1. Introduction

One of the most promising materials over the past five decades has been polymer composites. Their application and access to new markets have increased steadily [

1]. These materials have versatility and the ability to satisfy a range of functionalities, making them a potent force in the market [

2]. The main advantages of polymer composite materials over other materials currently in use, such as metals or alloys, are their high specific tensile strength and stiffness, and corrosion resistance, permitting weight reduction in the finished products [

3]. Polymer composite materials perform better in comparison to constituent materials because the distinct materials retain their individual properties while working collectively to form a new material with improved properties [

4]. Polymer composite materials can be distinguished by the reinforcement used, such as fiber-reinforced polymer composite and particle-reinforced composite, or hybrid composite [

5]. Polymer composites have emerged as versatile materials with superior tensile strength, stiffness, and corrosion resistance, enabling their use across diverse sectors including aerospace, automotive, marine, energy, and infrastructure [

6,

7]. Their mechanical performance arises from the synergy between the reinforcement, whether fiber, particle, or hybrid, and the polymer matrix, which ensures efficient load transfer [

8,

9]. The choice of reinforcement significantly influences composite properties, as it governs interfacial bonding, load-bearing capacity, and overall structural integrity. As a result, composite performance depends on the type, distribution, and interaction of the reinforcement within the matrix, as well as the interphase region, which together determine the stiffness, strength, and toughness of the final material [

10].

Extensive studies have been conducted on the mechanical characteristics of agricultural waste-reinforced polymer composites to examine the possibilities of applying agricultural waste fillers to improve the performance of polymer composites [

11,

12,

13,

14,

15]. For example, Naik et al. [

16] utilized the readily available agricultural waste in India to examine the usage of tamarind seed particles as reinforcement in epoxy resin composites. The composite specimens were made using epoxy resin and tamarind seed powder with varying weight percentages. The results indicated that the composites have enhanced mechanical characteristics, including higher tensile strength, impact strength, modulus of rupture (MOR), and modulus of elasticity (MOE). This study emphasizes the potential of epoxy composites reinforced with tamarind seed particles for use in coatings, structural applications, and automotive design. Chand et al. [

17] focused on using banana and bagasse fibers, which are readily available and low-cost, as reinforcement components in epoxy composites. To improve the adhesion qualities, sodium hydroxide (NaOH) and sodium chloride (NaCl) solutions were applied to the fibers. Tensile and flexural tests were used to assess the mechanical properties of the composite materials with various fiber volume fractions. The findings demonstrate the promise of these composites in a variety of applications by showing that increasing the volume percentage of fibers, especially at 30%, resulted in improved stiffness, elasticity, and ultimate tensile strength (UTS). The use of oil palm empty fruit bunch fibers as reinforcement for epoxy composites was investigated by Yusup et al. [

18]. Examination of how varied alkaline treatment times affected the fibers’ mechanical, physical, and morphological properties was carried out. Also, the flexural and impact strengths of the composite samples, which were created using mold casting techniques, were determined. The findings suggest that composite materials with fibers treated for 24 h had the maximum flexural strength (83.63 MPa) and impact strength (1.1527 J/mm

2), making them promising materials for sporting goods. The porosity ranges from 1.57% to 2.02%, while the density of the composites is between 1.1479 and 1.1527 g/cm

3. Ghazi and Jaddan [

19] studied the use of date palm waste as a reinforcing filler in green composite materials for insulation and interior parts in the shipbuilding and automotive industries. Six composites were created using various fillers and loading percentages. The filler volume fraction and type affected the thermal properties, with the seed date palm obtaining the lowest values at the highest volume fraction (30%). The lowest thermal conductivity was demonstrated by the epoxy hybrid composites, which made them ideal for use in thermal insulation applications. The thermal conductivity of the seed date palm filler at maximum loading was found to be 0.138 W/m·K, along with thermal diffusivity of 0.0201 J/kg·K and specific heat of 720 m

2/s.

While natural fillers such as banana fiber and bagasse have been explored in prior studies, comparative analysis across multiple agricultural waste types within a consistent polymer system remains limited. Moreover, few studies comprehensively address damping behavior via DMA or correlate it with microstructural and thermal observations. In addition to the above examples, other agricultural wastes have also been studied, including coconut shells [

20,

21,

22,

23], coffee beans [

24,

25], and walnut shell particles [

26,

27]. This paper offers the like-for-like, systematic comparison of the three agricultural waste fillers, that is, coconut shell, coffee bean, and walnut shell, within the same epoxy matrix, therefore removing polymer-system variability that has hampered previous works. We marry macroscopic mechanical testing, dynamic mechanical analysis (DMA), thermal characterization, and cross-section SEM of post-impacts to directly correlate damping, stiffness, and strength to microstructure and thermal behavior. The simultaneous experimental comparison of particulate matrices and laminated composites under a unified experimental framework provides novel, applicable guidance on filler-dependent performance and scalability, and a clear roadmap on the selection and treatment of agricultural waste particles applicable to composite use in the industrial context.

