1. Introduction

In a competitive global market, manufacturing industries must continuously optimize their processes to meet high-quality standards and economic demands [

1]. Machining processes, particularly milling, play an important role in producing complex geometries with high precision across various materials [

2]. Among these, pocket milling is widely used in die and mold manufacturing, where surface roughness directly impacts functional properties, such as wear resistance and coating adhesion [

3,

4].

To keep-in par with the market, the optimization of machining parameters is essential, such as cutting speed, feed rate, and depth of cut, along with tool path strategies, which play a crucial role in determining surface roughness. Previous studies have shown that optimizing machining parameters can greatly enhance surface finish [

5], demonstrating that optimized machining conditions could improve surface roughness by 250% [

6], while finding that depth of cut had a lesser influence compared to cutting speed and feed rate. Balaji et al. and Davim [

7,

8] identified spindle speed, feed rate, and cutting velocity as dominant factors in surface quality, whereas Nalbant et al. [

9] emphasized the role of insert radius and feed over depth of cut.

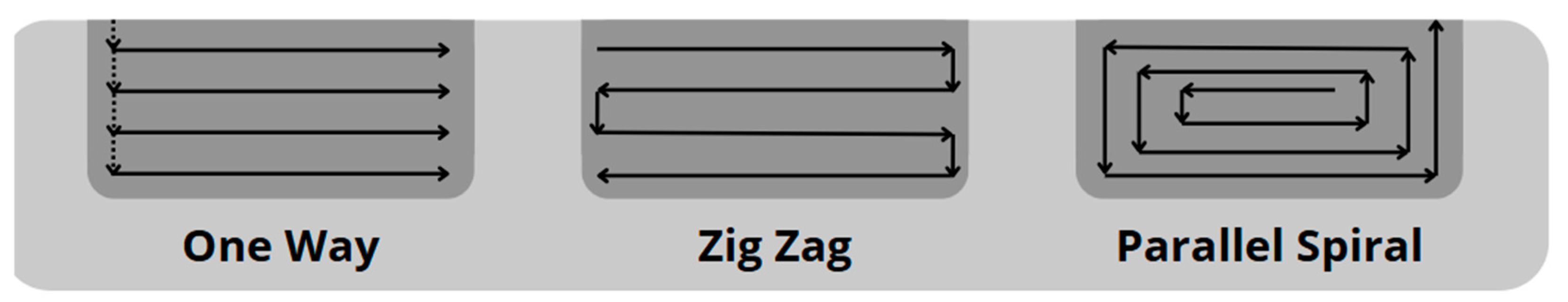

Tool path strategies have gained attention as a key factor influencing machining performance and surface integrity. Studies have shown how workpiece inclination and cutting speed affect cutting forces, tool deflection, and roughness [

10,

11,

12], while Lazoglu et al. [

13] optimized tool paths for freeform machining, showing that One-Way and Zig-Zag strategies provided superior results over Spiral paths. Further studies highlighted that the inclination angle had the most significant effect on surface roughness in multi-axis milling, followed by feed rate and cutting speed [

14]. Abdulrazaq et al. [

15] conducted a study to identify the optimal combination of machining parameters for maximizing production efficiency and minimizing surface roughness, employing the Taguchi method in conjunction with ANOVA statistical analysis. Upadrashta et al. [

16] conducted a similar analysis on a heat-treated magnesium alloy, exploring how variations in cutting depth, feed rate, and cutting speed influenced the machining process. Another study presented by Ribeiro et al. [

17] demonstrates that the Taguchi method can be effectively applied to different machining process types, focusing on the influence of the feed rate variation in the burnishing process. These findings indicate the importance of selecting appropriate tool paths and machining conditions to achieve optimal surfaces in machining.

Taguchi’s method [

18] provides a structured approach to experimental design using orthogonal arrays, enabling the identification of optimal cutting parameters for individual performance criteria, such as surface roughness [

19]. However, Grey Relational Analysis (GRA) becomes a valuable tool when evaluating multiple quality characteristics, as it ranks parameter combinations according to their relative significance [

20]. Integrating these methods with Analysis of Variance (ANOVA) enables a comprehensive evaluation of parameter effects and facilitates effective process optimization.

