Investigation of UV Picosecond Laser Damage Threshold of Anti-Reflection Coated Windows

Abstract

1. Introduction

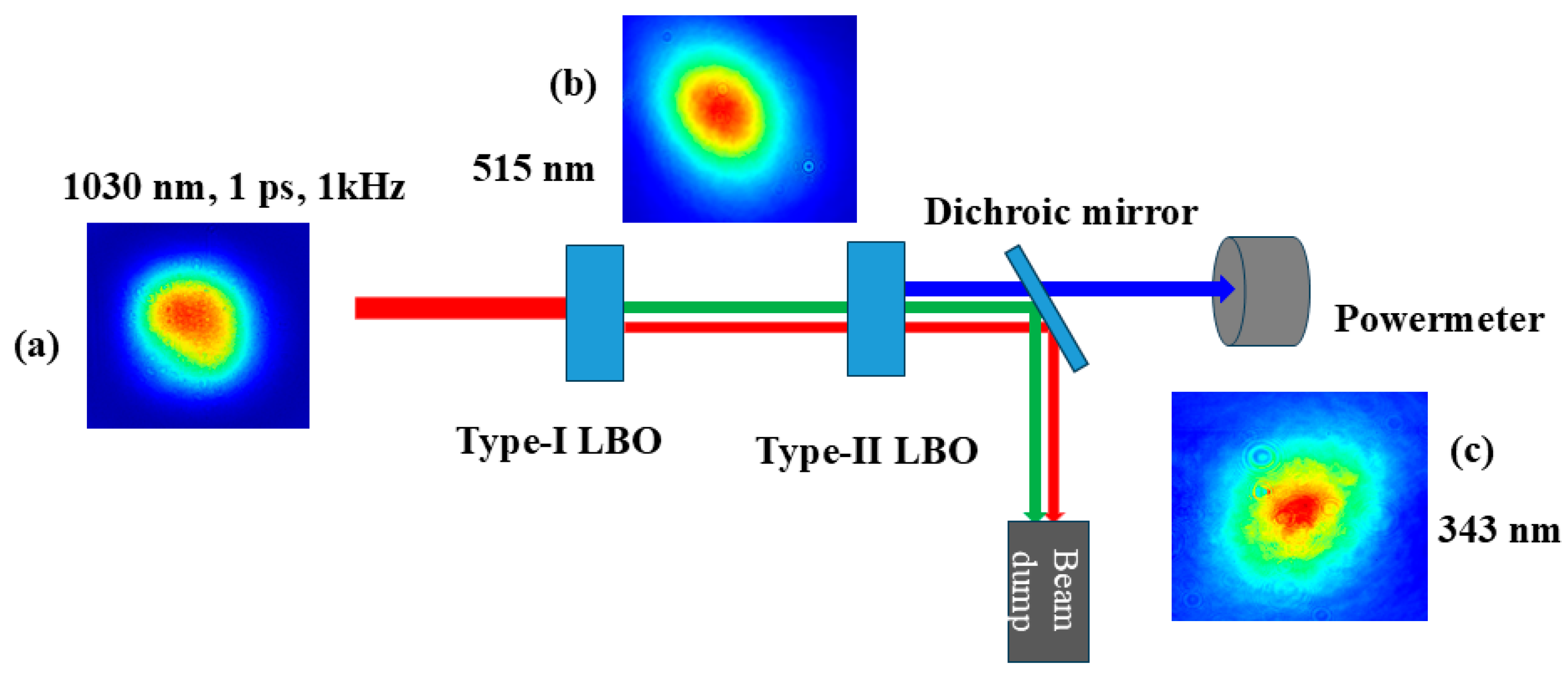

2. Materials and Methods

3. Results and Discussion

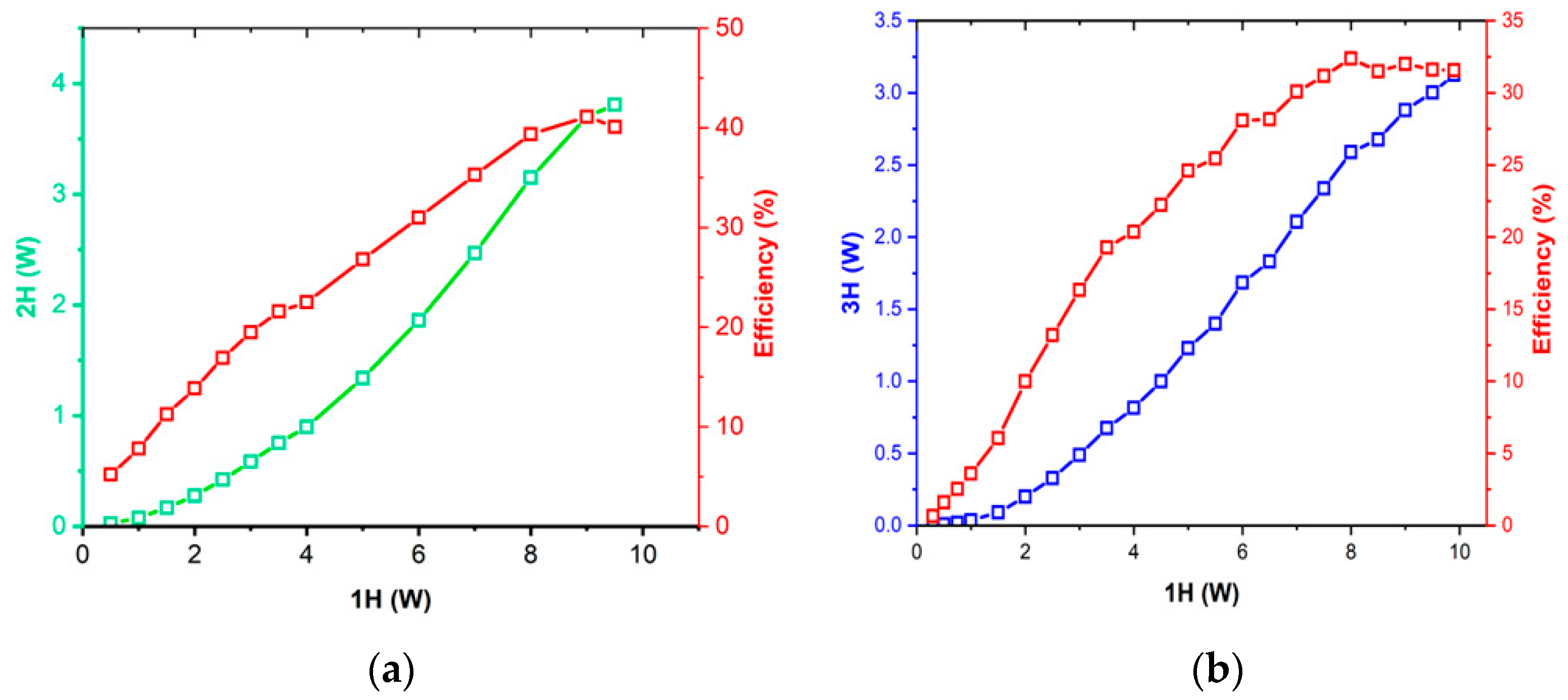

3.1. Third-Harmonic Generation for LIDT

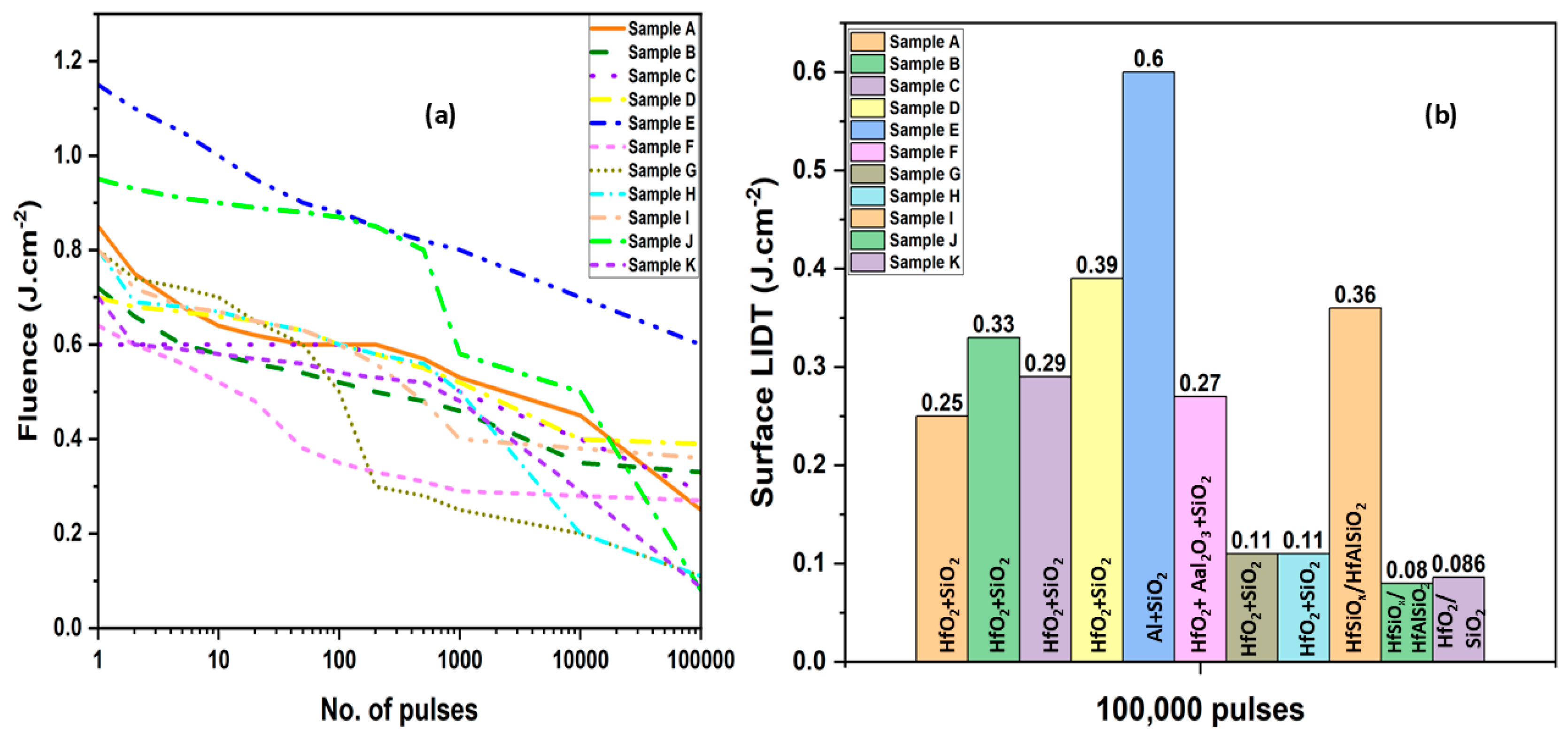

3.2. UV Laser-Induced Damage Threshold Testing

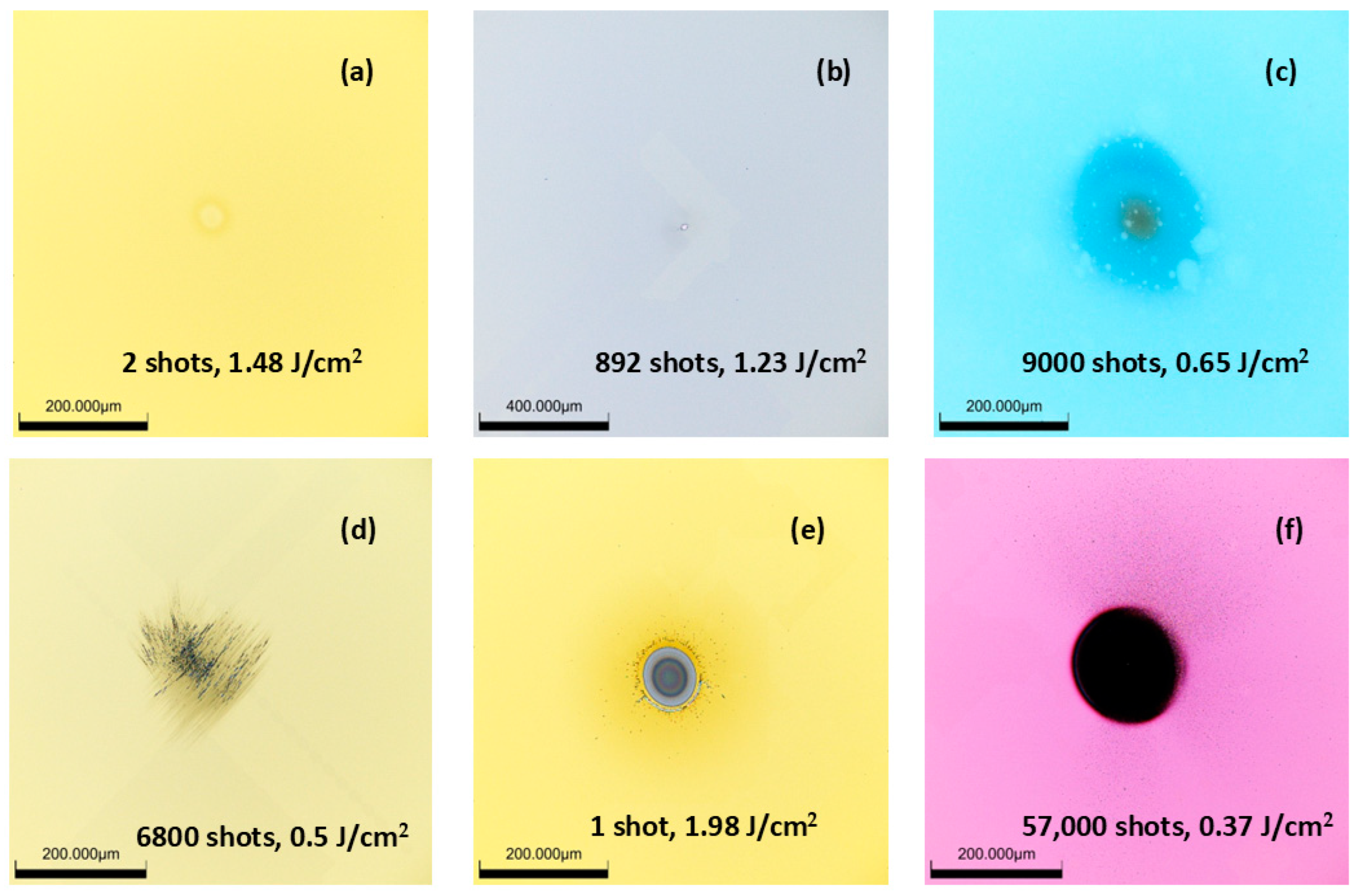

3.3. Morphology of Laser Damage

