Adaptive Robotic Deburring of Molded Parts via 3D Vision and Tolerance-Constrained Non-Rigid Registration

Abstract

1. Introduction

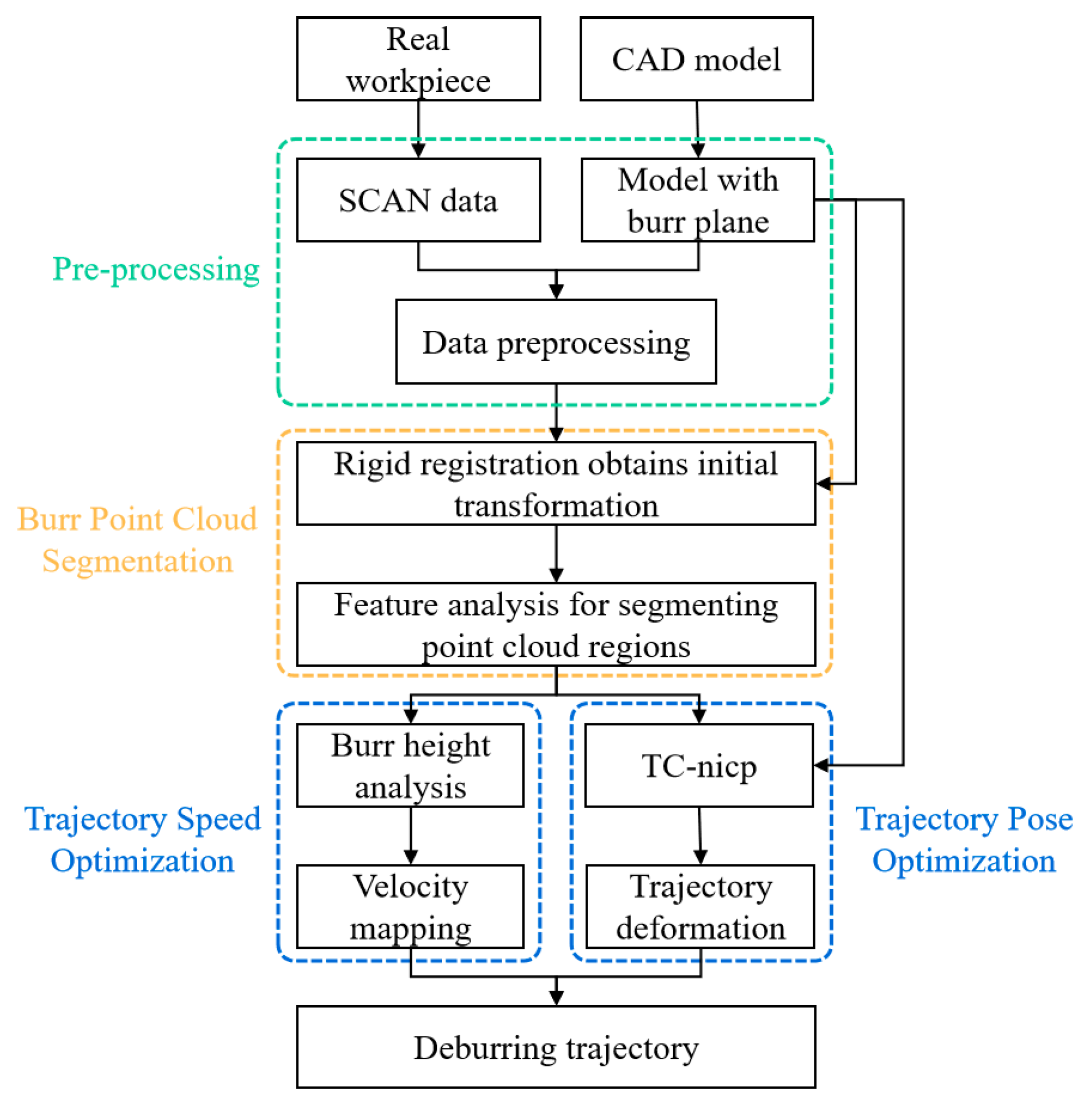

