Experimental and Numerical Analyses of Diameter Reduction via Laser Turning with Respect to Laser Parameters

Abstract

1. Introduction

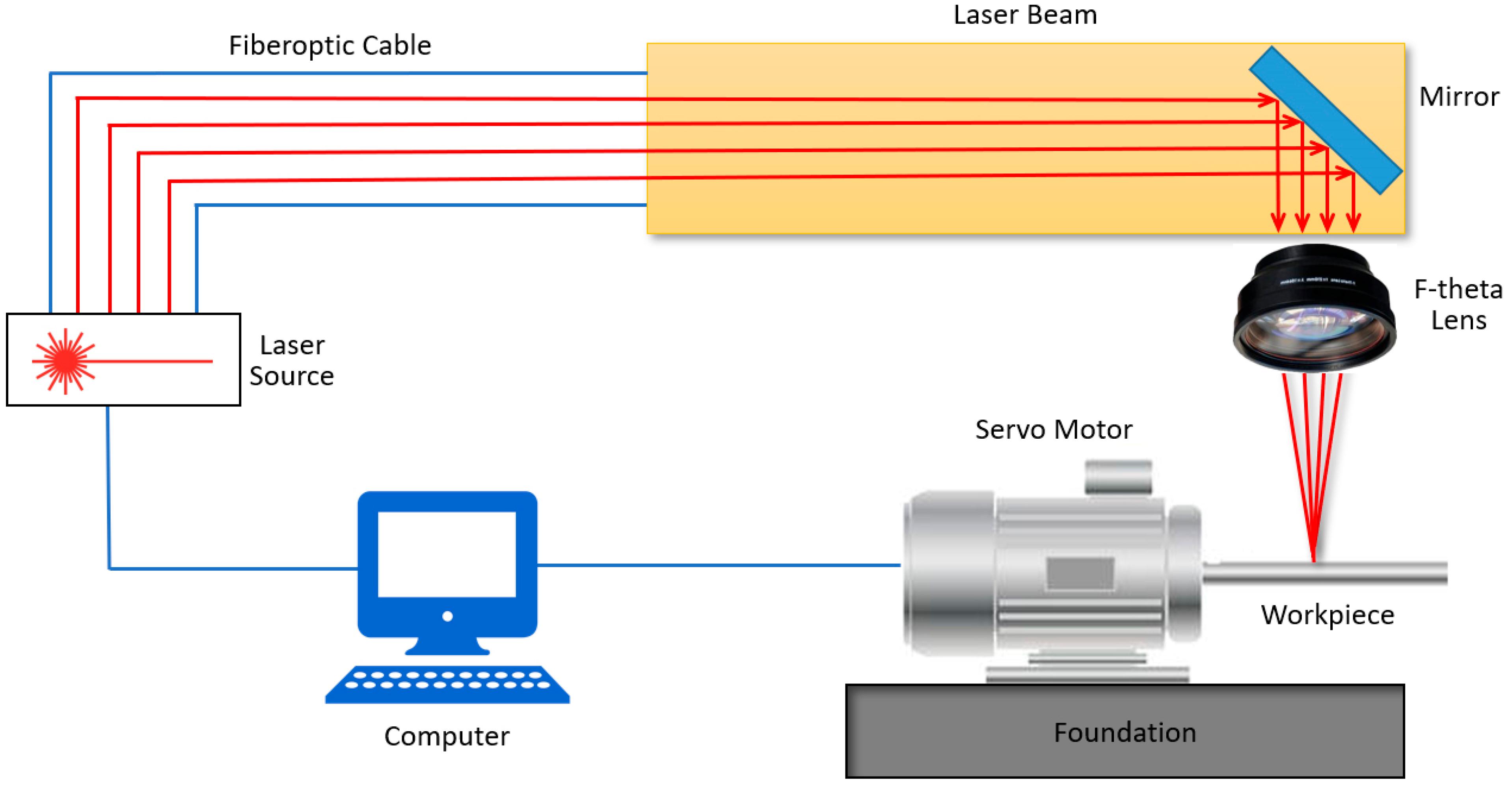

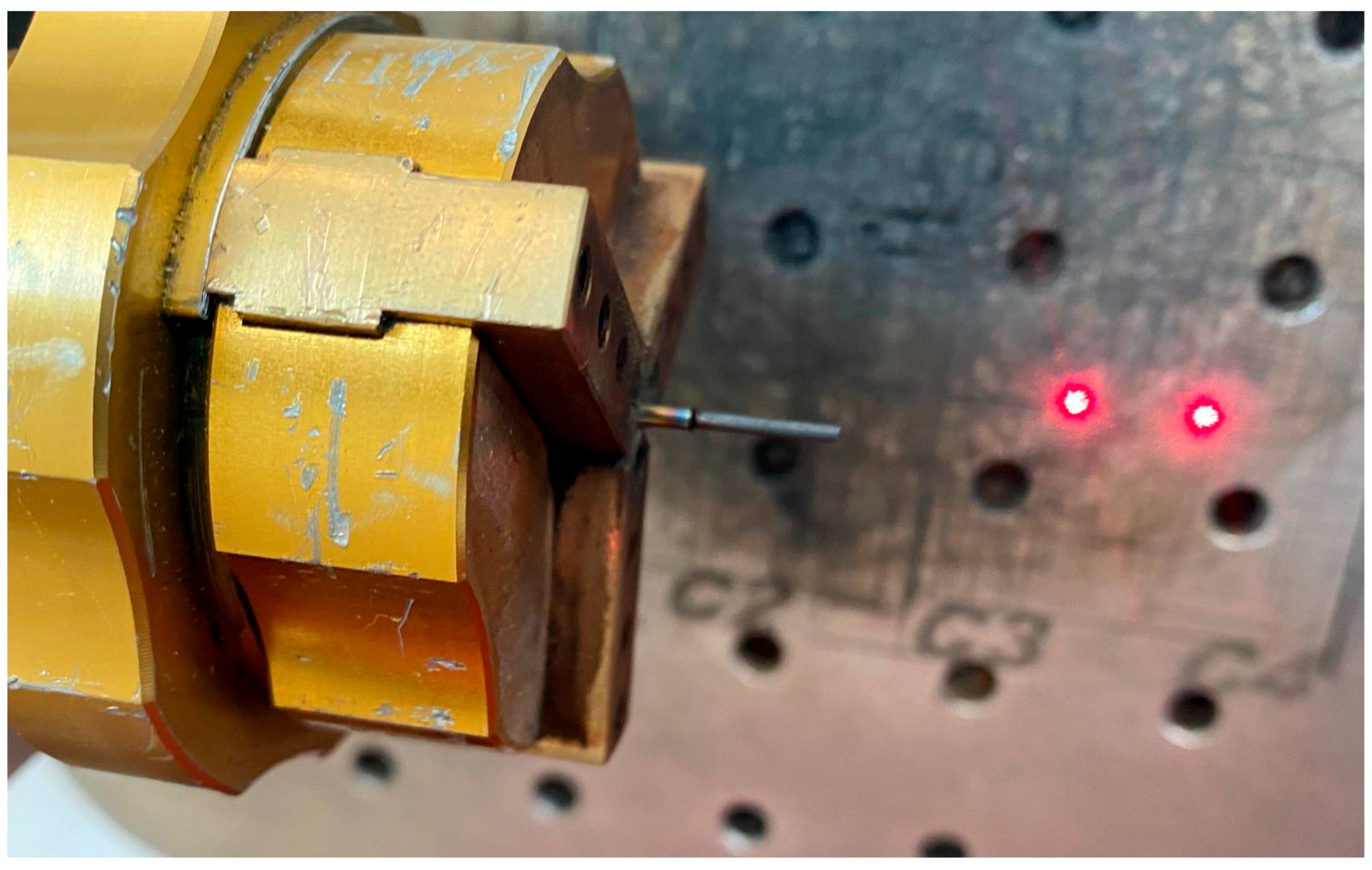

2. Materials and Methods

3. Results and Discussion

- 1.

- The frequency parameter introduces a considerable nonlinear effect in the process, suggesting that certain frequency values may give rise to currently unidentified physical phenomena.

- 2.

