Effect of Hybrid Fibres on the Durability Characteristics of Ternary Blend Geopolymer Concrete

Abstract

:1. Introduction

2. Experimental Programme

2.1. Materials and Mix Proportion

2.2. Mixing, Casting, and Curing Procedures

2.3. Test Methods

2.3.1. Water Absorption Test

2.3.2. Sorptivity Test

- —Cumulative water absorption per unit area of inflow surface

- —Sorptivity

- —elapsed time

2.3.3. Abrasion Resistance Test

- —Initial volume of the sample

- —Surface area of the sample

2.3.4. Acid Attack Test

- —Compressive strength of cube immersed in water

- —Compressive strength of cube immersed in sulphuric acid

2.3.5. Marine Attack Test

2.3.6. Sulphate Attack Test

3. Test Results and Discussions

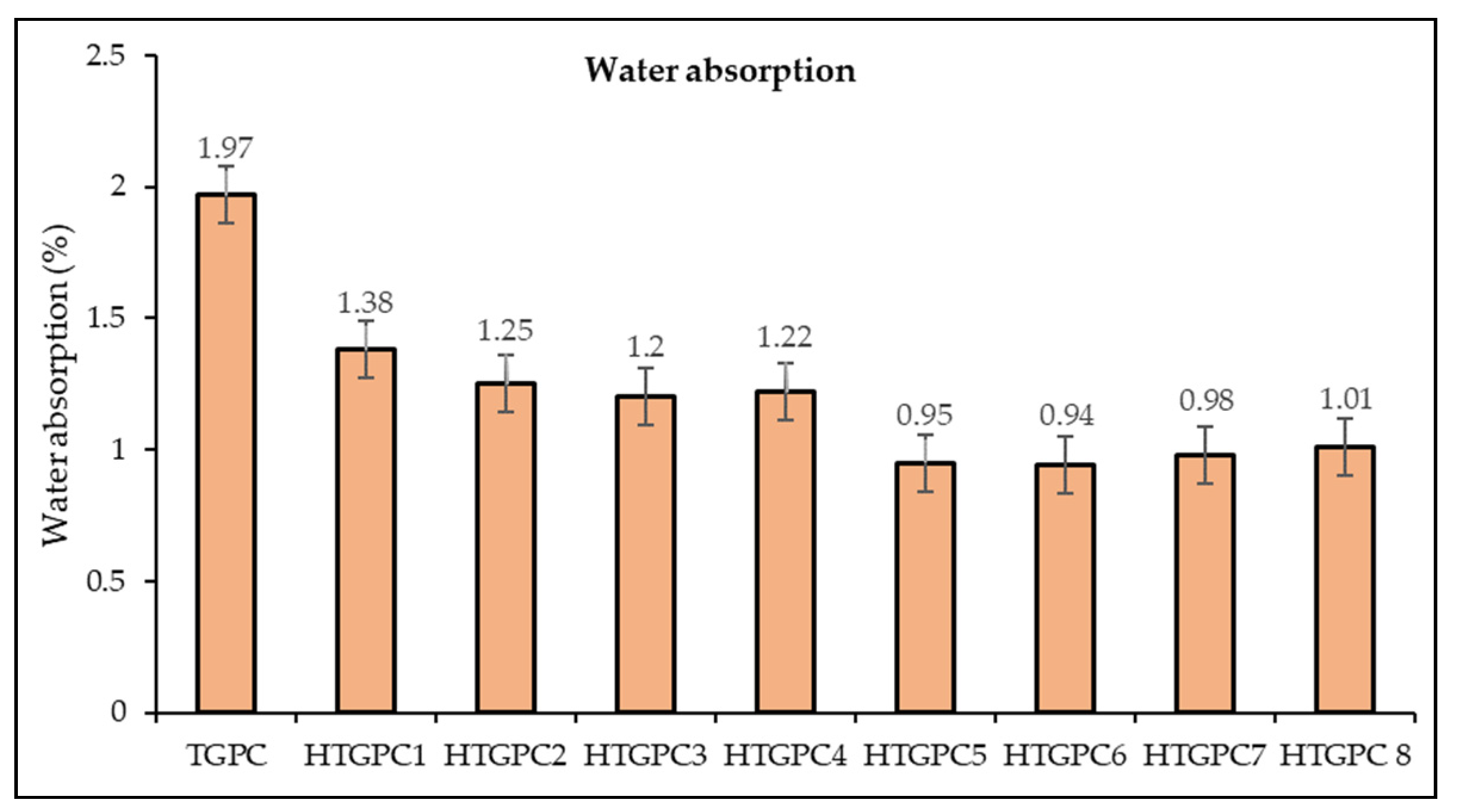

3.1. Water Absorption

3.2. Sorptivity

3.3. Abrasion Resistance

3.4. Acid Attack

3.5. Marine Attack

3.6. Sulphate Attack

| Sample | Vf | Vp | Water Absorpt. | Sorptivity × 10−2 | Loss in Thickness | Acid Attack | Marine Attack | Sulphate Attack | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (mm/min0.5) | (mm) | %Wt. Loss | %Loss in Strength | %Wt. Loss | %Loss in Strength | %Wt. Loss | %Loss in Strength | |

| TGPC | 0 | 0 | 1.97 | 11.01 | 0.58 | 1.50 | 16.9 | 0.93 | 9.27 | 1.14 | 13.61 |

| HTGPC1 | 0 | 0.1 | 1.38 | 10.16 | 0.43 | 0.68 | 13.62 | 0.64 | 5.17 | 0.68 | 7.93 |

| HTGPC2 | 0.15 | 1.25 | 10.10 | 0.39 | 0.70 | 12.52 | 0.63 | 5.00 | 0.65 | 7.04 | |