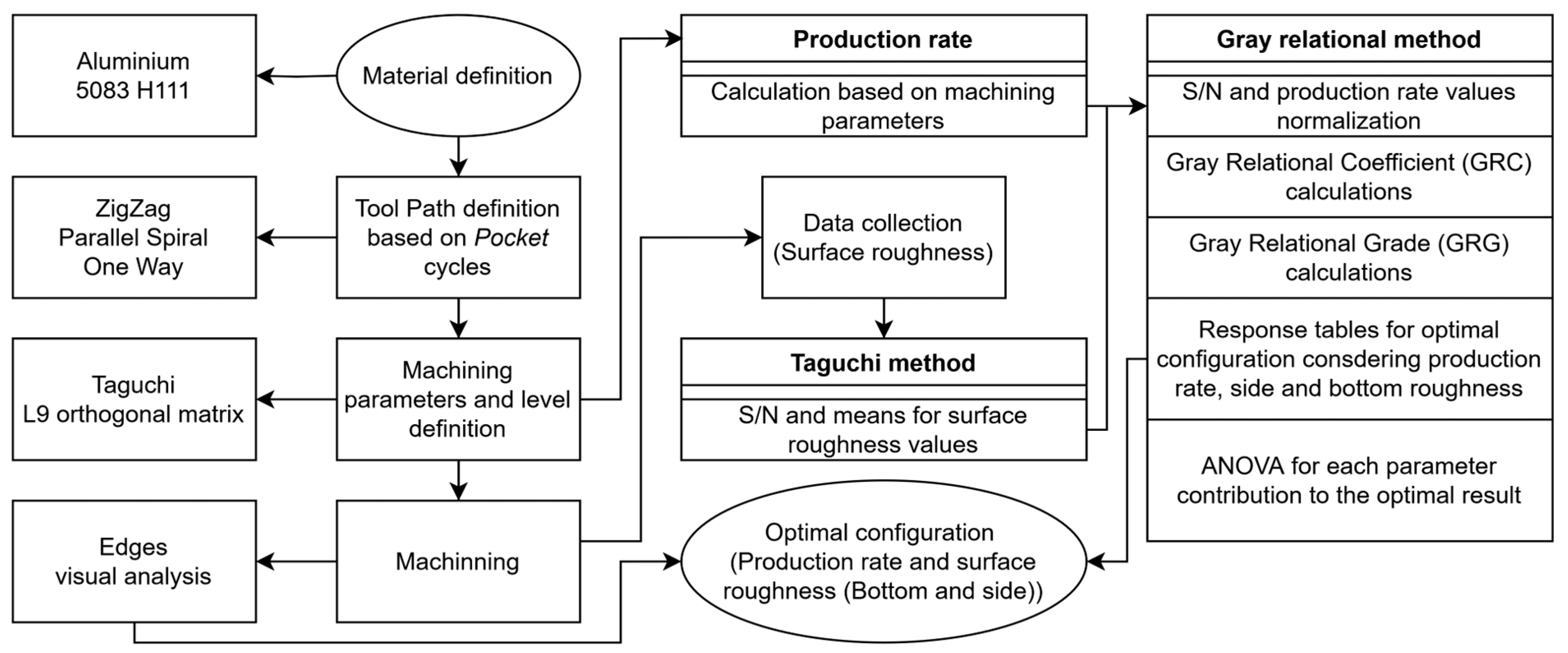

This study aims to optimize pocket milling parameters to minimize surface roughness and maximize the production rate of the 5083 H111 aluminum alloy, with particular emphasis on the machined pocket walls. Three toolpath strategies are evaluated using the Taguchi method and Grey Relational Analysis (GRA), while ANOVA is employed to assess the statistical significance of each parameter. The key contribution of this work is the in-depth analysis of the machined lateral walls, highlighting how different toolpath strategies affect the final surface finish.

3. Results

Using the parameters outlined in

Table 1, the L9 orthogonal array proposed by the Taguchi method [

15] can be constructed, incorporating the parameter variations required for the experimental accomplishment.

