Experimental and Numerical Investigation on the Steel Reinforced Grout (SRG) Composite-to-Concrete Bond

Abstract

:1. Introduction

- (i)

- Check the effectiveness of the medium density steel fabric as a reinforcement of an SRG strengthening system. Due to the reduced dimension of the spacing between steel cords in medium density steel fabrics, in fact, the inorganic matrix could not be able to penetrate and cover the individual steel cords reducing the bond between the strengthening system and the substrate.

- (ii)

- Evaluate the influence of some parameters on the bond performances of medium-density SRG to-concrete joints. In particular, the parameters considered were the bonded length (100, 200, 250, 330, and 450 mm) and the age of the composite (14th, 21st, and 28th day after the bonding).

2. Experimental Investigation

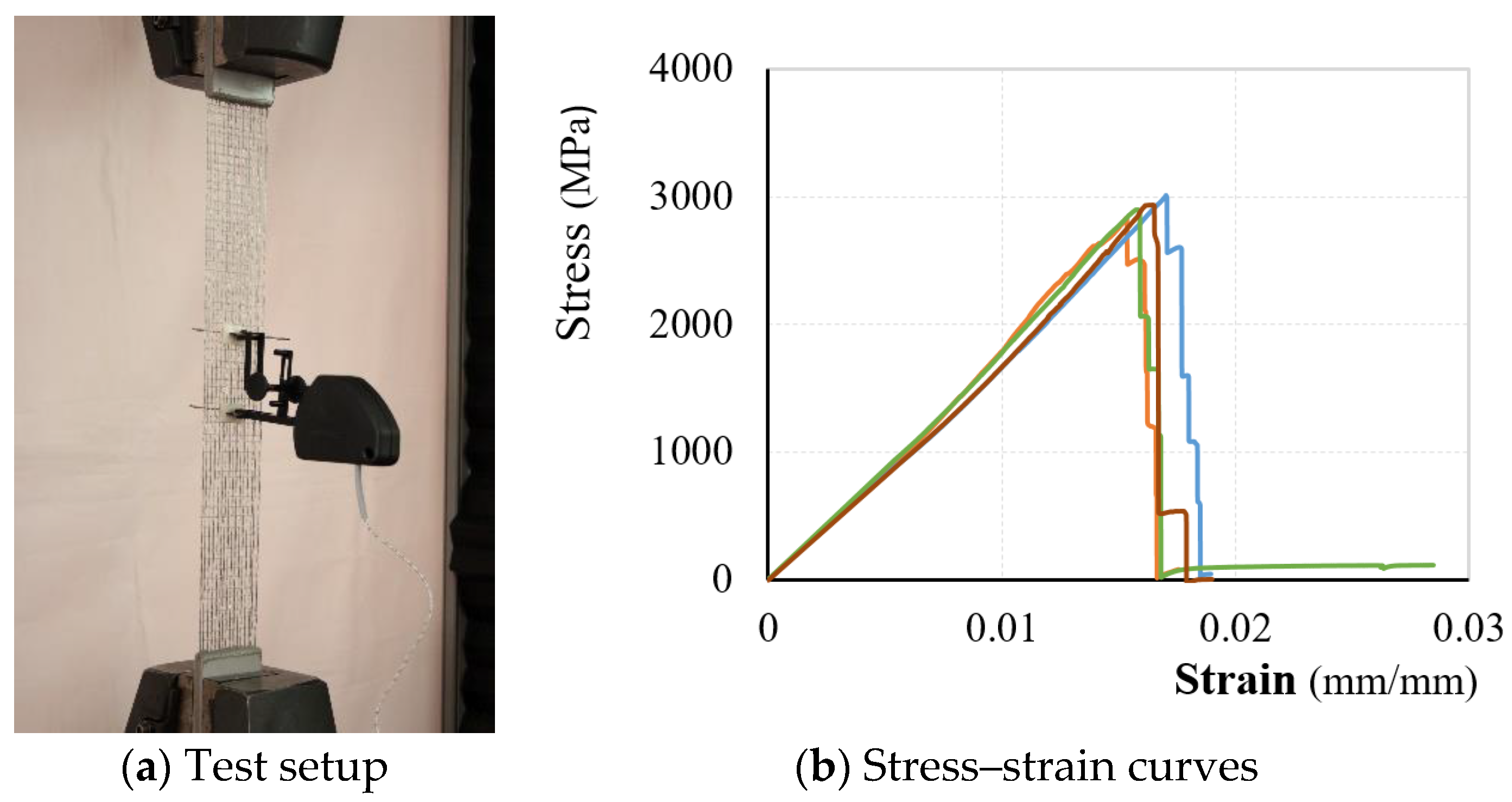

2.1. Materials

2.2. Specimen Preparation

2.3. Test Set-Up

3. Results

3.1. Failure Modes

3.2. Peak Stress and Strains

3.3. Load–Slip Diagrams

3.3.1. Effect of the Bonded Length

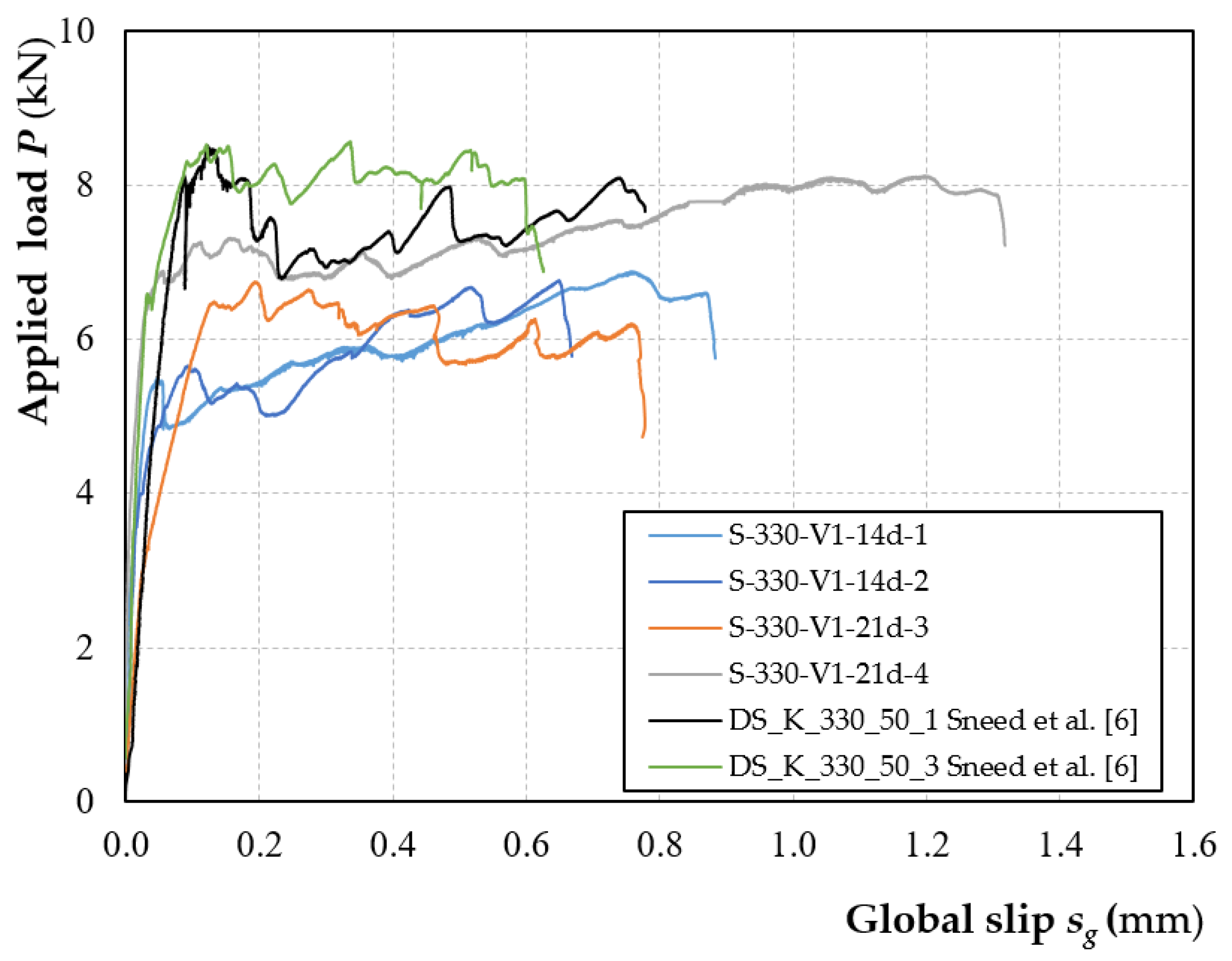

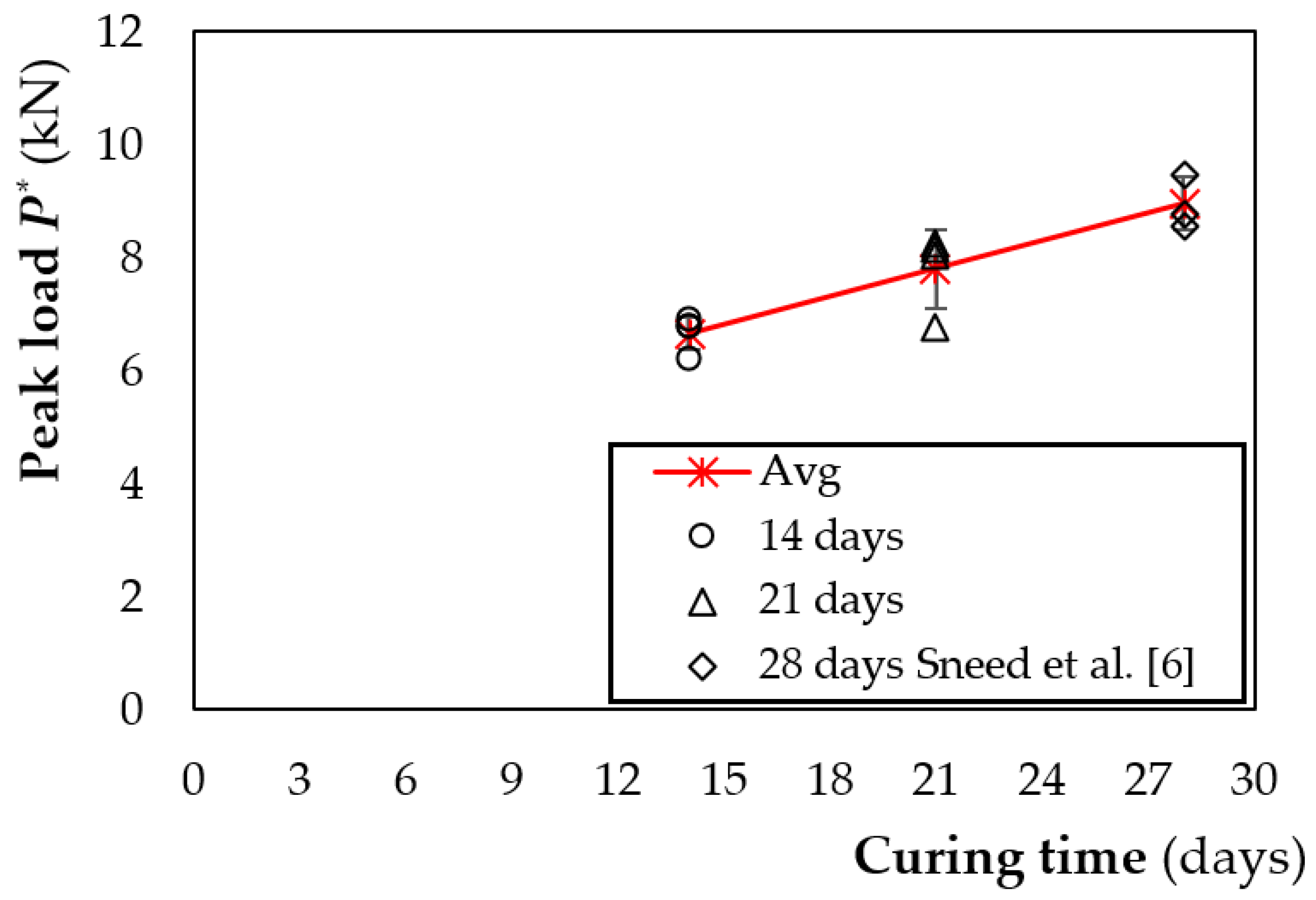

3.3.2. Effect of Age of the SRG Strips

3.3.3. Influence of the Rotation of the Concrete Block

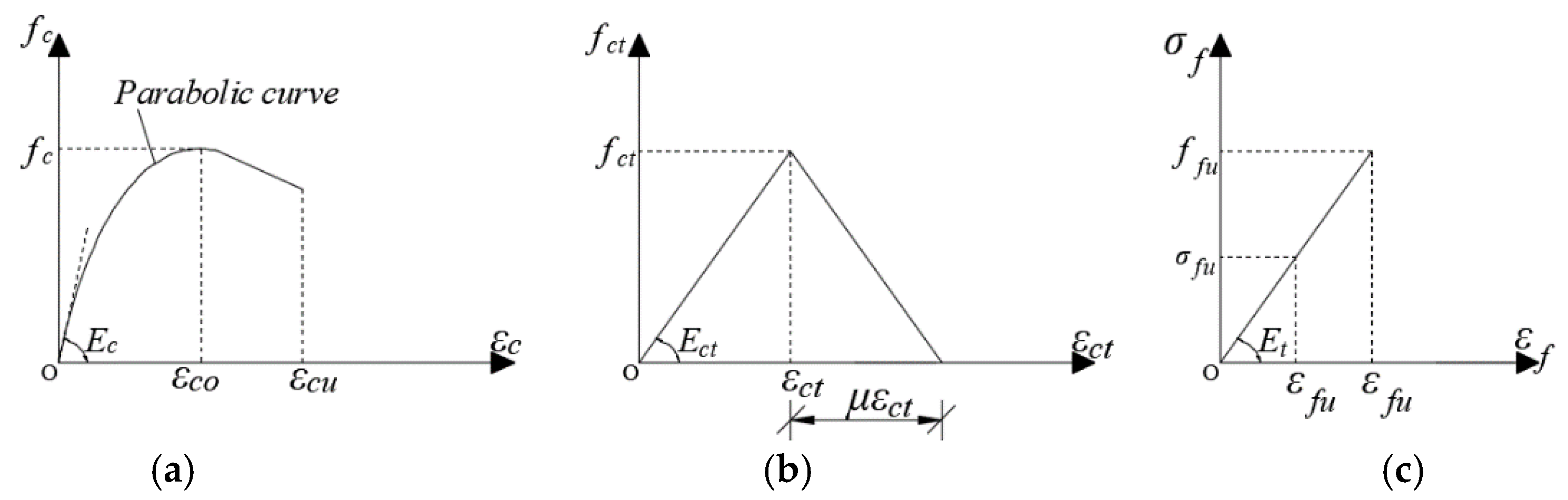

4. Numerical Modeling

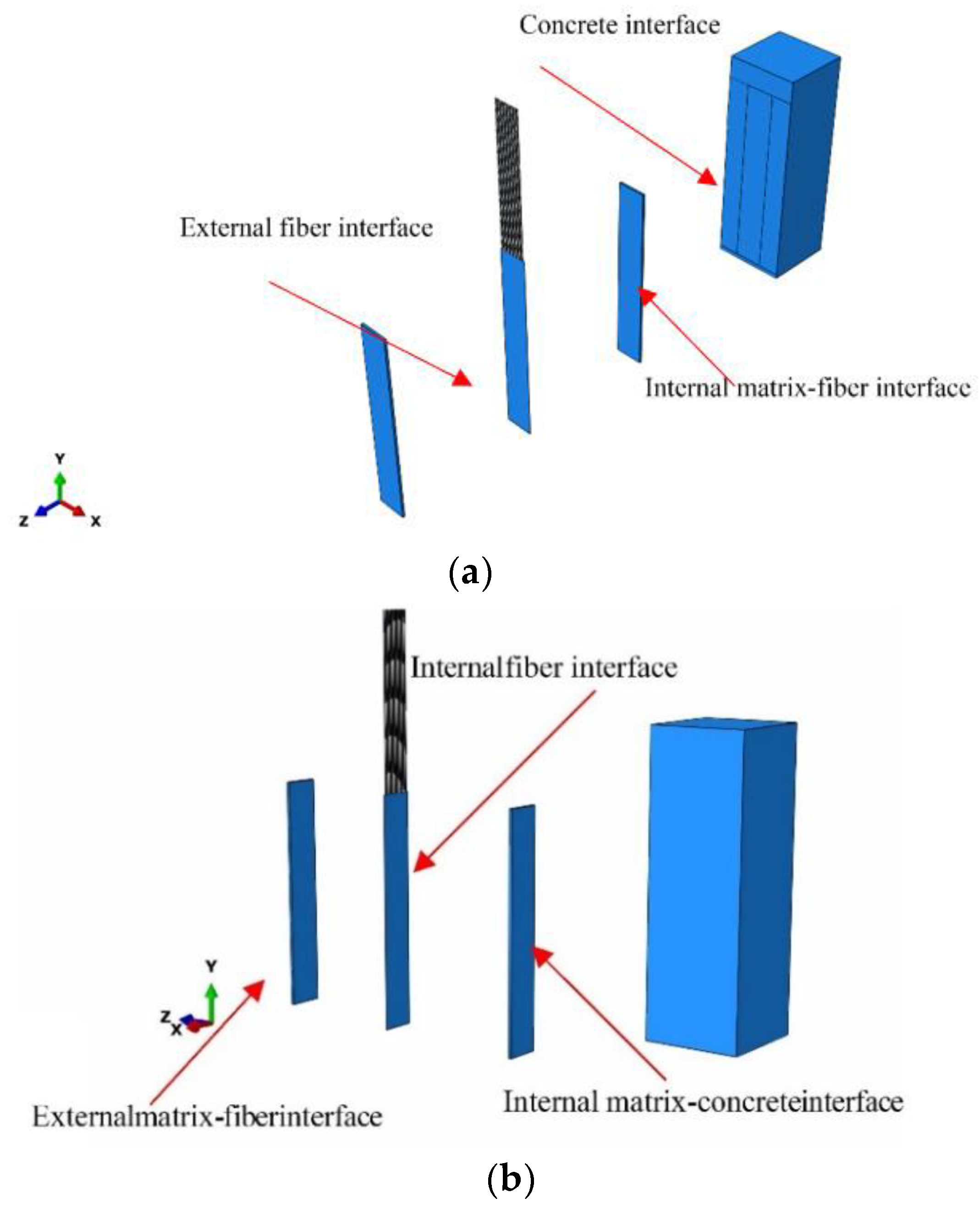

4.1. Geometrical Modeling

4.1.1. Materials and Interface Modeling

4.1.2. Numerical Solution

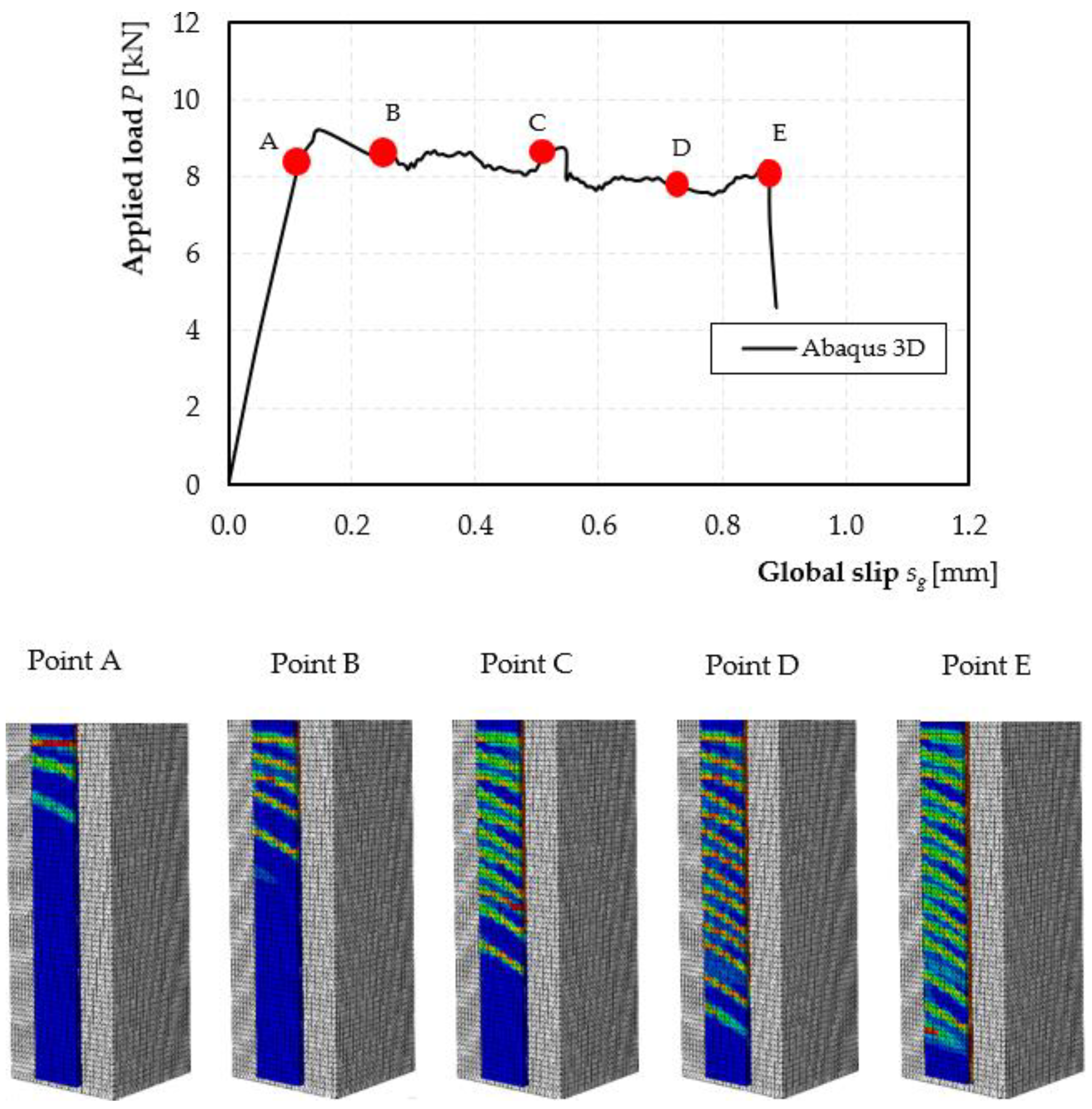

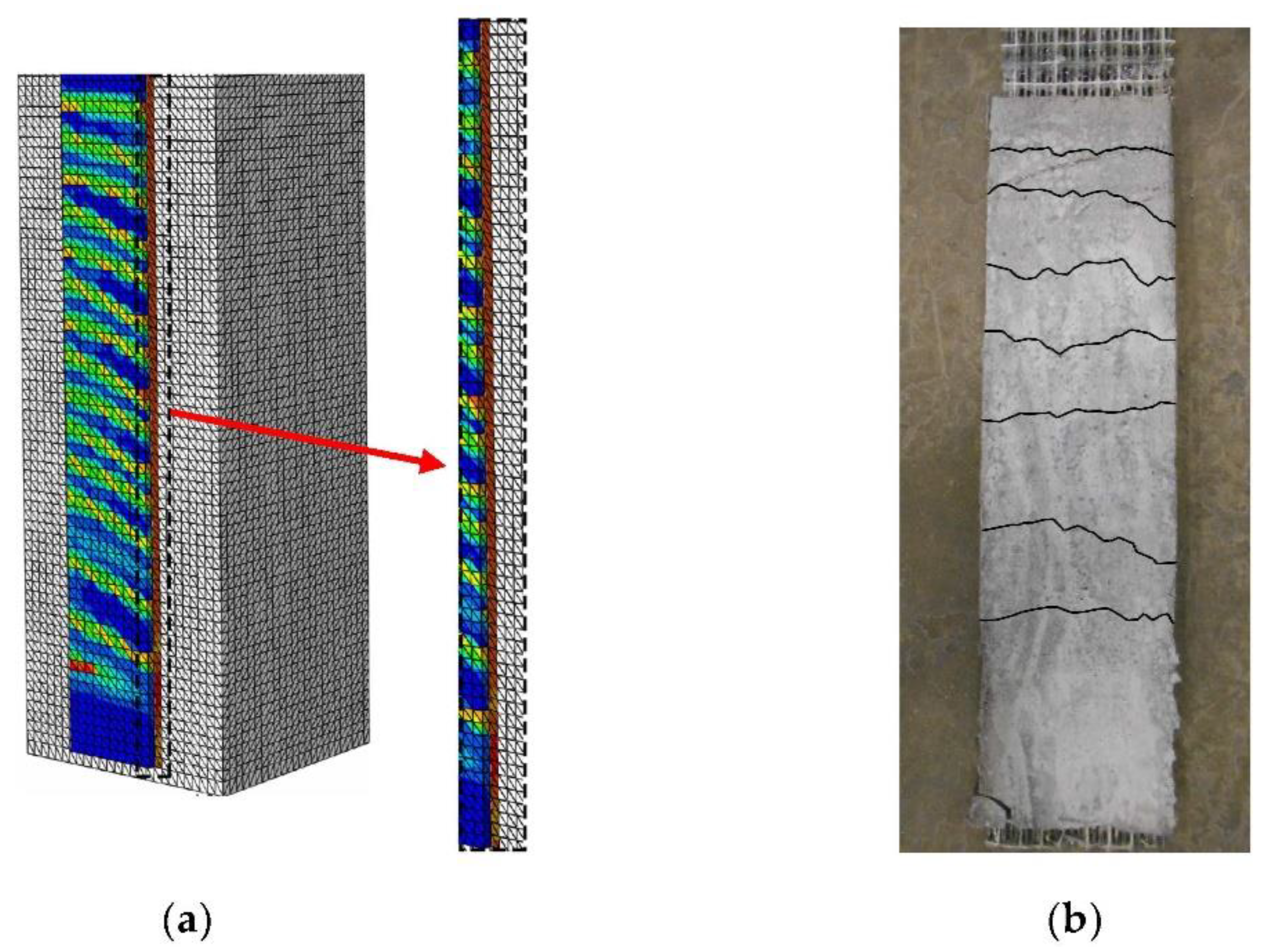

4.2. Experimental/Numerical Comparison

Present and Sneed et al. Investigations

5. Conclusions