| HTGPC3 | 0.2 | 1.20 | 9.93 | 0.35 | 0.68 | 12.84 | 0.61 | 5.02 | 0.65 | 6.94 | |

| HTGPC4 | 0.25 | 1.22 | 9.92 | 0.34 | 0.71 | 12.82 | 0.62 | 5.10 | 0.68 | 6.30 | |

| HTGPC5 | 1 | 0.1 | 0.95 | 9.79 | 0.28 | 0.67 | 11.28 | 0.53 | 3.89 | 0.62 | 5.98 |

| HTGPC6 | 0.15 | 0.94 | 9.76 | 0.25 | 0.64 | 11.05 | 0.50 | 3.18 | 0.58 | 5.48 | |

| HTGPC7 | 0.2 | 0.98 | 9.82 | 0.25 | 0.60 | 11.23 | 0.52 | 3.20 | 0.57 | 5.50 | |

| HTGPC8 | 0.25 | 1.01 | 9.85 | 0.26 | 0.63 | 11.25 | 0.51 | 3.25 | 0.57 | 5.52 | |

4. Conclusions

- The water absorption values of TGPC and HTGPC were less than 10%, which is well below the mentioned value in the standards. The water absorption property was improved by 53% with the addition of hybrid fibres.

- Sorptivity test results of TGPC and HTGPC indicate that the capillary pressure exerted by the pore structure is considerably less. The maximum improvement in the sorptivity was around 11% with the addition of hybrid fibres.

- The abrasion resistance of TGPC and HTGPC is less than the limiting value of 2 mm for heavy-duty floor tiles, and hence the concrete can be used for highways, runways, etc. The abrasion resistance was improved by 55% with the addition of 1% steel fibres and 40% with 0.5% steel fibres.

- The results for the chemical attack show that HTGPC samples were more resistant than the TGPC. Results of loss in weight and compressive strength imply that HTGPC with 1% steel fibres performed better in all the cases.