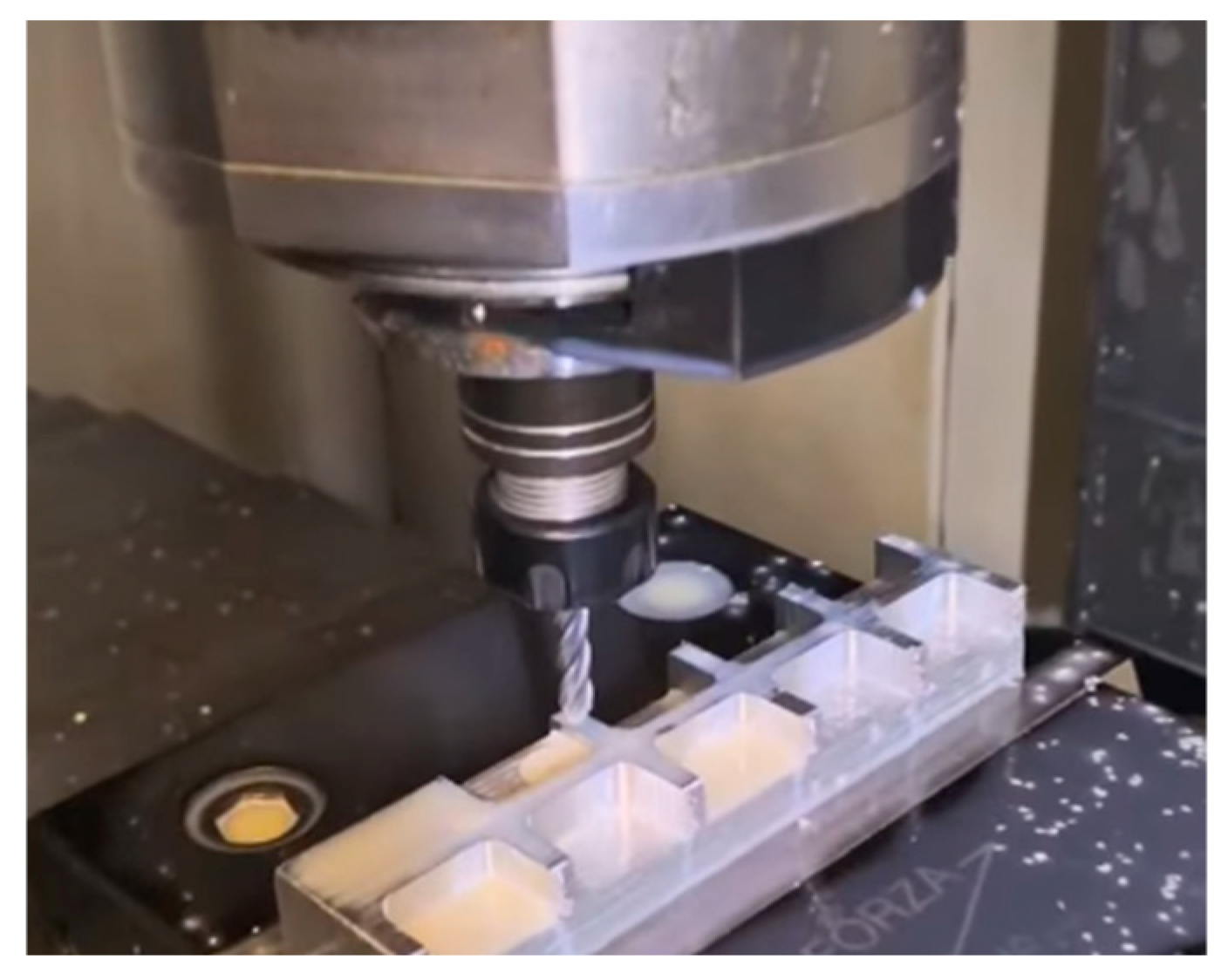

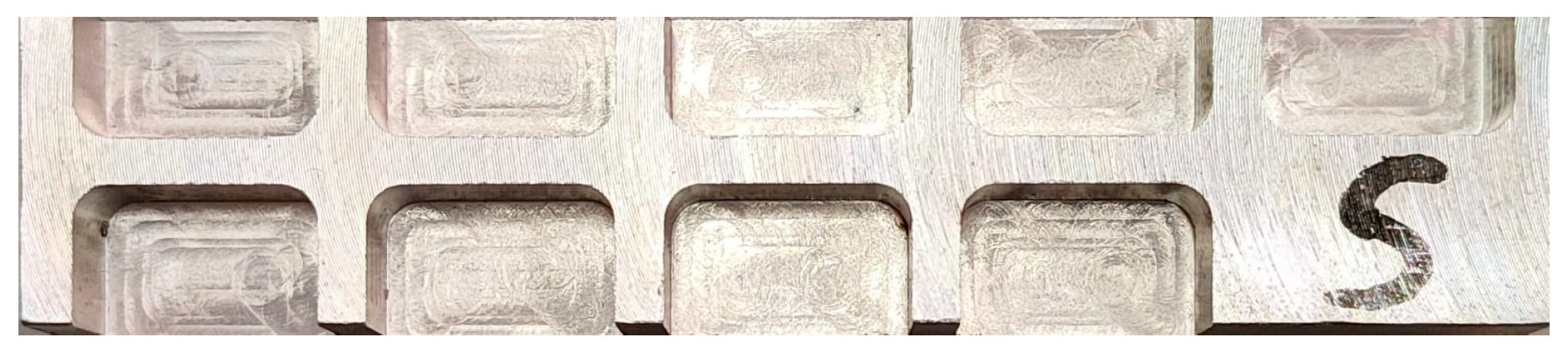

Table 4 presents the L9 orthogonal configuration, detailing the parameter settings for each sample. Since the experimental design is structured around individual toolpaths, each selected toolpath corresponds to a set of nine experimental samples, with a total of 27 experimental samples, ensuring a systematic evaluation of machining conditions.

Table 4 also presents the Material Removal Rate (MRR) corresponding to each L9 orthogonal configuration. The MRR values were computed using Equation (1).

Following the parameters outlined in

Table 3, the CNC milling process can be carried out, and the resulting machined samples can be observed in

Figure 4,

Figure 5 and

Figure 6.

