Simulating Mold Filling in Compression Resin Transfer Molding (CRTM) Using a Three-Dimensional Finite-Volume Formulation

Abstract

:1. Introduction

2. Basic Fluid Mechanic Equations for Mold Filling Simulations

3. Finite-Volume CRTM Mold Filling Simulation Method and Implementation to OpenFOAM

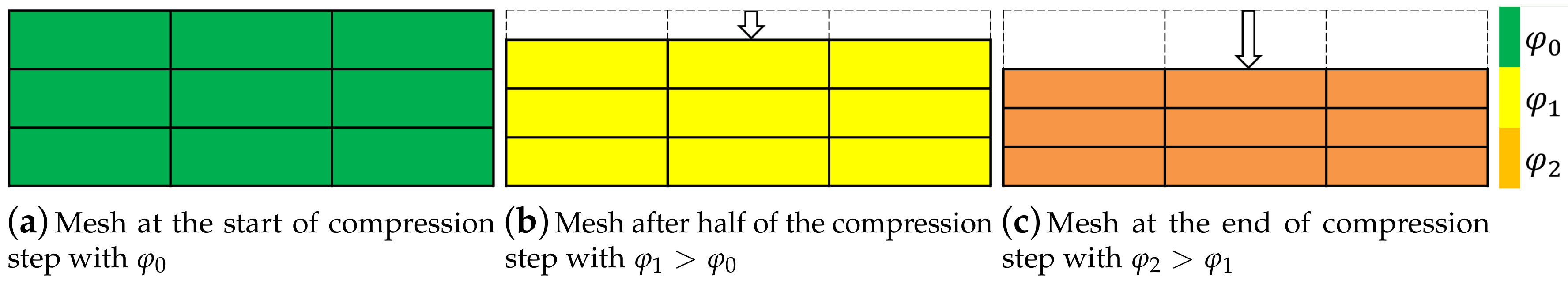

3.1. Treatment of the Mesh Deformation during the Compression Step

3.2. Modeling of the Fluid Velocity

