Analyzing Joinery for Furniture Designed for Disassembly

Abstract

1. Introduction

1.1. The Transformative Role of Information Technology in the Furniture Industry

1.2. Overspecialised Designs

1.3. Inefficient Material Usage in Production and Shipping

1.4. Difficulties in End-of-Life Management

2. Methods

- Identification, classification, and DfD evaluation of current furniture joinery techniques. Reviewing industry publications, manuals, online resources, and scientific literature identified standard methods for joining furniture components. A novel classification framework was developed to categorize these techniques based on their varying suitability to DfD. The suitability of each identified joinery technique was then evaluated for DfD suitability through a combination of theoretical analysis of fastener design and function, practical observations of fastener behavior during assembly and disassembly (including destructiveness and ease), and publicly available data (including technical specifications and manufacturer data) supplemented by practical experimentation where possible.

- Generalization of results. The findings of the DfD evaluation of each furniture joinery technique were organized and presented in a table. This format allowed for a direct comparison of the characteristics of different joinery methods.

- Conclusions were formulated on the suitability of the analyzed joinery methods for disassembly.

Study Limitations

- This study is limited to evaluating commonly used furniture joinery techniques. Innovative solutions that are not yet widely widespread in technology may exhibit different characteristics.

- The practical evaluation was based on limited observations and may not cover all possible scenarios.

3. Results

3.1. Identification, Classification, and DfD Evaluation of the Furniture Joinery Systems

3.1.1. Identification and Classification of Furniture Joinery Systems

- (1)

- Traditional joinery systems encompass classic methods such as mortise and tenon, dovetail, and rabbet joints, which offer strong and durable connections but can be time-consuming during woodworking.

- (2)

- Pins/biscuits fasteners rely on a wooden “pin-shape” dowel inserted into holes made in connected furniture members; or thin, oval-shaped wooden biscuits placed in preformed slots. Both types of fasteners are standard in flat-pack furniture and cabinetry as auxiliary fasteners used with other mechanical fastener types or with glue.

- (3)

- Hammered refers to joints assembled using nails, staples, or other hammered fasteners. Relatively quick and straightforward in assembly, but they may not be as strong or aesthetically pleasing as other methods. They are not intended for disassembly. However, disassembly is possible.

- (4)

- Directly screwed connections are made by driving furniture screws directly through one component and into another. While offering fast and easy assembly with standard tools, these fasteners weaken the connection between furniture parts after repeated disassembly.

- (5)

- Snap-on-type fasteners employ interlocking plastic or metal features that engage during assembly (often with an audible “click”). Designed for quick, toolless assembly. Common in modern, flat-pack furniture, where ease of assembly is prioritized. These fasteners exhibit various designs, ranging from invisibility after assembly to requiring specialized disassembly tools or offering easy disassembly.

- (6)

- Expandable fasteners use mechanisms that expand within a pre-drilled hole or slot. This expansion creates a tight fit against the interior surfaces of the hole or slot, thus securing the fastener within the furniture component.

- (7)

- The bolt or cam fasteners employ threaded screw-nut fasteners or a cam lock–pin pair. These fasteners offer strong, adjustable connections, allowing for repeated assembly and disassembly. Common in RtA furniture and cabinetry.

3.1.2. DfD Evaluation of Furniture Joinery Techniques

3.2. Generalization of Results

4. Discussion

- Current concepts, such as RtA modular furniture systems with standardized components [62], naturally align with DfD principles by inherently facilitating disassembly. This is because RtA prioritizes ease of assembly for end-users without engineering experience, acknowledging the need for assembly beyond the factory.

- Sociological research confirms the potential to increase furniture sustainability, revealing that younger consumers are willing to pay a premium for environmentally friendly options [63].

- CAD programs can enable DfD by offering essential tools for designing products that facilitate easy disassembly [64]. For example, 3D-PDNet, a graph-based learning approach, uses 3D CAD models to generate feasible disassembly sequences, significantly exceeding existing baseline methods [65]. This technology has been further enhanced with the development of Autodesk Fusion 360 plug-ins, which generate disassembly sequence animations [65].

- Employ lightweight materials for easier component handling.

- Design component sizes to align with the planned handling methods.

- Design a separate structure and cladding for adaptable building envelopes.

- All components intended for disassembly should be readily accessible.

- Arrange components hierarchically according to their anticipated lifespan.

- Allow parallel disassembly, minimizing the sequential processes.

