Enhancing Mechanical Properties of Hemp and Sisal Fiber-Reinforced Composites Through Alkali and Fungal Treatments for Sustainable Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Alkali Treatment

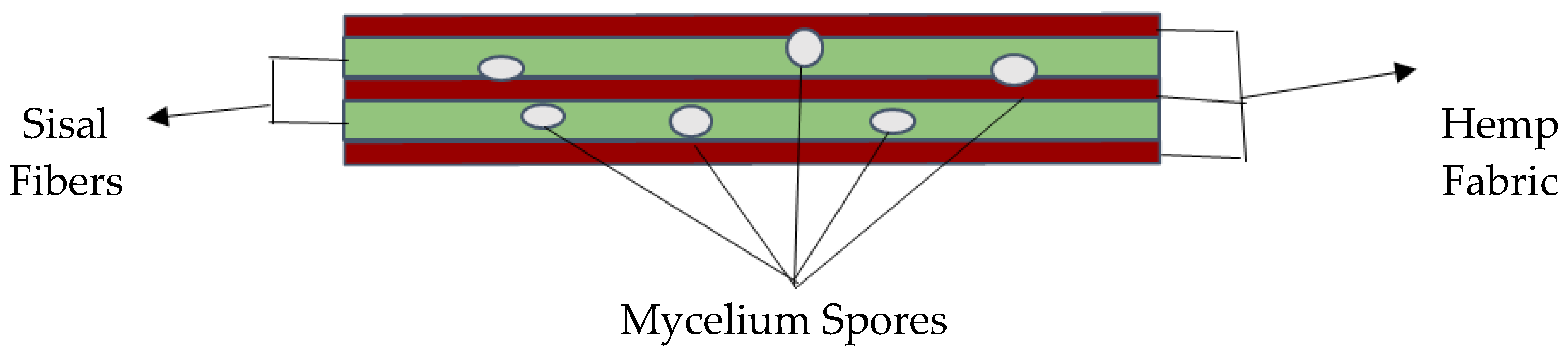

2.3. Fiber Architecture and Layup Design

2.4. Fungal Treatment

2.4.1. Substrate Preparation

2.4.2. Inoculation and Incubation

2.4.3. Drying and Final Preparation

2.5. Design of Experiments

