Influence of Structural Components on Thermal Deformations in Large Machine Tools

Abstract

1. Introduction

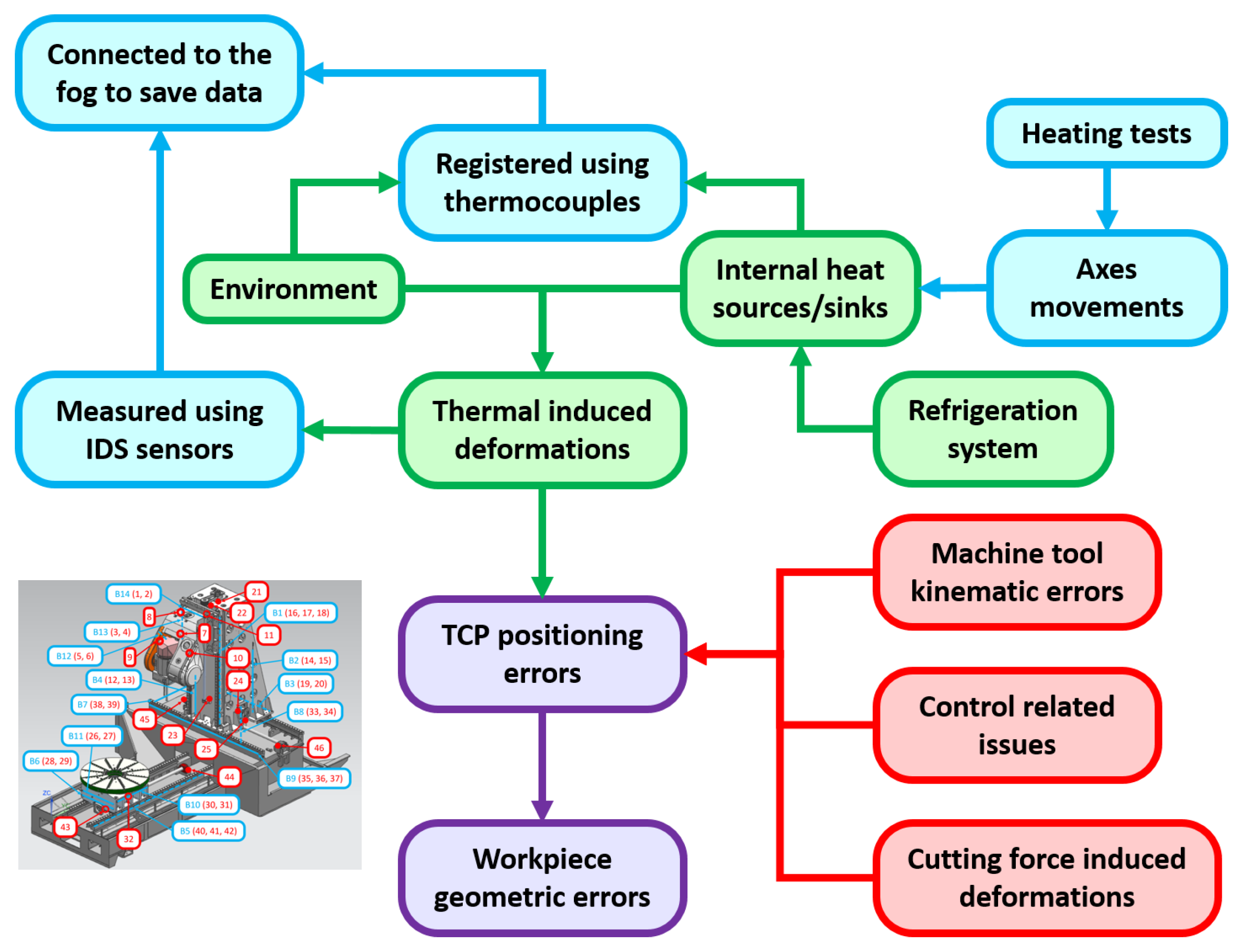

2. Materials and Methods

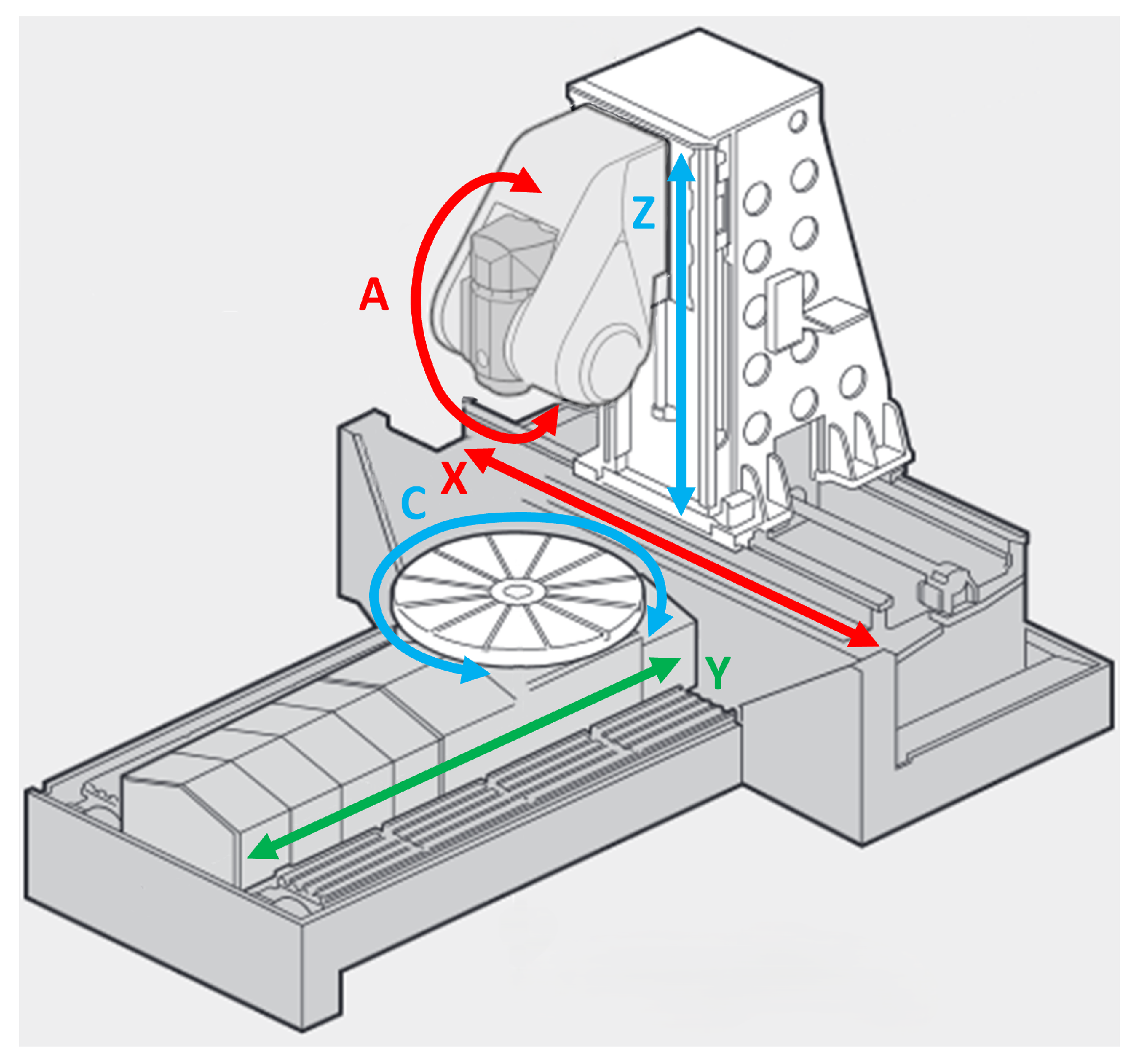

2.1. Machine

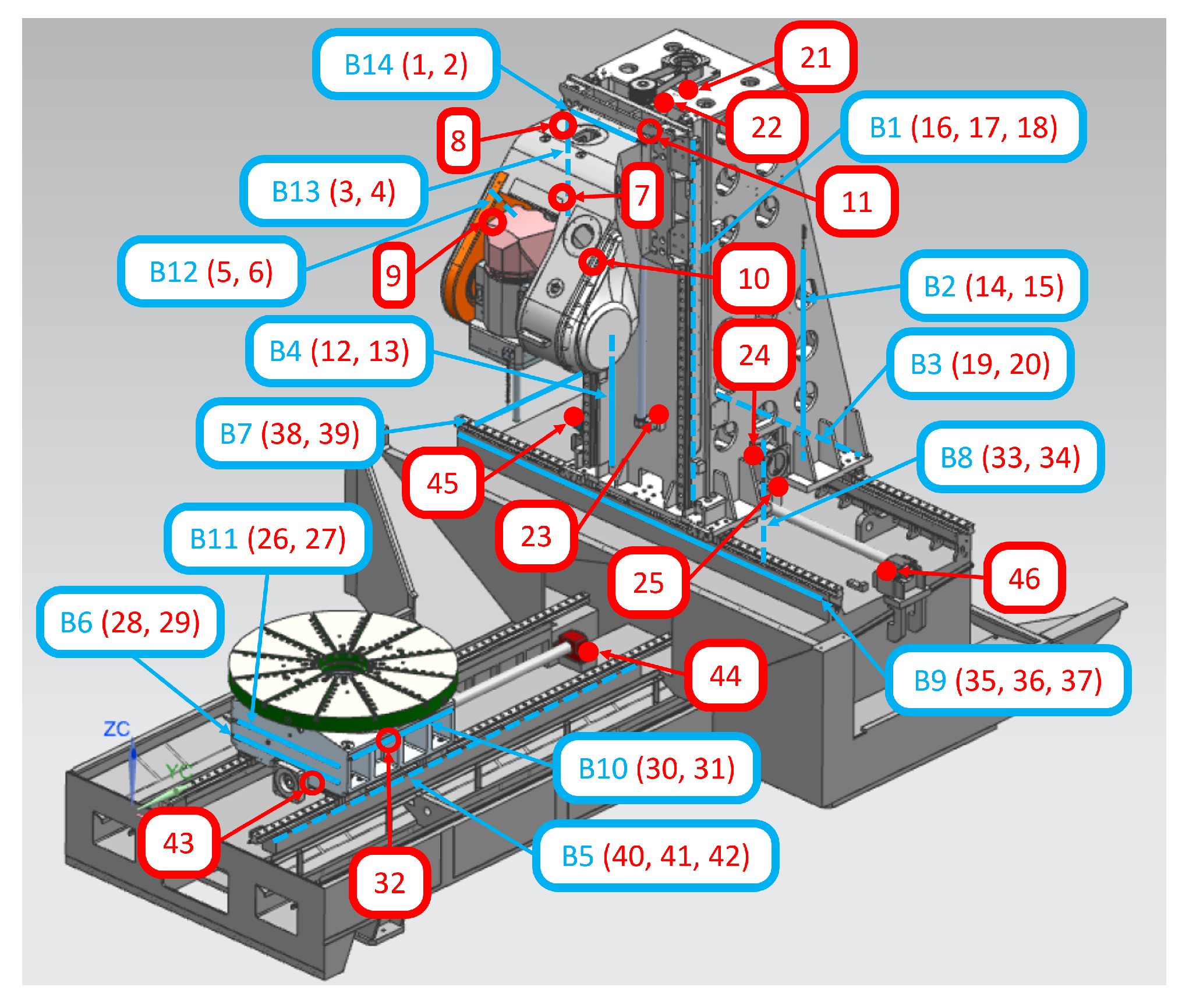

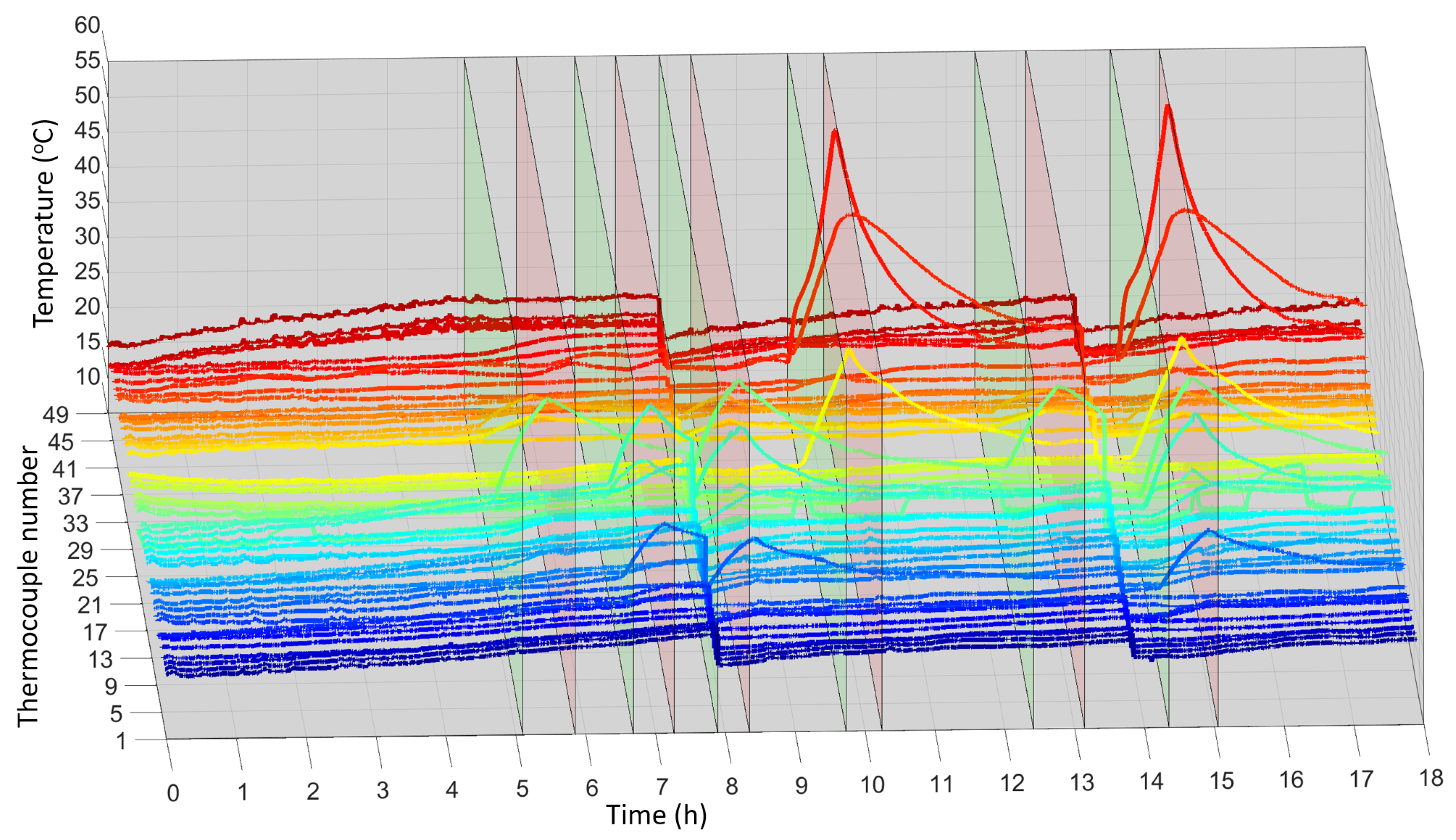

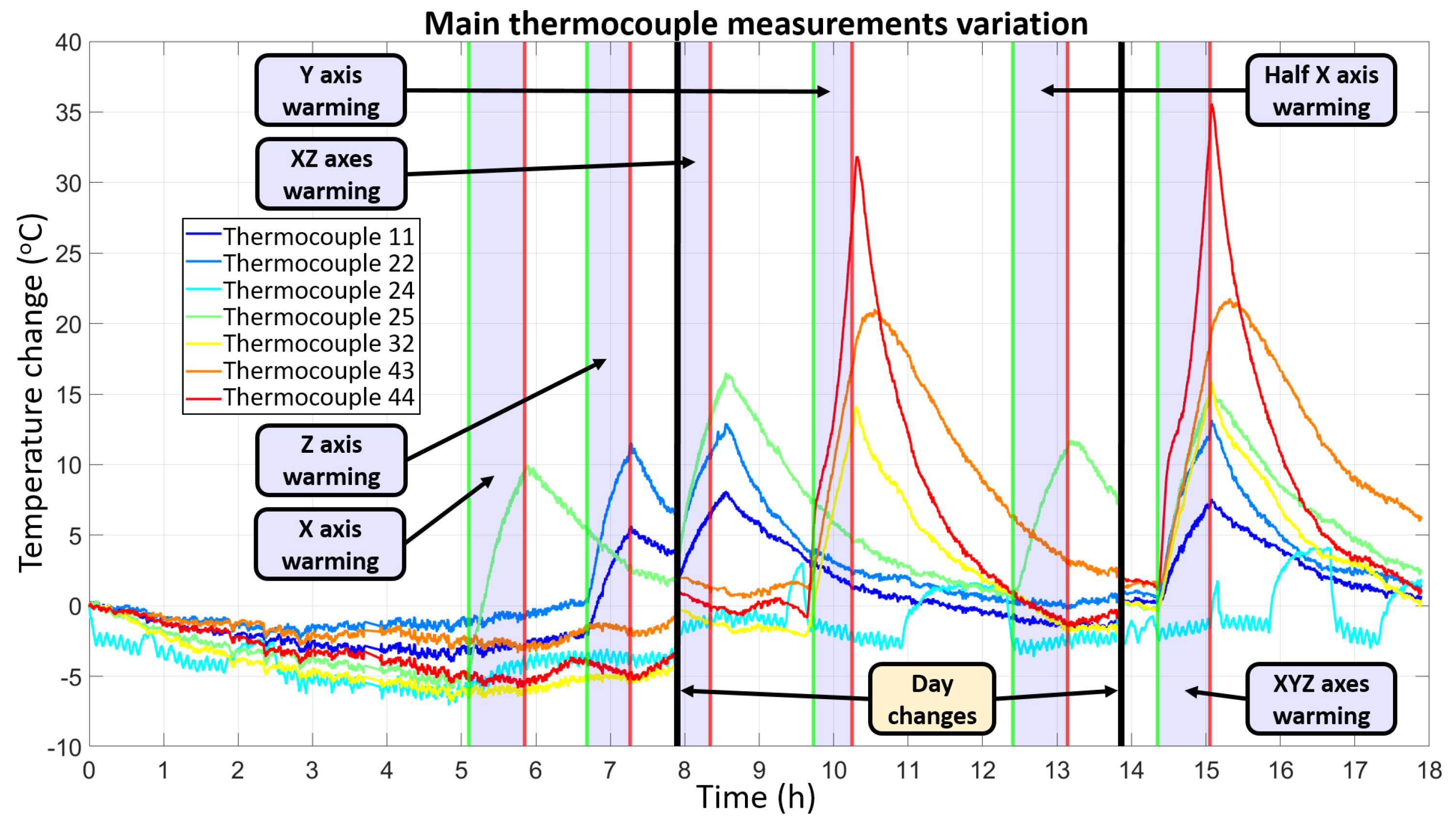

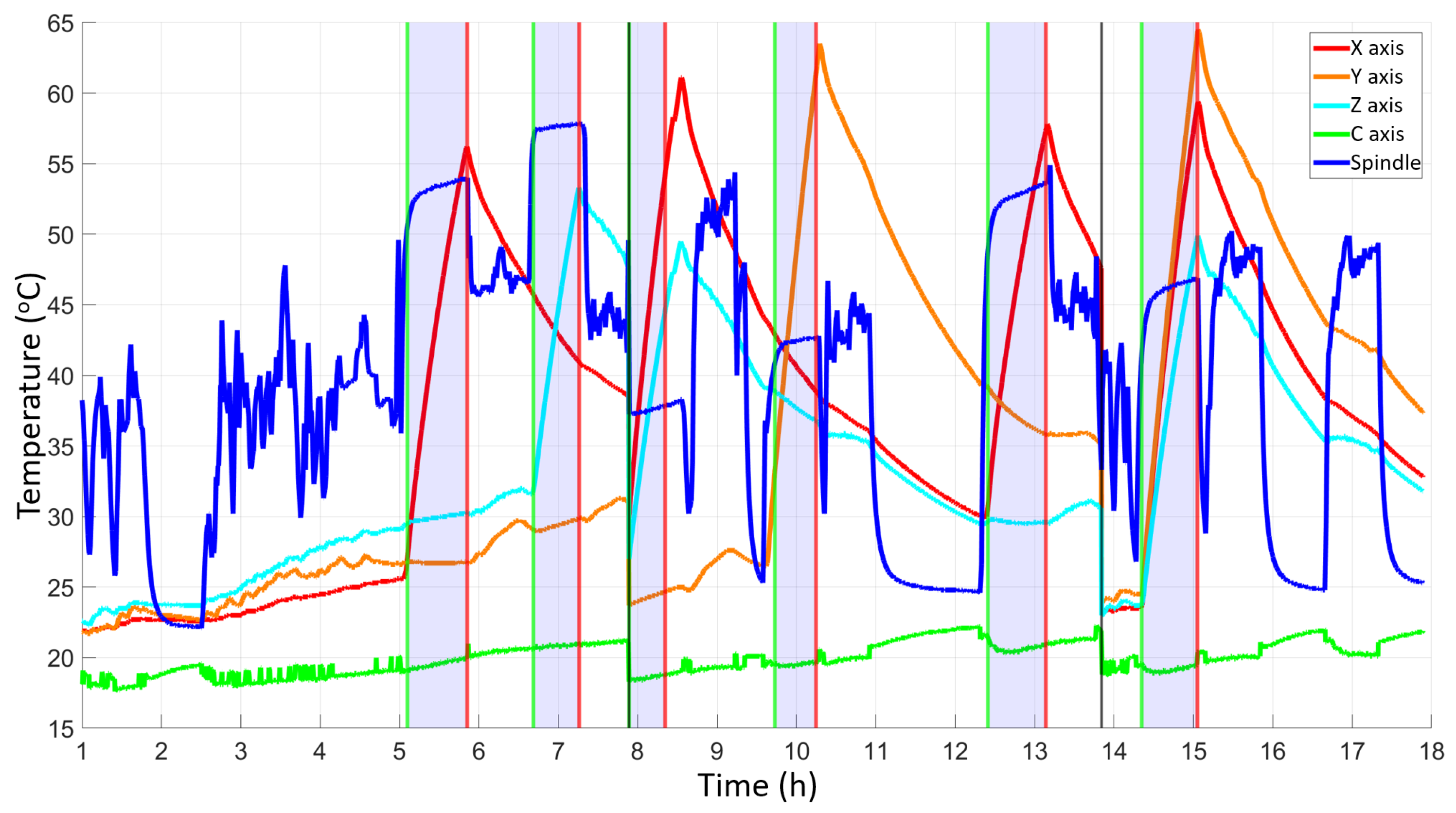

2.2. Installed Sensors

2.3. Data Acquisition System

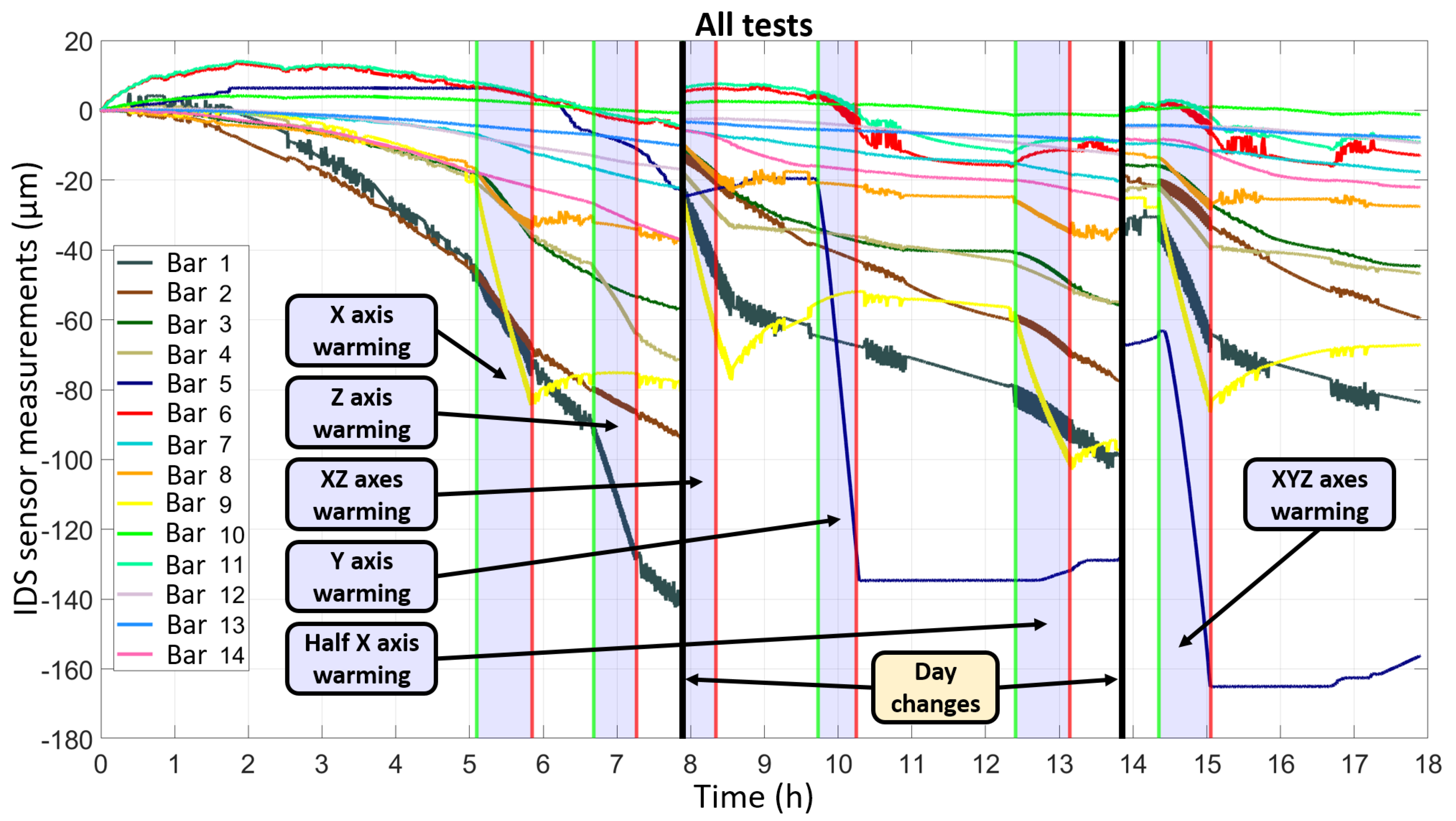

2.4. Conducted Experimental Tests

3. Results and Discussion

3.1. Structural Elements Deformations

3.2. Heating of Axis Drives

3.3. Deformations Due to Cooling System

- Modifying cooling system operation: Implementing continuous control instead of cyclic on–off operation would prevent these deformations, thereby stabilising temperatures.

- Preventing contact between cooling pipes and the structure: This is not always feasible due to movements of the structural components.

- Using the cooling system to maintain more components at stable temperatures: The additional introduced deformations would be outweighed by the elimination of heating effects.

4. Study Limitations and Further Research

- Ambient conditions were not controlled and test times were limited to short periods of time, making difficult to obtain valuable results in terms of ambient temperature effect. However, the goal of the research was to identify the effect of each axis movement on the deformation of different machine structural components, which could be successfully accomplished.

- The performed tests were limited to some internal heating conditions that can help to understand the deformation of each component; however, compensation model development would require more testing, and this research was mainly focused on improving design decisions.

- Certain heat sources and sinks were not studied in detail, such as movements of the rotary axes and main spindle, heat induced by machining operations, and the use of cutting fluid.

- Including a deeper analysis of the effect of rotary axes (A and C) and the main spindle

- Studying the effect of ambient temperature changes without internal heat generation and using a much longer test time (i.e., a whole year), as these changes were seen to have significant impact on machine deformations

- Using the results of this work to refine the design of large-scale machine tools, mainly focusing on the improvement of refrigeration systems

- Studying the effect of long-term wear or material property changes on thermal behaviour as well as the effect of other deformation sources (dynamic effects, cutting forces, etc.) on positioning errors

5. Conclusions

- Ambient temperature variations are the primary source of thermal deformations in large-scale machine tools. About 60 % of deformation in the performed tests was due to ambient temperature changes, where ambient temperature varied 8.7 °C, significantly less than the 35 °C due to internal heat sources.

- The thermal effects of axis drives on machine structure are localised, but lead to significant deformations up to about 100 m, predominately in the Y and Z directions.

- The axis drives primarily generate heat in the ball screw bearings and nuts rather than in the guides or other components. In the performed tests, these components reached temperature increases of 15 to 35 °C.

- The greatest thermal deformations occurred in the machine bed and column, reaching over 100 m in the X direction and 170 m in the Y direction for the bed and nearly 150 m in the Z direction for the column.

- The direct influence of heating by the refrigerated motors (particularly milling or turning spindles) on structural component deformation was minimal. The sensors closest to the spindles showed temperature increases under 1 °C, and the most affected IDS bars detected deformations well under 5 m.

- Proper cooling significantly improves machine performance.

- Cooling the ball screw bearings and axis drive motors could substantially enhance thermal performance.

- The results of this research can be easily applied in industrial contexts thanks to our close collaboration with machine tool manufacturers during the course of this research.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaulagi, M.N.; Sonawane, H.A. Thermal network-based compensation model for a vertical machining center subjected to ambient temperature fluctuations. Int. J. Adv. Manuf. Technol. 2023, 124, 3973–3994. [Google Scholar] [CrossRef]

- Mayr, J.; Jedrzejewski, J.; Uhlmann, E.; Donmez, M.A.; Knapp, W.; Härtig, F.; Wendt, K.; Moriwaki, T.; Shore, P.; Schmitt, R.; et al. Thermal issues in machine tools. Cirp Ann. 2012, 61, 771–791. [Google Scholar] [CrossRef]

- Li, Y.; Yu, M.; Bai, Y.; Hou, Z.; Wu, W. A review of thermal error modeling methods for machine tools. Appl. Sci. 2021, 11, 5216. [Google Scholar] [CrossRef]

- Li, Q.; Li, H. A general method for thermal error measurement and modeling in CNC machine tools’ spindle. Int. J. Adv. Manuf. Technol. 2019, 103, 2739–2749. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Wang, S. Data-driven thermally-induced error compensation method of high-speed and precision five-axis machine tools. Mech. Syst. Signal Process. 2020, 138, 106538. [Google Scholar] [CrossRef]

- Yin, Q.; Tan, F.; Chen, H.; Yin, G. Spindle thermal error modeling based on selective ensemble BP neural networks. Int. J. Adv. Manuf. Technol. 2019, 101, 1699–1713. [Google Scholar] [CrossRef]

- Yau, H.T.; Kuo, P.H.; Chen, S.C.; Lai, P.Y. Transfer-Learning-Based Long Short-Term Memory Model for Machine Tool Spindle Thermal Displacement Compensation. IEEE Sens. J. 2023, 24, 132–143. [Google Scholar] [CrossRef]

- Iñigo, B.; Colinas-Armijo, N.; López de Lacalle, L.N.; Aguirre, G. Digital twin for volumetric thermal error compensation of large machine tools. Sensors 2024, 24, 6196. [Google Scholar] [CrossRef]

- Sáinz de la Maza García, A.; Sastoque Pinila, L.; López de Lacalle Marcaide, L.N. Thermally induced volumetric error modelling on large-scale machining centre. In Proceedings of the 4th International Conference on Thermal Issues in Machine Tools (ICTIMT2025), Zurich, Switzerland, 17–19 June 2025; Lecture Notes in Production Engineering . Springer: Cham, Switzerland, 2025. in press. [Google Scholar]

- Sáinz de la Maza García, A.; Sastoque Pinilla, L.; Amigo Fuertes, F.J.; Villarrazo Rubia, N.; Iñigo, B.; López de Lacalle Marcaide, L.N. Measuring thermally induced volumetric error of large-scale machining centre. In Proceedings of the XI Manufacturing Engineering Society International Conference (MESIC 2025), Bilbao, Spain, 18–20 June 2025. [Google Scholar]

- Ess, M. Simulation and Compensation of Thermal Errors of Machine Tools. Ph.D. Dissertation, ETH Zürich, Zürich, Switzerland, 2012. [Google Scholar]

- Ye, W.H.; Guo, Y.X.; Zhou, H.F.; Liang, R.J.; Chen, W.F. Thermal error regression modeling of the real-time deformation coefficient of the moving shaft of a gantry milling machine. Adv. Manuf. 2020, 8, 119–132. [Google Scholar] [CrossRef]

- Weng, L.; Gao, W.; Zhang, D.; Huang, T.; Liu, T.; Li, W.; Zheng, Y.; Shi, K.; Chang, W. Analytical modelling method for thermal balancing design of machine tool structural components. Int. J. Mach. Tools Manuf. 2021, 164, 103715. [Google Scholar] [CrossRef]

- Chu, W.L. Integrating machine learning and feature analysis for predicting and managing thermal deformation in machine tools. Case Stud. Therm. Eng. 2024, 57, 104343. [Google Scholar] [CrossRef]

- Winiarski, Z.; Jedrzejewski, J.; Kwaśny, W.; Ha, H. Reduction of precise machining centre column thermal deformations caused by changes in ambient temperature by means of liquid cooling. J. Manuf. Processes 2024, 110, 192–201. [Google Scholar] [CrossRef]

- Liu, P.; Yao, X.; Ge, G.; Du, Z.; Feng, X.; Yang, J. A Dynamic Linearization Modeling of Thermally Induced Error Based on Data-Driven Control for CNC Machine Tools. Int. J. Precis. Eng. Manuf. 2021, 22, 241–258. [Google Scholar] [CrossRef]

- Zheng, Y.; Fu, G.; Mu, S.; Lu, C.; Wang, X.; Wang, T. Thermal Error Transfer Prediction Modeling of Machine Tool Spindle with Self-Attention Mechanism-Based Feature Fusion. Machines 2024, 12, 728. [Google Scholar] [CrossRef]

- Chen, P.H.; Chang, P.Z.; Hu, Y.C.; Luo, T.L.; Tsai, C.Y.; Li, W.C. On the robustness and generalization of thermal error models for CNC machine tools. Int. J. Adv. Manuf. Technol. 2024, 130, 1635–1651. [Google Scholar] [CrossRef]

- Abdulshahed, A.M.; Longstaff, A.P.; Fletcher, S.; Myers, A. Thermal error modelling of machine tools based on ANFIS with fuzzy c-means clustering using a thermal imaging camera. Appl. Math. Model. 2015, 39, 1837–1852. [Google Scholar] [CrossRef]

- Chiang, M.; Zhang, T. Fog and IoT: An overview of research opportunities. IEEE Internet Things J. 2016, 3, 854–864. [Google Scholar] [CrossRef]

- Brecher, C.; Klatte, M.; Lee, T.H.; Tzanetos, F. Metrological analysis of a mechatronic system based on novel deformation sensors for thermal issues in machine tools. Procedia CIRP 2018, 77, 517–520. [Google Scholar] [CrossRef]

- Baum, C.; Brecher, C.; Klatte, M.; Lee, T.H.; Tzanetos, F. Thermally induced volumetric error compensation by means of integral deformation sensors. Procedia CIRP 2018, 72, 1148–1153. [Google Scholar] [CrossRef]

- Naumann, C.; Naumann, A.; Bertaggia, N.; Geist, A.; Glänzel, J.; Herzog, R.; Zontar, D.; Brecher, C.; Dix, M. Hybrid thermal error compensation combining integrated deformation sensor and regression analysis based models for complex machine tool designs. In International Conference on Thermal Issues in Machine Tools; Lecture Notes in Production Engineering; Springer: Cham, Switzerland, 2023; pp. 28–40. [Google Scholar] [CrossRef]

- Tapia, E.; Lopez-Novoa, U.; Sastoque-Pinilla, L.; López-de-Lacalle, L.N. Implementation of a scalable platform for real-time monitoring of machine tools. Comput. Ind. 2024, 155, 104065. [Google Scholar] [CrossRef]

- Gebhardt, M.; Wegener, K. Temperatureinfluss auf Werkzeugmaschinen. Maschinenbau 2013, 42, 59–63. [Google Scholar] [CrossRef]

- Shabi, L.; Weber, J.; Weber, J. Investigation of the Potential of Different Cooling System Structures for Machine Tools. In Fluid Power Networks: Proceedings: 19th–21th March 2018: 11th International Fluid Power Conference; Aachen, Germany, 19–21 March 2018, RWTH Aachen University: Aachen, Germany, 2018; Volume 1, pp. 82–95. [Google Scholar] [CrossRef]

- Liu, T.; Gao, W.; Tian, Y.; Zhang, H.; Chang, W.; Mao, K.; Zhang, D. A differentiated multi-loops bath recirculation system for precision machine tools. Appl. Therm. Eng. 2015, 76, 54–63. [Google Scholar] [CrossRef]

- Gao, W.; Ibaraki, S.; Donmez, M.A.; Kono, D.; Mayer, J.R.R.; Chen, Y.L.; Szipka, K.; Archenti, A.; Linares, J.M.; Suzuki, N. Machine tool calibration: Measurement, modeling, and compensation of machine tool errors. Int. J. Mach. Tools Manuf. 2023, 187, 104017. [Google Scholar] [CrossRef]

- Zhang, J.F.; Feng, P.F.; Wu, Z.J.; Yu, D.W.; Chen, C. Thermal structure design and analysis of a machine tool headstock. Mechanika 2013, 19, 478–485. [Google Scholar] [CrossRef]

- Sun, J.; Liu, Z.; Qiu, C.; Luo, J.; He, L.; Liu, H.; Sa, G.; Jiang, Z.; Tan, J. Machining accuracy prediction and adaptive compensation method of CNC machine tool under absence of machining process sensing. J. Intell. Manuf. 2025, 36, 3923–3940. [Google Scholar] [CrossRef]

- Mareš, M.; Horejš, O.; Fiala, Š.; Havlik, L.; Stříteský, P. Effects of cooling systems on the thermal behaviour of machine tools and thermal error models. J. Mach. Eng. 2020, 20, 5–27. [Google Scholar] [CrossRef]

- Mayr, J.; Gebhardt, M.; Massow, B.B.; Weikert, S.; Wegener, K. Cutting fluid influence on thermal behavior of 5-axis machine tools. Procedia CIRP 2014, 14, 395–400. [Google Scholar] [CrossRef]

| Heat Test | Linear Speed (m/min) | Rotation Speed (rpm) | Range | ||||

|---|---|---|---|---|---|---|---|

| X | Y | Z | A | C | Spindle | ||

| X axis | 30 | 0 | 0 | 0 | 0 | 0 | Full |

| Y axis | 0 | 25 | 0 | 0 | 0 | 0 | Full |

| Z axis | 0 | 0 | 30 | 0 | 0 | 0 | Full |

| XZ axes | 30 | 0 | 30 | 0 | 0 | 0 | Full |

| XYZ axes | 30 | 25 | 30 | 0 | 0 | 0 | Full |

| Half X axis | 30 | 0 | 0 | 0 | 0 | 0 | Last half |

| Day | Starting Time | Ending Time | Duration |

|---|---|---|---|

| 6 November 2024 | 7:59 | 15:52 | 7:53 |

| 7 November 2024 | 7:54 | 13:52 | 5:58 |

| 8 November 2024 | 7:46 | 11:49 | 4:03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sáinz de la Maza García, Á.; Sastoque Pinilla, L.; López de Lacalle Marcaide, L.N. Influence of Structural Components on Thermal Deformations in Large Machine Tools. J. Manuf. Mater. Process. 2025, 9, 267. https://doi.org/10.3390/jmmp9080267

Sáinz de la Maza García Á, Sastoque Pinilla L, López de Lacalle Marcaide LN. Influence of Structural Components on Thermal Deformations in Large Machine Tools. Journal of Manufacturing and Materials Processing. 2025; 9(8):267. https://doi.org/10.3390/jmmp9080267

Chicago/Turabian StyleSáinz de la Maza García, Álvaro, Leonardo Sastoque Pinilla, and Luis Norberto López de Lacalle Marcaide. 2025. "Influence of Structural Components on Thermal Deformations in Large Machine Tools" Journal of Manufacturing and Materials Processing 9, no. 8: 267. https://doi.org/10.3390/jmmp9080267

APA StyleSáinz de la Maza García, Á., Sastoque Pinilla, L., & López de Lacalle Marcaide, L. N. (2025). Influence of Structural Components on Thermal Deformations in Large Machine Tools. Journal of Manufacturing and Materials Processing, 9(8), 267. https://doi.org/10.3390/jmmp9080267