Knowledge Generation of Wire Laser-Beam-Directed Energy Deposition Process Combining Process Data and Metrology Responses

Abstract

1. Introduction

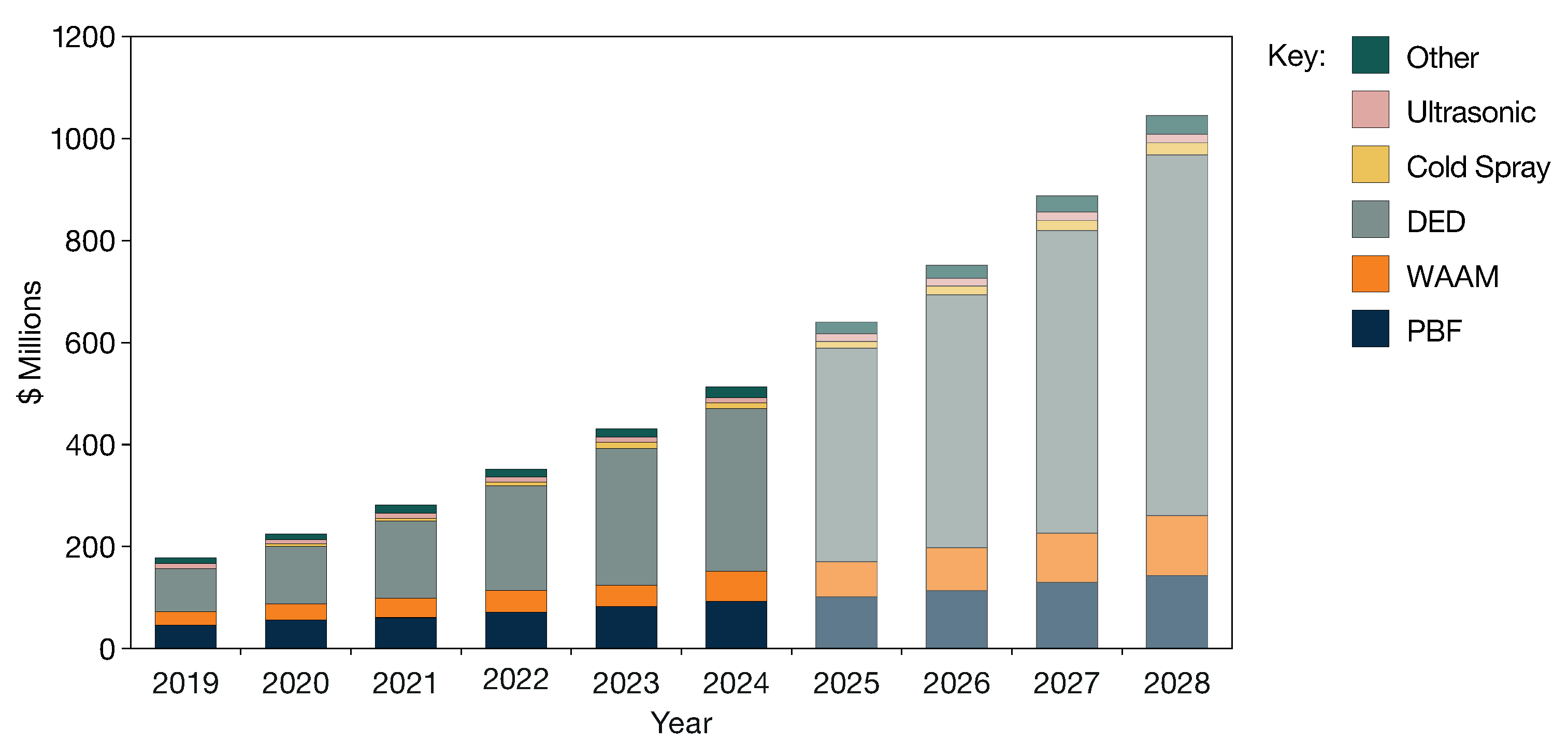

1.1. Directed Energy Deposition (DED) Market Adoption

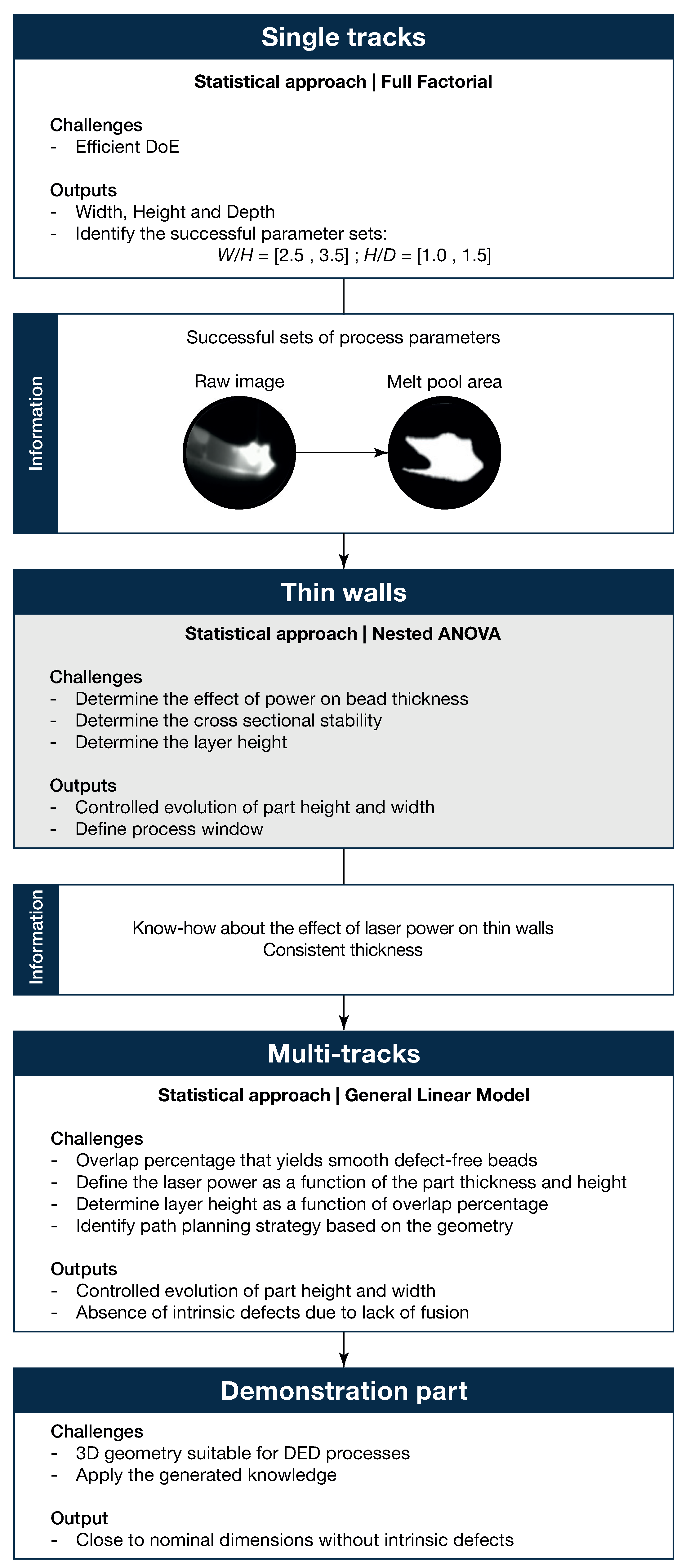

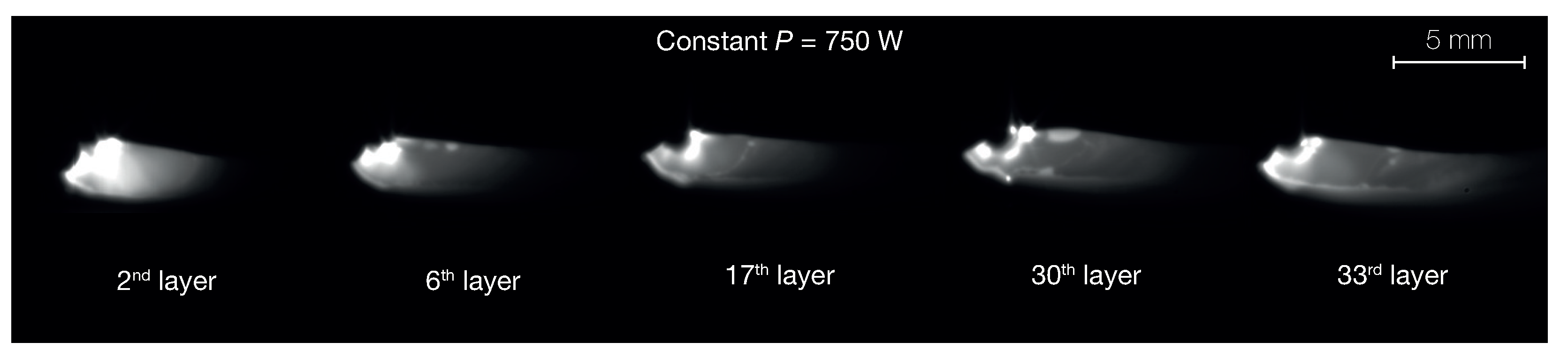

1.2. Wire DED-LB Process Window Development

2. State of Practice on Part Inspection

3. Experimental Set-Up

4. Materials and Methods

4.1. Selection of Sample Geometry

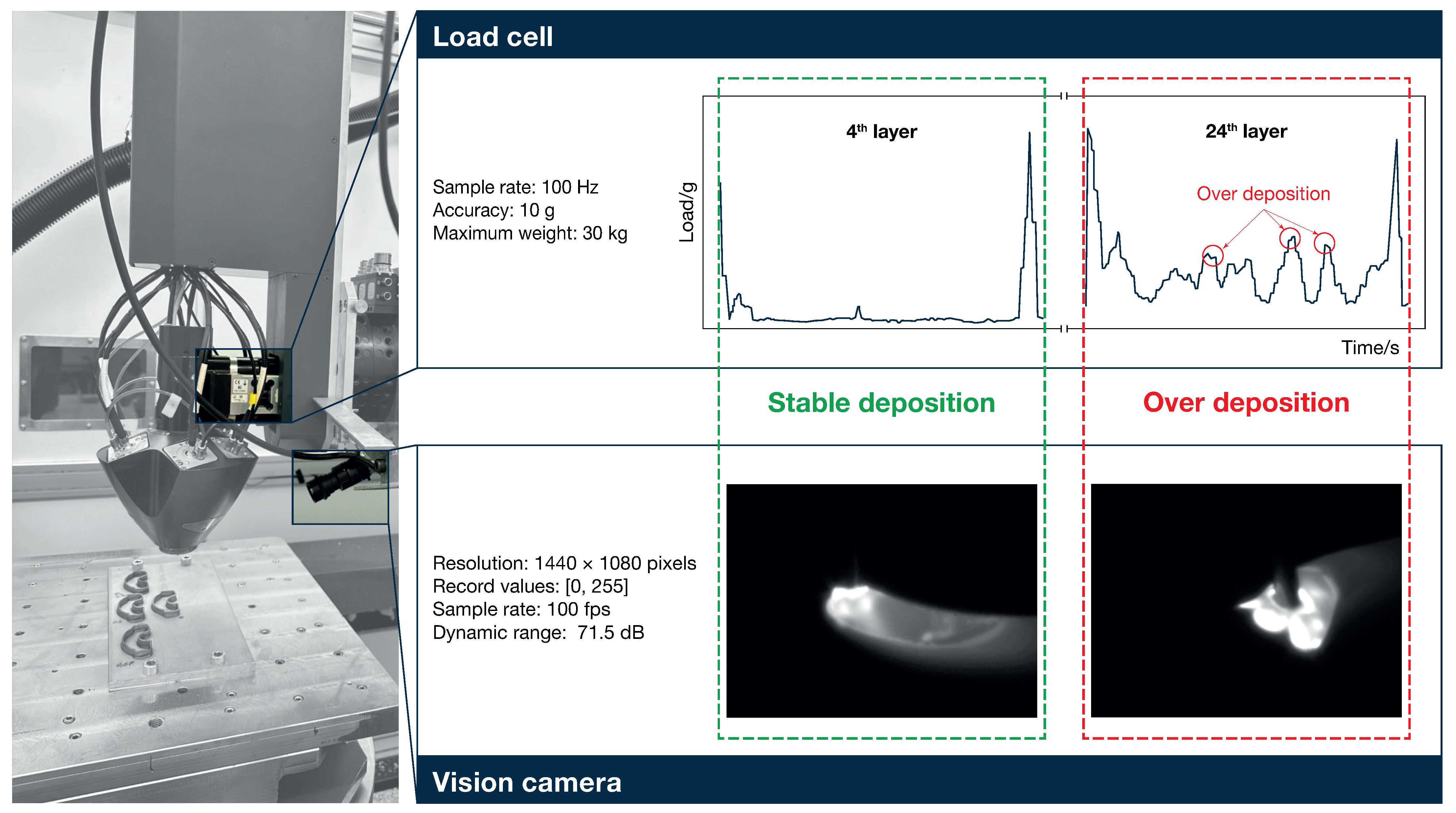

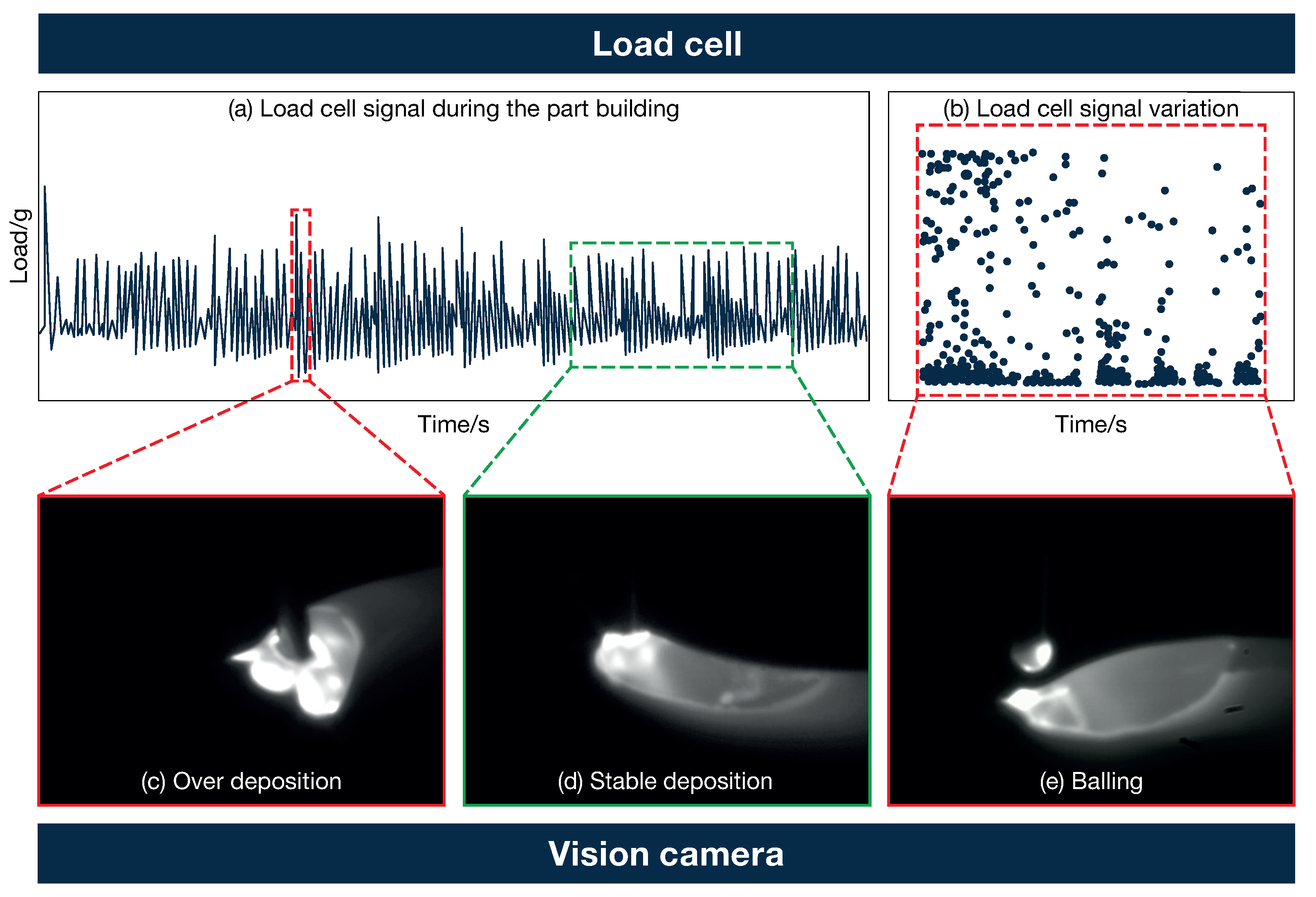

4.2. Wire DED-LB Process Phenomena and Their Effect on Process Stability

4.3. Thin-Wall Development as a Multi-Factorial Problem

4.4. Challenges on the Data Analysis

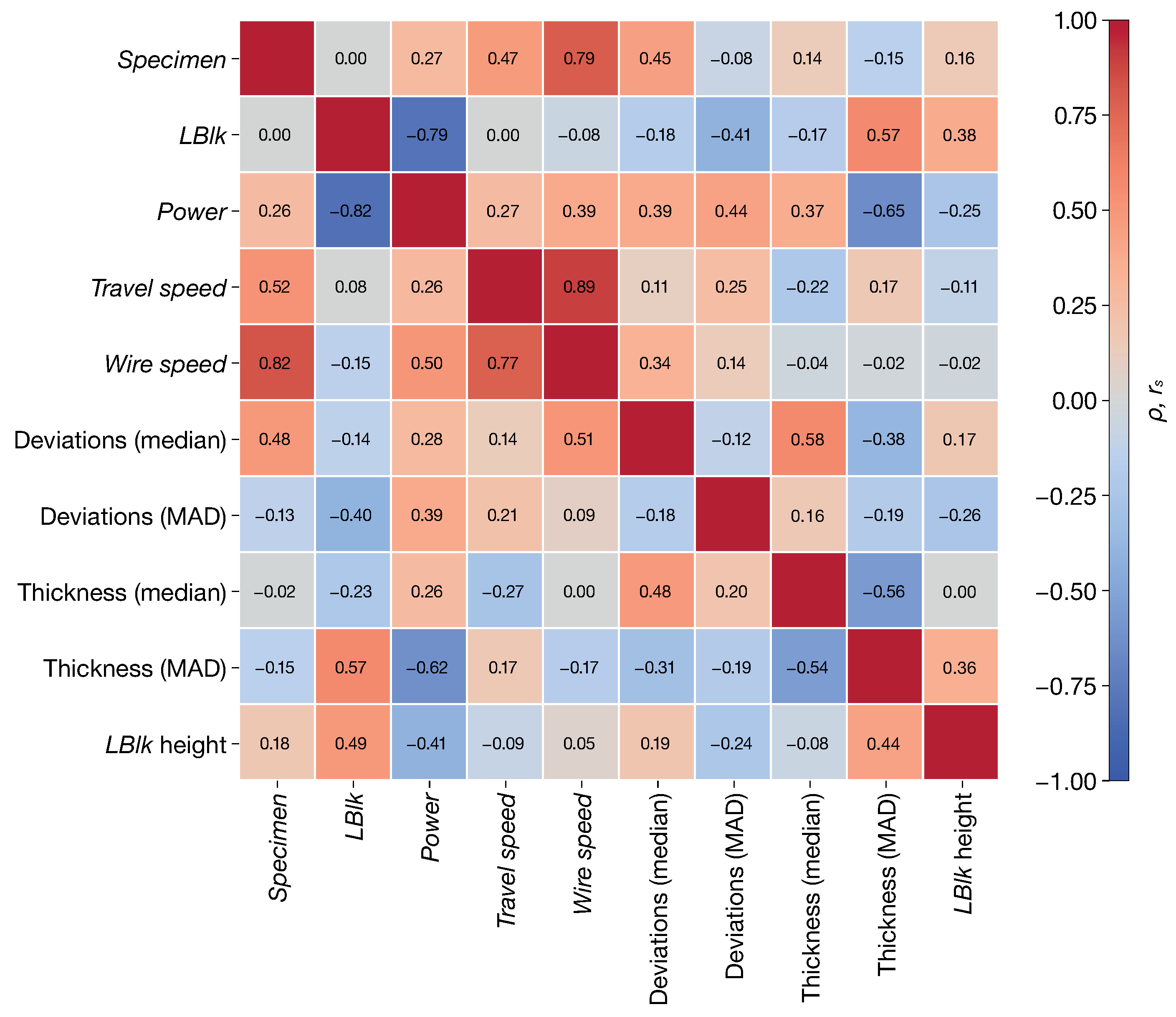

4.5. Structure of Statistical Model

5. Results and Discussion

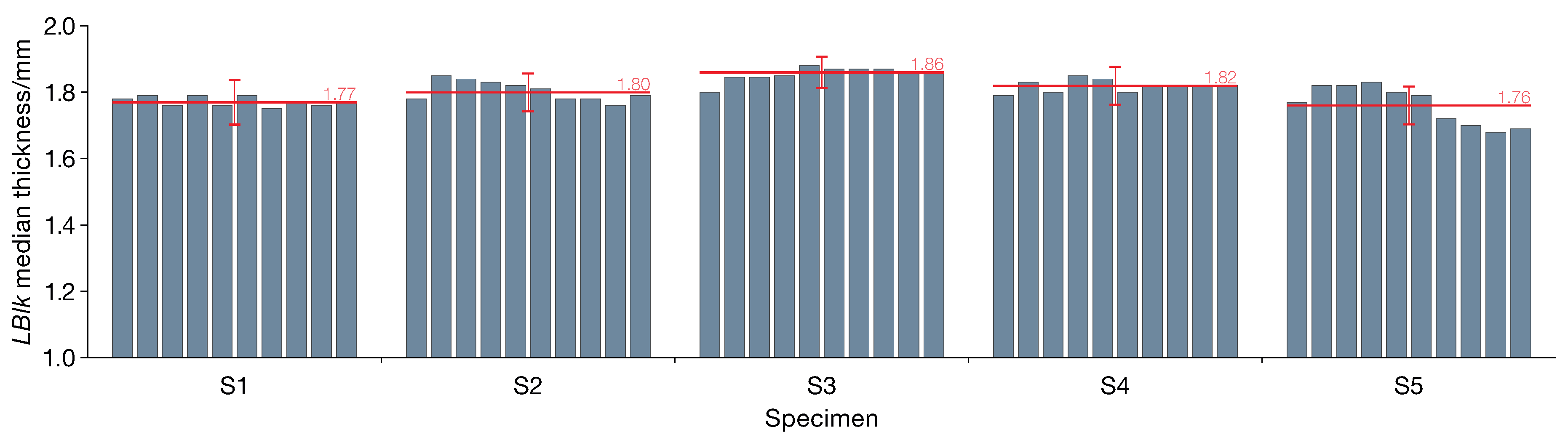

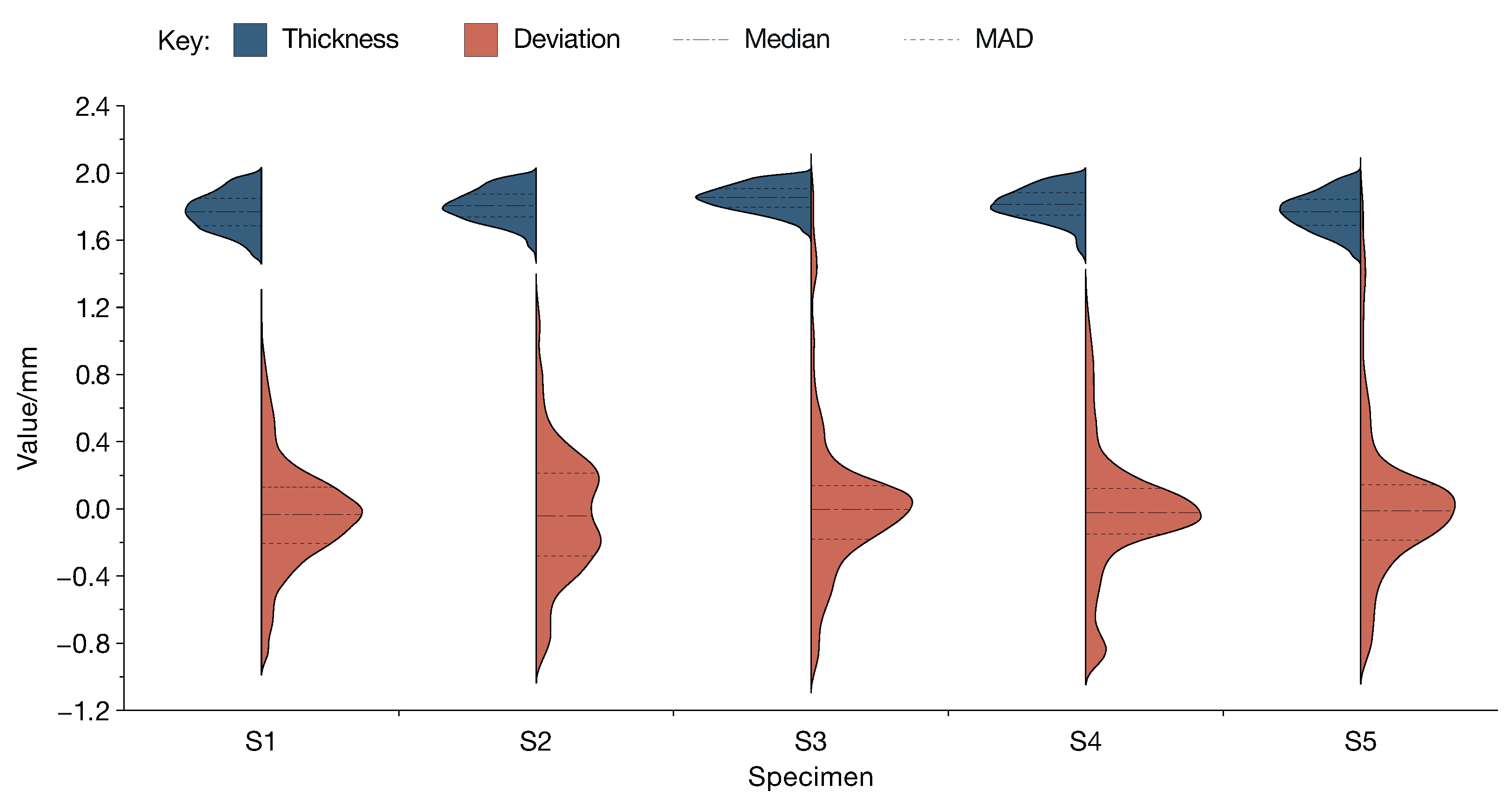

5.1. Thickness Analysis

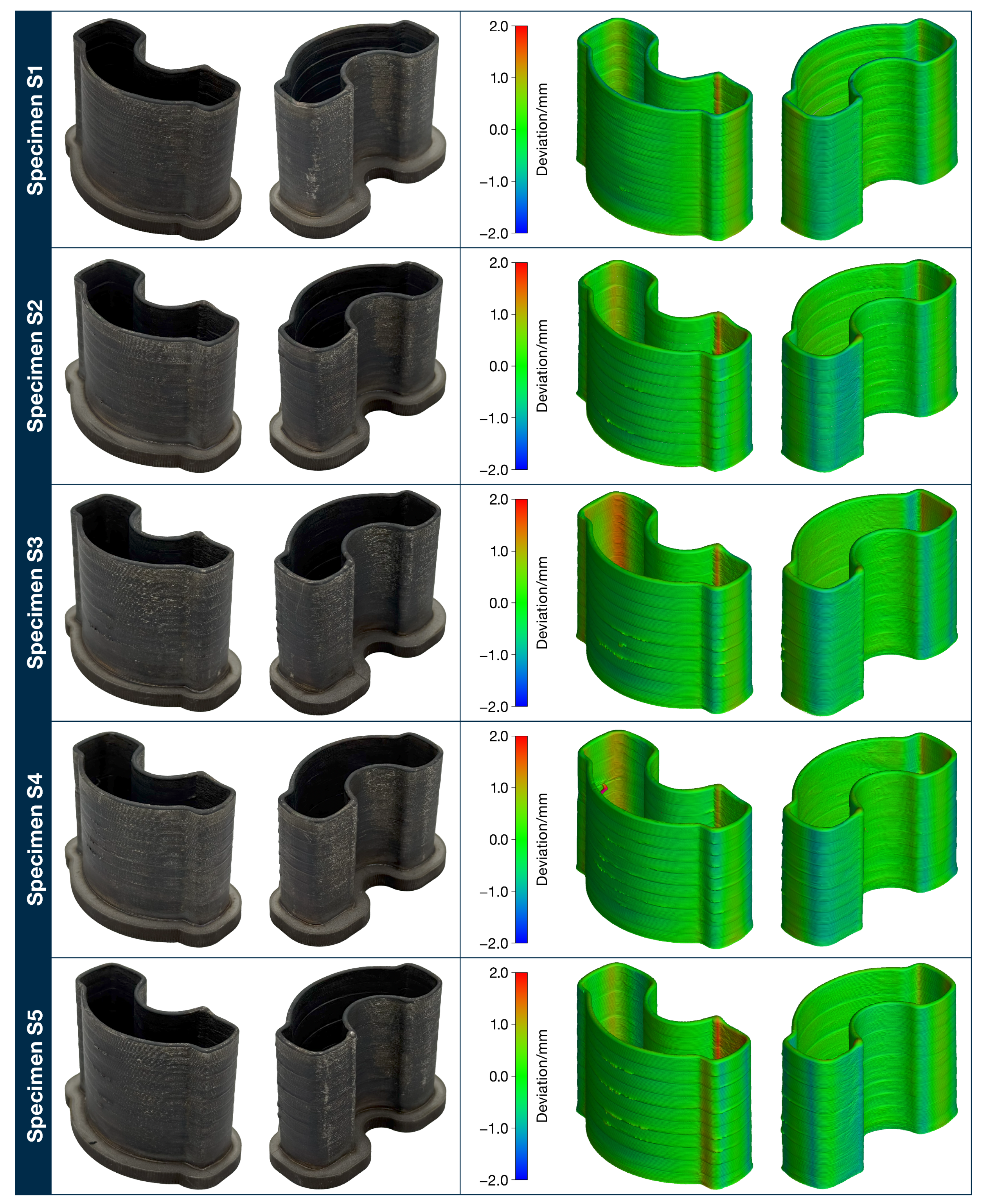

5.2. Surface Deviation Analysis

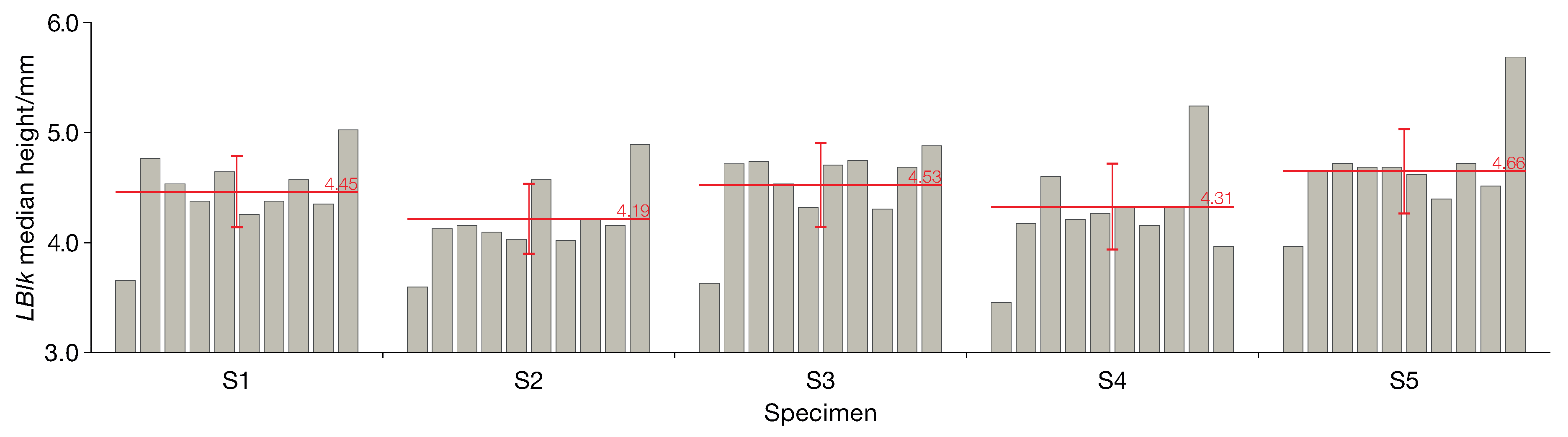

5.3. Height Analysis

6. Conclusions

- A clear relationship was identified between the laser power decay strategy and cross-sectional stability, offering insights into which levels of power reduction lead to process stability without compromising bead width.

- The analysis of height response highlighted a direct correlation with bead width, underlining the importance of maintaining a continuous and consistent mass flow throughout the build.

- It was observed that the process should first reach a plateau in heat accumulation, which corresponds to a shift in the heat diffusion mechanism from the substrate toward the deposited material. Only after this condition is met should the laser power be reduced. Otherwise, a premature drop in energy input may cause narrower and taller beads, increasing the risk of lack of fusion and cumulative geometric instability.

- The investigation also defined the acceptable range of laser power reduction, identifying thresholds beyond which reduced heat input degrades process stability.

- Although based on thin-wall geometries, the insights obtained are transferable to the deposition of solid parts. The effect of laser power on bead dimensions follows the same underlying thermal principles, even with different control strategies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DED-LB | Laser-Beam-Directed Energy Deposition |

| AM | Additive Manufacturing |

| CT | Computed Tomography |

| ANOVA | Analysis of Variance |

| SMEs | Small–medium enterprises |

| 3D CAD | Three-dimensional Computer-aided design |

| DED | Directed Energy Deposition |

| DfAM | Design for Additive Manufacturing |

| PBF | Powder Bed Fusion |

| WAAM | Wire Arc DED |

| PPE | Personal Protective Equipment |

| HAZ | Heat affected zone |

| SoD | standoff distance |

| P | Laser Power |

| CMM | Coordinate-Measuring Machines |

| wire EDM | Wire Electrical Discharge Machining |

| FOV | field of view |

| KPIs | Key performance indicators |

| Layers Block | |

| v | Robot scan speed |

| Wire Feed Rate | |

| MAD | Median absolute deviation |

| Sum of Square | |

| Mean Square | |

| GLS | Generalized Least Squares |

| AR(1) | Autoregressive model of order 1 |

| SL | Significance level |

References

- Porevopoulos, N.; Tzimanis, K.; Souflas, T.; Bikas, H.; Panagiotopoulou, V.C.; Stavropoulos, P. Decision support for repair with DED AM processes based on sustainability and techno-economical evaluation. Procedia CIRP 2024, 130, 9–14. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Gardner Business Media, Inc. AM for Repair of Large Shafts. Additive Manufacturing by Gardner Business Media. 2025. Available online: https://www.additivemanufacturing.media/articles/video-am-for-repair-of-large-shafts (accessed on 17 June 2025).