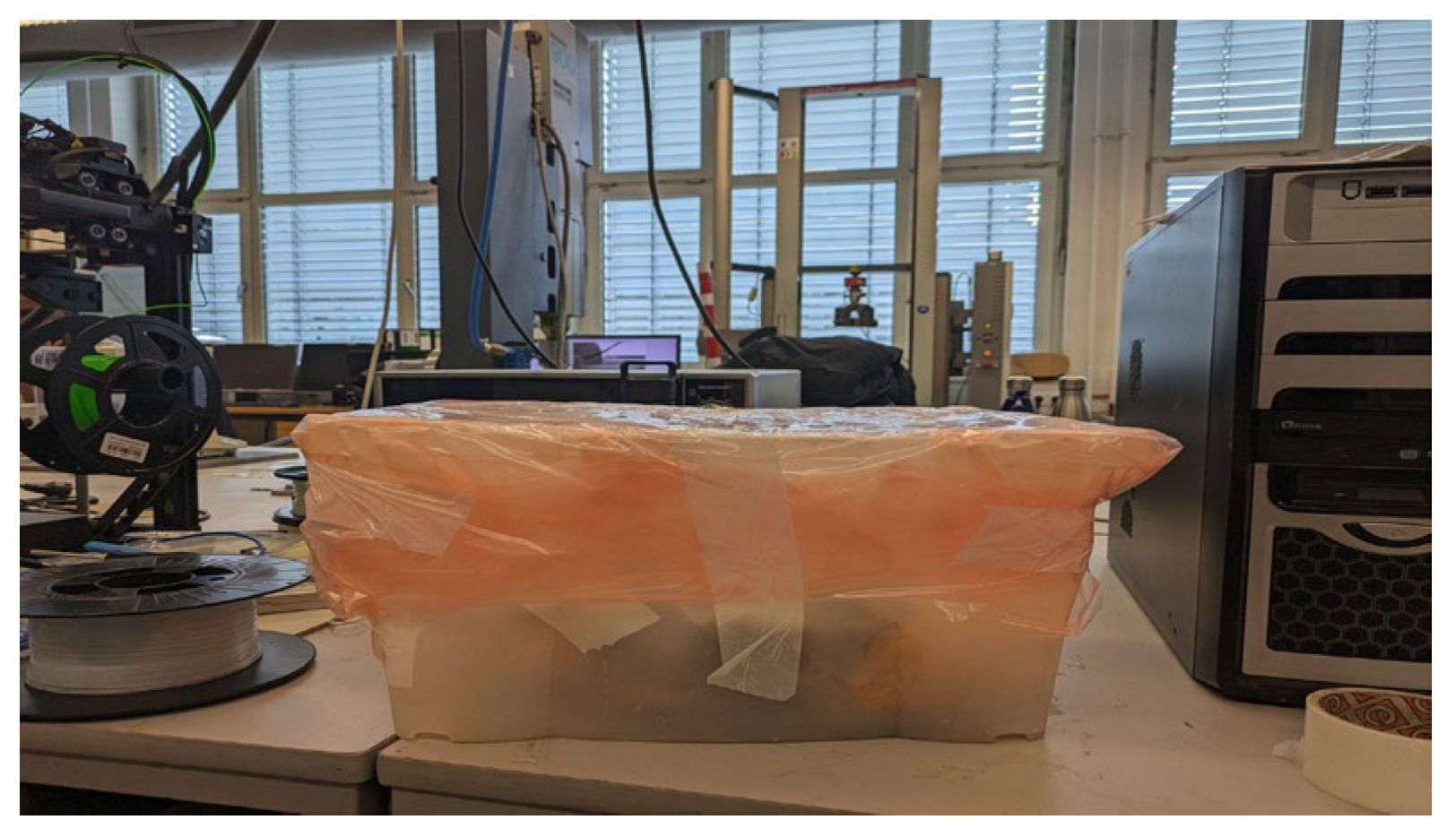

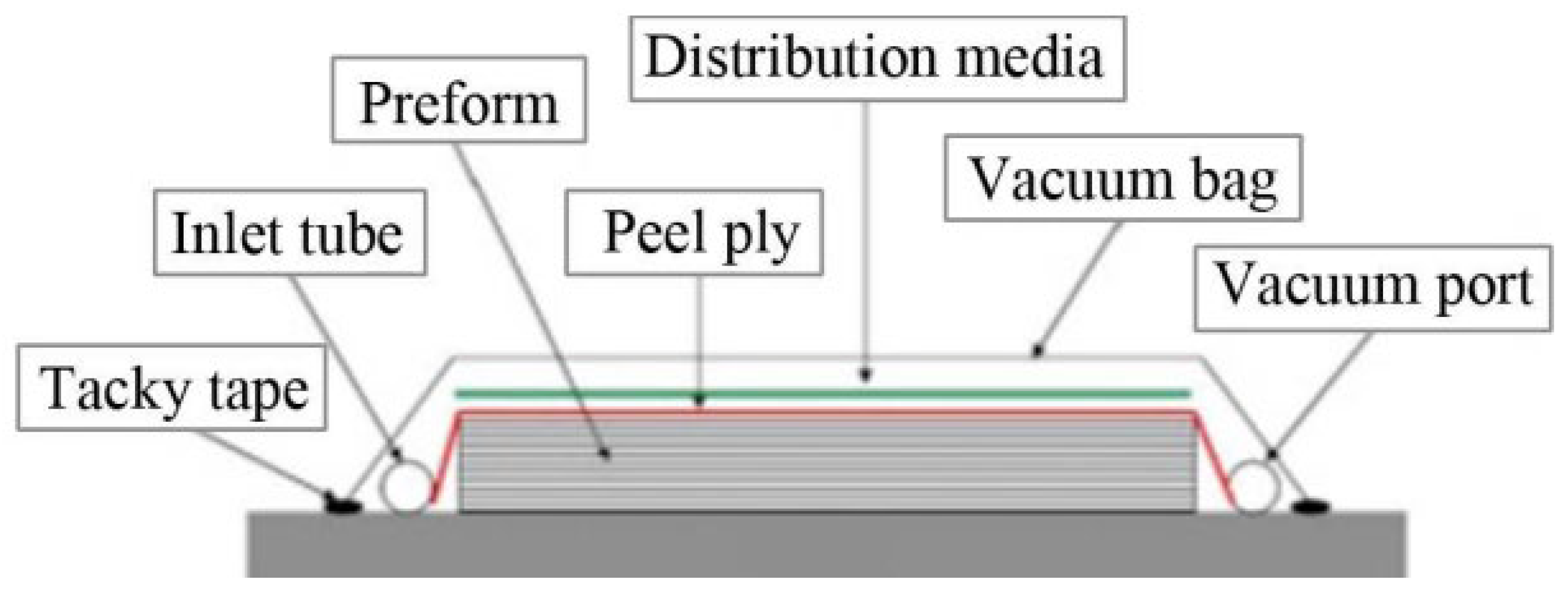

2.6. Sample Preparation

2.7. Test Equipment and Test Parameters

2.7.1. Tensile Test

2.7.2. Flexural Test

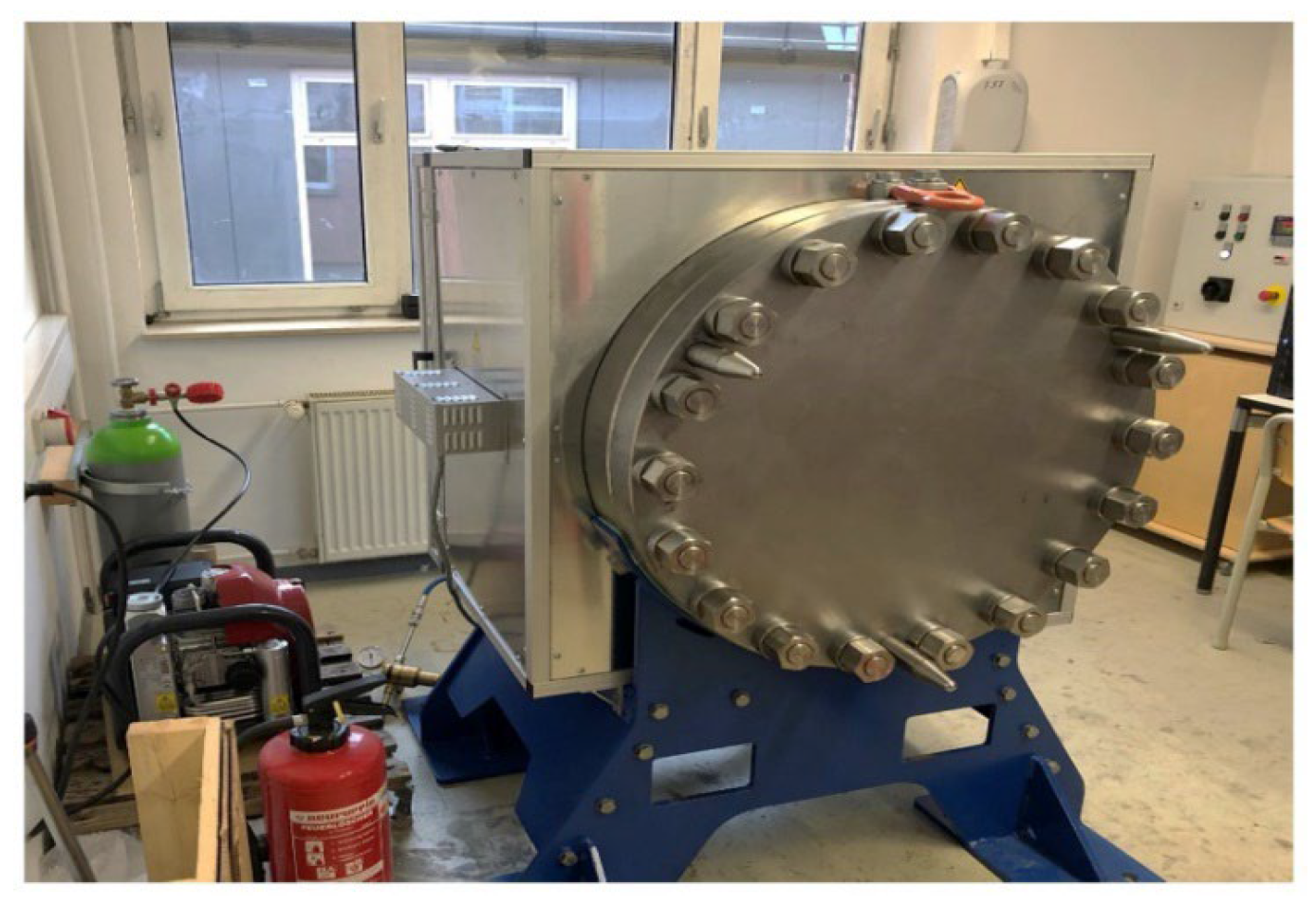

2.7.3. Impact Test

2.7.4. Shore Hardness

2.7.5. Water Absorption Test

2.7.6. Optical Microscopy

3. Results

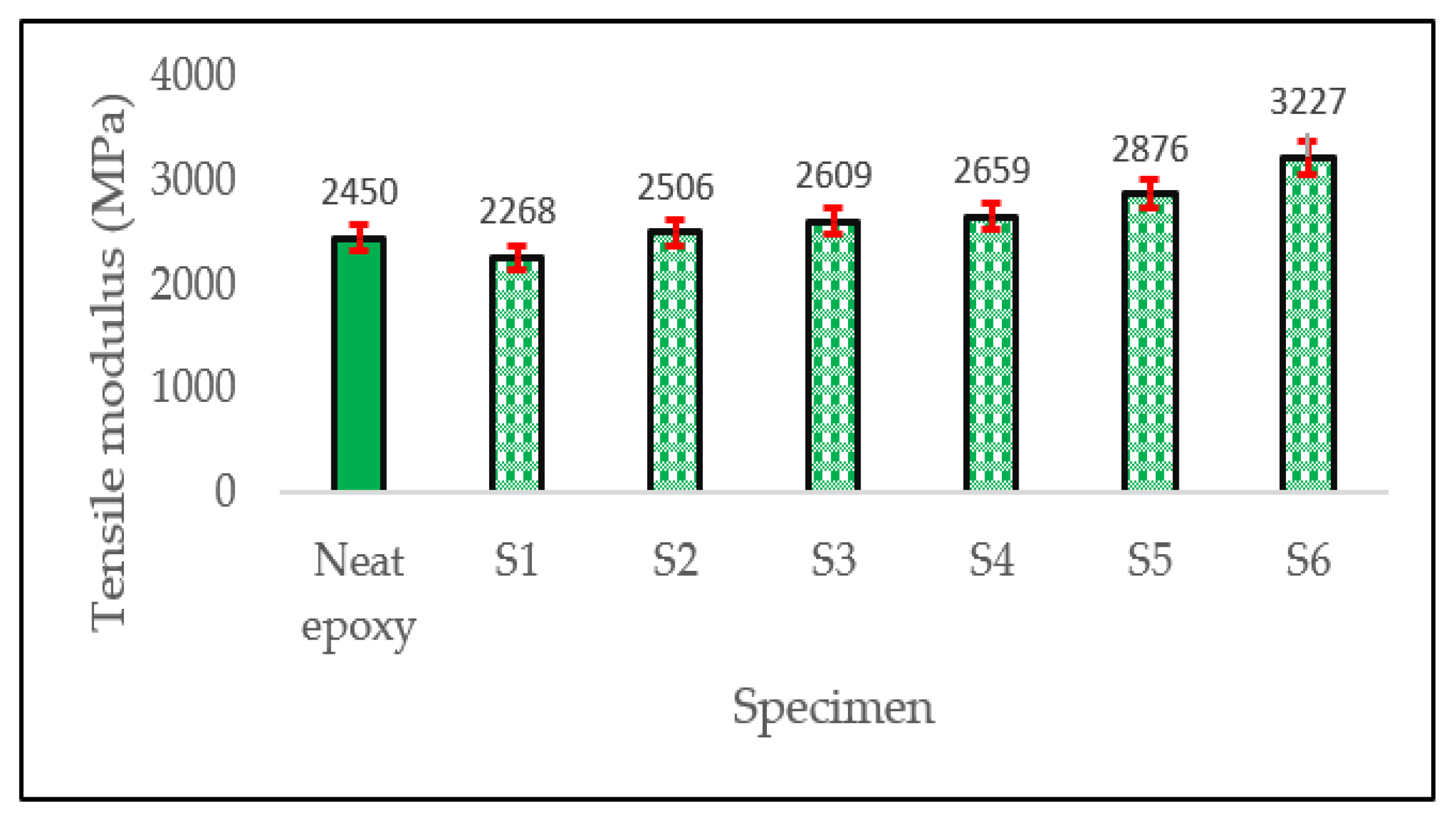

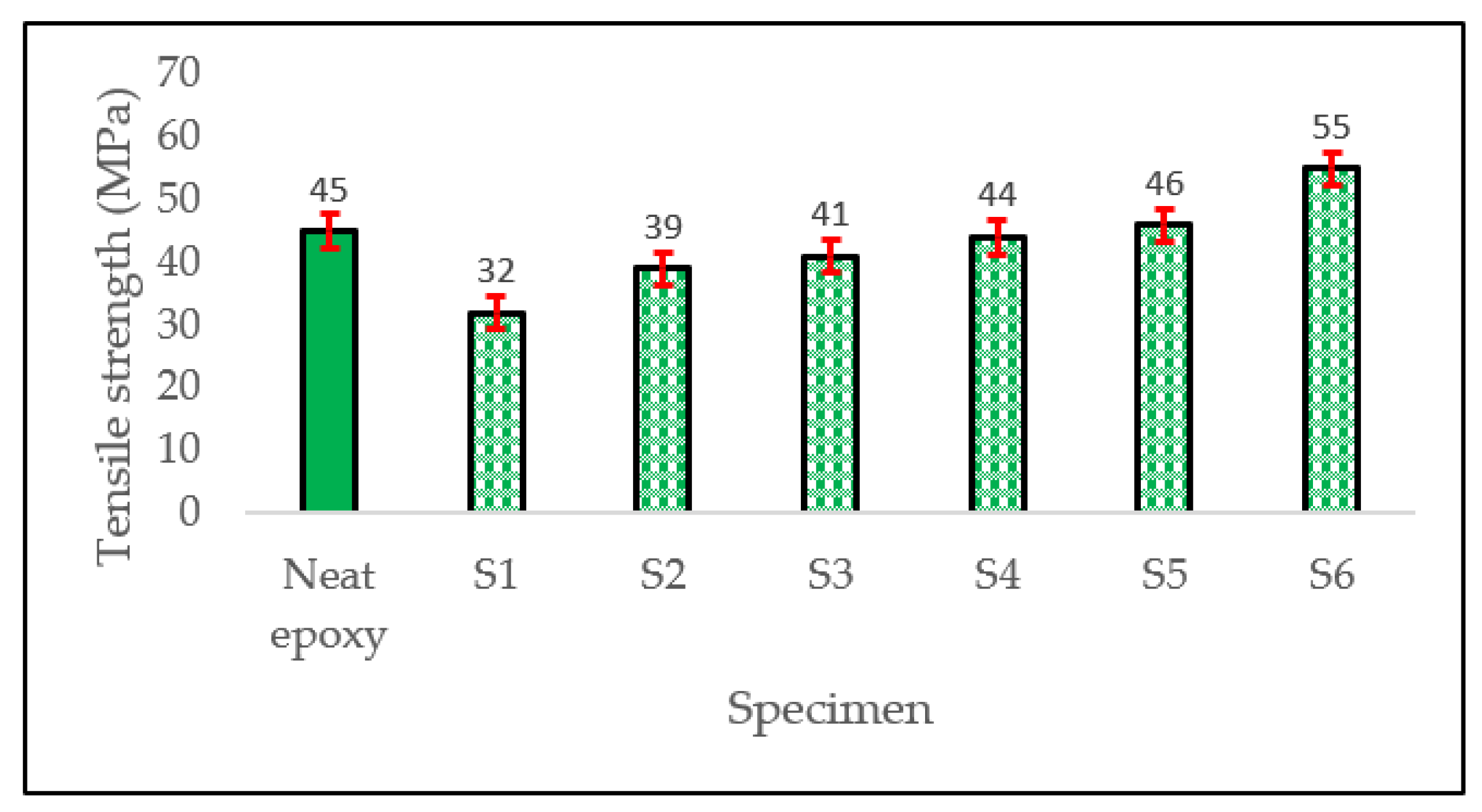

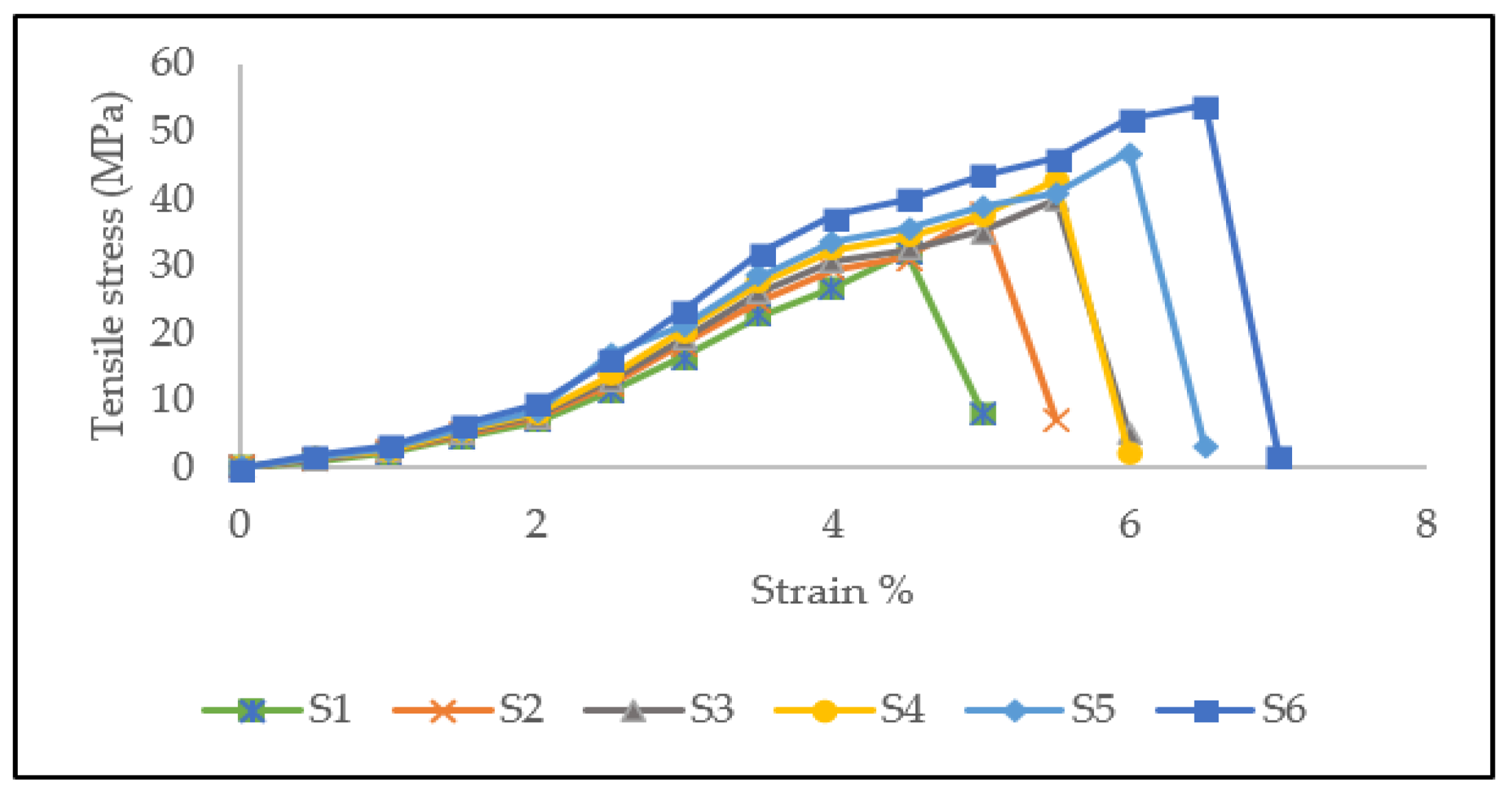

