Processing, Microstructure, and Mechanical Behavior of Tungsten Heavy Alloys for Kinetic Energy Penetrators: A Critical Review

Abstract

1. Introduction

2. Processing of WHAs

2.1. Sintering of WHAs

| Composition (wt.%) | Mixing Technique and Duration | Ball-to-Powder Ratio | Compaction Methods | Ref. |

|---|---|---|---|---|

| 93W-4.9Ni-2.1Fe | Tumbler mixing for 30 h | - | CIP at 180 MPa | [60] |

| 92.5W-6.4Ni-1.1Fe | Turbula mixing for 30 min | - | Hydraulic pressing at 200 MPa | [61] |

| 90W-6Ni-2Fe-2Co | Ball milling for 24 h | 2:1, SS balls | CIP at 200 MPa | [27] |

| 93W-4.2Ni-1.2Fe-1.6Co | Ball milling for 48 h at 50 rpm | 2:1 | CIP at 250 MPa | [99] |

| 90.5W-7.1Ni-1.65Fe-0.5Co-0.25Mo | Ball milling at 35 rpm | 1:1, SS balls | CIP at 250 MPa | [77] |

| 90 W-6Ni-4Cu | Turbula mixing for 10 h at 96 rpm | - | Hydraulic pressing at 400 MPa | [83] |

| 91W-6Ni-3Co | Drum mixing for 20 h | - | Hydraulic pressing at 200 MPa | [82] |

| 90W-5Ni-2Fe-3Co | Ball milling for 48 h at 40 rpm | 1:1 | CIP at 250 MPa | [70] |

| 90W-7Ni-3Fe | Vibratory milling at 1000 rpm | - | Hydraulic press | [26] |

| 95W-3.5Ni-1.5Fe | Planetary ball milling for 5 h at 180 rpm | 5:1 | CIP at 200 MPa | [92] |

2.1.1. Solid-State Sintering of WHA

2.1.2. Liquid-Phase Sintering of WHAs

2.1.3. Spark Plasma Sintering of WHAs

2.1.4. Microwave Sintering of WHAs

2.2. Additive Manufacturing of WHAs

2.3. Post-Processing of WHAs

3. Effect of Composition on the WHA Characteristics

| Feature/Elements | Fe | Co | Mo | Re | Mn |

|---|---|---|---|---|---|

| Effect on the matrix | Solid solution strengthening | Solid solution strengthening | Solid solution strengthening | Strong solid solution strengthening | Limited solid solution strengthening |

| Grain size effect | Grain refinement at moderate Fe content; excessive Fe can lead to grain coarsening | Grain refinement at moderate Co content | Grain refinement and coarsening resistance | Strong grain refinement | Limited grain refinement |

| Sintering behavior | Improves wettability up to moderate Fe content; reduces at high Fe content | Improves wettability up to moderate Co content; reduces at high Fe content | Enhances densification | Enhances sintering kinetics and diffusivity | Improves wettability; assists in densification |

| Ductility | Decreases due to the formation of brittle intermetallic phases | Decreases above 6 wt.% due to brittle intermetallic phases | Maintains or slightly decreases | Improves both room- and high-temperature ductility | Slightly decreases |

| Intermetallic compounds | Fe7W6 | Co3W, Co7W6 | MoNi-type intermetallic compound | No intermetallics | Specific intermetallic compound not reported; however, MnO can form during sintering and can reduce density |

| Precipitate formation | Fe-rich precipitate forms at the W/matrix interface | Co-rich precipitates at the W/matrix interface | Mo-rich precipitates at grain boundaries | None, remains in solid solution | None |

| Specific mechanical properties | High strength and moderate ductility | High strength and moderate ductility | High-temperature strength and creep resistance | Superior high-temperature strength and ductility | Not ideal for high-temperature applications |

4. Microstructure of WHAs

5. Mechanical Properties of WHAs

6. Deformation Behavior of WHAs

7. Modeling and Simulation of WHAs

8. Conclusions and Future Work

- Development of matrix compositions and alloying strategies that enhance thermal softening and shear localization without compromising ductility.

- Design and integration of HEA or multi-principal-element alloy matrices for improved bonding and thermal stability.

- Optimization of AM parameters to overcome defects such as porosity and cracking, enabling the fabrication of net-shape, high-performance WHA components.

- Use of ODS alloys to promote fine grain size, inhibit crack propagation, and enhance high-temperature performance.

- Implementation of data-driven approaches and modeling frameworks to predict phase evolution, densification behavior, and dynamic failure mechanisms under impact conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Magier, M. The Conception of the Segmented Kinetic Energy Penetrators for Tank Guns. J. Appl. Mech. Trans. ASME 2010, 77, 051802. [Google Scholar] [CrossRef]

- Chen, P.; Guo, L.; Wang, C.; Jin, S.; Gao, H.; Wang, G.; Ma, Y.; He, Y.; He, Y. Preparation and Penetration Behavior of the Reactive Fine-Grained Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2023, 115, 106306. [Google Scholar] [CrossRef]

- Upadhyaya, A. Processing Strategy for Consolidating Tungsten Heavy Alloys for Ordnance Applications. Mater. Chem. Phys. 2001, 67, 101–110. [Google Scholar] [CrossRef]

- Gu, D.; Guo, M.; Zhang, H.; Sun, Y.; Wang, R.; Zhang, L. Effects of Laser Scanning Strategies on Selective Laser Melting of Pure Tungsten. Int. J. Extrem. Manuf. 2020, 2, 025001. [Google Scholar] [CrossRef]

- Pan, S.H.; Yao, G.C.; Cui, Y.N.; Meng, F.S.; Luo, C.; Zheng, T.Q.; Singh, G. Additive Manufacturing of Tungsten, Tungsten-Based Alloys, and Tungsten Matrix Composites. Tungsten 2023, 5, 1–31. [Google Scholar] [CrossRef]

- Şahin, Y. Recent Progress in Processing of Tungsten Heavy Alloys. J. Powder Technol. 2014, 2014, 764306. [Google Scholar] [CrossRef]

- Manikandan, R.; Raja Annamalai, A. Tungsten Heavy Alloys Processing via Microwave Sintering, Spark Plasma Sintering, and Additive Manufacturing: A Review. Processes 2022, 10, 2352. [Google Scholar] [CrossRef]

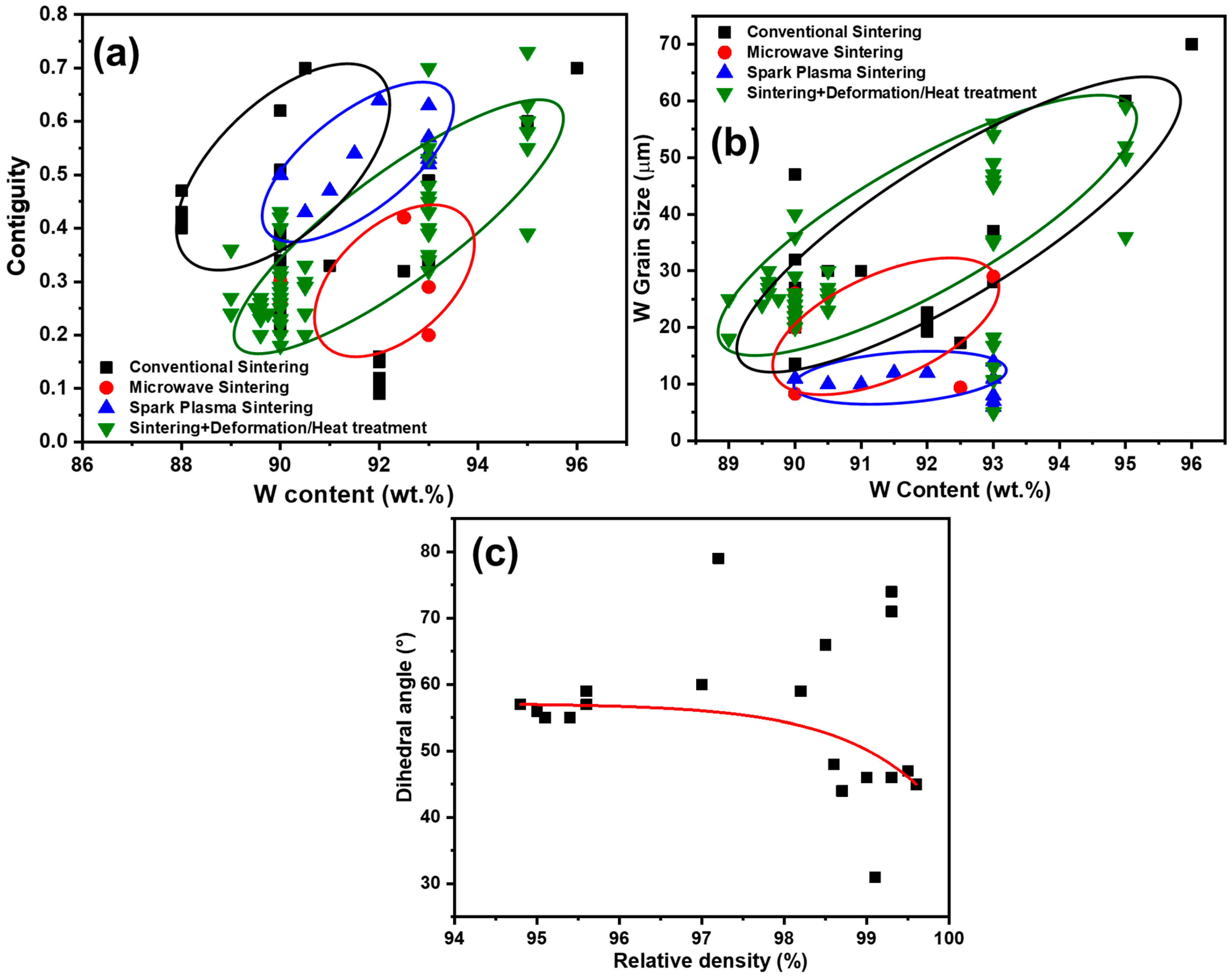

- German, R.M. Sintered Tungsten Heavy Alloys: Review of Microstructure, Strength, Densification, and Distortion. Int. J. Refract. Met. Hard Mater. 2022, 108, 105940. [Google Scholar] [CrossRef]

- Mudda, S.; Annamalai, A.R.; Muthuchamy, A. Additive Manufacturing of Pure Tungsten and Tungsten Heavy Alloys-State-of-the-Art Processes. Met. Mater. Int. 2025, 1–32. [Google Scholar] [CrossRef]

- Senthilnathan, N.; Raja Annamalai, A.; Venkatachalam, G. Sintering of Tungsten and Tungsten Heavy Alloys of W–Ni–Fe and W–Ni–Cu: A Review. Trans. Indian Inst. Met. 2017, 70, 1161–1176. [Google Scholar] [CrossRef]

- Goroch, O.; Gulbinowicz, Z.; Magier, M.; Bednarczyk, E.; Skoczylas, P.; Pankowski, Z.; Sweklej, P.; Zochowski, P.; Jedrzejewski, W. Development and Experimental Verification of the New WHA Sinters Intended for Kinetic Energy Projectiles. Contin. Mech. Thermodyn. 2023, 35, 2193–2205. [Google Scholar] [CrossRef]

- Arora, A.; Gopal Rao, V.G. Tungsten Heavy Alloy for Defence Applications. Mater. Technol. 2004, 19, 210–216. [Google Scholar] [CrossRef]

- Senthilnathan, N.; Annamalai, A.R.; Venkatachalam, G. Microstructure and Mechanical Properties of Spark Plasma Sintered Tungsten Heavy Alloys. Mater. Sci. Eng. A 2018, 710, 66–73. [Google Scholar] [CrossRef]

- Das, J.; Kiran, U.R.; Chakraborty, A.; Prasad, N.E. Hardness and Tensile Properties of Tungsten Based Heavy Alloys Prepared by Liquid Phase Sintering Technique. Int. J. Refract. Met. Hard Mater. 2009, 27, 577–583. [Google Scholar] [CrossRef]

- Jacobs, J.; Haque, A.; Kulkarni, A.; Singh, J.; Matson, L. Microstructure of Tungsten Metal Alloys Produced by Field Assisted Sintering Technology (FAST). Int. J. Refract. Met. Hard Mater. 2019, 84, 104976. [Google Scholar] [CrossRef]

- Yin, Y.; Wang, T.; Qin, S.; Wang, W.; Shi, Y.; Yu, H. Research on Microstructure, Mechanical Properties, and High-Temperature Stability of Hot-Rolled Tungsten Hafnium Alloy. Materials 2024, 17, 3663. [Google Scholar] [CrossRef]

