In-Depth Thermal Analysis of Different Pin Configurations in Friction Stir Spot Welding of Similar and Dissimilar Alloys

Abstract

1. Introduction

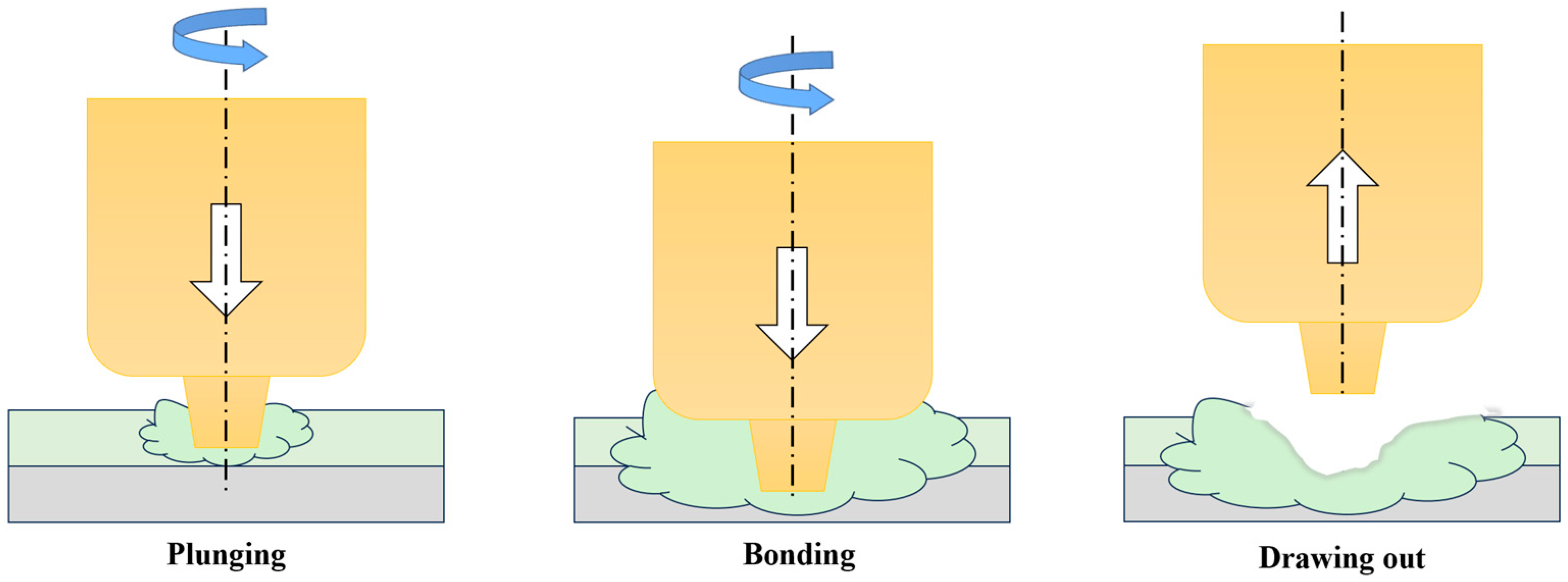

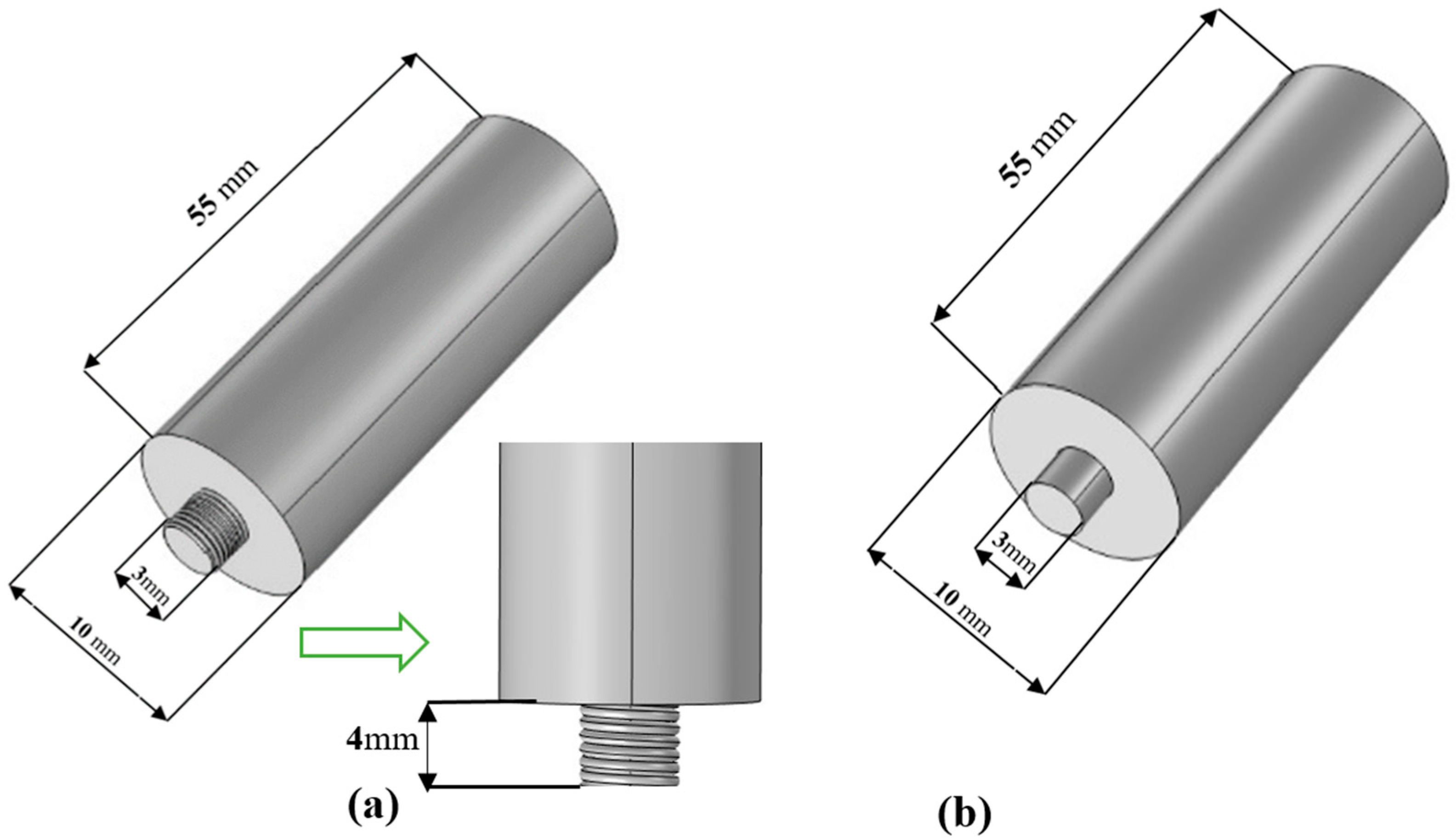

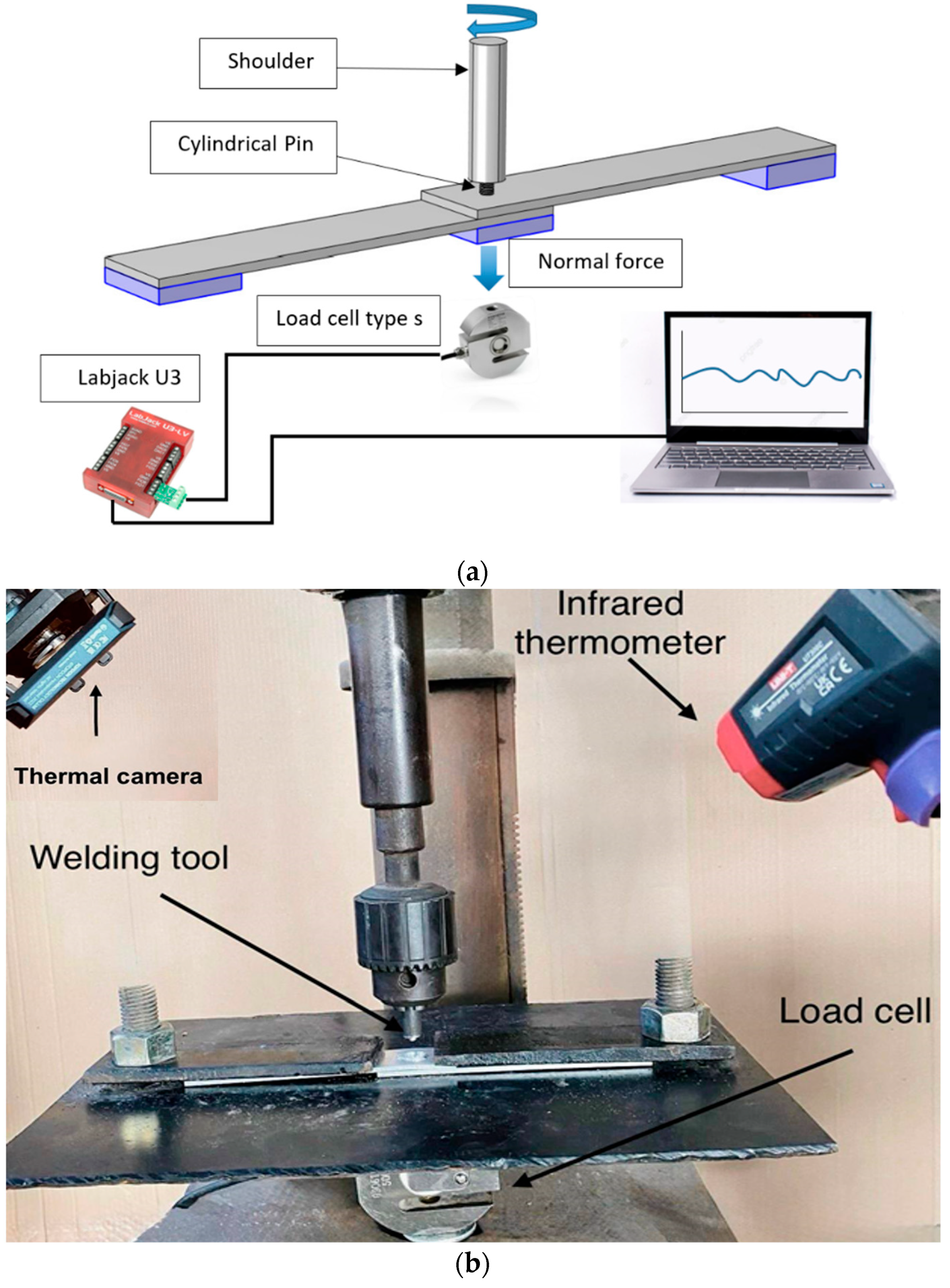

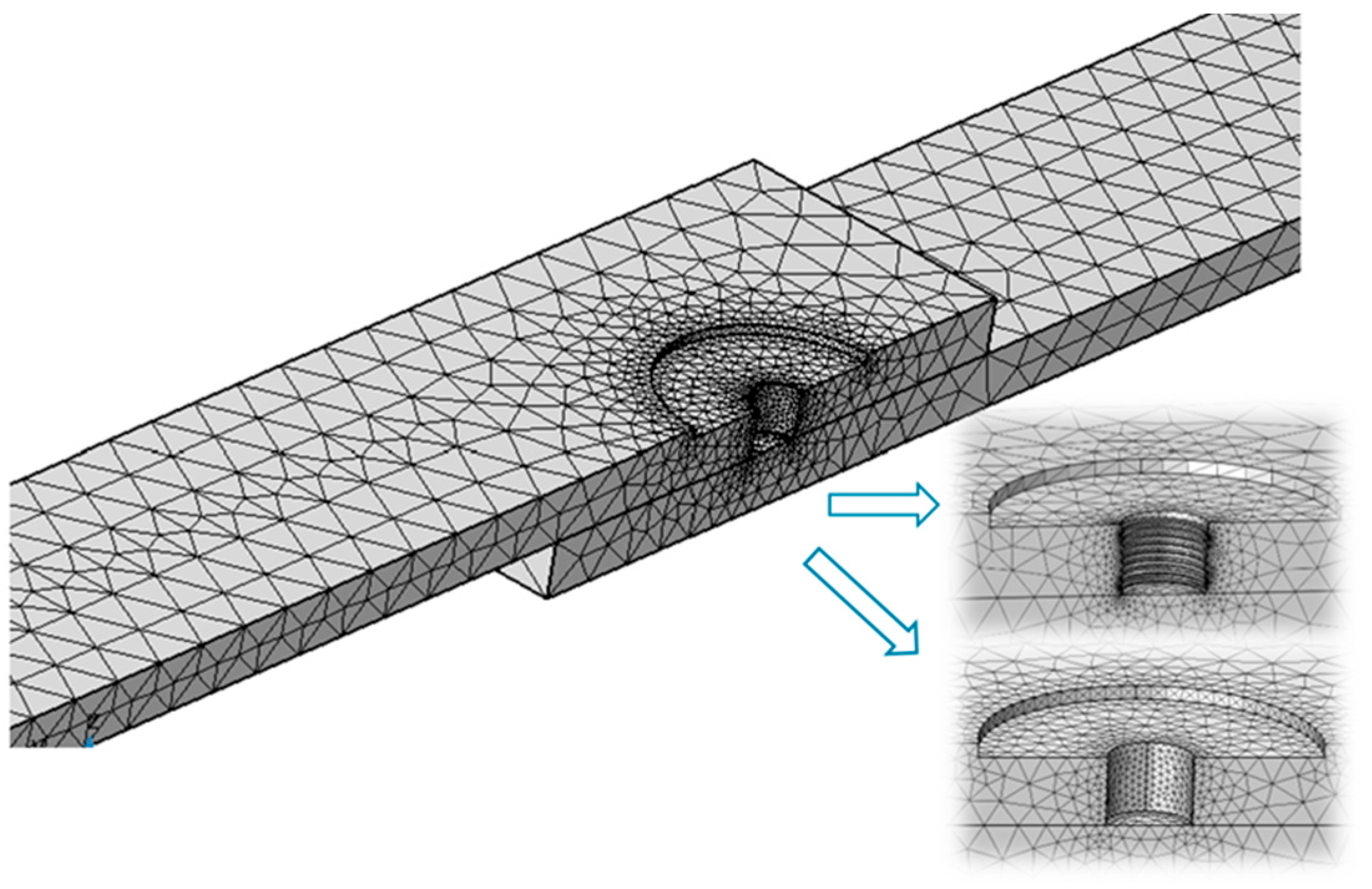

2. Materials and Methods

3. Results and Discussions

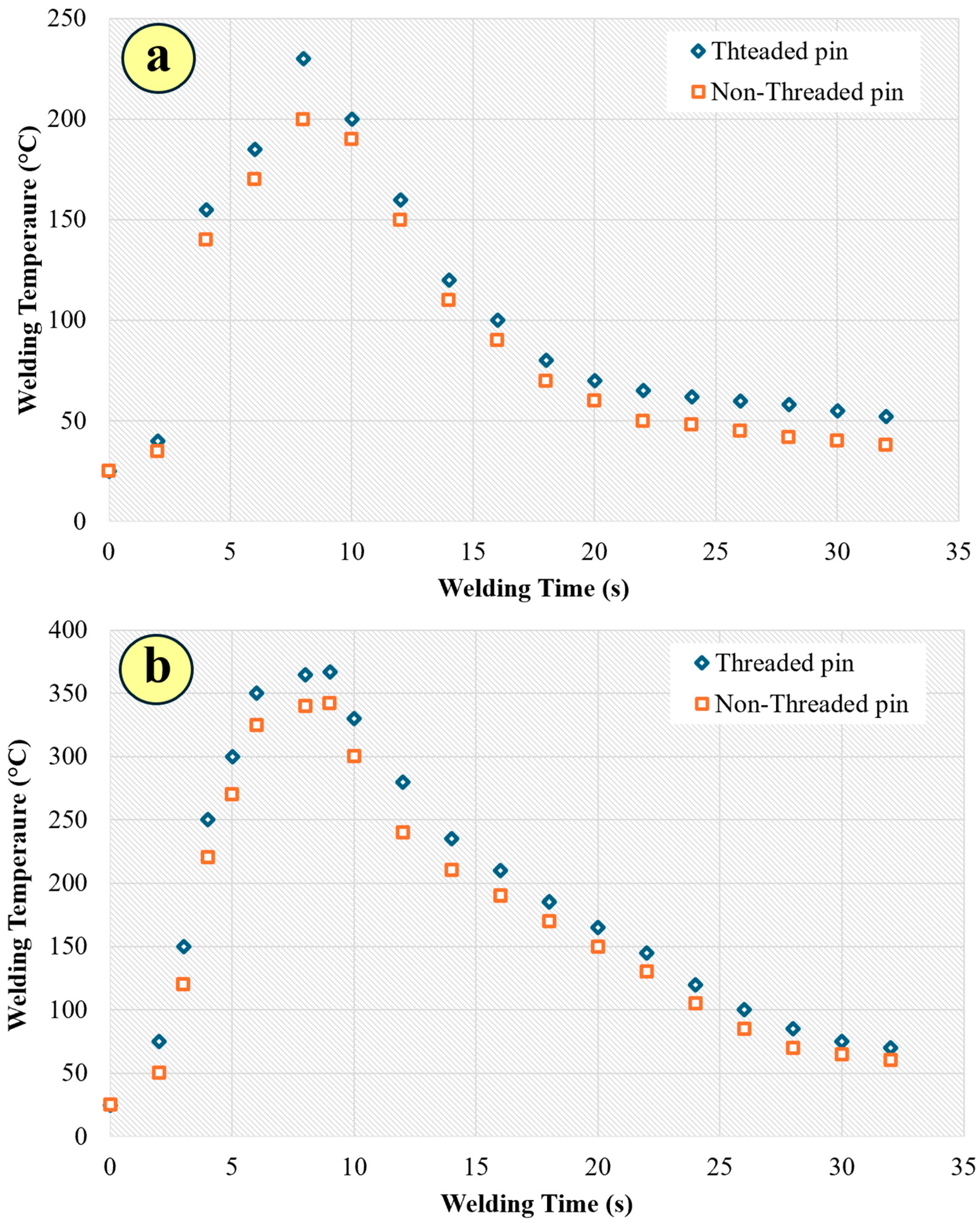

3.1. Effect of Pin Configuration on Thermal Analysis

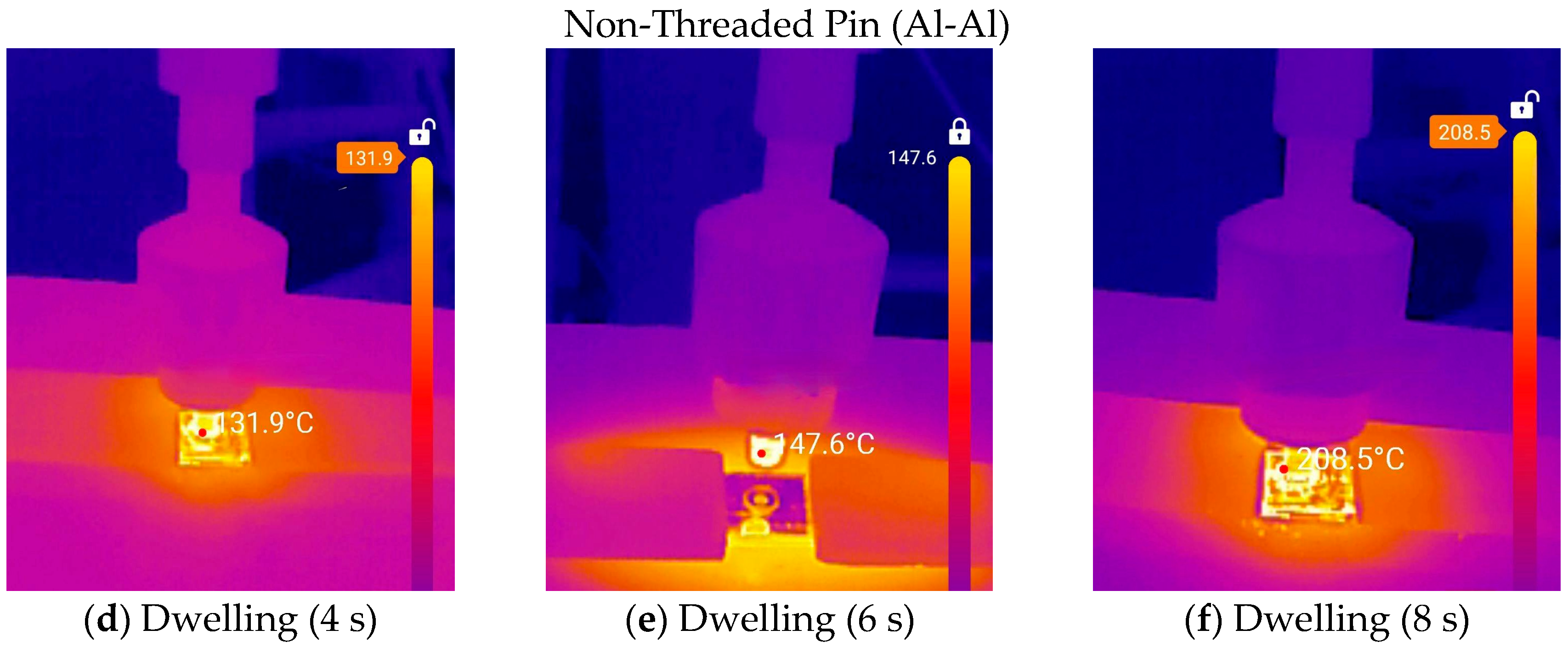

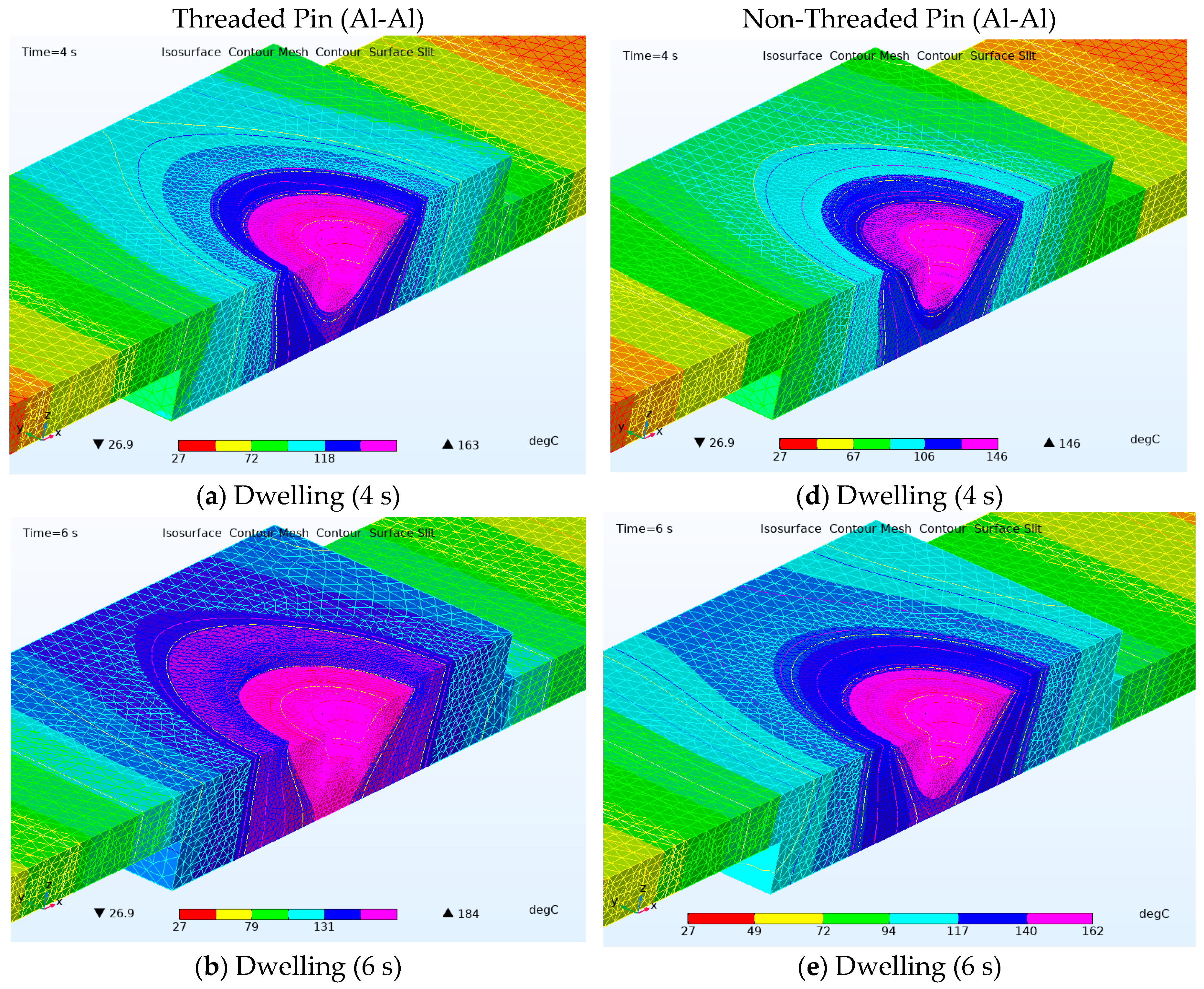

3.1.1. Thermal Analysis in Similar Alloys

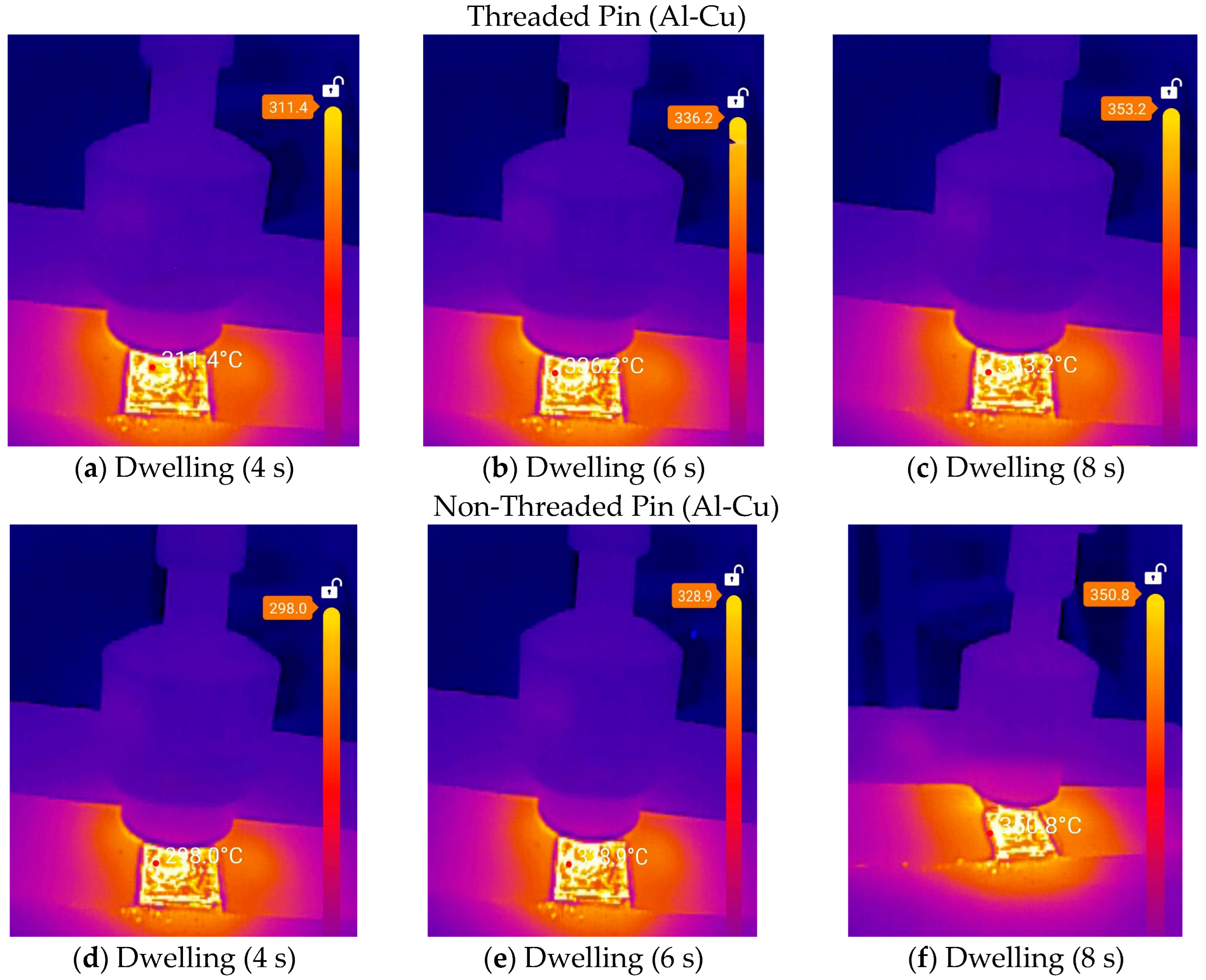

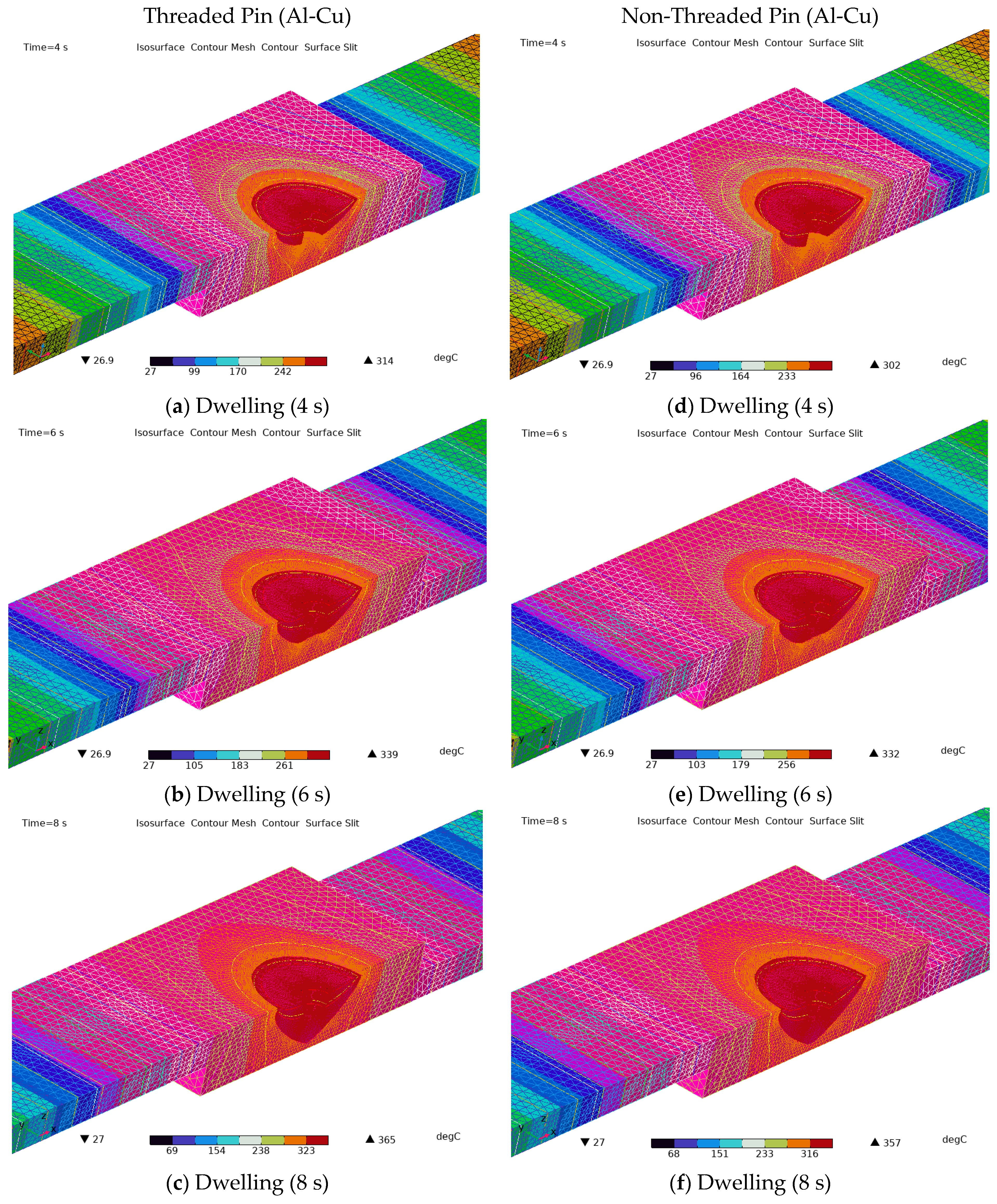

3.1.2. Thermal Analysis in Dissimilar Alloys

3.2. Effect of Pin Configuration Temperature Profiles

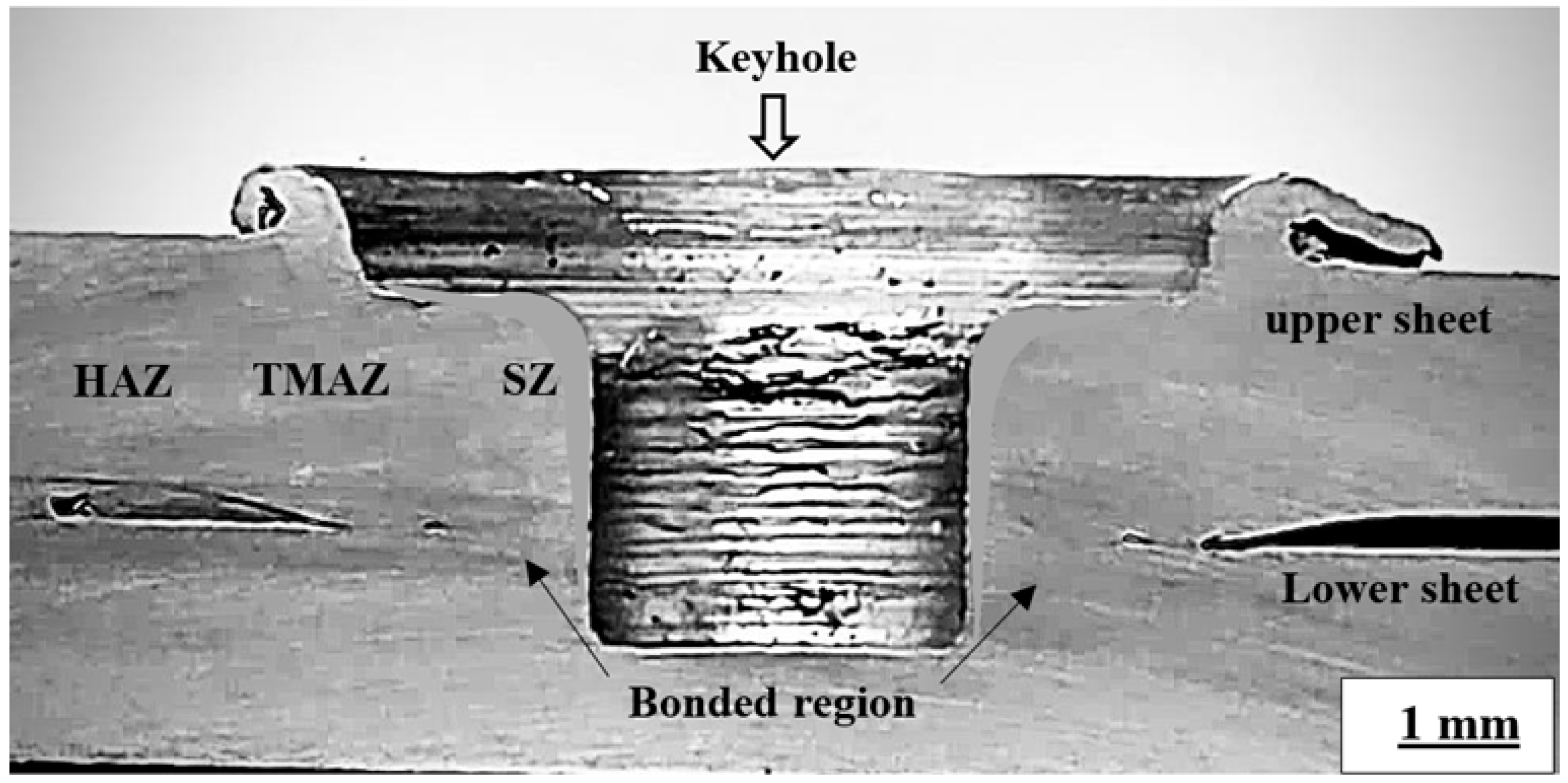

3.3. Effect of Pin Configuration on the Joint Shape

4. Conclusions

- When welding dissimilar metals, the heat required to complete a smooth and successful FSSW process is higher. There is often a significant difference in the material flow between the two weld plates, with the flow being faster and greater in aluminum than copper. This