2. Methods and Experimental Procedure

2.1. Methods

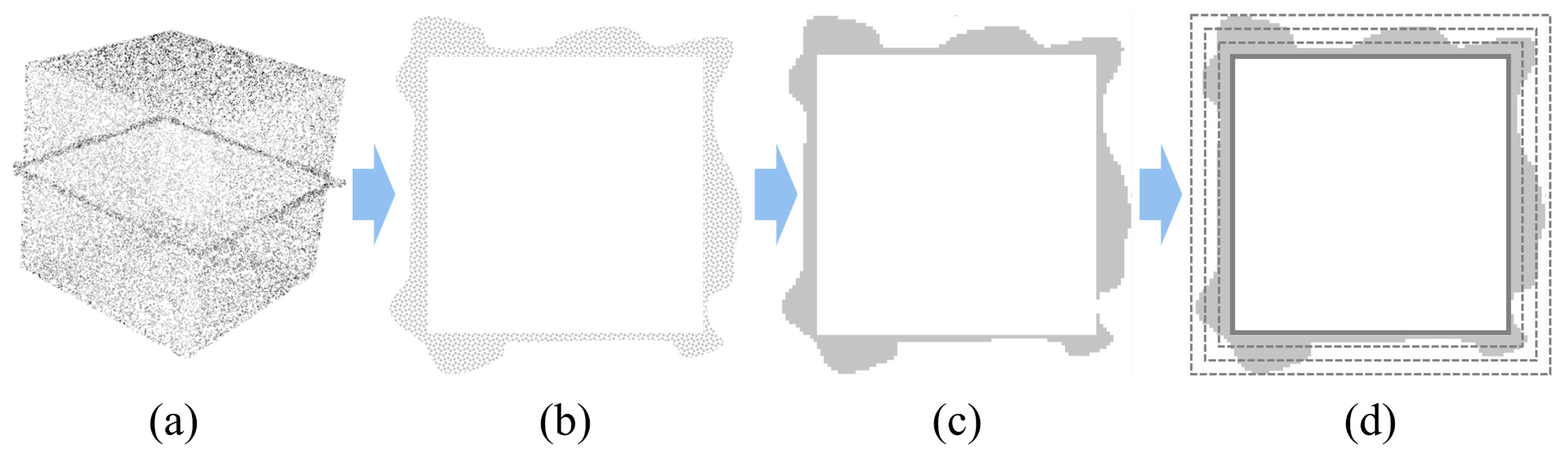

2.1.1. Data Acquisition and Pre-Processing