- Buzi, L.; Yeh, M.; Yeh, Y.W.; Donaldson, O.K.; Patino, M.I.; Trelewicz, J.R.; Yao, N.; Doerner, R.; Koel, B.E. Deuterium and Helium Ion Irradiation of Nanograined Tungsten and Tungsten–Titanium Alloys. Nucl. Mater. Energy 2019, 21, 100713. [Google Scholar] [CrossRef]

- Liu, B.; Dong, H.; Li, P.; Ai, T.; Li, W. Study on Microstructure and Mechanical Properties of W-Ni3Al Alloys Prepared by Ball Milling and Two-Step Sintering. Mater. Res. Express 2021, 8, 036505. [Google Scholar] [CrossRef]

- Mao, R.; Xiang, D. Significantly Elevated Strength of W-Ni3Al Alloy by Adding Trace Boron Element. Int. J. Refract. Met. Hard Mater. 2023, 111, 106091. [Google Scholar] [CrossRef]

- Hu, L.; Xiang, D.; Mao, R.; Gui, Z. Microstructure Evolution and Mechanical Property of W-Ni3Al Alloy by Adding Minor Co Element. J. Alloys Compd. 2024, 976, 173286. [Google Scholar] [CrossRef]

- Ravi Kiran, U.; Panchal, A.; Prem Kumar, M.; Sankaranarayana, M.; Nageswara Rao, G.V.S.; Nandy, T.K. Refractory Metal Alloying: A New Method for Improving Mechanical Properties of Tungsten Heavy Alloys. J. Alloys Compd. 2017, 709, 609–619. [Google Scholar] [CrossRef]

- Kiran, U.R.; Panchal, A.; Sankaranarayana, M.; Nandy, T.K. Tensile and Impact Behavior of Swaged Tungsten Heavy Alloys Processed by Liquid Phase Sintering. Int. J. Refract. Met. Hard Mater. 2013, 37, 1–11. [Google Scholar] [CrossRef]

- Liu, J.; German, R.M. Microstructure Effect on Dihedral Angle in Liquid-Phase Sintering. Metall. Mater. Trans. A 2001, 32, 165–169. [Google Scholar] [CrossRef]

- Wu, Y.; German, R.M.; Marx, B.; Suri, P.; Bollina, R. Comparison of Densification and Distortion Behaviors of W-Ni-Cu and W-Ni-Fe Heavy Alloys in Liquid-Phase Sintering. J. Mater. Sci. 2003, 38, 2271–2281. [Google Scholar] [CrossRef]

- Gurwell, W.E. Solid-State Sintering of Tungsten Heavy Alloys. Mater. Manuf. Process 1994, 9, 1115–1126. [Google Scholar] [CrossRef]

- Akhtar, F. An Investigation on the Solid State Sintering of Mechanically Alloyed Nano-Structured 90W-Ni-Fe Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2008, 26, 145–151. [Google Scholar] [CrossRef]

- Prabhu, G.; Arvind Kumar, N.; Sankaranarayana, M.; Nandy, T.K. Tensile and Impact Properties of Microwave Sintered Tungsten Heavy Alloys. Mater. Sci. Eng. A 2014, 607, 63–70. [Google Scholar] [CrossRef]

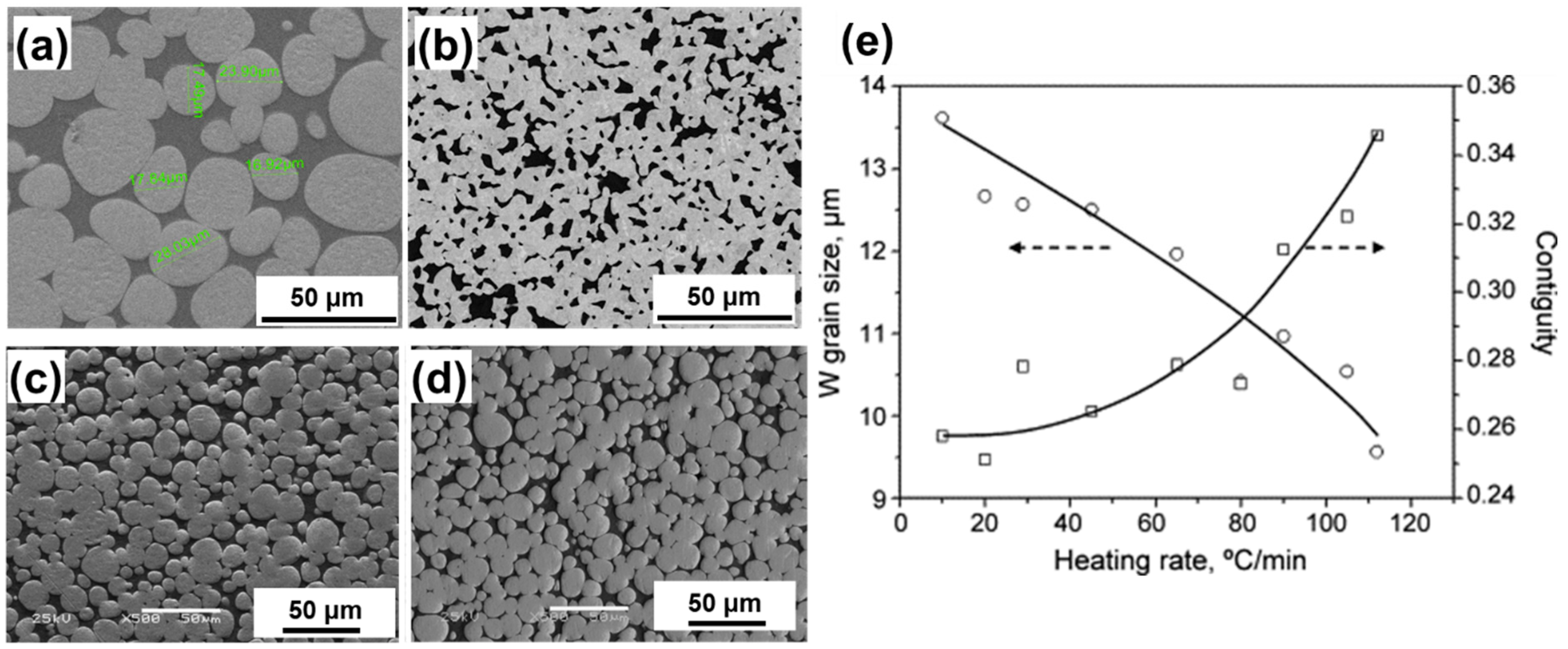

- Zhou, C.; Yi, J.; Luo, S.; Peng, Y.; Li, L.; Chen, G. Effect of Heating Rate on the Microwave Sintered W-Ni-Fe Heavy Alloys. J. Alloys Compd. 2009, 482, L6. [Google Scholar] [CrossRef]

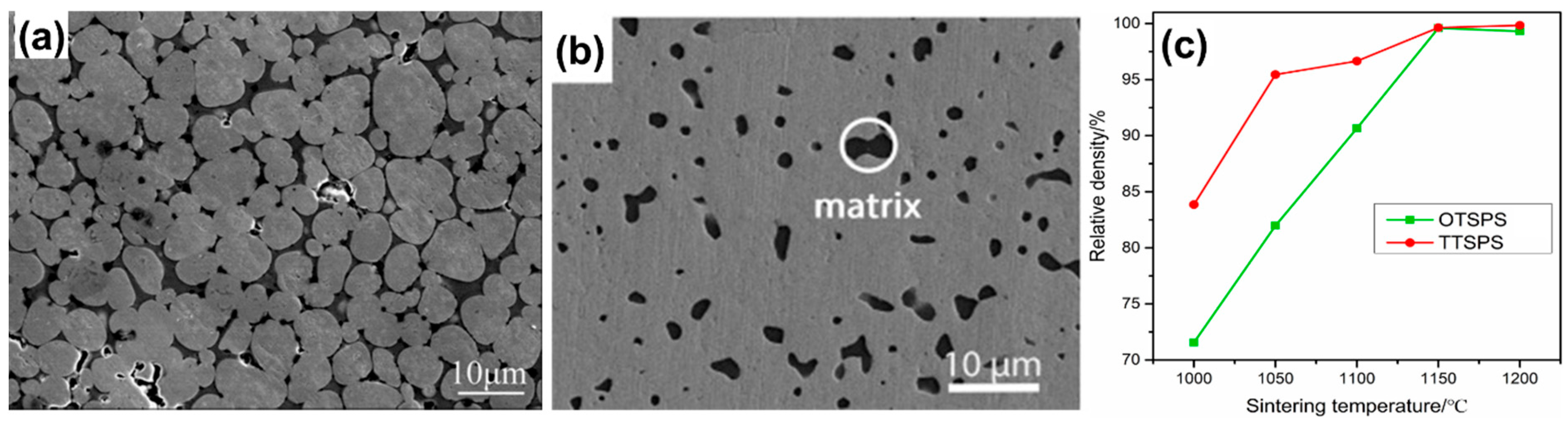

- Fan, Z.S.; Xiang, D.P.; Pan, Y.L.; Jiang, H. Effect of Two-Time Spark Plasma Sintering on Microstructure and Mechanical Properties of W–6Ni–4Mn Alloy. Mater. Sci. Eng. A 2019, 745, 300–306. [Google Scholar] [CrossRef]

- Choi, J.; Sung, H.M.; Roh, K.B.; Hong, S.H.; Kim, G.H.; Han, H.N. Fabrication of Sintered Tungsten by Spark Plasma Sintering and Investigation of Thermal Stability. Int. J. Refract. Met. Hard Mater. 2017, 69, 164–169. [Google Scholar] [CrossRef]

- Chen, W.; Shi, Y.; Dong, L.; Wang, L.; Li, H.; Fu, Y. Infiltration Sintering of WCu Alloys from Copper-Coated Tungsten Composite Powders for Superior Mechanical Properties and Arc-Ablation Resistance. J. Alloys Compd. 2017, 728, 196–205. [Google Scholar] [CrossRef]

- Fang, X.; Liu, J.; Wang, X.; Li, S.; Guo, W. Investigation on the Penetration Performance and “Self-Sharpening” Behavior of the 80W-14Cu-6Zn Penetrators. Int. J. Refract. Met. Hard Mater. 2016, 54, 237–243. [Google Scholar] [CrossRef]

- Caceres, P.G. Effect of Microstructure on the Abrasive Wear Properties of Infiltrated Tungsten Alloys. Mater. Charact. 2002, 49, 1–9. [Google Scholar] [CrossRef]

- Mohsin, I.U.; Gierl, C.; Danninger, H.; Momeni, M. Thermal De-Binding Kinetics of Injection Molded W-8%Ni-2%Cu. Int. J. Refract. Met. Hard Mater. 2011, 29, 729–732. [Google Scholar] [CrossRef]

- Zu, Y.S.; Lin, S.T. Optimizing the Mechanical Properties of Injection Molded W 4.9%Ni 2.1%Fe in Debinding. J. Mater. Process Technol. 1997, 71, 337–342. [Google Scholar] [CrossRef]

- Loewenhoff, T.; Antusch, S.; Pintsuk, G.; Rieth, M.; Wirtz, M. High Pulse Number Thermal Shock Testing of Tungsten Alloys Produced by Powder Injection Molding. Nucl. Mater. Energy 2019, 20, 100680. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of Metal Matrix Composites by Metal Injection Molding—A Review. J. Mater. Process Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef]

- Suri, P.; German, R.M.; de Souza, J.P. Influence of Mixing and Effect of Agglomerates on the Green and Sintered Properties of 97W–2.1Ni–0.9Fe Heavy Alloys. Int. J. Refract. Met. Hard Mater. 2009, 27, 683–687. [Google Scholar] [CrossRef]

- Loh, N.H.; Tor, S.B.; Khor, K.A. Production of Metal Matrix Composite Part by Powder Injection Molding. J. Mater. Process Technol. 2001, 108, 398–407. [Google Scholar] [CrossRef]

- Xue, J.; Feng, Z.; Tang, J.; Tang, C.; Zhao, Z. Selective Laser Melting Additive Manufacturing of Tungsten with Niobium Alloying: Microstructure and Suppression Mechanism of Microcracks. J. Alloys Compd. 2021, 874, 159879. [Google Scholar] [CrossRef]

- Ahn, S.Y.; Kim, E.S.; Karthik, G.M.; Ramkumar, K.R.; Jeong, S.G.; Kim, R.E.; Gu, G.H.; Kim, H.S. Thickness Effect on the Microstructures, Mechanical Properties, and Anisotropy of Laser-Powder Bed Fusion Processed 316L Stainless Steel. J. Mater. Sci. 2022, 57, 18101–18117. [Google Scholar] [CrossRef]

- Kwon, J.; Karthik, G.M.; Estrin, Y.; Kim, H.S. Constitutive Modeling of Cellular-Structured Metals Produced by Additive Manufacturing. Acta Mater. 2022, 241, 118421. [Google Scholar] [CrossRef]

- Karthik, G.M.; Sathiyamoorthi, P.; Zargaran, A.; Park, J.M.; Asghari-Rad, P.; Son, S.; Park, S.H.; Kim, H.S. Novel Precipitation and Enhanced Tensile Properties in Selective Laser Melted Cu-Sn Alloy. Materials 2020, 13, 100861. [Google Scholar] [CrossRef]

- Xie, J.; Lu, H.; Lu, J.; Song, X.; Wu, S.; Lei, J. Additive Manufacturing of Tungsten Using Directed Energy Deposition for Potential Nuclear Fusion Application. Surf. Coat. Technol. 2021, 409, 126884. [Google Scholar] [CrossRef]

- Kim, E.S.; Ahn, S.Y.; Jeong, S.G.; Go, E.H.; Bae, J.W.; Hong, S.J.; Wang, J.; Lee, B.J.; Karthik, G.M.; Kim, H.S. Cellular Structure Assisted Enhanced Deformation-Induced Martensitic Transformation in Laser-Directed Energy Deposited Ferrous Medium-Entropy Alloy. Mater. Sci. Eng. A 2025, 922, 147631. [Google Scholar] [CrossRef]

- Jeong, S.G.; Ahn, S.Y.; Kim, E.S.; Karthik, G.M.; Baik, Y.; Seong, D.; Kim, Y.S.; Woo, W.; Kim, H.S. Effect of Substrate Yield Strength and Grain Size on the Residual Stress of Direct Energy Deposition Additive Manufacturing Measured by Neutron Diffraction. Mater. Sci. Eng. A 2022, 851, 143632. [Google Scholar] [CrossRef]

- Nigarura, S.; Shah, R.; Karhumaa, T.; Trasorras, J.L. Manufacturing Process and Mechanical Properties of BJ3DP Tungsten Heavy Alloy Components. Int. J. Refract. Met. Hard Mater. 2022, 108, 105954. [Google Scholar] [CrossRef]

- Bose, A.; Reidy, J.P.; Tuncer, N.; Jorgensen, L. Processing of Tungsten Heavy Alloy by Extrusion-Based Additive Manufacturing. Int. J. Refract. Met. Hard Mater. 2023, 110, 106021. [Google Scholar] [CrossRef]

- Bose, A.; Schuh, C.A.; Tobia, J.C.; Tuncer, N.; Mykulowycz, N.M.; Preston, A.; Barbati, A.C.; Kernan, B.; Gibson, M.A.; Krause, D.; et al. Traditional and Additive Manufacturing of a New Tungsten Heavy Alloy Alternative. Int. J. Refract. Met. Hard Mater. 2018, 73, 22–28. [Google Scholar] [CrossRef]

- Zarinejad, M.; Tong, Y.; Salehi, M.; Mu, C.; Wang, N.; Xu, Y.; Rimaz, S.; Tian, L.; Kuah, K.X.; Chen, X. Advancements and Perspectives in Additive Manufacturing of Tungsten Alloys and Composites: Challenges and Solutions. Crystals 2024, 14, 665. [Google Scholar] [CrossRef]

- Hu, B.; Cai, G.; Fu, J.; Xin, Y.; Zhang, D.; Yuan, Y.; Guo, S. Densification Behavior of Tungsten Alloy Powders during Hot Isostatic Pressing. Mater. Today Commun. 2022, 31, 103576. [Google Scholar] [CrossRef]

- Kovářík, O.; Čech, J.; Čapek, J.; Hajíček, M.; Klečka, J.; Siegl, J. Mechanical Properties of Forged Tungsten Heavy Alloys. Acta Polytech. CTU Proc. 2020, 27, 149–154. [Google Scholar] [CrossRef]

- Alam, M.E.; Wang, J.; Henager, C.H.; Setyawan, W.; Odette, G.R. The Effect of Hot Rolling on the Strength and Fracture Toughness of 90W–7Ni3Fe Tungsten Heavy Metal Alloys. Mater. Sci. Eng. A 2021, 824, 141738. [Google Scholar] [CrossRef]

- Liu, J.; Shukui, L.; Xiaoqing, Z.; Zhaohui, Z.; Haiyun, Z.; Yingchun, W. Adiabatic Shear Banding in a Tungsten Heavy Alloy Processed by Hot-Hydrostatic Extrusion and Hot Torsion. Scr. Mater. 2008, 59, 1271–1274. [Google Scholar] [CrossRef]

- Panchal, A.; Reddy, K.V.; Azeem, P.A.; Nandy, T.K.; Singh, A.K. Microstructure, Texture, Tensile Flow and Work Hardening Behavior of Tungsten Heavy Alloys in Swaged and Swaged + Aged Conditions. Metallogr. Microstruct. Anal. 2020, 9, 438–456. [Google Scholar] [CrossRef]

- Ravi Kiran, U.; Venkat, S.; Rishikesh, B.; Iyer, V.K.; Sankaranarayana, M.; Nandy, T.K. Effect of Tungsten Content on Microstructure and Mechanical Properties of Swaged Tungsten Heavy Alloys. Mater. Sci. Eng. A 2013, 582, 389–396. [Google Scholar] [CrossRef]

- Shen, J.; Campbell, L.; Suri, P.; German, R.M. Quantitative Microstructure Analysis of Tungsten Heavy Alloys (W–Ni–Cu) during Initial Stage Liquid Phase Sintering. Int. J. Refract. Met. Hard Mater. 2005, 23, 99–108. [Google Scholar] [CrossRef]

- Das, J.; Appa Rao, G.; Pabi, S.K. Microstructure and Mechanical Properties of Tungsten Heavy Alloys. Mater. Sci. Eng. A 2010, 527, 7841–7847. [Google Scholar] [CrossRef]

- Mondal, A.; Upadhyaya, A.; Agrawal, D. Microwave and Conventional Sintering of Premixed and Prealloyed Tungsten Heavy Alloys. Mater. Sci. Technol. Oct. 2008, 4, 5–9. [Google Scholar]

- Yang, Y.; Lianxi, H.; Erde, W. Microstructure and Mechanical Properties of a Hot-Hydrostatically Extruded 93W-4.9Ni-2.1Fe Alloy. Mater. Sci. Eng. A 2006, 435, 620–624. [Google Scholar] [CrossRef]

- Upadhyaya, A.; Tiwari, S.K.; Mishra, P. Microwave Sintering of W-Ni-Fe Alloy. Scr. Mater. 2007, 56, 5–8. [Google Scholar] [CrossRef]

- Zhou, C.; Yi, J.; Luo, S. Sintering High Tungsten Content W-Ni-Fe Heavy Alloys by Microwave Radiation. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2014, 45, 455–463. [Google Scholar] [CrossRef]

- Kim, D.-K.; Lee, S.; Baek, W.H. Microstructural Study of Adiabatic Shear Bands Formed by High-Speed Impact in a Tungsten Heavy Alloy Penetrator. Mater. Sci. Eng. A 1998, 249, 197–205. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, W.; Ma, Y.; Ye, X.; Wu, Y. An Improved Two-Stage Sintering Method for Tungsten Heavy Alloys: Conventional Solidphase Sintering Followed by Microwave Heating. Int. J. Mater. Res. 2015, 106, 80–82. [Google Scholar] [CrossRef]

- Li, Y.; Hu, K.; Li, X.; Ai, X.; Qu, S. Fine-Grained 93W-5.6Ni-1.4Fe Heavy Alloys with Enhanced Performance Prepared by Spark Plasma Sintering. Mater. Sci. Eng. A 2013, 573, 245–252. [Google Scholar] [CrossRef]

- Humail, I.S.; Akhtar, F.; Askari, S.J.; Tufail, M.; Qu, X. Tensile Behavior Change Depending on the Varying Tungsten Content of W-Ni-Fe Alloys. Int. J. Refract. Met. Hard Mater. 2007, 25, 380–385. [Google Scholar] [CrossRef]

- Lakshmi Prasad, B.S.; Raja Annamalai, A. Effect of Rhenium Addition on Tungsten Heavy Alloys Processed through Spark Plasma Sintering. Ain. Shams. Eng. J. 2021, 12, 2957–2963. [Google Scholar] [CrossRef]

- Panchal, A.; Reddy, K.V.; Azeem, P.A.; Nandy, T.K.; Singh, A.K. On the Flow and Work Hardening Behavior of Tungsten Heavy Alloy 92W-5.5Ni-2.5Fe. Int. J. Refract. Met. Hard Mater. 2020, 88, 105203. [Google Scholar] [CrossRef]

- Çalişkan, N.K.; Durlu, N.; Bor, Ş. Swaging of Liquid Phase Sintered 90W-7Ni-3Fe Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2013, 36, 260–264. [Google Scholar] [CrossRef]

- Kiran, U.R.; Sankaranarayana, M.; Nageswara Rao, G.V.S.; Nandy, T.K. Effect of Cobalt Addition on Microstructure and Mechanical Properties of Tungsten Heavy Alloys. Trans. Indian Inst. Met. 2017, 70, 615–622. [Google Scholar] [CrossRef]

- Kumari, A.; Prabhu, G.; Sankaranarayana, M.; Nandy, T.K. Effect of Solution Treatment Temperature and Cooling Rate on the Mechanical Properties of Tungsten Heavy Alloy. Mater. Sci. Eng. A 2017, 688, 225–236. [Google Scholar] [CrossRef]

- Damodaram, R.; Karthik, G.M.; Lalam, S.V. Microstructure and Mechanical Properties of a Rotary Friction Welded Tungsten Heavy Alloy. Mater. Test. 2019, 61, 209–212. [Google Scholar] [CrossRef]

- Ravi Kiran, U.; Kumar, J.; Kumar, V.; Sankaranarayana, M.; Nageswara Rao, G.V.S.; Nandy, T.K. Effect of Cyclic Heat Treatment and Swaging on Mechanical Properties of the Tungsten Heavy Alloys. Mater. Sci. Eng. A 2016, 656, 256–265. [Google Scholar] [CrossRef]

- Das, J.; Sankaranarayana, M.; Nandy, T.K. Serrated Flow Behavior in Tungsten Heavy Alloy. Mater. Sci. Eng. A 2015, 646, 75–81. [Google Scholar] [CrossRef]

- Das, J.; Rao, G.A.; Pabi, S.K.; Sankaranarayana, M.; Nandy, T.K. Thermo-Mechanical Processing, Microstructure and Tensile Properties of a Tungsten Heavy Alloy. Mater. Sci. Eng. A 2014, 613, 48–59. [Google Scholar] [CrossRef]

- Panchal, A.; Nandy, T.K. Effect of Composition, Heat Treatment and Deformation on Mechanical Properties of Tungsten Heavy Alloys. Mater. Sci. Eng. A 2018, 733, 374–384. [Google Scholar] [CrossRef]

- Das, J.; Appa Rao, G.; Pabi, S.K.; Sankaranarayana, M.; Sarma, B. Deformation Behaviour of a Newer Tungsten Heavy Alloy. Mater. Sci. Eng. A 2011, 528, 6235–6247. [Google Scholar] [CrossRef]

- Kumari, A.; Sankaranarayana, M.; Nandy, T.K. On Structure Property Correlation in High Strength Tungsten Heavy Alloys. Int. J. Refract. Met. Hard Mater. 2017, 67, 18–31. [Google Scholar] [CrossRef]

- Kumari, A.; Prabhu, G.; Nandy, T.K. Effect of Nickel to Cobalt Ratio on Mechanical Properties of Tungsten Heavy Alloys. J. Alloys Metall. Syst. 2023, 3, 100030. [Google Scholar] [CrossRef]

- Skoczylas, P.; Kaczorowski, M. The Influence of Co Addition on the Structure and Mechanical Properties of Tungsten Heavy Alloys. Materials 2022, 15, 9064. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Klečková, Z. Effects of Sintering Conditions on Structures and Properties of Sintered Tungsten Heavy Alloy. Materials 2020, 13, 2338. [Google Scholar] [CrossRef] [PubMed]

- Skoczylas, P.; Goroch, O.; Gulbinowicz, Z.; Penkul, A. The Effect of Cold Swaging of Tungsten Heavy Alloy with the Composition W91-6Ni-3Co on the Mechanical Properties. Materials 2021, 14, 7300. [Google Scholar] [CrossRef]

- Shakunt, N.S.; Gouthama; Upadhyaya, A. Effect of Fe Addition in W-Ni-Cu Heavy Alloy Processed through Powder Metallurgy on Microstructure and Mechanical Properties. J. Alloys Compd. 2024, 970, 172578. [Google Scholar] [CrossRef]

- Rajaei, M.; Raoufi, M.; Mostaan, H.; Beiranvand, Z.M.; Naeimi, A. The Effect of Pressure and Temperature on the Properties of 88 W-10Ni-2Mn Tungsten Heavy Alloy Produced by Cold Press Method. Int. J. Refract. Met. Hard Mater. 2024, 124, 106781. [Google Scholar] [CrossRef]

- Manikandan, R.; Raja Annamalai, A. Effect of Mn Addition in W-Ni-Cu Heavy Alloy Processed through Hot Press Sintering Techniques on Microstructure, Microtexture and Grain Boundary Character Evolution. Mater. Charact. 2024, 210, 113808. [Google Scholar] [CrossRef]

- Ma, Y.; Tang, X.; Wang, X.; Zhang, M.; Hu, H.; Gong, P.; Wang, X. Preparation and Mechanical Properties of Tungsten-Particle-Reinforced Zr-Based Bulk-Metallic-Glass Composites. Mater. Sci. Eng. A 2021, 815, 141312. [Google Scholar] [CrossRef]

- Hu, H.; Jin, H.; Chi, J.; Du, Y.; Ma, Y. Behavior of Tungsten-Particle-Reinforced Zirconium-Based Bulk Metallic Glass Composites When Penetrating a Semi-Infinite Target. Intermetallics 2025, 177, 108601. [Google Scholar] [CrossRef]

- Zhou, S.; Liang, Y.J.; Zhu, Y.; Jian, R.; Wang, B.; Xue, Y.; Wang, L.; Wang, F. High Entropy Alloy: A Promising Matrix for High-Performance Tungsten Heavy Alloys. J. Alloys Compd. 2019, 777, 1184–1190. [Google Scholar] [CrossRef]

- Satyanarayana, P.V.; Sokkalingam, R.; Jena, P.K.; Sivaprasad, K.; Prashanth, K.G. Tungsten Matrix Composite Reinforced with Cocrfemnni High-Entropy Alloy: Impact of Processing Routes on Microstructure and Mechanical Properties. Metals 2019, 9, 992. [Google Scholar] [CrossRef]

- Panigrahi, A.; Acharya, T.S.; Sengupta, P.; Kumar, D.; Sarangi, L.; Kumar, N.; Debasish, D.; Suwas, S.; Basu, S.; Debata, M. Microstructure and Mechanical Properties of Novel Tungsten Heavy Alloys Prepared Using FeNiCoCrCu HEA as Binder. Mater. Sci. Eng. A 2022, 832, 142451. [Google Scholar] [CrossRef]

- Ma, H.; Shao, Y.; Shek, C.H. Microstructure, Grain Growth Behavior and Mechanical Properties of W-CoCuFeNi Tungsten Heavy Alloys Prepared by Infiltration. Int. J. Refract. Met. Hard Mater. 2021, 98, 105572. [Google Scholar] [CrossRef]

- Gong, X.; Fan, J.L.; Ding, F.; Song, M.; Huang, B.Y. Effect of Tungsten Content on Microstructure and Quasi-Static Tensile Fracture Characteristics of Rapidly Hot-Extruded W-Ni-Fe Alloys. Int. J. Refract. Met. Hard Mater. 2012, 30, 71–77. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical Alloying and Milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Eroglu, S.; Baykara, T. Effects of Powder Mixing Technique and Tungsten Powder Size on the Properties of Tungsten Heavy Alloys. J. Mater. Process Technol. 2000, 103, 288–292. [Google Scholar] [CrossRef]

- Chen, C.L.; Ma, S.H. Study on Characteristics and Sintering Behavior of W-Ni-Co Tungsten Heavy Alloy by a Secondary Ball Milling Method. J. Alloys Compd. 2018, 731, 78–83. [Google Scholar] [CrossRef]

- Abdallah, A.; Fayed, A.; Abdo, G.; Sallam, M. Effect of Cold Isostatic Pressing On The Physical and Mechanical Properties of Tungsten Heavy Alloys. J. Eng. Sci. Mil. Technol. 2017, 17, 1–12. [Google Scholar] [CrossRef]

- Shao, Y.; Yu, W.; Wu, J.; Ma, H. Effect of Sintering Temperatures on Grain Coarsening Behaviors and Mechanical Properties of W-NiTi Heavy Tungsten Alloys. Materials 2022, 15, 8035. [Google Scholar] [CrossRef]

- Srikanth, V.; Upadhyaya, G.S. Effect of Tungsten Particle Size on Sintered Properties of Heavy Alloys. Powder Technol. 1984, 39, 61–67. [Google Scholar] [CrossRef]

- Ravi Kiran, U.; Panchal, A.; Sankaranarayana, M.; Nageswara Rao, G.V.S.; Nandy, T.K. Effect of Alloying Addition and Microstructural Parameters on Mechanical Properties of 93% Tungsten Heavy Alloys. Mater. Sci. Eng. A 2015, 640, 82–90. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, Y.; Zhang, J.; Conejo, A.N.; Liu, Z. The Grain Growth and Grain Boundary Migrations during Solid-Phase Sintering of Fe2O3: Experiments and Simulations. Chem. Eng. Sci. 2022, 262, 118038. [Google Scholar] [CrossRef]

- Shi, R.; Wood, M.; Heo, T.W.; Wood, B.C.; Ye, J. Towards Understanding Particle Rigid-Body Motion during Solid-State Sintering. J. Eur. Ceram. Soc. 2021, 41, 211–231. [Google Scholar] [CrossRef]

- German, R.M. Sintering Trajectories: Description on How Density, Surface Area, and Grain Size Change. JOM 2016, 68, 878–884. [Google Scholar] [CrossRef]

- Gouvêa, D. Thermodynamic of Solid-State Sintering: Contributions of Grain Boundary Energy. J. Eur. Ceram. Soc. 2024, 44, 116677. [Google Scholar] [CrossRef]

- Ryu, J.; Hong, S.H.; Baek, W.H. Mechanical Alloying Process of 93W-5.6Ni-1.4Fe Tungsten Heavy Alloy. J. Mater. Process. Technol. 1997, 63, 292–297. [Google Scholar] [CrossRef]

- Bose, A.; Sadangi, R.; German, R.M. A Review on Alloying in Tungsten Heavy Alloys. In TMS 2012 141st Annual Meeting and Exhibition, Materials Processing and Interfaces; John Wiley & Sons: Hoboken, NJ, USA, 2012; Volume 1, p. 455. [Google Scholar]

- Price, G.H.S. Copper-Nickel-Tungsten Alloys Sintered with a Liquid Phase Present. J. Inst. Met. 1938, 62, 239–264. [Google Scholar]

- German, R.M.; Suri, P.; Park, S.J. Review: Liquid Phase Sintering. J. Mater. Sci. 2009, 44, 1–39. [Google Scholar] [CrossRef]

- Liu, J.; German, R.M. Densification and Shape Distortion in Liquid-Phase Sintering. Metall. Mater. Trans. A 1999, 30, 3211–3217. [Google Scholar] [CrossRef]

- Bollina, R.; German, R.M. Heating Rate Effects on Microstructural Properties of Liquid Phase Sintered Tungsten Heavy Alloys. Int. J. Refract. Met. Hard Mater. 2004, 22, 117–127. [Google Scholar] [CrossRef]

- Olevsky, E.A.; German, R.M.; Upadhyaya, A. Effect of Gravity on Dimensional Change during Sintering—II. Shape Distortion. Acta Mater. 2000, 48, 1167–1180. [Google Scholar] [CrossRef]

- Li, Z.B.; Zhang, H.; Zhang, G.H.; Chou, K.C. Fabrication and Characterization of Tungsten Heavy Alloys with High W Content by Powder Metallurgy. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2022, 53, 1085–1098. [Google Scholar] [CrossRef]

- Saiprasad, M.; Atchayakumar, R.; Thiruppathi, K.; Raghuraman, S. Consolidation of Copper and Aluminium Powders by Spark Plasma Sintering. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2016; Volume 149. [Google Scholar]

- Hu, K.; Li, X.Q.; Yang, C.; Li, Y.Y. Densification and Microstructure Evolution during SPS Consolidation Process in W-Ni-Fe System. Trans. Nonferrous Met. Soc. China 2011, 21, 493–501. [Google Scholar] [CrossRef]

- Pan, Y.; Xiang, D.; Wang, N.; Li, H.; Fan, Z. Mechanical Milling-Assisted Spark Plasma Sintering of Fine-Grained W-Ni-Mn Alloy. Materials 2018, 11, 1323. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.-L.; Ding, L.; Xiang, D.-P. ping Microstructure Evolution and Mechanical Properties of Spark Plasma Sintered W–Ni–Mn Alloy. Trans. Nonferrous Met. Soc. China 2017, 27, 1588–1593. [Google Scholar] [CrossRef]

- Singh, I.; Dabhade, V.V. Transient Liquid Phase Sintering in Spark Plasma Sintered Tungsten Heavy Alloys with Nb and Mo Additives. Int. J. Refract. Met. Hard Mater. 2024, 124, 106849. [Google Scholar] [CrossRef]

- Chaurasia, J.; Ayyapan, M.; Patel, P.; Rajan, R.A.A. Activated Sintering of Tungsten Heavy Alloy. Sci. Sinter. 2017, 49, 445–453. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Nokhrin, A.V.; Boldin, M.S.; Baranov, G.V.; Sakharov, N.V.; Belov, V.Y.; Lantsev, E.A.; Popov, A.A.; Melekhin, N.V.; Lopatin, Y.G.; et al. Impact of Mechanical Activation on Sintering Kinetics and Mechanical Properties of Ultrafine-Grained 95W-Ni-Fe Tungsten Heavy Alloys. J. Alloys Compd. 2019, 773, 666–688. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave-Material Interaction Phenomena: Heating Mechanisms, Challenges and Opportunities in Material Processing. Compos. Part A Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Singh, S.; Gupta, D.; Jain, V.; Sharma, A.K. Microwave Processing of Materials and Applications in Manufacturing Industries: A Review. Mater. Manuf. Process 2015, 30, 1–29. [Google Scholar] [CrossRef]

- Srinath, M.S.; Sharma, A.K.; Kumar, P. Investigation on Microstructural and Mechanical Properties of Microwave Processed Dissimilar Joints. J. Manuf. Process 2011, 13, 141–146. [Google Scholar] [CrossRef]

- Sharma, A.K.; Mishra, R.R. Role of Particle Size in Microwave Processing of Metallic Material Systems. Mater. Sci. Technol. 2018, 34, 123–137. [Google Scholar] [CrossRef]

- Upadhyaya, A.; Sethi, G. Effect of Heating Mode on the Densification and Microstructural Homogenization Response of Premixed Bronze. Scr. Mater. 2007, 56, 469–472. [Google Scholar] [CrossRef]

- Singh, S.; Bhaskar, R.; Narayanan, K.B.; Kumar, A.; Debnath, K. Development of Silicon Carbide (SiC)-Based Composites as Microwave-Absorbing Materials (MAMs): A Review. J. Eur. Ceram. Soc. 2024, 44, 7411–7431. [Google Scholar] [CrossRef]

- Siores, E.; Do Rego, M.D. Materials Processing Technology Microwave Applications in Materials Joining. J. Mater. Process. Technol. 1995, 48, 619–625. [Google Scholar] [CrossRef]

- Prabhu, G.; Chakraborty, A.; Sarma, B. Microwave Sintering of Tungsten. Int. J. Refract. Met. Hard Mater. 2009, 27, 545–548. [Google Scholar] [CrossRef]

- Liu, W.; Ma, Y.; Zhang, J. Properties and Microstructural Evolution of W-Ni-Fe Alloy via Microwave Sintering. Int. J. Refract. Met. Hard Mater. 2012, 35, 138–142. [Google Scholar] [CrossRef]

- Roy, R.; Agrawal, D.; Cheng, J.; Gedevanishvili, S. Full Sintering of Powdered-Metal Bodies in a Microwave Field. Nature 1999, 399, 668–670. [Google Scholar] [CrossRef]