generates more heat to generate the friction necessary for plastic deformation in copper, similar to aluminum. In contrast, when welding aluminum to copper, the maximum heat generated can reach 350 °C and occurs in a dowelling time of 6 s. This temperature is close to aluminum’s recrystallization temperature, which explains why the deformation in the aluminum plate is greater than that in the copper plate. Moreover, the temperature obtained from the threaded pin was higher than that of the non-threaded pin.

- As the dwell time increases, the temperature rises enough to generate a weld pool, resulting in plastic deformation. This deformation, in turn, facilitates the tools’ sliding across the weld and thus reduces friction. However, the increase in the dwelling time must be controlled and within certain limits, because an excessive increase can lead to uncontrolled plastic deformation, greater penetration depth, and weld failure.

- For industrial applications prioritizing maximum joint strength and reliability, like in automotive lightweight structures or aerospace skin–stringer assemblies, threaded pins are generally recommended. Operating them at moderate rotational speeds (around 1500 rpm) with controlled dwelling times (around 6–8 s) effectively balances heat input with mechanical integrity. Conversely, non-threaded pins are more suitable where minimal thermal exposure is crucial. This makes them a good option for joining heat-sensitive materials or when preserving the original microstructure is a primary concern.

- The temperatures obtained from the simulation model show strong agreement with those measured by the thermal camera, both in the weld zone and in surrounding regions. This convergence extends even to areas not directly influenced by the FSSW process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, N.Z.; Khan, Z.A.; Siddiquee, A.N.; Al-ahmari, A.M.; Abidi, M.H. Analysis of defects in clean fabrication process of friction stir welding. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2017, 27, 1507–1516. [Google Scholar] [CrossRef]

- Morshed-Behbahani, K.; Aliyu, A.; Bishop, D.P.; Nasiri, A. Additive manufacturing of copper-based alloys for high-temperature aerospace applications: A review. Mater. Today Commun. 2024, 38, 108395. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needhan, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. International Patent Application PCT/GB92/02203. GB Patent Application 9125978.8, 6 December 1991. [Google Scholar]

- Radisavljevic, I.; Zivkovic, A.; Radovic, N.; Grabulov, V. Influence of FSW parameters on formation quality and mechanical properties of Al 2024-T351 butt welded joints. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2013, 23, 3525–3539. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Kishore, H.; Sidana, A. Optimization of FSW input parameters for dissimilar butt-welded joints of Al6061-AZ31 alloys by GRA. J Adhes. Sci. Technol. 2025, 39, 1579–1601. [Google Scholar] [CrossRef]

- Chikh, A.; Serier, M.; Al-Sabur, R.; Siddiquee, A.N.; Gangil, N. Thermal Modeling of Tool-Work Interface during Friction Stir Welding Process. Russ. J. Non-Ferr. Met. 2022, 63, 690–700. [Google Scholar] [CrossRef]

- Al-Sabur, R.; Serier, M.; Siddiquee, A.N. Analysis and construction of a pneumatic-powered portable friction stir welding tool for polymer joining. Adv. Mater. Process. Technol. 2023, 10, 1052–1066. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-Sabur, R. Friction Stir Techniques Exploring Fracture and Fatigue Behavior in Hybrid Composite Joints. In Utilizing Friction Stir Techniques for Composite Hybridization; IGI Global: Hershey, PA, USA, 2024; Chapter 7; pp. 108–134. [Google Scholar] [CrossRef]

- Mehrez, S.; Paidar, M.; Cooke, K.; Vignesh, R.V.; Ojo, O.O.; Babaei, B. A comparative study on weld characteristics of AA5083-H112 to AA6061-T6 sheets produced by MFSC and FSSW processes. Vacuum 2021, 190, 110298. [Google Scholar] [CrossRef]

- Al-Sabur, R.K.; Jassim, A.K. Friction Stir Spot Welding Applied to Weld Dissimilar Metals of AA1100 Al-alloy and C11000 Copper. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012087. [Google Scholar] [CrossRef]

- Abdullah, I.T.; Mejbel, M.K.; Al-bhadle, B.M.A. Double Stage Friction Stir Spot Extrusion Welding: A Novel Manufacturing Technique for Joining Sheets. Exp. Tech. 2024, 48, 323–342. [Google Scholar] [CrossRef]

- Carr, G.E.; Biocca, N.; Lombera, G.A.; Urquiza, S.A. FEM modelling of the three stages of friction stir spot welding. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2023, 237, 3483–3492. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Ahmed, E.; Reyad, H.A.; Alsaleh, N.A.; Albaijan, I. A Novel Friction Stir Deposition Technique to Refill Keyhole of Friction Stir Spot Welded AA6082-T6 Dissimilar Joints of Different Sheet Thicknesses. Materials 2022, 15, 6799. [Google Scholar] [CrossRef] [PubMed]

- Kabirmohammadi, M.; Yazdani, S.; Saeid, T.; Pouranvari, M. Microstructural evolution and mechanical performance of friction stir spot welded ultrafine carbide-free bainitic steel: Role of dwell time. J. Mater. Res. Technol. 2024, 33, 4033–4046. [Google Scholar] [CrossRef]

- Pan, T.Y. Friction stir spot welding (FSSW)—A literature review. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Feng, Z.; Santella, M.L.; David, S.A.; Steel, R.J.; Packer, S.M.; Pan, T.; Kuo, M.; Bhatnagar, R.S. Friction Stir Spot Welding of Advanced High-Strength Steels—A Feasibility Study. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Bakavos, D.; Prangnell, P.B. Effect of reduced or zero pin length and anvil insulation on friction stir spot welding thin gauge 6111 automotive sheet. Sci. Technol. Weld. Join. 2009, 14, 443–456. [Google Scholar] [CrossRef]