4. Verification of the CRTM Mold Filling Simulation Method

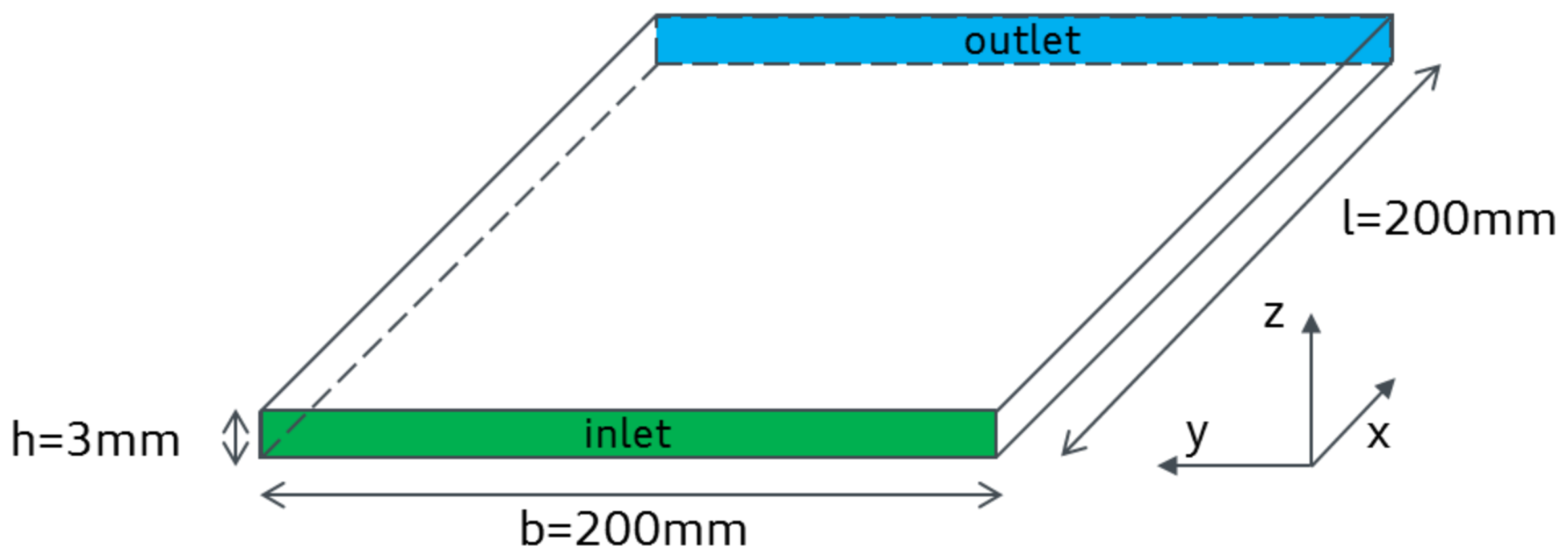

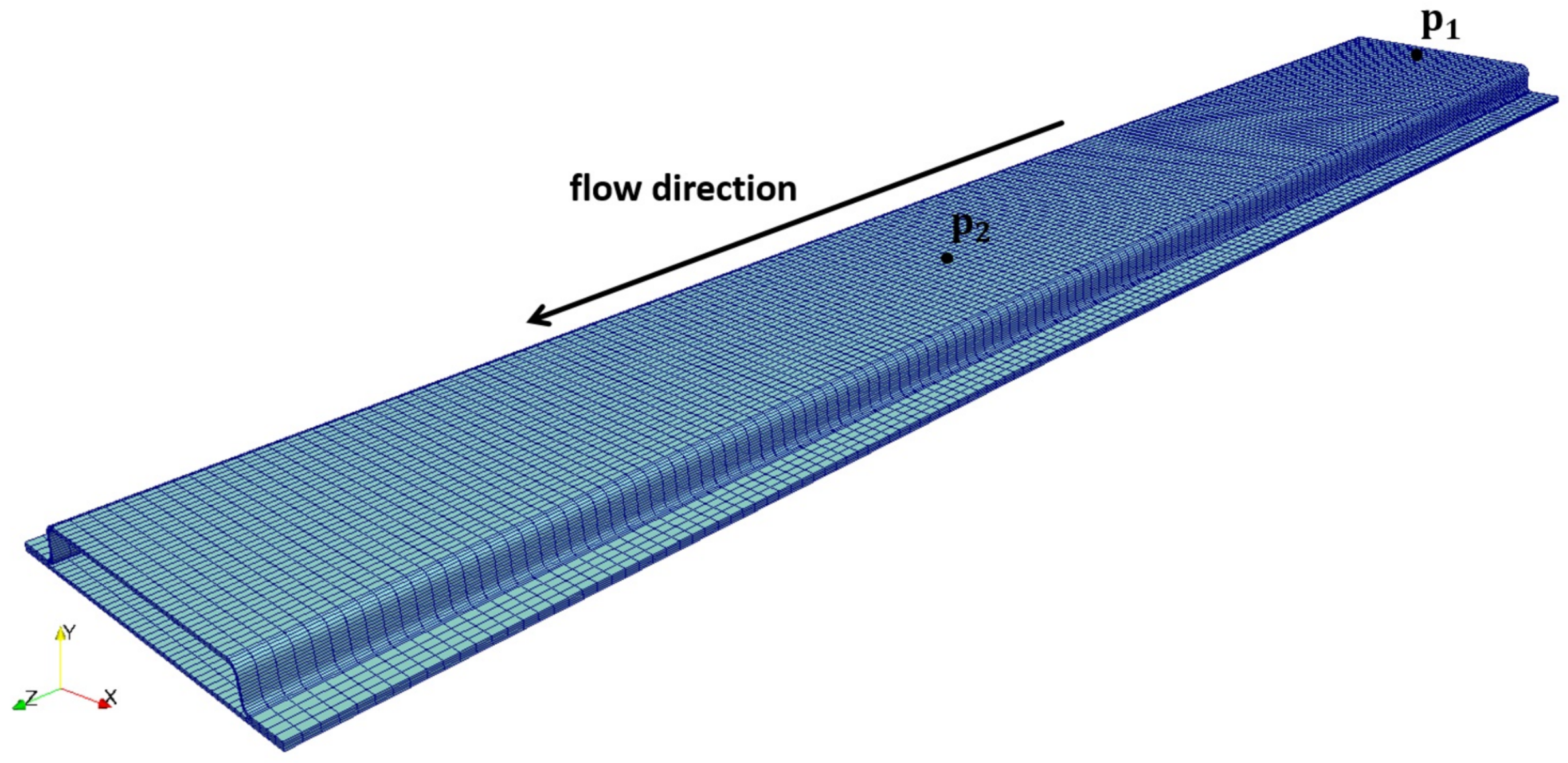

4.1. Simulation Model and Parameters

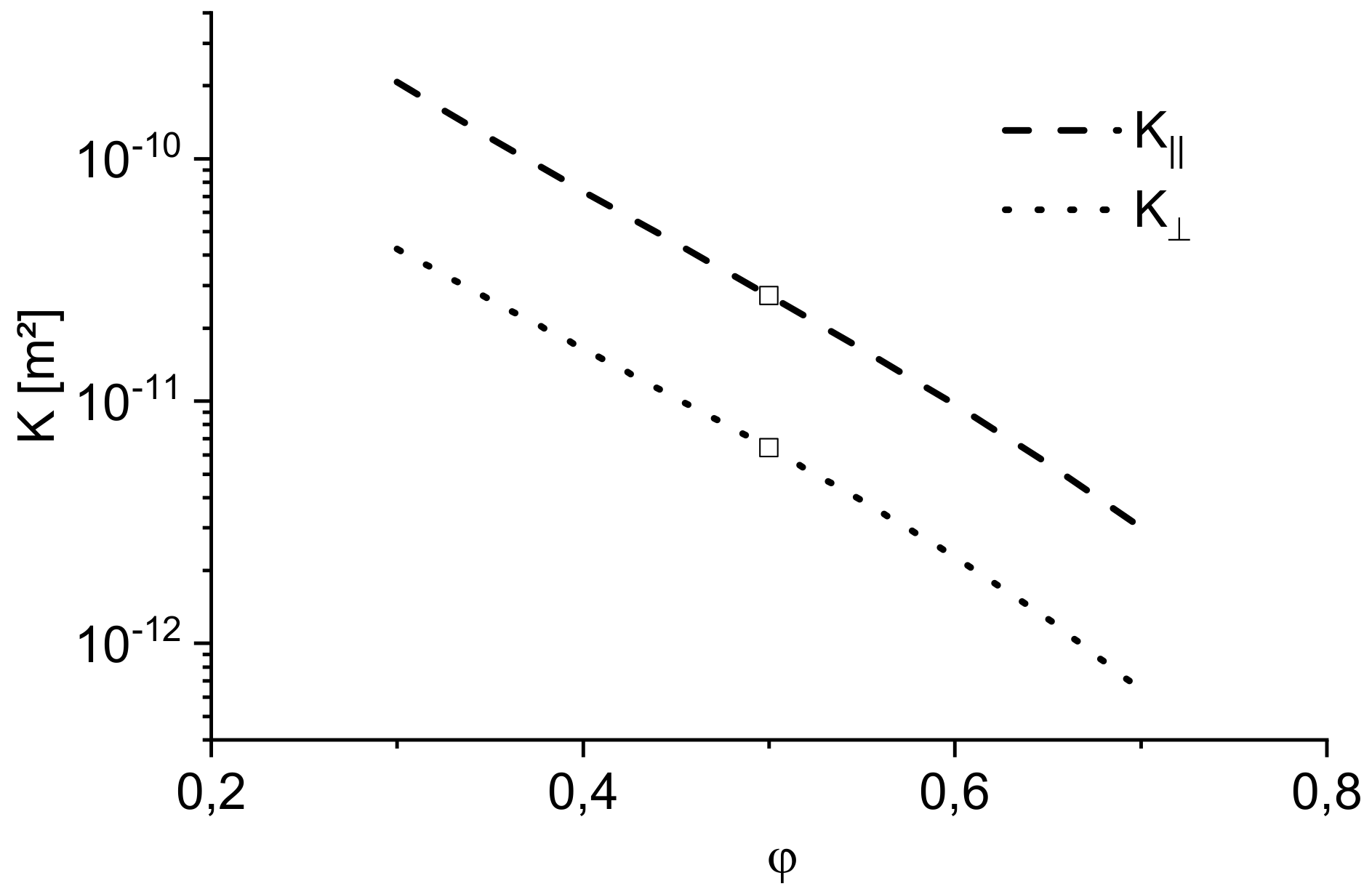