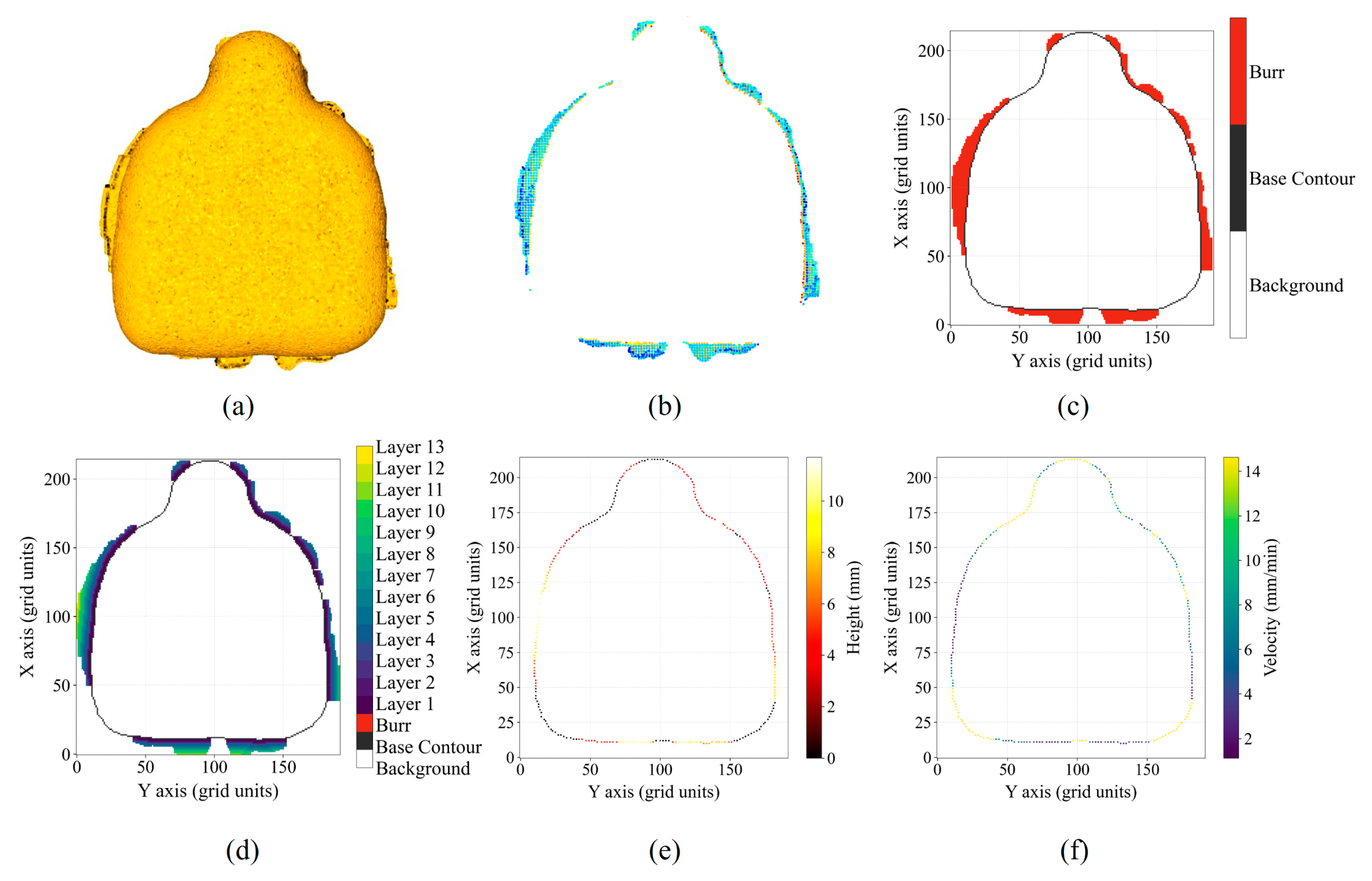

2.1.2. Feature-Based Burr Point Cloud Segmentation

- (a)

- Euclidean distance feature:

- (b)

- Normal vector difference feature:

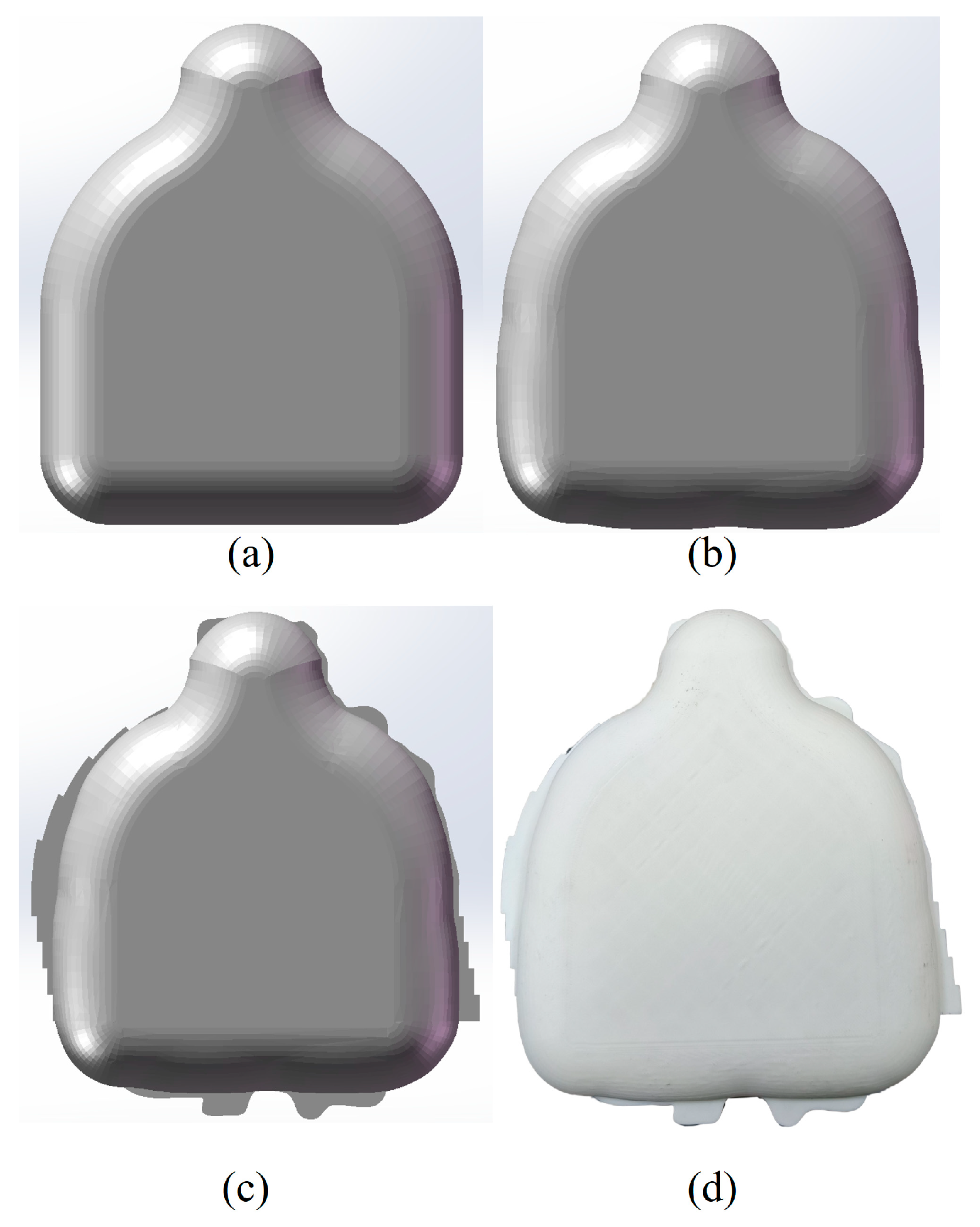

2.1.3. Trajectory Pose Optimization Under Tolerance Constraints

- (1)

- Data term: , measuring point cloud alignment error;

- (2)

- Regularization term: , constraining deformation field continuity;

- (3)

- Constraint term , where is the deformation threshold based on manufacturing tolerances and is the Heaviside function used to penalize deformations exceeding the threshold.

2.1.4. Trajectory Speed Optimization Based on Point Cloud Mesh Analysis

2.2. Experimental Procedure

2.2.1. Experimental Setup

2.2.2. Pre-Experiment for Parameter Determination

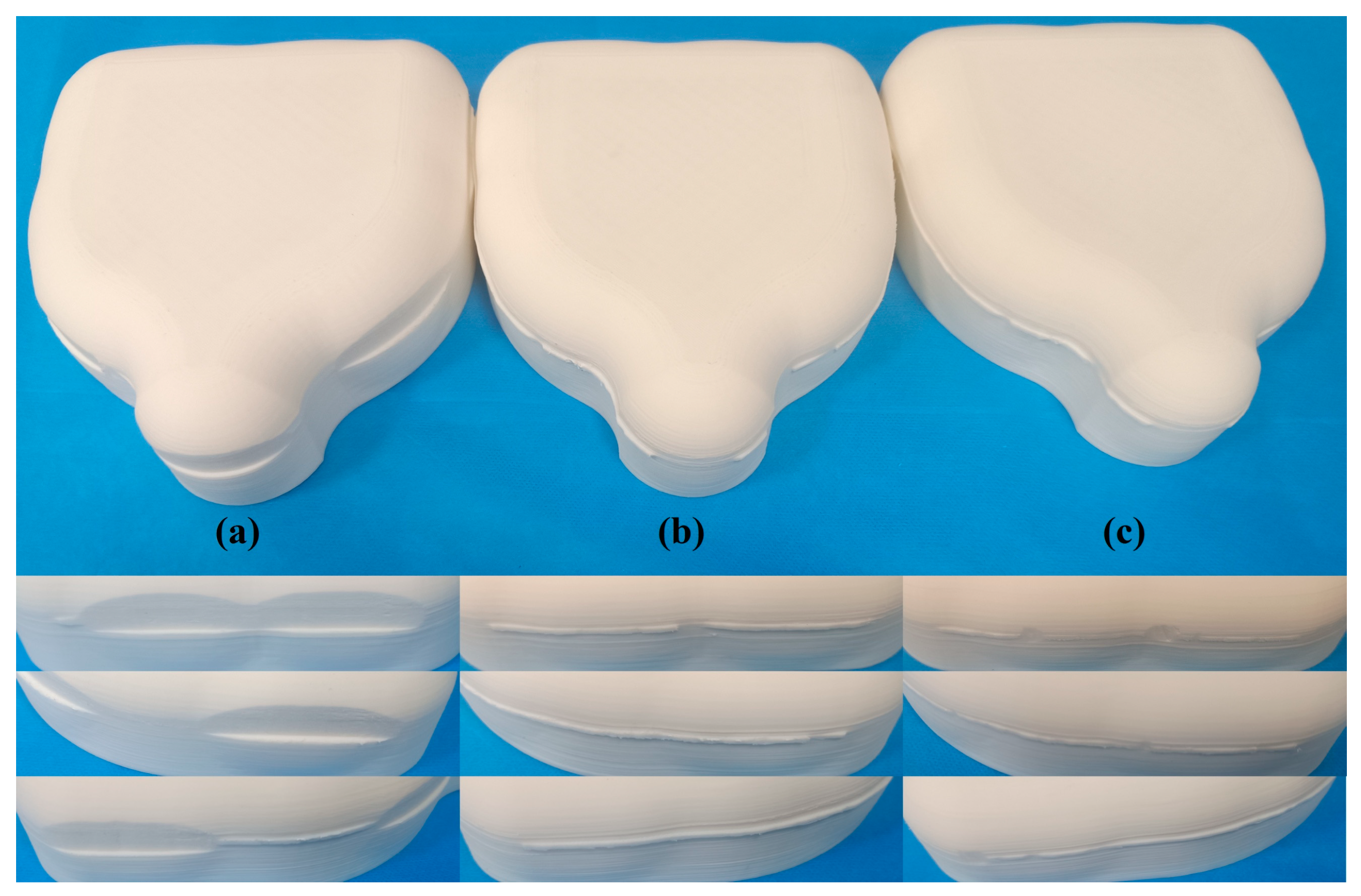

2.2.3. Workpiece Deburring Experiment

3. Results and Discussion

4. Conclusions

- (1)

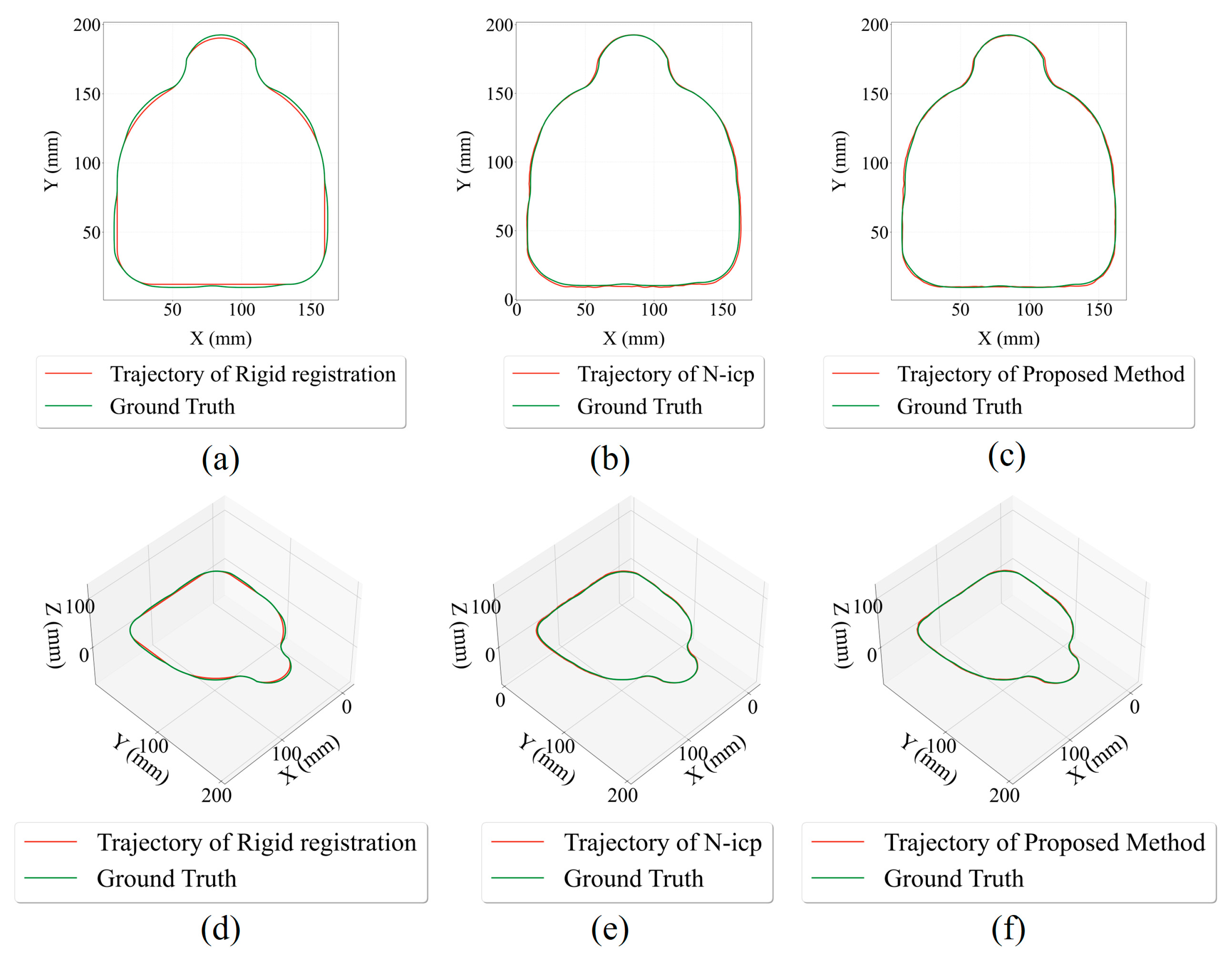

- The proposed feature-based burr segmentation combined with a tolerance-constrained non-rigid registration algorithm effectively enables automatic trajectory generation under conditions involving workpiece deformation. Experimental results confirmed that this method achieves significantly higher accuracy in trajectory positioning compared to traditional rigid and non-rigid registration methods.

- (2)

- Dynamic trajectory speed optimization based on quantitative burr height analysis substantially enhanced deburring efficiency without compromising processing quality. By adjusting robot feed rates according to burr distribution characteristics, the proposed method demonstrated a 68% reduction in processing time compared to conventional constant-speed methods. This dynamic feed rate adjustment ensures an optimal balance between machining efficiency and surface quality.

- (3)

- The experimental validation revealed that the method provides a precise and efficient solution suitable for automated deburring of complex molded parts, showcasing promising potential for practical industrial applications. However, the current method’s effectiveness with more complex workpiece geometries remains to be explored further, suggesting potential research avenues for enhancing burr recognition accuracy and trajectory planning capabilities in more challenging scenarios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Onstein, I.F.; Semeniuta, O.; Bjerkeng, M. Deburring Using Robot Manipulators: A Review. In Proceedings of the 2020 3rd International Symposium on Small-Scale Intelligent Manufacturing Systems (SIMS), Gjovik, Norway, 10–12 June 2020. IEEE Conference Proceedings. [Google Scholar] [CrossRef]

- Shin, H.; Park, E.S. Analysis of Incomplete Filling Defect for Injection-Molded Air Cleaner Cover Using Moldflow Simulation. J. Polym. 2013, 2013, 720209. [Google Scholar] [CrossRef]

