Low–Cost 3D–Printed Standard Gain Horn Antennas for Millimetre–Wave Applications

Abstract

1. Introduction

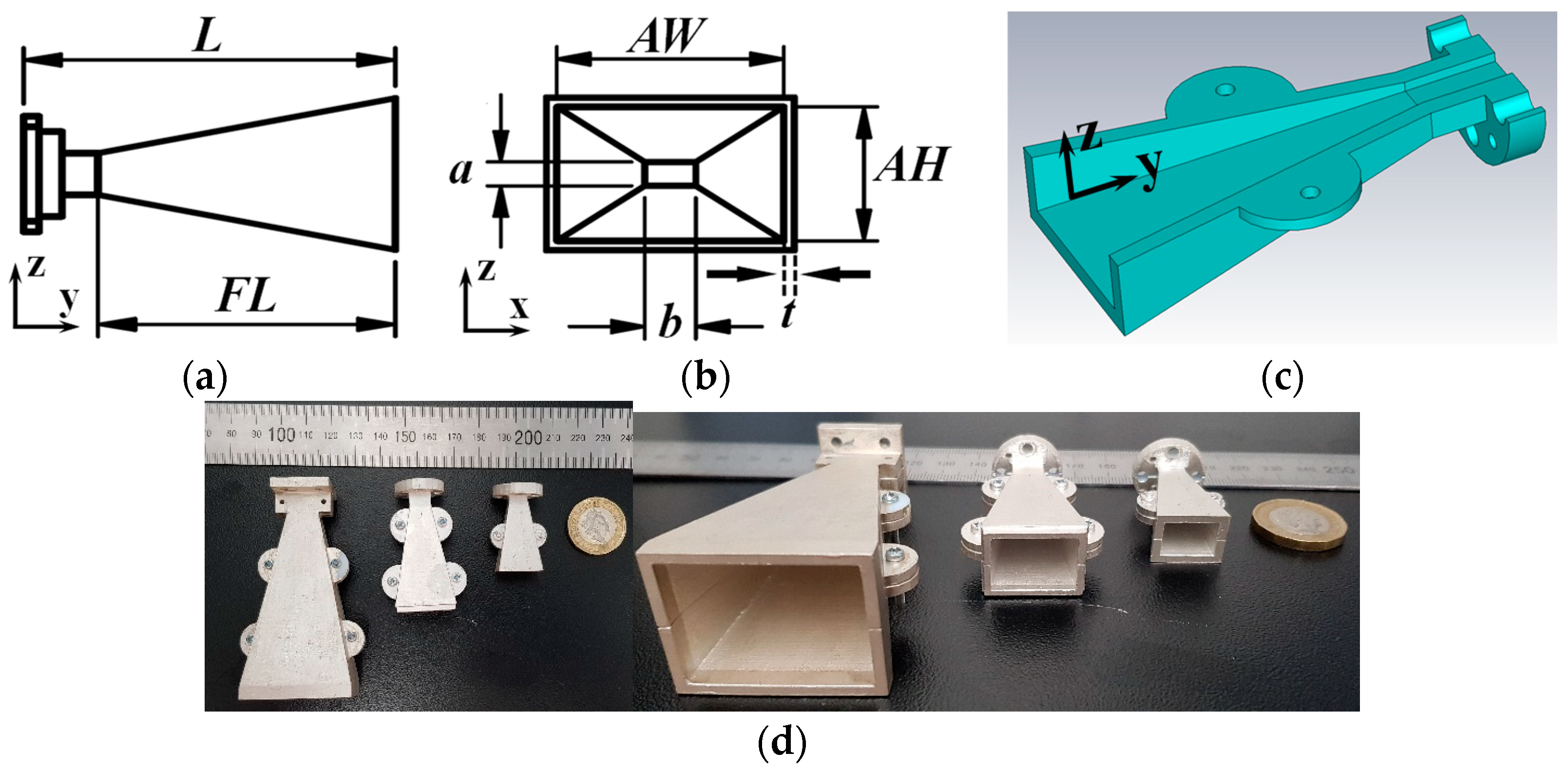

2. Antenna Structure