- The TGPC samples with and without hybrid fibres convincingly met all the durability expectations considered in this study. The combination of 1% steel fibres and 0.15% polypropylene fibres exhibits better durability behaviour than the other mix proportions considered in this study. The results also confirmed that the durability properties are highly significant with the steel fibres rather than the polypropylene fibres used in this study.

Author Contributions

Funding

Conflicts of Interest

References

- Bondar, D.; Lynsdale, C.J.; Milestone, N.B.; Hassani, N.; Ramezanianpour, A.A. Engineering properties of alkali-activated natural pozzolan concrete. ACI Mater. J. 2011, 108, 64–72. [Google Scholar]

- Mustafa Al Bakri, A.M.; Kamarudin, H.; Bnhussain, M.; Rafiza, A.R.; Zarina, Y. Effect of Na2SiO3/NaOH ratios and NaOH molarities on compressive strength of fly-ash-based geopolymer. ACI Mater. J. 2012, 109, 503–508. [Google Scholar]

- Singh, N.; Kumar, M.; Rai, S. Geopolymer cement and concrete: Properties. Mater. Today Proc. 2020, 29, 743–748. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Man-made rock geosynthesis and the resulting development of very early high strength cement. J. Mater. Educ. 1994, 16, 91–139. [Google Scholar]

- Nodehi, M.; Taghvaee, V.M. Alkali-activated materials and geopolymer: A review of common precursors and activators addressing circular economy. Circ. Econ. Sustain. 2021, 1, 1–32. [Google Scholar] [CrossRef]

- Rangan, B.V. Engineering properties of geopolymer concrete. In Geopolymers; Provis, J.L., van Deventer, J.S.J., Eds.; Woodhead Publishing: Washington, DC, USA, 2009; pp. 211–226. [Google Scholar]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete: A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Kumar, V.S.; Ganesan, N.; Indira, P. Engineering Properties of Hybrid Fibre Reinforced Ternary Blend Geopolymer Concrete. J. Compos. Sci. 2021, 5, 203. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2020, 270, 121857. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Nodehi, M. A comparative review on foam-based versus lightweight aggregate-based alkali-activated materials and geopolymer. Innov. Infrastruct. Solut. 2021, 6, 1–20. [Google Scholar] [CrossRef]

- Nodehi, M.; Aguayo, F. Ultra high performance and high strength geopolymer concrete. J. Build. Pathol. Rehabil. 2021, 6, 34. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Raj, S.D. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476. [Google Scholar] [CrossRef]

- Paul, S.C.; Van Zijl, G.P.; Šavija, B. Effect of fibers on durability of concrete: A practical review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef] [PubMed]

- Yoo, D.-Y.; Banthia, N.; Yoon, Y.S. Impact resistance of reinforced ultra-high-performance concrete beams with different steel fibers. ACI Struct. J. 2017, 114, 113–124. [Google Scholar] [CrossRef]

- Singh, M.; Sheikh, A.H.; Ali, M.M.; Visintin, P.; Griffith, M.C. Experimental and numerical study of the flexural behaviour of ultra-high performance fibre reinforced concrete beams. Constr. Build. Mater. 2017, 138, 12–25. [Google Scholar] [CrossRef]

- Ali, B.; Raza, S.S.; Hussain, I.; Iqbal, M. Influence of different fibers on mechanical and durability performance of concrete with silica fume. Struct. Concr. 2020, 22, 318–333. [Google Scholar] [CrossRef]

- Sivakumar, A.; Santhanam, M. Mechanical properties of high strength concrete reinforced with metallic and non-metallic fibres. Cem. Concr. Compos. 2007, 29, 603–608. [Google Scholar] [CrossRef]

- Raza, A.; Khan, Q.U.Z. Experimental and numerical behavior of hybrid-fiber-reinforced concrete compression members under concentric loading. SN Appl. Sci. 2020, 2, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Das, S.; Sobuz, H.R.; Tam, V.W.; Akid, A.S.M.; Sutan, N.M.; Rahman, F.M. Effects of incorporating hybrid fibres on rheological and mechanical properties of fibre reinforced concrete. Constr. Build. Mater. 2020, 262, 120561. [Google Scholar] [CrossRef]