- Prabhu, G.; Sankaranarayana, M.; Nandy, T.K. Microwave Sintering of Tungsten Heavy Alloys. J. Appl. Res. Technol. 2018, 16, 115–125. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, J.; Liu, W.; Yue, P.; Huang, B. Microstructure and Dynamic Mechanical Properties of Tungsten-Based Alloys in the Form of Extruded Rods via Microwave Heating. Int. J. Refract. Met. Hard Mater. 2014, 42, 71–76. [Google Scholar] [CrossRef]

- Liu, W.; Ma, Y.; Cai, Q. Consolidation of MA W-Ni-Fe Alloyed Powder by Microwave-Assisted Sintering. Mater. Sci. Appl. 2011, 2, 609–614. [Google Scholar] [CrossRef][Green Version]

- Zhang, D.; Cai, Q.; Liu, J.; Li, R. Research on Process and Microstructure Formation of W-Ni-Fe Alloy Fabricated by Selective Laser Melting. J. Mater. Eng. Perform. 2011, 20, 1049–1054. [Google Scholar] [CrossRef]

- Wang, X.; Wraith, M.; Burke, S.; Rathbun, H.; DeVlugt, K. Densification of W-Ni-Fe Powders Using Laser Sintering. Int. J. Refract. Met. Hard Mater. 2016, 56, 145–150. [Google Scholar] [CrossRef]

- Stawovy, M.T.; Myers, K.; Ohm, S. Binder Jet Printing of Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2019, 83, 104981. [Google Scholar] [CrossRef]

- Iveković, A.; Omidvari, N.; Vrancken, B.; Lietaert, K.; Thijs, L.; Vanmeensel, K.; Vleugels, J.; Kruth, J.P. Selective Laser Melting of Tungsten and Tungsten Alloys. Int. J. Refract. Met. Hard Mater. 2018, 72, 27–32. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.; Ma, S.; Yang, X.; Li, J.; Zhou, Y.; Liu, X.; Tang, J.; Wang, X.; Le, G. Densification, Microstructural Evolutions of 90W-7Ni-3Fe Tungsten Heavy Alloys during Laser Melting Deposition Process. Int. J. Refract. Met. Hard Mater. 2020, 91, 105254. [Google Scholar] [CrossRef]

- Su, S.; Lu, Y. Densified W[Sbnd]Cu Composite Fabricated via Laser Additive Manufacturing. Int. J. Refract. Met. Hard Mater. 2020, 87, 105122. [Google Scholar] [CrossRef]

- Gu, D.; Dai, D.; Chen, W.; Chen, H. Selective Laser Melting Additive Manufacturing of Hard-to-Process Tungsten-Based Alloy Parts with Novel Crystalline Growth Morphology and Enhanced Performance. J. Manuf. Sci. Eng. Trans. ASME 2016, 138, 081003. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Liu, J.; Xie, Z.; Wang, Z. Selective Laser Melting W-10 Wt.% Cu Composite Powders. Int. J. Adv. Manuf. Technol. 2010, 48, 597–605. [Google Scholar] [CrossRef]

- Chen, H.; Zi, X.; Han, Y.; Dong, J.; Liu, S.; Chen, C. Microstructure and Mechanical Properties of Additive Manufactured W-Ni-Fe-Co Composite Produced by Selective Laser Melting. Int. J. Refract. Met. Hard Mater. 2020, 86, 105111. [Google Scholar] [CrossRef]

- Dorow-Gerspach, D.; Kirchner, A.; Loewenhoff, T.; Pintsuk, G.; Weißgärber, T.; Wirtz, M. Additive Manufacturing of High Density Pure Tungsten by Electron Beam Melting. Nucl. Mater. Energy 2021, 28, 101046. [Google Scholar] [CrossRef]

- Vrancken, B.; King, W.E.; Matthews, M.J. In-Situ Characterization of Tungsten Microcracking in Selective Laser Melting. In Procedia CIRP; Elsevier, B.V.: Fürth, Germany, 2018; Volume 74, pp. 107–110. [Google Scholar]

- Kim, R.E.; Karthik, G.M.; Amanov, A.; Heo, Y.U.; Jeong, S.G.; Gu, G.H.; Park, H.; Kim, E.S.; Lee, D.W.; Kim, H.S. Superior Gradient Heterostructured Alloys Fabricated by Laser Powder Bed Fusion via Annealing and Ultrasonic Nanocrystal Surface Modification. Scr. Mater. 2023, 230, 115422. [Google Scholar] [CrossRef]

- Karthik, G.M.; Kim, H.S. Heterogeneous Aspects of Additive Manufactured Metallic Parts: A Review. Met. Mater. Int. 2021, 27, 1–39. [Google Scholar] [CrossRef]

- Schwanekamp, T.; Müller, A.; Reuber, M.; Gobran, H.; Gdoura, N.; von Cetto, S. Investigations on Laser Powder Bed Fusion of Tungsten Heavy Alloys. Int. J. Refract. Met. Hard Mater. 2022, 109. [Google Scholar] [CrossRef]

- Iveković, A.; Montero-Sistiaga, M.L.; Vanmeensel, K.; Kruth, J.-P.; Vleugels, J. Effect of Processing Parameters on Microstructure and Properties of Tungsten Heavy Alloys Fabricated by SLM. Int. J. Refract. Met. Hard Mater. 2019, 82, 23–30. [Google Scholar] [CrossRef]

- Wang, Y.P.; Ma, S.Y.; Yang, X.S.; Zhou, Y.Z.; Liu, X.; Li, J.F.; Zhang, J.J.; Li, C.; Wang, X.Y.; Le, G.M.; et al. Microstructure and Strengthening Mechanisms of 90W–7Ni–3Fe Alloys Prepared Using Laser Melting Deposition. J. Alloys Compd. 2020, 838, 155545. [Google Scholar] [CrossRef]

- Zhong, M.; Liu, W.; Ning, G.; Yang, L.; Chen, Y. Laser Direct Manufacturing of Tungsten Nickel Collimation Component. J. Mater. Process Technol. 2004, 147, 167–173. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Steinberg, D.M.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. The Influence of Laser Directed Energy Deposition (DED) Processing Parameters for Al5083 Studied by Central Composite Design. J. Mater. Res. Technol. 2022, 17, 3157–3171. [Google Scholar] [CrossRef]

- Wei, C.; Ye, H.; Zhao, Z.; Tang, J.; Shen, X.; Le, G.; Ye, K.; Le, F. Microstructure and Fracture Behavior of 90W-7Ni-3Fe Alloy Fabricated by Laser Directed Energy Deposition. J. Alloys Compd. 2021, 865, 158975. [Google Scholar] [CrossRef]

- Plotkowski, A.; Ferguson, J.; Stump, B.; Halsey, W.; Paquit, V.; Joslin, C.; Babu, S.S.; Marquez Rossy, A.; Kirka, M.M.; Dehoff, R.R. A Stochastic Scan Strategy for Grain Structure Control in Complex Geometries Using Electron Beam Powder Bed Fusion. Addit. Manuf. 2021, 46, 102092. [Google Scholar] [CrossRef]

- Ellis, E.A.I.; Sprayberry, M.A.; Ledford, C.; Hankwitz, J.P.; Kirka, M.M.; Rock, C.D.; Horn, T.J.; Katoh, Y.; Dehoff, R.R. Processing of Tungsten through Electron Beam Melting. J. Nucl. Mater. 2021, 555, 153041. [Google Scholar] [CrossRef]

- Wright, J. Additive Manufacturing of Tungsten via Selective Laser Melting and Electron Beam Melting; University of Sheffield: Sheffield, UK, 2019. [Google Scholar]

- Cordero, Z.C.; Dinwiddie, R.B.; Immel, D.; Dehoff, R.R. Nucleation and Growth of Chimney Pores during Electron-Beam Additive Manufacturing. J. Mater. Sci. 2017, 52, 3429–3435. [Google Scholar] [CrossRef]

- Yang, G.; Yang, P.; Yang, K.; Liu, N.; Jia, L.; Wang, J.; Tang, H. Effect of Processing Parameters on the Density, Microstructure and Strength of Pure Tungsten Fabricated by Selective Electron Beam Melting. Int. J. Refract. Met. Hard Mater. 2019, 84, 105040. [Google Scholar] [CrossRef]

- Doddapaneni, V.V.K.; Lee, K.; Aysal, H.E.; Paul, B.K.; Pasebani, S.; Sierros, K.A.; Okwudire, C.E.; Chang, C.H. A Review on Progress, Challenges, and Prospects of Material Jetting of Copper and Tungsten. Nanomaterials 2023, 13, 2303. [Google Scholar] [CrossRef]

- Vrancken, B.; Ganeriwala, R.K.; Matthews, M.J. Analysis of Laser-Induced Microcracking in Tungsten under Additive Manufacturing Conditions: Experiment and Simulation. Acta Mater. 2020, 194, 464–472. [Google Scholar] [CrossRef]

- Sidambe, A.T.; Tian, Y.; Prangnell, P.B.; Fox, P. Effect of Processing Parameters on the Densification, Microstructure and Crystallographic Texture during the Laser Powder Bed Fusion of Pure Tungsten. Int. J. Refract. Met. Hard Mater. 2019, 78, 254–263. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Y.; Guan, K.; Wang, Z.; Ma, Z. Pure Tungsten and Oxide Dispersion Strengthened Tungsten Manufactured by Selective Laser Melting: Microstructure and Cracking Mechanism. Addit. Manuf. 2020, 36, 101579. [Google Scholar] [CrossRef]

- Wang, D.-Z.; Li, K.-L.; Yu, C.-F.; Ma, J.; Liu, W.; Shen, Z.-J. Cracking Behavior in Additively Manufactured Pure Tungsten. Acta Metall. Sin. 2019, 32, 127–135. [Google Scholar] [CrossRef]

- Zhou, Z.; He, D.; Tan, Z.; Wang, Y.; Shao, W.; Guo, X.; Zhou, Z.; Wu, X.; Cui, L.; Wang, B. Grain Structure and Cracks Behaviors of Tungsten with Different Geometrical Shapes and Support Structure Prepared by Laser Powder Bed Fusion. J. Manuf. Process. 2022, 82, 253–264. [Google Scholar] [CrossRef]

- Chen, J.; Li, K.; Wang, Y.; Xing, L.; Yu, C.; Liu, H.; Ma, J.; Liu, W.; Shen, Z. The Effect of Hot Isostatic Pressing on Thermal Conductivity of Additively Manufactured Pure Tungsten. Int. J. Refract. Met. Hard Mater. 2020, 87, 105135. [Google Scholar] [CrossRef]

- Rebesan, P.; Bonesso, M.; Gennari, C.; Dima, R.; Pepato, A.; Vedani, M. Tungsten Fabricated by Laser Powder Bed FusionTungsten Hergestellt Durch Laserpulverbett-Fusion. BHM Berg. Hüttenmänn. Monatshefte 2021, 166, 263–269. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Attard, B.; Zhang, P.; Kuang, T. Selective Laser Melting of High-Performance Pure Tungsten: Parameter Design, Densification Behavior and Mechanical Properties. Sci. Technol. Adv. Mater. 2018, 19, 370–380. [Google Scholar] [CrossRef]

- Ren, X.; Liu, H.; Lu, F.; Huang, L.; Yi, X. Effects of Processing Parameters on the Densification, Microstructure and Mechanical Properties of Pure Tungsten Fabricated by Optimized Selective Laser Melting: From Single and Multiple Scan Tracks to Bulk Parts. Int. J. Refract. Met. Hard Mater. 2021, 96, 105490. [Google Scholar] [CrossRef]

- Wang, D.; Yu, C.; Zhou, X.; Ma, J.; Liu, W.; Shen, Z. Dense Pure Tungsten Fabricated by Selective Laser Melting. Appl. Sci. 2017, 7, 430. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.; Zhang, D.; Shen, Z.; Liu, W. Balling Phenomena in Selective Laser Melted Tungsten. J. Mater. Process Technol. 2015, 222, 33–42. [Google Scholar] [CrossRef]

- Morcos, P.; Elwany, A.; Karaman, I.; Arróyave, R. Review: Additive Manufacturing of Pure Tungsten and Tungsten-Based Alloys. J. Mater. Sci. 2022, 57, 9769–9806. [Google Scholar] [CrossRef]

- Ravi Kiran, U.; Sambasiva Rao, A.; Sankaranarayana, M.; Nandy, T.K. Swaging and Heat Treatment Studies on Sintered 90W-6Ni-2Fe-2Co Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2012, 33, 113–121. [Google Scholar] [CrossRef]

