Evolution of Microstructure, Phase Composition, and Mechanical Properties During Thermomechanical Treatment of Co-Cr-Mo Alloy

Abstract

:1. Introduction

2. Materials and Methods

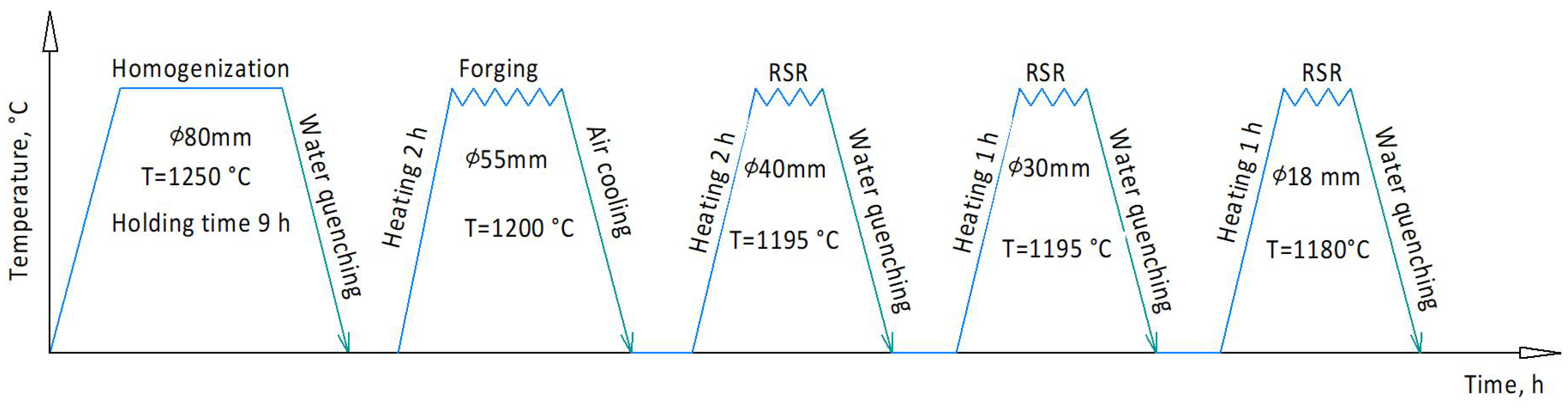

2.1. Experimental Procedure

- -

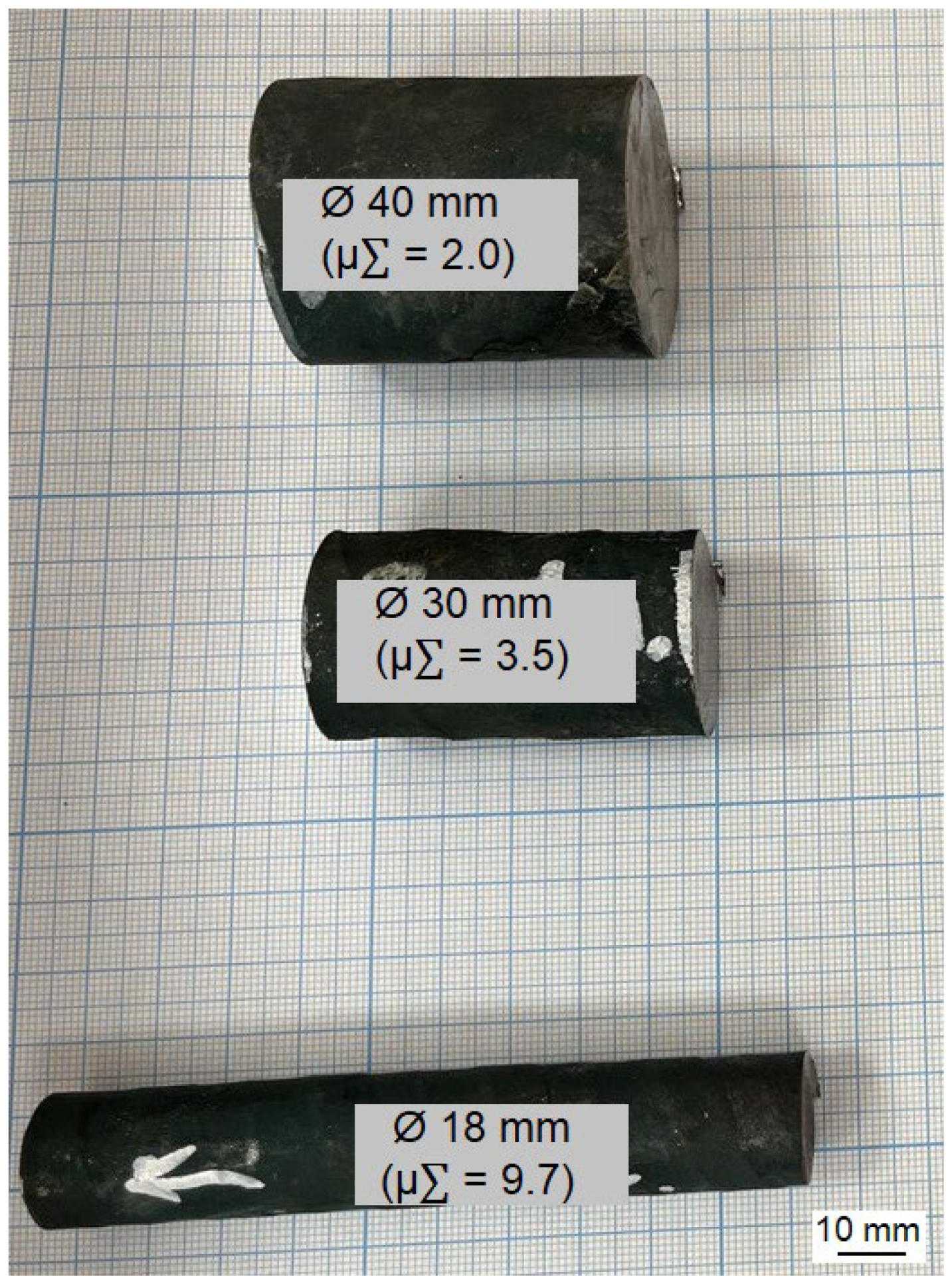

- Ø 56.5 → Ø 40 mm (total elongation ratio µΣ = 2.0);

- -

- Ø 40 → Ø 37.8 → Ø 33.9 → Ø 30 mm (total elongation ratio µΣ = 3.5);

- -

- Ø 30 → Ø 27 → Ø 21.5 → Ø 18 mm (total elongation ratio µΣ = 9.7).

