Fibre Length Reduction in Natural Fibre-Reinforced Polymers during Compounding and Injection Moulding—Experiments Versus Numerical Prediction of Fibre Breakage

Abstract

:1. Introduction

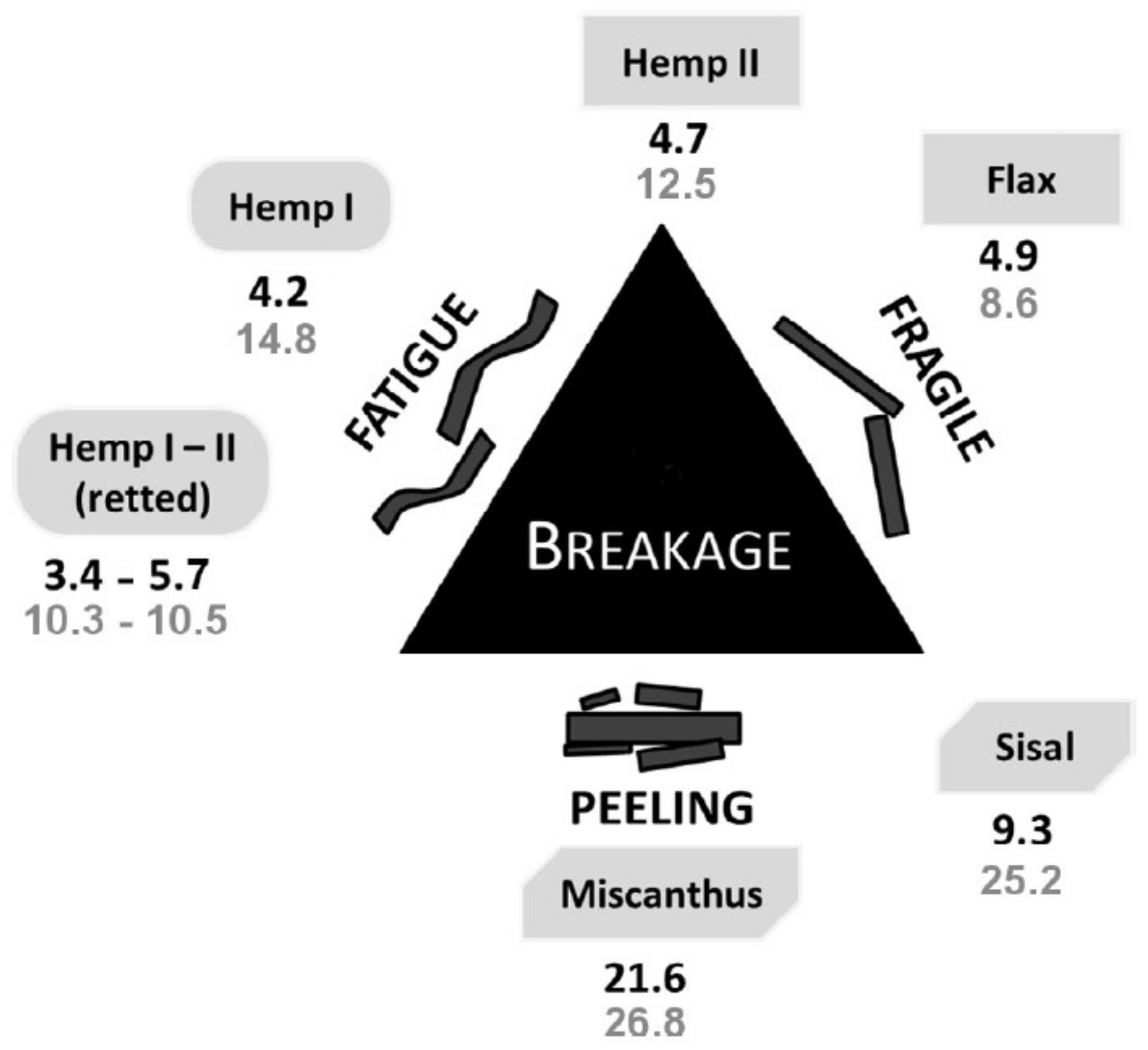

- “Fatigue-driven breakage: elements bend many times and then break”

- “Fragile behaviour: rigid elements bend and break”

- “Peeling: chunks are removed from fibre bundles” [36].

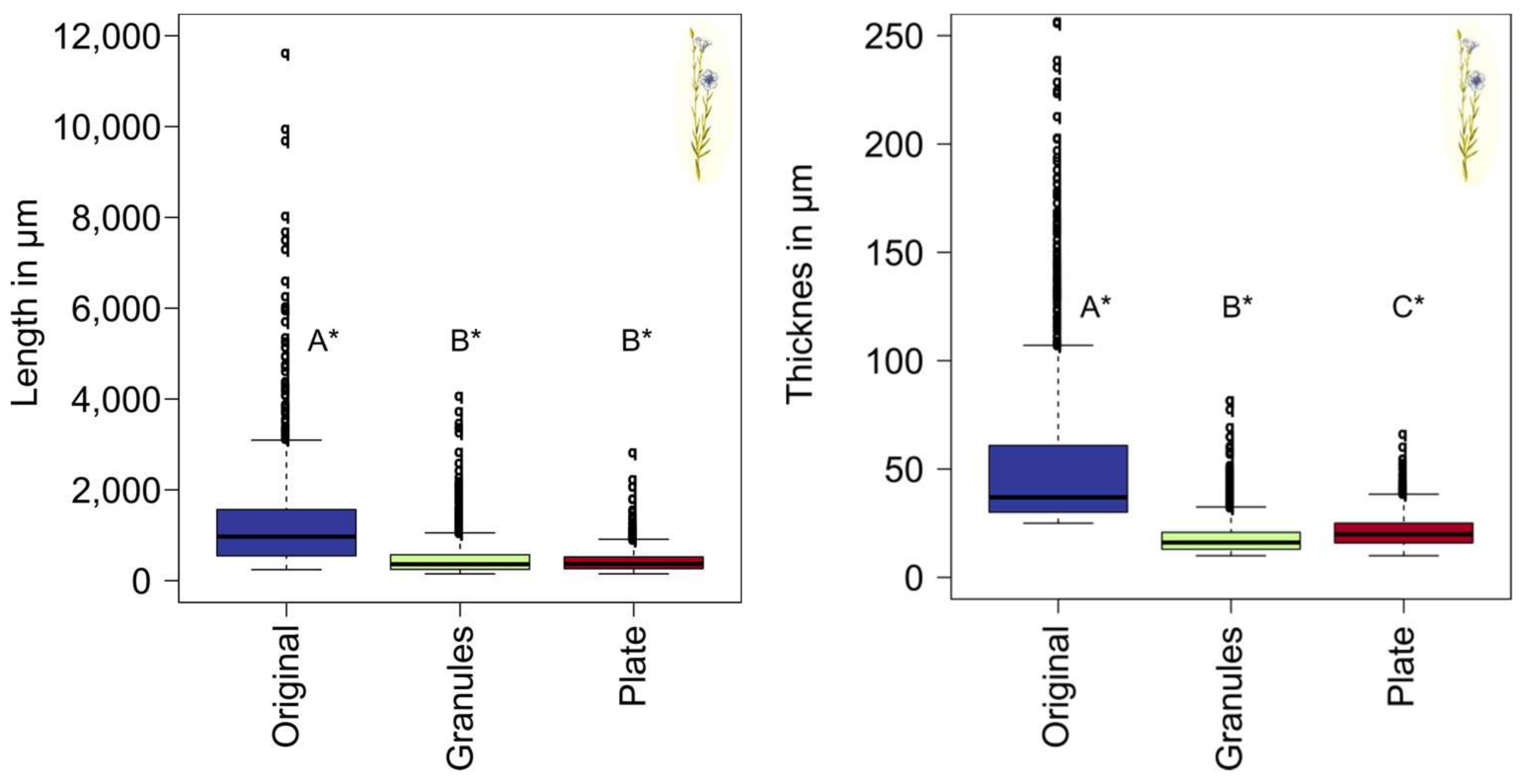

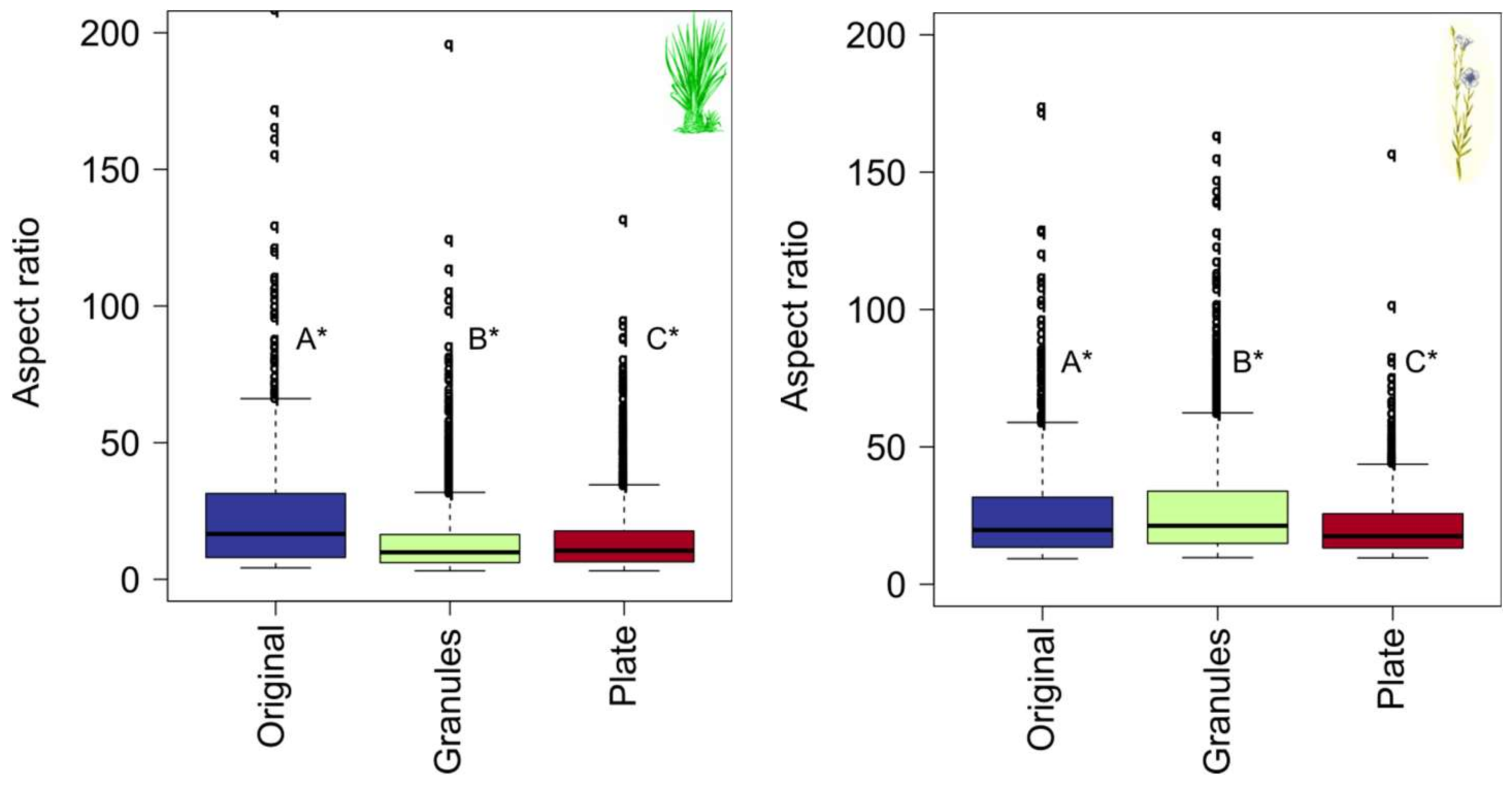

- During the two process steps, compounding and injection moulding, the fibre length and fibre width of sisal and flax is significantly reduced.

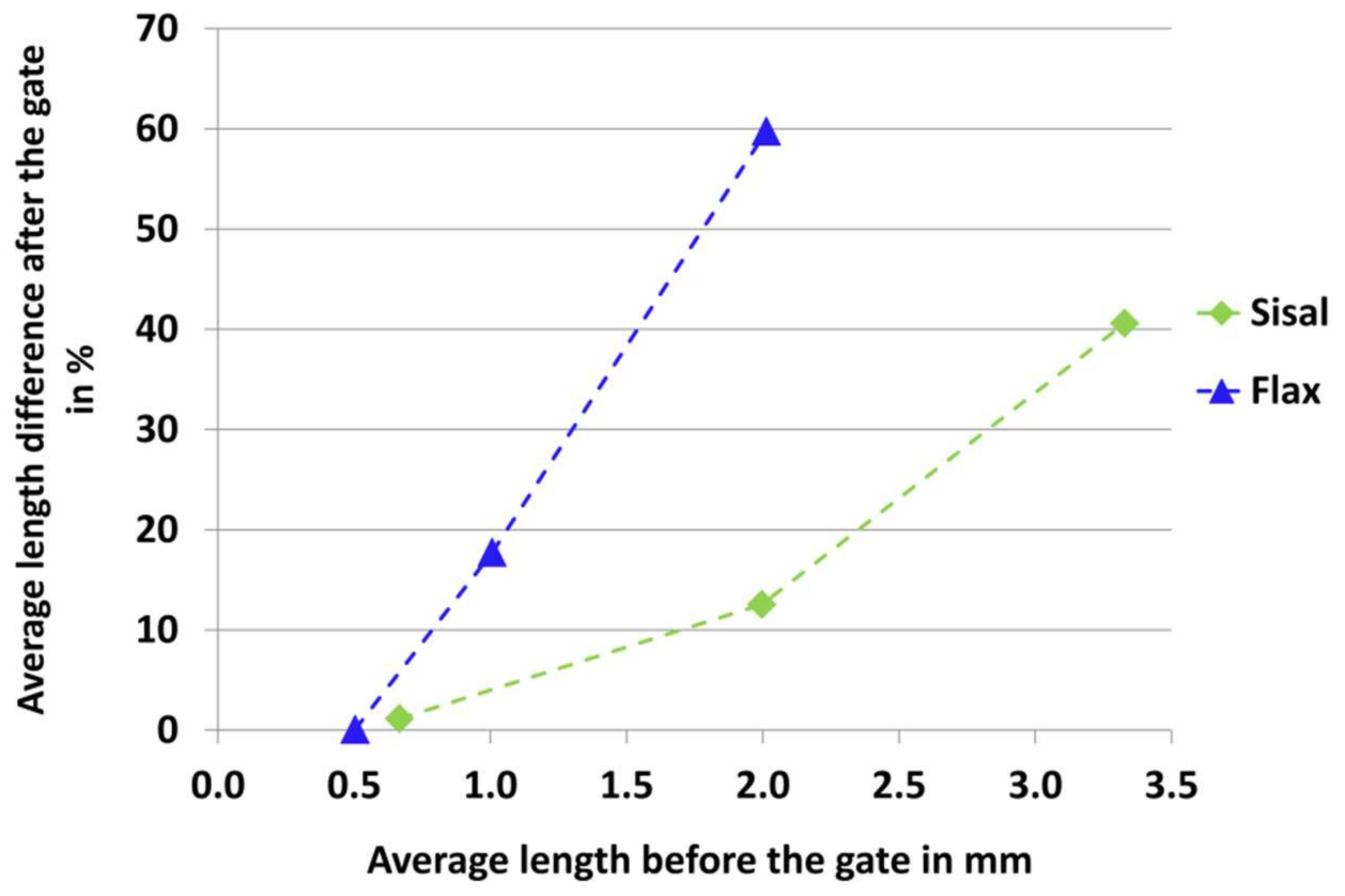

- The mechanistic model can predict the real fibre length reduction and can be used as a product development tool to determine the necessary fibre length in the compound to overachieve the critical fibre length in the injection-moulded component.