3.1. Surface Roughness

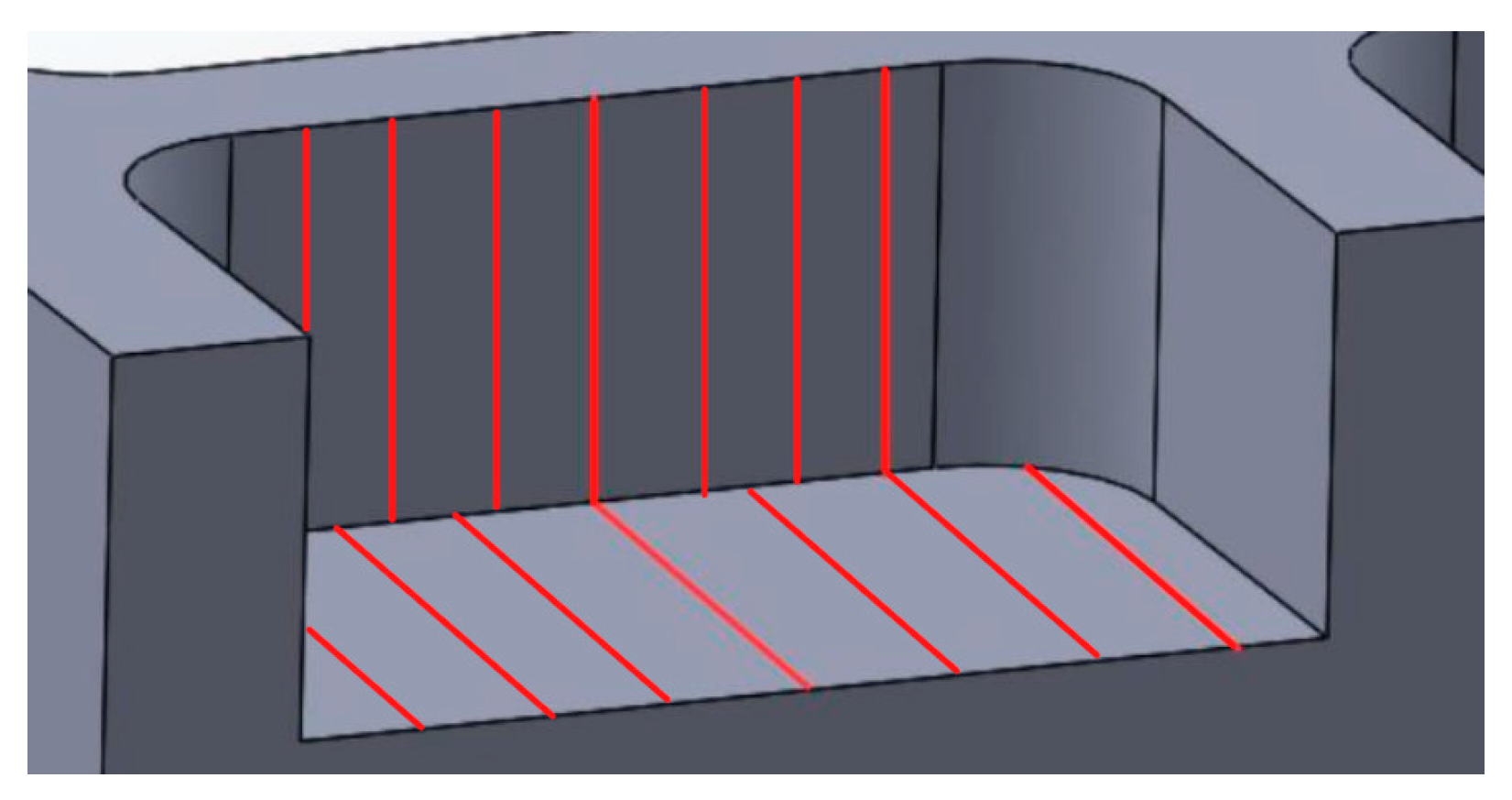

Surface roughness measurements were obtained using the Mitutoyo SJ-301 roughness tester (Mytutoyo, Kanagawa, Japan), with fourteen independent observations recorded for each pocket, systematically divided between side and bottom, as schematically illustrated in

Figure 7. This extensive dataset enabled the application of the Taguchi method, where the signal-to-noise (S/N) ratio for each pocket was computed using Equation (2), following the “smaller-the-better” criterion, which is generally preferred for surface roughness optimization.

Table 5 presents the signal-to-noise (S/N) ratio values corresponding to each measured parameter. Each column is labelled according to the type of data it represents, where the S/N ratio is (SN), the toolpath strategy used (Z, S, or O), and the measurement location (bottom (B) or side (S)). This column nomenclature method will be consistently applied throughout the manuscript to ensure clarity and coherence in data presentation.

3.2. Grey Relational Analysis

By using the S/N ratios for bottom and side roughness, along with the production rate, the Grey Relational Analysis (GRA) can be applied to determine the optimal parameter configuration for maximizing both surface quality and productivity. To ensure the proper implementation of the Grey method, a data normalization process must be conducted using the S/N values for surface roughness (bottom and side presented in

Table 5) and the material removal rate (MRR presented in

Table 4). Since the S/N ratio values are negative, the larger-the-better normalization, Equation (4), was selected to ensure consistency, where values closer to zero are considered optimal related to the S/N ratios. The normalized data are presented in

Table 6, columns N-B, N-S, and N-MRR.

Following the Grey method, the Grey Relational Coefficient (GRC) was computed based on the normalized data using Equation (6), considering a distinguishing coefficient ζ = 1/3, which assigns equal importance to all optimization parameters. The GRC values are presented in

Table 6, columns GRC-B, GRC-S, and GRC-MRR.

Finally, the Grey Relational Grade (GRG) was determined using Equation (7), quantifying the significance of each sample within its respective toolpath configuration. The results for GRG and the ranking order of significance for each toolpath strategy are systematically presented in

Table 6.

Based on the GRG values presented in

Table 4, the optimal parameters for each toolpath strategy can be ranked. This ranking is achieved by constructing a response table, where the highest GRG value is identified for each parameter within its respective toolpath.

Table 6 presents the response data for each parameter, segmented by toolpath, providing a structured approach to determining the optimal machining conditions.

From

Table 5, the optimal parameter configurations for each toolpath strategy can be identified for optimizing surface roughness (bottom and side) and material removal rate (MRR). For the Z toolpath, the optimal configuration is Vc = 150 m/min, fz = 0.035 mm/tooth, and ap = 2.0 mm (A3-B1-C3), which corresponds to Sample 7 in

Table 4. Since this parameter combination was already tested within the L9 orthogonal array, no further confirmation is required for the Z toolpath.

For the S toolpath, the optimal configuration is Vc = 150 m/min, fz = 0.025 mm/tooth, and ap = 1.0 mm (A3-B3-C1), which was not included in the L9 orthogonal array. Consequently, a confirmation test is essential to verify its efficacy, as outlined in the Confirmation section. Lastly, for the O toolpath, the optimal configuration is A3-B1-C3, which is also present in

Table 4 as part of the L9 orthogonal configuration, eliminating the need for additional confirmation testing.

Table 7 presents the results for the analysis of variance for the GRG; considering the contribution portion of each parameter, for the Z and S toolpaths, the cutting speed was the parameter that most influenced the proposed optimization; as for the O toolpath, both feed per tooth and axial penetration presented similar contributions.

The error observed for the O toolpath in

Table 8 may be attributed to the selection of parameters and levels, which the model was unable to fully explain. For example, choosing different parameters, such as insert types, lateral depth of cut, or using additional levels for the parameters analyzed in this study, could reduce the model’s variability. Employing a larger orthogonal array could help minimize residual error; however, this would make the optimization process more expensive and time-consuming.

3.3. Confirmation Test

For the S sample that obtained an optimal configuration that was not present in the L9 orthogonal array, it is necessary to conduct a prediction and validation based on the optimal parameters, which are V

c = 150 m/min, f

z = 0.025 mm/tooth, and a

p = 1.0 mm (A3-B3-C1). Using Equation (8) and the values presented in

Table 5, it is possible to obtain the predicted value for the optimal configuration, resulting in

= 0.7111. In the validation test, three additional pockets were machined alongside the initial 27, and the results are summarized in

Table 9.