- Bawagnih, A.H.; Al-Badour, F. Temperature and Stresses in AA 6082-T6 Friction Stir Spot Welding (FSSW) Using Coupled Eulerian–Lagrangian Finite Element Method. In Friction Stir Welding and Processing XIII (TMS 2025); Hovanski, Y., Sato, Y., Upadhyay, P., Kumar, N., Naumov, A.A., Eds.; Springer: Cham, Switzerland, 2025; pp. 289–302. [Google Scholar] [CrossRef]

- Jaiswal, R.; Singh, R.; Rizvi, S.A. Prediction of 3-dimensional heat treatment model during the friction stir spot welding of AA 6061. J. Eng. Res. 2023, 11, pp.290–300. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-Sabur, R.; Demiral, M.; Tomków, J.; Łabanowski, J.; Abdullah, M.E.; Derazkola, H.A. The Effects of Pin Profile on HDPE Thermomechanical Phenomena during FSW. Polymers 2022, 14, 4632. [Google Scholar] [CrossRef] [PubMed]

- Hamzah, M.N.; Bakhy, S.H.; Fliayyh, M.A. Numerical and Experimental Investigations of Transient Temperature Distribution in Friction Stir Spot Welding of Aluminum Alloy AA6061. AL-Qadisiya J. Eng. Sci. 2016, 9, 338–407. [Google Scholar]

- Al-Sabur, R.; Jassim, A.K.; Messele, E. Real-time monitoring applied to optimize friction stir spot welding joint for AA1230 Al-alloys. Mater. Today Proc. 2021, 42, 2018–2024. [Google Scholar] [CrossRef]

- Andrade, D.G.; Sabari, S.; Leitão, C.; Rodrigues, D.M. Shoulder related temperature thresholds in fssw of aluminium alloys. Materials 2021, 14, 4375. [Google Scholar] [CrossRef]

- Serier, M.; Jassim, R.J.; Al-Sabur, R.; Siddiquee, A.N. Thermal Diffusivity Modeling for Aluminum AA6060 Plates During Friction Stir Welding. AIP Conf. Proc. 2024, 3051, 070004. [Google Scholar] [CrossRef]

- Boopathi, S.; Lewise, K.A.S.; Dhas, J.E.R.; Satheesh, M. Mechanical Properties and Temperature Distribution of Friction Stir Spot Welding Process. In Friction Stir Spot Welding; CRC Press: Boca Raton, FL, USA, 2024; pp. 164–187. [Google Scholar] [CrossRef]

- Zhang, H.F.; Zhou, L.; Li, G.H.; Tang, Y.T.; Li, W.L.; Wang, R. Prediction and validation of temperature distribution and material flow during refill friction stir spot welding of AZ91D magnesium alloy. Sci. Technol. Weld. Join 2021, 26, 153–160. [Google Scholar] [CrossRef]

- Andrade, D.G.; Sabari, S.; Galvão, I.; Leitão, C.; Rodrigues, D.M. Temperature and torque in FSSW of steel sheets: Experimental measurements and modelling. Weld. World 2023, 67, 341–352. [Google Scholar] [CrossRef]

- Asmare, A.; Al-Sabur, R.; Messele, E. Experimental Investigation of Friction Stir Welding on 6061-T6 Aluminum Alloy Using Taguchi-Based GRA. Metals 2020, 10, 1480. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P.; Sadowski, T. A Review on Friction Stir Welding/Processing: Numerical Modeling. Materials 2023, 16, 5890. [Google Scholar] [CrossRef] [PubMed]

- Patel, M.M.; Badheka, V.J. A review on friction stir welding (FSW) process for dissimilar aluminium to steel metal systems. Weld. Int. 2024, 38, 91–115. [Google Scholar] [CrossRef]

- Bhattacharjee, R.; Biswas, P. Review on thermo-mechanical and material flow analysis of dissimilar friction stir welding. Weld. Int. 2021, 35, 295–332. [Google Scholar] [CrossRef]

- Das, D.; Bag, S.; Pal, S. Probing finite element modelling of defects in friction stir welding by tailoring mass scaling factor. Mater. Today Commun. 2023, 35, 105646. [Google Scholar] [CrossRef]

- Su, H.; Chen, J.; Wu, C. Effect of tool eccentricity on the periodic material flow in friction stir welding process. Int. J. Mech. Sci. 2022, 220, 107164. [Google Scholar] [CrossRef]

- Kesharwani, R.; Jha, K.K.; Imam, M.; Sarkar, C.; Barsoum, I. Correlation of microstructure, texture, and mechanical properties of friction stir welded Joints of AA7075-T6 plates using a flat tool pin profile. Heliyon 2024, 10, e25449. [Google Scholar] [CrossRef]

- Haider, F.; Hanif, M.W.; Jahanzaib, M. Investigating the effects of novel cylindrical pins geometries and aging on the mechanical characteristics of friction stir welded Al-2024/Al-5754 joints. Int. J. Interact. Des. Manuf. (IJIDeM) 2024. [Google Scholar] [CrossRef]

- Liu, S.; Chen, F.; Gao, Y. Effect of Progressive Pin and Pre-set Wires on the Quality of Corner Forming of Al/Cu FSW T-Lap Joints. J. Mater. Eng. Perform. 2025. [Google Scholar] [CrossRef]

- Verma, M.; Ahmed, S.; Saha, P. Challenges, process requisites/inputs, mechanics and weld performance of dissimilar micro-friction stir welding (dissimilar μFSW): A comprehensive review. J. Manuf. Process. 2021, 68, 249–276. [Google Scholar] [CrossRef]

- Ataya, S.; Ahmed, M.M.Z.; Seleman, M.M.E.-S.; Hajlaoui, K.; Latief, F.H.; Soliman, A.M.; Elshaghoul, Y.G.Y.; Habba, M.I.A. Effective Range of FSSW Parameters for High Load-Carrying Capacity of Dissimilar Steel A283M-C/Brass CuZn40 Joints. Materials 2022, 15, 1394. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.Y.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join Process. 2021, 3, 100059. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Q.; Huang, Y. Influence of heat input on pinless friction stir spot welding of aluminum-copper dissimilar materials. Mater. Charact. 2024, 218, 114456. [Google Scholar] [CrossRef]

- Habibizadeh, A.; Honarpisheh, M.; Golabi, S. Effect of friction stir spot welding parameters on the microstructure and properties of joints between aluminium and copper. Weld. World 2022, 66, 1757–1774. [Google Scholar] [CrossRef]

- Payak, V.; Paulraj, J.; Roy, B.S.; Bhargava, M.; Das, P. A review on recent development in aluminium-copper friction stir welding. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2024, 238, 1462–1506. [Google Scholar] [CrossRef]

- Alyani, A.; Kazeminezhad, M. Annealing behavior of aluminum after low-temperature severe plastic deformation. Mater. Sci. Eng. A 2021, 824, 141810. [Google Scholar] [CrossRef]