2. Materials and Methods

2.1. Fibres and Matrix

2.2. Fibre Extraction

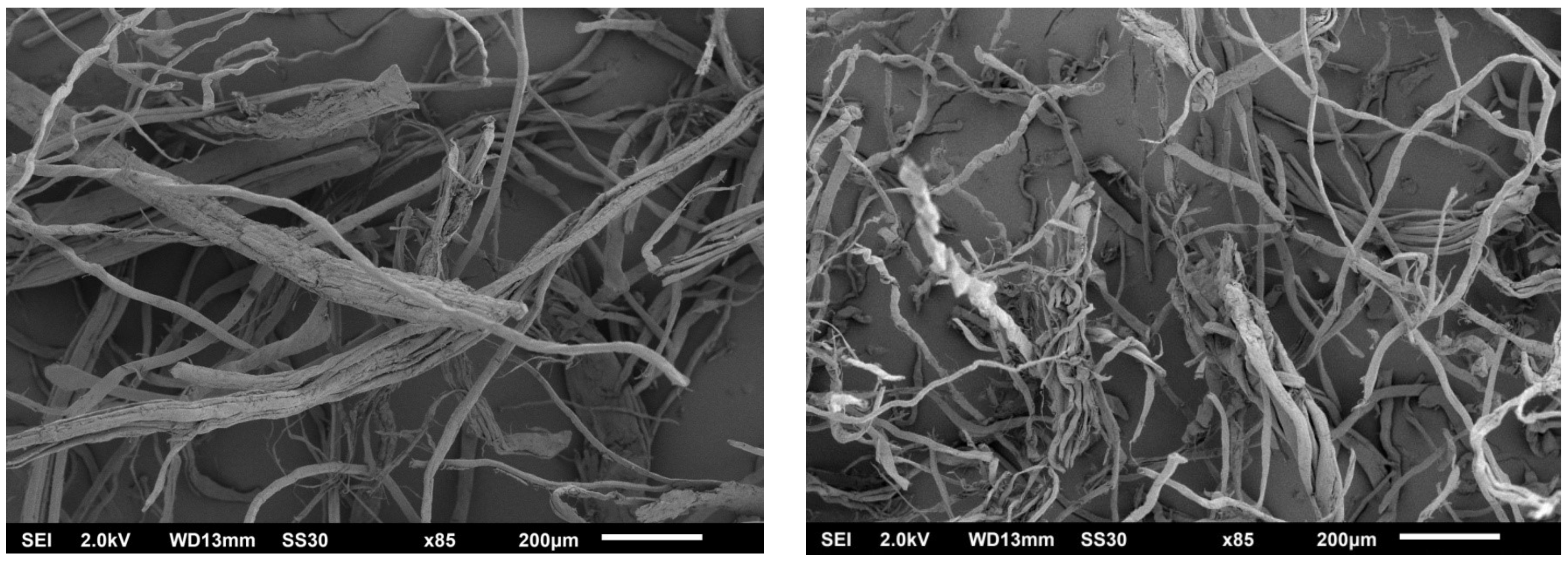

2.3. Fibre Morphology Analysis (SEM and Fibre Shape)

2.4. Statistics

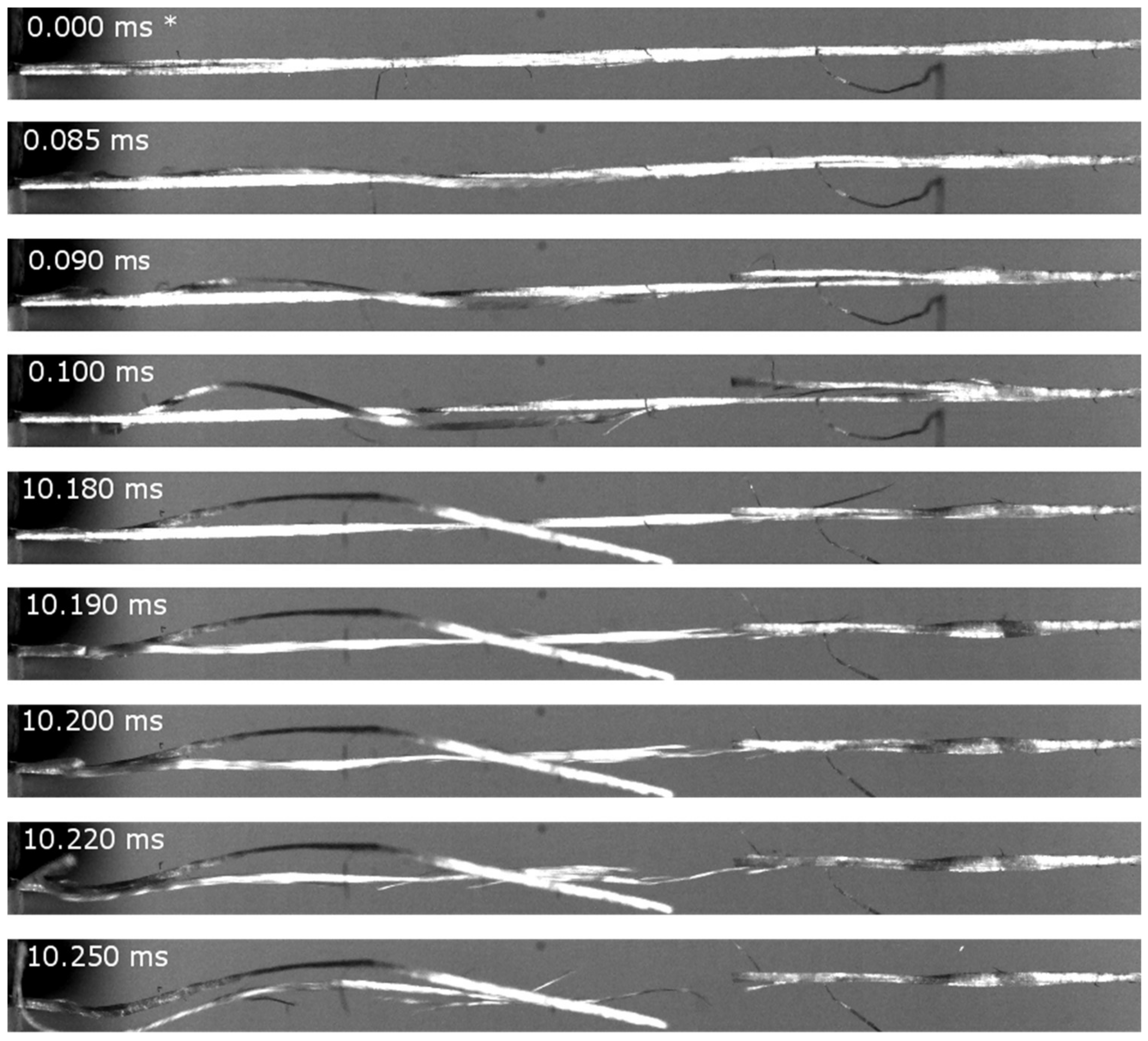

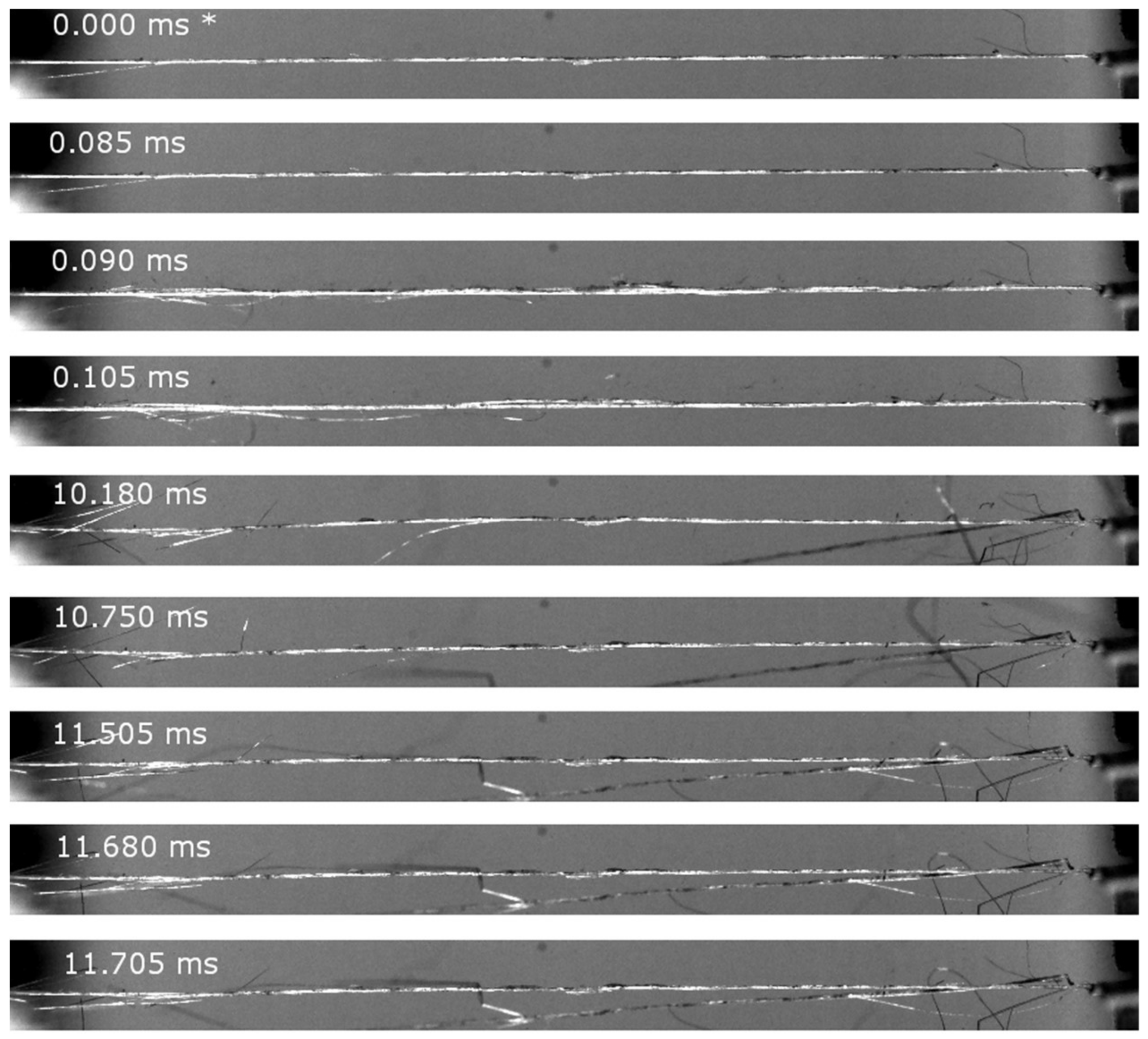

2.5. Ultra-High-Speed Camera

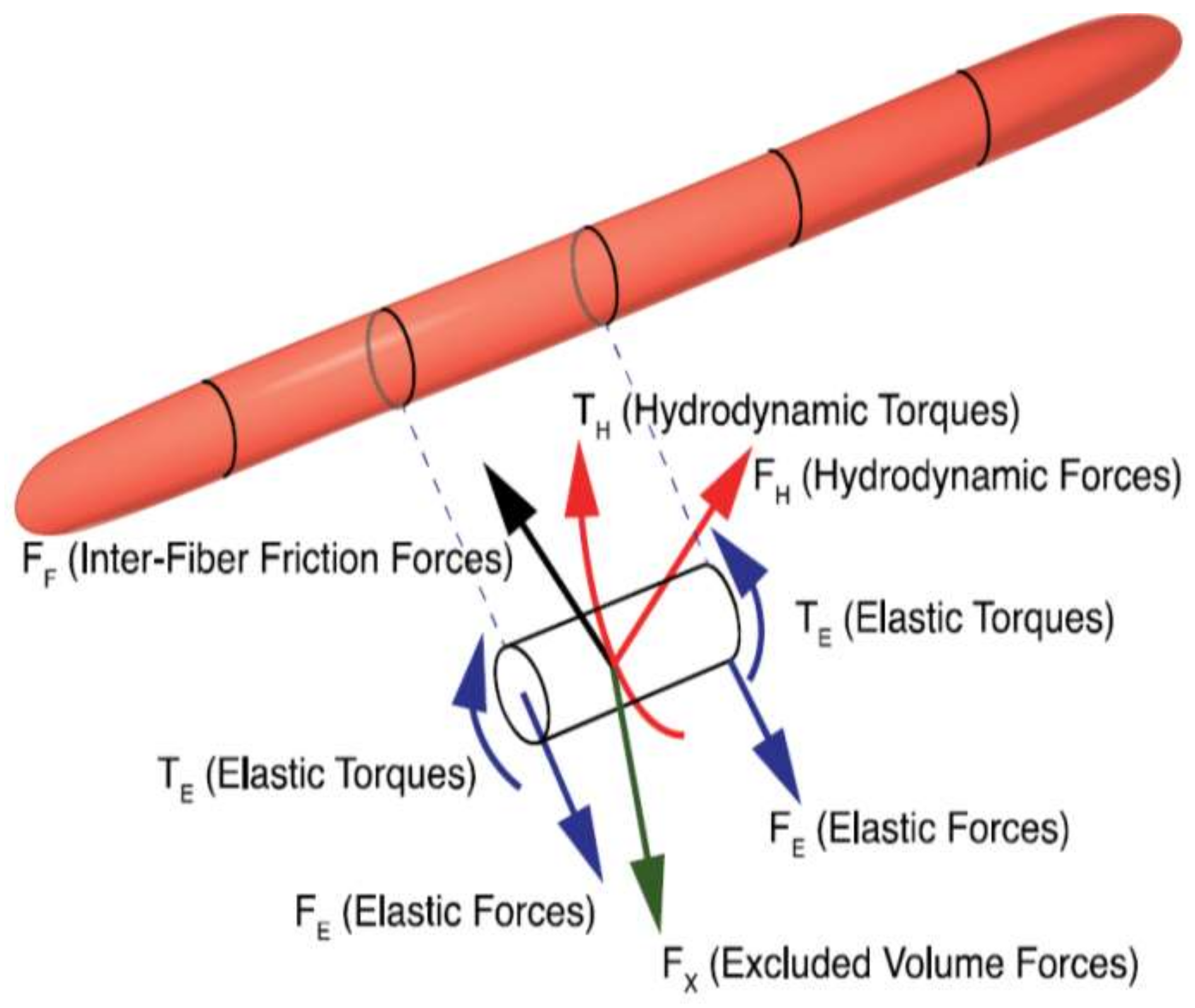

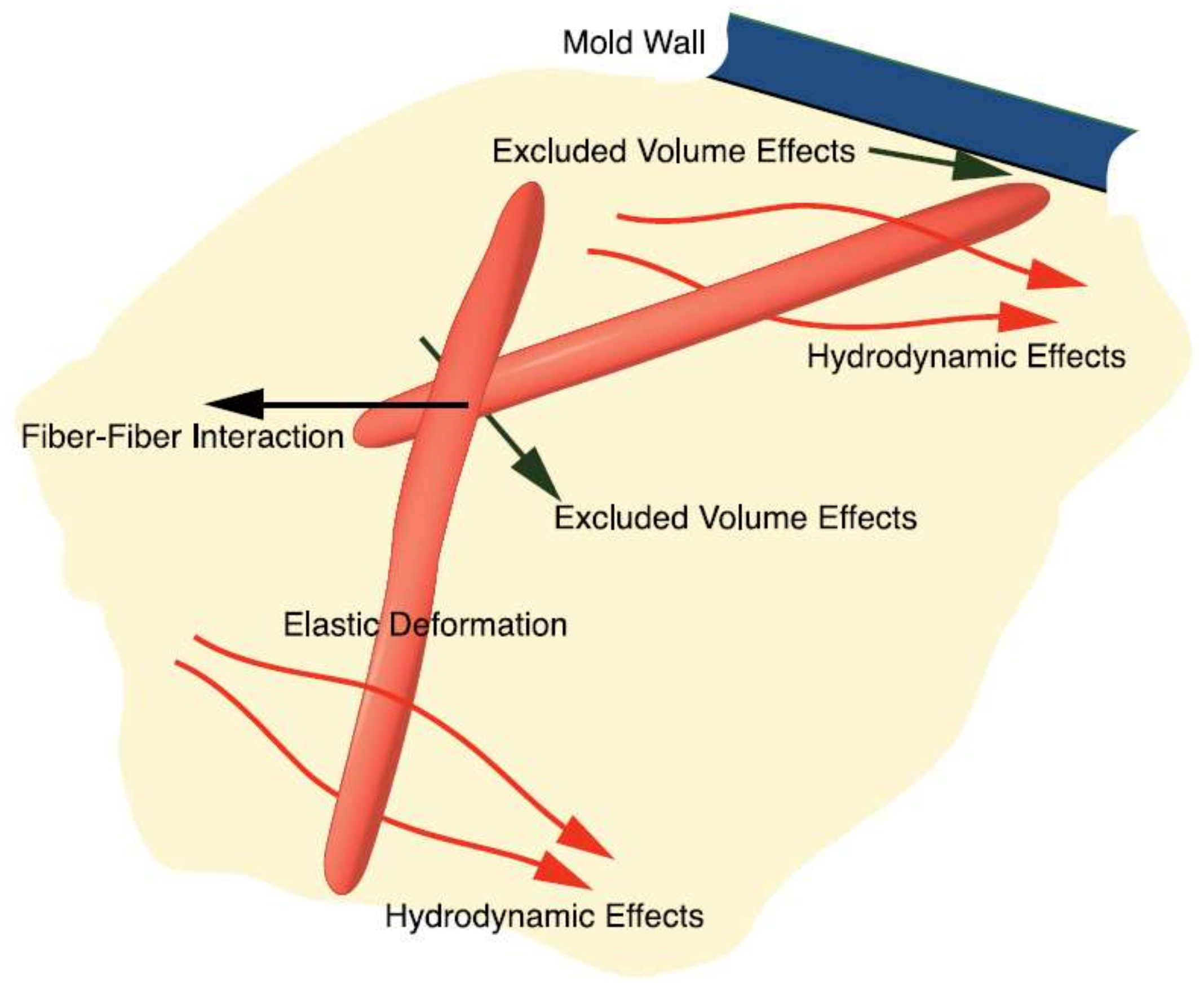

2.6. Micromechanical Model

3. Results and Discussion

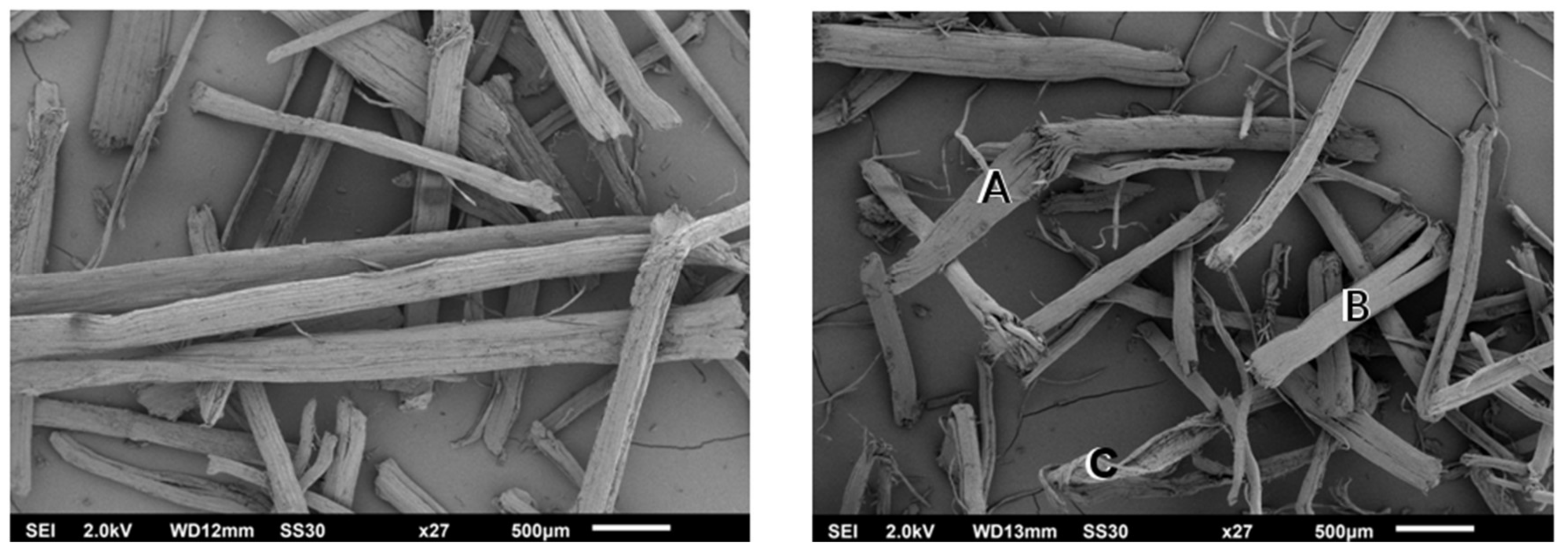

3.1. Optical Observations via SEM and Ultra-High-Speed Camera

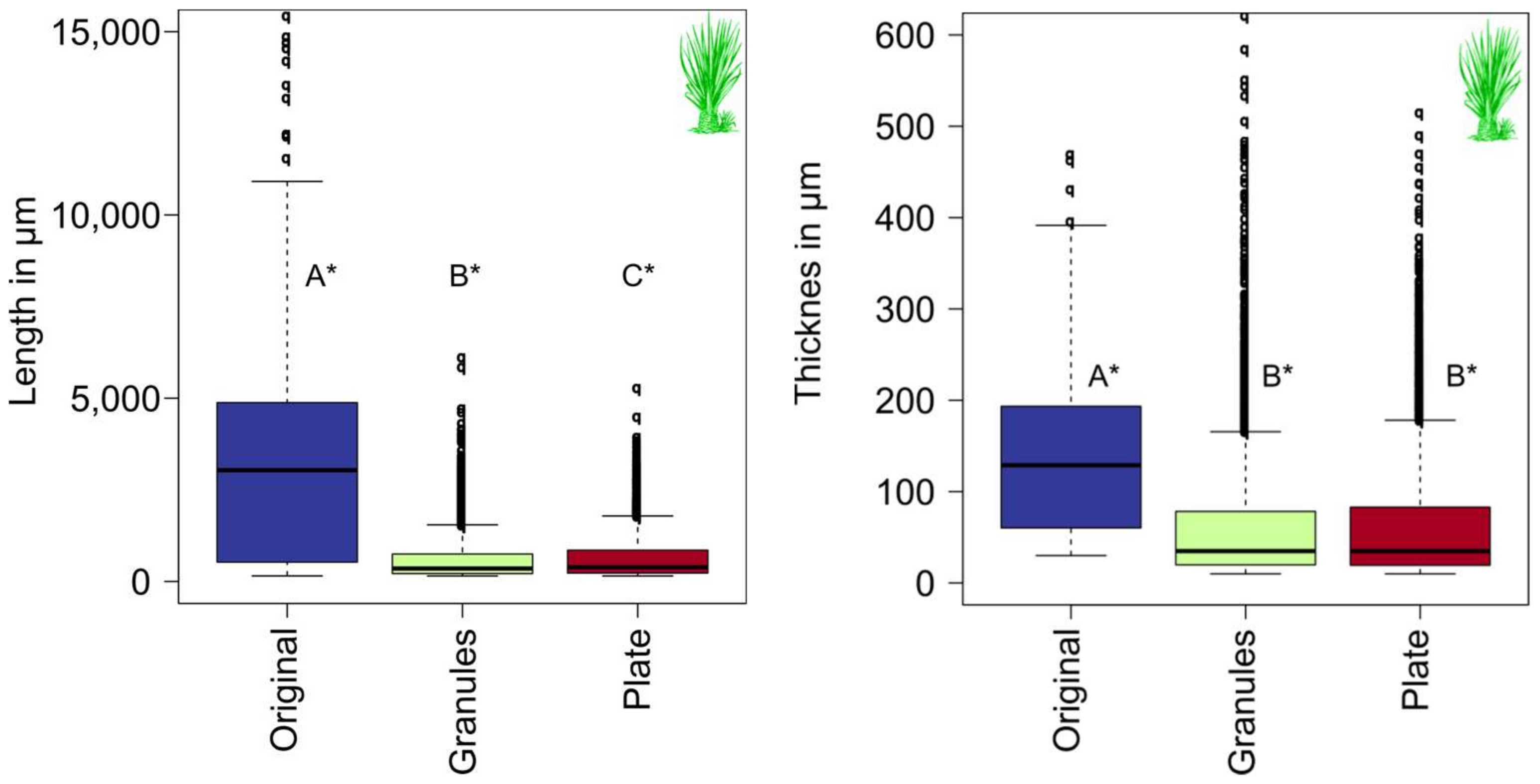

3.2. Morphological Analysis via FibreShape

3.3. Mechanistic Model

4. Conclusions

- The length and width were significantly reduced during the compounding process for sisal and flax fibres. Statistically, a large effect of the compounding was found for length and width.

- The injection moulding process showed neither any effect on a further length reduction nor further splitting for sisal and flax.

- It is important to generate long fibres/fibre bundles already in the compound to overachieve the critical fibre length in the injection moulded component.

- The micromechanical model can be used as a product development tool to predict the necessary object length in the granules to achieve the necessary object length in the injection moulded component to realize good mechanical properties.