- The medium density SRG system adopted in this investigation, as evidenced by the results of the experimental investigation described in [6] is effective as strengthening system. The bond SRG-to-concrete, analyzed in this investigation is, in fact, satisfactory (i.e., the values of the maximum load reached for bonded lengths greater than 200 mm are similar with a difference of around 5%).

- The efficiency of the medium density SRG system adopted in this investigation expressed by the exploitation ratio of the tensile strength of the textile was lower than 40%. This low efficiency is related to the occurrence of the interlaminar failure in all tested specimens.

- The effective bonded length of the SRG-to-concrete joints, referred to the end of the curing time of the SRG system (28th days), is about l = 200 mm.

- The curing time of the SRG system influences the bond; the peak load increased linearly with the age of the composite.

- The average of the out-of-plane displacements wc and wd of the specimens at the peak load increase with the age of the composite and bonded length; their values, however, appear to be small and allow to assume that the Mode-I component is negligible.

- The numerical approach furnishes good predictions of the experimental results mainly in terms of applied load–global slip curves. In particular, the predicted values of the peak load differ only by 3% with respect to the experimental values.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De Santis, S.; de Felice, G. Steel reinforced grout systems for the strengthening of masonry structures. Comp. Struct. 2015, 134, 533–548. [Google Scholar] [CrossRef]

- De Santis, S.; Ceroni, F.; de Felice, G.; Fagone, M.; Ghiassi, B.; Kwiecień, A.; Lignola, G.P.; Morganti, M.; Santandrea, M.; Valluzzi, M.R.; et