- Adopt a modular system that adheres to established industry standards.

- Utilize standardized tools and conventional technologies.

- Reduce the number of unique components and fastener types.

- Mechanical fastening methods are preferred over chemical adhesives.

- Identify all components referred to in the assembly and disassembly instructions.

- Develop an open design system that permits alternative design variants.

- Ensure components’ resistance to repeated assembly cycles.

- Facilitate disassembly at multiple scales, from individual components to structural units.

- Provide both assembly and disassembly instructions, including why disassembly might be necessary (furniture reconfiguration, repair, end of use).

- Prioritize easy access to frequently maintained, repaired, or replaced components due to their shorter lifespan (such as upholstery, cushions, moving parts like reclining mechanisms, hinges, drawer slides, and casters).

- Design with modularity in mind.

- Design modules with a minimal variety of materials, with standard components and fasteners, enabling assembly and disassembly using common hand tools.

- Label all interchangeable modules and their components with numbers or QR codes for easy identification.

- Design furniture assembly procedures to enable the independent removal of components or sub-assemblies, moving beyond a strictly linear disassembly sequence.

- Choose durable component materials capable of withstanding repeated assembly and disassembly cycles without degrading structural integrity or aesthetic quality.

- Employ disassemblable mechanical fasteners (screws, bolts, clips, interlocking mechanisms) as the primary means of joining components, avoiding or minimizing the use of permanent adhesives.

5. Conclusions

- Traditional joinery methods (shape, pin/biscuit, hammered) are generally incompatible with DfD, while modern fasteners (particularly bolt/cam-based) are well-suited.

- For DfD applications, snap-on-type fasteners must be engineered to enable non-destructive and straightforward disassembly. While specific designs facilitate this readily, others do not.

- Easy-to-assemble fasteners, such as screws, expandable, bolt, or cam types, are standard in ready-to-assemble (RtA) furniture. Since RtA furniture is designed for easy assembly after transportation and sometimes for reconfiguration through disassembly, the principle of ensuring complete disassemblability appears to be a logical extension.

- Although cost-effectiveness is a primary concern in furniture joinery standards, fully disassemblable systems do not inherently incur higher costs compared to non-decoupled alternatives. Importantly, by prioritizing fasteners that support DfD, furniture manufacturers can strategically position themselves within a circular economy, enabling the profitable recovery and reuse of furniture components and products.

- For a design to adhere to DfD principles, the following eight features are essential: attached disassembly instructions; prioritized access to fast-wearing components; furniture modularity; standardized parts within modules; labeled parts; the ability for independent component removal; the use of disassembly-resilient component materials; and the exclusive employment of fully disassemblable joint systems.

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Image | Name | Type of Furniture Joinery System | Disassemblability | ||

|---|---|---|---|---|---|

| Non-Disassemblable | Conditionally Disassemblable | Fully Disassemblable | |||

| Single trough mortise and tenon | Traditional | • | ||

| Single-covered mortise and tenon | • | |||

| Single bevel mortise and tenon | • | |||

| Slant dovetail | • | |||

| Semi-covered straight dovetail | • | |||

| Straight framed | • | |||

| Dowel | Pin, biscuit | • | ||

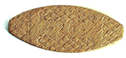

| Elliptic dowel (Domino, Festool GmbH, Wendlingen a. N., Germany) | • | |||

| Biscuit fastener (made of beechwood) | • | |||

| Biscuit fastener (made of plastic, Bisco P-14, Lamello AG, Bubendorf, Switzerland) | • | |||

| Self-tightening dowel (made of plastic, KNAPP®-Dowel, Knapp GmbH, Euratsfeld, Austria) | • | |||

| Standard nail | Hammered | • | ||

| Ring-shank nail | • | |||

| Staple | • | |||

| Standard small furniture screw | Directly screwed | • | ||

| Self-drilling furniture screw | • | |||

| Large furniture screw (requiring a pilot hole) | • | |||

| Self-clamping two-part connector (Tenso P-14, Lamello AG, Bubendorf, Switzerland) | Snap-on (click) | • | ||

| Shelving connector (Diwario P-18, Lamello AG, Bubendorf, Switzerland) | • | |||

| “Invisible” clickable snap-on connector (Quick set, Knapp GmbH, Euratsfeld, Austria) | • | |||

| “Invisible” snap-on connector (Normal 850, Effegibrevetti S.r.l., Milan, Italy) | • | |||