3. Results

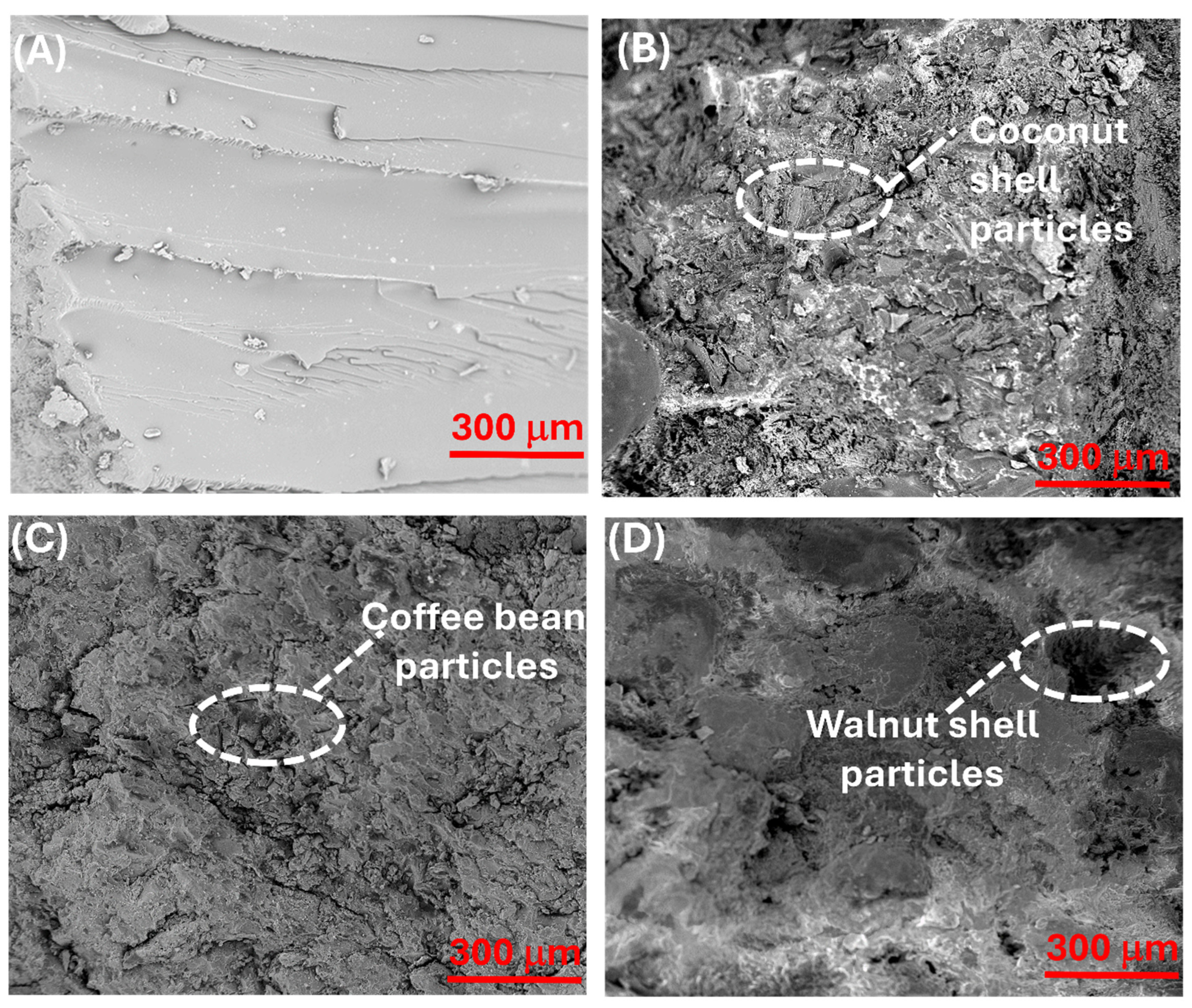

The morphology of the reinforced polymer composites was investigated with SEM micrographs. The control sample, which was just the epoxy matrix with no particles, had a smooth surface compared to the reinforced polymer composites, as seen in

Figure 1A.

Figure 1.

SEM micrographs of (A) Control (no particles) polymer. (B) Coconut shell reinforced polymer composites (CSRPC). (C) Coffee bean reinforced polymer composites (CBRPC). (D) Walnut shell reinforced polymer composites (WSRPC).

Figure 1.

SEM micrographs of (A) Control (no particles) polymer. (B) Coconut shell reinforced polymer composites (CSRPC). (C) Coffee bean reinforced polymer composites (CBRPC). (D) Walnut shell reinforced polymer composites (WSRPC).

However, the coconut shell, coffee beans, and walnut shell particles are evenly distributed in the epoxy matrix of their respective reinforced polymer composites, as shown in

Figure 1B–D. The distribution of the reinforcement within the polymer matrix is essential for improving the structural and non-structural properties of the as-synthesized composites.

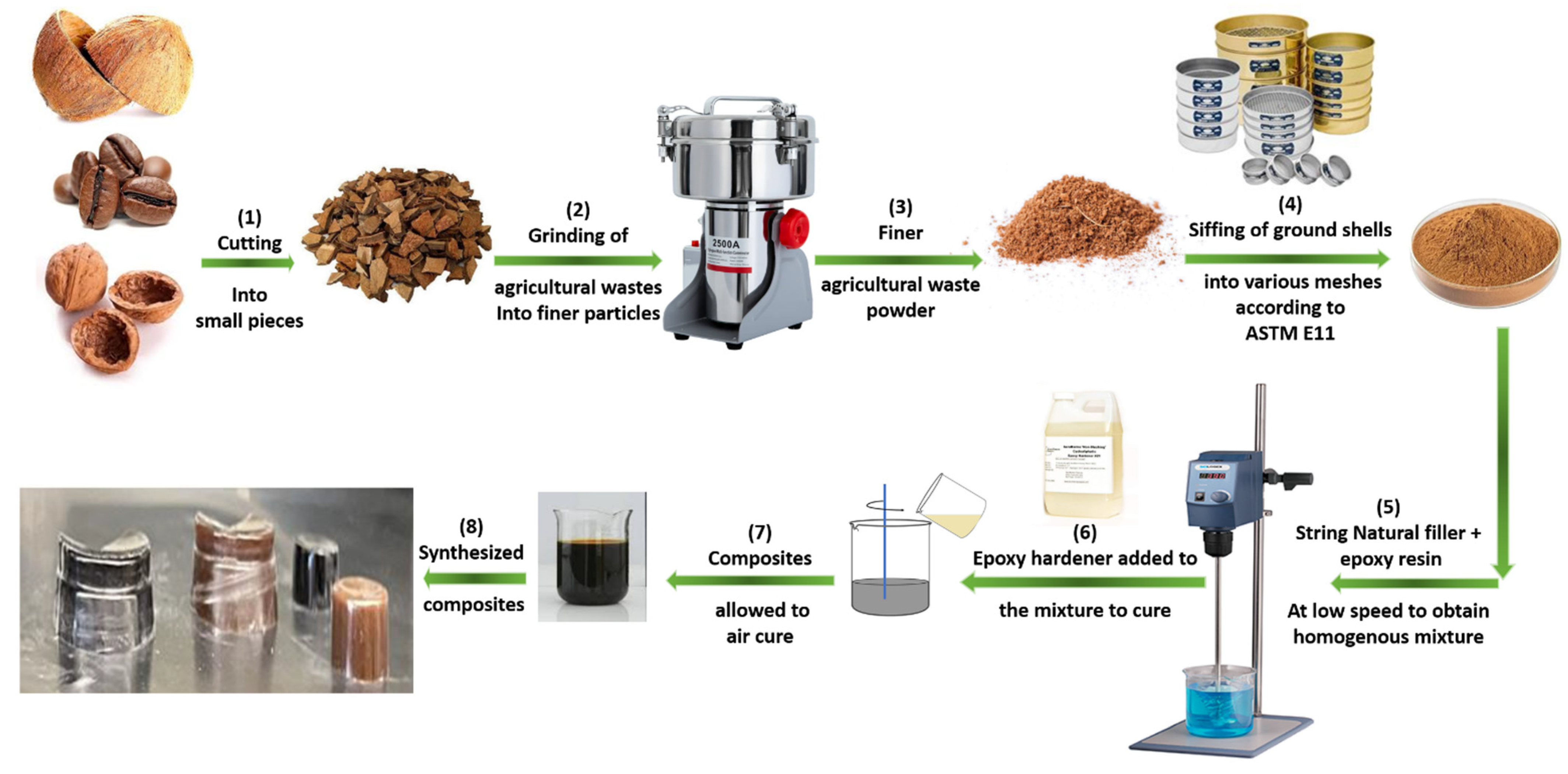

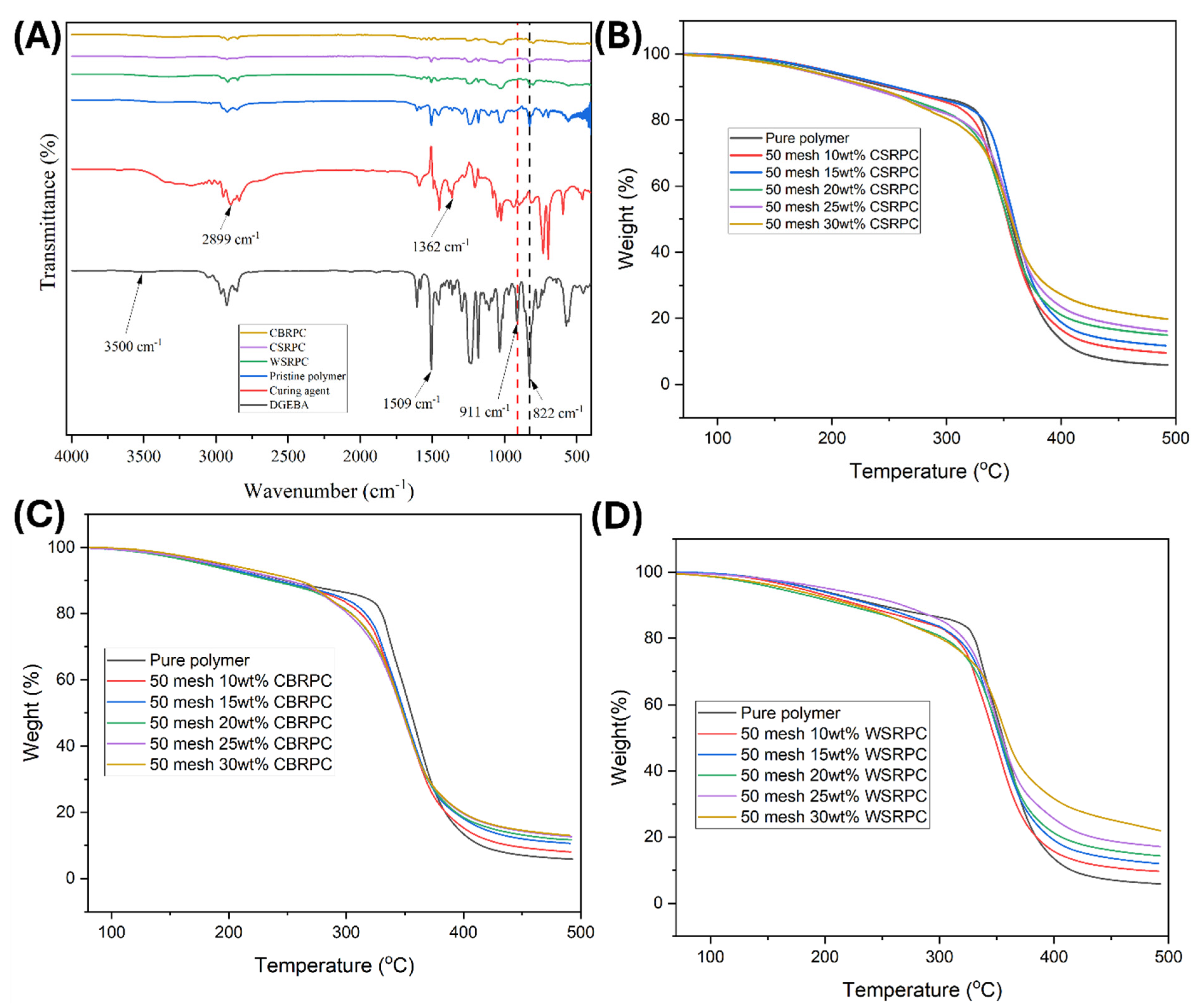

The intermolecular bond stretching in DGEBA, the curing agent, pure polymer, walnut shell (WSRPC), coconut shell (CSRPC), and the coffee bean reinforced polymer composites (CBRPC) was investigated using FT-IR, as shown in

Figure 2A. It can be observed that the peaks for DGEBA exhibit epoxide group characteristics at wavenumbers of 911 cm

−1 and 822 cm

−1. Two distinct peaks were detected at 1101 cm

−1 and 1033 cm

−1, respectively: the -C-N- absorption peak and the -C-O-C- strong peak [

33]. Additionally, the hydroxyl group (OH) is assigned the wavenumber at 3500 cm

−1. The characteristic of substituted aromatic rings is the absorption peak at 1509 cm

−1 [

34]. The N-H and C-N stretching is attributed to the curing agent’s peaks at 2899 cm

−1 and 1362 cm

−1, respectively. The epoxide group in the pure polymer and the composites reinforced with agricultural waste particles disappear at 911 cm

−1 and 822 cm

−1, respectively, indicating complete curing of the epoxy resin.