al. Round robin test on tensile and bond behaviour of steel reinforced grout systems. Comp. Part B Eng. 2017, 127, 100–120. [Google Scholar] [CrossRef]

- Ascione, L.; de Felice, G.; De Santis, S. A qualification method for externally bonded fibre reinforced cementitious matrix (FRCM) reinforcement systems. Comp. Part B Eng. 2015, 78, 497–506. [Google Scholar] [CrossRef]

- Huang, X.; Birman, V.; Nanni, A.; Tunis, G. Properties and potential for application of steel reinforced polymer and steel reinforced grout composites. Comp. Part B Eng. 2005, 36, 73–82. [Google Scholar] [CrossRef]

- Razavizadeh, A.; Ghiassi, B.; Oliveira, D.V. Bond behavior of SRG-strengthened masonry units: Testing and numerical modeling. Const. Build. Mater. 2014, 64, 387–397. [Google Scholar] [CrossRef]

- Sneed, L.H.; Verre, S.; Carloni, C.; Ombres, L. Flexural behavior of RC beams strengthened with steel-FRCM composite. Eng. Struct. 2016, 127, 686–699. [Google Scholar] [CrossRef]

- Napoli, A.; Realfonzo, R. Reinforced concrete beams strengthened with SRP/SRG systems: Experimental investigation. Constr. Build. Mater. 2015, 93, 654–677. [Google Scholar] [CrossRef]

- Ascione, F.; Lamberti, M.; Napoli, A.; Realfonzo, R. Experimental bond behavior of Steel Reinforced Grout systems for strengthening concrete elements. Constr. Build. Mater. 2020, 232, 117105. [Google Scholar] [CrossRef]

- Ascione, F.; Faella, C.; Lamberti, M.; Napoli, A.; Realfonzo, R. Strengthening of RC structures with SRP/SRG systems: Bond test. In Proceedings of the Durability and Sustainability of Concrete Structures (DSCS-2018)—Proc. of Durability and Sustainability of Concrete Structures (DSCS-2018), Moscow, Russia, 6–7 June 2018. [Google Scholar]