- Sharma, S. Modeling and Optimization of Die Casting Process for ZAMAK Alloy. J. Eng. Technol. 2014, 4, 87. [Google Scholar] [CrossRef]

- Aurich, J.C.; Dornfeld, D.; Arrazola, P.J.; Franke, V.; Leitz, L.; Min, S. Burrs—Analysis, control and removal. CIRP Ann. 2009, 58, 519–542. [Google Scholar] [CrossRef]

- Huang, W.; Mei, X.; Jiang, G.; Hou, D.; Bi, Y.; Wang, Y. An on-machine tool path generation method based on hybrid and local point cloud registration for laser deburring of ceramic cores. J. Intell. Manuf. 2022, 33, 2223–2238. [Google Scholar] [CrossRef]

- Jin, S.Y.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S.; Debnath, S. Burr formation and its treatments—A review. Int. J. Adv. Manuf. Technol. 2020, 107, 2189–2210. [Google Scholar] [CrossRef]

- Niknam, S.A.; Davoodi, B.; Davim, J.P.; Songmene, V. Mechanical deburring and edge-finishing processes for aluminum parts—A review. Int. J. Adv. Manuf. Technol. 2018, 95, 1101–1125. [Google Scholar] [CrossRef]

- Rodríguez, A.; Fernández, A.; López de Lacalle, L.N.; Sastoque Pinilla, L. Flexible abrasive tools for the deburring and finishing of holes in superalloys. J. Manuf. Mater. Process. 2018, 2, 82. [Google Scholar] [CrossRef]

- Falandys, K.; Kurc, K.; Burghardt, A.; Szybicki, D. Automation of the edge deburring process and analysis of the impact of selected parameters on forces and moments induced during the process. Appl. Sci. 2023, 13, 9646. [Google Scholar] [CrossRef]

- Liao, L.; Xi, F.F.; Liu, K. Modeling and control of automated polishing/deburring process using a dual-purpose compliant toolhead. Int. J. Mach. Tools Manuf. 2008, 48, 1454–1463. [Google Scholar] [CrossRef]

- Tellaeche, A.; Arana, R. Robust 3d object model reconstruction and matching for complex automated deburring operations. J. Imaging 2016, 2, 8. [Google Scholar] [CrossRef]

- Slavković, N.; Zivanovic, S.; Dimic, Z.; Kokotović, B. An advanced machining robot flexible programming methodology supported by verification in a virtual environment. Int. J. Comput. Integr. Manuf. 2024, 1–19. [Google Scholar] [CrossRef]

- Ting, C.C.; Huang, C.K.; Chiou, S.J.; Li, K.Y. The 3D Deburring Processing Trajectory Recognition Method and Its Application Base on Random Sample Consensus. Appl. Sci. 2022, 12, 4852. [Google Scholar] [CrossRef]

- Shen, S.; Ren, K.; Bao, Y.; Fu, M.; Li, Y. Machine vision—Based automatic planning for microdroplet coating trajectory on irregularly shaped regions of metal surfaces. J. Manuf. Process. 2023, 106, 117–129. [Google Scholar] [CrossRef]

- Xu, F.; Xu, Y.; Zhang, H.; Chen, S. Application of sensing technology in intelligent robotic arc welding: A review. J. Manuf. Process. 2022, 79, 854–880. [Google Scholar] [CrossRef]

- Nandagopal, A.; Beachy, J.; Acton, C.; Chen, X. A robotic surface inspection framework and machine—Learning based optimal segmentation for aerospace and precision manufacturing. J. Manuf. Process. 2025, 134, 146–157. [Google Scholar] [CrossRef]

- Wang, X.; Xie, Z.; Zhou, X.; Gao, J.; Li, F.; Gu, X. Adaptive path planning for the gantry welding robot system. J. Manuf. Process. 2022, 81, 386–395. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, X.; Xia, Z.; Gu, X. A survey of welding robot intelligent path optimization. J. Manuf. Process. 2021, 63, 14–23. [Google Scholar] [CrossRef]