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| LIDT | Laser-induced damage threshold |

| AR | Anti-reflective |

| IBS | Ion beam sputtering |

| LBO | Lithium borate |

| SHG | Second-harmonic generation |

| THG | Third-harmonic generation |

References

- Ristau, D.; Jupe, M.; Starke, K. Laser damage thresholds of optical coatings. Thin Solid Films 2009, 518, 1607–1613. [Google Scholar] [CrossRef]

- Smrž, M.; Chyla, M.; Muzik, J.; Nagisetty, S.S.; Novak, O. Compact picosecond KW-class thin-disk laser Perla for hi-tech industrial applications. MM Sci. J. 2019, 2019, 3620–3625. [Google Scholar] [CrossRef]

- Hauschwitz, P.; Jagdheesh, R.; Alamri, S.; Rostohar, D.; Kunze, T.; Brajer, J.; Kopeček, J.; Mocek, T. Fabrication of functional superhydrophobic surfaces on carbon fibre reinforced plastics by IR and UV direct laser interference patterning. Appl. Surf. Sci. 2020, 508, 144817. [Google Scholar] [CrossRef]

- Falmbigl, M.; Godin, K.; George, J.; Mühlig, C.; Rubin, B. Effect of annealing on properties and performance of HfO2/SiO2 optical coatings for UV-applications. Opt. Express 2022, 30, 12326–12336. [Google Scholar] [CrossRef]

- Douti, D.L.; Gallais, L.; Hecquet, C.; Begou, T.; Lumeau, J.; Commandre, M. Analysis of energy deposition and damage mechanisms in single layer optical thin films irradiated by IR and UV femtosecond pulses. Proc. SPIE 2015, 9627, 962718. [Google Scholar] [CrossRef]

- Kozlov, A.; Lambropoulos, J.C.; Oliver, J.B.; Hofman, B.N.; Demos, S.G. Mechanisms of picosecond laser induced damage in common multilayer dielectric coatings. Sci. Rep. 2019, 9, 607. [Google Scholar] [CrossRef]

- Qiu, S.R.; Norton, M.A.; Raman, R.N.; Rubenchik, A.M.; Boley, C.D.; Rigatti, A.; Mirkarimi, P.B.; Stolz, C.J.; Matthew, M.J. Impact of laser-contaminant interaction on the performance of the protective capping layer of 1 ω high-reflection mirror coatings. Appl. Opt. 2015, 54, 8607–8616. [Google Scholar] [CrossRef]

- Nuter, R.; Kandy, A.K.; Gallais, L.; Grosjean, S.; Lamaignere, L.; Wagner, F.; Natoli, J.-Y. Influence of laser polarization on the laser-induced damage threshold: Comparison with photonionization theory. J. Appl. Phys. 2025, 137, 025901. [Google Scholar] [CrossRef]

- Novák, O.; Miura, T.; Smrž, M.; Chyla, M.; Nagisetty, S.S.; Mužík, J.; Linnemann, J.; Turčičová, H.; Jambunathan, V.; Slezák, O.; et al. Status of the High Average Power Diode Pumped Solid State Lasers Development at HiLASE. Appl. Sci. 2015, 5, 637–665. [Google Scholar] [CrossRef]

- Vanda, J. Progress in design of advanced LIDT station in HiLASE project. Proc. SPIE 2015, 9442, 94421E. [Google Scholar] [CrossRef]

- Skoda, V.; Vanda, J.; Uxa, S. A comparison of LIDT behavior of metal-dielectric mirrors in ns and ps pulse regime at 1030 nm with regard to the coating technology. Proc. SPIE 2017, 10447, 1044729. [Google Scholar] [CrossRef]

- Divoky, M.; Smrz, M.; Chyla, M.; Sikocinski, P.; Severova, P.; Novák, O.; Huynh, J.; Nagisetty, S.S.; Miura, T.; Liberatore, C.; et al. HiLASE: Development of fully diode pumped disk lasers with high average power. Proc. SPIE 2014, 9255, 92550V. [Google Scholar] [CrossRef]

- Macuchova, K.; Hermanek, J.; Kaufman, J.; Muresan, M.G.; Ruzicka, J.; Rehakova, M.; Divoky, M.; Svandrlik, L.; Mocek, T. Laser beam distribution system for the HiLASE center. Proc. SPIE 2017, 10603, 1060306. [Google Scholar] [CrossRef]

- Boyd, R. Nonlinear Optics, 3rd ed.; Academic Press: Cambridge, UK, 2008. [Google Scholar]

- Smrž, M.; Mužík, J.; Štěpánková, D.; Turčičová, H.; Novák, O.; Chyla, M.; Hauschwitz, P.; Brajer, J.; Kubát, J.; Todorov, F.; et al. Picosecond thin-disk laser platform PERL A for multi-beam micromachining. OSA Continuum. 2021, 4, 940–952. [Google Scholar] [CrossRef]

- Andral, U.; Walch, P.; Moreno, V.; Mahieu, B.; Produit, T.; Lozano, M.; Bizet, L.; Herkommer, C.; Moret, M.; André, Y.B.; et al. Second and third harmonic generation from simultaneous high peak- and high average-power thin disk laser. Appl. Phys. B 2022, 128, 177. [Google Scholar] [CrossRef]

- Cech, P.; Vanda, J.; Muresan, M.G.; Mydlar, M.; Pilna, K.; Brajer, J. Laser induced damage threshold testing at HiLASE. MM Sci. J. 2019, 2019, 3657–3661. [Google Scholar] [CrossRef]

- Bischof, D.; Botha, R.; Vetsch, B.; Scherrer, U.; Michler, M.; Ziolek, C.; Ettemeyer, A. Introduction of an ultraviolet laser-induced degradation test system for optical coatings. In Optica OIC; Optica Publishing Group: Washington, DC, USA, 2016; ISBN 978-1-943580-13-2. [Google Scholar] [CrossRef]

- Ristau, D. Laser-Induced Damage in Optical Materials; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Vanda, J.; Sevcík, J.; Pupka, E.; Sciuka, M.; Melninkaitis, A.; Divoky, M.; Jambunathan, V.; Bonora, S.; Skoda, V.; Lucianetti, A.; et al. Comparative LIDT measurements of optical components for high-energy HiLASE lasers. High Power Laser Sci. 2016, 4, e11. [Google Scholar] [CrossRef]

- ISO 21254-2:2011; Lasers and Laser-Related Equipment—Test Methods for Laser-Induced Damage Threshold—Part 2: Threshold Determination. ISO: Geneva, Switzerland, 2011.