2.2. Analysis of Microstructure and Phase Composition

2.3. Tensile Test

3. Results

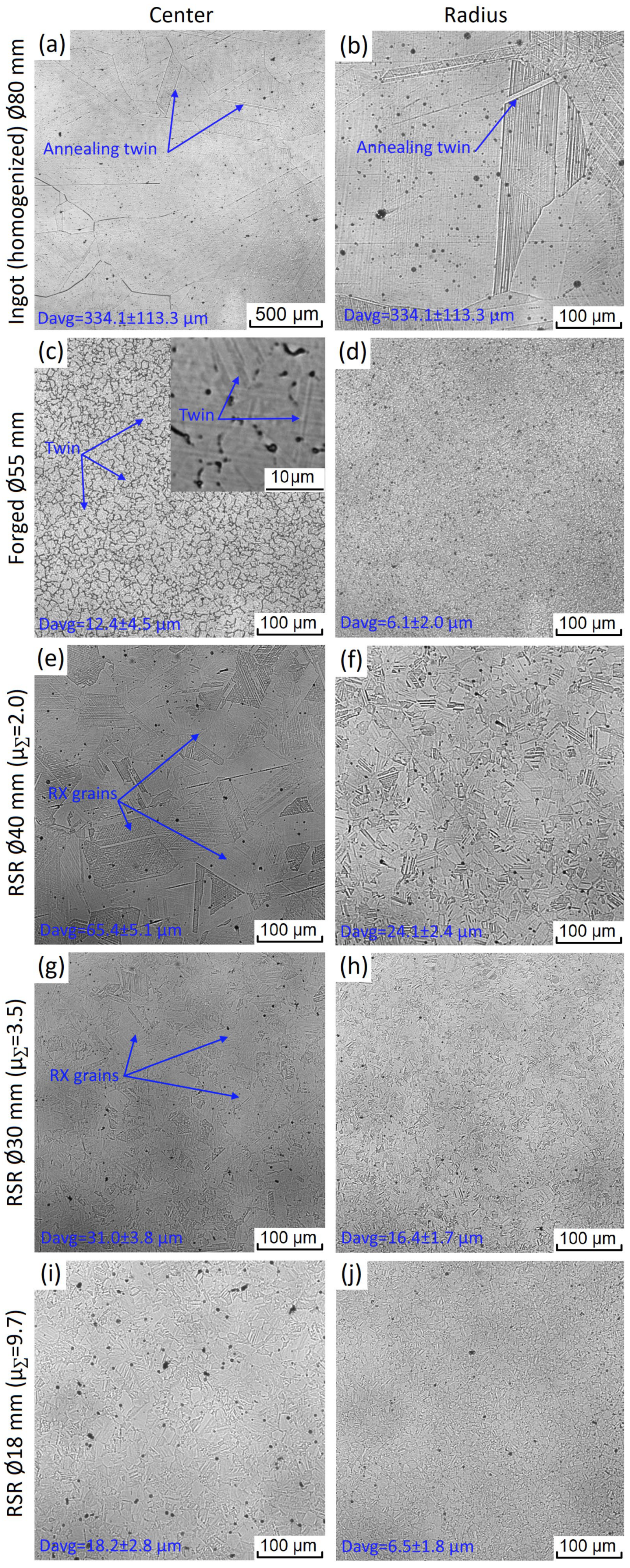

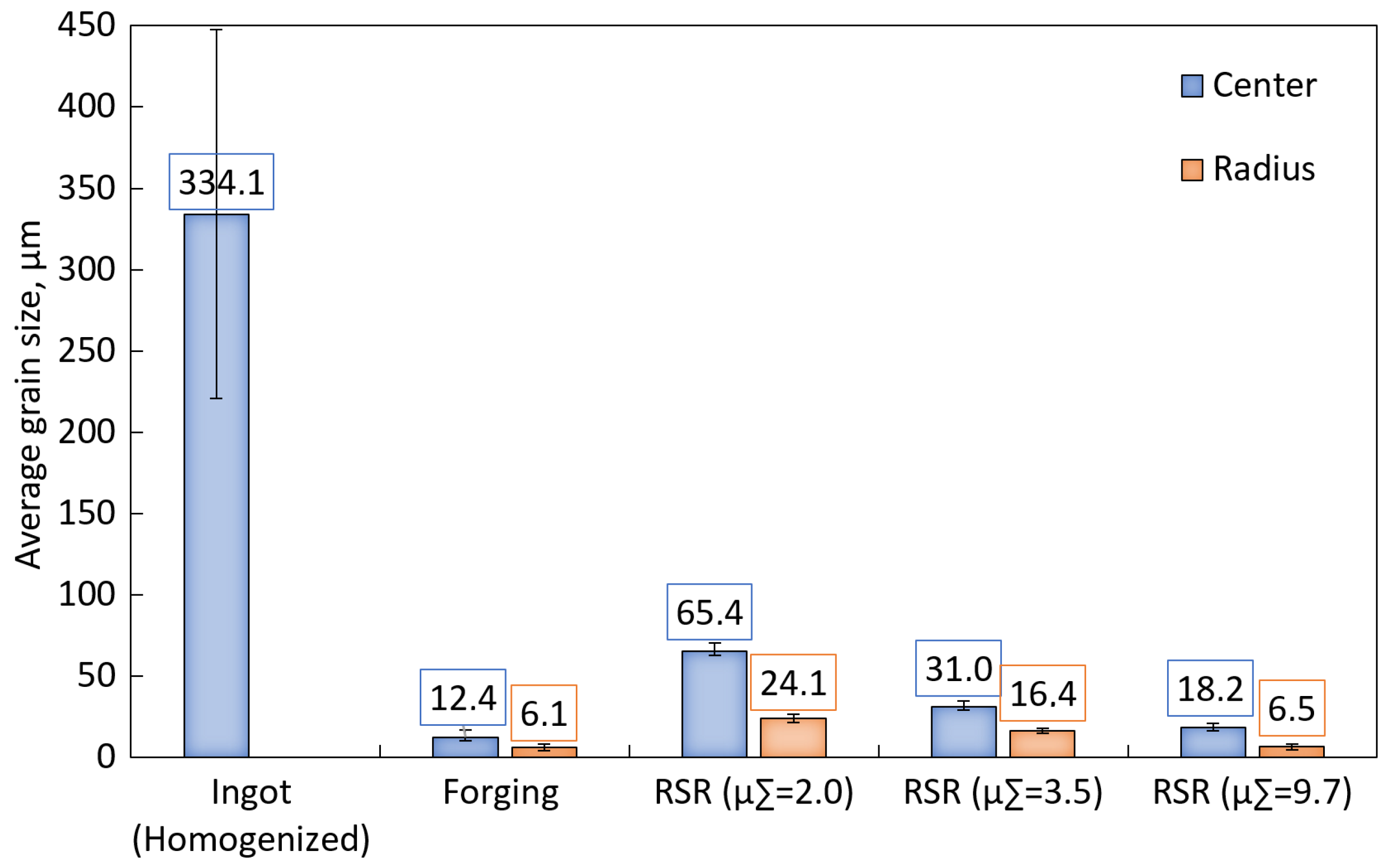

3.1. Microstructure

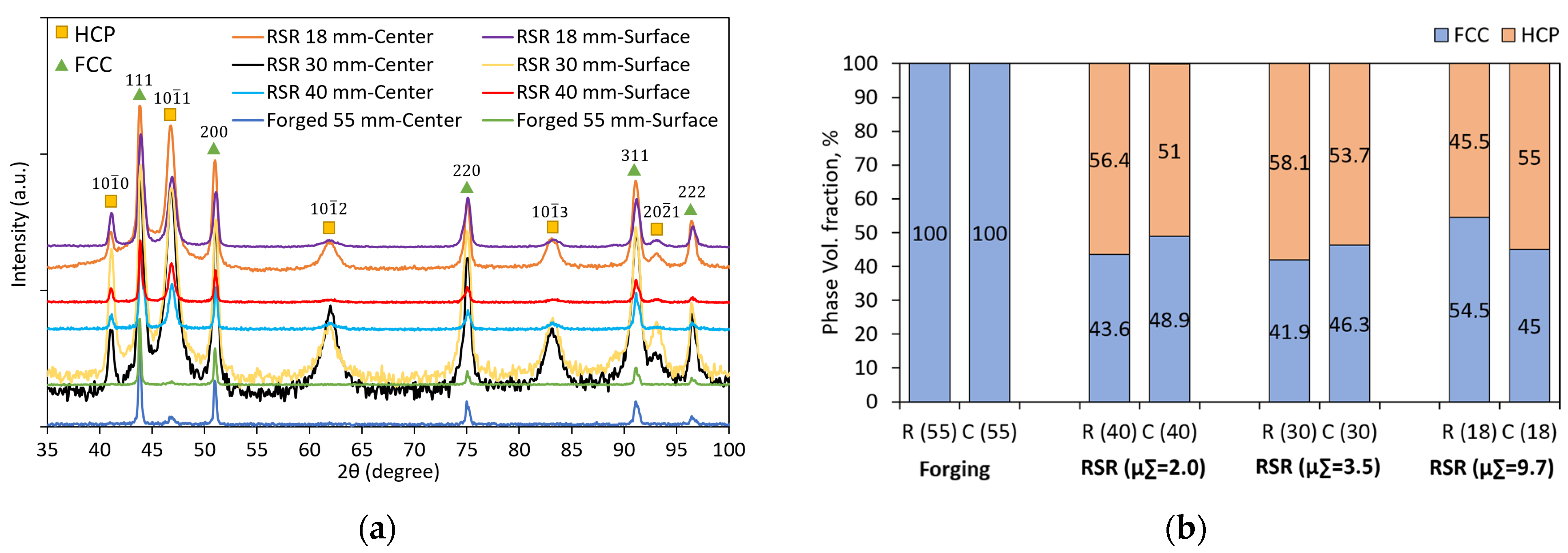

3.2. Phase Composition

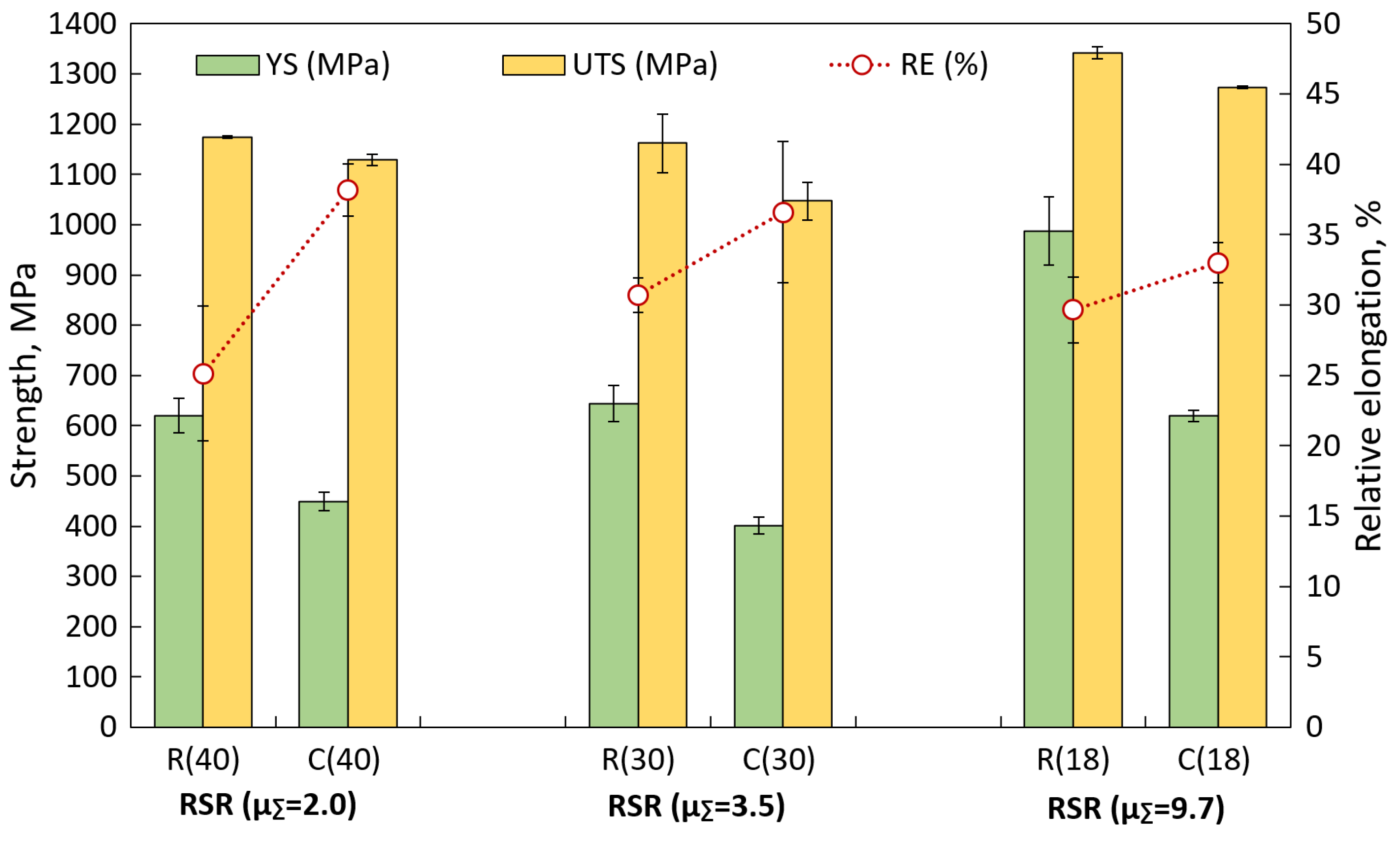

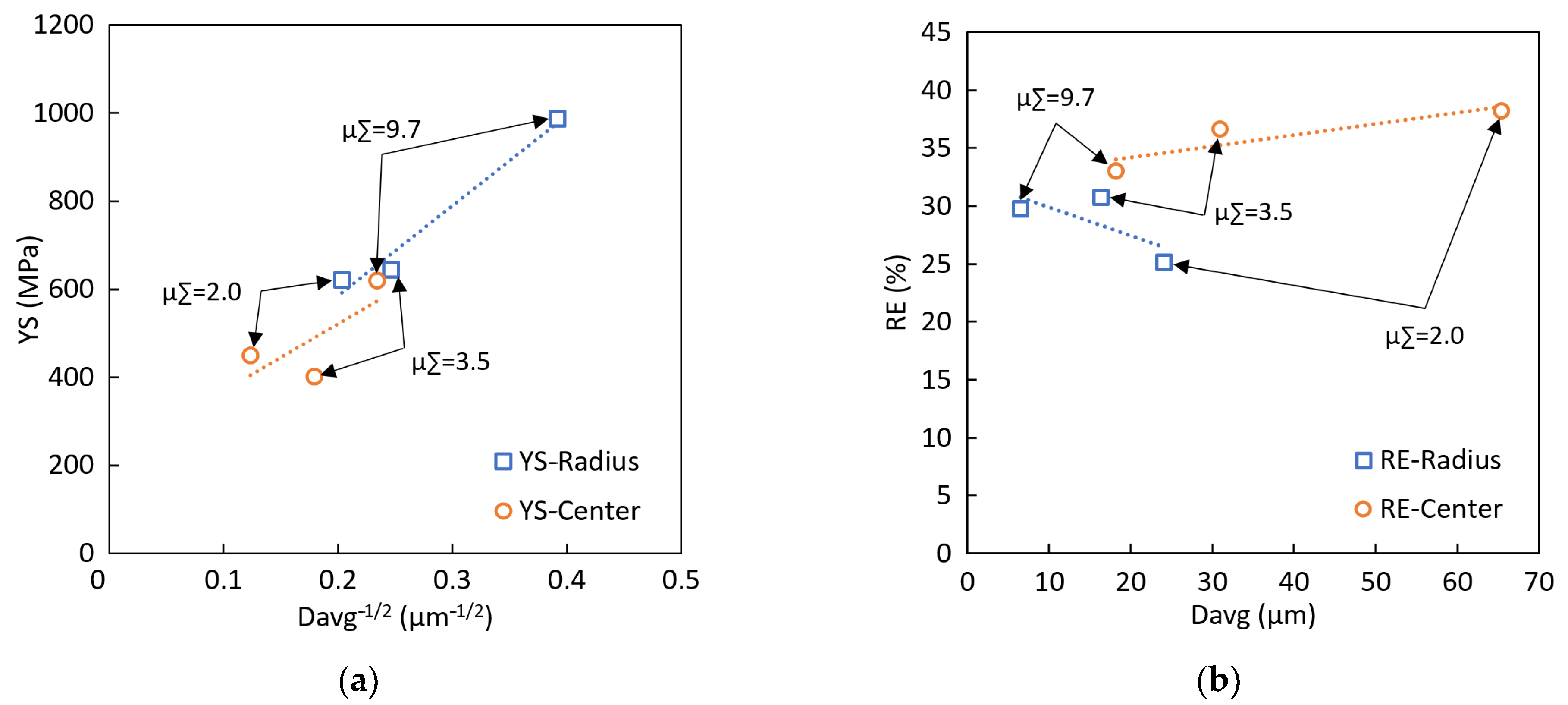

3.3. Mechanical Properties

4. Discussion

5. Conclusions

- The forging of the homogenized ingot allowed for significant refinement of the grain structure, resulting in a substantial increase in yield strength by 2.75 times and ultimate tensile strength by 1.7 times compared to the initial state. At the same time, the relative elongation remained at the same level.

- During the deformation processing, microstructure, phase composition, and mechanical properties changed significantly at each stage of treatment. Strength properties increase to a large extent after hot forging due to the grain refinement. However, at RSR, a significant increase in both strength and ductility was observed simultaneously due to the unique formation of the microstructure and phase composition.

- During the isothermal forging with subsequent air cooling, a single-phase FCC structure was obtained. Subsequent deformation treatment (RSR) in the high-temperature region and quenching in water resulted in the formation of a two-phase structure (FCC+HCP phases) in approximately equal proportions in both the central and surface zones.

- The gradient of the structure during RSR decreased as the total elongation ratio increased, which was confirmed by the values of the average grain size and the level of mechanical properties both in the center and in the surface zone of the bars.

- The thermomechanical treatment of the Co-28Cr-6Mo alloy, combining isothermal forging and RSR with various types of post-deformation cooling, provides a significant improvement in both the strength and plastic properties of the obtained bars due to the formation of a two-phase composition and fine-grained structure.