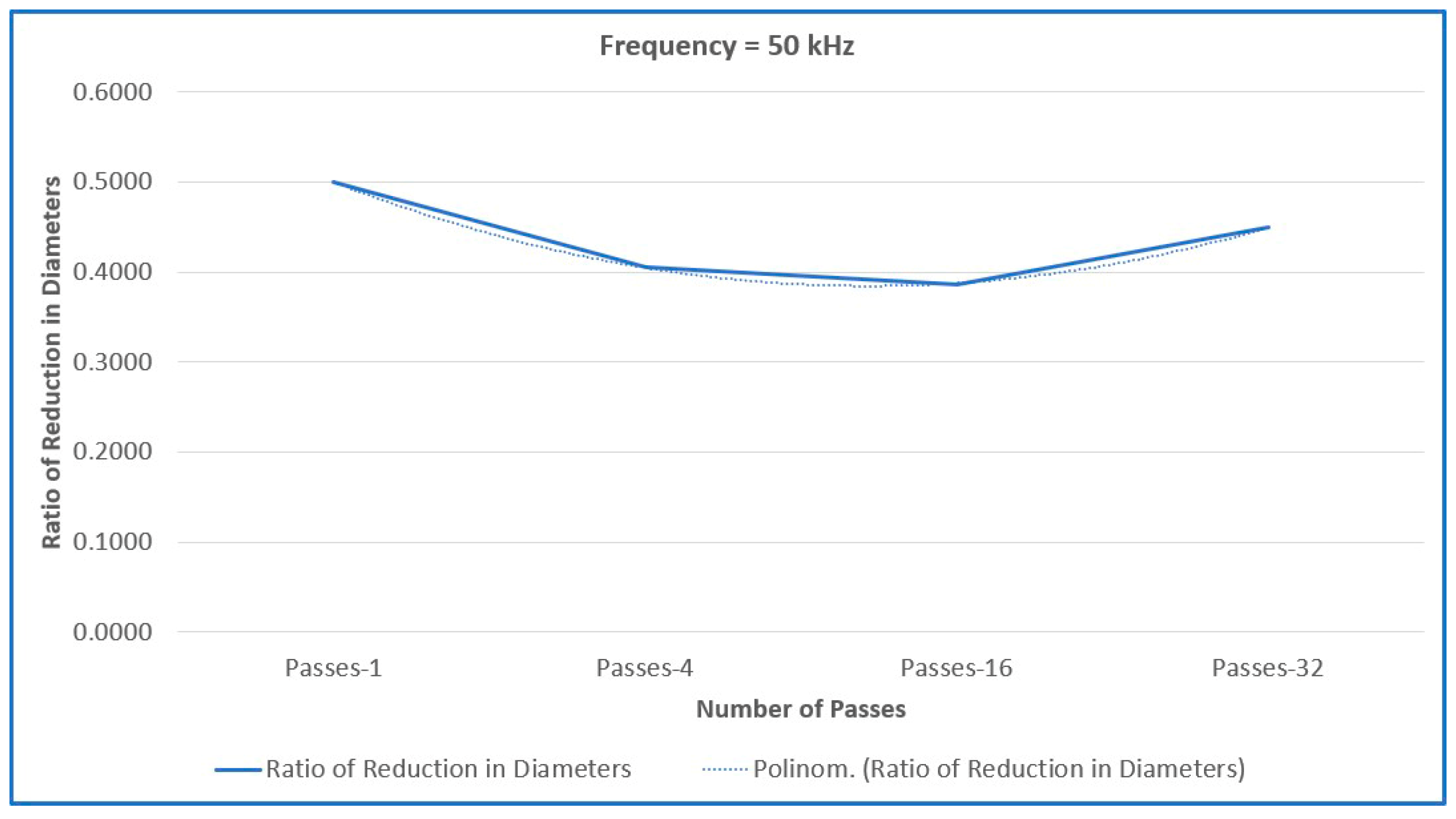

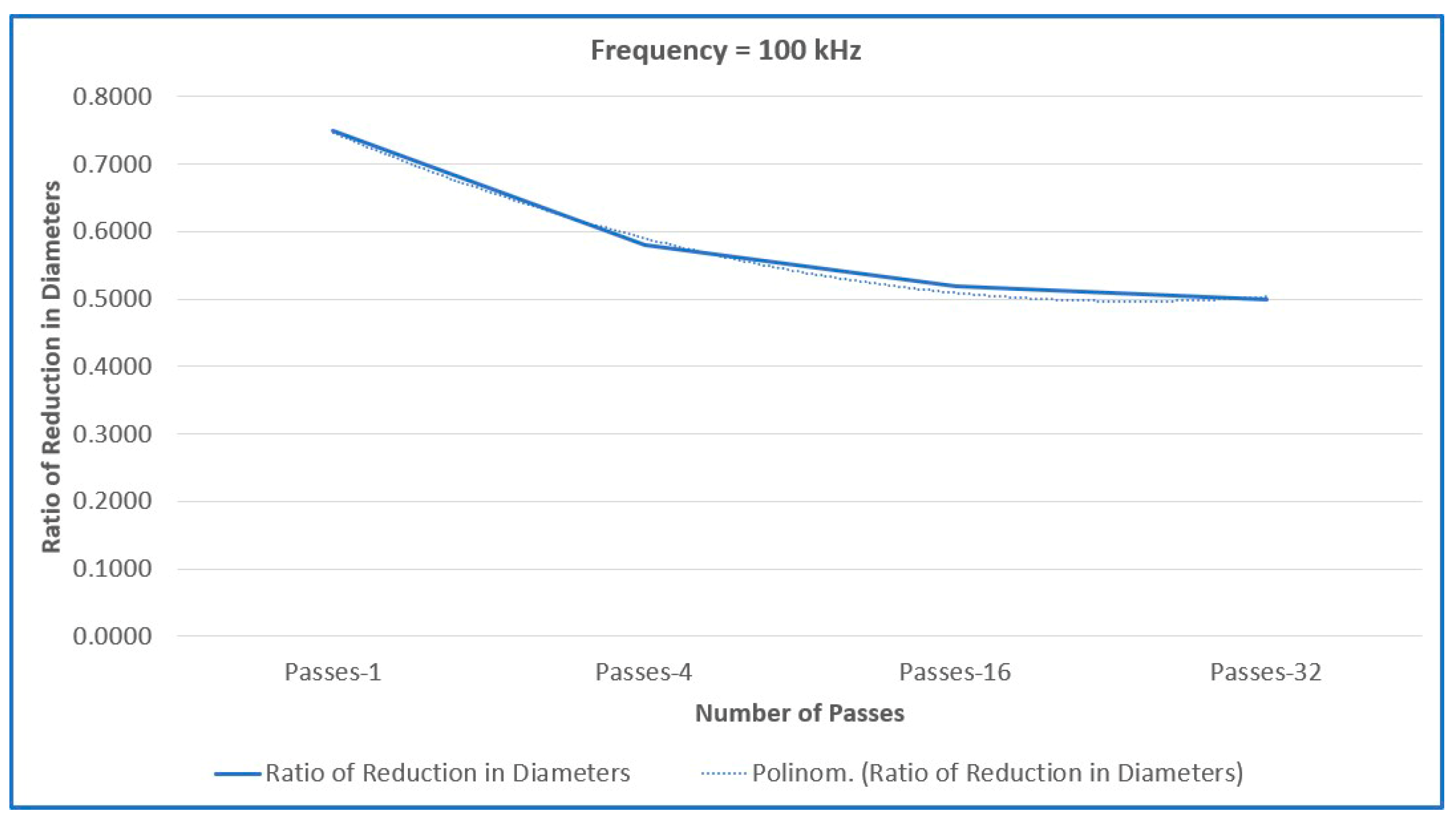

- Although the number of passes may have a linear influence on diameter reduction when all other parameters are held constant, its effect becomes nonlinear under varying frequencies. The reduction ratio fluctuates around the expected 0.5—exceeding it in some regions and falling below it in others. This behavior is hypothesized to result from an interaction between increasing pass count and frequency:

- In regions where the ratio exceeds 0.5, the incubation effect may be dominant.

- In regions where the ratio is less than 0.5, plasma shielding likely contributes to reduced effectiveness.

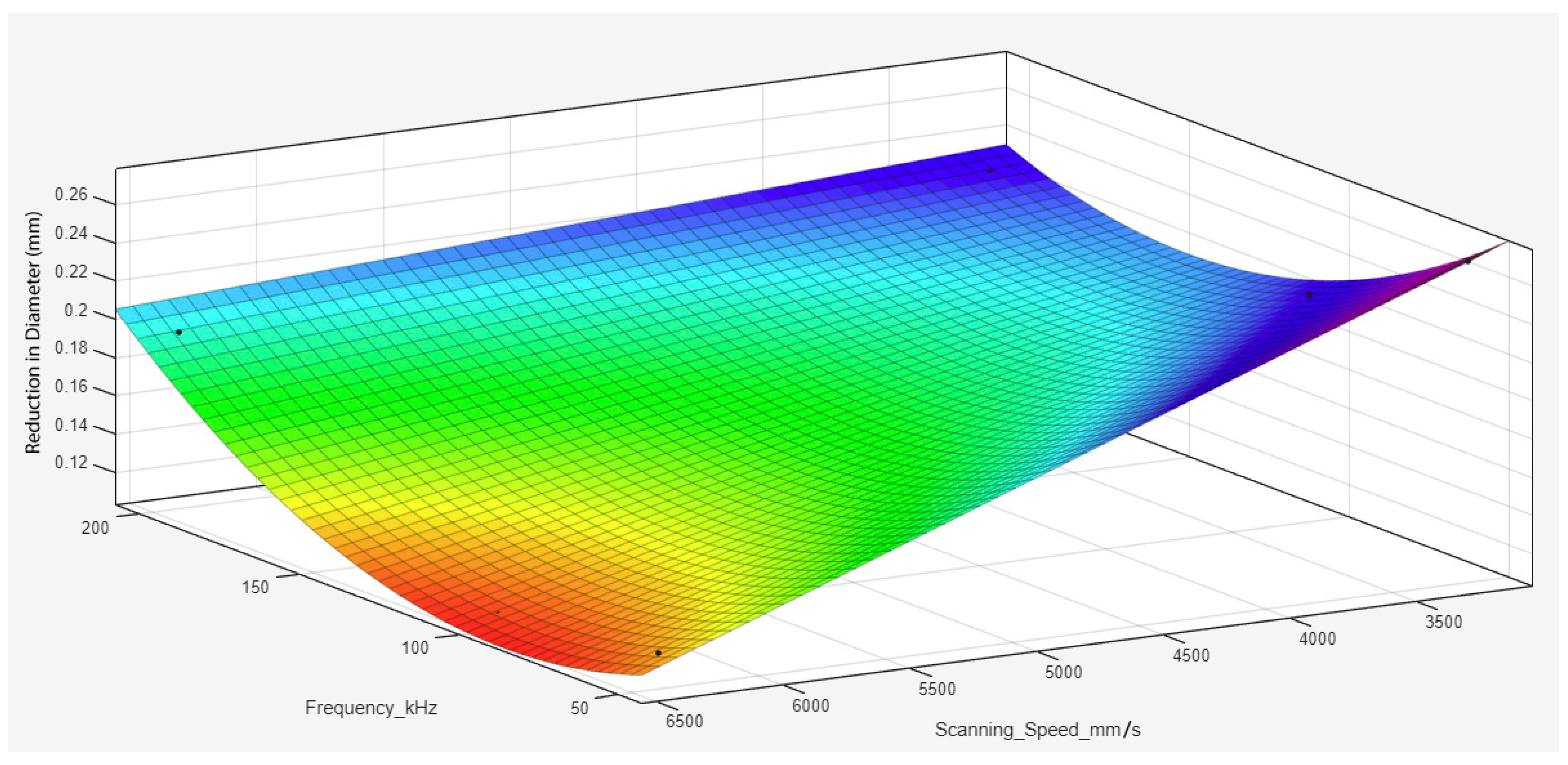

- where the input and output variables are as follows:

- x: Frequency (kHz);

- y: Scanning speed (mm/s);

- f: Reduction in diameter (mm).