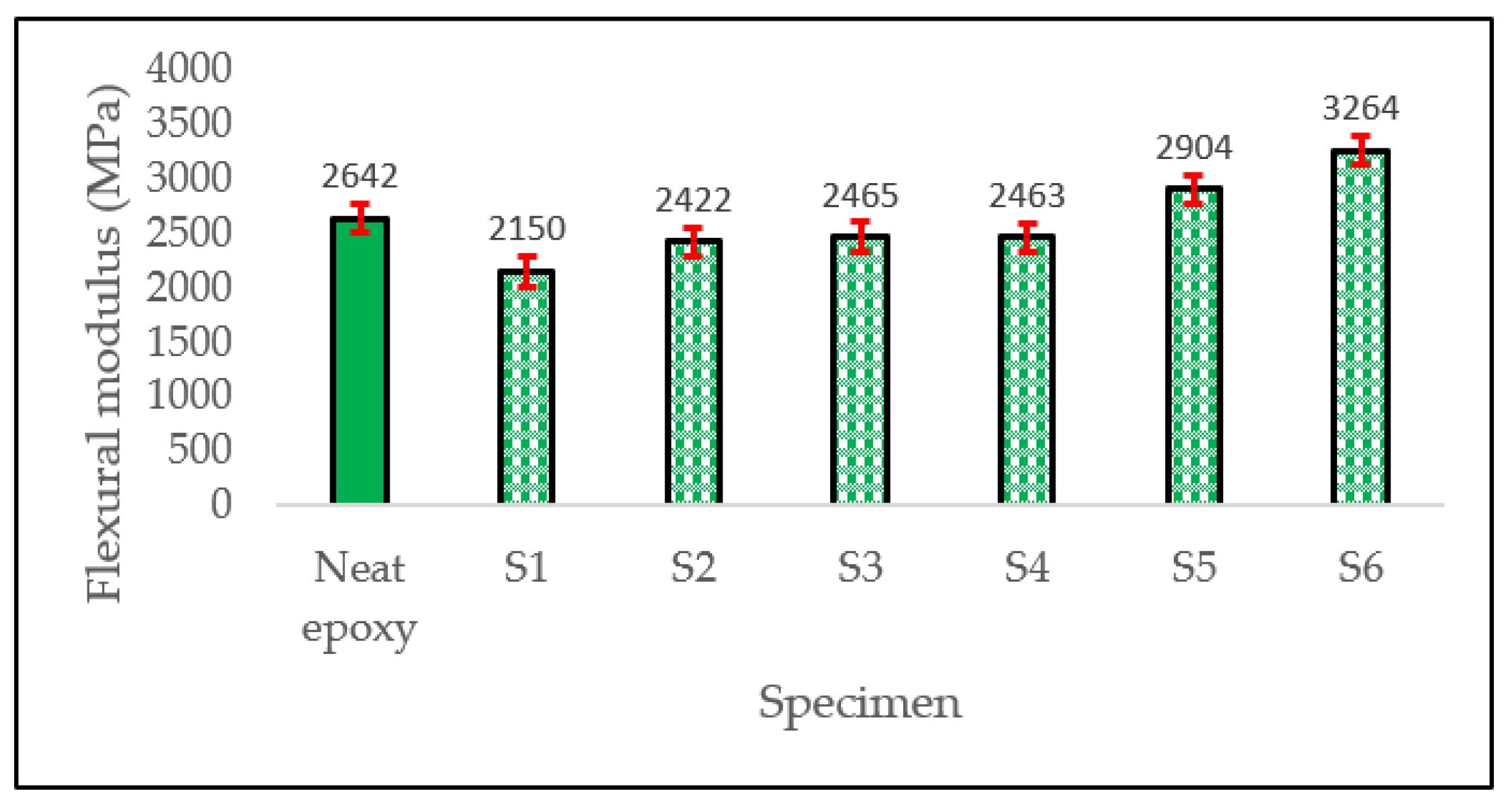

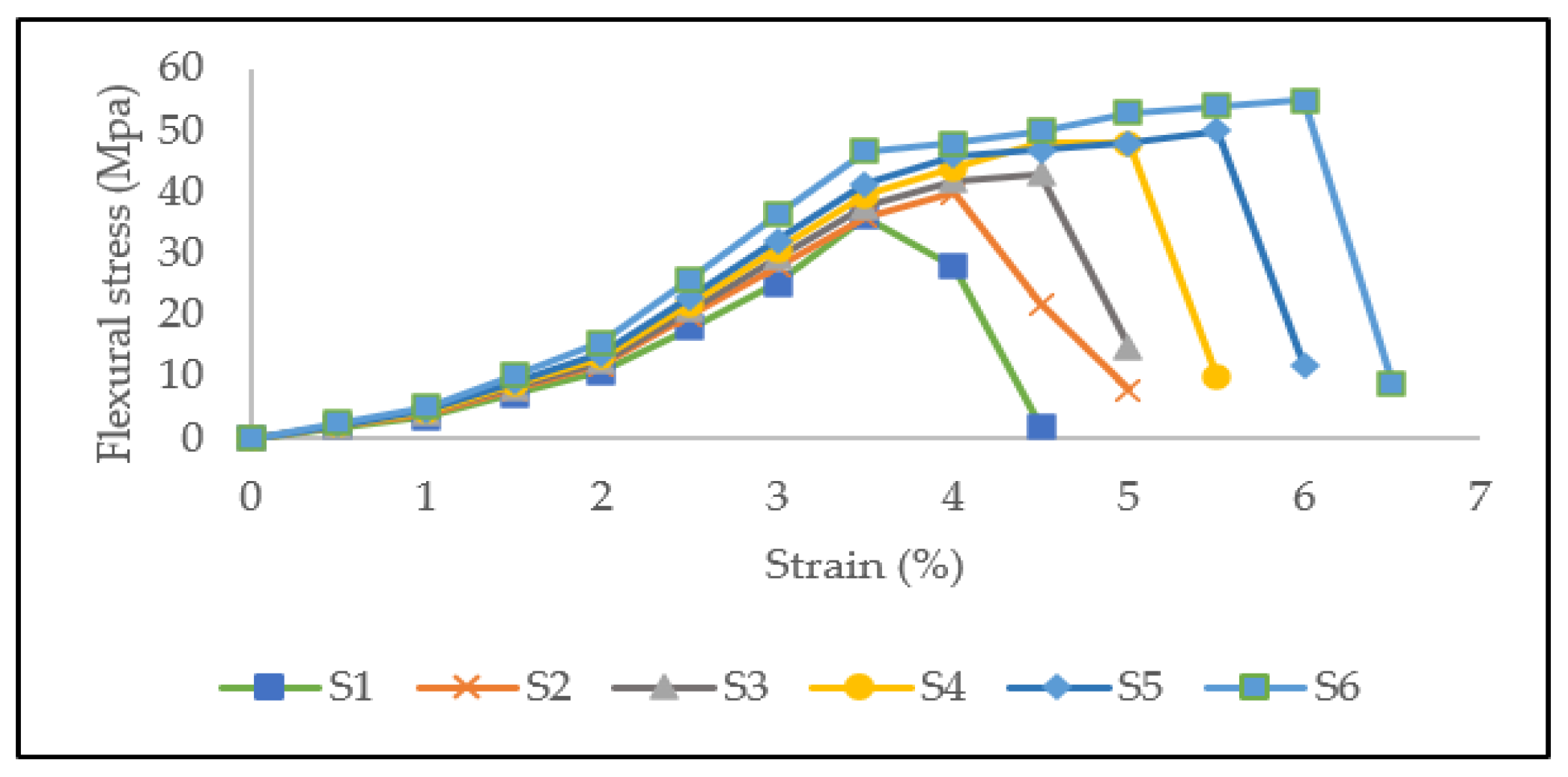

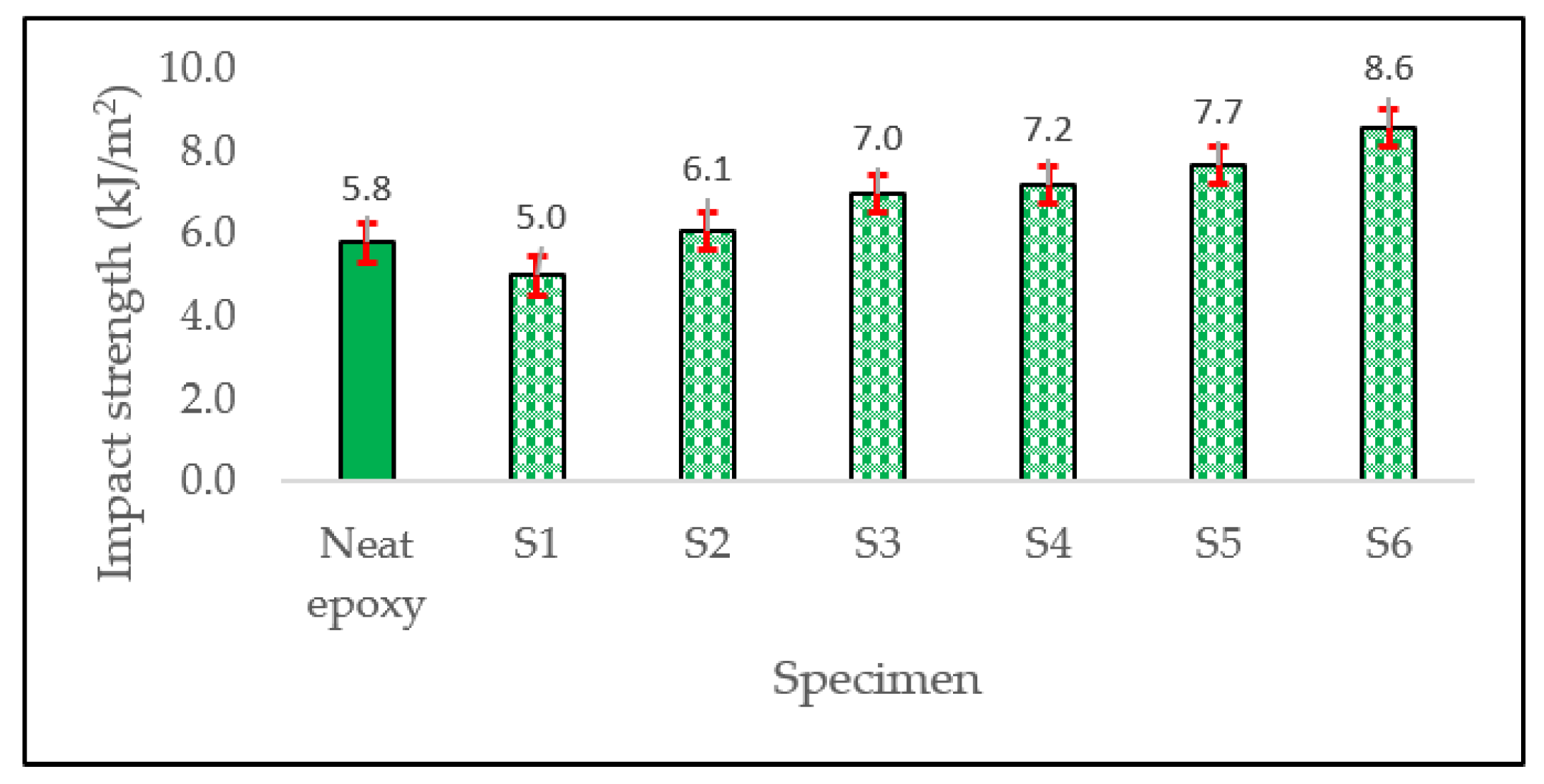

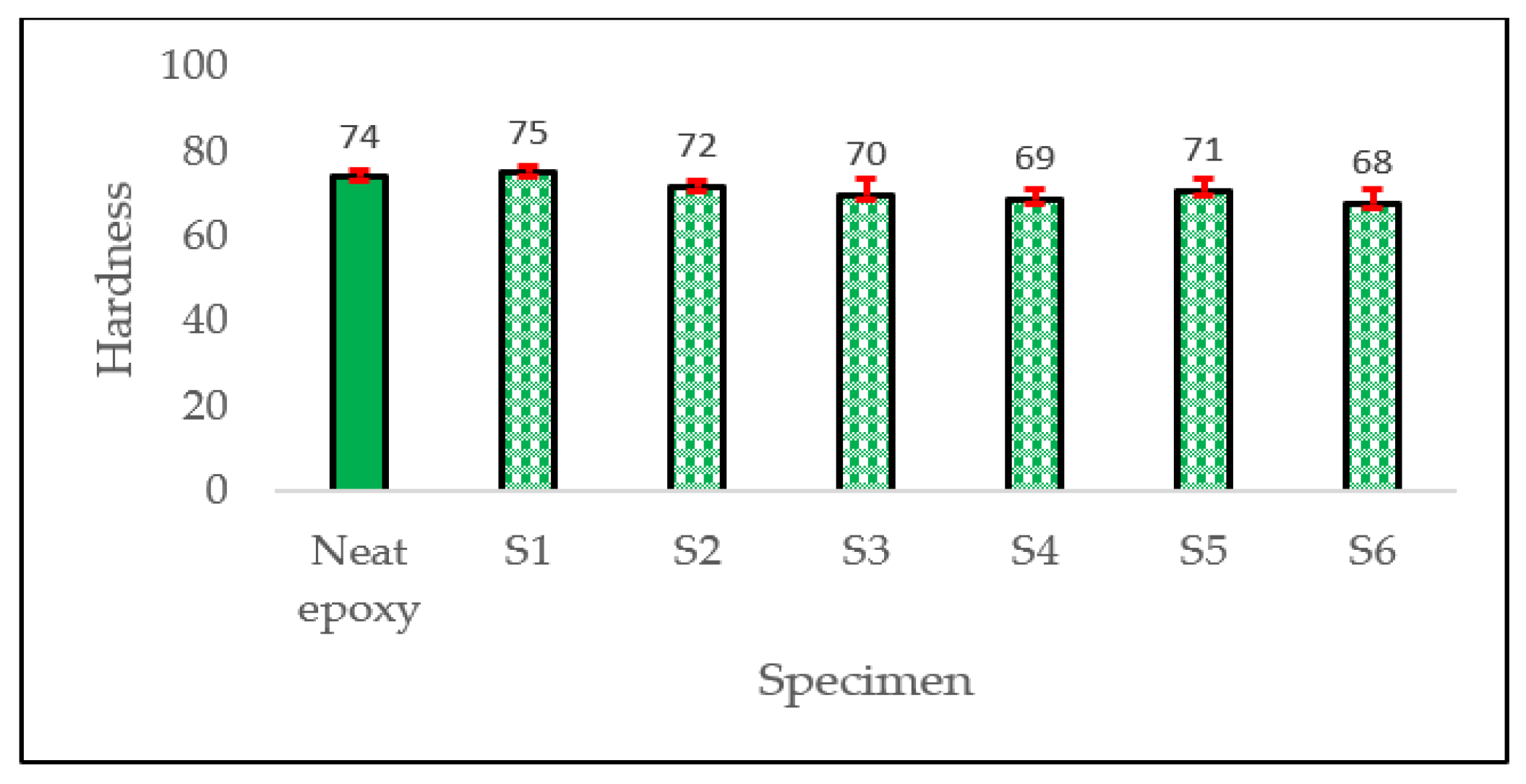

3.1. Mechanical Properties

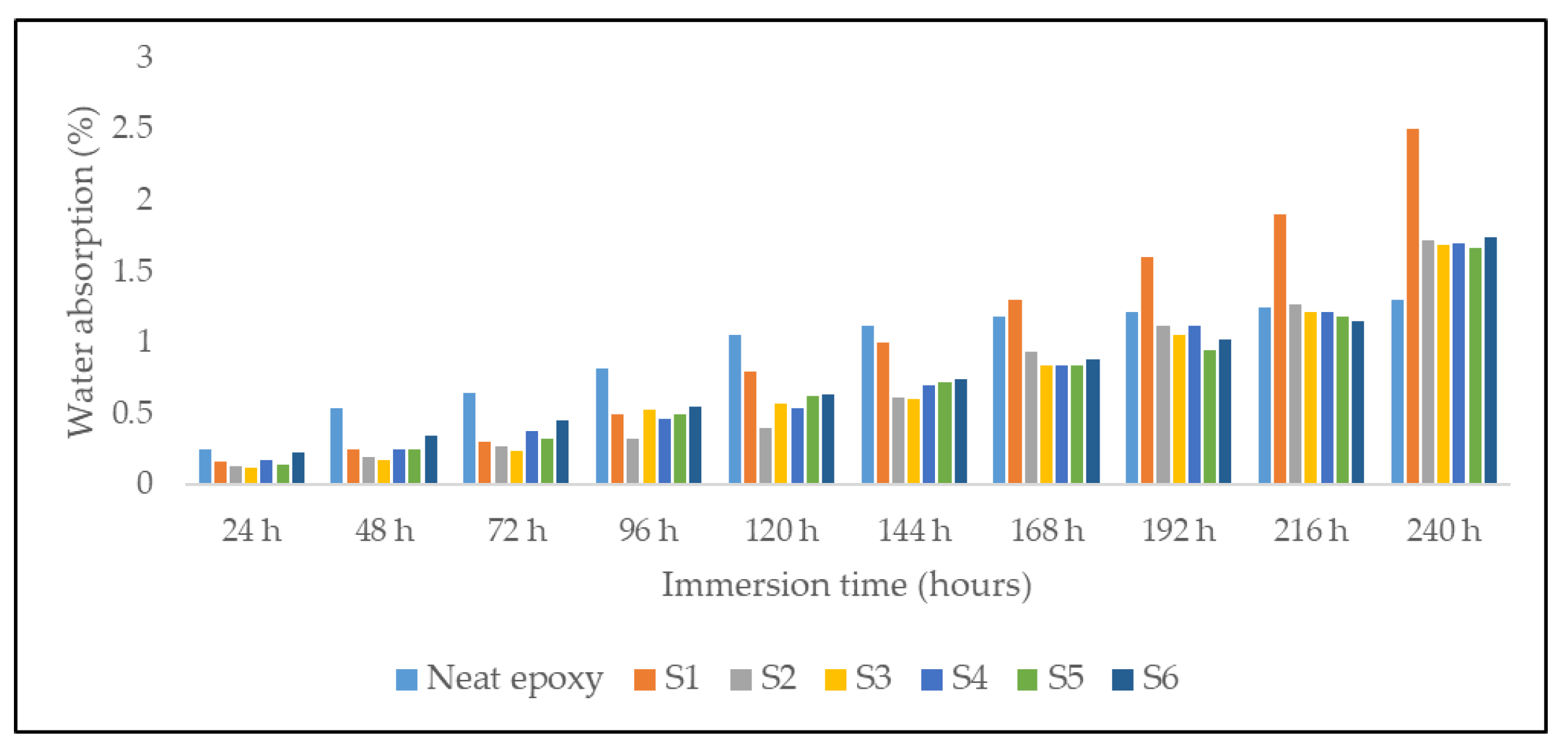

3.2. Hydrophillic Properties

3.3. Morphology Studies

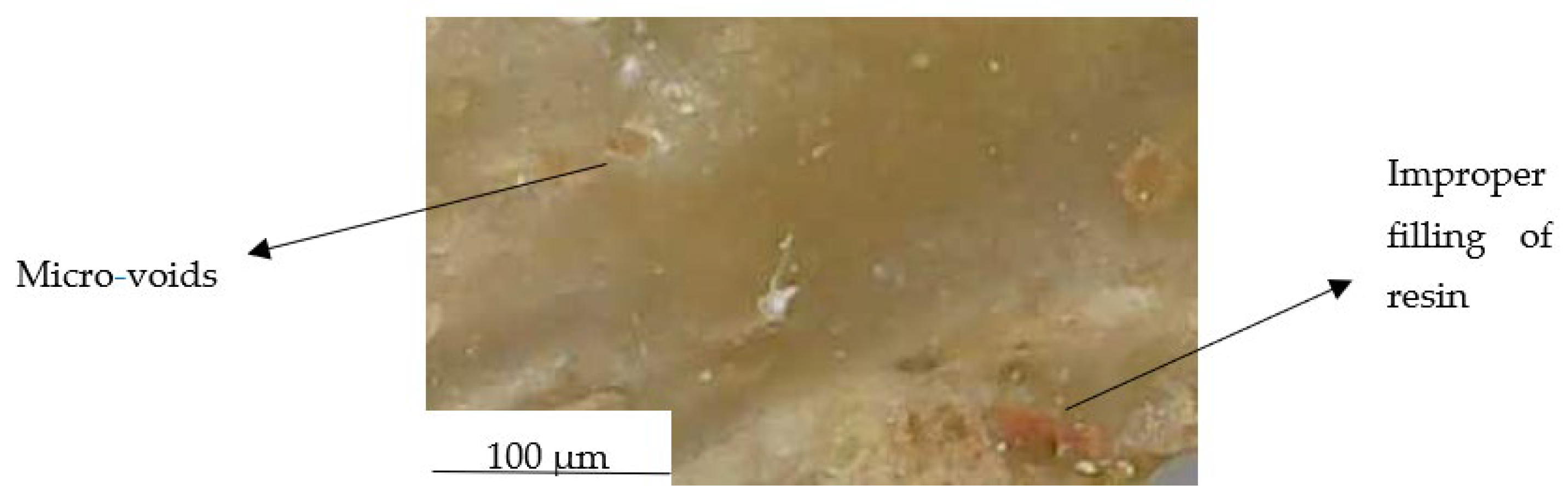

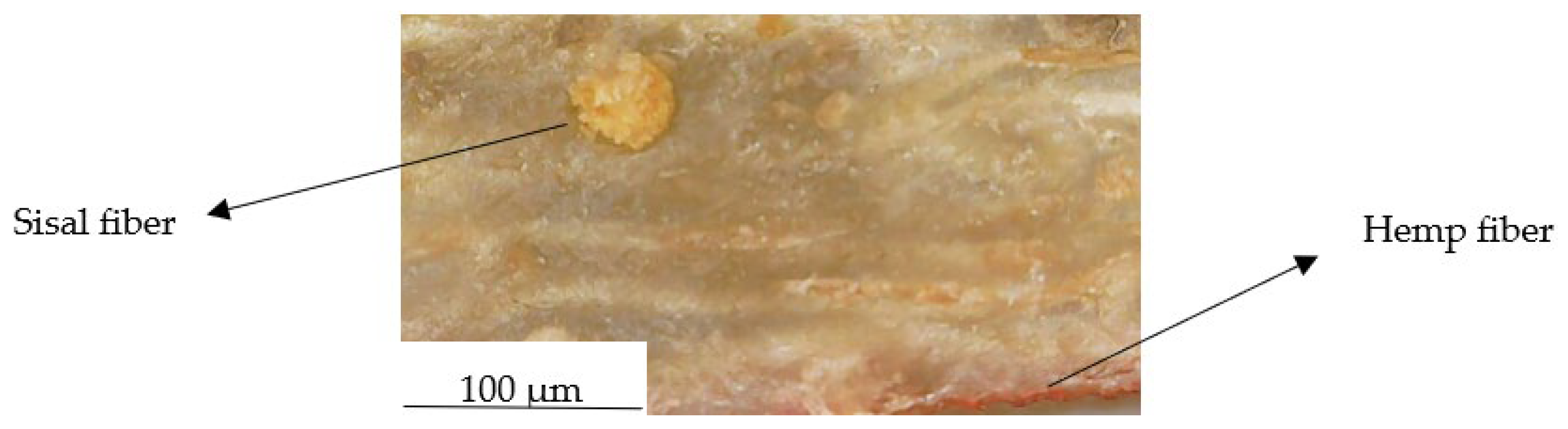

3.3.1. Alkali-Treated Specimens

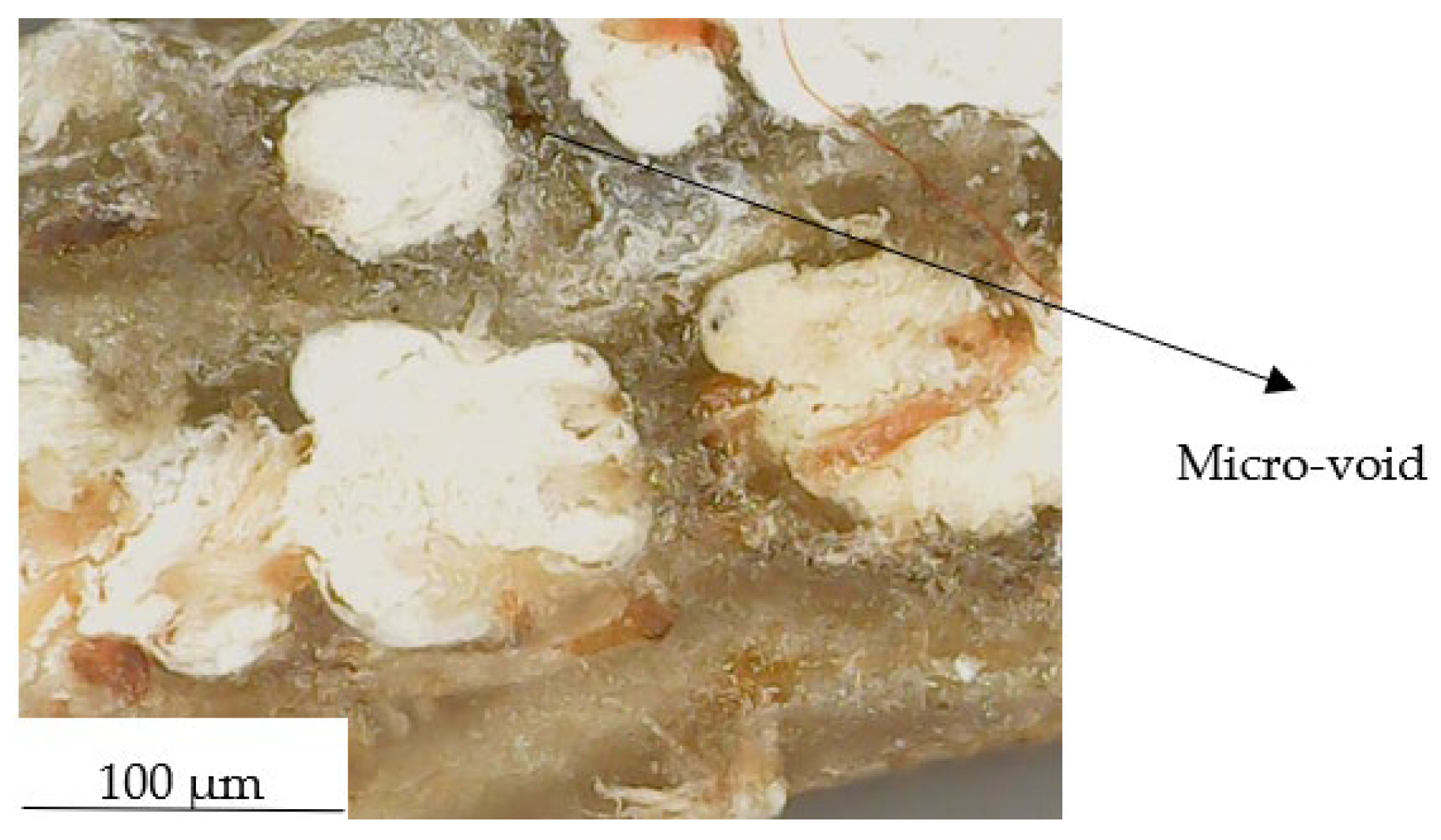