- Smalakys, L.; Momgaudis, B.; Grigutis, R.; Kičas, S.; Melninkaitis, A. Contrasted fatigue behavior of laser-induced damage mechanisms in single layer ZrO2 optical coating. Opt. Express 2019, 27, 26088–26101. [Google Scholar] [CrossRef]

- Sladek, J.; Mirza, I.M. Laser induced damage threshold of silicon with native and artificial SiO2 layer. MM Sci. J. 2019, 2019, 3579–3584. [Google Scholar] [CrossRef]

- Rudenko, A.; Mauclair, C.; Garrelie, F.; Stoian, R.; Colombier, J.P. Light absorption by surface nanoholes and nanobumps. Appl. Surf. Sci. 2019, 470, 228–233. [Google Scholar] [CrossRef]

- Rubenchik, A.M.; Feit, M.D. Initiation, Growth and Mitigation of UV Laser Induced Damage in Fused Silica. Proc. SPIE 2002, 4679, 79–95. [Google Scholar] [CrossRef]

| Sample Code | Coating Material | Coating Technique | No. of Layers | Coating Thickness (mm) | Damage Threshold (J/cm2) |

|---|---|---|---|---|---|

| A | HfO2/SiO2 | IBS | 2 | 92.91 nm | 0.26 |

| B | HfO2/SiO2 | IBS | 2 | 92.96 nm | 0.33 |

| C | HfO2/SiO2 | IBS | 2 | 90 nm | 0.29 |

| D | HfO2/SiO2 | IBS | 2 | 91 nm | 0.39 |

| E | Al2O3/SiO2 | IBS | 2 | 91.51 nm | 0.6 |

| F | HfO2/Al2O3/SiO2 | e-Beam evaporation | 3 | - | 0.27 |

| G | HfO2/SiO2 | e-Beam evaporation | 2 | 89.1 nm | 0.11 |

| H | HfO2/SiO2 | e-Beam evaporation | 2 | - | 0.11 |

| I | HfSiOx/HfAlOx | IBS | 2 | - | 0.36 |

| J | HfSiOx/HfAlOx | IBS | 2 | - | 0.08 |

| K | HfO2/SiO2 | e-Beam evaporation | 2 | 90 nm | 0.086 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narayanasamy, P.; Mydlář, M.; Turčičová, H.; Mureșan, M.G.; Novák, O.; Vanda, J.; Brajer, J. Investigation of UV Picosecond Laser Damage Threshold of Anti-Reflection Coated Windows. J. Manuf. Mater. Process. 2025, 9, 180. https://doi.org/10.3390/jmmp9060180

Narayanasamy P, Mydlář M, Turčičová H, Mureșan MG, Novák O, Vanda J, Brajer J. Investigation of UV Picosecond Laser Damage Threshold of Anti-Reflection Coated Windows. Journal of Manufacturing and Materials Processing. 2025; 9(6):180. https://doi.org/10.3390/jmmp9060180

Chicago/Turabian StyleNarayanasamy, Priyadarshani, Martin Mydlář, Hana Turčičová, Mihai George Mureșan, Ondřej Novák, Jan Vanda, and Jan Brajer. 2025. "Investigation of UV Picosecond Laser Damage Threshold of Anti-Reflection Coated Windows" Journal of Manufacturing and Materials Processing 9, no. 6: 180. https://doi.org/10.3390/jmmp9060180

APA StyleNarayanasamy, P., Mydlář, M., Turčičová, H., Mureșan, M. G., Novák, O., Vanda, J., & Brajer, J. (2025). Investigation of UV Picosecond Laser Damage Threshold of Anti-Reflection Coated Windows. Journal of Manufacturing and Materials Processing, 9(6), 180. https://doi.org/10.3390/jmmp9060180