- A constant term;

- Frequency;

- Laser scanning speed;

- Interaction term between the frequency and laser scanning speed.

- The constant term tends to increase steadily with the number of passes. As the number of passes increases, its effect initially increases geometrically between 1 and 4 passes and then increases linearly from 4 to 32 passes. The geometric increase in the constant term observed between one and four passes is presumed to be associated with the incubation effect.

- The effect of frequency increases linearly with the number of passes. Additionally, the presence of a second-order (quadratic) term related to frequency has been observed. With an increasing number of passes, the influence of this quadratic term first decreases but then increases again, indicating nonmonotonic behavior.

- As the number of passes increases, the effect of the laser scanning speed on diameter reduction initially increases geometrically but then decreases geometrically. The absence of a second-order term for the laser scanning speed confirms that its direct influence on diameter reduction is linear. However, the observed trend suggests the existence of a nonlinear interaction between the laser scanning speed and the number of passes.

- With an increasing number of passes, the interaction term initially decreases but then increases. This behavior indicates a nonlinear interaction between the interaction term and the number of passes. To fully interpret this relationship, the nonlinear behavior associated with the frequency term must be understood first, as it plays a central role in shaping the overall interaction.

4. Conclusions and Future Work

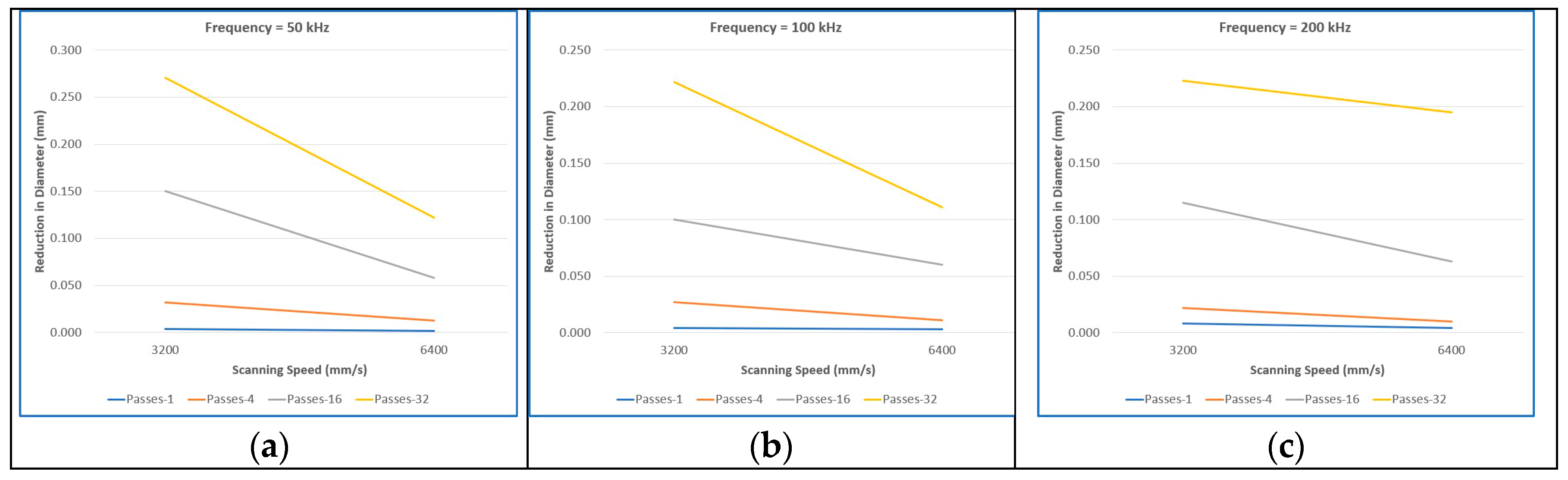

- The DLT process yielded measurable reductions in diameter under scanning speeds of 3200 mm/s and 6400 mm/s. The maximum diameter reduction was observed to be 0.271 mm at 3200 mm/s and 50 kHz, while a reduction of 0.195 mm was achieved at 6400 mm/s and 200 kHz.

- Increasing the scanning speed from 3200 mm/s to 6400 mm/s, especially when coupled with a higher number of passes, led to a significant decrease in the extent of diameter reduction.

- At a constant frequency, diameter reduction exhibited a linear increase with the number of passes. A robust correlation (R2 = 0.99) between pass count and diameter reduction underscores the process’s high predictability.

- At a fixed scanning speed of 3200 mm/s, diameter reduction increased with frequency during single-pass operations. However, for multi-pass conditions, a reverse trend was noted, with reductions generally decreasing as frequency increased. A similar inconsistency was observed at 6400 mm/s, where no clear trend emerged across different pass numbers, suggesting complex frequency-dependent behavior.