- Govindhan, S.; Eniyachandramouli, G.; Ranjithselvan, K.; Hariharan, S. Performance of HYBRID fibres in concrete. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Behnia, A.; Alengaram, U.J.; Jumaat, M.Z. Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar. Mater. Des. 2014, 59, 532–539. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M. Effect of hybrid basalt fibre length and content on properties of cementitious composites. Mag. Concr. Res. 2021, 73, 487–498. [Google Scholar] [CrossRef]

- Kumar, V.S.; Ganesan, N.; Indira, P.V. Effect of molarity of sodium hydroxide and curing method on the compressive strength of ternary blend geopolymer concrete. IOP Conf. Ser. Earth Environ. Sci. 2017, 80, 012011. [Google Scholar] [CrossRef] [Green Version]

- Ganesan, N.; Indira, P.V.; Kumar, V.S. Effect of alkaline activator to binder ratio on the compressive strength of ternary blend geopolymer concrete. ICI J. 2017, 17, 22–27. [Google Scholar]

- Kumar, V.S.; Indira, P.V.; Ganesan, N. Tension stiffening and cracking behaviour of hybrid fibre reinforced ternary blend geopolymer concrete. J. Struct. Eng. 2019, 46, 257–266. [Google Scholar]

- IS 3812:2003. Pulvarized Fuel Ash—Specification; Bureau of Indian Standards: New Delhi, India, 2003.

- BS 6699:1992. Ground Granulated Blast Furnace Slag for use with Portland Cement—Specification; British Standards Institution London: London, UK, 1992. [Google Scholar]

- IS 383:1970. Specification for Coarse and Fine Aggregates from Natural Sources for Concrete; Bureau of Indian Standards: New Delhi, India, 2002.

- Rangan, B.V.; Lloyd, N.A. Fly ash Based Geopolymer Concrete; Int. Work. Geopolymer Cem. Concr.; Allied Publishers: New Delhi, India, 2010; pp. 68–106. [Google Scholar]

- Ukritnukun, S.; Koshy, P.; Rawal, A.; Castel, A.; Sorrell, C.C. Predictive model of setting times and compressive strengths for low-alkali, ambient-cured, fly ash/slag-based geopolymers. Minerals 2020, 10, 920. [Google Scholar] [CrossRef]

- IS 2185 (Part 1):2005. Concrete Masonry Units—Specification; Bureau of Indian Standards: New Delhi, India, 2005.

- Neville, A.M. Properties of Concrete, 4th ed.; Longman & John Wiley: London, UK, 1995. [Google Scholar]

- ASTM C1585. Test Methods for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- IS 1237. Specification for Cement Concrete Flooring Tiles; Bureau of Indian Standards: New Delhi, India, 2012.

- Singh, M.; Siddique, R. Compressive strength, drying shrinkage and chemical resistance of concrete incorporating coal bottom ash as partial or total replacement of sand. Constr. Build. Mater. 2014, 68, 39–48. [Google Scholar] [CrossRef]

- Al-Swaidani, A.; Soud, A.; Hammami, A. Improvement of the early-age compressive strength, water permeability, and sulfuric acid resistance of scoria-based mortars/concrete using limestone filler. Adv. Mater. Sci. Eng. 2017, 2017, 1–17. [Google Scholar] [CrossRef] [Green Version]

- ASTM D1141-98. Standard Practice for the Preparation of Substitute Ocean Water; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Bolat, H.; Şimşek, O.; Çullu, M.; Durmuş, G. The effects of macro synthetic fiber reinforcement use on physical and mechanical properties of concrete. Compos. Part B Eng. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Rashid, M.U. Experimental investigation on durability characteristics of steel and polypropylene fiber reinforced concrete exposed to natural weathering action. Constr. Build. Mater. 2020, 250, 118910. [Google Scholar] [CrossRef]