- Wensheng, L.; Yunzhu, M.A.; Baiyun, H. Influence of Minor Elements Additions on Microstructure and Properties of 93W-4⋅9Ni-2⋅1Fe Alloys. Bull. Mater. Sci. 2008, 31, 1–6. [Google Scholar]

- Wang, Z.; Yuan, Y.; Arshad, K.; Wang, J.; Zhou, Z.; Tang, J.; Lu, G.H. Effects of Tantalum Concentration on the Microstructures and Mechanical Properties of Tungsten-Tantalum Alloys. Fusion. Eng. Des. 2017, 125, 496–502. [Google Scholar] [CrossRef]

- Chen, B.; Li, Z.B.; Liu, J.R.; Zhang, G.H. Effect of Molybdenum Addition on Microstructure and Mechanical Properties of 90% Tungsten Heavy Alloys. Int. J. Refract. Met. Hard Mater. 2022, 106, 105868. [Google Scholar] [CrossRef]

- Hong, M.-H.; Noh, J.-W.; Hyung Baek, W.; Kim, E.-P.; Song, H.-S.; Lee, S. A Study on the Improvement of the Sintered Density of W-Ni-Mn Heavy Alloy. Met. Mater. Trans. B 1997, 28, 835–839. [Google Scholar] [CrossRef]

- Prabhu, G.; Arockia Kumar, R.; Nandy, T.K. Fine Tungsten Precipitates in the Matrix Phase and Their Influence on the Mechanical Properties of a Tungsten Heavy Alloy. Philos. Mag. 2021, 101, 2004–2023. [Google Scholar] [CrossRef]

- Kumari, A.; Sarkar, R.; Panchal, A.; Prabhu, G.; Nandy, T.K. The Effect of Fine W Precipitates in Matrix Phase on Mechanical Properties of Tungsten Heavy Alloys. J. Appl. Res. Technol. 2022, 20, 487–501. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, N.; Ma, Z.; Liu, C.; Guo, Q.; Alothman, Z.A.; Yamauchi, Y.; Md Hossain, S.A.; Liu, Y. Microstructure Refinement in W-Y2O3 Alloy Fabricated by Wet Chemical Method with Surfactant Addition and Subsequent Spark Plasma Sintering. Sci. Rep. 2017, 7, 6051. [Google Scholar] [CrossRef]

- Park, S.; Kim, D.-K.; Lee, S.; Kim, D.-K.; Ryu, H.J.; Hong, S.H.; Ryu, H.J. Dynamic Deformation Behavior of an Oxide-Dispersed Tungsten Heavy Alloy Fabricated by Mechanical Alloying. Metall. Mater. Trans. A 2001, 32, 2011–2020. [Google Scholar] [CrossRef]

- Xiao, F.; Barriere, T.; Cheng, G.; Miao, Q.; Zuo, S.; Wei, S.; Xu, L. Extremely Uniform Nanosized Oxide Particles Dispersion Strengthened Tungsten Alloy with High Tensile and Compressive Strengths Fabricated Involving Liquid-Liquid Method. J. Alloys Compd. 2021, 878, 160335. [Google Scholar] [CrossRef]

- Sarkar, R.; Singh, V.; Kumar, S.; Rao, Y.V.; Ghosal, P.; Nandy, T.K. Structure and Orientation of an Intermetallic Phase in a W-Ni-Co Alloy. Philos. Mag. 2019, 99, 1240–1258. [Google Scholar] [CrossRef]

- Hsu, C.-S.; Lin, S.-T. Effect of Molybdenum on Grain Growth of W-Mo-Ni-Fe Heavy Alloys. J. Mater. Sci. 2003, 38, 1543–1549. [Google Scholar] [CrossRef]

- German, R.M. The Microstructures of Liquid Phase Sintered Materials. In Sintering Technology; CRC Press: Boca Raton, FL, USA, 2020; pp. 213–220. [Google Scholar]

- Mao, R.; Xiang, D. Improved Mechanical Properties of Tungsten Alloy by Flaky Ni3Al and Trace B2O3 Synergistic Reinforcement. J. Alloys Compd. 2022, 923, 166467. [Google Scholar] [CrossRef]

- German, R.M. The Two-Dimensional Connectivity of Liquid Phase Sintered Microstructures. Metall. Mater. Trans. A 1987, 18, 909–914. [Google Scholar] [CrossRef]

- Lu, K.; German, R.M. Microstructure Analysis of Samples Sintered at Different Gravitational Conditions. J. Mater. Sci. 2010, 45, 4454–4461. [Google Scholar] [CrossRef]

- Liu, Y.; German, R.M.; Iacocca, R.G. Microstructure Quantification Procedures in Liquid-Phase Sintered Materials. Acta Mater. 1999, 47, 915–926. [Google Scholar] [CrossRef]

- German, R.M.; Bose, A.; Mani, S.S. Sintering Time and Atmosphere Influences on the Microstructure and Mechanical Properties of Tungsten Heavy Alloys. Metall. Trans. A 1992, 23, 211–219. [Google Scholar] [CrossRef]

- Fang, Z.; Patterson, B.R. Experimental Investigation of Particle Size Distribution Influence on Diffusion Controlled Coarsening. Acta Metall. Mater. 1993, 41, 2017–2024. [Google Scholar] [CrossRef]

- Yang, S.-C.; Mani, S.S.; German, R.M. The Effect of Contiguity on Growth Kinetics in Liquid-Phase Sintering. JOM 1990, 42, 16–19. [Google Scholar] [CrossRef]

- Greger, M.; Čížek, L.; Widomska, M. Structure and Mechanical Properties of Formed Tungsten Based Materials. J. Mater. Process. Technol. 2004, 157, 683–687. [Google Scholar] [CrossRef]

- Lai, X.; Wang, Z.; Qin, N. Comparative Studies of the Constitutive Models for Tungsten Heavy Alloy (95W-3.5Ni-1.5Fe) at High Strain Rates. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2022, 236, 3636–3650. [Google Scholar] [CrossRef]

- Panchal, A.; Venugopal Reddy, K.; Azeem, P.A.; Sarkar, R.; Paradkar, A.; Nandy, T.K.; Singh, A.K. Effect of Ni/Fe Ratio on Microstructure, Tensile Flow and Work Hardening Behaviour of Tungsten Heavy Alloys in Heat Treated and Swaged Conditions. Philos. Mag. 2021, 101, 211–241. [Google Scholar] [CrossRef]

- Knipling, K.E.; Zeman, G.; Marte, J.S.; Kelly, S.M.; Kampe, S.L. Effect of Dissolved Tungsten on the Deformation of 70Ni-30Fe Alloys. Metall. Mater. Trans. A 2004, 35, 2821–2828. [Google Scholar] [CrossRef]

- Alam, M.E.; Odette, G.R. On the Remarkable Fracture Toughness of 90 to 97W-NiFe Alloys Revealing Powerful New Ductile Phase Toughening Mechanisms. Acta Mater. 2020, 186, 324–340. [Google Scholar] [CrossRef]

- Dinçer, O.; Pehlivanoğlu, M.K.; Çalişkan, N.K.; Karakaya, I.; Kalkanli, A. Processing and Microstructural Characterization of Liquid Phase Sintered Tungsten-Nickel-Cobalt Heavy Alloys. Int. J. Refract. Met. Hard Mater. 2015, 50, 106–112. [Google Scholar] [CrossRef]

- International Agency for Research on Cancer. Chlorinated Drinking-Water, Chlorination by-Products: Some Other Halogenated Compounds, Cobalt and Cobalt Compounds; IARC: Lyon, France, 1991; ISBN 9283212525. [Google Scholar]

- Cury, R.; Issartel, F.; Joubert, J.M.; Couque, H. Evolution of Cobalt-Free Tungsten Heavy Alloys for Kinetic Energy Penetrators. Powder Metall. 2013, 56, 347–350. [Google Scholar] [CrossRef]

- Natarajan, S.; Gopalan, V.; Annamalai, R.; Rajan, A.; Jen, C.-P. Materials Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W-Ni-Fe Alloy—A Review. Materials 2021, 14, 1660. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.-K.; Lee, S.; Song, H. Effect of Tungsten Particle Shape on Dynamic Deformation and Fracture Behavior of Tungsten Heavy Alloys. Metall. Mater. Trans. A 1998, 29, 1057–1069. [Google Scholar] [CrossRef]

- Ryu, H.J.; Hong, S.H.; Kim, D.-K.; Lee, S. Impact and Dynamic Deformation Behavior of Mechanically Alloyed Tungsten Heavy Alloy. Met. Mater. 1998, 4, 367–371. [Google Scholar] [CrossRef]

- Gong, X.; Fan, J.L.; Huang, B.Y.; Tian, J.M. Microstructure Characteristics and a Deformation Mechanism of Fine-Grained Tungsten Heavy Alloy under High Strain Rate Compression. Mater. Sci. Eng. A 2010, 527, 7565–7570. [Google Scholar] [CrossRef]

- Magness, L.S. High Strain Rate Deformation Behaviors of Kinetic Energy Penetrator Materials during Ballistic Impact. Mech. Mater. 1994, 17, 147–154. [Google Scholar] [CrossRef]

- Ramesh, K.T.; Coates, R.S. Microstructural Influences on the Dynamic Response of Tungsten Heavy Alloys. Metall. Mater. Trans. A 1992, 23, 2625–2630. [Google Scholar] [CrossRef]

- Bless, S.; Chau, R. Tensile Failure of Tungsten Alloys. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2006; Volume 845, pp. 603–606. [Google Scholar]

- Millett, J.C.F.; Bourne, N.K.; Rosenberg, Z.; Field, J.E. Shear Strength Measurements in a Tungsten Alloy during Shock Loading. J. Appl. Phys. 1999, 86, 6707–6709. [Google Scholar] [CrossRef]

- Dandekar, D.P.; Weisgerber, W.J. Shock Response of a Heavy Tungsten Alloy. Int. J. Plast. 1999, 15, 1291–1309. [Google Scholar] [CrossRef]

- Zhou, M.; Clifton, R.J. Dynamic Constitutive and Failure Behavior of a Two-Phase Tungsten Composite. J. Appl. Mech. 1997, 64, 487–494. [Google Scholar] [CrossRef]

- Wei, Z.; Yu, J.; Hu, S.; Li, Y. Influence of Microstructure on Adiabatic Shear Localization of Pre-Twisted Tungsten Heavy Alloys. Int. J. Impact Eng. 2000, 24, 747–758. [Google Scholar] [CrossRef]

- Bose, A.; German, R.N. Matrix Composition Effects on the Tensile Properties of Tungsten-Molybdenum Heavy Alloys. Metall. Trans. A Phys. Metall. Mater. Sci. 1990, 21, 1325–1327. [Google Scholar] [CrossRef]

- Wei, Q.; Jiao, T.; Ramesh, K.T.; Ma, E.; Kecskes, L.J.; Magness, L.; Dowding, R.; Kazykhanov, V.U.; Valiev, R.Z. Mechanical Behavior and Dynamic Failure of High-Strength Ultrafine Grained Tungsten under Uniaxial Compression. Acta Mater. 2006, 54, 77–87. [Google Scholar] [CrossRef]

- Xiaoqing, Z.; Shukui, L.; Jinxu, L.; Yingchun, W.; Xing, W. Self-Sharpening Behavior during Ballistic Impact of the Tungsten Heavy Alloy Rod Penetrators Processed by Hot-Hydrostatic Extrusion and Hot Torsion. Mater. Sci. Eng. A 2010, 527, 4881–4886. [Google Scholar] [CrossRef]

- Lee, W.-S.; Xiea, G.-L.; Lin, C.-F. The Strain Rate and Temperature Dependence of the Dynamic Impact Response of Tungsten Composite. Mater. Sci. Eng. A 1998, 257, 256–267. [Google Scholar] [CrossRef]

- Zhou, M.; Clifton, R.J.; Needleman, A. Shear Band Formation in a W--Ni--Fe Alloy Under Plate Impact. Tungsten Tungsten Alloys 1992, 343–356. [Google Scholar]

- Zhou, M. Finite Element Simulations of Shear Localization in Plane Impact. J. Mech. Phy. Solid 1975, 23, 239–264. [Google Scholar]

- Couque, H.; Nicolas, G.; Altmayer, C. Relation between Shear Banding and Penetration Characteristics of Conventional Tungsten Alloys. Int. J. Impact Eng. 2007, 34, 412–423. [Google Scholar] [CrossRef]