- SmarTech Analysis. Industry Analysis, Market Forecasting and Data for the Additive Manufacturing Business; SmarTech Publishing: Charlottesville, VA, USA, 2024; Available online: https://www.smartechpublishing.com (accessed on 16 November 2024).

- Stavropoulos, P.; Bikas, H.; Souflas, T.; Tzimanis, K.; Papaioannou, C.; Porevopoulos, N. Additive Manufacturing in the Automotive Industry. In 3D Printing. Fundamentals to Emerging Applications; Gupta, R.K., Ed.; CRC Press: Boca Raton, FL, USA, 2023; pp. 453–470. [Google Scholar] [CrossRef]

- Surmen, H.; Ortes, F.; Arslan, Y.Z. Fundamentals of 3D Printing and Its Applications in Biomedical Engineering. In 3D Printing Applications in Biomedical Engineering; Springer: Singapore, 2020; pp. 23–41. [Google Scholar] [CrossRef]

- NASA. Principles of Directed Energy Deposition for Aerospace Applications. NASA Technical Reports Server. 2025. Available online: https://ntrs.nasa.gov/ (accessed on 17 June 2025).

- Stavropoulos, P. AM Applications. In Additive Manufacturing: Design, Processes and Applications; Springer International Publishing: Cham, Switzerland, 2023; pp. 95–121. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Pastras, G.; Tzimanis, K.; Bourlesas, N. Addressing the challenge of process stability control in wire DED-LB/M process. CIRP Ann. 2024, 73, 129–132. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Associates, W. Wohlers Report 2023. Available online: https://wohlersassociates.com/product/wr2023/ (accessed on 24 September 2023).

- Holdings, D. The Leading Source of Industry Analysis, Market Forecasting and Data for the Additive Manufacturing Business. Available online: https://additivemanufacturingresearch.com/ (accessed on 6 December 2024).

- Digital Media Innovations, LLC. Hybrid Manufacturing Markets. GlobeNewswire by Notified. 2024. Available online: https://www.globenewswire.com/NewsRoom/AttachmentNg/bd835b5c-4818-4c99-ab1d-e2fa31d4b16b (accessed on 6 December 2024).

- Technologies, F. Printing and Certifying AM Propellers: The Future of Large Component Repair and Manufacture. 2024. Available online: https://www.faro.com/en/Resource-Library/Case-Study/printing-certifying-am-propellers-the-future-of-large-component-repair-manufacture (accessed on 8 March 2024).

- Additive Manufacturing Media. How Additive Manufacturing Plus Robotic Finishing Will Expand Capacity for Blade Repair. 2024. Available online: https://www.additivemanufacturing.media/articles/turbine-blade-mro-how-additive-manufacturing-plus-robot-finishing-will-scale-repair (accessed on 24 March 2024).

- Stavropoulos, P.; Bikas, H.; Tzimanis, K.; Porevopoulos, N.; Pilagatti, A.N.; Atzeni, E.; Iuliano, L.; Salmi, A. Process window development of DED-LB/M process with coaxial wire for stainless steel AISI 316L. Int. J. Exp. Des. Process Optim. 2024, 7, 1–26. [Google Scholar] [CrossRef]

- Rey, P.; Prieto, C.; González, C.; Tzimanis, K.; Souflas, T.; Stavropoulos, P.; Rathore, J.S.; Bergeaud, V.; Vienne, C.; Bredif, P. Data analysis to assess part quality in DED-LB/M based on in-situ process monitoring. Procedia CIRP 2022, 111, 345–350. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Liao, S.; Jeong, J.; Zha, R.; Xue, T.; Cao, J. Simulation-guided feedforward-feedback control of melt pool temperature in directed energy deposition. CIRP Ann. 2023, 72, 157–160. [Google Scholar] [CrossRef]

- Hirono, Y.; Mori, T.; Sugimoto, S.; Miyata, Y. Investigation on influence of thermal history on quality of workpiece created by directed energy deposition. CIRP Ann. 2024, 73, 133–136. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Pastras, G.; Souflas, T.; Tzimanis, K.; Bikas, H. A Computationally Efficient Multi-Scale Thermal Modelling Approach for PBF-LB/M Based on the Enthalpy Method. Metals 2022, 12, 1853. [Google Scholar] [CrossRef]

- Gapinski, B.; Janicki, P.; Marciniak-Podsadna, L.; Jakubowicz, M. Application of the Computed Tomography to Control Parts Made on Additive Manufacturing Process. Procedia Eng. 2016, 149, 105–121. [Google Scholar] [CrossRef]

- Piscopo, G.; Salmi, A.; Atzeni, E. Investigation of dimensional and geometrical tolerances of laser powder directed energy deposition process. Precis. Eng. 2024, 85, 217–225. [Google Scholar] [CrossRef]

- Jardon, Z.; Ertveldt, J.; Hinderdael, M.; Guillaume, P. Process parameter study for enhancement of directed energy deposition powder efficiency based on single-track geometry evaluation. J. Laser Appl. 2021, 33, 042023. [Google Scholar] [CrossRef]

- Savio, E.; De Chiffre, L.; Schmitt, R. Metrology of freeform shaped parts. CIRP Ann. 2007, 56, 810–835. [Google Scholar] [CrossRef]

- Mueller, K.; Xu, F.; Neophytou, N. Why do commodity graphics hardware boards (GPUs) work so well for acceleration of computed tomography? In Computational Imaging V; Bouman, C.A., Miller, E.L., Pollak, I., Eds.; International Society for Optics and Photonics, SPIE: San Jose, CA, USA, 2007; Volume 6498, pp. 183–194. [Google Scholar] [CrossRef]

- Kruth, J.; Bartscher, M.; Carmignato, S.; Schmitt, R.; De Chiffre, L.; Weckenmann, A. Computed tomography for dimensional metrology. CIRP Ann. 2011, 60, 821–842. [Google Scholar] [CrossRef]

- Acko, B. Calibration of measuring instruments on a coordinate measuring machine. Adv. Prod. Eng. Manag. 2007, 2, 4–127. [Google Scholar]

- Trapet, E.; Savio, E.; De Chiffre, L. New advances in traceability of CMMs for almost the entire range of industrial dimensional metrology needs. CIRP Ann. 2004, 53, 433–438. [Google Scholar] [CrossRef]

- Rocchini, C.; Cignoni, P.; Montani, C.; Pingi, P.; Scopigno, R. A low cost 3D scanner based on structured light. Comput. Graph. Forum 2001, 20, 299–308. [Google Scholar] [CrossRef]

- Withers, P.J.; Bouman, C.; Carmignato, S.; Cnudde, V.; Grimaldi, D.; Hagen, C.K.; Maire, E.; Manley, M.; Du Plessis, A.; Stock, S.R. X-ray computed tomography. Nat. Rev. Methods Prim. 2021, 1, 18. [Google Scholar] [CrossRef]

- Calaon, M.; Yeh, H.P.; Shan, S.; Hattel, J.H.; Zhang, Y.; Hansen, H.N. Advancing quality prediction in polymer PBF-LB: A hybrid AI and physics-guided approach. CIRP Ann. 2025. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Alexopoulos, K.; Makris, S.; Papacharalampopoulos, A.; Dhondt, S.; Chryssolouris, G. AI in manufacturing and the role of humans: Processes, robots, and systems. In Handbook of Artificial Intelligence at Work; Edward Elgar Publishing: Cheltenham, UK, 2024; pp. 119–141. [Google Scholar] [CrossRef]

- Gao, R.X.; Krüger, J.; Merklein, M.; Möhring, H.C.; Váncza, J. Artificial Intelligence in manufacturing: State of the art, perspectives, and future directions. CIRP Ann. 2024, 73, 723–749. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Y.; Han, C.; Wei, Y.; Liu, Z.; Tai, Z.; Zhang, S.; Wang, D. Laser directed energy deposition/milling hybrid additive manufacturing of thin-walled GH4169 alloy: Effect of processing strategy on its microstructure and mechanical properties. Mater. Sci. Eng. A 2023, 882, 145480. [Google Scholar] [CrossRef]

- Gudur, S.; Shukla, S.; John Rozario Jegaraj, J.; Mastanaiah, P.; Gopinath, M.; Simhambhatla, S. Controlling Waviness in Additive Manufacturing of Thin Walls by Laser-Directed Energy Deposition Process; Springer Nature Singapore: Singapore, 2023; pp. 81–90. [Google Scholar] [CrossRef]

- Bourlesas, N.; Tzimanis, K.; Sabatakakis, K.; Bikas, H.; Stavropoulos, P. Over-deposition assessment of Direct Energy Deposition (DED) using melt pool geometric features and Machine Learning. Procedia CIRP 2024, 124, 797–802. [Google Scholar] [CrossRef]

- Ben Hammouda, A.; Mrad, H.; Marouani, H.; Frikha, A.; Belem, T. Process Optimization and Distortion Prediction in Directed Energy Deposition. J. Manuf. Mater. Process. 2024, 8, 116. [Google Scholar] [CrossRef]

- Ng, A.; Ma, T. Stanford University CS229 Lecture Notes. Available online: https://cs229.stanford.edu/main_notes.pdf (accessed on 1 July 2025).

- Hoaglin, D.; Mosteller, F.; Tukey, J. Understanding Robust and Exploratory Data Analysis; Wiley: New York, NY, USA, 1983. [Google Scholar]

- Bambach, M.; Sideris, I.; Fabbri, M.; Wegener, K. Faster than real-time path-sensitive temperature modeling of wire-arc additive manufacturing by a data-driven finite volume method. CIRP Ann. 2022, 71, 189–192. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Wits, W.W.; Carmignato, S.; Zanini, F.; Vaneker, T.H. Porosity testing methods for the quality assessment of selective laser melted parts. CIRP Ann. 2016, 65, 201–204. [Google Scholar] [CrossRef]

- Yao, M.; Kong, F. A review on laser cladding with wire feeding: Process fundamentals, theoretical analyses, online monitoring, and quality controls. Int. J. Adv. Manuf. Technol. 2025, 137, 4209–4242. [Google Scholar] [CrossRef]

- Genta, G.; Maculotti, G. Thin coatings thickness measurement by augmented nanoindentation data fusion. CIRP Ann. 2024, 73, 409–412. [Google Scholar] [CrossRef]

- Reinhart, C.; Weg, W. Industrial Computer Tomography: A Universal Inspection Tool. In Proceedings of the Industrial Computed Tomography Conference, Shanghai, China, 25–28 October 2008. [Google Scholar]

- Villarraga Gómez, H. Studies of Dimensional Metrology with X-ray CAT Scan. Ph.D. Thesis, University of North Carolina at Charlotte, Charlotte, NC, USA, 2018. [Google Scholar]

- Roberts, M.; Xia, M.; Kennedy, A. Data-driven Process Parameter Optimisation for Laser Wire Metal Additive Manufacturing. In Proceedings of the 2022 27th International Conference on Automation and Computing (ICAC), Bristol, UK, 1–3 September 2022. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Li, D.; Garmestani, H.; Liang, S.Y. Residual Stress Modeling Considering Microstructure Evolution in Metal Additive Manufacturing. J. Manuf. Process. 2021, 68, 383–397. [Google Scholar] [CrossRef]

- Jamnikar, N.; Liu, S.; Brice, C.; Zhang, X. Comprehensive Molten Pool Condition-Process Relations Modeling Using CNN for Wire-Feed Laser Additive Manufacturing. J. Manuf. Process. 2023, 98, 42–53. [Google Scholar] [CrossRef]

- Piscopo, G.; Atzeni, E.; Salmi, A.; Iuliano, L.; Gatto, A.; Marchiandi, G.; Balestrucci, A. Mesoscale modelling of laser powder-based directed energy deposition process. Procedia CIRP 2020, 88, 393–398. [Google Scholar] [CrossRef]

- Guan, X.; Zhao, Y.F. Modeling of the laser powder–based directed energy deposition process for additive manufacturing: A review. Int. J. Adv. Manuf. Technol. 2020, 107, 1959–1982. [Google Scholar] [CrossRef]

- Zapata, A.; Benda, A.; Spreitler, M.; Zhao, X.F.; Bernauer, C.; Yoshioka, H.; Zaeh, M.F. A Model-Based Approach to Reduce Kinematics-Related Overfill in Robot-Guided Laser Directed Energy Deposition. CIRP J. Manuf. Sci. Technol. 2023, 45, 200–209. [Google Scholar] [CrossRef]

- Verna, E.; Puttero, S.; Genta, G.; Galetto, M. Toward a concept of digital twin for monitoring assembly and disassembly processes. Qual. Eng. 2023, 36, 453–470. [Google Scholar] [CrossRef]

- Rossi Sebastiano, A.; Poles, K.; Gualtiero, S.; Romeo, M.; Galigani, M.; Bruno, V.; Fossataro, C.; Garbarini, F. Balancing the Senses: Electrophysiological Responses Reveal the Interplay between Somatosensory and Visual Processing During Body-Related Multisensory Conflict. J. Neurosci. 2024, 44, e1397232024. [Google Scholar] [CrossRef]

- Javidrad, H.; Aydin, H.; Karakaş, B.; Alptekin, S.; Kahraman, A.S.; Koc, B. Process Parameter Optimization for Laser Powder Directed Energy Deposition of Inconel 738LC. Opt. Laser Technol. 2024, 176, 110940. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Steinberg, D.M.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. The Influence of Laser Directed Energy Deposition (DED) Processing Parameters for Al5083 Studied by Central Composite Design. J. Mater. Res. Technol. 2022, 17, 3157–3171. [Google Scholar] [CrossRef]