- The results obtained can be used as a basis for the implementation of the technology for the production of deformed semi-finished products from the Co-Cr-Mo alloy system on an industrial scale.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Doroshenko, V.; Aksenov, A.; Fortuna, A.; Gorlov, L.; Prosviryakov, A.; Cherkasov, S.; Strekalina, D. Impact of Calcium Addition on Microstructural and Mechanical Properties of Al-3% Mg-0.8% Mn Alloy Under Different Treatment Paths. Met. Mater. Int. 2025. [Google Scholar] [CrossRef]

- Tsydenov, K.A.; Belov, N.A.; Doroshenko, V.V.; Shcherbakova, O.O.; Muravyeva, T.I. Comparative analysis of the effect of magnesium and zinc on the structure and mechanical properties of hot-rolled and cold-rolled alloy Al–2%Cu–1.5%Mn sheets. Metallurgist 2024, 68, 406–417. [Google Scholar] [CrossRef]

- Galkin, S.P.; Kin, T.Y.; Gamin, Y.V.; Aleshchenko, A.S.; Karpov, B.V. Review of scientific-applied research and industrial application of radial shear rolling technology. CIS Iron Steel Rev. 2024, 27, 35–47. [Google Scholar] [CrossRef]

- Palacheva, V.V.; Mochugovskiy, A.G.; Chubov, D.G.; Koshmin, A.N.; Cheverikin, V.V.; Cifre, J. Influence of mechanical and heat treatment on structure evolution and functional properties of Fe-Al-Tb alloys. Mater. Lett. 2022, 310, 131521. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Sato, S.; Chiba, A. Stacking-fault strengthening of biomedical Co–Cr–Mo alloy via multipass thermomechanical processing. Sci. Rep. 2017, 7, 10808. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Avila, J.D.; Mitra, I.; Bose, S. 1.3.3C–CoCr Alloys. In Biomaterials Science, 4th ed.; Wagner, W.R., Sakiyama-Elbert, S.E., Zhang, G., Yaszemski, M.J., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 257–269. [Google Scholar] [CrossRef]

- Tanzi, M.C.; Farè, S.; Candiani, G. (Eds.) Chapter 4—Biomaterials and Applications. In Foundations of Biomaterials Engineering, 1st ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 199–287. [Google Scholar] [CrossRef]

- Narushima, T. (Ed.) 19—New-generation metallic biomaterials. In Woodhead Publishing Series in Biomaterials, Metals for Biomedical Devices, 2nd ed.; Woodhead Publishing: Sawston, UK, 2019; pp. 495–521. [Google Scholar] [CrossRef]

- Niinomi, M. 4—Co–Cr-based alloys. In Woodhead Publishing Series in Biomaterials, Structural Biomaterials; Wen, C., Ed.; Woodhead Publishing: Sawston, UK, 2021; pp. 103–126. [Google Scholar] [CrossRef]

- Narushima, T.; Ueda, K.; Alfirano. Co-Cr Alloys as Effective Metallic Biomaterials. In Advances in Metallic Biomaterials; Niinomi, M., Narushima, T., Nakai, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 157–196. [Google Scholar] [CrossRef]

- Patel, B.; Favaro, G.; Inam, F.; Reece, M.J.; Angadji, A.; Bonfield, W.; Huang, J. Cobalt-based orthopaedic alloys: Relationship between forming route, microstructure and tribological performance. Mater. Sci. Eng. C 2012, 32, 1222–1229. [Google Scholar] [CrossRef]

- Mori, M.; Guo, T.; Yamanaka, K.; Wang, Z.; Yoshida, K.; Onuki, Y.; Sato, S.; Chiba, A.; Misra, R.D.K. The significance of thermomechanical processing on the cellular response of biomedical Co-Cr-Mo alloys. J. Mech. Behav. Biomed. Mater. 2022, 133, 105360. [Google Scholar] [CrossRef]

- Okazaki, Y. Effects of Heat Treatment and Hot Forging on Microstructure and Mechanical Properties of Co-Cr-Mo Alloy for 417 Surgical Implants. Mater. Trans. 2008, 49, 817–823. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Chiba, A. Mechanical properties of as-forged Ni-free Co–29Cr–6Mo alloys with ultrafine-grained mi-443 crostructure. Mater. Sci. Eng. A 2011, 528, 5961–5966. [Google Scholar] [CrossRef]

- Mori, M.; Yamanaka, K.; Sato, S.; Tsubaki, S.; Satoh, K.; Kumagai, M.; Imafuku, M.; Shobu, T.; Chiba, A. Strengthening of biomedical Ni-free Co-Cr-Mo alloy by multipass “low-strain-per-pass” thermomechanical processing. Acta Biomater. 2015, 28, 215–224. [Google Scholar] [CrossRef]

- Kurosu, S.; Matsumoto, H.; Chiba, A. Isothermal Phase Transformation in Biomedical Co-29Cr-6Mo Alloy without Addition of Carbon or Nitrogen. Met. Mater. Trans. A 2010, 41, 2613–2625. [Google Scholar] [CrossRef]

- Gamin, Y.V.; Skugorev, A.V.; Karashaev, M.M.; Kin, T.Y.; Galkin, S.P.; Mahmoud Alhaj Ali, A.; Cheverikin, V.V. Analysis of Microstructure Evolution of Co-Cr-Mo Alloy during Isothermal Forging. Metals 2023, 13, 1583. [Google Scholar] [CrossRef]

- Gamin, Y.; Kin, T.; Galkin, S.; Skugorev, A.; Karashaev, M.; Mahmoud Alhaj Ali, A. Formation of Microstructure and Mechanical Properties of Co-Cr-Mo Alloy by Hot Forging and Subsequent Radial Shear Rolling. Met. Mater. Int. 2024, 31, 1106–1115. [Google Scholar] [CrossRef]

- ISO 5832-12:2019; Implants for Surgery—Metallic Materials—Part 12: Wrought Cobalt-Chromium-Molybdenum Alloy. ISO (International Organization for Standardization): Geneva, Switzerland, 2019.

