1. Introduction

The global production of metal sheet parts is impressive in its extent and serves all economic sectors, including the aerospace industry, construction machinery, agriculture, means of transportation, medical apparatuses, etc. The digital era, started by Industry 4.0 in all manufacturing processes, brings new challenges in terms of dimensional accuracy and product quality, productivity, and the environment [

1]. An important category of industrial applications is related to the processing of metal sheets coated with different protective layers, through which different parts are obtained, such as those manufactured by plastic deformation (deep drawing, bending, embossing, etc.). A modern procedure for manufacturing metal sheet parts that is economically effective, highly accurate and environmentally friendly is electromagnetic forming (EMF). The main difference between EMF and conventional forming methods is the contact-free application of force [

2]. The lack of contact between a moving tool and a workpiece gives EMF a major advantage for manufacturing net shape parts that do not require subsequent finishing or coating operations. Beckschwarte et al. [

3] emphasized the advantage of contact-free application of the forming force in their paper, in which the embossing of optical and functional microstructures was carried out, and the application of EMF in the replication of structures with retroreflective and tribological properties was demonstrated.

Coating metal surfaces with thin layers of all kinds (paint, deposited metal layers, sputtered thin films, etc.) is performed for decorative purposes, for providing corrosion protection, or for improving surface properties. The required properties of coating materials include mechanical (scratch resistance, toughness, and flexibility), chemical (resistance to substances) and thermal (stability at high temperatures) properties. Coatings can be applied to metal surfaces, either before or after plastic deformation, depending on the forming method applied [

4].

The importance of the coating-forming problem for industry is demonstrated by some published articles analyzing what happens to certain metals coated with paints and then plastically deformed by various methods (biaxial stretching, uniaxial tension, bending, etc.), but not by the EMF method. The EMF process is characterized by high-speed forming, with the values indicated in the specialized literature being between 100 m/s and 300 m/s: typically exceeding 100 m/s [

5], commonly 200 m/s [

6] and reaching up to 300 m/s [

7]. These high forming speed values lead to a productivity of about 600 parts/h, i.e., 10 parts/min. Subsequent painting of these parts electromagnetically formed, piece by piece, becomes economically inefficient in relation to the high productivity achieved during forming and the high paint losses.

Another problem, especially present in classic pressing methods, is that after pressing, metal sheet parts have traces of lubricants on their surfaces that must be removed through cleaning operations with various solvents, which incurs related costs, including environmental ones. These disadvantages can be eliminated by cutting (stamping) the workpieces from an already painted sheet of metal and performing EMF. Therefore, the application of the coating to flat-sheet metal workpieces has economic, technological and ecological advantages [

8]. Only a few papers include general references to the possibility of deformation by EMF of coated metal parts [

9,

10]. Thomas and Triantafyllidis [

11] present a study on EMF of coated tubes, but they do not focus on the behavior of the coating during high-speed forming.

These aspects motivated the onset of the experimental research, the results of which are presented in this paper.

The research conducted by Liu and Chen [

12] aimed to investigate the deformation mechanism and failure-tolerant characteristics of laminated polymer-coated metal sheets under different loading conditions. The authors determined that under dynamic incremental deformation loads, the failure modes included single-layer fracture, double-layer fracture, delamination and their mixed case. Pre-painted metal sheets provide corrosion protection, so they must resist failures through cracking or delamination during forming. Failure of coatings during forming is due to large deformations, and to understand surface strains, Sorce et al. [

13] proposed the application of the T-bend test. The maximum surface stresses during bending were predicted using finite element modeling and then verified experimentally using digital image correlation. Finally, a new analytical model was established to determine the maximum surface stresses. To understand the behavior of a metal sheet coating during forming, Sorce et al. [

14] performed Erichsen cupping tests, which provided answers to questions regarding the connections that must exist between the formability, material properties and chemical structure of the polymer for the development of better coatings. A master curve of maximum strain versus indentation depth (Erichsen index) was determined, which allows the determination of the coating’s maximum strain on a metal substrate.

The forming behavior of a Z100 steel sheet coated with a polyester resin was studied by Ciccarelli et al. [

15]. They performed interrupted tensile tests at different strain levels, through which the elongation characteristic of both the paint layer and the steel substrate was evaluated. The occurrence of superficial damage on the paint layer was also detected and the pre-painted sheet’s thinning of each layer was evaluated according to the strain levels. The forming behavior of pre-painted steel sheets was also investigated by Forcellese et al. [

16]. They added the hemispherical punch test to study the forming behavior of pre-painted sheets under uniaxial and biaxial stretching conditions, respectively. The tests were also performed with interruption to detect the appearance of superficial damage on the paint layer and they highlighted that superficial damages to the paint layer occur earlier in the case of biaxial stretching of the sheet. Muto et al. [

17] compared water-based and solvent-based coatings for pre-painted steel sheets, and the results of dynamic mechanical analysis showed that the crosslink density of the entire water-based paint film was higher than that of the solvent-based film. This conclusion will contribute to the improvement of design and performance of water-based pre-painted steel sheets as environmentally friendly alternatives to solvent-based coatings.

Friction plays a major role in forming processes, being a local phenomenon influenced by the contact conditions at the tool–material interface. Friction mainly produces heat and leads to increased energy consumption by increasing the required deformation force. In this regard, researchers are interested in the tribological evaluation of different coating materials and the design of new coating materials that also possess lubricating properties. Friction issues of coated sheets in forming processes have been addressed by Shisode et al. [

18]. They developed a multi-scale friction model applicable to coated sheets for boundary lubrication regime, which takes into account the physical behavior of the coating and the measured surface topographies of the sheet and tools. The friction model was validated by different sets of laboratory-scale friction tests and cup drawing experiments on zinc-coated steel sheets.

Dessie and Lukacs [

19] examined the impact of thermal cycling applied during painting of steel sheets and concluded that pre-painted steel becomes more susceptible to springback, due to the interaction between material characteristics, processing techniques and forming conditions that lead to the amplification of springback phenomena.

In their paper, Vayeda and Wang [

20] present a new method for evaluating the adhesion of coatings made on formed metal sheets, based on the concept of forming limit diagram. The proposed methodology combines the notch-coating adhesion test, the cross-hatch tape test, accelerated conditioning, the uniaxial tensile test, and the rectangular stretch bend test. The experimental results showed that the coating adhesion can be affected by the plastic deformation of the substrate. Barai and Weng [

21] have sought the dependence properties of nanocrystalline coatings such as its yield strength, hardness, and wear resistance on the grain size in order to obtain the strongest state of the coating material. The study led to the theoretical model’s development of composite plate, with which can be established the grain size dependence of plastic strength in nanocrystalline coatings. Bouzakis et al. [

22] have developed a method that shows the residual stresses after load removal remain into the coating layers of the formed parts. The method is based on the finite element simulation and experimental verification by the nanoindentation test, and this can determine the residual stresses in a coating which undergoes an elastic or plastic deformation. The influence of interface on epoxy-polyester films’ deformation, deposited by electrostatic spraying, was studied by Barletta et al. [

23] by applying the micro-scratch test. The influence of the substrate was also studied by scratch tests of films deposited on rigid surfaces and on soft silicon substrates.

Paper [

24] presents a new method for carrying out bending tests, where the sample is subjected to the full range of curvatures desired in a single test. The blade shape sample (diamond-like carbon multilayer coating) is gradually pressed on a bending snail and a surface with variable curvature is obtained, which allows the determination of the critical strains where damage appears. The adhesion with polymer coating of metal sheets after applying a stretch plastic deformation was studied by Huang and Wang [

25]. The authors have performed a set of experiments for evaluating the strength of the coating before and after uniaxial stretching. A model for predicting the adhesion loss of the coating after plastic deformation has been proposed and validated by comparison with experimental results.

The plastic deformation behavior [

26] in the case of polyester series used for cross-linked coatings has been studied as well. Through tensile tests under a range of temperatures and strain rates, the time and temperature dependencies on the mechanical response were investigated and a visco-elastic model based on the stress–strain tensile curve obtained for paint was established. In other applications [

27], the ability of nanolayers sputtered to plastic deformation by combining the traditional nanoindentation test with microcompression test was evaluated. The conclusion is that the nanolayers exhibit unique plastic deformation behavior, with a small-scale plasticity transition and a scaling activation behavior of small volume with intrinsic size.

To understand the failure mechanisms and predict the lifetime of the coating layers, it is important to determine the interfacial adhesion energies. Zhu et al. [

28] have applied a cohesive zone finite element model and a compression test, by which the interfacial adhesion energy was determined and measured the failure process of buckling, coating spallation and delamination arising from an artificial defect. Another problem of interest is to achieve adhesive bonding of coated high-strength steel for automotive components subjected to impact loadings [

29]. Determination of bond strength was made by the usual testing methods (i.e., butt-joint or lap-shear tests) and revealed the following findings. Coatings and paints considerably influence the mechanical strength of adhesive bonding; there is a significant dependence on the nature of the paint; it was observed that the weakest layer in the whole joint is the coating or the paint. Apart from plastic deformation, coated metal sheets can be processed through the stamping operation. Correctly designing a stamping process must prevent defects, such as delamination and tearing [

30]. The study was conducted by stamping a polymer-coated metal sheet and development of a defect diagram, which proved to be effective and appropriate for real stamping process design.

A synthesis of the investigations in this field presented above shows that the preferred methods of verifying the coating adhesion are the classics, uniaxial tensile and bending tests. However, these are tests conducted at low speeds of deformation, which does not cover all practical situations, such as the one in which the material is subjected to shock loading. The disadvantage of the other methods for adhesion testing after plastic deformation, i.e., pull-off stress, is that the formed specimen must have a flat surface on which the investigations can be made. The analysis of the studies mentioned above reveals two research directions that converge towards a common goal. On the one hand, metal forming specialists perform different types of tests to elucidate the plastic deformation behavior of metals coated with certain layers and search for the best forming methods that do not destroy the coating. On the other hand, coating researchers await the results of the forming tests in order to analyze the behavior of the coatings and to be able to develop new recipes for coating materials with improved properties. The common question that researchers must answer, regardless of the forming method applied, is as follows: What is the maximum plastic strain of the metal substrate that corresponds to a maximum elastic strain of the coating layer so as not to cause cracking of the coating?

In this study, our focus has shifted to behavior testing under plastic deformation by EMF of some metal sheets with covered surfaces. Regarding the EMF, a shock loading is applied to the material, but contact-free; thus, the test method proposed in the present paper is unique. The paper analyzes what happens with a painted sheet when it is electromagnetically formed.

3. Results and Discussion

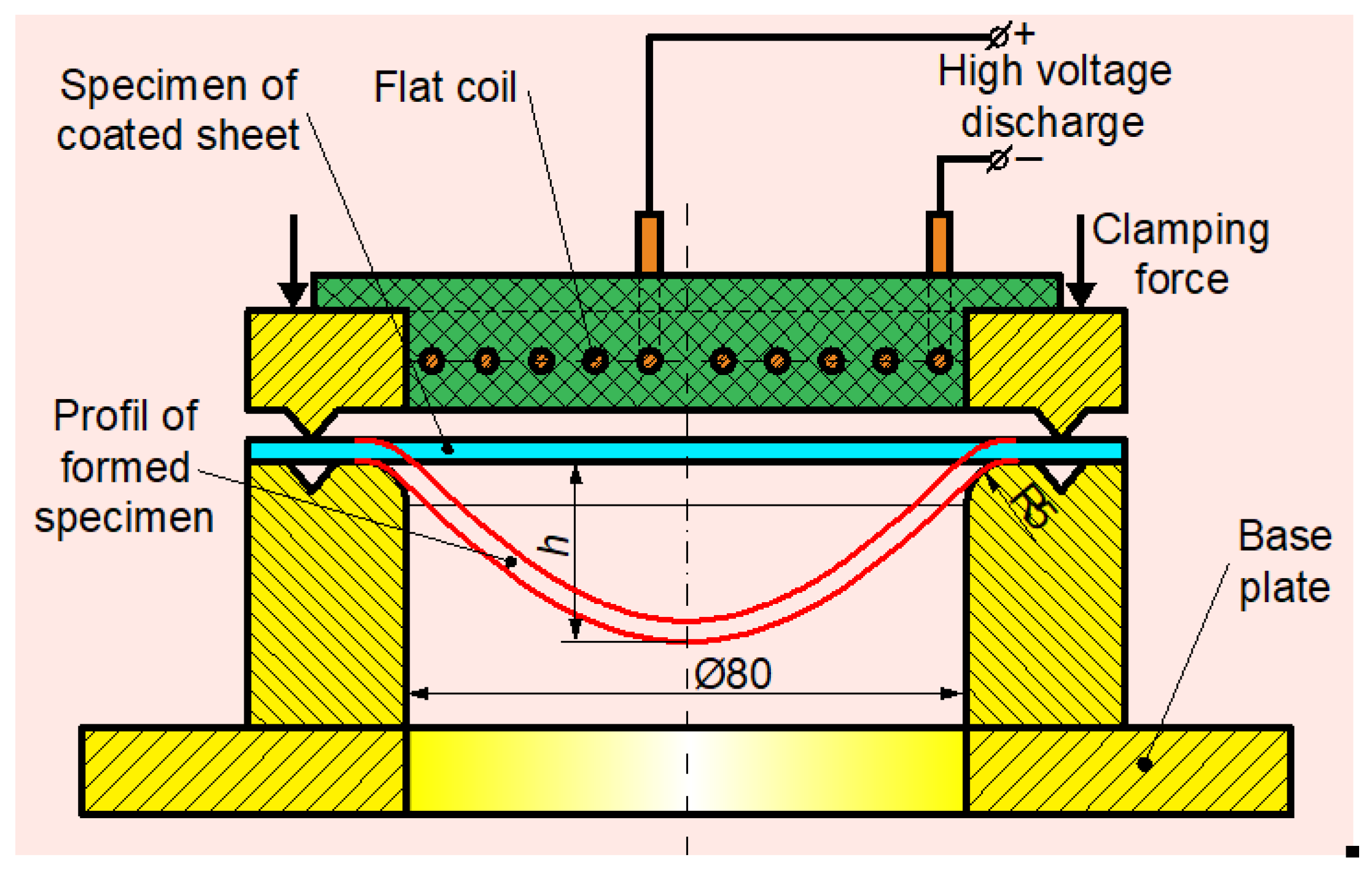

SSCb (with blocking), with 1.0 mm thickness substrate, were first tested. For this set of tests, different deformation energies were applied, with values between 0.900 and 1.600 kJ. The range of used energies could be finely adjusted by controlling the charging voltage of the capacitor bank, the ability to adjust the EMF machine being at a level of 10 V. Plastically deformed samples were studied under a microscope to detect the occurrence of cracks in the paint layer. After noticing the occurrence of cracks on the coated surface, tests were continued with lower values of applied deformation energy, in order to determine the extent to which the coating layer can be formed elastically (no cracks) together with plastic deformation of the substrate. From the tests carried out, the experiments that led to the achievement of the mentioned purpose (occurrence of cracks in the paint) were retained and the results are noted in

Table 6, in the order of execution.

The deformation energy pulse applied to the specimen was calculated with the equation:

where

C and

V are the capacitance and the charging voltage of the capacitor bank, respectively.

The limit up to which the substrate can be plastically deformed without damaging the coating layer was established considering the elongation of the base material. The elongation was calculated by the equation:

where

is the final length after deformation and

is the initial length of the specimen.

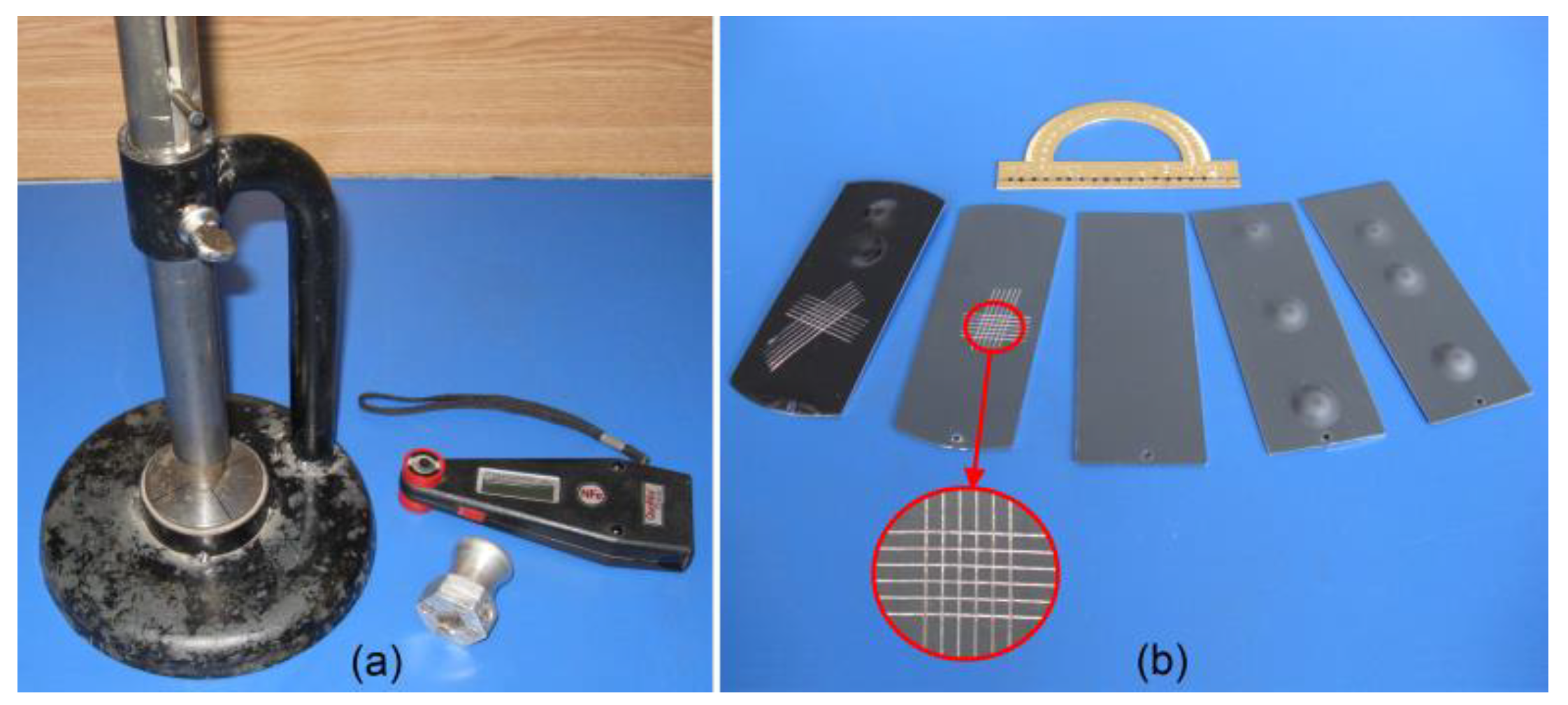

The initial length was considered on one of the straight sides of the specimen and the final length was measured on the same side after the application of electromagnetic force. The final (profile) length was measured with MarVision MM 320 (Aerospace Manufacturing and Design, Valley View, OH, USA) video measuring microscope using automatic edge detection, a feature provided by its software. This device has a resolution of 1 µm and a maximum permissible indication error (MPE E X/Y) of 1.9 µm.

Further, the SSCb set (without blocking) was electromagnetically formed. This time the substrate was formed more than the first set for the same amount of energy applied. The elongation obtained and observations relating to the occurrence of cracks in the paint layer are shown in

Table 7.

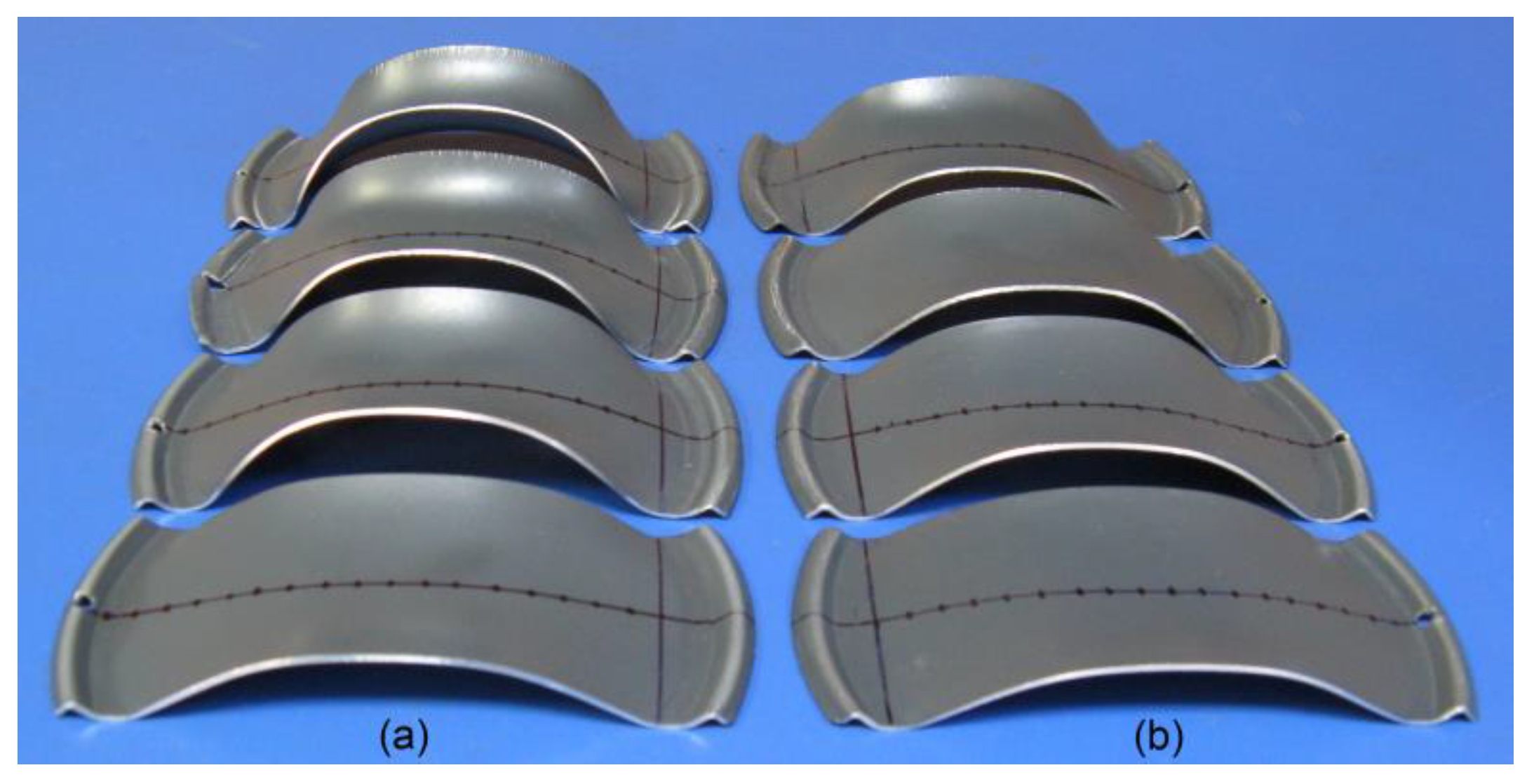

Some of the electromagnetically formed SSCb by the two plastic deformation paths are shown in

Figure 5.

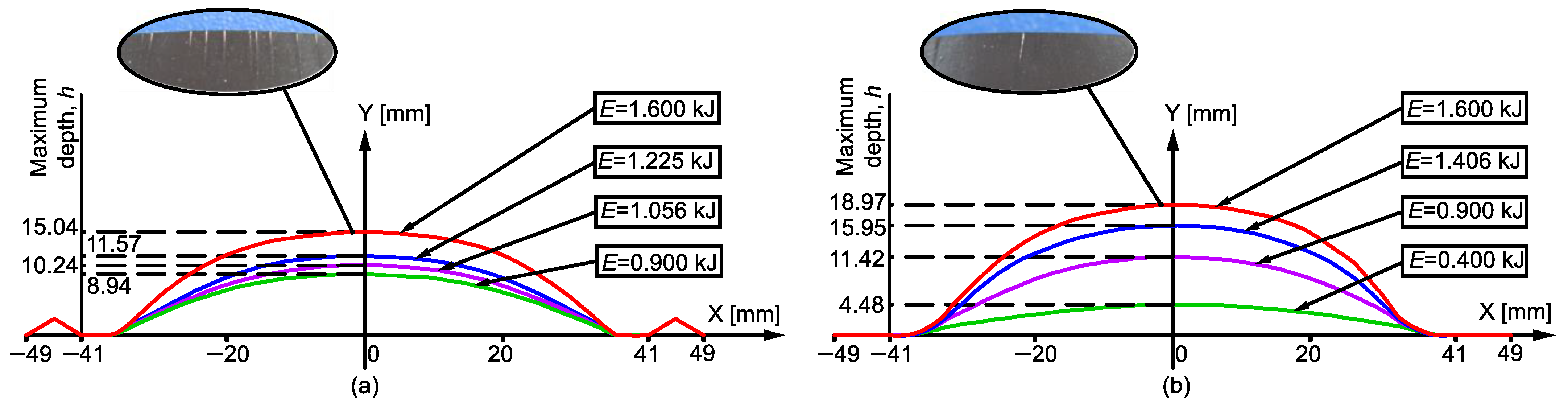

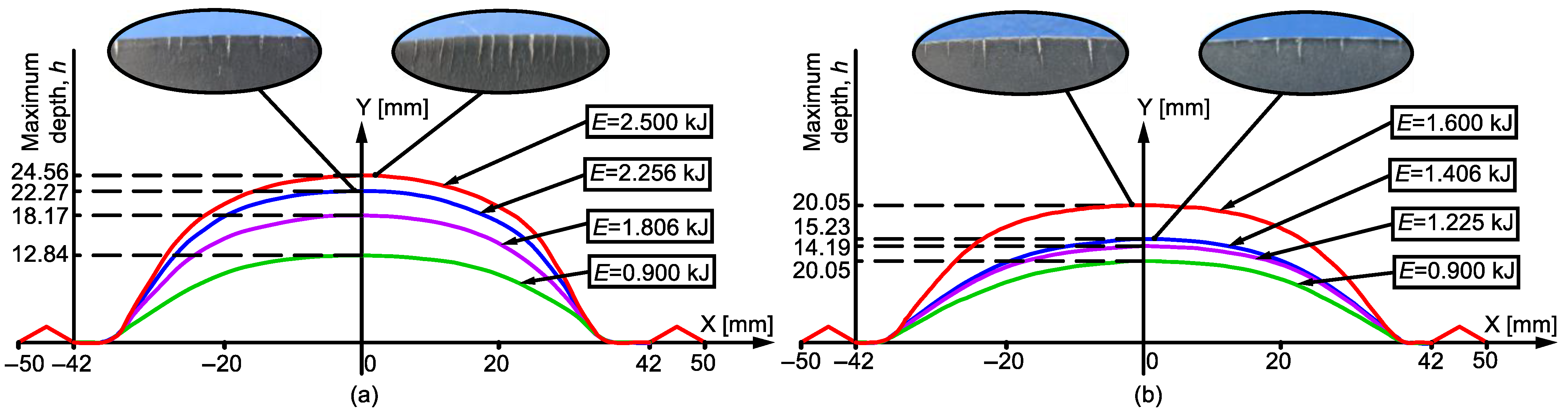

The range of energies applied to the second set of specimens was between 0.400 and 1.600 kJ. A comparative image regarding the influence of plastic deformation for the same type of interface (Al 99.00-polyester powder film) on the occurrence of cracks in the coating layer is shown in

Figure 6.

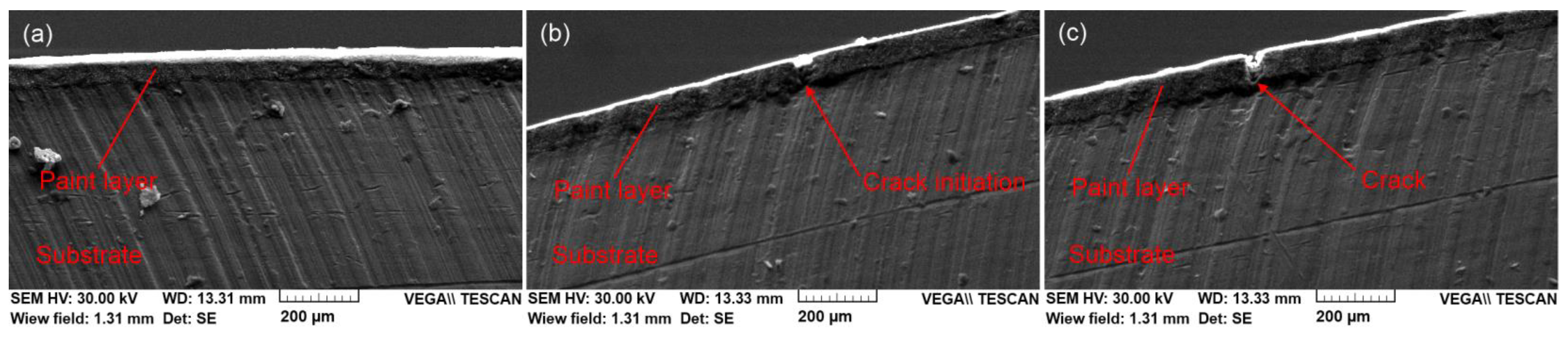

After the EMF tests, the obtained samples were examined by SEM. The SEM images show the paint layer status for various strains of the substrate (Al 99.0) obtained by EMF. SEM analysis performed on the coating layer–metal sheet interface is presented in a few images in

Figure 7.

The SEM images show that cracks, developed after EMF, are defined as “surface cracking”. These cracks were laterally propagated through the paint layer in a channeling process due to high tensile stresses. This mode of damage is encountered in coatings with high residual stress and crack propagation on the surface of the formed sample due to the relaxation of elastic strain energy stored in the coating thickness. These processes occur because the energy with which the paint is formed exceeds the adhesion energy limit between the paint layer and the aluminum substrate.

The next set of tests was carried out with SCD. The working procedure and the method of detecting the appearance of cracks were similar to those applied in the two previous sets. Results chosen for presentation are given in

Table 8.

In the last set of tests, EMF at SSCg was applied. Relevant results are shown in

Table 9, together with the findings obtained. The methods of plastic deformation, measurement and observation of cracks in the coating layer were similar.

For the last set of tests, deformation energy with values between 0.900 and 1.600 kJ was applied. Some of the SDC and SSCg tested by EMF are shown in

Figure 8.

A comparative image regarding the interface’s role (SSC or SDC) using the same method of plastic deformation in the occurrence of cracks in the coating layer is shown in

Figure 9.

As an indicator for adhesion loss after EMF of painted metal sheets, the specific energy applied to the surface of the specimen is proposed. The specific energy is calculated by the ratio:

where

E is the energy applied and

A is the formed portion area of the specimen.

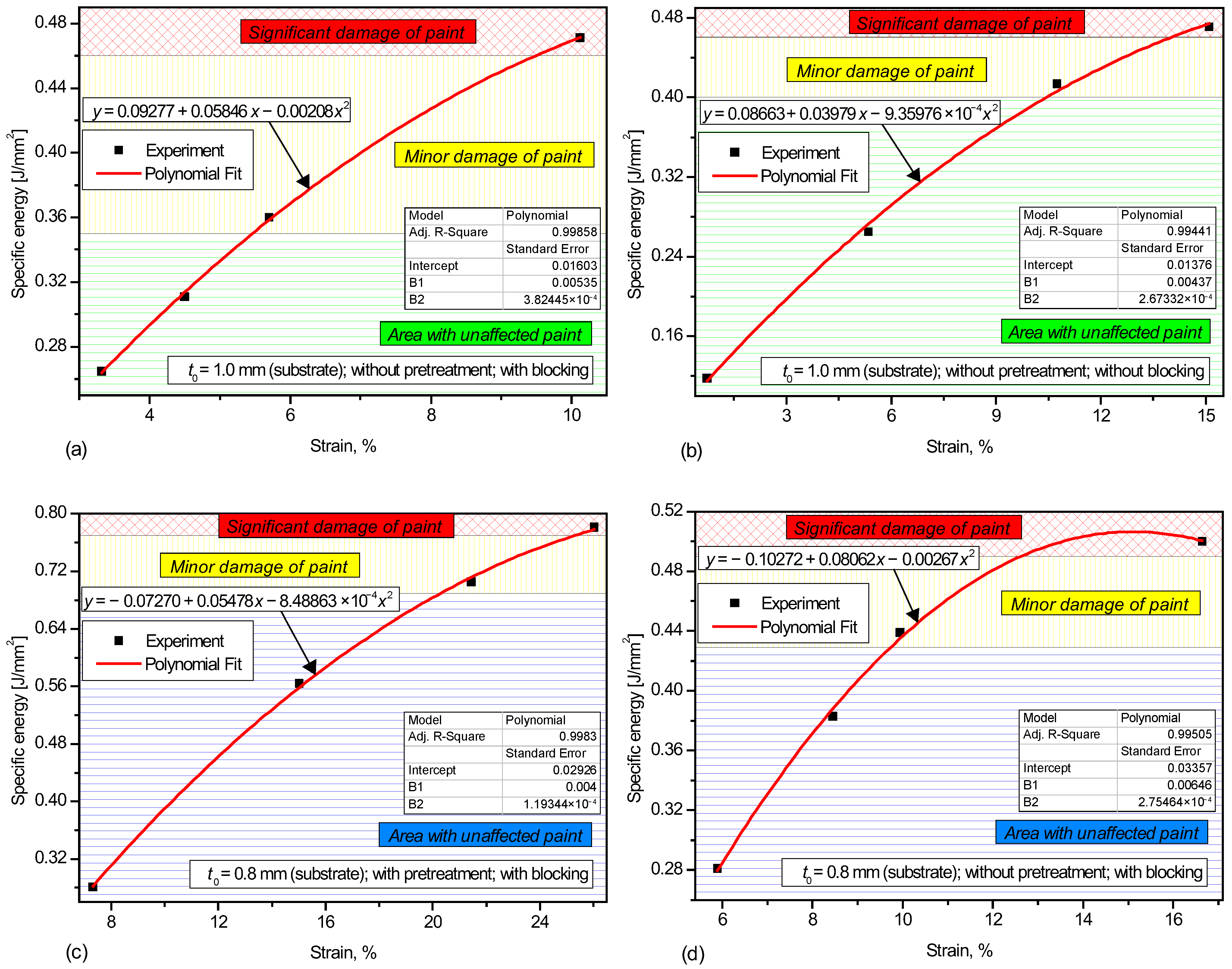

The cumulative influences of the Al 99.0 substrate’s initial thickness of the pretreatment applied (chromatizing) to the base material and of the plastic deformation’s path (with/without blocking) on the adhesion loss of the metal surface’s paint are summarized in

Figure 10. From

Figure 10a,b we can observe a larger area and a higher limit for maintaining the paint integrity in samples that were electromagnetically formed without blocking vs. those that have been blocked.

The latter were loaded by stretching, with the stress state in the metal–paint structure being less favorable for plastic deformation than in samples formed without blocking the edges.

A better adhesion of the paint was observed on the specimens that were pretreated by degreasing and chromatizing, and the paint incurred a higher plastic deformation of the substrate. In this case, as shown in

Figure 10c,d, the first signs of damage to the coating occurs after large strains, which shows that the paint has better resistance after the mechanical shock is applied.