- When the average laser power was held constant and the scanning speed was doubled, the effective fluence was halved, yielding a fluence ratio of 0.5. This consistent ratio enabled an original analysis of how fluence reduction influences diameter reduction as a function of pass count. A second-order parabolic relationship was confirmed between diameter reduction and pass number, with an exceptionally high R2 of 0.99. Notably, at high frequencies, even at reduced fluence levels, the onset of material evaporation due to the incubation effect was observed.

- Analysis of polynomial regression terms revealed that the constant term significantly contributes to diameter reduction. It increased linearly with the number of passes but exhibited a geometric rise between one and four passes, indicating a cumulative thermal effect in the early stages of processing.

- The effect of laser frequency on diameter reduction was shown to be nonlinear. First-order terms varied linearly with pass count, while second-order terms revealed complex, nonmonotonic behaviors, suggesting that frequency exerts a compound physical influence on the ablation process, which warrants further investigation.

- Scanning speed generally had a linearly controllable impact on diameter reduction, with increases in pass count amplifying material removal. However, an anomalous interaction was noted at four passes, pointing to a unique physical interplay between scanning speed and pass count under this condition.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sofuoglu, M.A.; Orak, S. Prediction of stable cutting depths in turning operation using soft computing methods. Appl. Soft Comput. 2016, 38, 907–921. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Mofakkirul Islam, M. Prediction of tool wear and surface finish using ANFIS modelling during turning of Carbon Fiber Reinforced Plastic (CFRP) composites. Manuf. Lett. 2024, 41, 658–669. [Google Scholar] [CrossRef]

- Kadivar, M.; Azrhoushang, B.; Zahedi, A.; Müller, C. Laser-assisted micro-milling of austenitic stainless steel X5CrNi18-10. J. Manuf. Process. 2019, 48, 174–184. [Google Scholar] [CrossRef]

- Parandoush, P.; Hossain, A. A review of modeling and simulation of laser beam machining. Int. J. Mach. Tools Manuf. 2014, 85, 135–145. [Google Scholar] [CrossRef]

- Wei, Y.; Park, C.; Park, S.S. Experimental evaluation of direct laser assisted turning through a sapphire tool. Procedia Manuf. 2017, 10, 546–556. [Google Scholar] [CrossRef]

- Chen, K.; Yao, Y.L. Process optimisation in pulsed laser micromachining with applications in medical device manufacturing. Int. J. Adv. Manuf. Technol. 2000, 16, 243–249. [Google Scholar] [CrossRef]

- Choi, W.C.; Chryssolouris, G. Analysis of the laser grooving and cutting processes. J. Phys. D Appl. Phys. 1995, 28, 873–878. [Google Scholar] [CrossRef]

- Booth, H.J. Recent applications of pulsed lasers in advanced materials processing. Thin Solid Films 2004, 453, 450–457. [Google Scholar] [CrossRef]

- Lendner, F. Smart ultrafast laser processing with rotating beam–Laser micro drilling, cutting and turning. In 12th Mittweidaer Lasertagung; Hochschule: Mittweida, Germany, 2021; pp. 83–86. [Google Scholar]

- Meijer, J. Laser beam machining (LBM), state of the art and new opportunities. J. Mater. Process. Technol. 2004, 149, 2–17. [Google Scholar] [CrossRef]

- Zhao, F.; Bernstein, W.Z.; Naik, G.; Cheng, G.J. Environmental assessment of laser assisted manufacturing: Case studies on laser shock peening and laser assisted turning. J. Clean. Prod. 2010, 18, 1311–1319. [Google Scholar] [CrossRef]

- Khatir, F.A.; Sadeghi, M.H.; Akar, S. Investigation of surface roughness in laser-assisted hard turning of AISI 4340. Mater. Today Proc. 2021, 38, 3085–3090. [Google Scholar] [CrossRef]

- You, K.; Liu, G.; Wang, W.; Fang, F. Laser assisted diamond turning of silicon freeform surface. J. Mater. Process. Technol. 2023, 322, 118172. [Google Scholar] [CrossRef]

- Deswal, N.; Kant, R. Machinability and surface integrity analysis of magnesium AZ31B alloy during laser assisted turning. J. Manuf. Process. 2023, 101, 527–545. [Google Scholar] [CrossRef]

- Naresh, C.; Bose, P.S.C.; Suryaprakash Rao, C.; Selvaraj, N. Prediction of cutting force of AISI 304 stainless steel during laser-assisted turning process using ANFIS. Mater. Today Proc. 2021, 38, 2366–2371. [Google Scholar] [CrossRef]

- Yasmin, F.; Tamrin, K.F.; Sheikh, N.A.; Barroy, P.; Yassin, A.; Khan, A.A.; Mohamaddan, S. Laser-assisted high speed machining of 316 stainless steel: The effect of water-soluble sago starch based cutting fluid on surface roughness and tool wear. Materials 2021, 14, 1311. [Google Scholar] [CrossRef]

- Szymański, M.; Kukliński, M. Geometrical structure of surface after turning of 316L stainless steel in laser assisted conditions. Arch. Mech. Technol. Mater. 2019, 39, 66–73. [Google Scholar] [CrossRef]