4.1.1. Material Parameters

4.1.2. Boundary Conditions

4.2. Analytic Solution

4.3. Simulation Results

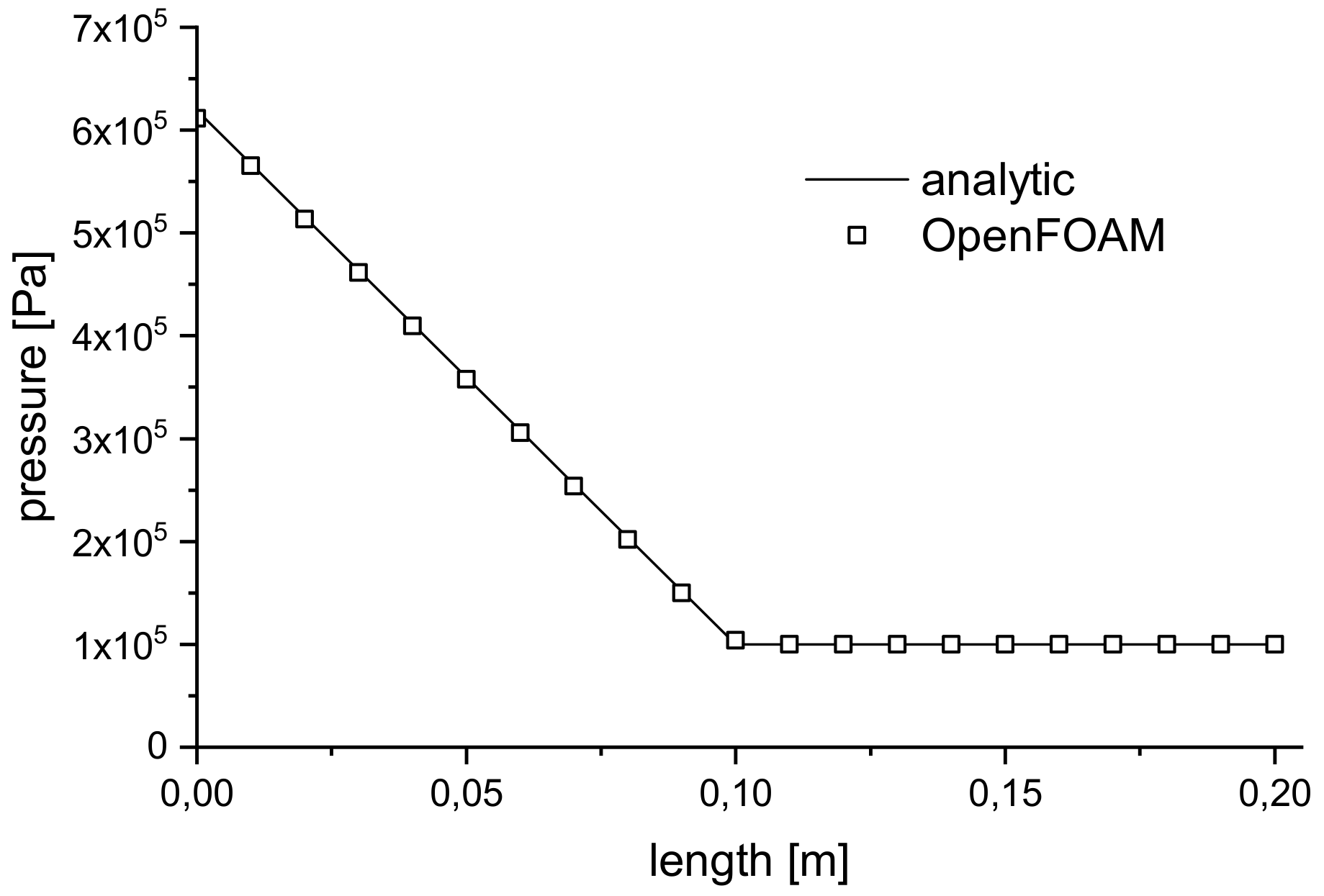

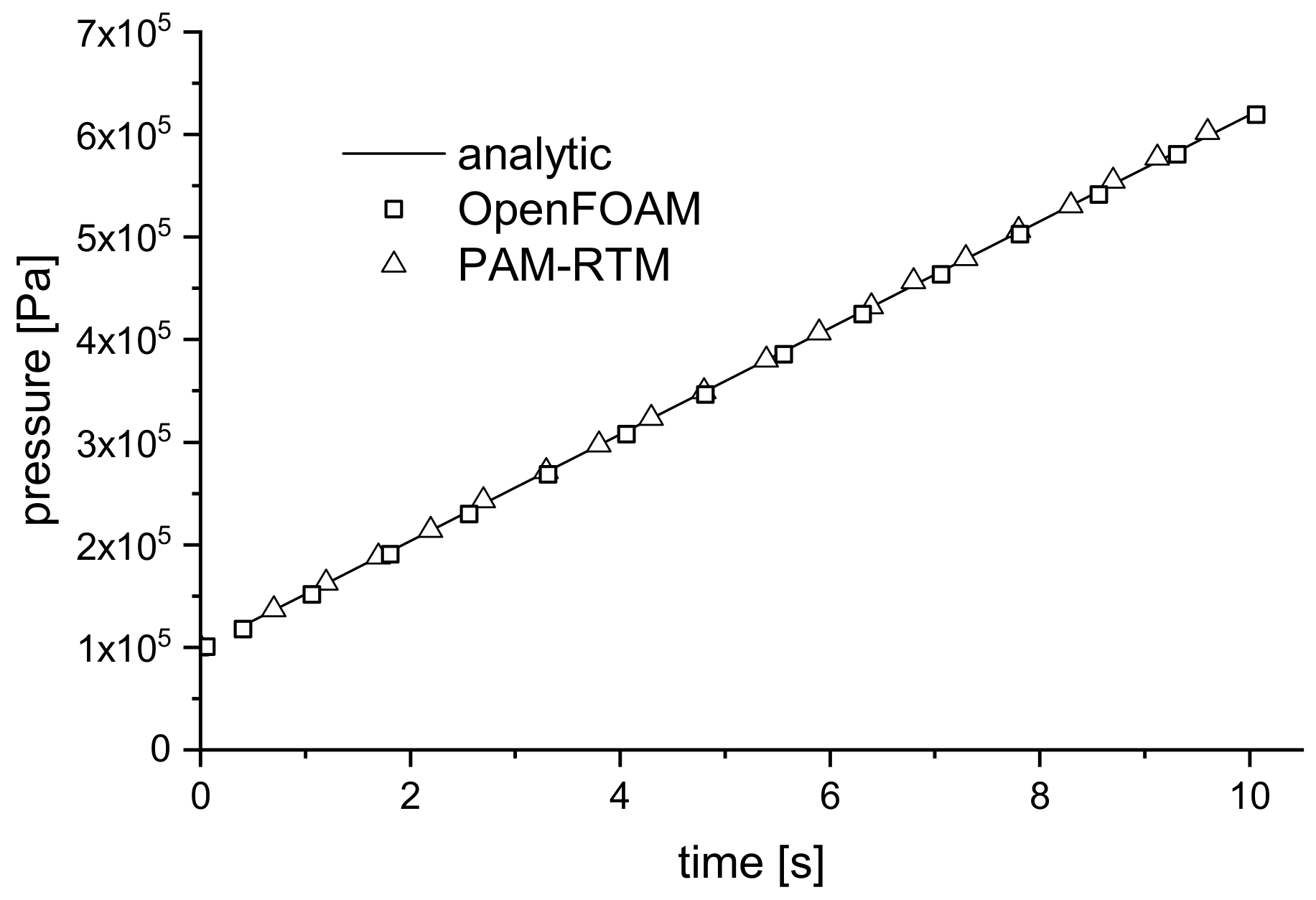

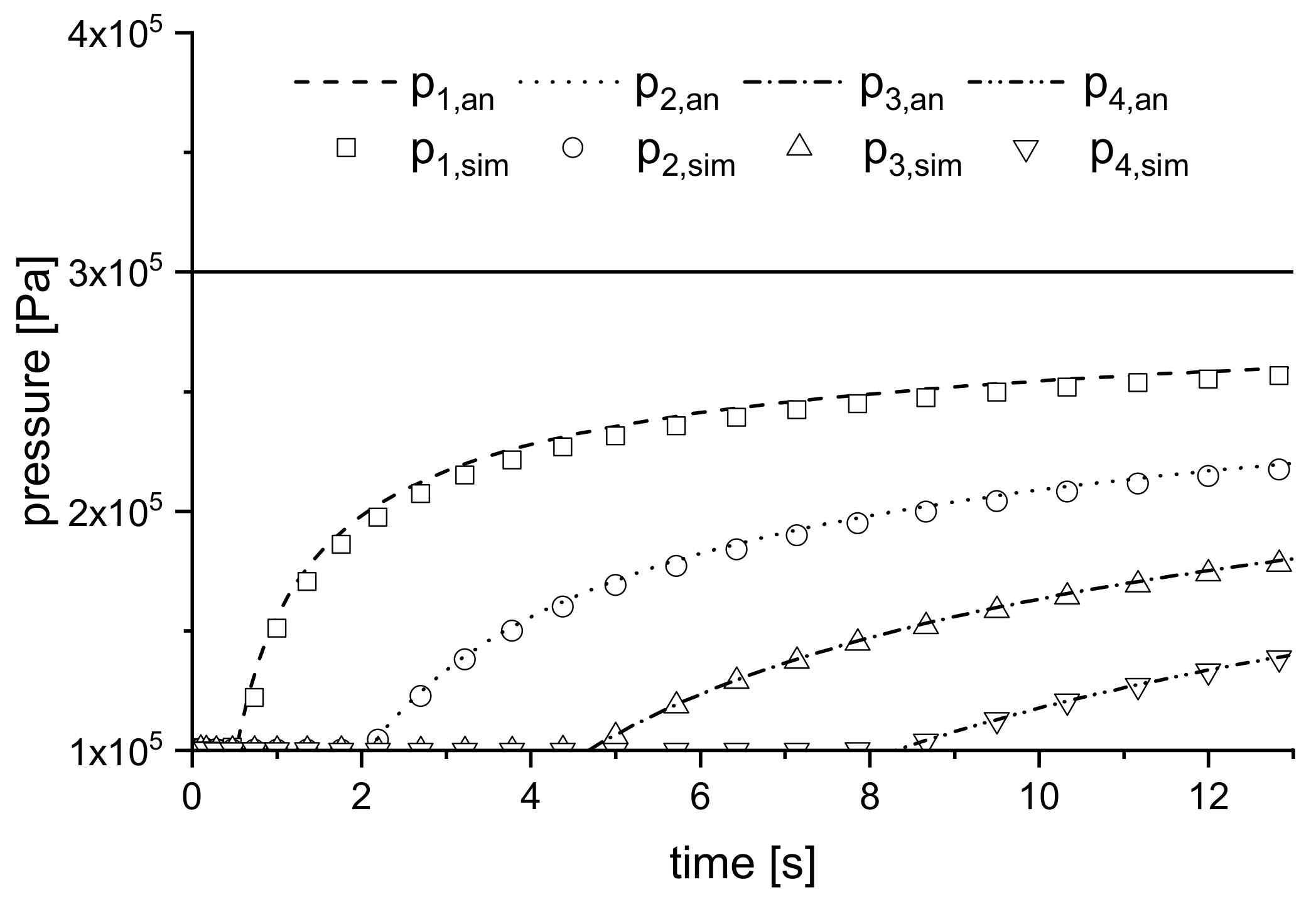

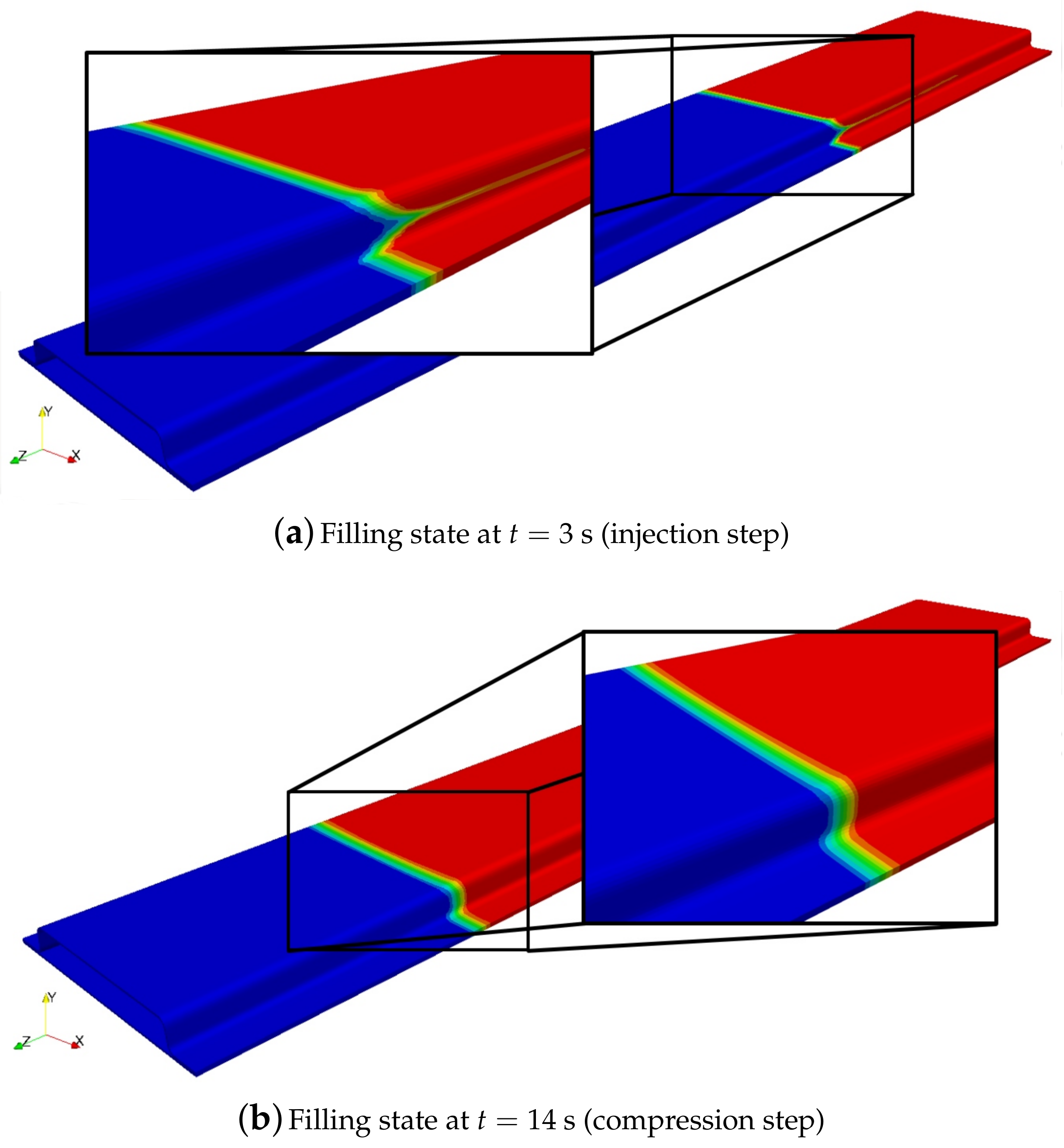

4.3.1. Results for Injection-RTM Boundary Conditions

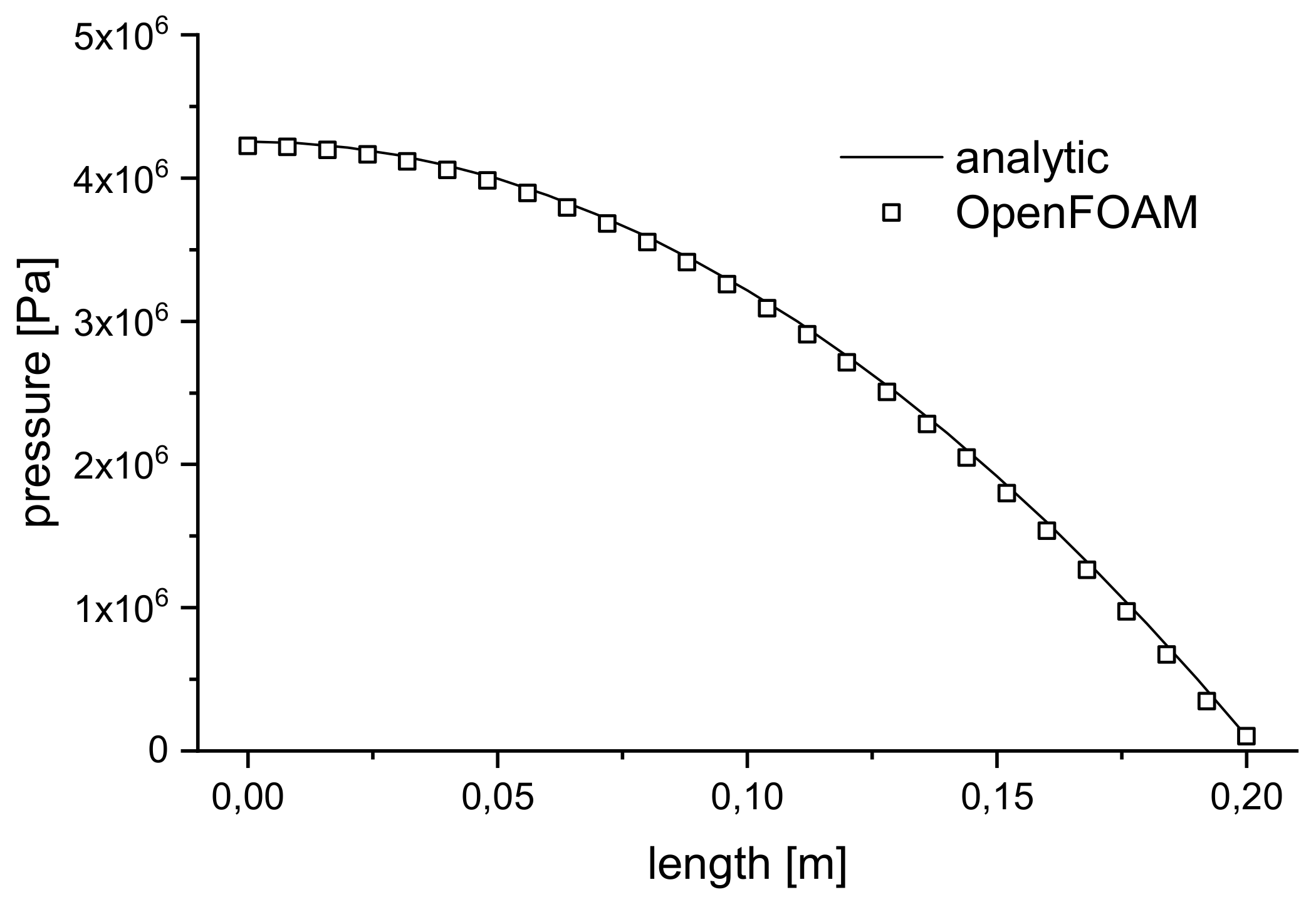

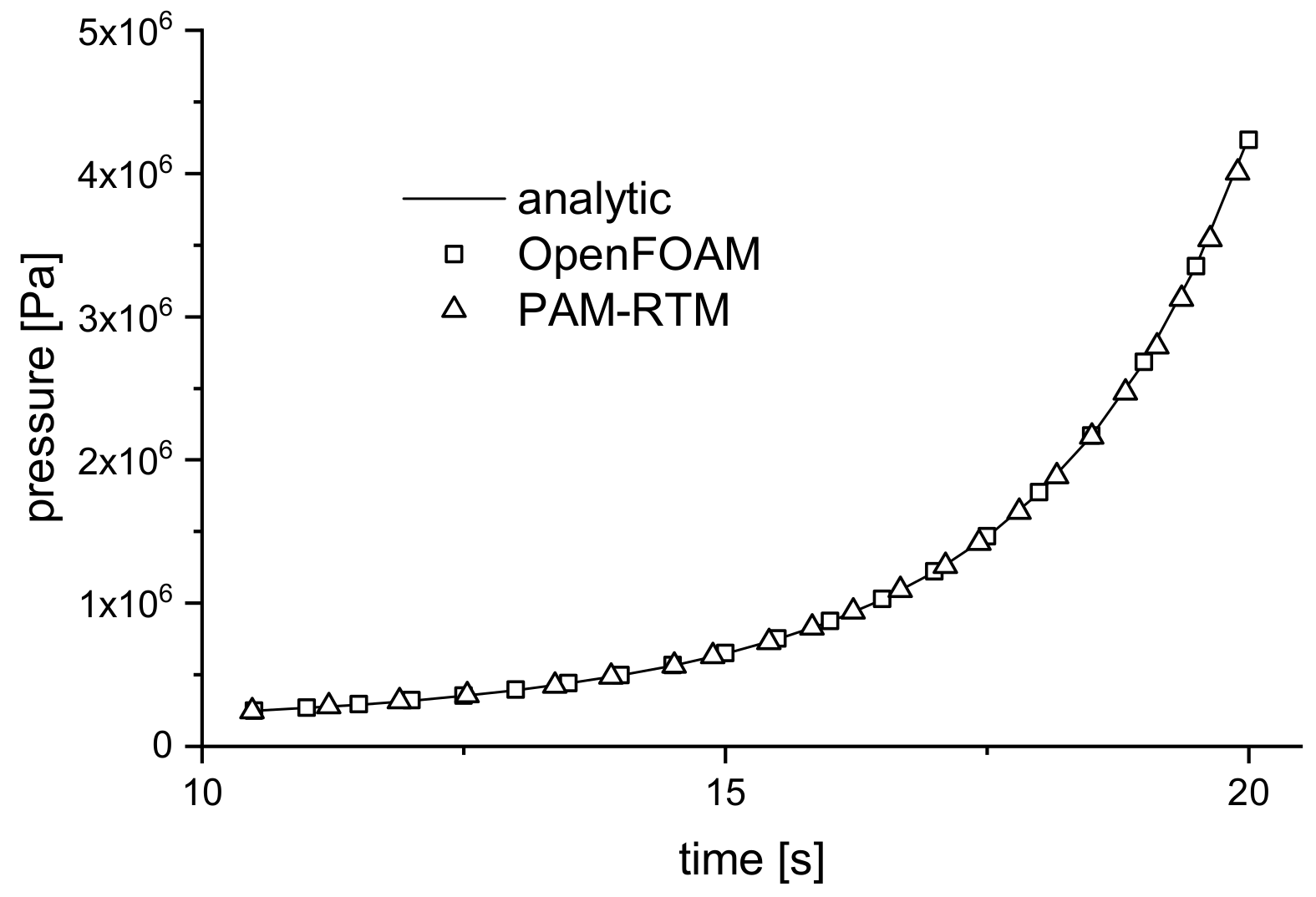