3. Manufacturing Method

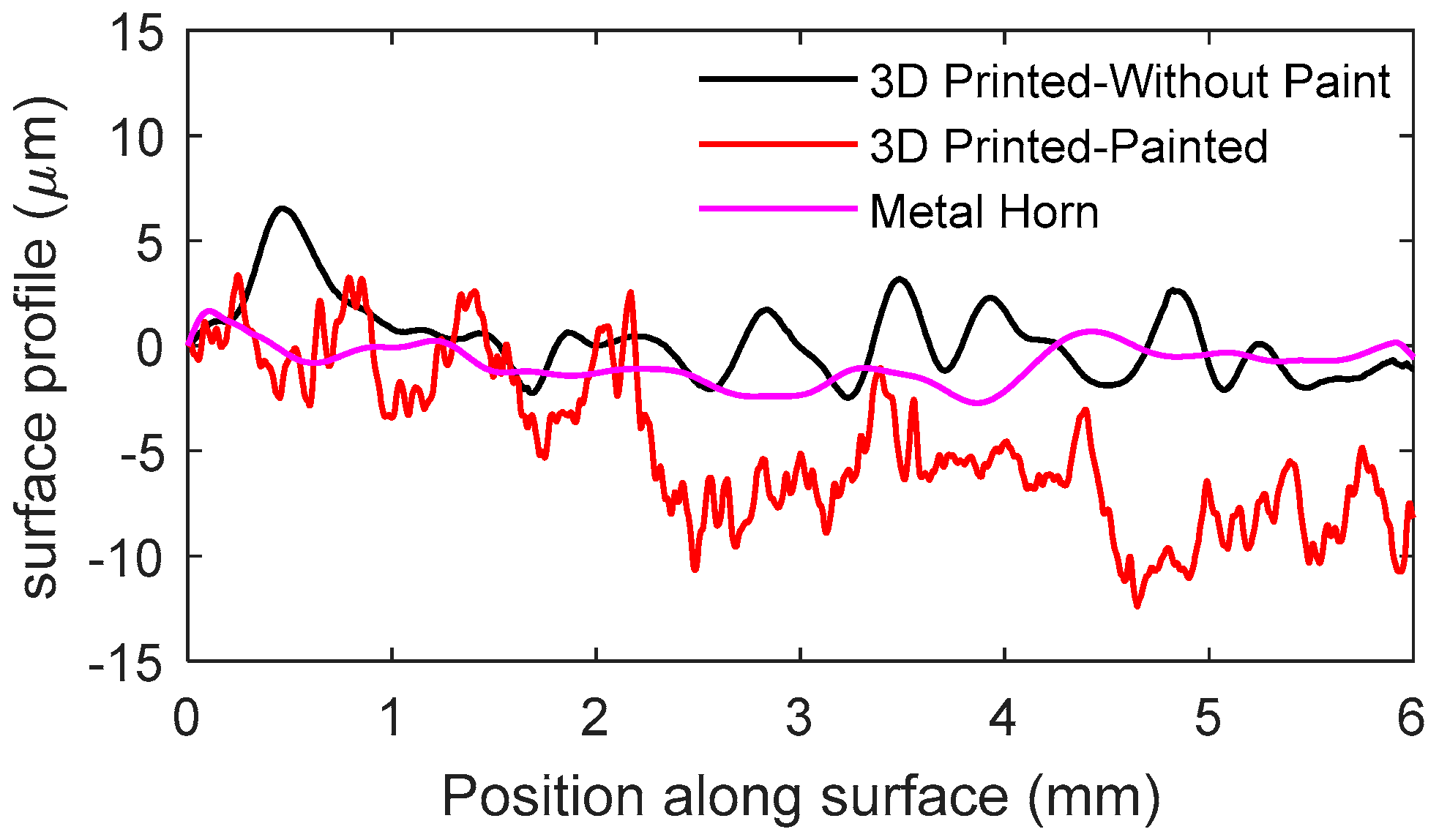

3.1. 3D–Printing

3.2. Metallization

3.3. Metallic Horns

3.4. Mechanical and Thermal