3.3.2. Fungal-Treated Specimens

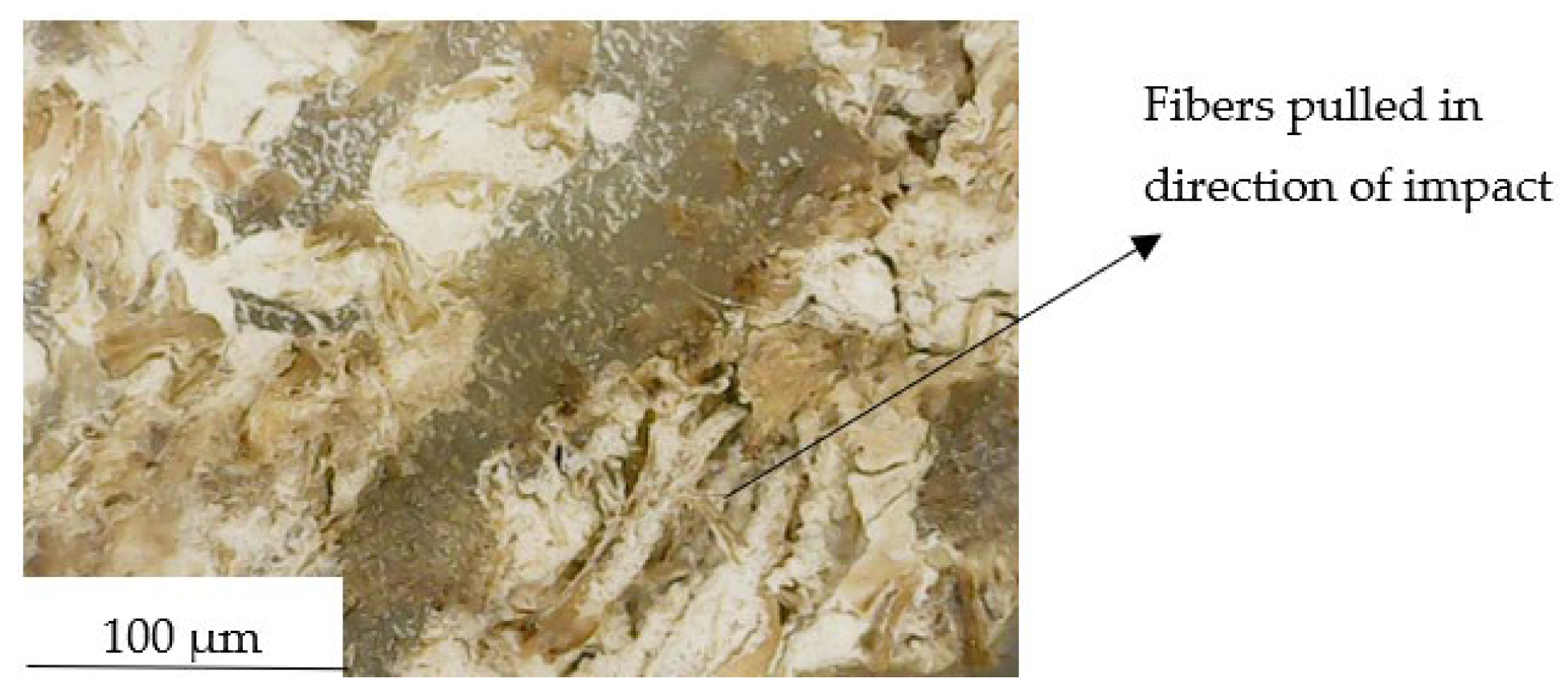

3.3.3. Failure Analysis

4. Discussion

5. Conclusions

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Balaga, U.K.; Gunes, A.; Ozdemir, T.; Blackwell, C.; Davis, M.; Sauerbrunn, S.; Fuessel, L.; Deitzel, J.M.; Heider, D. Optimization of the Recycling Process for Aligned Short Carbon Fiber TuFF Composites. Recycling 2025, 10, 55. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Naveen, J.A.