- Safiuddin, M.; Abdel-Sayed, G.; Hearn, N. Absorption and strength properties of short carbon fiber reinforced mortar composite. Buildings 2021, 11, 300. [Google Scholar] [CrossRef]

- Skvara, F.; Kopecky, L.; Nemecek, J.; Bittnar, Z.D.E.N.I.K. Microstructure of geopolymer materials based on fly ash. Ceram. Silikáty 2006, 50, 208–215. [Google Scholar]

- Vafaei, D.; Hassanli, R.; Ma, X.; Duan, J.; Zhuge, Y. Sorptivity and mechanical properties of fiber-reinforced concrete made with seawater and dredged sea-sand. Constr. Build. Mater. 2020, 270, 121436. [Google Scholar] [CrossRef]

- Akid, A.S.M.; Hossain, S.; Munshi, I.U.; A Elahi, M.; Sobuz, H.R.; Tam, V.W.; Islam, S. Assessing the influence of fly ash and polypropylene fiber on fresh, mechanical and durability properties of concrete. J. King Saud. Univ. Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Esmaeili, M.; Ghahari, S.; Najafi, M. Laboratory study on the effect of polypropylene fiber on durability, and physical and mechanical characteristic of concrete for application in sleepers. Constr. Build. Mater. 2013, 44, 411–418. [Google Scholar] [CrossRef]

- Horszczaruk, E. Abrasion resistance of high strength fibre-reinforced concrete. In Proceedings of the 6th International RILEM Symposium on Fibre Reinforced Concretes, Varenna, Italy, 20–22 September 2004; pp. 257–266. [Google Scholar]

- Ristić, N.; Topliĉić-Ćurĉić, G.; GRDIĆ, D. Abrasion resistance of concrete made with micro fibers and recycled granulated rubber. Zast. Mater. 2015, 56, 435–445. [Google Scholar] [CrossRef] [Green Version]

- Shagñay, S.; Ramón, L.; Fernández-Álvarez, M.; Bautista, A.; Velasco, F.; Torres-Carrasco, M. Eco-efficient hybrid cements: Pozzolanic, mechanical and abrasion properties. Appl. Sci. 2020, 10, 8986. [Google Scholar] [CrossRef]

- Shagñay, S.; Velasco, F.; del Campo, A.; Torres-Carrasco, M. Wear behavior in pastes of alkali-activated materials: Influence of precursor and alkali solution. Tribol. Int. 2020, 147, 106293. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Ngian, S.P.; Tahir, M.M. Performance evaluation of sustainable concrete comprising waste polypropylene food tray fibers and palm oil fuel ash exposed to sulfate and acid attacks. Crystals 2021, 11, 966. [Google Scholar] [CrossRef]

- Pacheco, F.; Christ, R.; Quinino, U.; Tutikian, B.F. Effects of fiber hybridisation in advanced cementitious composites durability in humid and aggressive environments. Revistamateria 2018, 23, 1–13. [Google Scholar]

- Lavanya, G.; Jegan, J. Durability Study on High Calcium Fly Ash Based Geopolymer Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Irassar, E.; González, M.; Rahhal, V. Sulphate resistance of type V cements with limestone filler and natural pozzolana. Cem. Concr. Compos. 2000, 22, 361–368. [Google Scholar] [CrossRef]

- Kobayashi, K.; Kojima, Y. Effect of fine crack width and water cement ratio of SHCC on chloride ingress and rebar corrosion. Cem. Concr. Compos. 2017, 80, 235–244. [Google Scholar] [CrossRef]