The thermal stability of the pure polymer and the fabricated agricultural waste particle reinforced polymer composites was investigated with the thermogravimetric analyzer. The analysis was performed by comparing the pure polymer with different weight percentages of the reinforcement in a 50 mesh.

Figure 2B–D shows the weight loss of the samples as a function of temperature. At 110 °C, every sample had a weight decrease due to the evaporation of the absorbed water molecules. The samples all had a significant decrease in weight at 320 °C, which was due to the degradation of the polymer’s functional groups.

From the derivative thermogravimetry (DTG) analysis, as shown in

Figure S4a–c, it is evident that all samples experienced the fastest decomposition between 350 and 360 °C (the peak temperature corresponding to the DTG curve), which corresponds with the degradation of the polymer’s functional group. However, the weight loss of the composites and the pure polymer differed significantly at 460 °C because of the interaction between the functional groups within the agricultural waste, which helped in increasing the thermal stability of the agricultural waste particle reinforced polymer composite compared with the pure polymer. The residual weight of the polymer increased with the increase in reinforcement weight percentage; the 30 wt.% of all the reinforced polymer composites had the highest residual weight at 460 °C. However, 50 mesh 30 wt.% WSRPC had the highest residue of 24.43 wt.% among the reinforced polymer composites, followed by 50 mesh 30 wt.% CSRPC with 21.32 wt.% residue, and 50 mesh 30 wt.% CBRPC with 14.10 wt.% residue, which are all greater than the pure polymer with 6.66 wt.% residue. The thermal properties analysis of the polymer and the reinforced polymer composites using TGA was also summarized in

Table 1,

Table 2 and

Table 3.

Table 1.

Thermal properties analysis of pure polymer and coconut shell reinforced polymer composites (CSRPC) using TGA.

Table 1.

Thermal properties analysis of pure polymer and coconut shell reinforced polymer composites (CSRPC) using TGA.

| Samples | wt.% Loss

@ 110 °C | T5%

(°C) | wt.% Loss

@ 320 °C | Tmax

(°C) | Residue wt.%

@ 460 °C |

|---|

| Pure Polymer | 0.57 | 189.74 | 15.83 | 354.92 | 6.66 |

| 50 mesh 10 wt.% CSRPC | 0.41 | 194.72 | 18.67 | 356.47 | 10.50 |

| 50 mesh 15 wt.% CSRPC | 0.52 | 194.10 | 16.54 | 359.45 | 12.76 |

| 50 mesh 20 wt.% CSRPC | 0.93 | 178.41 | 22.42 | 346.60 | 16.02 |

| 50 mesh 25 wt.% CSRPC | 1.08 | 174.73 | 21.87 | 356.86 | 17.50 |

| 50 mesh 30 wt.% CSRPC | 1.26 | 177.21 | 24.01 | 354.05 | 21.32 |

Table 2.

Thermal properties analysis of pure polymer and coffee bean reinforced polymer composites (CBRPC) using TGA.

Table 2.

Thermal properties analysis of pure polymer and coffee bean reinforced polymer composites (CBRPC) using TGA.

| Samples | wt.% Loss

@ 110 °C | T5%

(°C) | wt.% Loss

@ 320 °C | Tmax

(°C) | Residue wt.%

@ 460 °C |

|---|

| Pure Polymer | 0.57 | 189.74 | 15.83 | 354.92 | 6.66 |

| 50 mesh 10 wt.% CBRPC | 0.66 | 183.15 | 23.77 | 359.47 | 8.99 |

| 50 mesh 15 wt.% CBRPC | 0.47 | 184.58 | 21.58 | 350.71 | 11.54 |

| 50 mesh 20 wt.% CBRPC | 0.88 | 177.87 | 26.28 | 360.23 | 12.68 |

| 50 mesh 25 wt.% CBRPC | 0.78 | 187.85 | 27.45 | 349.33 | 13.83 |

| 50 mesh 30 wt.% CBRPC | 0.33 | 196.04 | 26.01 | 350.81 | 14.10 |

Table 3.

Thermal properties analysis of pure polymer and walnut shell reinforced polymer composites (WSRPC) using TGA.

Table 3.