- If sisal and flax fall below a certain length during the compounding process, no further reduction of the fibre length can be observed during injection moulding. In the present study this phenomenon could be shown by experiments and simulations for a length of 500 µm (mean value) for flax and 600 µm (mean value) for sisal.

- Splitting during processing is a very important fact for natural fibre bundles. The reduction of the fibre bundle width has a large influence on the aspect ratio (L/D). This phenomenon is not yet implemented in simulation. Before it can be implemented in the simulation, ambitious experiments are necessary to understand and measure the splitting of fibre bundles at the middle lamella.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Alkbir, M.F.M.; Sapuan, S.M.; Nuraini, A.A.; Ishak, M.R. Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: A literature review. Compos. Struct. 2016, 148, 59–73. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.-W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Mertens, O.; Gurr, J.; Krause, A. The utilization of thermomechanical pulp fibers in WPC: A review. J. Appl. Polym. Sci. 2017, 134, 45161. [Google Scholar] [CrossRef]

- Müssig, J.; Fischer, H.; Graupner, N.; Drieling, A. Testing Methods for Measuring Physical and Mechanical Fibre Properties (Plant and Animal Fibres). In Industrial Application Natural Fibres: Structures, Properties and Technical Applications; Müssig, J., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; pp. 267–309. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Shah, D.U. Natural fibre composites: Comprehensive ashby-type materials selection charts. Mater. Des. 2014, 62, 21–31. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Beaugrand, J.; Berzin, F. (2013): Lignocellulosic Fiber Reinforced Composites: Influence of Compounding Conditions on Defibrization and Mechanical Properties. J. Appl. Polym. Sci. 2013, 128, 1227–1238. [Google Scholar] [CrossRef]

- Graupner, N.; Albrecht, K.; Ziegmann, G.; Enzler, H.; Müssig, J. Influence of reprocessing on fibre length distribution, tensile strength and impact strength of injection moulded cellulose fibre-reinforced polylactide (PLA) composites. Express Polym. Lett. 2016, 10, 647–663. [Google Scholar] [CrossRef]

- Osswald, T.A.; Menges, G. Anisotropy Development during Processing. In Material Science Polymers Engineers, 3rd ed.; Osswald, T.A., Menges, G., Eds.; Hanser: Munich, Germany, 2012; pp. 263–294. [Google Scholar] [CrossRef]

- Rohde-Tibitanzl, M. State of the Art. In Direct Processing Long Fiber Reinforced Thermoplastic Composites Their Mechanical Behavior Static Dynamic Load; Carl Hanser Verlag GmbH & Co.: Munich, Germany, 2015; pp. 3–68. [Google Scholar] [CrossRef]