- Carloni, C.; Verre, S.; Sneed, L.H.; Ombres, L. Loading rate effect on the debonding phenomenon in fiber reinforced cementitious matrix-concrete joints. Comp. Part B Eng. 2017, 108, 301–314. [Google Scholar] [CrossRef]

- Bencardino, F.; Nisticò, M.; Verre, S. Experimental investigation and numerical analysis of bond behavior in SRG-strengthened masonry prisms using UHTSS and stainless-steel fibers. Fibers 2020, 8, 8. [Google Scholar] [CrossRef] [Green Version]

- Abaqus Code. Finite Element Code; Karlsson, Hibbitt & Sorensen, Inc.: Pawtucket, RI, USA, 2012. [Google Scholar]

- ASTM C39 Standard Test Method for Compressive Strength of Concrete Cylinder Specimens; ASTM: West Conshohocken, PA, USA, 2016; 7p.

- ASTM C496 Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM: West Conshohocken, PA, USA, 2011; 5p.

- Kerakoll, S.p.A. Available online: www.kerakoll.com (accessed on 1 February 2016).

- ASTM. Standard Practice for Use of Unbonded Caps in Determination of Compressive Strength of Concrete Cylinders (C1231); ASTM: West Conshohocken, PA, USA, 2014; 5p. [Google Scholar]

- D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. Effect of the inherent eccentricity in a single-lap direct-shear tests of PBO FRCM-concrete joints. Comp. Struct. 2016, 142, 117–129. [Google Scholar] [CrossRef]

- Ombres, L.; Iorfida, A.; Verre, S. FRCM/SRG—Masonry Joints: Experimental Investigation and Numerical Modelling. Key Eng. Mater. 2019, 817, 3–8. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Flexural Strengthening of RC Beams with Steel-Reinforced Grout: Experimental and Numerical Investigation. J. Comp. Const. 2019, 23. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Numerical Modeling Approaches of FRCMs/SRG Confined Masonry Columns. Front. Built Environ. 2019, 5, 143. [Google Scholar] [CrossRef] [Green Version]

- Hognestad, E. Study of Combined Bending and Axial Load in Reinforced Concrete Members. University of Illinois. Engineering Experiment Station. Available online: https://trid.trb.org/view/618359 (accessed on 3 December 2020).

- Kara, I.F.; Ashour, A.F.; Köroğlu, M.A. Flexural behavior of hybrid FRP/steel reinforced concrete beams. Comp. Struct. 2015, 129, 111–121. [Google Scholar] [CrossRef]

- Lu, X.Z.; Teng, J.G.; Ye, L.P.; Jiang, J.J. Bond slip models for FRP sheet/plates bonded to concrete. Eng. Struct. 2005, 27, 920–937. [Google Scholar] [CrossRef]

- Chen, G.M.; Teng, J.G.; Chen, J.F.; Xiao, Q.C. Finite element modeling of the debonding failures in FRP-strengthened RC beams: A dynamic approach. Comp. Struct. 2015, 158, 167–183. [Google Scholar] [CrossRef] [Green Version]

- Carloni, C.; D’Antino, T.; Sneed, L.H.; Pellegrino, C. Three-Dimensional Numerical Modeling of Single-Lap Direct Shear Tests of FRCM-Concrete Joints Using a Cohesive Damaged Contact Approach. J. Compos. Constr. 2018, 22. [Google Scholar] [CrossRef]

| Concrete Batch | Compressive Strength (MPa) (C.o.V.) | Tensile Strength (MPa) (C.o.V.) |

|---|---|---|

| C1 | 31.5 (0.02) | 3.1 (0.05) |

| C2 | 40.9 (0.03) | 3.5 (0.08) |

| Elastic Modulus (GPa) (C.o.V.) | Tensile Stress (GPa) (C.o.V.) | Ultimate Strain (mm/mm) (C.o.V.) | |

|---|---|---|---|

| Steel fabric | 200 (0.081) | 3.01 (0.010) | 0.020 (0.08) |

| Matrix Batch | Compressive Strength (MPa) (C.o.V.) | Tensile Strength (MPa) (C.o.V.) |

|---|---|---|

| M1 | 20.53 (0.12) | 2.65 (0.21) |

| M2 | 25.96 (0.03) | 2.61 (0.27) |

| M3 | 28.27 (0.14) | 2.63 (0.21) |

| M4 | 37.31 (0.04) | 4.22 (0.18) |

| Specimens | Concrete/Mortar Batch | Peak Load, P* (kN) | Peak Stress, σ* (MPa) | Exploitation Ratio, σ*/ffu | Average Values of σ*/ffu | εf |