- Wei, C.; Guo, W.; Gao, B.; Wang, Y.; Sun, Z.; Li, L. Understanding the behaviour of workpieces’ bulk temperature during laser-assisted turning of Ti6Al4V alloy and heating of Al-SiC metal-matrix composite rods. Opt. Laser Technol. 2021, 139, 106951. [Google Scholar] [CrossRef]

- Przestacki, D. Conventional and laser assisted machining of composite A359/20SiCp. Procedia CIRP 2014, 14, 229–233. [Google Scholar] [CrossRef]

- Abedinzadeh, R.; Norouzi, E.; Toghraie, D. Study on machining characteristics of SiC–Al2O3 reinforced aluminum hybrid nanocomposite in conventional and laser-assisted turning. Ceram. Int. 2022, 48, 29205–29216. [Google Scholar] [CrossRef]

- Bejjani, R.; Shi, B.; Attia, H.; Balazinski, M. Laser assisted turning of Titanium metal matrix composite. CIRP Ann. 2011, 60, 61–64. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A Mater. Sci. Process. 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Yokotani, A.; Kawahara, K.; Kurogi, Y.; Matsuo, N.; Sawada, H.; Kurosawa, K. Development of laser turning using femtosecond laser ablation. In Second International Symposium on Laser Precision Microfabrication; SPIE: California, CA, USA, 2002; pp. 90–93. [Google Scholar]

- Kibria, G.; Doloi, B.; Bhattacharyya, B. Experimental analysis on Nd:YAG laser micro-turning of alumina ceramic. Int. J. Adv. Manuf. Technol. 2010, 50, 643–650. [Google Scholar] [CrossRef]

- Sriram, D.; Jayaprakash, G.; Arulkirubakaran, D.; Prabu, M.; Ajithkumar, A. Laser turning of alumina (Al2O3) ceramic by Nd:YAG laser technique. Mater. Today Proc. 2021, 39, 731–735. [Google Scholar] [CrossRef]

- Kibria, G.; Doloi, B.; Bhattacharyya, B. Predictive model and process parameters optimization of Nd:YAG laser micro-turning of ceramics. Int. J. Adv. Manuf. Technol. 2012, 65, 213–229. [Google Scholar] [CrossRef]

- Dhupal, D.; Doloi, B.; Bhattacharyya, B. Pulsed Nd:YAG laser turning of micro-groove on aluminum oxide ceramic (Al2O3). Int. J. Mach. Tools Manuf. 2008, 48, 236–248. [Google Scholar] [CrossRef]

- Zettl, J.; Bischoff, K.; Esen, C.; Hellmann, R. Laser turning of PMMA with ultrashort laser pulses using UV and IR. In Proceedings of the Laser-Based Micro-and Nanoprocessing XVIII, San Francisco, CA, USA, 29 January–1 February 2024; SPIE: Bellingham, WA, USA, 2024; pp. 297–304. [Google Scholar]

- Kibria, G.; Doloi, B.; Bhattacharyya, B. Experimental investigation and multi-objective optimization of Nd:YAG laser micro-turning process of alumina ceramic using orthogonal array and grey relational analysis. Opt. Laser Technol. 2013, 48, 16–27. [Google Scholar] [CrossRef]

- Zettl, J.; Rung, S.; Esen, C.; Hellmann, R. Tangential laser turning of fused silica using ultra-short laser pulses. J. Laser Micro Nanoeng. 2021, 16, 42–46. [Google Scholar] [CrossRef]

- Zettl, J.; Klar, M.; Rung, S.; Esen, C.; Hellmann, R. Laser turning with ultrashort laser pulses. J. Manuf. Process. 2021, 68, 1562–1568. [Google Scholar] [CrossRef]

- Dhupal, D.; Doloi, B.; Bhattacharyya, B. Modeling and optimization on Nd:YAG laser turned micro-grooving of cylindrical ceramic material. Opt. Lasers Eng. 2009, 47, 917–925. [Google Scholar] [CrossRef]

- Kibria, G.; Doloi, B.; Bhattacharyya, B. Investigation into the effect of overlap factors and process parameters on surface roughness and machined depth during micro-turning process with Nd:YAG laser. Opt. Laser Technol. 2014, 60, 90–98. [Google Scholar] [CrossRef]

- Zettl, J.; Esen, C.; Hellmann, R. Fundamental considerations and analysis of the energy distribution in laser turning with ultrashort laser pulses. Micromachines 2023, 14, 1838. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Fleming, T.G.; Clark, S.J.; Fezzaa, K.; Getley, A.C.M.; Marussi, S.; Wang, H.; Leung, C.L.A.; Kao, A.; Lee, P.D. Magnetic modulation of keyhole instability during laser welding and additive manufacturing. Science 2025, 387, 864–869. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Guo, W.; Li, H.; Xie, Y.; Shi, J.; Liang, Z.; Han, P.; Li, S.; Zhang, H. Nano-scale microstructural evolution and mechanical property enhancement mechanism during crack inhibition in nickel-based superalloys fabricated by laser powder bed fusion. Addit. Manuf. 2025, 100, 104685. [Google Scholar] [CrossRef]

- Shannon, G.; Hypsh, S. Femtosecond Lasers Improve Processing of Metal, Plastic Parts. Available online: https://www.assemblymag.com/articles/93059-femtosecond-lasers-improve-processing-of-metal-plastic-parts (accessed on 21 May 2025).