- Ding, S.; Khan, S.A.; Yanagimoto, J. Metadynamic recrystallization behavior of 5083 aluminum alloy under double-pass compression and stress relaxation tests. Mater. Sci. Eng. A 2021, 822, 141673. [Google Scholar] [CrossRef]

- Beygi, R.; Carbas, R.J.C.; Marques, E.A.S.; Barbosa, A.Q.; Kasaei, M.M.; da Silva, L.F.M. Mechanism of toughness enhancement of brittle fracture by intermittent η-intermetallic in Al/Cu joint made by FSW. Mater. Sci. Eng. A 2024, 890, 145907. [Google Scholar] [CrossRef]

- Cao, F.; Li, J.; Hou, W.; Shen, Y.; Ni, R. Microstructural evolution and mechanical properties of the friction stir welded Al–Cu dissimilar joint enhanced by post-weld heat treatment. Mater. Charact. 2021, 174, 110998. [Google Scholar] [CrossRef]

- Sharma, N.; Khan, Z.A.; Siddiquee, A.N.; Shihab, S.K.; Wahid, M.A. Effect of process parameters on microstructure and electrical conductivity during FSW of Al-6101 and Pure Copper. Mater. Res. Express 2018, 5, 046519. [Google Scholar] [CrossRef]

- Zhao, W.; Zhu, Y.; Liu, Z.; Fu, A.; He, H. Mechanism of ultrasonic effects on thermal-stress field in Cu/Al-FSW process. Int. J. Mech. Sci. 2024, 270, 109101. [Google Scholar] [CrossRef]

- Raj, A.; Pratap Kumar, J.; Ramesha, K.; Rout, I.S. Modelling, Temperature Analysis, and Mechanical Properties of Friction Stir Welding of Al-Cu Joints with Hardened OHNS Steel Tools. J. Mines Met. Fuels 2022, 70, 462–470. [Google Scholar] [CrossRef]

- Mypati, O.; Mishra, D.; Sahu, S.; Pal, S.K.; Srirangam, P. A Study on Electrical and Electrochemical Characteristics of Friction Stir Welded Lithium-Ion Battery Tabs for Electric Vehicles. J. Electron. Mater. 2020, 49, 72–87. [Google Scholar] [CrossRef]

- Gu, C.; Yang, X.; Tang, W.; Luo, T.; Wang, R. Softening behavior of stationary shoulder friction stir welded joint for thick-plate Al-Li-Cu alloy. J. Mater. Res. Technol. 2022, 20, 3008–3024. [Google Scholar] [CrossRef]

- Ji, S.; Cui, X.; Ma, L.; Liu, H.; Zuo, Y.; Zhang, Z. Achieving High-Quality Aluminum to Copper Dissimilar Metals Joint via Friction Stir Double-Riveting Welding. Acta Metall. Sin. (Engl. Lett.) 2023, 36, 552–572. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.K.; Herbert, M.A.; GC, M.P.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Li, M.; Zhang, C.; Wang, D.; Zhou, L.; Wellmann, D.; Tian, Y. Friction stir spot welding of aluminum and copper: A review. Materials 2020, 13, 156. [Google Scholar] [CrossRef]

- Raja, K.; Bejaxhin, A.B.H.; Jayaprakash, G.; Gopi Krishnan, P.; Ramanan, N. Microstructural and mechanical analysis of achieving crack-free joints in high-speed friction stir spot welding of Cu–Al dissimilar material. Int. J. Interact. Des. Manuf. 2024, 19, 325–336. [Google Scholar] [CrossRef]

- Zhou, L.; Li, G.; Zhang, R.; Zhou, W.; He, W.; Huang, Y.; Song, X. Microstructure evolution and mechanical properties of friction stir spot welded dissimilar aluminum-copper joint. J. Alloys Compd. 2019, 775, 372–382. [Google Scholar] [CrossRef]

| Element | AA6061 | Element | C11000 |

|---|---|---|---|

| Cr | 0.26 | Cr | 0.003 |

| Cu | 0.34 | Pb | 0.0005 |

| Mg | 1.08 | Mg | 0.0001 |

| Fe | 0.66 | Ti | 0.0003 |

| Si | 0.55 | Si | 0.0005 |

| Mn | 0.11 | Mn | 0.0003 |

| Ti | 0.16 | Zn | 0.009 |

| Zn | 0.223 | Al | 0.001 |

| Al | balance | Cu | balance |

| Sheet Metal | Hardness (HV) | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|---|

| AA 6061 [28] | 40 | 310 | 276 |

| C11000 [10] | 55–115 | 210–310 | 69 @ Strain 0.5% |

| Elements | Mo | Cr | Mn | Si | V | C |

|---|---|---|---|---|---|---|

| % | 1.00 | 12.00 | 0.40 | 0.30 | 0.90 | 1.50 |

| Parameter | Values |

|---|---|

| Surface emissivity | 0.3 |

| plunging rate | 15 mm/min |

| Aluminum melting temperature | 933 K |

| Plunge force | 20 kN |

| Pin heat capacity | 500 J/kg K |

| Tool density | 7800 kg/m3 |

| Tool rotational speed | 1500 rpm |

| Heat transfer coefficient (upside) | 12.25 W/(m2.K) |

| Heat transfer coefficient (downside) | 6.25 W/(m2.K) |

| Pin radius | 0.0015 m |

| Shoulder radius | 0.005 m |

| Initial temperature | 298 K |

| Dwelling Time (s) | Threaded Pin | Non-Threaded Pin | ||

|---|---|---|---|---|

| Exp. (°C) | FEM (°C) | Exp. (°C) | FEM (°C) | |

| 4 | 145 | 163 | 132 | 146 |

| 6 | 167 | 184 | 148 | 162 |

| 8 | 219 | 227 | 208 | 219 |

| Dwelling Time (s) | Threaded Pin | Non-Threaded Pin | ||

|---|---|---|---|---|

| Exp. (°C) | FEM (°C) | Exp. (°C) | FEM (°C) | |

| 4 | 311 | 314 | 298 | 302 |

| 6 | 336 | 339 | 329 | 323 |

| 8 | 353 | 365 | 351 | 357 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alasdi, S.N.; Al-Sabur, R. In-Depth Thermal Analysis of Different Pin Configurations in Friction Stir Spot Welding of Similar and Dissimilar Alloys. J. Manuf. Mater. Process. 2025, 9, 184. https://doi.org/10.3390/jmmp9060184

Alasdi SN, Al-Sabur R. In-Depth Thermal Analysis of Different Pin Configurations in Friction Stir Spot Welding of Similar and Dissimilar Alloys. Journal of Manufacturing and Materials Processing. 2025; 9(6):184. https://doi.org/10.3390/jmmp9060184

Chicago/Turabian StyleAlasdi, Sajad N., and Raheem Al-Sabur. 2025. "In-Depth Thermal Analysis of Different Pin Configurations in Friction Stir Spot Welding of Similar and Dissimilar Alloys" Journal of Manufacturing and Materials Processing 9, no. 6: 184. https://doi.org/10.3390/jmmp9060184

APA StyleAlasdi, S. N., & Al-Sabur, R. (2025). In-Depth Thermal Analysis of Different Pin Configurations in Friction Stir Spot Welding of Similar and Dissimilar Alloys. Journal of Manufacturing and Materials Processing, 9(6), 184. https://doi.org/10.3390/jmmp9060184