Properities of the 3D–Printed Antennas

3.5. Fabrication Cost

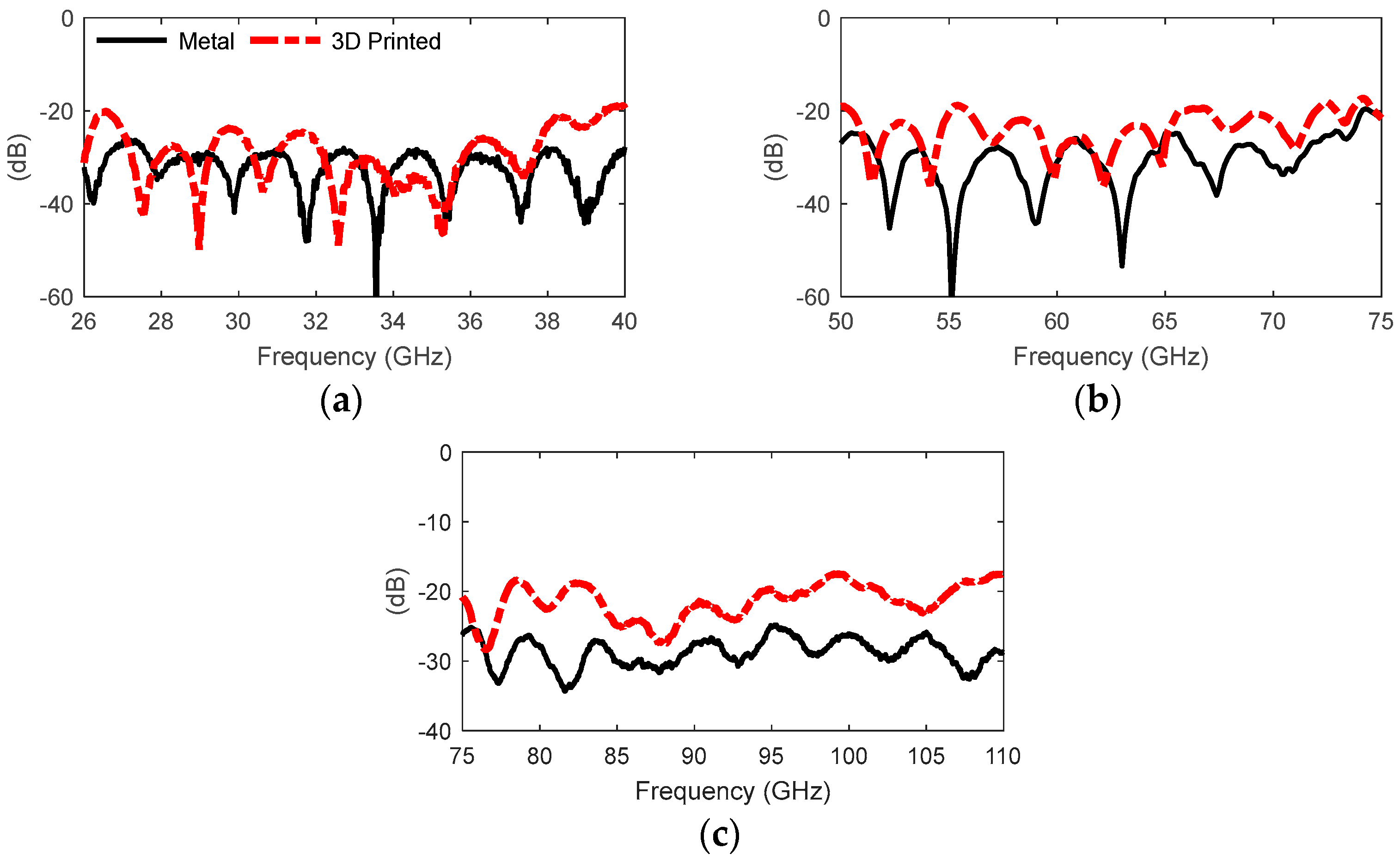

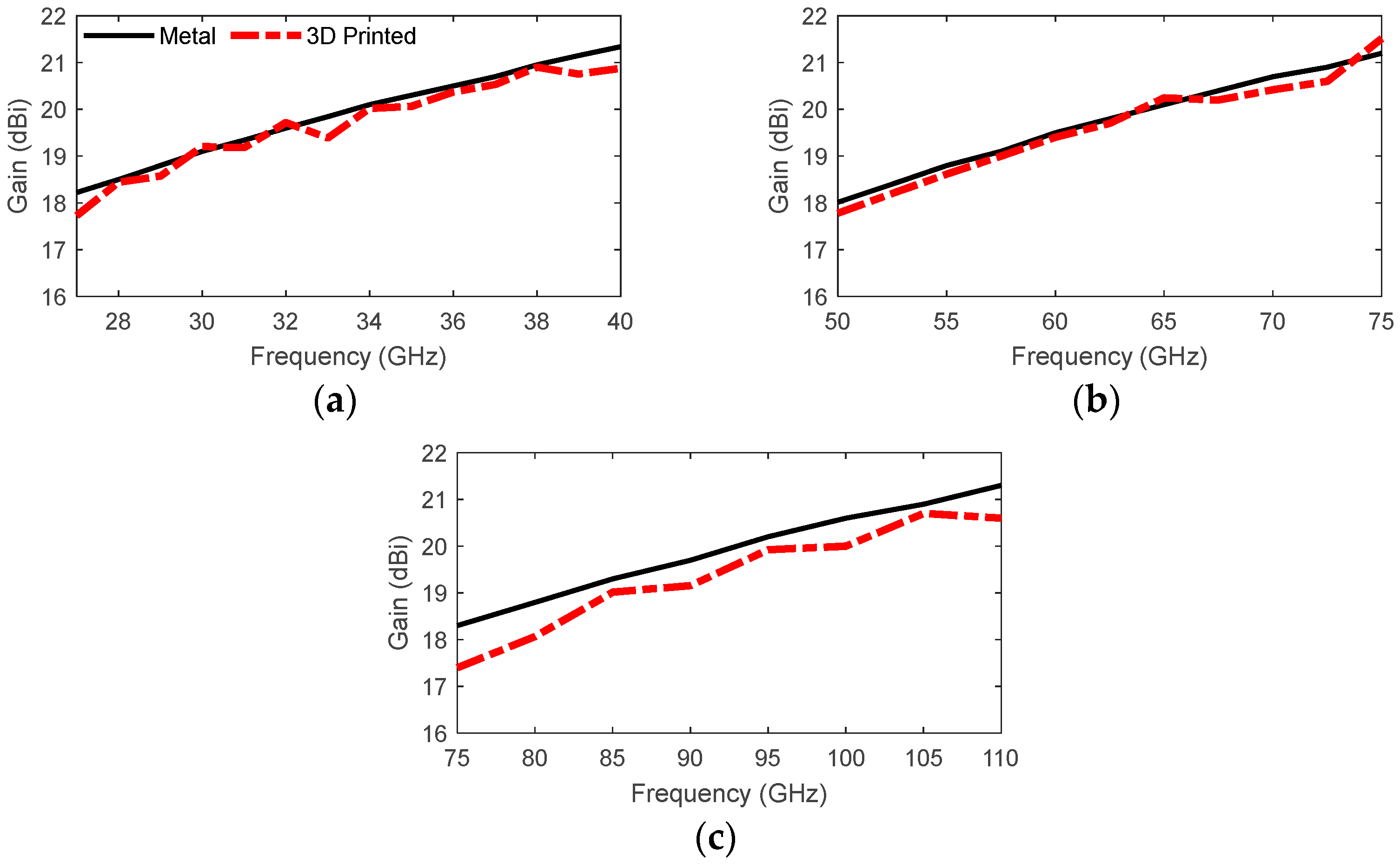

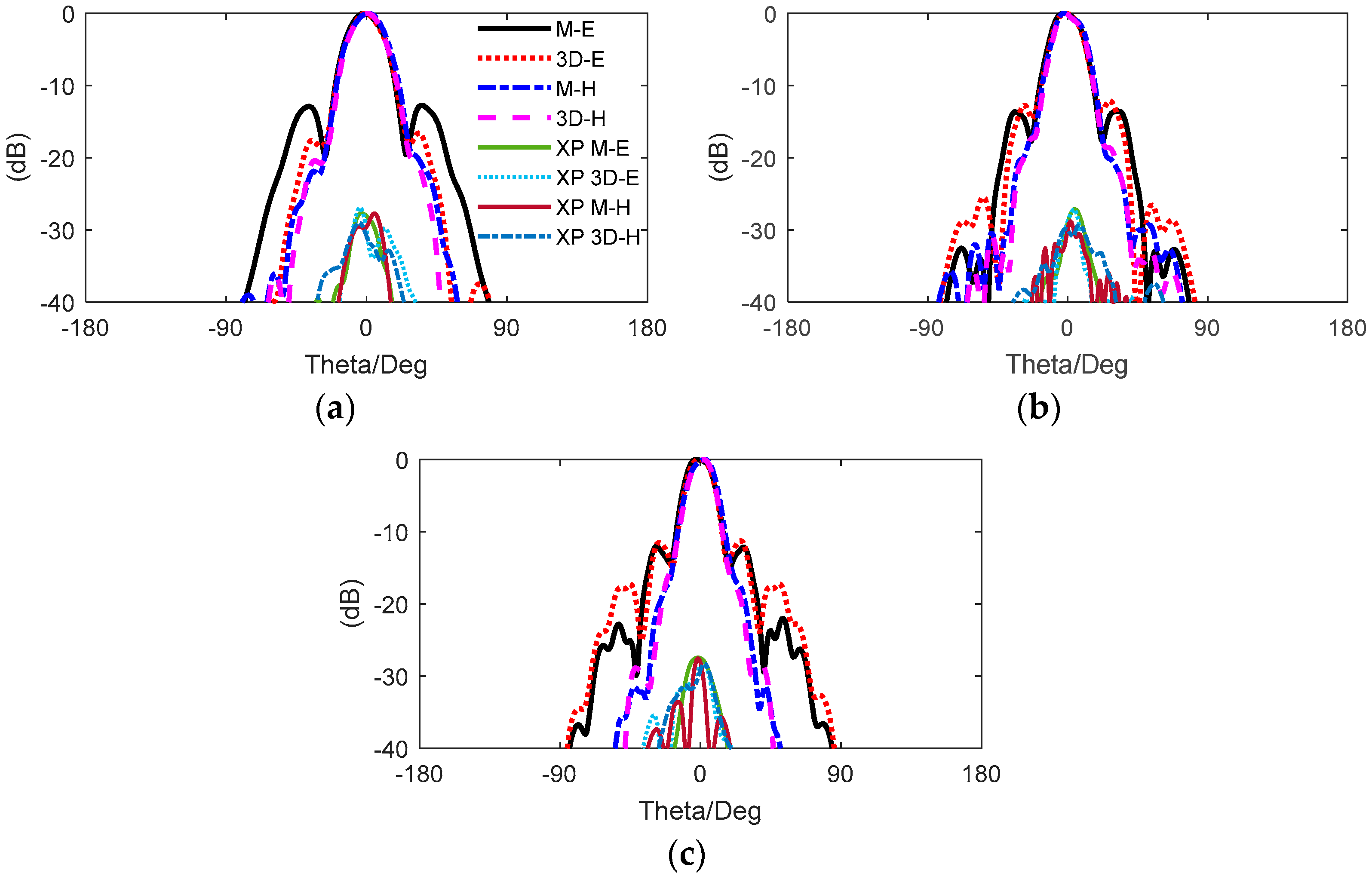

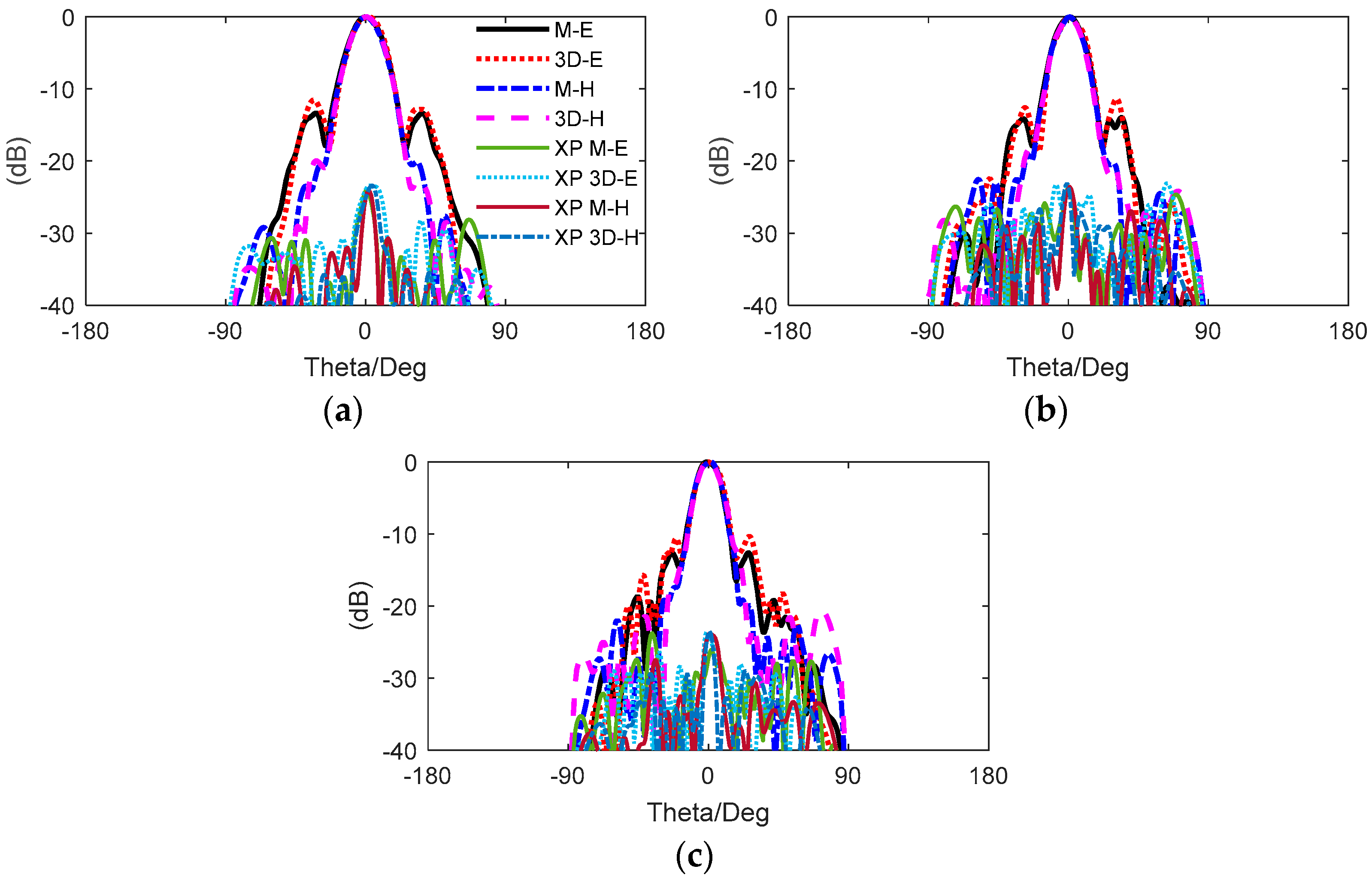

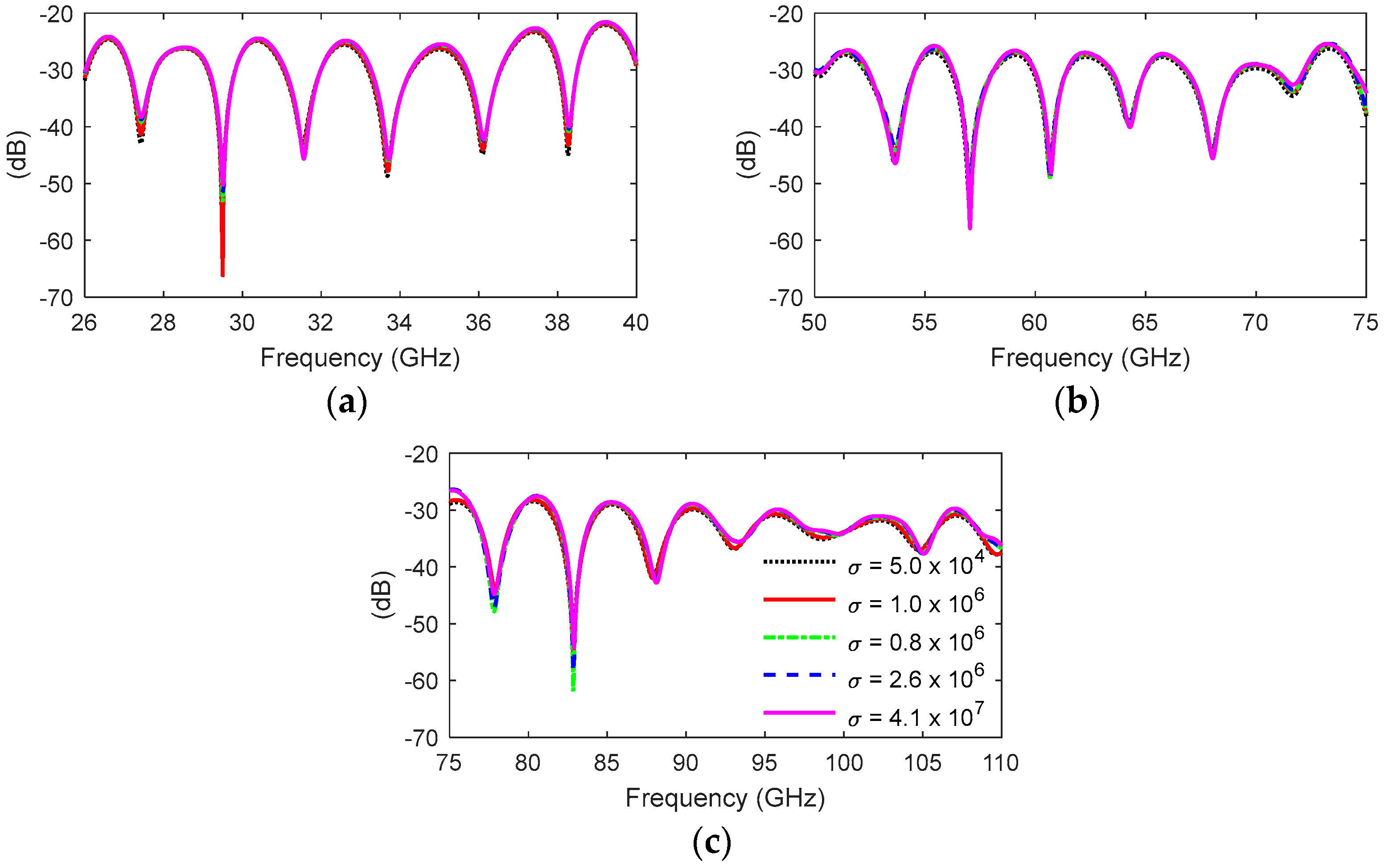

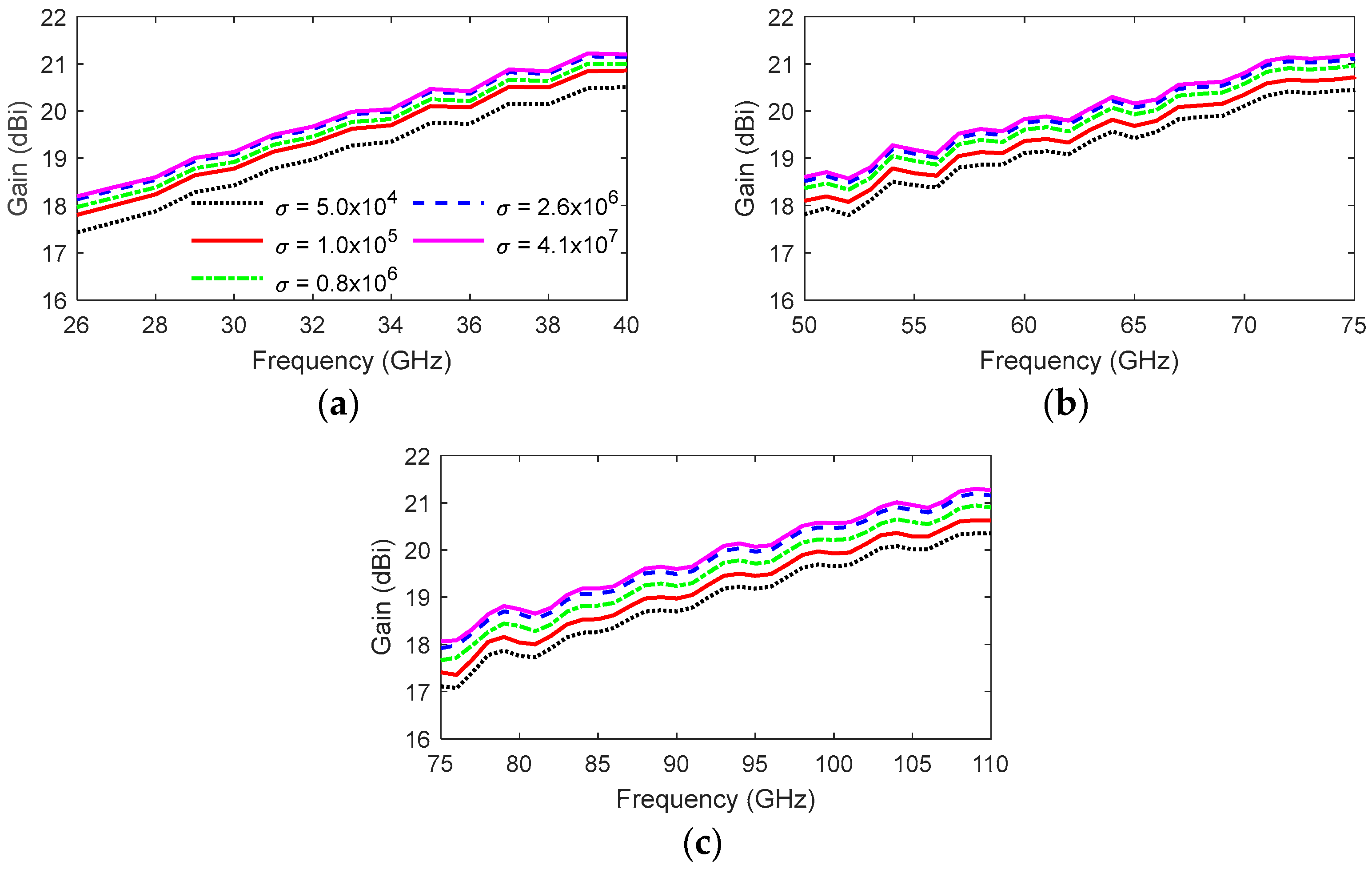

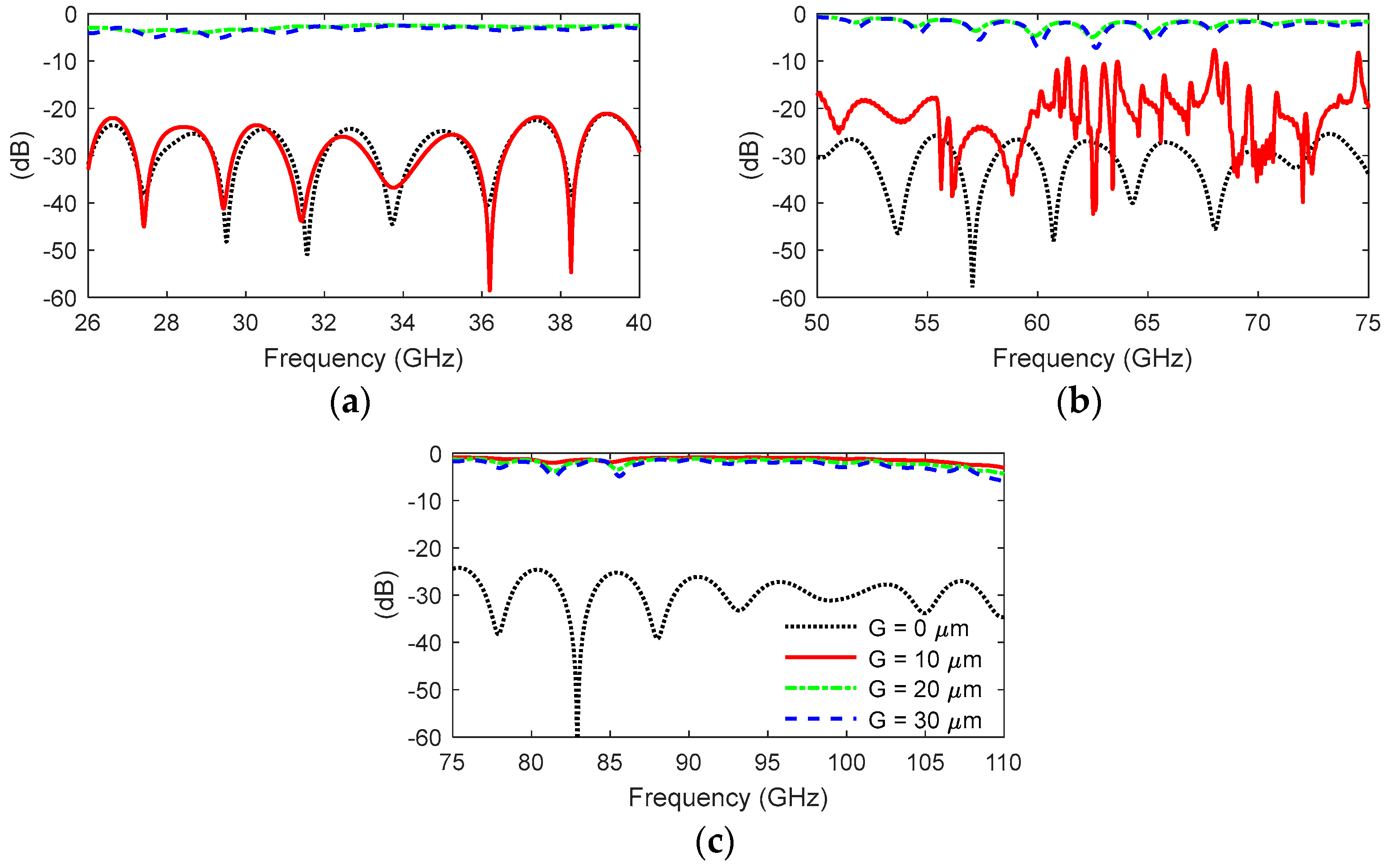

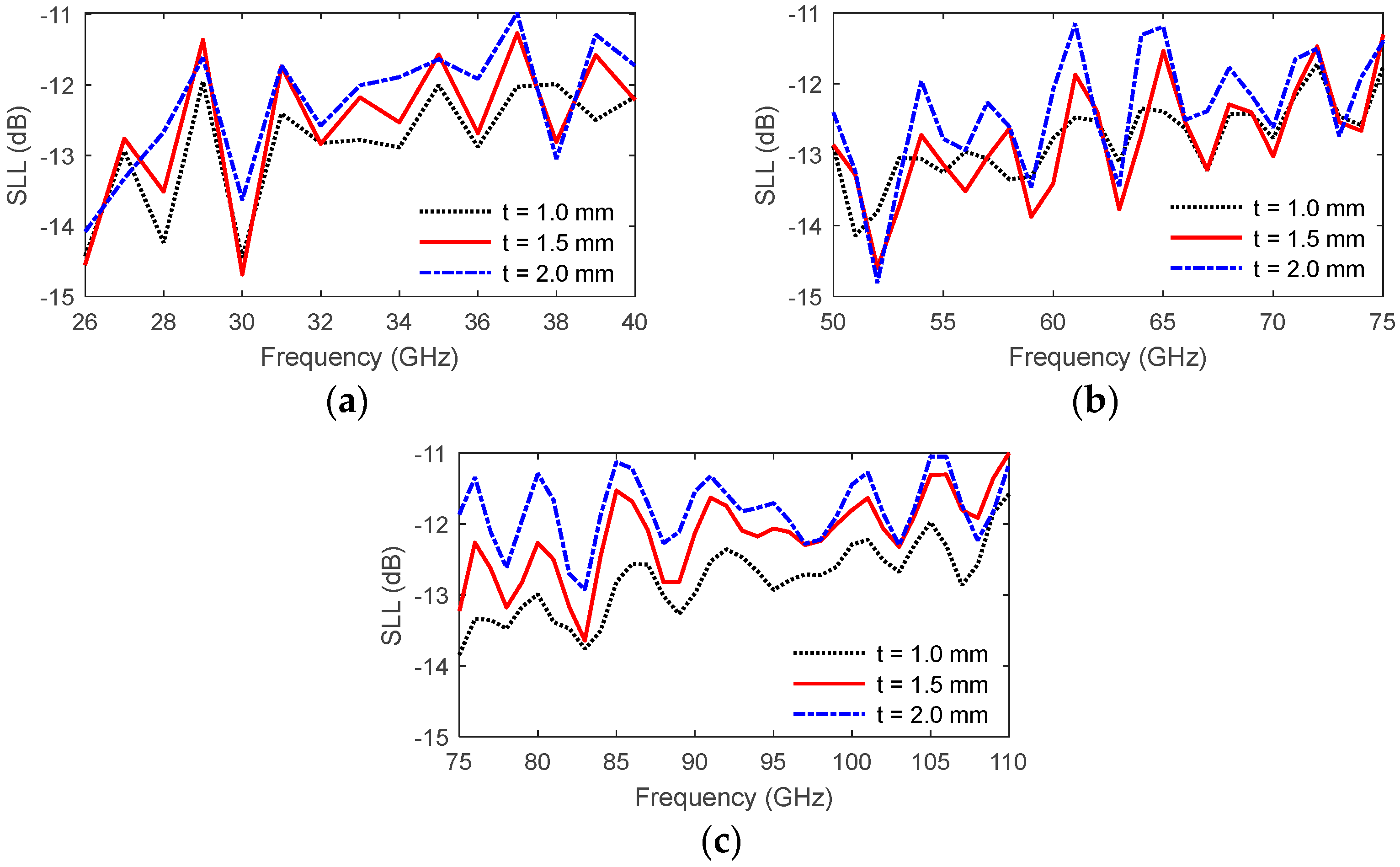

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, G.; Zhou, S.; Sim, C.; Chio, T.; Yuan, T. Lightweight Perforated Waveguide Structure Realized by 3–D Printing for RF Applications. IEEE Trans. Antennas Propag. 2017, 65, 3897–3904. [Google Scholar] [CrossRef]

- Hajisaeid, E.; Dericioglu, A.F.; Akyurtlu, A. All 3–D Printed Free–Space Setup for Microwave Dielectric Characterization of Materials. IEEE Trans. Instrum. Meas. 2018, 67, 1877–1886. [Google Scholar] [CrossRef]

- Alkaraki, S.; Gao, Y.; Stremsdoerfer, S.; Gayets, E.; Parini, C.G. 3D Printed Corrugated Plate Antennas with High Aperture Efficiency and High Gain at X–Band and Ka–Band. IEEE Access 2020, 8, 30643–30654. [Google Scholar] [CrossRef]

- Alkaraki, S.; Gao, Y.; Torrico, M.O.M.; Stremsdoerfer, S.; Gayets, E.; Parini, C. Performance Comparison of Simple and Low Cost Metallization Techniques for 3D Printed Antennas at 10 GHz and 30 GHz. IEEE Access 2018, 6, 64261–64269. [Google Scholar] [CrossRef]

- Chieh, J.C.S.; Dick, B.; Loui, S.; Rockway, J.D. Development of a Ku–band Corrugated conical horn using 3–D print Technology. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 201–204. [Google Scholar] [CrossRef]

- Hoel, K.V.; Ignatenko, M.; Kristoffersen, S.; Lier, E.; Filipovic, D.S. 3–D Printed Monolithic GRIN Dielectric–Loaded Double–Ridged Horn Antennas. IEEE Trans. Antennas Propag. 2020, 68, 533–539. [Google Scholar] [CrossRef]

- Wu, L.; Chu, H.; Cao, D.; Peng, S.; Guo, Y. 3–D Printed Antenna Subsystem with Dual–Polarization and its Test in System Level for Radiometer Applications. IEEE Access 2020, 8, 127856–127865. [Google Scholar] [CrossRef]

- Addamo, G.; Peverini, O.A.; Calignano, F.; Manfredi, D.; Paonessa, F.; Virone, G. 3–D Printing of High–Performance Feed Horns from Ku– to V–Bands. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2036–2040. [Google Scholar] [CrossRef]

- Lomakin, K.; Pavlenko, T.; Ankenbrand, M.; Ankenbrand, M.; Sippel, M.; Ringel, J.; Scheetz, M. Evaluation and Characterization of 3–D Printed Pyramid Horn Antennas Utilizing Different Deposition Techniques for Conductive Material. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 1998–2006. [Google Scholar] [CrossRef]

- Liu, X.; Peng, L.; Liu, Y.-F.; Yu, W.-S.; Zhao, Q.-X.; Jiang, X. Ultra–broadband All Dielectric Transmit Array Designing Based on Genetic Algorithm Optimization and 3D Print Technology. IEEE Trans. Antennas Propag. 2021, 69, 2003–2012. [Google Scholar] [CrossRef]

- Le Sage, G.P. 3D printed waveguide slot array antennas. IEEE Access 2016, 4, 1258–1265. [Google Scholar] [CrossRef]

- Shin, S.; Alyasiri, D.F.; D’Auria, M.; Otter, W.J.; Myant, C.W.; Stokes, D. Polymer–Based 3–D Printed Ku–Band Steerable Phased–Array Antenna Subsystem. IEEE Access 2019, 7, 106662–106673. [Google Scholar] [CrossRef]

- Rashid, S.; Jofre, L.; Garrido, A.; Gonzalez, G.; Ding, Y.; Aguasca, A.; O’Callaghan, J.; Romeu, J. 3–D Printed UWB Microwave Bodyscope for Biomedical Measurements. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 626–630. [Google Scholar] [CrossRef]

- Sarjoghian, S.; Sagor, M.H.; Alfadhl, Y.; Chen, X. A 3D–Printed High–Dielectric Filled Elliptical Double–Ridged Horn Antenna for Biomedical Monitoring Applications. IEEE Access 2019, 7, 94977–94985. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, L.; Zhou, Y.; Yang, Y.; Zhu, H.; Cheng, F.; Chen, Q.; Huang, K. A K–Band 3–D Printed Focal–Shifted Two–Dimensional Beam–Scanning Lens Antenna with Nonuniform Feed cubest. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 2721–2725. [Google Scholar] [CrossRef]

- Zhang, B.; Li, R.; Wu, L.; Sun, H.; Guo, Y. A Highly Integrated 3–D Printed Metallic K–Band Passive Front End as the Unit Cell in a Large Array for Satellite Communication. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2046–2050. [Google Scholar] [CrossRef]

- Rojas–Nastrucci, E.A.; Nussbaum, J.T.; Crane, N.B.; Weller, T.M. Ka–Band Characterization of Binder Jetting for 3–D Printing of Metallic Rectangular Waveguide Circuits and Antennas. IEEE Trans. Microw. Theory Tech. 2017, 65, 3099–3108. [Google Scholar] [CrossRef]

- Alkaraki, S.; Andy, A.S.; Gao, Y.; Tong, K.F.; Ying, Z.; Donnan, R.; Parini, C. Compact and Low–Cost 3–D Printed Antennas Metalized Using Spray–Coating Technology for 5G mm–Wave Communication Systems. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2051–2055. [Google Scholar] [CrossRef]

- Alkaraki, S.; Gao, Y. mm–Wave Low–Cost 3D Printed MIMO Antennas With Beam Switching Capabilities for 5G Communication Systems. IEEE Access 2020, 8, 32531–32541. [Google Scholar] [CrossRef]

- Agnihotri, I.; Sharma, S.K. Design of a 3D Metal Printed Axial Corrugated Horn Antenna Covering Full Ka–Band. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 522–526. [Google Scholar] [CrossRef]

- Li, Y.; Ge, L.; Wang, J.; Da, S.; Cao, D.; Wang, J.; Liu, Y. 3–D Printed High–Gain Wideband Waveguide Fed Horn Antenna Arrays for Millimeter–Wave Applications. IEEE Trans. Antennas Propag. 2019, 67, 2868–2877. [Google Scholar] [CrossRef]

- Saeidi–Manesh, H.; Saeedi, S.; Mirmozafari, M.; Zhang, G.; Sigmarsson, H.H. Design and Fabrication of Orthogonal–Mode Transducer Using 3–D Printing Technology. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2013–2016. [Google Scholar] [CrossRef]

- Shen, J.; Ricketts, D.S. Compact W–Band “Swan Neck” Turnstile Junction Orthomode Transducer Implemented by 3–D Printing. IEEE Trans. Microw. Theory Tech. 2020, 68, 3408–3417. [Google Scholar] [CrossRef]

- Lu, K.; Leung, K.W.; Yang, N. 3D–Printed Circularly Polarized Twisted–ridge Horn Antenna. IEEE Trans. Antennas Propag. 2021, 69, 1746–1750. [Google Scholar] [CrossRef]

- Zhang, B.; Zirath, H. A Metallic 3–D Printed E–Band Radio Front End. IEEE Microw. Wirel. Compon. Lett. 2016, 26, 331–333. [Google Scholar] [CrossRef]

- Gu, C.; Gao, S.; Fusco, V.; Gibbons, G.; Sanz–Izquierdo, B.; Standaert, A.; Reynaert, P.; Bösch, W.; Gadringer, M.; Xu, R.; et al. A D–Band 3D–Printed Antenna. IEEE Trans. Terahertz Sci. Technol. 2020, 10, 433–442. [Google Scholar] [CrossRef]

- Wu, G.B.; Chan, K.F.; Qu, S.W.; Tong, K.F.; Chan, C.H. Orbital Angular Momentum (OAM) Mode–Reconfigurable Discrete Dielectric Lens Operating at 300 GHz. IEEE Trans. Terahertz Sci. Technol. 2020, 10, 480–489. [Google Scholar] [CrossRef]

- Shen, J.; Ricketts, D.S. Additive Manufacturing of Complex Millimeter–Wave Waveguides Structures Using Digital Light Processing. IEEE Trans. Microw. Theory Tech. 2019, 67, 883–895. [Google Scholar] [CrossRef]

- Tak, J.; Kantemur, A.; Sharma, Y.; Xin, H. A 3–D–Printed W–Band Slotted Waveguide Array Antenna Optimized Using Machine Learning. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2008–2012. [Google Scholar] [CrossRef]

- Zhang, B.; Zhan, Z.; Cao, Y.; Gulan, H.; Linner, P.; Sun, J.; Zwick, T.; Zirath, H. Metallic 3–D printed antennas for millimeter– and submillimeter wave applications. IEEE Trans. Teraherz. Sci. Technol. 2016, 6, 592–600. [Google Scholar] [CrossRef]

- Jammes, A.; Petisme, M.; Staelens, K. Metallization and selective metallization of silver by spraying. Surf. Coat. Technol. 2017, 332, 560–563. [Google Scholar] [CrossRef]

- Stratsys Ltd. Vero Material Data Sheet. Available online: https://www.stratasys.com/en/materials/materials-catalog/polyjet-materials/verovivid/ (accessed on 15 April 2025).

- Electrolube Ltd. Silver Conductive Paint (SCP) Technical Data Sheet. Available online: https://www.ulbrich.cz/chemical–technical–products/TDS_ELECTROLUBE_SCP_Silver_Conductive_Paint_eng.pdf (accessed on 15 April 2025).

- Balanis, C.A. Antenna measurement. In Antenna Theory, 3rd ed.; Wiley: Hoboken, NJ, USA, 2005; Chapter 17, Section 4.2; pp. 1033–1034. [Google Scholar]

| 22240–20 | 25240–20 | 27240–20 | |

|---|---|---|---|

| Length (L) | 86.00 | 48.0 | 32.50 |

| Aperture width (AW) | 34.20 | 18.50 | 12.40 |

| Aperture height (AH) | 24.80 | 12.80 | 9.00 |

| Waveguide Width (b) | 7.112 | 3.759 | 2.540 |

| Waveguide height (a) | 3.556 | 1.880 | 1.270 |

| Flare Length (FL) | 75.00 | 38.00 | 26.00 |

| Thickness (t)—3D printed | 2 | 2 | 2 |

| Thickness (t)—Metal | 0.9 | 1 | 1.1 |

| Weight (Grams) | Material Cost (USD) | Metallization Cost (USD) | |

|---|---|---|---|

| 22240–20 Horn | 22.4 | ≈5.6 | ≈5.6 |

| 25240–20 Horn | 9.1 | ≈2.3 | ≈2.3 |

| 27240–20 Horn | 4.72 | ≈1.2 | ≈1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkaraki, S.; Ullah Khan, Z.; Jilani, S.F.; Andre Sarker, A.; Kelly, J.R.; Alomainy, A. Low–Cost 3D–Printed Standard Gain Horn Antennas for Millimetre–Wave Applications. J. Manuf. Mater. Process. 2025, 9, 222. https://doi.org/10.3390/jmmp9070222

Alkaraki S, Ullah Khan Z, Jilani SF, Andre Sarker A, Kelly JR, Alomainy A. Low–Cost 3D–Printed Standard Gain Horn Antennas for Millimetre–Wave Applications. Journal of Manufacturing and Materials Processing. 2025; 9(7):222. https://doi.org/10.3390/jmmp9070222

Chicago/Turabian StyleAlkaraki, Shaker, Zia Ullah Khan, Syeda Fizzah Jilani, Andy Andre Sarker, James R. Kelly, and Akram Alomainy. 2025. "Low–Cost 3D–Printed Standard Gain Horn Antennas for Millimetre–Wave Applications" Journal of Manufacturing and Materials Processing 9, no. 7: 222. https://doi.org/10.3390/jmmp9070222

APA StyleAlkaraki, S., Ullah Khan, Z., Jilani, S. F., Andre Sarker, A., Kelly, J. R., & Alomainy, A. (2025). Low–Cost 3D–Printed Standard Gain Horn Antennas for Millimetre–Wave Applications. Journal of Manufacturing and Materials Processing, 9(7), 222. https://doi.org/10.3390/jmmp9070222