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. J. Polym. Process. Inst. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

- Chawla, K.K.; Chawla, K.K. Carbon fiber composites. In Composite Materials: Science and Engineering; Springer: Cham, Switzerland, 1998; pp. 252–277. [Google Scholar]

- Kumar, P.; Sharan Gupta, H.; Singh, M.; Chaudhari, A.S.; Maurya, A.K.; Manik, G. Mechanical, Thermal, and Morphological Analysis of Himalayan Agave Fiber/GO Coated Fly Ash Hybrid Polypropylene Composites. Chem.–Eur. J. 2025, 31, e202402393. [Google Scholar] [CrossRef] [PubMed]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization oatural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Reddy, K.O.; Guduri, B.R.; Rajulu, A.V. Structural characterization and tensile properties of borassus fruit fibers. J. Appl. Polym. Sci. 2009, 114, 603–611. [Google Scholar] [CrossRef]

- Reddy, K.O.; Reddy, K.R.N.; Zhang, J.; Zhang, J.; Varada Rajulu, A. Effect of alkali treatment on the properties of century fiber. J. Nat. Fibers 2013, 10, 282–296. [Google Scholar] [CrossRef]

- Kommula, V.P.; Reddy, K.O.; Shukla, M.; Marwala, T.; Rajulu, A.V. Mechanical properties, water absorption, and chemical resistance of Napier grass fiber strand–reinforced epoxy resin composites. Int. J. Polym. Anal. Charact. 2014, 19, 693–708. [Google Scholar] [CrossRef]