| Slide-in connector (Chico, Knapp GmbH, Euratsfeld, Austria) | • | |||

| “Invisible” sliding snap-on connector (OVVO V-0930, Santech Innovations, Paris, France) | • | |||

| Click connector (Solo 32, Häfele SE & Co KG, Nagold, Germany) | • | |||

| “Invisible” snap-on connector (Bone, SISO A/S, Skovlunde, Denmark) | • | |||

| Expandable fastener (Ixconnect SC 8/25, Häfele SE & Co KG, Nagold, Germany) | Expandable | • | ||

| Expandable fastener (Ixconnect SC 8/60, Häfele SE & Co KG, Nagold, Germany) | • | |||

| Expandable fastener (Domino KV D8/50, Festool GmbH, Wendlingen a. N., Germany) | • | |||

| Expandable fastener (BLU-8, CAR S.r.l, Padova, Italy) | • | |||

| Expandable fastener (Quicklock expando, Titus Group, Prestons, Australia) | • | |||

| Cam lock fastener, with inner rotating cam in plastic case, screwable directly in furniture member (Rafix, Häfele SE & Co KG: Nagold, Germany) | • | |||

| Cam lock fastener, with inner rotating cam in metal case, screwable directly in furniture member | • | |||

| Cam lock fastener, rotating in a socket, screwable directly in furniture member | Bolt or cam-based | • | ||

| Cam lock fastener with insert nut | • | |||

| Furniture bolt with nut | • | |||

| Furniture bolt with claw-nut | • | |||

| Detachable connector with lever mechanism (Clamex P-14, Lamello AG, Bubendorf, Switzerland) | • | |||

| Hidden connector with magnetic drive (Invis Mx2, Lamello AG, Bubendorf, Switzerland) | • | |||

| One-piece connector (Cabineo, Lamello AG, Bubendorf, Switzerland) | • | |||

| One-piece connector (Elefant, Italiana Ferramenta S.r.l., Brugnera, Italy) | • | |||

| Worktop connector (Quick, Italiana Ferramenta, S.r.l., Brugnera, Italy) | • | |||

| Drawer connector (Face&edge, system 3, Titus Group, Prestons, Australia) | • | |||

| Worktop connector (AVB 5, Hettich Group, Westphalia, Germany) | • | |||

| Cam connector (42,0700, Blum GmbH, Herford, Germany) | • | |||

| Bolt-metal muff connector (serie GN500, O.M.M) | • | |||

References

- Červený, L.; Sloup, R.; Červená, T. The Potential of Smart Factories and Innovative Industry 4.0 Technologies—A Case Study of Different-Sized Companies in the Furniture Industry in Central Europe. Forests 2022, 13, 2171. [Google Scholar] [CrossRef]

- Erdinler, E.S.; Koç, K.H. Evaluation of Computer Aided Design (CAD) Systems and Their Usage Efficiency in Türkiye Furniture Industry. Artvin Çoruh Üniversitesi Orman. Fakültesi Derg. 2024, 25, 85–97. [Google Scholar] [CrossRef]

- Feng, J.; Conway, D.; Su, D.; Mottram, J.; Rutherford, S. Web Based Collaboration for Furniture Design: Survey and the Structure of a Collaborative Working Environment. In Proceedings of the DET 2008, 5th International Conference on Digital Enterprise Technology, Nantes, France, 22–24 October 2008; Publibook: Paris, France, 2008; pp. 41–55, ISBN 978-2-7483-4598-8. [Google Scholar]

- Chen, Y.H.; Wang, Y.Z.; Wong, M.H. A Web-Based Fuzzy Mass Customization System. J. Manuf. Syst. 2001, 20, 280–287. [Google Scholar] [CrossRef]

- Mengoni, M.; Peruzzini, M.; Bordegoni, M.; Mecella, M. Toward an Integrated Platform to Support Contract Furniture Industry. Comput. Aided Des. Appl. 2016, 13, 662–674. [Google Scholar] [CrossRef]

- Gaiani, M.; Deserti, A.; Brevi, F.; Ferioli, S. Tools and Methods to Assist the Product Customization in the Field of Furniture Design. Des. Princ. Pract. Int. J. Annu. Rev. 2011, 5, 221–238. [Google Scholar] [CrossRef]

- Maulana, F.I.; Kurniawan, B.K.; Pramono, A.; Purnomo, A.; Abdulah, M.E.B.Z.; Mohamed, M. Internet of Things for Smart Furniture: A Systematic Review. In Proceedings of the 2024 International Conference on ICT for Smart Society (ICISS), Yogyakarta, Indonesia, 4–5 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Wan, D. Magic Wardrobe: Situated Shopping from Your Own Bedroom. Pers. Personal Technol. 2000, 4, 234–237. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, J. Advancing Wooden Furniture Manufacturing through Intelligent Manufacturing: The Past, Recent Research Activities and Future Perspectives. Wood Mater. Sci. Eng. 2025; preprint. [Google Scholar] [CrossRef]

- Külschbach, A.; Leiting, T.; Stich, V. Do-It-Together Concept for Production Ecosystems. In Proceedings of the Conference on Production Systems and Logistics: CPSL 2020, Stellenbosch, South Africa, 17–20 March 2020. [Google Scholar] [CrossRef]

- Leiting, T.; Külschbach, A.; Stich, V. Development of a Platform Business Model for Co-Creation Ecosystems for Sustainable Furniture. J. Innov. Econ. Manag. 2023, 40, 81–107. [Google Scholar] [CrossRef]

- Chorbikj, M.; Turchi, T.; Cavallaro, M.; Gigante Valencia, F.; Núñez Ariño, M.J.; Taboas Carrero, C.; Martín Casado, C. A Method and Tool for Sustainability-Driven Computer-Aided Process Planning with User-Tuneable Optimization. EJSD 2024, 13, 24. [Google Scholar] [CrossRef]

- Zielenbach, F.; Schröer, T.; Stich, V. Customer Perspective on the Purchase and Use of Sustainable and Innovative Furniture in a Co-Creation Process. In Proceedings of the Conference on Production Systems and Logistics: CPSL 2023-1, Querétaro, Mexico, 28 February–2 March 2023; Institute for Production and Logistics Research GbR Herberger & Hübner: Offenburg, Germany, 2023; pp. 570–579. [Google Scholar] [CrossRef]

- Abu, F.; Gholami, H.; Saman, M.Z.M.; Zakuan, N.; Sharif, S.; Streimikiene, D. Pathways of Lean Manufacturing in Wood and Furniture Industries: A Bibliometric and Systematic Review. Eur. J. Wood Prod. 2021, 79, 753–772. [Google Scholar] [CrossRef]

- Ghahremani-Nahr, J.; Aliahmadi, A.; Nozari, H. An IoT-Based Sustainable Supply Chain Framework and Blockchain. IJIE 2022, 2, 12–21. [Google Scholar] [CrossRef]

- Arangiaro, V.; Vishkaei, B.M.; De Giovanni, P. Blockchain for Circular Economy in the Furniture Sector: The Case of Cubo Design S.r.l. In Cases on Circular Economy in Practice; De Giovanni, P., Ed.; IGI Global: Hershey, PA, USA, 2022; pp. 238–275. ISBN 978-1-66845-001-7. [Google Scholar]

- Michelsen, O.; Fet, A.M.; Dahlsrud, A. Eco-Efficiency in Extended Supply Chains: A Case Study of Furniture Production. J. Environ. Manag. 2006, 79, 290–297. [Google Scholar] [CrossRef] [PubMed]

- Iritani, D.R.; Silva, D.A.L.; Saavedra, Y.M.B.; Grael, P.F.F.; Ometto, A.R. Sustainable Strategies Analysis through Life Cycle Assessment: A Case Study in a Furniture Industry. J. Clean. Prod. 2015, 96, 308–318. [Google Scholar] [CrossRef]

- Mahalakshmi, S.; Nallasivam, A.; Kumar, H.; Kautish, S.; Madan, S. From Assembly to Reassembly: Ikea’s Circular Design for a Sustainable Future. In Advances in Logistics, Operations, and Management Science; Singh, K., Dubey, R.S., Renwick, D.W.S., Crichton, R., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 261–280. ISBN 9798369323465. [Google Scholar]

- Liu, L. The Exploration of Recycling Design of Furniture Products Based on Structure. AMR 2012, 605–607, 44–48. [Google Scholar] [CrossRef]

- Efimova, T.; Ishchenko, T.; Pikalov, L. Modern Furniture Market Trends 2019. Actual. Dir. Sci. Res. XXI Century Theory Pract. 2020, 8, 198–202. [Google Scholar] [CrossRef]

- A, A.A.R. How Personalization Is Shaping Consumer Behavior: An Analysis of Data-Driven Marketing Trends. Int. J. Sci. Res. Sci. Eng. Technol. 2024, 11, 237–241. [Google Scholar] [CrossRef]

- Bumgardner, M.S.; Nicholls, D.L. Sustainable Practices in Furniture Design: A Literature Study on Customization, Biomimicry, Competitiveness, and Product Communication. Forests 2020, 11, 1277. [Google Scholar] [CrossRef]

- Lange, J.; Lis, P. Dimensional Analysis of Seating Furniture from the 1960s and 1970s Intended for Redesign. Drewno. Pr. Naukowe. Doniesienia. Komun. 2025, 68, 00053. [Google Scholar] [CrossRef]

- Kirchmer, K. Assemble-It-Yourself: The Perceived Value of Residential Furniture. In Transforming Issues in Housing Design; Guler, K., Ed.; Wiley: Hoboken, NJ, USA, 2023; pp. 171–185. ISBN 978-1-119-85716-7. [Google Scholar]

- Davis, S.M. Future Perfect; Springer: New York, NY, USA, 1990; ISBN 1-349-11257-7. [Google Scholar]

- Skorupińska, E.; Hitka, M.; Sydor, M. Surveying Quality Management Methodologies in Wooden Furniture Production. Systems 2024, 12, 51. [Google Scholar] [CrossRef]

- Xiong, X.; Ma, Q.; YingyingYuan; Wu, Z.; Zhang, M. Current Situation and Key Manufacturing Considerations of Green Furniture in China: A Review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Boothroyd, G.; Alting, L. Design for Assembly and Disassembly. CIRP Ann. 1992, 41, 625–636. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Issues in Environmentally Conscious Manufacturing and Product Recovery: A Survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Harivardhini, S.; Chakrabarti, A. Analyzing Conflicts Between Product Assembly and Disassembly for Achieving Sustainability. In ICoRD’13; Chakrabarti, A., Prakash, R.V., Eds.; Lecture Notes in Mechanical Engineering; Springer India: New Delhi, India, 2013; pp. 557–567. ISBN 978-81-322-1049-8. [Google Scholar]

- Song, P.; Fu, C.-W.; Jin, Y.; Xu, H.; Liu, L.; Heng, P.-A.; Cohen-Or, D. Reconfigurable Interlocking Furniture. ACM Trans. Graph. 2017, 36, 1–14. [Google Scholar] [CrossRef]

- Carlos, R.L.; De Souza, E.B.; Mattos, C.A. Enhancing Circular Economy Practices through the Adoption of Digital Technologies. Bus. Strat. Dev. 2024, 7, e330. [Google Scholar] [CrossRef]

- Dalipi, F.; Kurti, A.; Ferati, M. APPEND: A Blockchain-Based Model of Digital Product Passport for Furniture Industry. In Human Interaction and Emerging Technologies (IHIET-AI 2024); AHFE: Orlando, FL, USA, 2024. [Google Scholar]

- Smardzewski, J. Furniture Design; Springer International Publishing AG: Basel, Switzerland, 2015; ISBN 3-319-19532-8. [Google Scholar]

- Diderot, D.; d’Alembert, J.L.R. Encyclopedia, or a Systematic Dictionary of the Sciences, Arts and Crafts; Pergamon Press: Oxford, UK, 1757; Volume 2, ISBN 0-08-090105-0. [Google Scholar]

- He, Q.; Wang, X.; Zhang, T.; Chakma, M.; Hou, Q.; Zhang, D.; Zhan, T.; Yang, D.; Li, S. Bonding Performance of Chinese Fir Heartwood and Sapwood with Different Coatings under a High Voltage Electric Field. Ind. Crops Prod. 2024, 220, 118816. [Google Scholar] [CrossRef]

- Yan, Y.; Xu, Z.; Zhu, L.; Lv, J. Innovative Design Model for the Mortise and Tenon Structure. BioRes 2024, 19, 5413–5434. [Google Scholar] [CrossRef]

- Tankut, N. The Effect of Adhesive Type and Bond Line Thickness on the Strength of Mortise and Tenon Joints. Int. J. Adhes. Adhes. 2007, 27, 493–498. [Google Scholar] [CrossRef]

- Han, L.; Kutnar, A.; Sandak, J.; Šušteršič, I.; Sandberg, D. Adhesive-and Metal-Free Assembly Techniques for Prefabricated Multi-Layer Engineered Wood Products: A Review on Wooden Connectors. Forests 2023, 14, 311. [Google Scholar] [CrossRef]

- Hao, J.; Xu, L.; Wu, X.; Li, X. Analysis and Modeling of the Dowel Connection in Wood T Type Joint for Optimal Performance. Compos. Struct. 2020, 253, 112754. [Google Scholar] [CrossRef]

- Atar, M.; Ozcifci, A.; Altinok, M.; Celikel, U. Determination of Diagonal Compression and Tension Performances for Case Furniture Corner Joints Constructed with Wood Biscuits. Mater. Des. 2009, 30, 665–670. [Google Scholar] [CrossRef]

- DOMINO. Beech D 4x20/450 BU. Item Number 495661; Festool GmbH: Wendlingen, Germany, 2025; Available online: https://www.festool.com/accessory/joining/accessories-for-joining/dominos/495661---d-4x20450-bu#Functions (accessed on 12 May 2025).

- Catalogue 2024/2025. Art. No. 9880050 EN; Lamello AG: Bubendorf, Switzerland, 2025; Available online: https://lamello.com/fileadmin/Downloads/Katalog/Catalogue_EN_2024_2025.pdf (accessed on 12 May 2025).

- Erdil, Y.Z.; Zhang, J.L.; Eckelman, C.A. Staple Holding Strength of Furniture Frame Joints Constructed of Plywood and Oriented Strandboard. For. Prod. J. 2003, 53, 70–75. [Google Scholar]

- Sydor, M. Geometry of Wood Screws: A Patent Review. Eur. J. Wood Prod. 2019, 77, 93–103. [Google Scholar] [CrossRef]

- Sodhi, R.S.; Sonnenberg, M.; Das, S. Use of Snap-Fit Fasteners in the Multi-Life-Cycle Design of Products. In Proceedings of the 1999 IEEE International Symposium on Electronics and the Environment, Danvers, MA, USA, 13 May 1999; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 1999; pp. 160–165, ISBN 0-7803-5495-8. [Google Scholar]

- Giunti a Scatto. Snap Fittings. V. 2022 Rev. 4; Effegibrevetti S.r.l.: Milan, Italy, 2025; Available online: https://www.effegibrevetti.com/uploads/effegibrevetti-giunti-snap-cat-2022-rev4-742.pdf (accessed on 12 May 2025).

- Sydor, M. Innovations in Joining Systems of Cabinet Furniture. Technical Analysis of Selected Fasteners. Fastener 2019, 1, 52–56. [Google Scholar]

- Branowski, B.; Starczewski, K.; Zabłocki, M.; Sydor, M. Design Issues of Innovative Furniture Fasteners for Wood-Based Boards. BioResources 2020, 15, 8472–8495. [Google Scholar] [CrossRef]

- Sydor, M.; Kwapich, A.; Pohl, P. Strength Comparative Analysis of Furniture Joints Made of Various Materials. Ann. WULS SGGW For. Wood Technol. 2021, 113, 89–97. [Google Scholar] [CrossRef]

- The Complete Hafele Part 2 “Technology Edition”. V. 4.9.6; Häfele SE & Co KG: Nagold, Germany, 2023; Available online: https://www.hafele.ie/en/info/services/literature-library/32211/ (accessed on 12 May 2025).

- BLU. The Beginning of a Journey Called Flat-Pack; CAR S.r.l.: Padova, Italy, 2025; Available online: https://www.car-fittings.it/wp-content/uploads/2022/02/NEW-BROCHURE-blu_A4_media-1.pdf (accessed on 12 May 2025).

- Worktop Connectors; Italiana Ferramenta S.r.l.: Brugnera, Italy, 2025; Available online: https://www.italianaferramenta.it/materials/dati/documenti/Company/capitoliCatalogo/en/05_Worktop_Connectors.pdf?v110&_gl=1*zv0qm0*_up*MQ..*_ga*MTE4MjIxODgyNS4xNzQxMzU3MDUz*_ga_R0Q37TTJV6*MTc0MTM1NzA1MS4xLjAuMTc0MTM1NzA1MS4wLjAuMA (accessed on 12 May 2025).

- Titus Furniture Fittings Systems; Titus Group: Prestons, Australia, 2025; Available online: https://www.titustekform.com.au/file/open/69_e7d87f001e0a5/stat/Titus+Furniture+Fittings+Systems.pdf (accessed on 12 May 2025).

- Chu, C.-H.; Cheng, C.-Y.; Wu, C.-W. Applications of the Web-Based Collaborative Visualization in Distributed Product Development. Comput. Ind. 2006, 57, 272–282. [Google Scholar] [CrossRef]

- Krzyżaniak, Ł.; Smardzewski, J. Modeling of Externally Invisible Cabinet Furniture Joints. In Implementation of Wood Science in Woodworking Sector; Župčić, I., Živković, V., Miklečić, J., Eds.; University of Zagreb—Faculty of Forestry: Zagreb, Croatia, 2017; pp. 191–197. [Google Scholar]

- Ratnasingam, J. Joints in Furniture. In Furniture Manufacturing: A Production Engineering Approach; Ratnasingam, J., Ed.; Springer: Singapore, 2022; pp. 65–77. ISBN 978-981-16-9412-7. [Google Scholar]

- Deshpande, A.; Kim, I. The Effects of Augmented Reality on Improving Spatial Problem Solving for Object Assembly. Adv. Eng. Inform. 2018, 38, 760–775. [Google Scholar] [CrossRef]

- Elhassan, G.E.; Yasser, I.; Faizal, M.O.; Zia, H. Optimizing Furniture Assembly: A CNN-Based Mobile Application for Guided Assembly and Verification. In Proceedings of the 2023 9th International Conference on Optimization and Applications (ICOA), Abu Dhabi, United Arab Emirates, 5–6 October 2023; IEEE: Abu Dhabi, United Arab Emirates, 2023; pp. 1–6. [Google Scholar]

- Suárez-Ruiz, F.; Zhou, X.; Pham, Q.-C. Can Robots Assemble an IKEA Chair? Sci. Robot. 2018, 3, eaat6385. [Google Scholar] [CrossRef]

- Koszewska, M.; Bielecki, M. How to Make Furniture Industry More Circular? The Role of Component Standardisation in Ready-to-Assemble Furniture. JESI 2020, 7, 1688–1707. [Google Scholar] [CrossRef]

- Shahsavar, T.; Kubeš, V.; Baran, D. Willingness to Pay for Eco-Friendly Furniture Based on Demographic Factors. J. Clean. Prod. 2020, 250, 119466. [Google Scholar] [CrossRef]

- González, B.; Adenso-Díaz, B. A Bill of Materials-Based Approach for End-of-Life Decision Making in Design for the Environment. Int. J. Prod. Res. 2005, 43, 2071–2099. [Google Scholar] [CrossRef]

- Upadhyay, A.; Ladrecha, B.; Dubey, A.; Kuriakose, S.M.; Goenka, P. 3D-PDNet: Automated Product Disassembly Sequence Planning. Res. Sq. 2023; (Version 1). preprint. [Google Scholar] [CrossRef]

- Antifakos, S.; Michahelles, F.; Schiele, B. Proactive Instructions for Furniture Assembly. In UbiComp 2002: Ubiquitous Computing; Borriello, G., Holmquist, L.E., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2002; Volume 2498, pp. 351–360. ISBN 978-3-540-44267-7. [Google Scholar]

- Wiking, S.; Brattfjell, M.L.; Iversen, E.E.; Malinowska, K.; Mikkelsen, R.L.; Røed, L.P.; Westgren, J.E. Sex Differences in Furniture Assembly Performance: An Experimental Study. Appl. Cogn. Psychol. 2016, 30, 226–233. [Google Scholar] [CrossRef]

- Heiser, J.; Phan, D.; Agrawala, M.; Tversky, B.; Hanrahan, P. Identification and Validation of Cognitive Design Principles for Automated Generation of Assembly Instructions. In Proceedings of the Working Conference on Advanced Visual Interfaces, Genoa, Italy, 25–28 May 2004; ACM: Gallipoli, Italy, 2004; pp. 311–319. [Google Scholar] [CrossRef]

- Crowther, P. Historic Trends in Building Disassembly. In Proceedings of the Technology in Transition: Mastering the Impacts, Montreal, QC, Canada, 25–27 June 1999; Davidson, C., Ed.; Association of Collegiate Schools of Architecture: Washington, DC, USA, 1999; pp. 33–36. Available online: https://www.acsa-arch.org/chapter/historic-trends-in-building-disassembly/ (accessed on 12 May 2025).

- Ankarberg, L.; Terzioğlu, N.; Sundin, E. Circular Furniture Design: A Case Study from Swedish Furniture Industry. In EcoDesign for Sustainable Products, Services and Social Systems I; Fukushige, S., Kobayashi, H., Yamasue, E., Hara, K., Eds.; Springer Nature: Singapore, 2023; pp. 269–284. ISBN 978-981-9938-17-9. [Google Scholar]

- Wen, Q.; Liao, H. The Combination and Application of CAD Data and Deep Learning Algorithms in Industrial Design. CADA 2024, 21, 306–321. [Google Scholar] [CrossRef]

| Aspect | Description | Key Literature Sources |

|---|---|---|

| Design and customization | Co-creating furniture with customers | [3,4,5] |

| Manufacturing | Facilitation of production processes | [14,15,16] |

| Service | Selling, delivering, using, maintaining, and disposing | [17,18,19] |

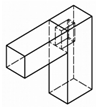

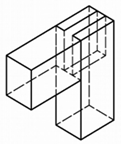

| Image |  |  |  |

| Name | Bridle joint (or open mortise and tenon, or tongue and fork joint) | Mortise and tenon joint (a fully-encapsulated bridle joint) | Miter joint (both connected components have been beveled) |

| Reference | own study | ||

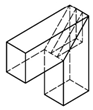

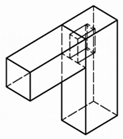

| Image |  |  |  |

| Name | Beech dowel | Beech biscuit (Domino, Festool GmbH, Wendlingen a.N., Germany) | Wood biscuit 20, Lamello AG, Bubendorf, Switzerland |

| References | photo M.S. | [43] | [44] |

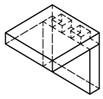

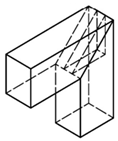

| Image |  |  |  |

| Name | Nail | Ring-shank nail | Staple |

| Reference | own study | ||

| Image |  |  |  |

| Name | Small furniture screw | Self-drilling furniture screw | Largest furniture screw, requiring a pilot hole |

| Reference | Own study | ||

| Image |  |  |  |

| Name | Tenso P-14, Lamello AG, Bubendorf, Switzerland | Diwario P-18, Lamello AG, Bubendorf, Switzerland | Normal 850, Effegibrevetti S.r.l., Milan, Italy |

| Reference | [44] | [44] | [48] |

| Image |  |  |  |

| Name | Domino KV D8/50, Festool GmbH, Wendlingen a. N., Germany | Ixconnect SC 8/60, Häfele SE & Co KG, Nagold, Germany | BLU-8/BLU-12, CAR S.r.l., Padova, Italy |

| References | [52] | [52] | [53] |

| Image |  |  |  |

| Name | Furniture bolt with nut | Furniture bolt with claw-nut | Invis Mx2, Lamello AG, Bubendorf, Switzerland |

| Sources | [52] | Own study | [44] |

| Image |  |  |  |

| Name | Worktop connector, Quick, Italiana Ferramenta S.r.l., Brugnera, Italy | Cam fastener | Face-edge, system 3, Titus Group, Prestons, Australia |

| Sources | [54] | Own study | [55] |

| Type of Furniture Joinery System | Glue Required | Destructive Disassembly | Easy to Disassemble | Supporting the DfD |

|---|---|---|---|---|

| Traditional | Yes | Yes | No | No |

| Pin/biscuit | Yes | Yes | No | No |

| Hammered | No | Yes | No | No |

| Directly screwed | No | Yes | Yes | No |

| Snap-on | No | No | It depends on the design | Not always |

| Expandable | No | Partially yes | Yes | Partially yes |

| Bolt or cam | No | No | Yes | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sydor, M.; Stańczyk, K. Analyzing Joinery for Furniture Designed for Disassembly. J. Manuf. Mater. Process. 2025, 9, 162. https://doi.org/10.3390/jmmp9050162

Sydor M, Stańczyk K. Analyzing Joinery for Furniture Designed for Disassembly. Journal of Manufacturing and Materials Processing. 2025; 9(5):162. https://doi.org/10.3390/jmmp9050162

Chicago/Turabian StyleSydor, Maciej, and Kacper Stańczyk. 2025. "Analyzing Joinery for Furniture Designed for Disassembly" Journal of Manufacturing and Materials Processing 9, no. 5: 162. https://doi.org/10.3390/jmmp9050162

APA StyleSydor, M., & Stańczyk, K. (2025). Analyzing Joinery for Furniture Designed for Disassembly. Journal of Manufacturing and Materials Processing, 9(5), 162. https://doi.org/10.3390/jmmp9050162