3.4. Visual Analysis

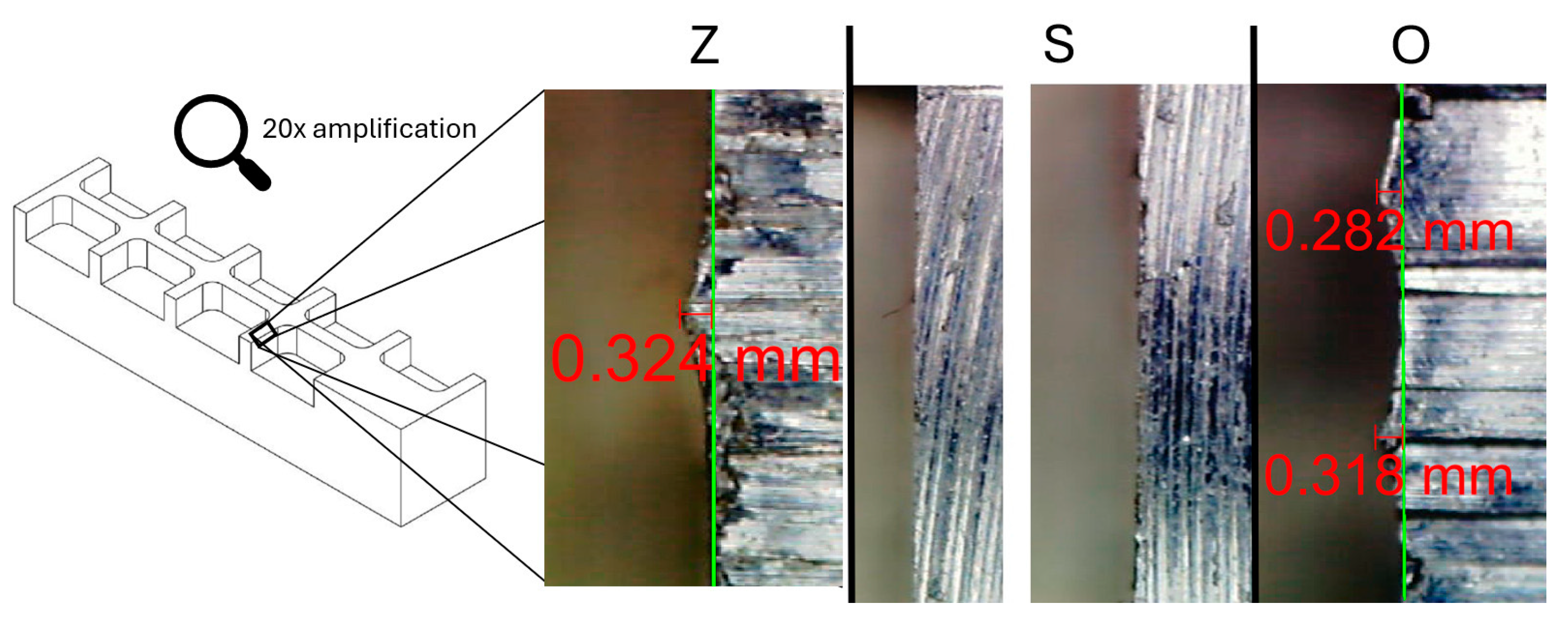

All pockets were evaluated using an electronic magnifier, enabling detailed observation of surfaces with roughness exceeding the resolution limits of the roughness tester. This method provided a more comprehensive assessment of surface characteristics.

Table 9 displays the average R

z measurements obtained from the visual analysis for all pockets corresponding to each toolpath, while

Figure 8 illustrates the specific locations where the data were acquired.

As presented in

Figure 8, the S toolpath exhibited surface roughness levels below the threshold for visual detection. In contrast, certain Z and O samples displayed significantly higher roughness values, exceeding 300 µm, with average roughness measurements of 285 µm for the Z toolpath and 297 µm for the O toolpath as presented in

Table 10.

This phenomenon is attributed to the characteristics of the toolpath strategy. As illustrated in

Figure 5, the O and Z toolpaths generate a radius difference along the pocket walls where the tool passes perpendicularly to the surface. This occurs due to the combination of the tool diameter and displacement between successive tool passes, leading to the formation of ridge-like peaks, as shown in

Figure 5.

Table 10 quantifies the disparity between the parallel and perpendicular pocket walls, revealing that the maximum roughness difference between these orientations ranges from 220 to 290 times, a variation that is far from negligible. To mitigate this effect, an additional finishing pass along the perpendicular walls is required, increasing machining time and reducing process efficiency, which contradicts the intended productivity gains of pocket milling cycles.

3.5. Performance Evaluation

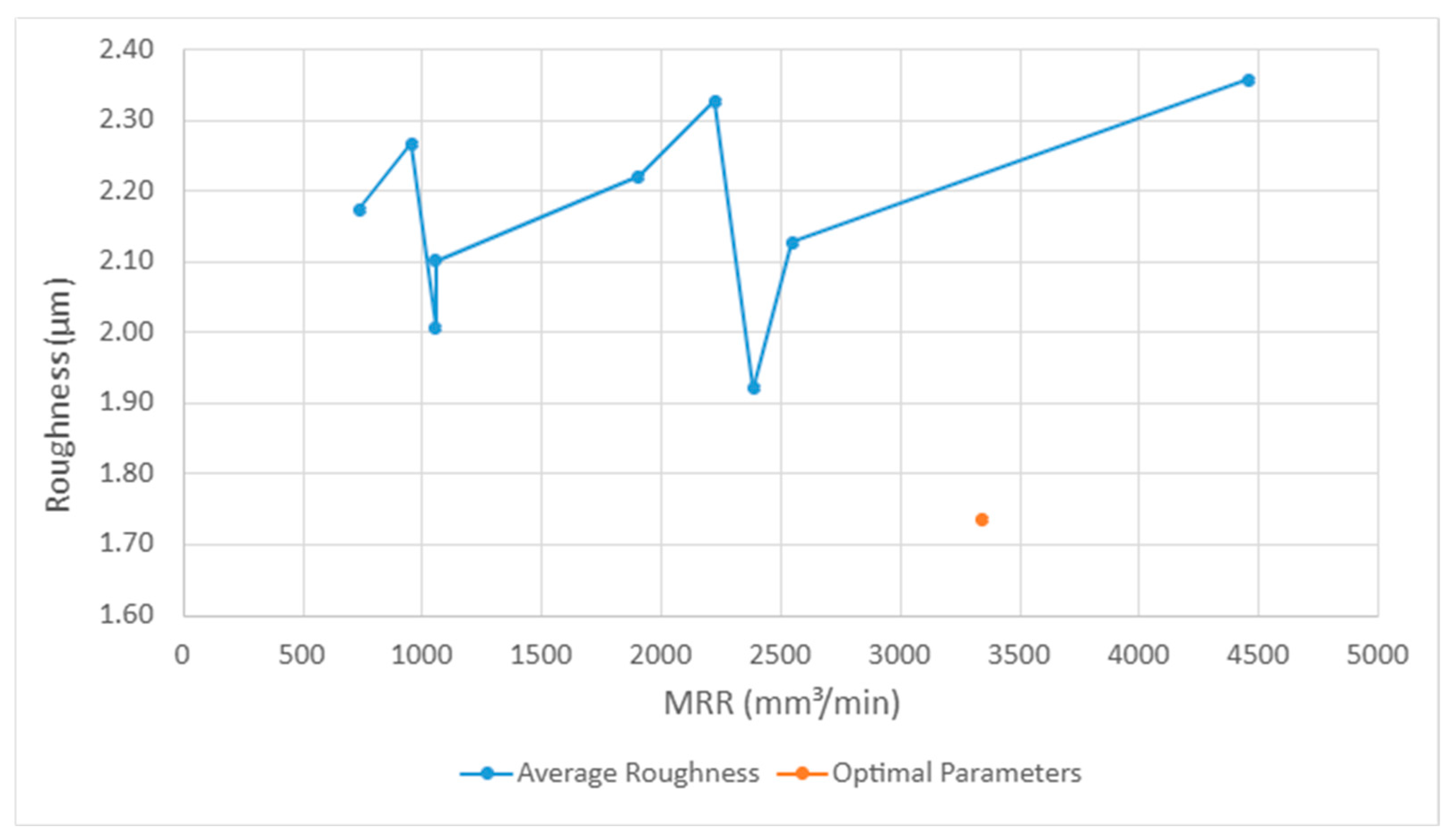

The cost of the CNC machining process is typically associated with the Material Removal Rate (MRR). In general, higher productivity corresponds to lower operational costs.

Figure 9 illustrates the relationship between surface quality and productivity, revealing that, on average, an increase in MRR, particularly beyond 2400 mm

3/min, is associated with a decline in surface quality. This occurs as the cutting speed remains constant beyond this point, leading to increased cutting forces. However, by applying the optimal parameters identified through Grey Relational Analysis, represented by the orange marker (Ra = 1.73 μm and 3342.36 mm

3/min), it was possible to achieve a lower surface roughness while maintaining a high MRR, thus overcoming the typical trade-off between cost and quality.

4. Conclusions

This study demonstrated that integrating statistical techniques such as the Taguchi method, Grey Relational Analysis (GRA), and ANOVA enables the efficient optimization of milling parameters, enhancing both surface quality and productivity.

The results indicated that cutting speed was the most influential parameter in reducing surface roughness for the Zig-Zag and Parallel Spiral toolpaths, whereas axial penetration had a greater impact in the One-Way toolpath, particularly in maximizing material removal rate. Regarding Grey Relational Analysis, the Parallel Spiral toolpath emerged as the most balanced approach, with the Vc = 150 m/min, fz = 0.025 mm/tooth, and ap = 1.0 mm (A3-B3-C1) configuration effectively meeting both surface quality and productivity requirements, making it the most favourable solution for practical applications. It achieves an optimal equilibrium between cost efficiency and product quality, thereby establishing a balanced framework conducive to industrial implementation.