- Marquard, H.; Deshpande, A.M.; Aditya, S. Effect of Environmental Aging on the Thermal and Chemical Properties of Flax Fiber-Polypropylene Natural Fiber Reinforced Thermoplastic Composites. In Proceedings of the 2024 ASC Technical Conference, San Diego, CA, USA, 23–24 October 2024. [Google Scholar]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Gulati, D.; Sain, M. Fungal-modification of natural fibers: A novel method of treating natural fibers for composite reinforcement. J. Polym. Environ. 2006, 14, 347–352. [Google Scholar] [CrossRef]

- Sałasińska, K.; Cabulis, P.; Kirpluks, M.; Kovalovs, A.; Kozikowski, P.; Barczewski, M.; Celiński, M.; Mizera, K.; Gałecka, M.; Skukis, E.; et al. The effect of manufacture process on mechanical properties and burning behavior of epoxy-based hybrid composites. Materials 2022, 15, 301. [Google Scholar] [CrossRef]

- Bangaru, P.D.; Schuster, J.; Shaik, Y.P.; Müller, D. Evaluation of mechanical properties and hydrophilicity of alkaline and plasma treated abaca fiber epoxy composite with mineral waste as fillers. J. Mater. Sci. Technol. Res. 2024, 11, 15–24. [Google Scholar] [CrossRef]

- Carl ROTH—International|Homepage. (n.d.). Available online: https://carlroth.com/ (accessed on 15 April 2024).

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Zervakis, G.; Philippoussis, A.; Ioannidou, S.; Diamantopoulou, P. Mycelium growth kinetics and optimal temperature conditions for the cultivation of edible mushroom species on lignocellulosic substrates. Folia Microbiol. 2001, 46, 231–234. [Google Scholar] [CrossRef] [PubMed]

- Gougouli, M.; Koutsoumanis, K.P. Relation between germination and mycelium growth of individual fungal spores. Int. J. Food Microbiol. 2013, 161, 231–239. [Google Scholar] [CrossRef]

- Schuster, J.; Govignon, Q.; Bickerton, S. Processability of biobased thermoset resins and flax fibres reinforcements using vacuum assisted resin transfer moulding. Open J. Compos. Mater. 2014, 4, 1–11. [Google Scholar] [CrossRef]

- Bender, D.; Schuster, J.; Heider, D. Flow rate control during vacuum-assisted resin transfer molding (VARTM) processing. Compos. Sci. Technol. 2006, 66, 2265–2271. [Google Scholar] [CrossRef]

- Abdurohman, K.; Satrio, T.; Muzayadah, N.L.; Teten. A comparison process between hand lay-up, vacuum infusion and vacuum bagging method toward E-glass EW 185/lycal composites. J. Phys. Conf. Ser. 2018, 1130, 012018. [Google Scholar] [CrossRef]

- Mujahid, Y.; Sallih, N.; Abdullah, M.Z.; Mustapha, M. Effects of processing parameters for vacuum-bag-only method on void content and mechanical properties of laminated composites. Polym. Compos. 2021, 42, 567–582. [Google Scholar] [CrossRef]

- Hall, W.; Javanbakht, Z.; Hall, W.; Javanbakht, Z. Advanced methods—Vacuum bagging and prepreg moulding. In Design and Manufacture of Fibre-Reinforced Composites; Springer: Cham, Switzerland, 2021; pp. 55–68. [Google Scholar]

- EN ISO 527-5:2009; Plastics–Determination of Tensile Properties. British Standard; BSEN ISO: London, UK, 1997. [Google Scholar]

- DIN EN ISO 178; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- DIN EN ISO 179; Plastics—Determination of Charpy impact properties. International Organization for Standardization: Geneva, Switzerland, 2010.

- DIN 53505; Testing of rubber—Determination of hardness (Shore Hardness). Deutsches Institut für Normung: Berlin, Germany, 2000.

- ASTM D570-98; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 1998.

- Samper, M.D.; Ferri, J.M.; Carbonell-Verdu, A.; Balart, R.; Fenollar, O. Properties of biobased epoxy resins from epoxidized linseed oil (ELO) crosslinked with a mixture of cyclic anhydride and maleinized linseed oil. Express Polym. Lett. 2019, 13, 407–418. [Google Scholar] [CrossRef]

- Hasan, M.Z.; Salit, M.S.; Hamdan, N.S.; Aziz, F.A.; Khan, A. Environmental life cycle analysis of natural fiber composites in energy sector. Phys. Sci. Rev. 2025, 10, 229–243. [Google Scholar] [CrossRef]

| Fiber Type | Tensile Strength (MPa) | Young’s Modulus (GPa) | Density (g/cm3) |

|---|---|---|---|

| Hemp [6] | 250–900 | 30–60 | 1.4–1.5 |

| Sisal [7] | 400–700 | 9–22 | 1.3–1.5 |

| Flax [8,9] | 500–1500 | 50–70 | 1.4–1.5 |

| Jute [10] | 200–800 | 10–30 | 1.3–1.5 |

| E-Glass [11] | 2000–3500 | 70–85 | 2.54 |

| Carbon [12] | 4000–6000 | 230–600 | 1.75–2.00 |

| Property | Value |

|---|---|

| Tensile strength | 250–900 MPa |

| Young’s modulus | 30–60 GPa |

| Density | 1.4–1.5 g/cm3 |

| Property | Value |

|---|---|

| Tensile strength | 400–700 MPa |

| Young’s modulus | 9–22 GPa |

| Density | 1.3–1.5 g/cm3 |

| Property | Value |

|---|---|

| Tensile strength | 63.5–73.5 MPa |

| Young’s modulus | 2.6–3.8 GPa |

| Flexural modulus | 3.35 GPa |

| Density | 1.5 g/cm3 |

| Viscosity (at 20 °C) | 200–450 mPa.s. |

| Sample ID | Hemp (wt.-%) | Sisal (wt.-%) | Fiber vol. (ϕf) | Epoxy (wt.-%) | Alkali Treatment | Fungal Treatment |

|---|---|---|---|---|---|---|

| S1 | 15 | 20 | 36.2 | 65 | Untreated | Untreated |

| S2 | 15 | 15 | 30.1 | 70 | Treated | Untreated |

| S3 | 15 | 20 | 36.2 | 65 | Treated | Untreated |

| S4 | 15 | 15 | 30.1 | 70 | Treated | Treated |

| S5 | 15 | 20 | 36.2 | 65 | Treated | Treated |

| S6 | 15 | 25 | 41.3 | 60 | Treated | Treated |

| Specimen | Water Absorption at 240 h (%) | Diffusion Coefficient (m2/s) |

|---|---|---|

| Neat epoxy | 1.3 | 1.66 × 10−12 |

| S1 | 2.4 | 3.56 × 10−13 |

| S2 | 1.7 | 3.63 × 10−13 |

| S3 | 1.6 | 4.54 × 10−13 |

| S4 | 1.65 | 4.44 × 10−13 |

| S5 | 1.6 | 4.88 × 10−13 |

| S6 | 1.7 | 5.26 × 10−13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kovuru, R.; Schuster, J. Enhancing Mechanical Properties of Hemp and Sisal Fiber-Reinforced Composites Through Alkali and Fungal Treatments for Sustainable Applications. J. Manuf. Mater. Process. 2025, 9, 191. https://doi.org/10.3390/jmmp9060191

Kovuru R, Schuster J. Enhancing Mechanical Properties of Hemp and Sisal Fiber-Reinforced Composites Through Alkali and Fungal Treatments for Sustainable Applications. Journal of Manufacturing and Materials Processing. 2025; 9(6):191. https://doi.org/10.3390/jmmp9060191

Chicago/Turabian StyleKovuru, Rahul, and Jens Schuster. 2025. "Enhancing Mechanical Properties of Hemp and Sisal Fiber-Reinforced Composites Through Alkali and Fungal Treatments for Sustainable Applications" Journal of Manufacturing and Materials Processing 9, no. 6: 191. https://doi.org/10.3390/jmmp9060191

APA StyleKovuru, R., & Schuster, J. (2025). Enhancing Mechanical Properties of Hemp and Sisal Fiber-Reinforced Composites Through Alkali and Fungal Treatments for Sustainable Applications. Journal of Manufacturing and Materials Processing, 9(6), 191. https://doi.org/10.3390/jmmp9060191