- Abdennadher, A. Injection Moulding of Natural Fibre Reinforced Polypropylene: Process, Microstructure and Properties. Ph.D. Thesis, Ecole Nationale Supérieure des Mines de Paris, Frankreich, Paris, France, 2015. [Google Scholar]

- Albrecht, K.; Baur, E.; Endres, H.-J.; Gente, R.; Graupner, N.; Koch, M.; Neudecker, M.; Osswald, T.; Schmidtke, P.; Wartzack, S.; et al. Measuring fibre orientation in sisal fibre-reinforced, injection moulded polypropylene-Pros and cons of the experimental methods to validate injection moulding simulation. Compos. Part A Appl. Sci. Manuf. 2017, 95, 54–64. [Google Scholar] [CrossRef]

- Azaman, M.D.; Sapuan, S.M.; Sulaiman, S.; Zainudin, E.S.; Abdan, K. An investigation of the processability of natural fibre reinforced polymer composites on shallow and flat thin-walled parts by injection moulding process. Mater. Des. 2013, 50, 451–456. [Google Scholar] [CrossRef] [Green Version]

- Ford Forschungszentrum Aachen GmbH, IAC Group GmbH, LyondellBasell, Kunststoffwerk Voerde, Simcon Kunststofftechnische Software GmbH, M-Base Engineering und Software GmbH, Hochschule Hannover, Hochschule Bremen, Technische Universität Clausthal, Fraunhofer LBF & University of Wisconsin-Madison. Werkstoff-und Fließmodelle für naturfaserverstärkte Spritzgießmaterialien für den praktischen Einsatz in der Automobilindustrie. Final Report of the Project “NFC-Simulation”. 2014. Available online: http://www.fnr-server.de/ftp/pdf/berichte/22005511.pdf (accessed on 23 March 2018). (In German).