Thermal properties analysis of pure polymer and walnut shell reinforced polymer composites (WSRPC) using TGA.

| Samples | wt.% Loss

@ 110 °C | T5%

(°C) | wt.% Loss

@ 320 °C | Tmax

(°C) | Residue wt.%

@ 460 °C |

|---|

| Pure Polymer | 0.57 | 189.74 | 15.83 | 354.92 | 6.66 |

| 50 mesh 10 wt.% WSRPC | 0.51 | 178.71 | 22.45 | 347.07 | 10.47 |

| 50 mesh 15 wt.% WSRPC | 0.44 | 187.87 | 21.54 | 353.75 | 13.12 |

| 50 mesh 20 wt.% WSRPC | 1.55 | 159.28 | 24.39 | 357.17 | 15.50 |

| 50 mesh 25 wt.% WSRPC | 0.71 | 203.45 | 19.65 | 351.80 | 18.33 |

| 50 mesh 30 wt.% WSRPC | 1.43 | 168.061 | 24.48 | 355.41 | 24.43 |

The Differential Scanning Calorimeter (DSC) was used to analyze the glass transition temperature (T

g) of the pure polymer as well as the fabricated 50 mesh 30 wt.% CSRPC, WSRPC, and CBRPC, as shown in

Figure S4d. The glass transition temperature (T

g) of the polymer plays an important role in determining the mechanical properties of the samples with respect to their thermal stability; this confirms the operating range of a material in which the mechanical strength is retained. The T

g of the pure polymer was 55.60 °C; however, when the polymer was reinforced as CBRPC, CSRPC, and WSRPC, the T

g increased to 56.84, 57.27, and 60.33 °C, respectively. The increase in T

g of the reinforced polymer composites is due to the filler limiting the mobility of the polymer chains with increasing temperature.

Density measurements were carried out to evaluate the potential thermal insulation capabilities of the as-fabricated agricultural waste (coconut shells, coffee beans, walnut shells) reinforced polymer composites. Different weight compositions and mesh sizes were used for the density analysis of the fillers. For the coconut shell particles, the density is reduced with an increase in weight composition. From

Table S1, for 50 mesh, CSRPC had a density of 1.89 g/cm

3 for 10 wt.%, which decreased by 18.5% to a density of 1.54 for 30 wt.%. However, the density increased with increasing mesh sizes. Maintaining the weight composition at 10 wt.%, 50 mesh CSRPC had a density of 1.89 g/cm

3, which increased to 2.09

g·cm−3 for 300 mesh CSRPC. 30 wt.% 50 mesh coconut shell reinforced polymer composite had the lowest density of 1.5443

g·cm−3, which is about 35.6% less than the density of 10 wt.% composite containing 200 mesh coconut shell particles that recorded the highest density. A similar trend was identified for CBRPC and WSRPC in

Table S1, indicating that the agricultural waste fillers have a significant effect on the density of the composites.

The low-impact velocity testing was conducted to determine the mechanical behaviour of the laminated composites using the particulate composite as matrix, and the control laminated composite using the pure polymer as matrix. The composite laminates were synthesized using 2, 4, and 6 wt.% of CSRPC, CBRPC, and WSRPC with respect to the entire laminate composite.

Figure 3A shows the representative load and energy plots for the glass fabric-reinforced CSRPC laminate.

Li et al. [

35] stated that crack initiation energy is a metric used to evaluate the specimen’s elastic energy transfer potential. The impact energy corresponding to the peak impact load from the low-velocity impact test is referred to as the crack initiation energy [

36]. The crack initiation energy is observed to increase with increasing wt.% of CSRPC filler used in the glass-fiber/CSRPC laminate, as shown in

Figure 3B. The crack initiation energy increased by 142% (from 4.92 J to 11.91 J), and the peak load increased by 162% (from 1.23 kN to 3.22 kN) for 6 wt.% CSRPC laminates compared to the control. Similarly, the glass-fiber/CBRPC and glass-fiber/WSRPC laminates resulted in increasing crack initiation energy and peak load for the same wt.% as displayed in

Figure 3C,D, respectively. The increase in the crack initiation energy and peak load shows an increase in the impact resistance with the addition of the agricultural waste reinforcement due to the interaction of the functional groups of the reinforcement with the polymer matrix and the glass fiber.