- Rosenthal, R.; Cardoso, B.R.; Bott, I.S.; Paranhos, R.P.R.; Carvalho, E.A. Phase characterization in as-cast F-75 Co–Cr–Mo–C 419 alloy. J. Mater. Sci. 2010, 45, 4021–4028. [Google Scholar] [CrossRef]

- Giacchi, J.V.; Morando, C.N.; Fornaro, O.; Palacio, H.A. Microstructural characterization of as-cast biocompatible Co–Cr–Mo alloys. Mater. Charact. 2011, 62, 53–61. [Google Scholar] [CrossRef]

- Galkin, S.P.; Gamin, Y.V.; Aleshchenko, A.S.; Romantsev, B.A. Modern development of elements of theory, technology and mini-mills of radial-shear rolling. Chernye Met. 2021, 12, 51–58. [Google Scholar] [CrossRef]

- Arbuz, A.; Kawalek, A.; Ozhmegov, K.; Panin, E.; Magzhanov, M.; Lutchenko, N.; Yurchenko, V. Obtaining an Equiaxed Ultrafine-Grained State of the Longlength Bulk Zirconium Alloy Bars by Extralarge Shear Deformations with a Vortex Metal Flow. Materials 2023, 16, 1062. [Google Scholar] [CrossRef]

- Rotenberg, Z.Y.; Budnikov, A.S. Experimental testing of a new helical rolling technology. Metallurgist 2024, 68, 1065–1072. [Google Scholar] [CrossRef]

- Shelekhov, E.V.; Sviridova, T.A. Programs for X-ray analysis of polycrystals. Met. Sci. Heat Treat. 2000, 42, 309–313. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Kurosu, S.; Matsumoto, H.; Chibo, A. Ultrafine Grain Refinement of Biomedical Co-29Cr-6Mo Alloy during Conventional Hot-Compression Deformation. Met. Mater. Trans. A 2009, 40, 1980–1994. [Google Scholar] [CrossRef]

- Skripalenko, M.M.; Rogachev, S.O.; Bazhenov, V.E.; Romantsev, B.A.; Skripalenko, M.N.; Karpov, B.V.; Titov, A.Y.; Koltygin, A.V.; Danilin, A.V. Research of Three-High Screw Rolling of Aluminum Billets with Copper Inserts at Different Rolls Feed Angles. Metals 2023, 13, 1671. [Google Scholar] [CrossRef]

- Gamin, Y.V.; Galkin, S.P.; Koshmin, A.N.; Mahmoud Alhaj Ali, A.; Nguyen, X.D.; ELDeeb, I.S. High-reduction radial shear rolling of aluminum alloy bars using custom-calibrated rolls. Int. J. Mater. Form. 2024, 17, 5. [Google Scholar] [CrossRef]

- Galkin, S.P.; Gamin, Y.V.; Kin, T.Y. Analysis of Temperature Influence on Strain–Speed Parameters of Radial-Shear Rolling of Al-Zn-Mg-Ni-Fe Alloy. Materials 2022, 15, 7202. [Google Scholar] [CrossRef]

- Bajor, T.; Kulakowska, A.; Dyja, H. Analysis of the Rolling Process of Alloy 6005 in a Three-High Skew Rolling Mill. Materials 2020, 13, 1114. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.; López, H. Strain induced ε-martensite in a Co–Cr–Mo alloy: Grain size effects. Mater. Lett. 1999, 39, 244–248. [Google Scholar] [CrossRef]

- Song, C.; Park, H.; Seong, H.; Lopez, H.F. Development of athermal and isothermalε-martensite in atomized Co-Cr-Mo-C implant alloy powders. Met. Mater. Trans. A 2006, 37, 3197–3204. [Google Scholar] [CrossRef]

- Huang, P.; López, H.F. Effects of grain size on development of athermal and strain induced ɛ martensite in Co–Cr–Mo implant alloy. Mater. Sci. Technol. 1999, 15, 157–164. [Google Scholar] [CrossRef]

- Kamikawa, N.; Huang, X.; Tsuji, N.; Hansen, N. Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed. Acta Mater. 2009, 57, 4198–4208. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Gamin, Y.V.; Akopyan, T.K.; Skugorev, A.V.; Nguyen, X.D.; Prosviryakov, A.S.; Cheverikin, V.V.; Fortuna, A.S.; Savonkin, M.B. Microstructure and Mechanical Properties of Al–Zn–Mg–Ni–Fe Alloy Processed by Hot Extrusion and Subsequent Radial Shear Rolling. Metall. Mater. Trans. A 2024, 55, 3576–3590. [Google Scholar] [CrossRef]

- Naydenkin, E.V.; Ratochka, I.V.; Mishin, I.P.; Lykova, O.N. Evolution of the Structural-Phase State of a VT22 Titanium Alloy During Helical Rolling and Subsequent Aging. Russ. Phys. J. 2015, 58, 1068–1073. [Google Scholar] [CrossRef]