- Nikklä, M.; Filz, P. Injection Moulding and Simulation of Consumer Products with Aqvacomp Composites. In Proceedings of the Biocomposites Conference Cologne (BCC)—7th Conference on Wood and Natural Fibre Composites, Maternushaus, Germany, 6–7 December 2017; nova-Institut GmbH: Maternushaus, Germany, 2017. [Google Scholar]

- Wan Abdul Rahman, W.A.; Sin, L.T.; Rahmat, A.R. Injection moulding simulation analysis of natural fiber composite window frame. J. Mater. Process. Technol. 2008, 197, 22–30. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B.; Mai, Y.-W. Science and Engineering of Short Fibre Reinforced Polymer Composites; Woodhead Publishing in Materials; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 978-1-84569-269-8. [Google Scholar]

- Folgar, F.; Tucker, C.L. Orientation Behavior of Fibers in Concentrated Suspensions. J. Reinf. Plast. Compos. 1984, 3, 98–119. [Google Scholar] [CrossRef]

- Merodio, J.; Ogden, R.W. Instabilities and loss of ellipticity in fiber-reinforced compressible nonlinearly elastic solids under plane deformation. Int. J. Solids Struct. 2003, 40, 4707–4727. [Google Scholar] [CrossRef]

- Merodio, J.; Ogden, R.W. Material Instabilities for Fiber-Reinforced Nonlinearly Elastic solids under plane deformation. Arch. Mech. 2002, 54, 525–552. [Google Scholar]

- Berzin, F.; Beaugrand, J.; Dobosz, S.; Budtova, T.; Vergnes, B. Lignocellulosic fiber breakage in a molten polymer. Part 3. Modeling of the dimensional change of the fibers during compounding by twin screw extrusion. Compos. Part A Appl. Sci. Manuf. 2017, 101, 422–431. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Hu, X.; Yue, C.-Y. Effects of fiber length and orientation distributions on the mechanical properties of short-fiber-reinforced polymers—A review. J. Soc. Mater. Sci. 1999, 48, 74–83. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K.-T. Experimental and theoretical studies on the properties of injection moulded glass fibre reinforced mixed plastics composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 393–405. [Google Scholar] [CrossRef]

- Bijsterbosch, H.; Gaymans, R.J. Polyamide 6—Long glass fiber injection moldings. Polym. Compos. 1995, 16, 363–369. [Google Scholar] [CrossRef]

- Denault, J.; Vu-Khanh, T.; Foster, B. Tensile properties of injection molded long fiber thermoplastic composites. Polym. Compos. 1989, 10, 313–321. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B. Characterization of tensile behaviour of hybrid short glass fibre/calcite particle/ABS composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 575–583. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B. Fracture resistance of unfilled and calcite-particle-filled ABS composites reinforced by short glass fibers (SGF) under impact load. Compos. Part A Appl. Sci. Manuf. 1998, 29, 631–641. [Google Scholar] [CrossRef]

- Jaszkiewicz, A.; Meljon, A.; Bledzki, A.K.; Radwanski, M. Gaining knowledge on the processability of PLA-based short-fibre compounds—A comprehensive comparison with their PP counterparts. Compos. Part A Appl. Sci. Manuf. 2016, 83, 140–151. [Google Scholar] [CrossRef]

- Ramani, K.; Bank, D.; Kraemer, N. Effect of screw design on fiber damage in extrusion compounding and composite properties. Polym. Compos. 1995, 16, 258–266. [Google Scholar] [CrossRef]

- von Turkovich, R.; Erwin, L. Fiber fracture in reinforced thermoplastic processing. Polym. Eng. Sci. 1983, 23, 743–749. [Google Scholar] [CrossRef]

- Curtis, P.T.; Bader, M.G.; Bailey, J.E. The stiffness and strength of a polyamide thermoplastic reinforced with glass and carbon fibres. J. Mater. Sci. 1978, 13, 377–390. [Google Scholar] [CrossRef]

- Müssig, J.; Martens, R. Quality Aspects in Hemp Fibre Production—Influence of Cultivation, Harvesting and Retting. J. Ind. Hemp 2003, 8, 11–32. [Google Scholar] [CrossRef]

- Schnegelsberg, G. Handbuch der Faser–Theorie und Systematik der Faser; Deutscher Fachverlag: Frankfurt am Main, Germany, 1999; ISBN 978-3871506246. (In German) [Google Scholar]

- Vincent, J. A unified nomenclature for plant fibres for industrial use. Appl. Compos. Mater. 2000, 7, 269–271. [Google Scholar] [CrossRef]

- Castellani, R.; Di Giuseppe, E.; Beaugrand, J.; Dobosz, S.; Berzin, F.; Vergnes, B.; Budtova, T. Lignocellulosic fiber breakage in a molten polymer. Part 1. Qualitative analysis using rheo-optical observations. Compos. Part A Appl. Sci. Manuf. 2016, 91, 229–237. [Google Scholar] [CrossRef]

- Di Giuseppe, E.; Castellani, R.; Budtova, T.; Vergnes, B. Lignocellulosic fiber breakage in a molten polymer. Part 2. Quantitative analysis of the breakage mechanisms during compounding. Compos. Part A Appl. Sci. Manuf. 2017, 95, 31–39. [Google Scholar] [CrossRef]

- Baley, C. Influence of kink bands on the tensile strength of flax fibers. J. Mater. Sci. 2004, 39, 331–334. [Google Scholar] [CrossRef]

- Duc, A.L.; Vergnes, B.; Budtova, T. Polypropylene/natural fibres composites: Analysis of fibre dimensions after compounding and observations of fibre rupture by rheo-optics. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1727–1737. [Google Scholar] [CrossRef]

- Hughes, M. Defects in natural fibres: Their origin, characteristics and implications for natural fibre-reinforced composites. J. Mater. Sci. 2012, 47, 599–609. [Google Scholar] [CrossRef]

- Bos, H.; Van Den Oever, M.; Peters, O. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Hernandez-Estrada, A.; Gusovius, H.-J.; Müssig, J.; Highes, M. Assessing the Susceptibility of Hemp Fibre to the Formation of Dislocations during Processing. Ind. Crops Prod. 2016, 85, 382–388. [Google Scholar] [CrossRef]

- Steuernagel, L.; Ziegmann, G.; Meiners, D. Recycling of fiber reinforced thermoplastics—Natural fibers vs. glass fibers. In Proceedings of the CompositesWeek@Leuven and TexComp-11 Conference, Leuven, Belgium, 16–20 September 2013. [Google Scholar]

- Neudecker, M.; Endres, H.-J. Processing and Manufacturing of Natural Fiber Reinforced Plastics to Specimens for Generating Simulation Data (NFC-Simulation). In Proceedings of the ANTEC® 2014—Technical Conference & Exhibition, Las Vegas, NV, USA, 28–30 April 2014; Society of Plastics Engineers: Bethel, CT, USA, 2014; pp. 707–711, ISBN 978-0-9850112-4-6. [Google Scholar]

- Albrecht, K.; Osswald, T.; Wartzack, S.; Müssig, J. Natural fibre-reinforced, injection moulded polymers for light weight constructions—Simulation of sustainable materials for the automotive industry. In Proceedings of the 20th International Conference Engineering Design (ICED15), Politecnico di Milano, Italy, 27–30 July 2015; Volume 4, pp. 313–322, ISBN 978-1-904670-67-4. [Google Scholar]

- Cohan, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Printed in the USA; Lawrence Erlbaum Associates: Lawrence, NJ, USA, 1988; ISBN 978-0-12-179060-8. [Google Scholar]

- Lenhard, W.; Lenhard, A. Calculation of Effect Sizes. Bibergau (Germany): Psychometrica. Available online: https://www.psychometrica.de/effect_size.html (accessed on 4 July 2017). [CrossRef]

- Bamberg, G.; Baur, F.; Krapp, M. Statistik. 14. Überarbeitete Auflage. Oldenbourgs Lehr-und Handbücher der Wirtschafts-u. Sozialwissenschaften; Oldenbourg Verlag: München, Germany, 2008; ISBN 978-3486272185. [Google Scholar]

- López, L.; Ramírez, D.; Osswald, T.A. Fiber Attrition and Orientation Productions of a Fiber Filled Polymer through a Gate—A Mechanistic Approach. In Proceedings of the ANTEC® 2013—Technical Conference & Exhibition, Cincinnati, OH, USA, 22–24 April 2013; Society of Plastics Engineers: Bethel, CT, USA, 2013; pp. 2163–2167, ISBN 978-1-63266-530-0. [Google Scholar]

- Baur, E.; Goris, S.; Ramírez, D.; Schmidtke, P.; Osswald, T. Mechanistic model to determine fiber orientation simulation material parameters. In Proceedings of the ANTEC® 2014—Technical Conference & Exhibition, Las Vegas, NV, USA, 28–30 April 2014; Society of Plastics Engineers: Bethel, CT, USA, 2014; pp. 1605–1610, ISBN 978-0-9850112-4-6. [Google Scholar]

- Ramírez, D. Study of Fiber Motion in Moding Processes by Means of a Mechanistic Model. Ph.D. Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2014. [Google Scholar]

- Walter, I.; Goris, S.; Teuwsen, J.; Tapia, A.; Perez, C.; Osswald, T.A. A direct particle level simulation coupled with the Folgar-Tucker RSC Model to predict fiber orientation in injection molding of long glass fiber reinforced thermoplastics. In Proceedings of the ANTEC® 2017—Technical Conference & Exhibition, Anaheim, CA, USA, 8–10 May 2017; Society of Plastics Engineers: Bethel, CT, USA, 2017. ISBN 978-0-692-88309-9. [Google Scholar]

- Oksman, K.; Mathew, A.P.; Langström, R.; Nyström, B.; Joseph, K. The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1847–1853. [Google Scholar] [CrossRef]

- Le Moigne, N.L.; van den Oever, M.; Budtova, T. A statistical analysis of fibre size and shape distribution after compounding in composites reinforced by natural fibres. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1542–1550. [Google Scholar] [CrossRef]

- Hamma, A.; Kaci, M.; Ishak, Z.A.M.; Pegoretti, A. Starch-grafted-polypropylene/kenaf fibres composites. Part 1: Mechanical performances and viscoelastic behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 56, 328–335. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Defersha, F.; Mohanty, A.K. Influence of processing parameters on the impact strength of biocomposites: A statistical approach. Compos. Part A Appl. Sci. Manuf. 2016, 83, 120–129. [Google Scholar] [CrossRef]

- Charlet, K.; Béakou, A. Mechanical properties of interfaces within a flax bundle—Part I: Experimental analysis. Int. J. Adhes. Adhes. 2011, 31, 875–881. [Google Scholar] [CrossRef]

- Pérez, C.; Ramírez, D.; Osswald, T.A. Mechanistic model simulation of a compression molding process: Fiber orientation and fiber-matrix separation. In Proceedings of the ANTEC® 2015—Technical Conference & Exhibition, Orlando, FL, USA, 23–25 March 2015; Society of Plastics Engineers: Bethel, CT, USA, 2015. ISBN 9780985011277. [Google Scholar]

- Berzin, F.; Vergnes, B.; Beaugrand, J. Evolution of lignocellulosic fibre lengths along the screw profile during twin screw compounding with polycaprolactone. Compos. Part A Appl. Sci. Manuf. 2014, 59, 30–36. [Google Scholar] [CrossRef]

| Flax | Original | Granules | Plate | |||

| n | 1110 | 2179 | 1275 | |||

| Mean ± SD | Median | Mean ± SD | Median | Mean ± SD | Median | |

| Length in µm | 1272 ± 1137 | 970 | 481 ± 376 | 362 | 438 ± 257 | 369 |

| Thickness in µm | 54 ± 41 | 37 | 18 ± 8 | 16 | 21 ± 8 | 20 |

| Aspect ratio | 26 ± 18 | 20 | 28 ± 20 | 21 | 21 ± 13 | 18 |

| Sisal | Original | Granules | Plate | |||

| n | 709 | 2436 | 2468 | |||

| Mean ± SD | Median | Mean ± SD | Median | Mean ± SD | Median | |

| Length in µm | 3590 ± 4026 | 3034 | 647 ± 702 | 353 | 666 ± 660 | 388 |

| Thickness in µm | 139 ± 88 | 129 | 69 ± 82 | 35 | 68 ± 75 | 35 |

| Aspect ratio | 25 ± 28 | 17 | 14 ± 12 | 10 | 14 ± 12 | 11 |

| PP-Compound (30 Mass % of Fibres) | CI |

|---|---|

| Flax | 0.0037 |

| Sisal | 0.0059 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albrecht, K.; Osswald, T.; Baur, E.; Meier, T.; Wartzack, S.; Müssig, J. Fibre Length Reduction in Natural Fibre-Reinforced Polymers during Compounding and Injection Moulding—Experiments Versus Numerical Prediction of Fibre Breakage. J. Compos. Sci. 2018, 2, 20. https://doi.org/10.3390/jcs2020020

Albrecht K, Osswald T, Baur E, Meier T, Wartzack S, Müssig J. Fibre Length Reduction in Natural Fibre-Reinforced Polymers during Compounding and Injection Moulding—Experiments Versus Numerical Prediction of Fibre Breakage. Journal of Composites Science. 2018; 2(2):20. https://doi.org/10.3390/jcs2020020

Chicago/Turabian StyleAlbrecht, Katharina, Tim Osswald, Erwin Baur, Thomas Meier, Sandro Wartzack, and Jörg Müssig. 2018. "Fibre Length Reduction in Natural Fibre-Reinforced Polymers during Compounding and Injection Moulding—Experiments Versus Numerical Prediction of Fibre Breakage" Journal of Composites Science 2, no. 2: 20. https://doi.org/10.3390/jcs2020020

APA StyleAlbrecht, K., Osswald, T., Baur, E., Meier, T., Wartzack, S., & Müssig, J. (2018). Fibre Length Reduction in Natural Fibre-Reinforced Polymers during Compounding and Injection Moulding—Experiments Versus Numerical Prediction of Fibre Breakage. Journal of Composites Science, 2(2), 20. https://doi.org/10.3390/jcs2020020