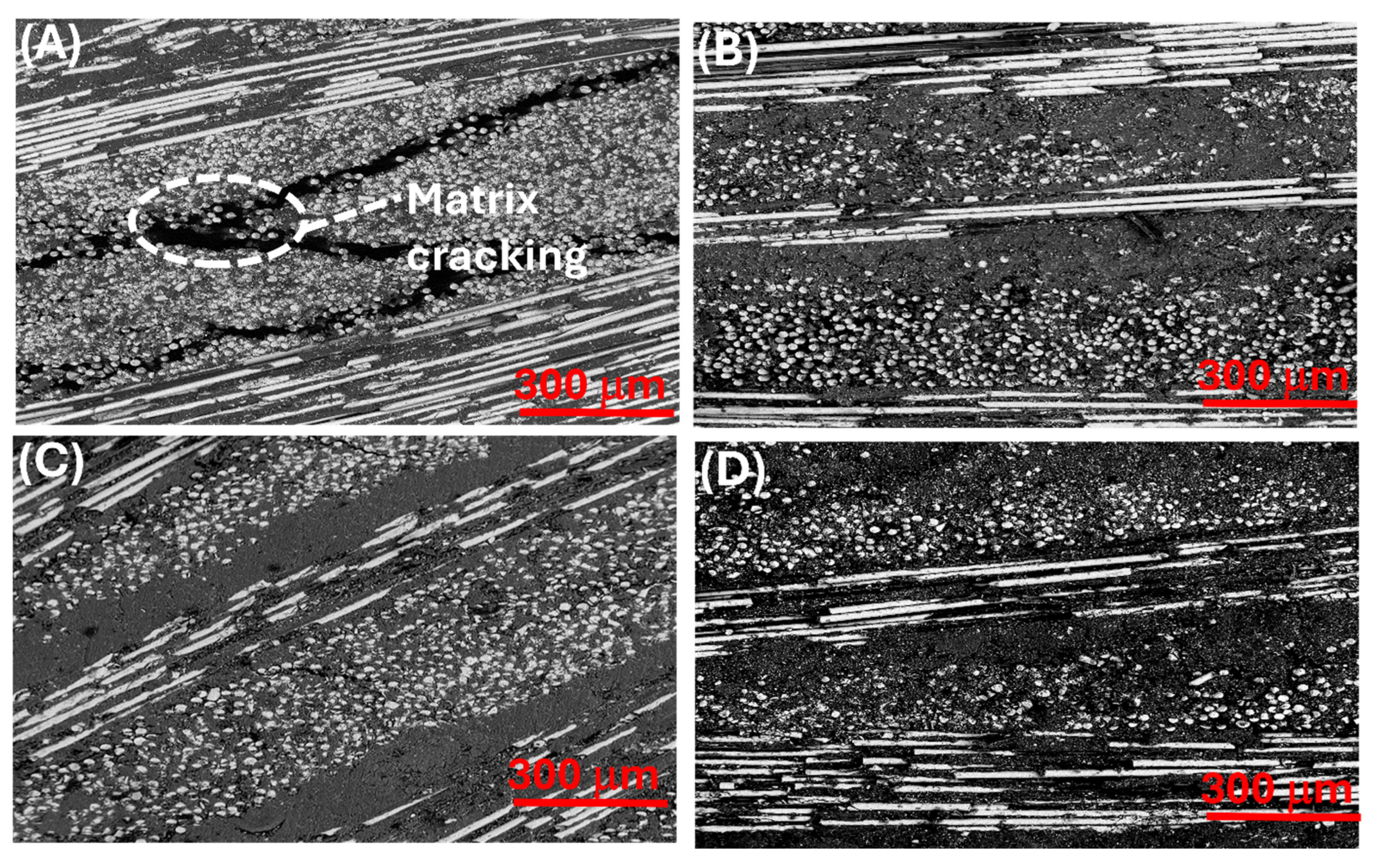

The impacted laminates were further subjected to SEM analysis to evaluate the impact of the damage on the surface of the laminates. For

Figure 4, impacted laminates were sectioned perpendicular to the impacted surface using a precision diamond saw. The cross-sectioning plane passed through the central axis of the impact site to capture the primary damage zone. Sections were progressively polished with 400–1200 grit SiC papers followed by 0.5 µm alumina slurry, rinsed, and dried. Samples were then sputter-coated with a thin layer (~10 nm) of gold to prevent charging. The resulting viewing plane reveals through-thickness crack propagation, fiber–matrix debonding, and resin fracture morphology relative to the point of impact. The control laminate showed visible cracks in the polymer matrix and breakage in the glass fiber, as displayed in

Figure 4A. However, the 6 wt.% of the glass-fiber/composite laminates showed no visible cracks, indicating the increase in impact resistance due to the addition of the agricultural waste fillers as seen in

Figure 4B–D.

To fully investigate the flexural mechanical properties of the laminate composites, the composites were tested at varying filler concentrations (2, 4, and 6 wt.%) to evaluate their flexural strength and flexural modulus, with a well-calibrated and credible mechanical testing machine equipped with a Three-Point Bending Test Fixture. The objective of this particular Mechanical Property Test is to basically comprehend the effect of the particulate natural fillers on the material’s flexural behavior in terms of structural integrity, stiffness, and its ultimate bending ability. Flexural strength and modulus data for all filler types are provided in