- Arbuz, A.; Kawalek, A.; Ozhmegov, K.; Dyja, H.; Panin, E.; Lepsibayev, A.; Sultanbekov, S.; Shamenova, R. Using of Radial-Shear Rolling to Improve the Structure and Radiation Resistance of Zirconium-Based Alloys. Materials 2020, 13, 4306. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhao, L.; Zhipeng, L.; Xijie, L.; Zheng, R.; Shi, X.; Liang, J. Deformation and microstructure radial gradient evolution of AZ31 magnesium alloy bar during three-roll skew rolling. J. Alloys Compd. 2024, 1006, 176331. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Chiba, A. Enhanced Mechanical Properties of As-Forged Co-Cr-Mo-N Alloys with Ultrafine-Grained Structures. Met. Mater. Trans. A 2012, 43, 5243–5257. [Google Scholar] [CrossRef]

- Koizumi, Y.; Suzuki, S.; Yamanaka, K.; Lee, B.S.; Sato, K.; Li, Y.; Kurosu, S.; Matsumoto, H.; Chiba, A. Strain-induced martensitic transformation near twin boundaries in a biomedical Co-Cr-Mo alloy with negative stacking fault energy. Acta Mater. 2013, 61, 1648–1661. [Google Scholar] [CrossRef]

- Chiba, A.; Kumagai, K.; Takeda, H.; Nomura, N. Mechanical properties of forged low Ni and C-containing Co-Cr-Mo biomedical implant alloy. Mater. Sci. Forum 2005, 475–479, 2317–2322. [Google Scholar] [CrossRef]

- Mori, M.; Yamanaka, K.; Sato, S.; Wagatsuma, K.; Chiba, A. Microstructures and Mechanical Properties of Biomedical Co-29Cr-6Mo-0.14N Alloys Processed by Hot Rolling. Met. Mater. Trans. A 2012, 43, 3108–3119. [Google Scholar] [CrossRef]

- Kurosu, S.; Matsumoto, H.; Chiba, A. Grain refinement of biomedical Co–27Cr–5Mo–0.16N alloy by reverse transformation. Mater Lett. 2010, 64, 49–52. [Google Scholar] [CrossRef]

- Lechartier, A.; Meyer, N.; Estevez, R.; Mantel, M.; Martin, G.; Parry, G.; Véron, M.; Deschamps, A. Deformation behavior of lean duplex stainless steels with strain induced martensitic transformation: Role of deformation mechanisms, alloy chemistry and predeformation. Materialia 2019, 5, 100190. [Google Scholar] [CrossRef]

- Moallemi, M.; Zarei-Hanzaki, A.; Eskandari, M.; Burrows, A.; Alimadadi, H. Comprehensive Deformation Analysis of a Newly Designed Ni-Free Duplex Stainless Steel with Enhanced Plasticity by Optimizing Austenite Stability. Met. Mater. Trans. A 2017, 48, 3675–3691. [Google Scholar] [CrossRef]

| Chemical Element wt. % | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Co | Cr | Mo | Ni | Fe | Si | Mn | C | N | S |

| Balance | 28.30 | 5.97 | 0.24 | 0.12 | 0.39 | 0.33 | 0.09 | 0.004 | 0.005 |

| Condition/Method | Area | Average Grain Size (µm) | YS (MPa) | UTS (MPa) | RE (%) | |

|---|---|---|---|---|---|---|

| Co-28Cr-6Mo (Present work) | Homogenized | - | 334 ± 113.3 | 263.3 | 537.6 | 20.0 |

| Hot forging | Center | 12.4 ± 4.5 | 649.4 | 905.3 | 19.5 | |

| Radius | 6.1 ± 2.0 | |||||

| RSR (µ∑ = 2.0) | Center | 65.4 ± 5.1 | 448.8 | 1129.2 | 38.2 | |

| Radius | 24.1 ± 2.4 | 620.5 | 1173.9 | 25.1 | ||

| RSR (µ∑ = 3.5) | Center | 31.0 ± 3.8 | 401.2 | 1047.1 | 36.6 | |

| Radius | 16.4 ± 1.7 | 643.9 | 1162.1 | 30.7 | ||

| RSR (µ∑ = 9.7) | Center | 18.2 ± 2.8 | 619.3 | 1273.2 | 33.0 | |

| Radius | 6.5 ± 1.8 | 987.4 | 1341.5 | 29.7 | ||

| CCM [40] | initial | - | ~100 | 570 | 570 | 16.8 |

| hot forging | 2.29 ± 0.14 | 800 | 1320 | 14.5 | ||

| hot forging | 1.34 ± 0.10 | 1050 | 1450 | 10.3 | ||

| hot forging | 0.82 ± 0.07 | 1330 | 1450 | 2.5 | ||

| Co-29Cr-6Mo [42] | hot forging | - | 43 | 590 | 718 | 15.1 |

| hot forging | 11 | 648 | 1050 | 22.6 | ||

| hot forging | 3 | 890 | 1415 | 21.6 | ||

| CCMN [40] | initial | - | ~100 | 540 | 988 | 25.2 |

| hot forging | 0.93 ± 0.18 | 1400 | 1620 | 21.8 | ||

| