Effects of Ultrasonic Vibration Intensity and Initial Powder Amount in the Hopper on Powder Dispensing Rate in Binder Jetting Additive Manufacturing

Abstract

1. Introduction

2. Materials and Methods

2.1. Feedstock Powder

2.2. Design of Experiments

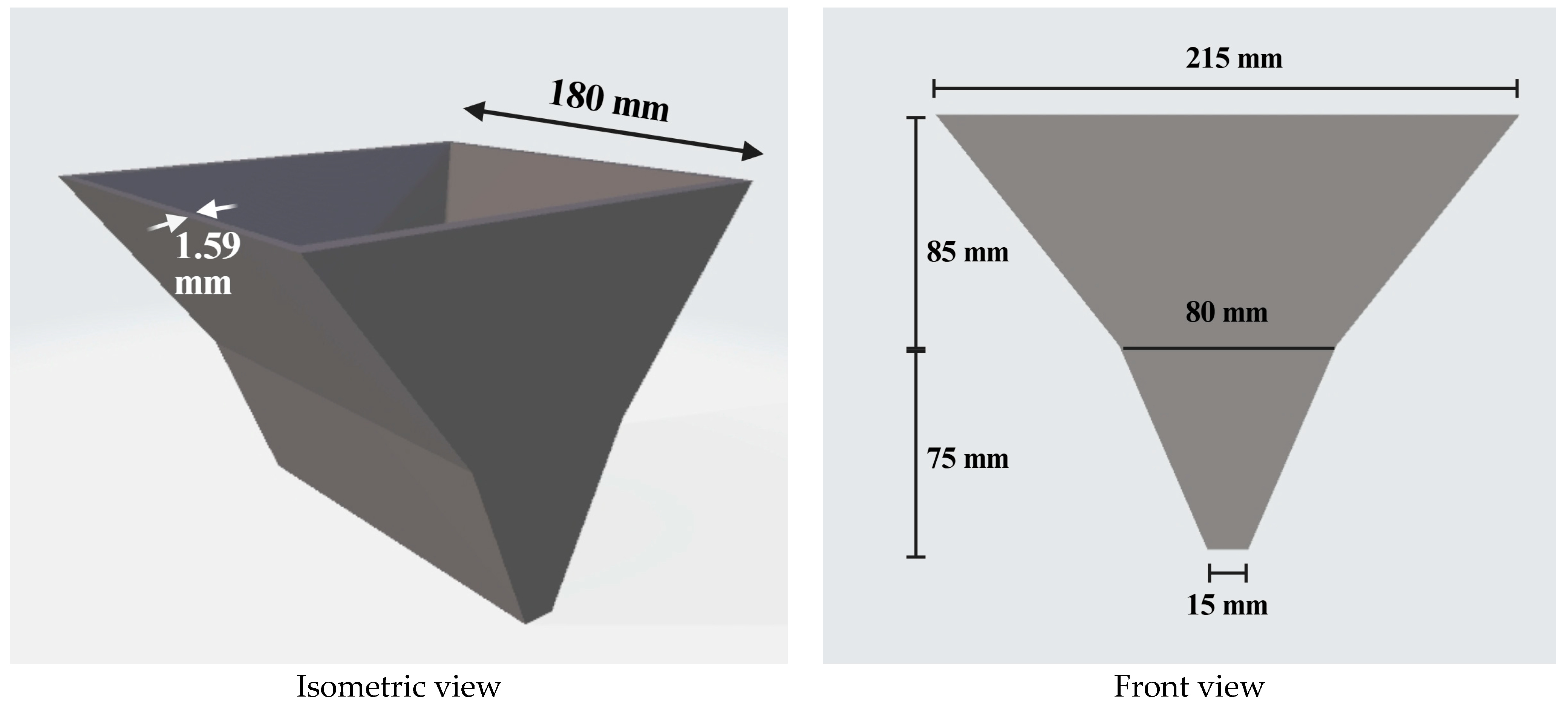

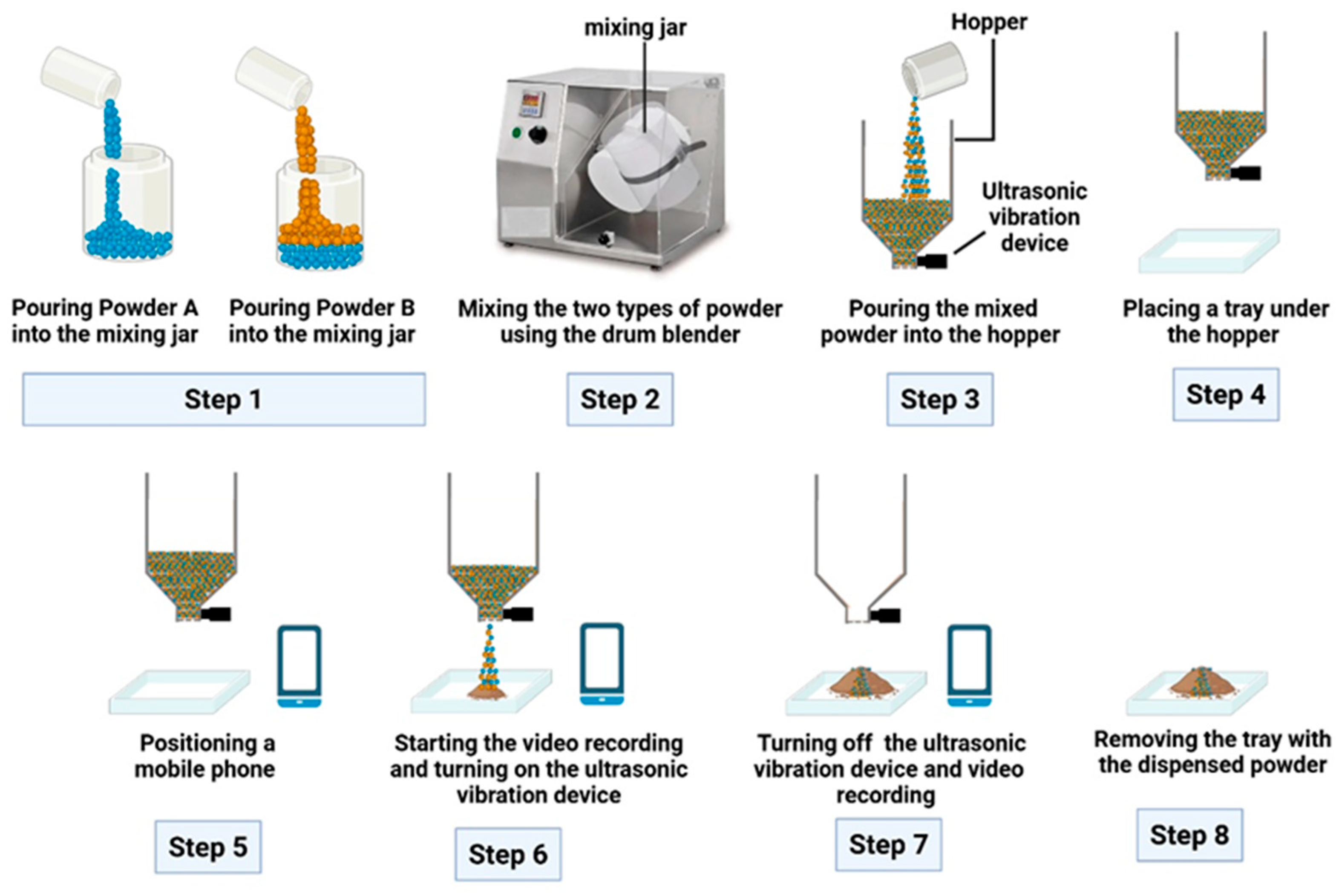

2.3. Experimental Procedure of Dispensing Feedstock Powder from the Hopper

2.4. Measurement of Dispensing Rate

3. Results and Discussion

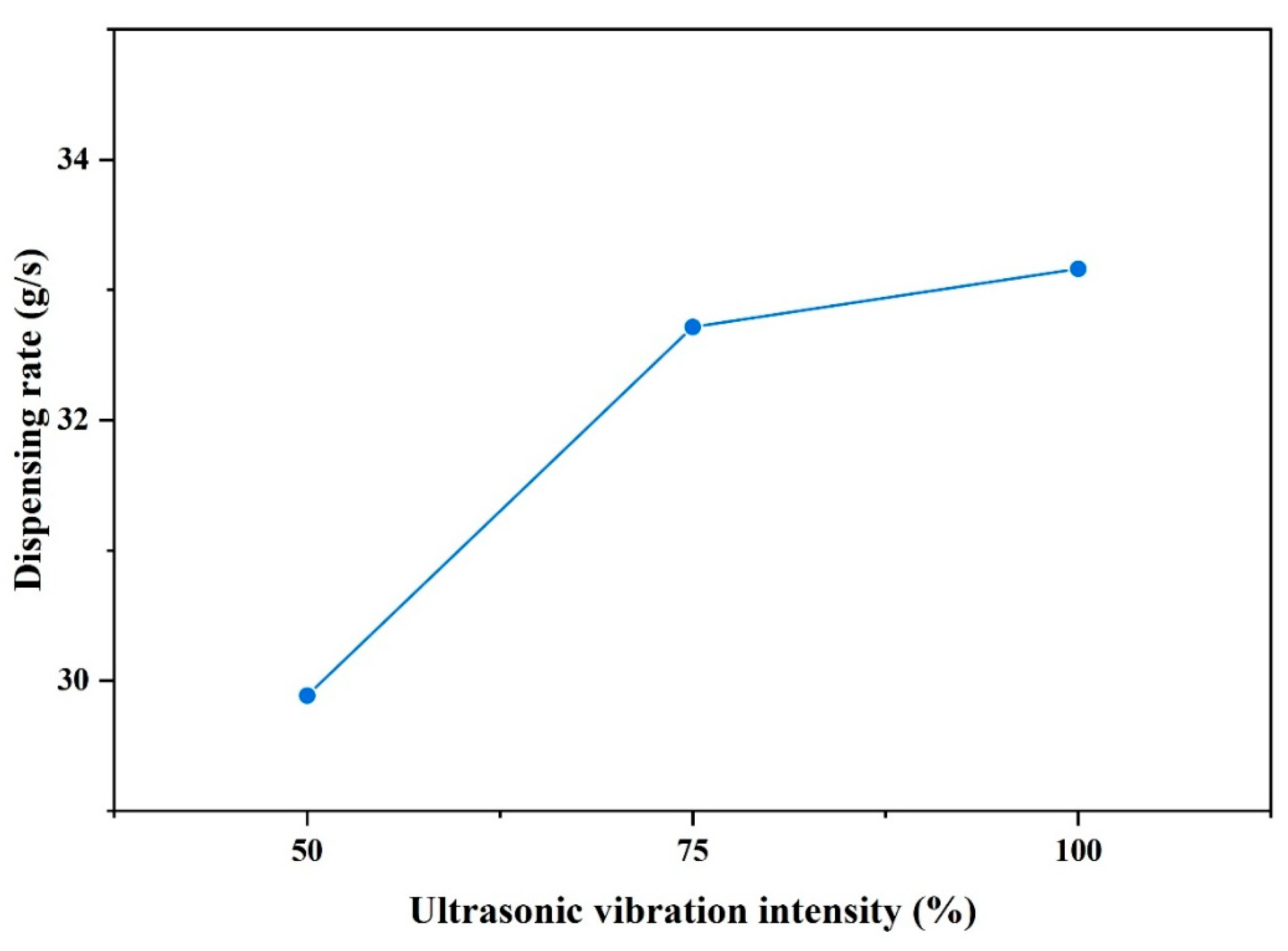

3.1. Main Effect of Ultrasonic Vibration Intensity

3.2. Main Effect of Initial Powder Amount