- Sun, S.; Brandt, M. Laser beam machining. In Nontraditional Machining Processes: Research Advances; Davim, J.P., Ed.; Springer: London, UK, 2013; pp. 35–96. [Google Scholar]

| Element | Fe | Cr | Ni | Mn | Si | C | P | S |

|---|---|---|---|---|---|---|---|---|

| Min. (%) | 63.8 | 19.5 | 9 | 1 | 0.25 | - | - | - |

| Max. (%) | 70.5 | 22 | 11 | 2.5 | 0.6 | 0.080 | 0.030 | 0.030 |

| Tensile Strength (MPa) | Yield Strength (MPa) | Modulus of Elasticity (GPa) | Poisson’s Ratio | Elongation (%) |

|---|---|---|---|---|

| 593 | 207 | 190–210 | 0.27–0.30 | 48 |

| Laser Type | Nanosecond Laser |

|---|---|

| Average output power (W) | 50 |

| Wavelength (nm) | 1060~1085 |

| Pulse duration (ns) | 120~150@50 kHz |

| Sample Group | Number of Passes | Frequency (kHz) | Scanning Speed (mm/s) |

|---|---|---|---|

| 1 | 1 | 50 | 6400 |

| 2 | 4 | 50 | 6400 |

| 3 | 16 | 50 | 6400 |

| 4 | 32 | 50 | 6400 |

| 5 | 1 | 100 | 6400 |

| 6 | 4 | 100 | 6400 |

| 7 | 16 | 100 | 6400 |

| 8 | 32 | 100 | 6400 |

| 9 | 1 | 200 | 6400 |

| 10 | 4 | 200 | 6400 |

| 11 | 16 | 200 | 6400 |

| 12 | 32 | 200 | 6400 |

| 13 | 1 | 50 | 3200 |

| 14 | 4 | 50 | 3200 |

| 15 | 16 | 50 | 3200 |

| 16 | 32 | 50 | 3200 |

| 17 | 1 | 100 | 3200 |

| 18 | 4 | 100 | 3200 |

| 19 | 16 | 100 | 3200 |

| 20 | 32 | 100 | 3200 |

| 21 | 1 | 200 | 3200 |

| 22 | 4 | 200 | 3200 |

| 23 | 16 | 200 | 3200 |

| 24 | 32 | 200 | 3200 |

| Frequency | Fitted Curve | R2 |

|---|---|---|

| 50 kHz | 0.9995 | |

| 100 kHz | 0.9937 | |

| 200 kHz | 0.9959 |

| NUMBER OF PASSES | COEFFICIENTS | ||||

|---|---|---|---|---|---|

| CONSTANT NUMBER | F | V | F2 | F.V | |

| 1 | +0.00382 | +0.00004 | −0.000020 | +0.000020 | −0.000030 |

| 4 | +0.0588 | −0.00020 | + 0.000006 | +0.000002 | −0.000009 |

| 16 | +0.2760 | −0.00140 | −0.000067 | +0.000004 | −0.000010 |

| 32 | +0.5464 | −0.00280 | −0.000100 | +0.000020 | −0.000070 |

| BAND OF PASSES | ΔN | ΔC | ΔV | ΔF/ΔF2 | Δ(F.V) |

| 1–4 | +4 | +15.39 | +1.3 | +6/−0.9 | −0.9 |

| 4–16 | +4 | +4.69 | +12.16 | +6/+2 | +0.1 |

| 16–32 | +2 | +2.085 | +1.49 | +2/+4 | +6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bastekeli, E.O.; Tasdemir, H.A.; Yucel, A.; Bastekeli, B.O. Experimental and Numerical Analyses of Diameter Reduction via Laser Turning with Respect to Laser Parameters. J. Manuf. Mater. Process. 2025, 9, 258. https://doi.org/10.3390/jmmp9080258

Bastekeli EO, Tasdemir HA, Yucel A, Bastekeli BO. Experimental and Numerical Analyses of Diameter Reduction via Laser Turning with Respect to Laser Parameters. Journal of Manufacturing and Materials Processing. 2025; 9(8):258. https://doi.org/10.3390/jmmp9080258

Chicago/Turabian StyleBastekeli, Emin O., Haci A. Tasdemir, Adil Yucel, and Buse Ortac Bastekeli. 2025. "Experimental and Numerical Analyses of Diameter Reduction via Laser Turning with Respect to Laser Parameters" Journal of Manufacturing and Materials Processing 9, no. 8: 258. https://doi.org/10.3390/jmmp9080258

APA StyleBastekeli, E. O., Tasdemir, H. A., Yucel, A., & Bastekeli, B. O. (2025). Experimental and Numerical Analyses of Diameter Reduction via Laser Turning with Respect to Laser Parameters. Journal of Manufacturing and Materials Processing, 9(8), 258. https://doi.org/10.3390/jmmp9080258