4.3.2. Results for Compression-RTM Boundary Conditions

5. Application Examples of CRTM Mold Filling Simulations

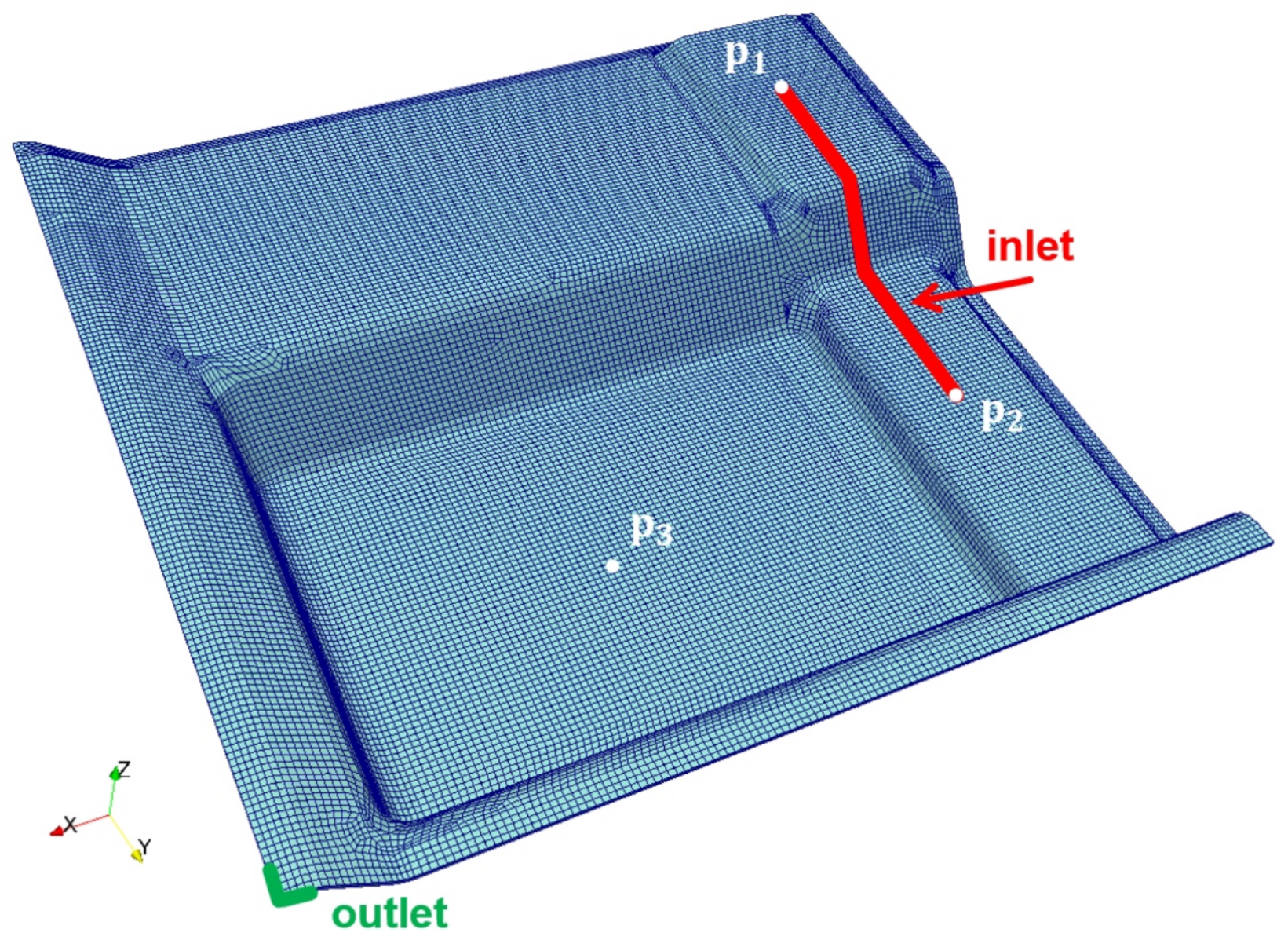

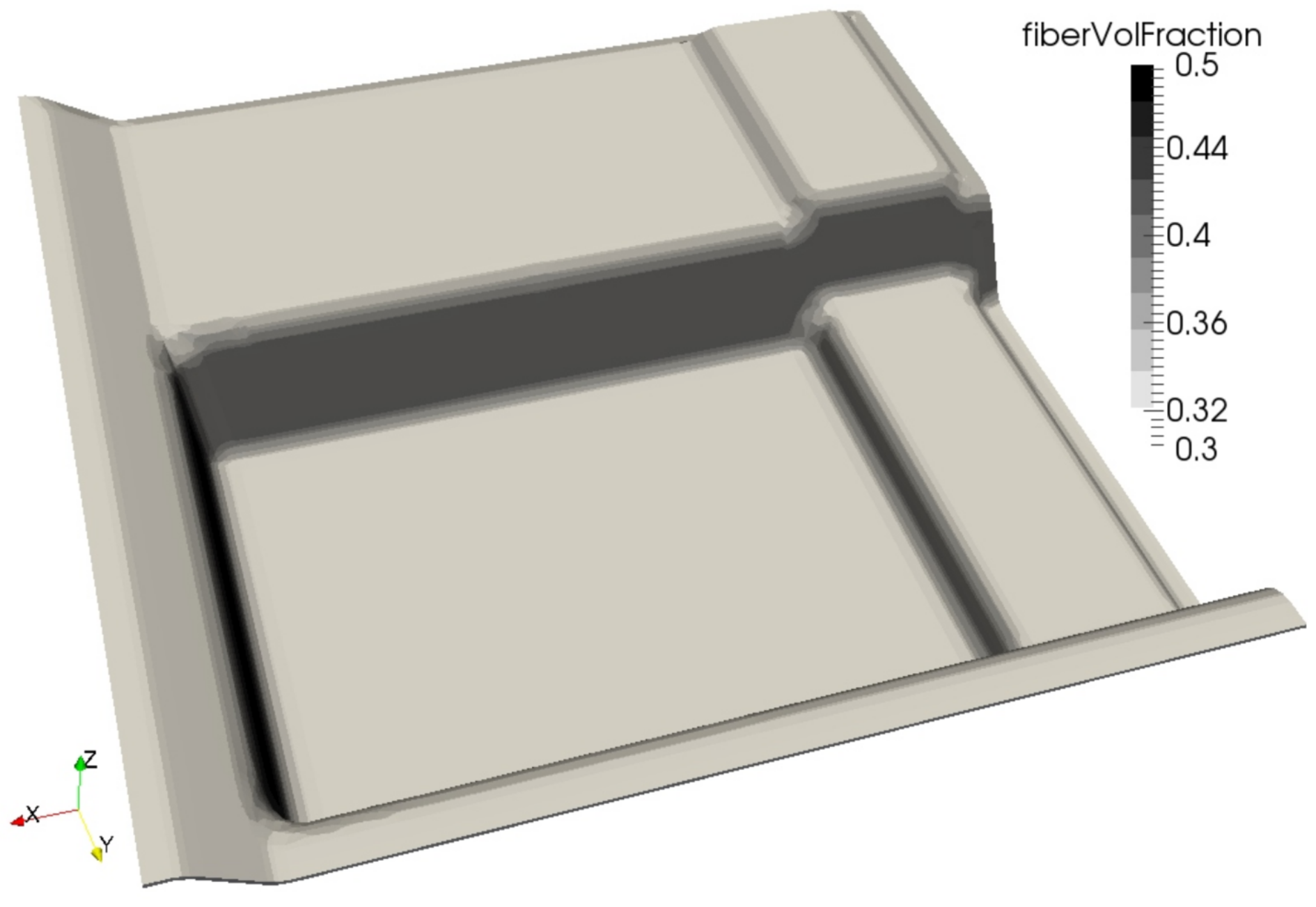

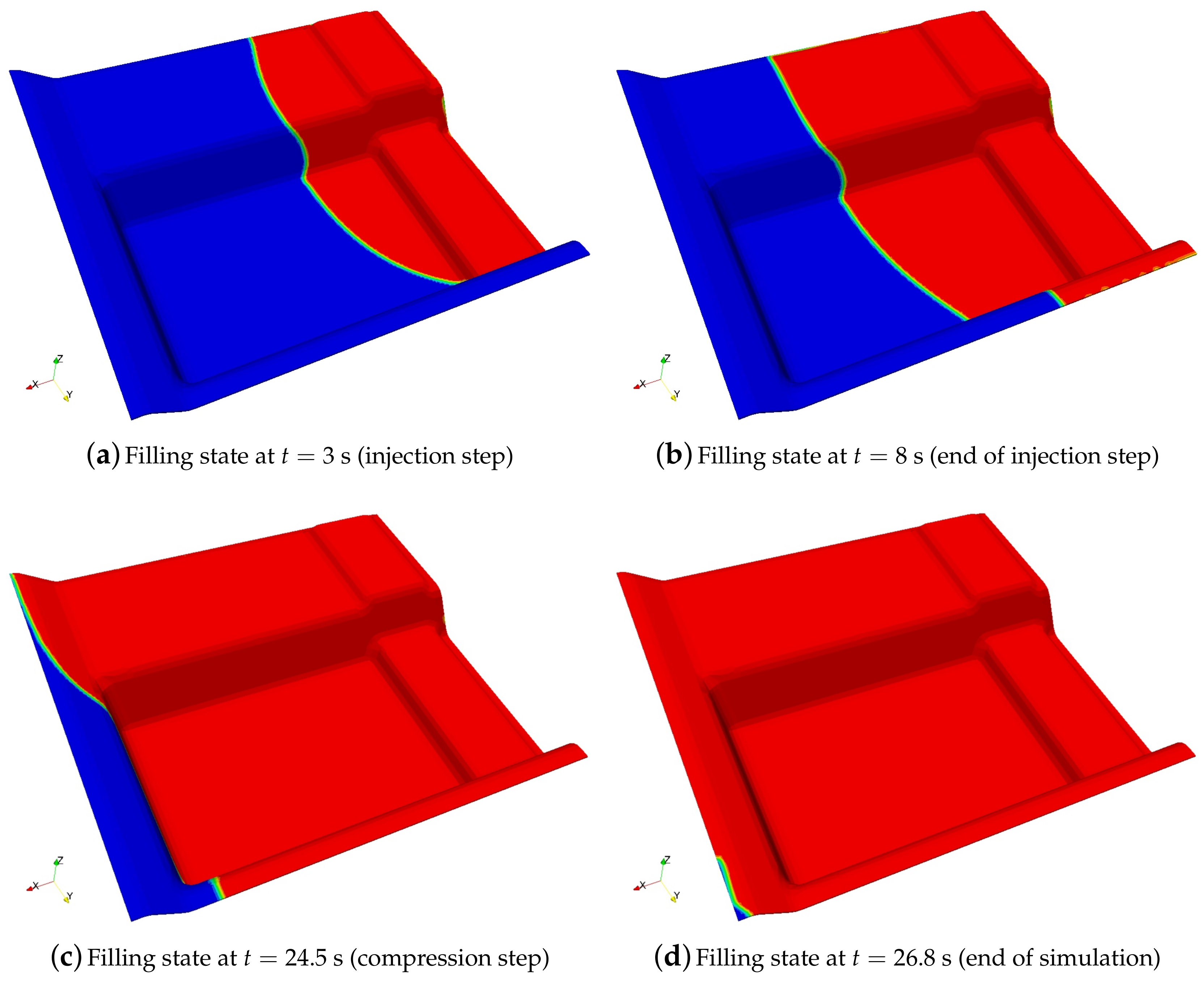

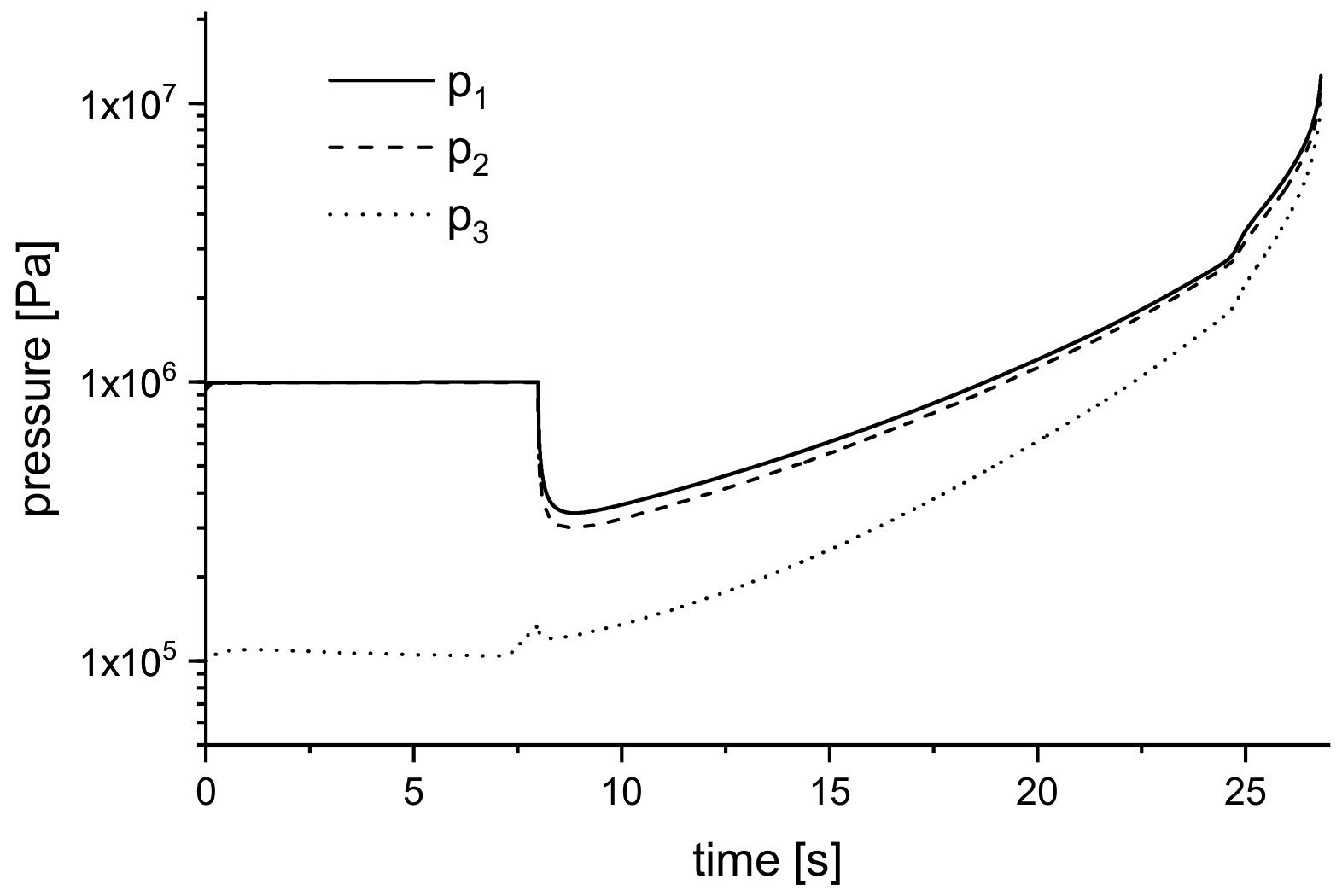

5.1. Application 1: Complex Geometry

5.2. Application 2: Sandwich Part

6. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Analytic Solution of 1D Compression RTM

References

- Soutis, C. Carbon fiber reinforced plastics in aircraft construction. Mater. Sci. Eng. A 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Parnas, R.S. Liquid Composite Molding; Carl Hanser Verlag: Munich, Germany, 2000. [Google Scholar]

- Potter, K. Resin Transfer Moulding; Springer: Dordrecht, The Netherlands, 1997. [Google Scholar]

- Young, W.B.; Rupel, K.; Han, K.; James Lee, L.; Liou, M. Analysis of resin injection molding in molds with preplaced fiber mats. II: Numerical simulation and experiments of mold filling. Polym. Compos. 1991, 12, 30–38. [Google Scholar] [CrossRef]

- Liu, B.; Bickerton, S.; Advani, S.G. Modelling and simulation of resin transfer moulding (RTM)—Gate control, venting and dry spot prediction. Compos. Part A Appl. Sci. Manuf. 1996, 27A, 135–141. [Google Scholar] [CrossRef]

- Trochu, F.; Ruiz, E.; Achim, V.; Soukane, S. Advanced numerical simulation of liquid composite molding for process analysis and optimization. Compos. Part A Appl. Sci. Manuf. 2006, 37, 890–902. [Google Scholar] [CrossRef]

- Magagnato, D.; Frey, M.; Bernath, A.; Steibler, P.; Henning, F. Experimentelle und numerische Untersuchung der Infiltration bei der RTM-Fertigung. In Proceedings Verbundwerkstoffe und Werkstoffverbunde; Deutsche Gesellschaft für Materialkunde e.V.: Frankfurt, Germany, 2013; pp. 511–517. [Google Scholar]

- Magagnato, D.; Henning, F. RTM molding simulation for unidirectional fiber reinforced composite components considering local fiber orientation and fiber volume fraction. J. Plast. Technol. 2016, 12, 136–156. [Google Scholar] [CrossRef]

- Grössing, H.; Stadlmajer, N.; Fauster, E.; Fleischmann, M.; Schledjewski, R. Flow front advancement during composite processing: Predictions from numerical filling simulation tools in comparison with real-world experiments. Polym. Compos. 2016, 37, 2782–2793. [Google Scholar] [CrossRef]

- Bhat, P.; Merotte, J.; Simacek, P.; Advani, S.G. Process analysis of compression resin transfer molding. Compos. Part A Appl. Sci. Manuf. 2009, 40, 431–441. [Google Scholar] [CrossRef]

- Pham, X.T.; Trochu, F.; Gauvin, R. Simulation of Compression Resin Transfer Molding with Displacement Control. J. Reinf. Plast. Compos. 1998, 17, 1525–1556. [Google Scholar] [CrossRef]

- Pham, X.T.; Trochu, F. Simulation of compression resin transfer molding to manufacture thin composite shells. Polym. Compos. 1999, 20, 436–459. [Google Scholar] [CrossRef]

- Shojaei, A. Numerical simulation of three-dimensional flow and analysis of filling process in compression resin transfer moulding. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1434–1450. [Google Scholar] [CrossRef]

- Simacek, P.; Advani, S.G.; Iobst, S.A. Modeling Flow in Compression Resin Transfer Molding for Manufacturing of Complex Lightweight High-Performance Automotive Parts. J. Compos. Mater. 2008, 42, 2523–2545. [Google Scholar] [CrossRef]

- Deinzer, G.; Kothmann, M.; Roquette, D.; Diebold, F. AUDI Ultra-RTM: A technology for high performance and cost effective CFRP parts for high volume production. In Proceedings of the 17th European Conference on Composite Materials ECCM17, Munich, Germany, 26–30 June 2016; MAI Carbon: Augsburg, Germany, 2016. [Google Scholar]

- Kärger, L.; Bernath, A.; Fritz, F.; Galkin, S.; Magagnato, D.; Oeckerath, A.; Schön, A.; Henning, F. Development and validation of a CAE chain for unidirectional fibre reinforced composite components. Compos. Struct. 2015, 132, 350–358. [Google Scholar] [CrossRef]

- Darcy, H. Les Fontaines Publiques de la ville de Dijon; Dalmont: Paris, France, 1856. [Google Scholar]

- Trochu, F.; Gauvin, R.; Zhang, Z. Simulation of mold filling in resin transfer molding by non-conforming finite elements. In Computer Aided Design in Composite Material Technology III; Springer: Dordrecht, The Netherlands, 1992; pp. 109–120. [Google Scholar]

- Jasak, H. Error Analysis and Estimation for the Finite Volume Method with Applications to Fluid Flows. Ph.D. Thesis, University of London, London, UK, 1996. [Google Scholar]

- Issa, R.I. Solution of the Implicitly Discretised Fluid Flow Equations by Operator-Splitting. J. Comput. Phys. 1985, 62, 40–65. [Google Scholar] [CrossRef]

- Ferziger, J.H.; Perić, M. Computational Methods for Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Deshpande, S.S.; Anumolu, L.; Trujillo, M.F. Evaluating the performance of the two-phase flow solver interFoam. Comput. Sci. Discov. 2012, 5, 014016. [Google Scholar] [CrossRef]

- Papathanasiou, T.D. Flow and Rheology in Polymer Composites Manufacturing; Composite Materials Series; Advani, S.G., Ed.; Elsevier Science: Amsterdam, The Netherlands, 1994; Volume 10. [Google Scholar]

- Gebart, B.R. Permeability of Unidirectional Reinforcements for RTM. J. Compos. Mater. 1992, 26, 1100–1133. [Google Scholar] [CrossRef]

- Magagnato, D.; Henning, F. Process-Oriented Determination of Preform Permeability and Matrix Viscosity during Mold Filling in Resin Transfer Molding. Mater. Sci. Forum 2015, 825, 822–829. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seuffert, J.; Kärger, L.; Henning, F. Simulating Mold Filling in Compression Resin Transfer Molding (CRTM) Using a Three-Dimensional Finite-Volume Formulation. J. Compos. Sci. 2018, 2, 23. https://doi.org/10.3390/jcs2020023

Seuffert J, Kärger L, Henning F. Simulating Mold Filling in Compression Resin Transfer Molding (CRTM) Using a Three-Dimensional Finite-Volume Formulation. Journal of Composites Science. 2018; 2(2):23. https://doi.org/10.3390/jcs2020023

Chicago/Turabian StyleSeuffert, Julian, Luise Kärger, and Frank Henning. 2018. "Simulating Mold Filling in Compression Resin Transfer Molding (CRTM) Using a Three-Dimensional Finite-Volume Formulation" Journal of Composites Science 2, no. 2: 23. https://doi.org/10.3390/jcs2020023

APA StyleSeuffert, J., Kärger, L., & Henning, F. (2018). Simulating Mold Filling in Compression Resin Transfer Molding (CRTM) Using a Three-Dimensional Finite-Volume Formulation. Journal of Composites Science, 2(2), 23. https://doi.org/10.3390/jcs2020023