3.3. Interaction Effect of Ultrasonic Vibration Intensity and Initial Powder Amount

4. Conclusions

- Both ultrasonic vibration intensity and initial powder amount in the hopper had significant effects on powder dispensing rate at the significant level of 0.05.

- Powder dispensing rate was higher when ultrasonic vibration intensity was higher, or initial powder amount was smaller.

- The interaction effect of ultrasonic vibration intensity and initial powder amount was statistically significant at the significant level of 0.05.

- Increasing initial powder amount from 600 to 1400 g resulted in a much bigger decrease in powder dispensing rate when ultrasonic vibration intensity was 50% than when ultrasonic vibration intensity was 100%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khan, F.; Arman, M.S.; Sanders, J.; Pasha, M.M.; Rahman, A.M.; Pei, Z.; Dong, T. Binder Jetting 3D Printing Utilizing Waste Algae Powder: A Feasibility Study. Intell. Sustain. Manuf. 2024, 1, 10016. [Google Scholar] [CrossRef]

- Khan, F.; Sanders, J.; Arman, M.S.; Pasha, M.M.; Kachur, S.; Pei, Z. Fabrication of SiC–Aluminum Composites via Binder Jetting 3D Printing and Infiltration: A Feasibility Study. J. Compos. Sci. 2025, 9, 111. [Google Scholar] [CrossRef]

- Lores, A.; Azurmendi, N.; Agote, I.; Zuza, E. A review on recent developments in binder jetting metal additive manufacturing: Materials and process characteristics. Powder Metall. 2019, 62, 267–296. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Du, W.; Singh, M.; Singh, D. Binder jetting additive manufacturing of silicon carbide ceramics: Development of bimodal powder feedstocks by modeling and experimental methods. Ceram. Int. 2020, 46, 19701–19707. [Google Scholar] [CrossRef]

- Pasha, M.M.; Arman, M.S.; Khan, F.; Pei, Z.; Kachur, S. Effects of Layer Thickness and Compaction Thickness on Green Part Density in Binder Jetting Additive Manufacturing of Silicon Carbide: Designed Experiments. J. Manuf. Mater. Process. 2024, 8, 148. [Google Scholar] [CrossRef]

- Mostafaei, A.; De Vecchis, P.R.; Kimes, K.A.; Elhassid, D.; Chmielus, M. Effect of binder saturation and drying time on microstructure and resulting properties of sinter-HIP binder-jet 3D-printed WC-Co composites. Addit. Manuf. 2021, 46, 102128. [Google Scholar] [CrossRef]

- Pasha, M.M.; Arman, M.S.; Pei, Z.; Khan, F.; Sanders, J.; Kachur, S. Effects of Compaction Thickness on Density, Integrity, and Microstructure of Green Parts in Binder Jetting Additive Manufacturing of Silicon Carbide. J. Manuf. Mater. Process. 2025, 9, 136. [Google Scholar] [CrossRef]

- Wei, X.; Moghadasi, M.; Du, W.; Ma, C.; Pei, Z. Experimental investigation on ultrasonic hopper dispensing system in powder bed additive manufacturing. J. Manuf. Process. 2021, 71, 106–112. [Google Scholar] [CrossRef]

- Dunst, P.; Bornmann, P.; Hemsel, T.; Sextro, W. Vibration-assisted handling of dry fine powders. Actuators 2018, 7, 18. [Google Scholar] [CrossRef]

- Kollmann, T.; Tomas, J. Effect of applied vibration on silo hopper design. Part. Sci. Technol. 2002, 20, 15–31. [Google Scholar] [CrossRef]

- Roberts, A. Vibration of fine powders and its application. In Handbook of Powder Science & Technology; Springer: Singapore, 1997; pp. 146–201. [Google Scholar]

- Miyanaji, H.; Rahman, K.M.; Da, M.; Williams, C.B. Effect of fine powder particles on quality of binder jetting parts. Addit. Manuf. 2020, 36, 101587. [Google Scholar] [CrossRef]

- Myers, K.; Paterson, A.; Iizuka, T.; Klein, A. The Effect of Print Speed on Surface Roughness and Density Uniformity of Parts Produced Using Binder Jet 3D Printing; University of Texas at Austin: Austin, TX, USA, 2019. [Google Scholar] [CrossRef]

- Shrestha, S.; Manogharan, G. Optimization of binder jetting using Taguchi method. Jom 2017, 69, 491–497. [Google Scholar] [CrossRef]

- Pasha, M.M.; Pei, Z.; Arman, M.S.; Gasdaska, C.J.; Kao, Y.-T. Effects of Mixing Speed and Mixing Time on Powder Segregation During Powder Mixing for Binder Jetting Additive Manufacturing: An Experimental Study. J. Manuf. Mater. Process. 2025, 9, 117. [Google Scholar] [CrossRef]

- Rahman, T.T.; Arman, M.S.; Perez, V.; Xu, B.; Li, J. Analysis of the operating conditions of pulse electric field–assisted EHD for sodium alginate printing using design of experiment approach. Int. J. Adv. Manuf. Technol. 2021, 115, 2037–2047. [Google Scholar] [CrossRef]

| Powder A | Powder B | |

|---|---|---|

| Material type | Metal | Ceramic |

| Average particle size (µm) | 118 | 230 |

| Particle shape | Irregular | Diamond |

| True density (g/cm3) | 7.93 | 3.86 |

| Variable | Level 1 (−1) | Level 2 (0) | Level 3 (+1) |

|---|---|---|---|

| Ultrasonic vibration intensity (%) | 50 | 75 | 100 |

| Initial powder amount (g) | 600 | 1000 | 1400 |

| Experiment Order | Run Order | Ultrasonic Vibration Intensity | Initial Feedstock Powder | Dispensing Rate (g/s) |

|---|---|---|---|---|

| 1 | 24 | −1 | −1 | 31.6 |

| 2 | 10 | −1 | 0 | 31.3 |

| 3 | 3 | −1 | 1 | 25.9 |

| 4 | 22 | 0 | −1 | 33.3 |

| 5 | 11 | 0 | 0 | 31.3 |

| 6 | 16 | 0 | 1 | 31.8 |

| 7 | 26 | 1 | −1 | 35.3 |

| 8 | 13 | 1 | 0 | 33.3 |

| 9 | 7 | 1 | 1 | 31.8 |

| 10 | 1 | −1 | −1 | 35.3 |

| 11 | 6 | −1 | 0 | 30.3 |

| 12 | 25 | −1 | 1 | 25.5 |

| 13 | 4 | 0 | −1 | 35.3 |

| 14 | 5 | 0 | 0 | 32.3 |

| 15 | 21 | 0 | 1 | 31.8 |

| 16 | 12 | 1 | −1 | 37.5 |

| 17 | 20 | 1 | 0 | 32.3 |

| 18 | 2 | 1 | 1 | 32.6 |

| 19 | 27 | −1 | −1 | 33.3 |

| 20 | 23 | −1 | 0 | 29.4 |

| 21 | 8 | −1 | 1 | 26.4 |

| 22 | 19 | 0 | −1 | 35.3 |

| 23 | 15 | 0 | 0 | 32.3 |

| 24 | 9 | 0 | 1 | 31.1 |

| 25 | 17 | 1 | −1 | 33.3 |

| 26 | 14 | 1 | 0 | 31.3 |

| 27 | 18 | 1 | 1 | 31.1 |

| Source of Variance | DF | Sum of Squares | Mean Square | F Value | p-Value |

|---|---|---|---|---|---|

| Ultrasonic vibration intensity | 2 | 56.83 | 28.41 | 20.84 | <0.0001 |

| Initial powder amount | 2 | 101.35 | 50.67 | 37.16 | <0.0001 |

| Interaction | 4 | 22.43 | 5.60 | 4.11 | 0.0154 |

| Model | 8 | 180.61 | 22.57 | 16.55 | <0.0001 |

| Error | 18 | 24.54 | 1.36 |

| Pair-Comparison (Ultrasonic Vibration Intensity) | p-Value |

|---|---|

| 75% vs. 50% | 0.0002 |

| 100% vs. 50% | <0.0001 |

| 100% vs. 75% | 0.7008 |

| Pair-Comparison (Initial Powder Amount) | p-Value |

|---|---|

| 1000 g vs. 600 g | 0.0001 |

| 1400 g vs. 600 g | <0.0001 |

| 1400 g vs. 1000 g | 0.0149 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasha, M.M.; Pei, Z.; Kao, Y.-T.; Dubovick, K. Effects of Ultrasonic Vibration Intensity and Initial Powder Amount in the Hopper on Powder Dispensing Rate in Binder Jetting Additive Manufacturing. J. Manuf. Mater. Process. 2025, 9, 268. https://doi.org/10.3390/jmmp9080268

Pasha MM, Pei Z, Kao Y-T, Dubovick K. Effects of Ultrasonic Vibration Intensity and Initial Powder Amount in the Hopper on Powder Dispensing Rate in Binder Jetting Additive Manufacturing. Journal of Manufacturing and Materials Processing. 2025; 9(8):268. https://doi.org/10.3390/jmmp9080268

Chicago/Turabian StylePasha, Mostafa Meraj, Zhijian Pei, Yi-Tang Kao, and Ken Dubovick. 2025. "Effects of Ultrasonic Vibration Intensity and Initial Powder Amount in the Hopper on Powder Dispensing Rate in Binder Jetting Additive Manufacturing" Journal of Manufacturing and Materials Processing 9, no. 8: 268. https://doi.org/10.3390/jmmp9080268

APA StylePasha, M. M., Pei, Z., Kao, Y.-T., & Dubovick, K. (2025). Effects of Ultrasonic Vibration Intensity and Initial Powder Amount in the Hopper on Powder Dispensing Rate in Binder Jetting Additive Manufacturing. Journal of Manufacturing and Materials Processing, 9(8), 268. https://doi.org/10.3390/jmmp9080268