- Liu, J.; Liu, S.; Song, M.; Ren, H.; Ji, H. Time-Optimal Robotic Arm Trajectory Planning for Coating Machinery Based on a Dynamic Adaptive PSO Algorithm. Coatings 2024, 15, 2. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, B.; Wu, F.; Han, T.; Zhang, L. An improved burr size prediction method based on the 1D-ResNet model and transfer learning. J. Manuf. Process. 2022, 84, 183–197. [Google Scholar] [CrossRef]

- Kuss, A.; Drust, M.; Verl, A. Detection of workpiece shape deviations for tool path adaptation in robotic deburring systems. Procedia CIRP 2016, 57, 545–550. [Google Scholar] [CrossRef]

- Peng, P.; Wu, C.; Yang, J.; Ding, H. Tool path correction for robotic deburring using local non-rigid 3D registration. Robot. Comput. Integr. Manuf. 2024, 89, 102745. [Google Scholar] [CrossRef]

- Xiong, R.; Lai, Z.; Guan, Y.; Yang, Y.; Cai, C. Local Deformable Template Matching in Robotic Deburring. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics (ROBIO), Kuala Lumpur, Malaysia, 12–15 December 2018. IEEE Conference Proceedings. [Google Scholar] [CrossRef]

- Lai, Z.; Xiong, R.; Wu, H.; Guan, Y. Integration of Visual Information and Robot Offline Programming System for Improving Automatic Deburring Process. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics (ROBIO), Kuala Lumpur, Malaysia, 12–15 December 2018. IEEE Conference Proceedings. [Google Scholar] [CrossRef]

- Besl, P.J.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Rusinkiewicz, S.; Levoy, M. Efficient variants of the ICP algorithm. In Proceedings of the Third International Conference on 3-D Digital Imaging and Modeling, Quebec City, QC, Canada, 28 May–1 June 2001. IEEE Conference Proceedings. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Rusu, R.B.; Blodow, N.; Beetz, M. Fast point feature histograms (FPFH) for 3D registration. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009. IEEE Conference Proceedings. [Google Scholar] [CrossRef]

- Altintas, Y.; Engin, S. Generalized Modeling of Mechanics and Dynamics of Milling Cutters. CIRP Ann. 2001, 50, 25–30. [Google Scholar] [CrossRef]

- Tsai, R.Y.; Lenz, R.K. A new technique for fully autonomous and efficient 3D robotics hand/eye calibration. IEEE Trans. Robot. Autom. 1989, 5, 345–358. [Google Scholar] [CrossRef]

| Cutting Depth (mm) | 2.0 | 4.0 | 6.0 | 8.0 | 10.0 |

| Max Feed Speed (mm/s) | 19.5 | 6.5 | 5.5 | 2.5 | 1.5 |

| Proposed Method | Rigid Registration | Non-Rigid Registration | |

| Point cloud RMSE (mm) | 0.49 | 2.08 | 0.06 |

| Trajectory RMSE (mm) | 0.79 | 1.55 | 1.05 |

| deburring time (s) | 169.4 | 525.5 | 527.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Sun, Z.; Luo, P. Adaptive Robotic Deburring of Molded Parts via 3D Vision and Tolerance-Constrained Non-Rigid Registration. J. Manuf. Mater. Process. 2025, 9, 294. https://doi.org/10.3390/jmmp9090294

Zhou Z, Sun Z, Luo P. Adaptive Robotic Deburring of Molded Parts via 3D Vision and Tolerance-Constrained Non-Rigid Registration. Journal of Manufacturing and Materials Processing. 2025; 9(9):294. https://doi.org/10.3390/jmmp9090294

Chicago/Turabian StyleZhou, Zuping, Zhilin Sun, and Pengfei Luo. 2025. "Adaptive Robotic Deburring of Molded Parts via 3D Vision and Tolerance-Constrained Non-Rigid Registration" Journal of Manufacturing and Materials Processing 9, no. 9: 294. https://doi.org/10.3390/jmmp9090294

APA StyleZhou, Z., Sun, Z., & Luo, P. (2025). Adaptive Robotic Deburring of Molded Parts via 3D Vision and Tolerance-Constrained Non-Rigid Registration. Journal of Manufacturing and Materials Processing, 9(9), 294. https://doi.org/10.3390/jmmp9090294