- Dick, R.D.; Ramachandran, V.; Williams, J.D.; Armstrong, R.W.; Holt, W.H.; Mock, W., Jr. Dynamic Deformation of W7Ni3Fe Alloy via Reverse-Ballistic Impact. In Tungsten and Tungsten Alloys; The Metallurgical Society Inc.: Warrendale, PA, USA, 1991. [Google Scholar]

- Johnson, G.R. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983. [Google Scholar]

- Lankford, J.; Couque, H.; Bose, A.; German, R. Dynamic Deformation and Failure of Tungsten Heavy Alloys; The Metallurgical Society Inc.: Warrendale, PA, USA, 2025. [Google Scholar]

- Zhou, M. The Growth of Shear Bands in Composite Microstructures. Int. J. Plast. 1998, 14, 733–754. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Y.; Yang, C.M.; Liu, Q.J. Mechanical Properties of Tungsten Heavy Alloy and Damage Behaviors after Hypervelocity Impact. Rare Met. 2014, 33, 414–418. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Alotaibi, S.M.; Liu, Y.; Wang, B.; Meyers, M.A. Adiabatic Shear Localization in the CrMnFeCoNi High-Entropy Alloy. Acta Mater. 2018, 151, 424–431. [Google Scholar] [CrossRef]

- Luo, R.; Huang, D.; Yang, M.; Tang, E.; Wang, M.; He, L. Penetrating Performance and “Self-Sharpening” Behavior of Fine-Grained Tungsten Heavy Alloy Rod Penetrators. Mater. Sci. Eng. A 2016, 675, 262–270. [Google Scholar] [CrossRef]

- Anwer, Z.; Umer, M.A.; Nisar, F.; Hafeez, M.A.; Yaqoob, K.; Luo, X.; Ahmad, I. Microstructure and Mechanical Properties of Hot Isostatic Pressed Tungsten Heavy Alloy with FeNiCoCrMn High Entropy Alloy Binder. J. Mater. Res. Technol. 2023, 22, 2897–2909. [Google Scholar] [CrossRef]

- Fang, X.; Liu, J.; Wang, X.; Li, S.; Zheng, L. Study on Improving “Self-Sharpening” Capacity of W–Cu–Zn Alloy by the Pressureless Infiltration Method. Mater. Sci. Eng. A 2014, 607, 454–459. [Google Scholar] [CrossRef]

- Nagireddi, S.; Majumdar, B.; Bonta, S.; Diraviam, A.B. High-Density Bulk Metallic Glasses and Their Composites for Kinetic Energy Penetrator Applications: Process, Structure and Properties. Trans. Indian Inst. Met. 2021, 74, 2117–2134. [Google Scholar] [CrossRef]

- Zhou, S.; Jian, R.; Liang, Y.J.; Zhu, Y.; Wang, B.; Wang, L.; Wang, L.; Ren, Y.; Xue, Y. High Susceptibility to Adiabatic Shear Banding and High Dynamic Strength in Tungsten Heavy Alloys with a High-Entropy Alloy Matrix. J. Alloys Compd. 2021, 859, 157796. [Google Scholar] [CrossRef]

- Karthik, G.M.; Panikar, S.; Ram, G.D.J.; Kottada, R.S. Additive Manufacturing of an Aluminum Matrix Composite Reinforced with Nanocrystalline High-Entropy Alloy Particles. Mater. Sci. Eng. A 2017, 679, 193–203. [Google Scholar] [CrossRef]

- Karthik, G.M.; Kim, Y.; Kim, E.S.; Zargaran, A.; Sathiyamoorthi, P.; Park, J.M.; Jeong, S.G.; Gu, G.H.; Amanov, A.; Ungar, T.; et al. Gradient Heterostructured Laser-Powder Bed Fusion Processed CoCrFeMnNi High Entropy Alloy. Addit. Manuf. 2022, 59, 103131. [Google Scholar] [CrossRef]

- Liu, X.F.; Tian, Z.L.; Zhang, X.F.; Chen, H.H.; Liu, T.W.; Chen, Y.; Wang, Y.J.; Dai, L.H. “Self-Sharpening” Tungsten High-Entropy Alloy. Acta Mater. 2020, 186, 257–266. [Google Scholar] [CrossRef]

- Sharma, V.; Namburu, S.A.S.; Lalwani, P.; Sagar, C.K.; Gupta, A.K. Constitutive Modelling and Processing Map Analysis of Tungsten Heavy Alloy (92.5 W-5.25Ni-2.25Fe) at Elevated Temperatures. Int. J. Refract. Met. Hard Mater. 2018, 76, 168–179. [Google Scholar] [CrossRef]

- Park, S.J.; Chung, S.H.; Johnson, J.L.; German, R.M. Finite Element Simulation of Liquid Phase Sintering with Tungsten Heavy Alloys. Mater. Trans. 2006, 47, 2745–2752. [Google Scholar] [CrossRef]

- Li, J.C.; Chen, X.W.; Huang, F.L. FEM Analysis on the “Self-Sharpening” Behavior of Tungsten Fiber/Metallic Glass Matrix Composite Long Rod. Int. J. Impact Eng. 2015, 86, 67–83. [Google Scholar] [CrossRef]

- Li, J.-C.; Chen, X.-W.; Huang, F.-L. Ballistic Performance of Tungsten Particle/Metallic Glass Matrix Composite Long Rod. Def. Technol. 2019, 15, 132–145. [Google Scholar] [CrossRef]

- Kennedy, C.; Murr, L.E. Comparison of Tungsten Heavy-Alloy Rod Penetration into Ductile and Hard Metal Targets: Microstructural Analysis and Computer Simulations. Mater. Sci. Eng. A 2002, 325, 131–143. [Google Scholar] [CrossRef]

- Hafızoğlu, H.; Durlu, N. Effect of Sintering Temperature on the High Strain Rate-Deformation of Tungsten Heavy Alloys. Int. J. Impact Eng. 2018, 121, 44–54. [Google Scholar] [CrossRef]

- Hafizoglu, H.; Durlu, N.; Konokman, H.E. Effects of Sintering Temperature and Ni/Fe Ratio on Ballistic Performance of Tungsten Heavy Alloy Fragments. Int. J. Refract. Met. Hard Mater. 2019, 81, 155–166. [Google Scholar] [CrossRef]

- Gong, X.; Fan, J.; Ding, F. Tensile Mechanical Properties and Fracture Behavior of Tungsten Heavy Alloys at 25-1100 °C. Mater. Sci. Eng. A 2015, 646, 315–321. [Google Scholar] [CrossRef]

- Tang, J.J.; Liang, Z.F.; Zhang, Y.W. A Two-Phase Constitutive Model with Damage for Tungsten Heavy Alloy. Int. J. Multiphysics 2021, 15, 211–233. [Google Scholar]

- Zhou, M.; Needleman, A.; Clifton, R.J. Finite Element Simulations of Shear Localization in Plate Impact. J. Mech. Phys. Solids 1994, 42, 423–458. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, L.; Huang, Y.; Chen, B.; Zhou, J.; Liu, W.; Ma, Y. Strain Hardening Rate and Strain Rate Sensitivity Behavior of Bcc/Fcc-Dual-Phase Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2023, 116, 106363. [Google Scholar] [CrossRef]

- Scapin, M. Mechanical Characterization and Modeling of the Heavy Tungsten Alloy IT180. Int. J. Refract. Met. Hard Mater. 2015, 50, 258–268. [Google Scholar] [CrossRef]

- Jinzhu, L.; Liansheng, Z.; Fenglei, H. Experiments and Simulations of Tungsten Alloy Rods Penetrating into Alumina Ceramic/603 Armor Steel Composite Targets. Int. J. Impact Eng. 2017, 101, 1–8. [Google Scholar] [CrossRef]

- Xiang, Y.; Chen, S.; Li, Z.; Yu, Y.; Hu, J. Spallation Damage of Tungsten Heavy Alloy under Shock Loading. Mater. Lett. 2024, 360, 135977. [Google Scholar] [CrossRef]

- Clayton, J.D. Modeling Dynamic Plasticity and Spall Fracture in High Density Polycrystalline Alloys. Int. J. Solids Struct. 2005, 42, 4613–4640. [Google Scholar] [CrossRef]

- Addessio, F.L.; Johnson, J.N. A Constitutive Model for the Dynamic Response of Brittle Materials. J. Appl. Phys. 1990, 67, 3275–3286. [Google Scholar] [CrossRef]

| Composition (wt.%) | Sintering Cycle and Sintering Atmosphere | Ref. |

|---|---|---|

| 93W-4.9Ni-2.1Fe, 93W-4.2Ni-1.2Fe-1.6Co, 93W-4.9Ni-1.9Fe-0.2Re | Sintering temperature: 1480 °C Holding time: 2 h in H2 Heating rate: 8 °C/min Cooling rate: 1 °C/min | [99] |

| 89.75W-6Ni-2Fe-2Co-0.25Mo | Pre-sintering temperature: 1300 °C/1 h Final sintering temperature: 1480 °C Holding time: 75 min in H2 Heating rate: 3–5 °C/min | [78] |

| 94.9W-3.4Ni-1.7Cu | Sintered temperature: 1500 °C Holding time: 1.5 h in H2 | [14] |

| 90W-5.7Ni-3.8Cu-0.5Fe | Degassing temperature: 1000 °C/20 min Final sintering temperature: 1400 °C Holding time: 1 h in H2 | [83] |

| 93W-6Ni-1Co | Sintering temperature: 1525 °C Holding time: 30 min in H2 | [81] |

| 88W-xNi-yCu; (x = 8.94–9.60, y = 2.4–3.06) | Debinding temperature: 500 °C/1 h/5 °C/min Pre-sintering: 500–1000 °C/1 h/5 °C/min/AC Final sintering temperature: 1412 °C Holding time: 1 to 10 min in H2. | [57] |

| 93W-4.9Ni-2.1Fe | Sintering temperature: 1493 °C Holding time: 3 h | [63] |

| 91W-6Ni-3Co | Sintering temperature: 1520 °C Holding time: 20 min in H2 | [82] |

| 90W-7Ni-3Fe | Pre-sintering: 1350 °C/15 °C/min/H2/15 min Then, till 1350–1450 °C/10 °C/min Final sintering: 1510 °C/5 °C/min/vacuum | [69] |

| 88W-8.4Ni-3.6Fe | Sintering: 1500 °C/30 min in H2/10 °C/min up to 800 °C, and 5 °C/min thereafter. During cooling, atmosphere changes from H2 to Ar. | [66] |

| 93W-4.9Ni-2.1Fe | Pre-sintering: 1380 °C/2 h under H2/AC, then microwave sintering: 1480 °C/10 min/10 at.% H2 + 90 at.% N2/15 °C/min | [64] |

| 97W-2.1Ni-0.9Fe, 99W-0.7Ni-0.3Fe | Sintering: 1600 °C/3h/Ar-20 vol.% and H2-200 mL/min | [111] |

| 89W-7Ni-3Fe-1Re | Sintering temperature: 1480 °C Holding time: 2 h in H2 | [21] |

| 92W-7.2Ni-0.8Co, 92W-6.4Ni-1.6Co, 92W-5.6Ni-2.4Co, 92W-4.8Ni-3.2Co, 92W-4Ni-4Co | Sintering temperature: 1520 °C Holding: 20 min in H2 | [80] |

| 90W-6Ni-4Co, 90W-7Ni-3Co, 90W-8Ni-2Co | Pre-sintering temperature: 1300 °C/1 h Final sintering: Between 1480 and 1490 °C Holding time: 75 min in H2 | [79] |

| 94.9W-3.4Ni-1.7Cu, 92.5W-5Ni-2.5Cu, 96.1–2.8Ni-1.1Cu, 96W-2.8Ni-1.1Cu-0.1Fe, 93.5W-4Ni-2Fe-0.5Co, 90.5W-7.2Ni-1.8Fe-0.45Co-0.05Mo, 74W-8Ni-2Fe-16Mo | Sintering temperature: 1500 °C Holding time: 2 h in H2 | [14] |

| Composition (wt.%) | Sintering Condition | Reference |

|---|---|---|

| 93W-5.6Ni-1.4Fe | Sintering temperature: 1050–1410 °C Pressure: 30 MPa Heating rate: 45–270 °C/min | [113] |

| 99W-1Ni-1Co-1Fe-1Mo-1Cu | Sintering temperature: 1200 °C Pressure: 20 MPa Heating rate: 1200 °C/min | [117] |

| 90W-6Ni-4Mn | Sintering temperature: 1000 °C to 1200 °C Pressure: 30 MPa Heating rate: 100 °C/min | [114] |

| 93W-5.6Ni-1.4Fe | Sintering temperature: 1360–1430 °C Pressure: 30 MPa Heating rate: 10–380 °C/min | [65] |