- Miyazato, S.; Hiraishi, Y. Durability against Steel Corrosion of HPFRCC with Bending Cracks. J. Adv. Concr. Technol. 2013, 11, 135–143. [Google Scholar] [CrossRef] [Green Version]

| Oxides%/Properties | Fly Ash | GGBS | Metakaolin |

|---|---|---|---|

| Alumina, Al2O3 | 27.75 | 20.86 | 42.38 |

| Silica, SiO2 | 55.36 | 32.49 | 56.64 |

| Iron oxide, Fe2O3 | 9.74 | 0.68 | 0.42 |

| Titanium dioxide, TiO2 | 3.54 | - | 0.1 |

| Potassium oxide, K2O | 2.55 | - | 0.04 |

| Calcium oxide, CaO | 1.07 | 37.04 | 0.1 |

| Magnesium oxide, MgO | - | 7.82 | 0.2 |

| Sulphur, S | - | 0.98 | - |

| Manganese, Mn | - | 0.11 | - |

| Chloride, Cl | - | 0.012 | - |

| Sodium oxide, NaO | - | - | 0.11 |

| Specific gravity | 2.3 | 2.88 | 2.56 |

| Average particle size | 75 microns | 30 microns | 2–3 microns |

| Colour | Dark grey | Off-white | Creamish ivory |

| Properties | Fine Aggregate | Coarse Aggregate |

|---|---|---|

| Specific gravity | 2.39 | 2.79 |

| Fineness modulus | 2.92 | 6.79 |

| Bulk density | 1840 kg/m3 | 1610 kg/m3 |

| Loose density | 1720 kg/m3 | 1450 kg/m3 |

| Water absorption | 6.5% | 1.67% |

| Percentage of voids | 30.30% | 32.30% |

| Properties | Steel Fibre | Polypropylene Fibre |

|---|---|---|

| Length | 30 mm | 12 mm |

| Diameter | 0.45 mm | 40 micron |

| Aspect ratio | 66 | 300 |

| Tensile strength | 800 MPa | 550–600 MPa |

| Density | 7950 kg/m3 | 950 kg/m3 |

| Materials | Quantity (kg/m3) |

|---|---|

| Fly ash | 237.47 |

| GGBS | 122.61 |

| Metakaolin | 64.53 |

| Coarse aggregate | 1293.60 |

| Fine aggregate | 554.40 |

| NaOH solution | 36.40 |

| Na2SiO3 | 90.99 |

| Superplasticizer | 6.37 |

| Water | 84.92 |

| Tests | Type of Samples | Size |

|---|---|---|

| Water absorption | Cube | 100 mm |

| Sorptivity | Cylinder | 150 mm dia × 50 mm |

| Abrasion resistance | Tiles | 70.7 × 70.7 × 25 mm |

| Acid attack | Cube | 100 mm |

| Marine attack | Cube | 100 mm |

| Sulphate attack | Cube | 100 mm |

| Composition | Concentration (g/lit) |

|---|---|

| Sodium chloride | 24.53 |

| Magnesium chloride | 5.2 |

| Sodium sulphate | 4.09 |

| Calcium chloride | 1.16 |

| Potassium chloride | 0.695 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sathish Kumar, V.; Ganesan, N.; Indira, P.V. Effect of Hybrid Fibres on the Durability Characteristics of Ternary Blend Geopolymer Concrete. J. Compos. Sci. 2021, 5, 279. https://doi.org/10.3390/jcs5100279

Sathish Kumar V, Ganesan N, Indira PV. Effect of Hybrid Fibres on the Durability Characteristics of Ternary Blend Geopolymer Concrete. Journal of Composites Science. 2021; 5(10):279. https://doi.org/10.3390/jcs5100279

Chicago/Turabian StyleSathish Kumar, V., N. Ganesan, and P. V. Indira. 2021. "Effect of Hybrid Fibres on the Durability Characteristics of Ternary Blend Geopolymer Concrete" Journal of Composites Science 5, no. 10: 279. https://doi.org/10.3390/jcs5100279

APA StyleSathish Kumar, V., Ganesan, N., & Indira, P. V. (2021). Effect of Hybrid Fibres on the Durability Characteristics of Ternary Blend Geopolymer Concrete. Journal of Composites Science, 5(10), 279. https://doi.org/10.3390/jcs5100279