- Gibson, B.T.; Bandari, Y.K.; Richardson, B.S.; Roschli, A.C.; Post, B.K.; Borish, M.C.; Thornton, A.; Henry, W.C.; Lamsey, M.; Love, L.J. Melt Pool Monitoring for Control and Data Analytics in Large-Scale Metal Additive Manufacturing. In Proceedings of the International Solid Freeform Fabrication Symposium (SFF 2019), Austin, TX, USA, 12–14 August 2019; pp. 1–19. [Google Scholar]

- Liu, Y.; Wang, L.; Brandt, M. Model Predictive Control of Laser Metal Deposition. Int. J. Adv. Manuf. Technol. 2019, 105, 1055–1067. [Google Scholar] [CrossRef]

| Inspection System | Advantages | Limitations | References |

|---|---|---|---|

| Contact Systems | High accuracy for accessible and regular surfaces | Limited by surface roughness and difficulty in accessing complex geometries | [30] |

| 3D Vision/Scanning Systems | Well-suited for freeform surfaces, fast acquisition times | Challenges with internal features, shadowed areas, and reflective surfaces | [26,31] |

| X-ray CT | Comprehensive inspection of internal and external surfaces, with material structure analysis | Long acquisition times, and higher costs | [32,33] |

| Specimen | LBlk | P/W | v/(mm·s−1) | /(mm·s−1) |

|---|---|---|---|---|

| S1 | 1 | 800 | 11 | 10 |

| 2 | 750 | 11 | 10 | |

| 3 | 700 | 11 | 10 | |

| 4 | 700 | 11 | 10 | |

| 5 | 650 | 11 | 10 | |

| 6 | 650 | 11 | 10 | |

| 7 | 620 | 11 | 10 | |

| 8 | 620 | 11 | 10 | |

| 9 | 620 | 11 | 10 | |

| 10 | 620 | 11 | 10 | |

| S2 | 1 | 950 | 13.1 | 11.9 |

| 2 | 850 | 13.1 | 11.9 | |

| 3 | 850 | 13.1 | 11.3 | |

| 4 | 800 | 13.1 | 11.3 | |

| 5 | 750 | 13.1 | 11.3 | |

| 6 | 750 | 13.1 | 11.3 | |

| 7 | 700 | 13.1 | 11.3 | |

| 8 | 700 | 13.1 | 11.3 | |

| 9 | 660 | 13.1 | 11.3 | |

| 10 | 660 | 13.1 | 11.3 | |

| S3 | 1 | 900 | 11 | 11 |

| 2 | 850 | 11 | 11 | |

| 3 | 775 | 11 | 11 | |

| 4 | 700 | 11 | 11 | |

| 5 | 720 | 11 | 11 | |

| 6 | 720 | 11 | 11 | |

| 7 | 720 | 11 | 11 | |

| 8 | 720 | 11 | 11 | |

| 9 | 720 | 11 | 11 | |

| 10 | 700 | 11 | 11 | |

| S4 | 1 | 900 | 12.4 | 11.3 |

| 2 | 850 | 12.4 | 11.3 | |

| 3 | 775 | 12.4 | 11.3 | |

| 4 | 750 | 12.4 | 11.3 | |

| 5 | 700 | 12.4 | 11.3 | |

| 6 | 650 | 12.4 | 11.3 | |

| 7 | 650 | 12.4 | 11.3 | |

| 8 | 650 | 12.4 | 11.3 | |

| 9 | 670 | 12.4 | 11.3 | |

| 10 | 670 | 12.4 | 11.3 | |

| S5 | 1 | 950 | 13.1 | 13.1 |

| 2 | 900 | 13.1 | 13.1 | |

| 3 | 850 | 13.1 | 13.1 | |

| 4 | 800 | 13.1 | 13.1 | |

| 5 | 800 | 13.1 | 12.5 | |

| 6 | 750 | 13.1 | 12.5 | |

| 7 | 700 | 13.1 | 12 | |

| 8 | 670 | 13.1 | 12 | |

| 9 | 670 | 13.1 | 12 | |

| 10 | 670 | 13.1 | 12 |

| CT Parameter | Value |

|---|---|

| Voltage, V/ | 200 |

| Current, I/ | 140 |

| Filter | 0.5 mm of Sn |

| Timing/ms | 333 |

| Averaging | 3 |

| Skip frames | 2 |

| Source | df | Contribution/% | SS | MS | F | p-Value/% |

|---|---|---|---|---|---|---|

| Specimen | 4 | 16.81 | 0.434 | 0.109 | 6.41 | 0.01 |

| P | 1 | 2.71 | 0.070 | 0.070 | 4.12 | 4.53 |

| v | 1 | 8.33 | 0.215 | 0.215 | 12.65 | 0.06 |

| WFR | 1 | 10.11 | 0.261 | 0.261 | 15.35 | 0.02 |

| Error | 92 | 64.90 | 1.602 | 0.017 | ||

| Total | 99 | 100.00 | 2.582 |

| Source | df | Contribution/% | SS | MS | F | p-Value/% |

|---|---|---|---|---|---|---|

| Specimen | 4 | 0.16 | 0.030 | 0.008 | 6.09 | <0.01 |

| P | 1 | 22.61 | 4.272 | 4.272 | 32.12 | <0.01 |

| v | 1 | 6.51 | 1.230 | 1.230 | 9.25 | 0.31 |

| WFR | 1 | 5.83 | 1.101 | 1.101 | 8.28 | 0.49 |

| Error | 92 | 64.90 | 12.262 | 0.133 | ||

| Total | 99 | 100.00 | 18.895 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pilagatti, A.N.; Atzeni, E.; Salmi, A.; Tzimanis, K.; Porevopoulos, N.; Stavropoulos, P. Knowledge Generation of Wire Laser-Beam-Directed Energy Deposition Process Combining Process Data and Metrology Responses. J. Manuf. Mater. Process. 2025, 9, 230. https://doi.org/10.3390/jmmp9070230

Pilagatti AN, Atzeni E, Salmi A, Tzimanis K, Porevopoulos N, Stavropoulos P. Knowledge Generation of Wire Laser-Beam-Directed Energy Deposition Process Combining Process Data and Metrology Responses. Journal of Manufacturing and Materials Processing. 2025; 9(7):230. https://doi.org/10.3390/jmmp9070230

Chicago/Turabian StylePilagatti, Adriano Nicola, Eleonora Atzeni, Alessandro Salmi, Konstantinos Tzimanis, Nikolas Porevopoulos, and Panagiotis Stavropoulos. 2025. "Knowledge Generation of Wire Laser-Beam-Directed Energy Deposition Process Combining Process Data and Metrology Responses" Journal of Manufacturing and Materials Processing 9, no. 7: 230. https://doi.org/10.3390/jmmp9070230

APA StylePilagatti, A. N., Atzeni, E., Salmi, A., Tzimanis, K., Porevopoulos, N., & Stavropoulos, P. (2025). Knowledge Generation of Wire Laser-Beam-Directed Energy Deposition Process Combining Process Data and Metrology Responses. Journal of Manufacturing and Materials Processing, 9(7), 230. https://doi.org/10.3390/jmmp9070230