|---|---|---|---|---|---|---|

| S-100-V1-1 | C2/M4 | 8.57 | 670 | 0.351 | 0.301 | 0.003268 |

| S-100-V1-2 | C2/M4 | 6.09 | 480 | 0.251 | 0.002341 | |

| S-200-V1-1 | C2/M4 | 9.34 | 730 | 0.383 | 0.393 | 0.003561 |

| S-200-V1-2 | C2/M4 | 9.67 | 750 | 0.393 | 0.003659 | |

| S-200-V1-3 | C2/M4 | 9.95 | 770 | 0.404 | 0.003756 | |

| S-250-V1-1 | C2/M4 | 9.53 | 740 | 0.388 | 0.402 | 0.003610 |

| S-250-V1-2 | C2/M4 | 9.67 | 750 | 0.393 | 0.003659 | |

| S 250-V1-3 | C2/M4 | 10.46 | 810 | 0.425 | 0.003951 | |

| DS_K_330_50_1 | C1/M3 | 9.48 | 740 | 0.388 | 0.367 | 0.003610 |

| DS_K_330_50_3 | C1/M3 | 8.57 | 670 | 0.351 | 0.003268 | |

| DS_K_330_50_4 | C1/M3 | 8.80 | 690 | 0.362 | 0.003366 | |

| S-450-V1-1 | C1/M3 | 8.57 | 670 | 0.351 | 0.375 | 0.003268 |

| S-450-V1-2 | C1/M3 | 9.37 | 730 | 0.383 | 0.003561 | |

| S-450-V1-3 | C1/M3 | 8.77 | 680 | 0.357 | 0.003317 | |

| S-450-V1-4 | C1/M2 | 9.99 | 780 | 0.409 | 0.003805 | |

| S-330-14d-1 | C2/M1 | 6.88 | 540 | 0.283 | 0.274 | 0.002634 |

| S-330-14d-2 | C2/M1 | 6.76 | 530 | 0.278 | 0.002585 | |

| S-330-14d-3 | C2/M1 | 6.22 | 490 | 0.257 | 0.002390 | |

| S-330-14d-4 | C2/M1 | 6.78 | 530 | 0.278 | 0.002585 | |

| S-330-21d-1 | C2/M1 | 8.26 | 640 | 0.336 | 0.318 | 0.003122 |

| S-330-21d-2 | C2/M1 | 8.05 | 630 | 0.330 | 0.003073 | |

| S-330-21d-3 | C2/M1 | 6.75 | 530 | 0.278 | 0.002585 | |

| S-330-21d-4 | C2/M1 | 8.13 | 630 | 0.330 | 0.003073 | |

| DS_K_330_L_1 | C1/M3 | 8.07 | 630 | 0.330 | 0.379 | 0.003073 |

| DS_K_330_L_2 | C1/M3 | 9.64 | 750 | 0.393 | 0.003659 | |

| DS_K_330_L_3 | C1/M3 | 9.92 | 770 | 0.404 | 0.003756 | |

| DS_K_330_L_4 | C1/M3 | 9.45 | 740 | 0.388 | 0.003610 |

| Specimens | w* (mm) | w*avg (mm) |

|---|---|---|

| S-100-V1-1 | 0.12 | 0.12 |

| S-100-V1-2 | 0.11 | |

| S-200-V1-1 | 0.29 | 0.31 |

| S-200-V1-2 | 0.31 | |

| S-200-V1-3 | 0.33 | |

| S-250-V1-1 | 0.42 | 0.40 |

| S-250-V1-2 | 0.37 | |

| S 250-V1-3 | 0.42 | |

| DS_K_330_50_1 | 0.50 | 0.45 |

| DS_K_330_50_3 | 0.48 | |

| DS_K_330_50_4 | 0.38 | |

| S-450-V1-1 | 0.51 | 0.76 |

| S-450-V1-2 | 0.78 | |

| S-450-V1-3 | 0.87 | |

| S-450-V1-4 | 0.90 | |

| S-330-14d-1 | 0.33 | 0.33 |

| S-330-14d-2 | 0.35 | |

| S-330-14d-3 | 0.32 | |

| S-330-14d-4 | 0.31 | |

| S-330-21d-1 | 0.40 | 0.38 |

| S-330-21d-2 | 0.40 | |

| S-330-21d-3 | 0.30 | |

| S-330-21d-4 | 0.42 | |

| DS_K_330_50_L_1 | 0.57 | 0.68 |

| DS_K_330_50_L_2 | 0.62 | |

| DS_K_330_50_L_3 | 0.79 | |

| DS_K_330_50_L_4 | 0.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ombres, L.; Verre, S. Experimental and Numerical Investigation on the Steel Reinforced Grout (SRG) Composite-to-Concrete Bond. J. Compos. Sci. 2020, 4, 182. https://doi.org/10.3390/jcs4040182

Ombres L, Verre S. Experimental and Numerical Investigation on the Steel Reinforced Grout (SRG) Composite-to-Concrete Bond. Journal of Composites Science. 2020; 4(4):182. https://doi.org/10.3390/jcs4040182

Chicago/Turabian StyleOmbres, Luciano, and Salvatore Verre. 2020. "Experimental and Numerical Investigation on the Steel Reinforced Grout (SRG) Composite-to-Concrete Bond" Journal of Composites Science 4, no. 4: 182. https://doi.org/10.3390/jcs4040182

APA StyleOmbres, L., & Verre, S. (2020). Experimental and Numerical Investigation on the Steel Reinforced Grout (SRG) Composite-to-Concrete Bond. Journal of Composites Science, 4(4), 182. https://doi.org/10.3390/jcs4040182