| 95W-3.5Ni-1.5Fe | Sintering temperature: 900–1300 °C Pressure: 50–70 MPa Heating rate: 50–300 °C/min | [118] |

| 90W-5.6Ni-2.4Fe-2Co | Sintering temperature: 1400 °C Pressure: 30 MPa Heating rate: 100 °C/min | [13] |

| 90W-6Ni-4Mn | First-step solid-phase-sintered at 1000 °C/100 °C/min/6 min, second-step sintering: 1000–1200/200 °C/min/3 min | [29] |

| 90W-7Ni-3Fe, 84W-7Ni3Fe-6Mo, 84W-7Ni-3Fe-6Nb | Sintering temperature: 1150–1275 °C Pressure: 30 MPa Heating rate: 100 °C/min | [116] |

| 88W-2Re-7Ni-3Fe | Sintering temperature: 1100 °C Pressure: 50 MPa Heating rate: 100 °C/min | [67] |

| Composition (wt.%) | Sintering Condition | Reference |

|---|---|---|

| 92.5W-6.4Ni-1.1Fe | Sintering temperature: 1500 °C Holding time: 20 min in H2 Heating rate: 20 °C/min | [61] |

| 90W-7Ni-3Fe | Sintering temperature: 1460 °C Holding time: 1 h in H2 Heating rate: 20 °C/min Susceptor: SiC | [27] |

| 90W-7Ni-3Fe | Sintering temperature: 1480 °C Holding time: 10 min in H2 Heating rate: 10–112 °C/min Susceptor: SiC | [28] |

| 90W-6Ni-2Fe-2Co | Sintering temperature: 1470 °C Holding time: 60 min in H2 Heating rate: 20 °C/min Susceptor: SiC | [27] |

| 93W-4.9Ni-2.1Fe | Sintering temperature: 1480 °C Holding time: 10 min in H2 Heating rate: 15 °C/min | [64] |

| 90W-7Ni-3Cu | Sintering temperature: 1300–1450 °C Heating rate: 22 °C/min | [59] |

| 93W-4.9Ni-2.1Fe | Sintering temperature: 1510 °C and 1520 °C Holding time: 1 h in H2 Heating rate: 20 °C/min | [129] |

| 93W-4.9Ni-2.1Fe | Pre-sintering temperature: 800 °C Sintering temperature: 1250–1500 °C Holding time: 5 min in 10 vol.% H2 and 90 vol.% N2 Heating rate: 30 °C/min | [127] |

| 93W-4.9Ni-2.1Fe | Extruded-rod-sintered at 1550 °C Holding time: 30 min in 10 vol.% H2 and 90 vol.% N2 | [130] |

| 93W-4.9Ni-2.1Fe | Sintering temperature: 1250–1500 °C Holding time: 5 min in 10 vol.% H2 and 90 vol.% N2 Heating rate: 30 | [131] |

| Property | Microwave | SPS | Conventional |

|---|---|---|---|

| Process Time | Very Low | Very Low | High |

| Grain Size | Fine | Very Fine | Coarse |

| Density | >98.5% | 95–98% | ~98% |

| W Solubility in the Matrix | Low | Low | High |

| W-W Contiguity | Low-Moderate | Low | High |

| Matrix Uniformity | High | High | Moderate |

| Hardness (HV) | High | High | Moderate |

| Tensile/Impact Strength | Superior | High | Low |

| Distortion Risk | Low to Moderate | Low to Moderate | Moderate to High |

| Composition (wt.%) | Processing Condition | YS (MPa) | UTS (MPa) | Elong. (%) | Impact Strength (J/cm2) | Work-Hardening Exponent (n) | Ref. |

|---|---|---|---|---|---|---|---|

| 90W-6Ni-4Co | Swaged (0.36 true strain) with six intermediate heat treatments (800–900 °C/3 h and 1100–1200 °C/4 h) | 1334 | 1372 | 4 | 19 | 0.002 | [79] |

| 90W-7Ni-3Co | Swaged (0.36 true strain) with six intermediate heat treatments (800–900 °C/3 h and 1100–1200 °C/4 h) | 1300 | 1339 | 10 | 281 | 0.003 | |

| 90W-8Ni-2Co | Swaged (0.36 true strain) with six intermediate heat treatments (800–900 °C/3 h and 1100–1200 °C/4 h) | 1236 | 1278 | 13 | 279 | 0.003 | |

| 90W-7Ni-3Co | Swaged (0.36 true strain) with eight intermediate heat treatments (800–900 °C/3 h and 1100–1200 °C/4 h) | 1341 | 1410 | 13 | 227 | 0.004 | |

| 90W-8Ni-2Co | Swaged (0.36 true strain) with eight intermediate heat treatments (800–900 °C/3 h and 1100–1200 °C/4 h) | 1247 | 1311 | 14 | 258 | 0.002 | |

| 90W-6Ni-2Fe-2Co | Swaged (0.71 true strain) with two intermediate heat treatments (1100 °C/1.5 h) | 1442 | 1461 | 5 | 71 | 0.05 | [78] |

| 89W-6Ni-2Fe-3Co | Swaged (0.71 true strain) with two intermediate heat treatments (1100 °C/1.5 h) | 1540 | 1582 | 4 | 70 | 0.04 | |

| 89.5W-6Ni-2Fe-2Co-0.5Mo | Swaged (0.71 true strain) with two intermediate heat treatments (1100 °C/1.5 h) | 1522 | 1551 | 6 | 53 | 0.05 | |

| 89.75W-6Ni-2Fe-2Co-0.25Mo | Swaged (0.71 true strain) with two intermediate heat treatments (1100 °C/1.5 h) | 1522 | 1547 | 5 | 47 | 0.05 | |

| 90W-6Ni-1.5Fe-2.5Co | Swaged (0.71 true strain) with two intermediate heat treatments (1100 °C/1.5 h) | 1561 | 1594 | 5 | 73 | 0.04 | |

| 90W-6Ni-1Fe-3Co | Swaged (0.71 true strain) with two intermediate heat treatments (1100 °C/1.5 h) | 1575 | 1612 | 6 | 121 | 0.05 | |

| 93W-4.9Ni-2.1Fe | Swaging to a 44% reduction with two intermediate heat treatments (1100 °C/2 h) | 1255 | 1286 | 3 | 13 | 0.018 | [99] |

| 93W-4.2Ni-1.2Fe-1.6Co | Swaging to a 44% reduction with two intermediate heat treatments (1100 °C/2 h) | 1219 | 1280 | 12 | 42 | 0.044 | |

| 93W-4.9Ni-1.9Fe-0.2Re | Swaging to a 44% reduction with two intermediate heat treatments (1100 °C/2 h) | 1347 | 1380 | 5 | 26 | 0.026 | |

| 90W-7Ni-2Fe-1Co | Total of 41% deformation with one intermediate heat treatment (1150 °C/2 h) | 1360 | 1400 | 10 | 65 | - | [56] |

| 93W-4.9Ni-1.4Fe-0.7Co | Total of 41% deformation with one intermediate heat treatment (1150 °C/2 h) | 1410 | 1435 | 7 | 45 | - | |

| 95W-3.5Ni-1.0Fe-0.5Co | Total of 41% deformation with one intermediate heat treatment (1150 °C/2 h) | 1418 | 1420 | 4 | 14 | - |

| Composition (wt.%) | Sintering Method | Contiguity | W Particle Size | UTS (MPa) | Elong. (%) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|

| 92.5W-6.4Ni-1.1Fe | Conventional sintering at 1500 °C | 0.32 | 17.3 | 642 | 3.5 | Microwave-sintered specimens give fine W grains, resulting in higher strength. | [61] |

| 92.5W-6.4Ni-1.1Fe | Microwave sintering at 1500 °C | 0.42 | 9.4 | 805 | 11.2 | ||

| 90W-7Ni-3Fe | Conventional sintering at 1480 °C, heating rate of 5 °C/min | - | - | 862 | 19.7 | [28] | |

| 90W-7Ni-3Fe | Microwave sintering at 1480 °C heating rate of 80 °C/min | - | - | 922 | 19.7 | ||

| 90W-7Ni-3Fe | Microwave sintering at 1460 °C | 0.26 | 21 | 740 | 9 | [27] | |

| 90W–7Ni-3Fe | Conventional sintering at 1460 °C | 0.51 | 32 | 650 | 5 | ||

| 90W-6Ni-2Fe-2Co | Microwave sintering at 1470 °C | 0.30 | 21 | 989 | 16 | Microwave-sintered specimens give lower contiguity and higher ductility. | |

| 90W-6Ni-2Fe-2Co | Conventional sintering at 1460 °C | 0.62 | 47 | 682 | 4 | ||

| 90W-7Ni-3Fe | SSS at 1350 °C | - | 2.2 | 1204 | - | SSS gives higher tensile strength because of fine W grains. | [26] |

| 90W-7Ni-3Fe | SPS at 1100 °C, heating rate of 100 °C/min, pressure of 50 MPa | - | - | 930 | 2.91 | SPS gives higher tensile strength but lower ductility. | [67] |

| Composition (wt.%) | Sintering method | Contiguity | W Particle Size | UTS (MPa) | Elong. (%) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|

| 92W-5.6Ni-2.4Fe | SPS, sintered at 1400 °C | 0.64 | 12.3 | 975 | 12 | Increasing the Co content increases the strength. A total of 1 wt.% Co gives the highest tensile strength. | [13] |

| 91.5W-5.6Ni-2.4Fe-0.5Co | SPS, sintered at 1400 °C | 0.54 | 11.56 | 961 | 16 | ||

| 91W-5.6Ni-2.4Fe-1.0Co | SPS, sintered at 1400 °C | 0.47 | 9.48 | 1508 | 20 | ||

| 90.5W-5.6Ni-2.4Fe-1.5Co | SPS, sintered at 1400 °C | 0.43 | 9.68 | 1330 | 21 | ||

| 90W-5.6Ni-2.4Fe-2.0Co | SPS, sintered at 1400 °C | 0.50 | 11.1 | 1256 | 18 | ||

| 93W-4.9Ni-2.1Fe | Conventional sintering at 1480 °C | 0.53 | 56 | 858 | 17 | Adding Co gives a slightly higher strength. Re refines the W grains. | [99] |

| 93W-4.2Ni-1.2Fe-1.6Co | Conventional sintering at 1480 °C | 0.43 | 54 | 869 | 18 | ||

| 93W-4.9Ni-1.9Fe-0.2Re | Conventional sintering at 1480 °C | 0.48 | 49 | 876 | 18 | ||

| 93.5W-4Ni-2Fe-0.5Co | Conventional sintering at 1500 °C | - | - | 853 | 14 | Adding Mo improves ductility due to a larger volume fraction of matrix. | [14] |

| 90.5W-7.2Ni-1.8Fe-0.45Co-0.05Mo | Conventional sintering at 1500 °C | - | - | 950 | 21 | ||

| 95W-3.5Ni-1.5Cu | Conventional sintering at 1510 °C | 0.6 | 60 | 660 | 3 | Tensile properties and hardness of the W-Ni-Cu alloy are inferior due to the coarser W grains. | [58] |

| 96W–3Ni–1Cu | Conventional sintering at 1510 °C | 0.7 | 70 | 660 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, R.; Karthik, G.M.; Sharma, P. Processing, Microstructure, and Mechanical Behavior of Tungsten Heavy Alloys for Kinetic Energy Penetrators: A Critical Review. J. Manuf. Mater. Process. 2025, 9, 186. https://doi.org/10.3390/jmmp9060186

Patel R, Karthik GM, Sharma P. Processing, Microstructure, and Mechanical Behavior of Tungsten Heavy Alloys for Kinetic Energy Penetrators: A Critical Review. Journal of Manufacturing and Materials Processing. 2025; 9(6):186. https://doi.org/10.3390/jmmp9060186

Chicago/Turabian StylePatel, Rajneesh, Gangaraju Manogna Karthik, and Pawan Sharma. 2025. "Processing, Microstructure, and Mechanical Behavior of Tungsten Heavy Alloys for Kinetic Energy Penetrators: A Critical Review" Journal of Manufacturing and Materials Processing 9, no. 6: 186. https://doi.org/10.3390/jmmp9060186

APA StylePatel, R., Karthik, G. M., & Sharma, P. (2025). Processing, Microstructure, and Mechanical Behavior of Tungsten Heavy Alloys for Kinetic Energy Penetrators: A Critical Review. Journal of Manufacturing and Materials Processing, 9(6), 186. https://doi.org/10.3390/jmmp9060186