Figures S7–S9 of the Supplementary Material.Both flexural modulus and flexural strength of laminate composites seem to depend on filler type and filler loading. With 2 wt.% loading, WSRPC had the flexural strength of 134 MPa and flexural modulus of 12.36 GPa, which is above the strength and modulus values recorded for the CSRPC (110 MPa, 9.50 GPa) and CBRPC (114 MPa, 14.91 GPa) fillers at the same loading. By augmenting the filler ratio to 6 wt.%, CBRPC exhibited the optimum balance with a flexural strength of 146 MPa and modulus of 10.08 GPa, showing a positive effect on adhesion as well as dispersion. However, CSRPC and WSRPC composites showed a decrease in stiffness at higher filler contents. With CSRPC, the 6 wt.% combination produced a strength of 122 MPa and a 10.71 GPa modulus, and in WSRPC, the 6 wt.% combination produced a strength of 115 MPa and a modulus of 10.37 GPa. This reduction of modulus at higher filler loading can be expected in terms of microstructural disruptions, especially filler agglomeration, that limits the ability of the filler to transfer stress within the matrix efficiently (

Figure 1). The performance profile of CBRPC was more consistent in all filler loadings and was indicative of better interfacial bonding and homogeneous dispersion. This led to an increase in the stiffness of the matrix and better loading distribution than CSRPC and WSRPC. Such observations are consistent with the particle-filler theories, which state that homogeneous dispersion promotes better mechanical interlocking and stress transfer. This performance is further supported by the DMA and SEM analysis (

Figures S10–S12).

A Dynamic Mechanical Analysis (DMA) test was performed to study the viscoelastic behavior of composites near the rubbery state and, in general, the mechanical properties of hybridized laminate composite with respect to temperature. DMA test was carried out on laminate composites within a temperature range from 28 °C to −110 °C with the objective of studying storage modulus (E′), loss modulus (E′′), and damping factor (tan δ) to understand material stiffness, energy dissipation, and efficiency in damping. The instrument used was the RSA-G2 TA Instrument equipped with a Three-point Bending fixture. Evidently, the stiffness, given by the storage modulus (E’), is different for different fillers and their concentrations. DMA Results can be seen in

Supplementary Figures S10–S12. At 6% by weight, CBRPC exhibits the highest stiffness, at 29.47 GPa at 35 °C, while the stiffness of CSRPC increases gradually from 2% to 6%, attaining its peak at 24.69 GPa at 32 °C. The higher storage modulus of CBRPC is consistent with the uniform filler distribution and minimal void formation observed in

Figure 1C and

Figure 4C, which enable efficient load transfer in the glassy region. WSRPC exhibited an increase in stiffness in the initial stages from 2% to 4% but declined at 6% with 6.01 GPa at 33 °C. The maximum value recorded for the loss modulus E’’ representing the energy dissipation for 6% of CBRPC is 4.56 GPa at 59 °C, and for 6% CSRPC, it is 3.51 GPa at 51 °C. This reflects the ability to dissipate the vibrational energy. Maximum damping efficiency as obtained from Tan Delta (δ) for 6% CSRPC, which is 0.365 at 55 °C, is indicative of superior energy dissipation and a T

g temperature around that value. The tests run before the DMA tests were TGA, DSC, and FT-IR/SEM; hence, the previous thermal and chemical/microstructural data were taken into consideration when interpreting the results of the DMA tests. These variations in damping factor (tan δ) are a combination of bulk polymer relaxations and interfacial energy dissipations. Since the DMA was conducted last, we directly linked the high or widened tan δ peaks with the microscale interfacial gap as viewed by the SEM and the FT-IR signals that demonstrate weaker interfacial chemistry (e.g., CSRPC, tan 6 = 0.365 at 55 °C). Oppositely, both lower tan δ and elevated Tg, along with high residue on TGA, are indicative of greater filler-to-matrix affinity (as is the case with some samples of walnuts and coffee). This experimental sequence further reinforces our inference that we saw changes in the tan δ, likely due to bulk viscoelasticity as well as the filler-matrix interfacial behavior.

These results depict that higher filler content, in general, increases the damping properties due to the homogeneous dispersion of fillers, which enhances the energy dissipation at the polymer-filler interface. The moderate Tg developed in coconut and coffee composites could indicate that the lignocellulose structures of the fillers may contribute to the stiffness and damping due to inherent rigidity and compatibility with the matrix. The lower stiffness of 6% walnut composites may relate to possible agglomeration at higher filler loads, reducing the effective stress transfer.

In conclusion, 6% coffee fillers exhibit the highest stiffness value, while at the same loading, coconut fillers provide the greatest damping efficiency; thus, filler-specific mechanical responses are suitable in the designed applications of advanced composites. Compared to graphene and carbon nanotubes, which cost $100–$500/kg, agricultural waste fillers are readily available at <$5/kg. While carbon-based nanofillers exhibit superior strength (~200 GPa), their poor dispersion and high cost limit scalability. Our composites showed flexural strengths up to 146 MPa and excellent damping behavior, offering a sustainable, cost-effective alternative with ~90% lower cost and simpler processing.