vu, X.H.; Michel, M.; Ferrier, E.; Larbi, A.S. Physical, chemical and thermomechanical characterisation of glass textile-reinforced concretes (TRC): Effect of elevated temperature and of cementitious matrix nature on properties of TRC. Mater. Today Commun. 2020, 25, 101580. [Google Scholar] [CrossRef]

- Long, G.T. Influence of boron treatment on oxidation of carbon fibre in air. J. Appl. Polym. Sci. 1996, 59, 915–921. [Google Scholar]

- Hatta, H.; Aoki, T.; Kogo, Y.; Yarii, T. High-temperature oxidation behavior of SiC-coated carbon fiber-reinforced carbon matrix composites. Compos. A Appl. Sci. Manuf. 1999, 30, 515–520. [Google Scholar] [CrossRef]

- Papakonstantinou, C.G.; Balaguru, P.; Lyon, R.E. Comparative study of high temperature composites. Compos. B Eng. 2001, 32, 637–649. [Google Scholar] [CrossRef]

- Khoury, G.A. Fire and concrete. In Proceedings of the Encontro Nacional Betão Estrutural, Guimarães, Portugal, 5–7 November 2008; pp. 21–34. [Google Scholar]

- Colombo, I.; Colombo, M.; Magri, A.; Zani, G.; Di Prisco, M. Textile reinforced mortar at high temperatures. Appl. Mech. 2011, 82, 202–207. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Vu, X.H.; Si Larbi, A.; Ferrier, E. Experimental study of the effect of simultaneous mechanical and high-temperature loadings on the behaviour of textile-reinforced concrete (TRC). Constr. Build. Mater. 2016, 125, 253–270. [Google Scholar] [CrossRef]

- Homoro, O.; Vu, X.H.; Ferrier, E. Experimental and analytical study of the thermo-mechanical behaviour of textile-reinforced concrete TRC at elevated temperatures: Role of discontinuous short glass fibres. Constr. Build. Mater. 2018, 190, 645–663. [Google Scholar] [CrossRef]

- Messori, M.; Nobili, A.; Signorini, C.; Sola, A. Effect of high temperature exposure on epoxy-coated glass textile reinforced mortar (GTRM) composites. Constr. Build. Mater. 2019, 212, 765–774. [Google Scholar] [CrossRef] [Green Version]

- Truong, G.T.; Park, S.H.; Choi, K.K. Tensile Behaviors of Lap-Spliced Carbon Fiber-Textile. Materials 2019, 12, 1512. [Google Scholar] [CrossRef] [Green Version]

- Kapsalis, P.; Triantafillou, T.; Korda, E.; Van Hemelrijck, D.; Tysmans, T. Tensile performance of textile reinforced concrete after fire exposure: Experimental investigation and analytical approach. J. Compos. Constr. Accepted.

- Tlaiji, T.; Vu, X.H.; Ferrier, E.; Si Larbi, A. Thermomechanical behaviour and residual properties of textile reinforced concrete (TRC) subjected to elevated and high temperature loading: Experimental and comparative study. Compos. B Eng. 2018, 144, 99–110. [Google Scholar] [CrossRef]

- Saidi, M.; Vu, X.H.; Ferrier, E. Experimental and analytial analysis of the thermomechanical behaviour at elevated temperature of the textile reinforced concrete (TRC) effet of the hydric state. In Proceedings of the 9th International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, Paris, France, 17–19 July 2018; pp. 844–852. [Google Scholar]

- Bisby, L.A. Fire Behaviour of Fibre-Reinforced Polymer (FRP) Reinforced or Confined Concrete. Ph.D. Thesis, Queen’s University, Kingston, ON, Canada, 2003. [Google Scholar]

- Antons, U.; Hegger, J.; Kulas, C.; Raupach, M. High-temperature tests on concrete specimens reinforced with alkali-resistant glass rovings under bending. In Proceedings of the 6th International Conference on FRP Composites in Civil Engineering, Rome, Italy, 13–15 June 2012; pp. 13–15. [Google Scholar]

- Krüger, M.; Reinhardt, H.W. Composite materials-6.4 fire resistance. In Textile Reinforced Concrete–State-of-the-Art Report of RILEM TC 201-TRC; Brameshuber, W., Ed.; RILEM Publications SARL: Bagneux, France, 2006; pp. 211–219. ISBN 2-912143-99-3. [Google Scholar]

- Buttner, T.; Orlowsky, J.; Raupach, M. Fire resistance tests of textile reinforced concrete under static loading-results and future developments. In Proceedings of the 5th International RILEM Workshop on High Performance Fiber Reinforced Cement Composites, Mainz, Germany, 10–13 July 2007; pp. 10–13. [Google Scholar]

- Xu, S.L.; Shen, L.H.; Wang, J.Y.; Fu, Y. High temperature mechanical performance and micro interfacial adhesive failure of textile reinforced concrete thin plate. J. Zhejiang Univ. Sci. A 2014, 15, 31–38. [Google Scholar] [CrossRef]

- Xu, S.L.; Shen, L.H.; Wang, J.Y. The high-temperature resistance performance of TRC thin-plates with different cementitious materials: Experimental study. Constr. Build. Mater. 2016, 115, 506–519. [Google Scholar] [CrossRef]

- Shen, L.H.; Xu, S.L.; Wang, J.Y. Mechanical behaviour of TRC thin plates exposed to high temperature: Experimental study. Mag. Concr. Res. 2015, 67, 1135–1149. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Y.; Dai, J.G. Flexural behavior and microstructure of hybrid basalt textile and steel fiber reinforced alkali-activated slag panels exposed to elevated temperatures. Constr. Build. Mater. 2017, 152, 651–660. [Google Scholar] [CrossRef]

- Kapsalis, P.; El Kadi, M.; Vervloet, J.; De Munck, M.; Wastiels, J.; Triantafillou, T.; Tysmans, T. Thermomechanical behavior of textile reinforced cementitious composites subjected to fire. Appl. Sci. 2019, 9, 747. [Google Scholar] [CrossRef] [Green Version]

- ISO (International Organization for Standardization). Fire-Resistance Tests: Elements of Building Construction, General Requirements, ISO 834-1; ISO: Geneva, Switzerland, 1999. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kapsalis, P.; Tysmans, T.; Van Hemelrijck, D.; Triantafillou, T. State-of-the-Art Review on Experimental Investigations of Textile-Reinforced Concrete Exposed to High Temperatures. J. Compos. Sci. 2021, 5, 290. https://doi.org/10.3390/jcs5110290

Kapsalis P, Tysmans T, Van Hemelrijck D, Triantafillou T. State-of-the-Art Review on Experimental Investigations of Textile-Reinforced Concrete Exposed to High Temperatures. Journal of Composites Science. 2021; 5(11):290. https://doi.org/10.3390/jcs5110290

Chicago/Turabian StyleKapsalis, Panagiotis, Tine Tysmans, Danny Van Hemelrijck, and Thanasis Triantafillou. 2021. "State-of-the-Art Review on Experimental Investigations of Textile-Reinforced Concrete Exposed to High Temperatures" Journal of Composites Science 5, no. 11: 290. https://doi.org/10.3390/jcs5110290

APA StyleKapsalis, P., Tysmans, T., Van Hemelrijck, D., & Triantafillou, T. (2021). State-of-the-Art Review on Experimental Investigations of Textile-Reinforced Concrete Exposed to High Temperatures. Journal of Composites Science, 5(11), 290. https://doi.org/10.3390/jcs5110290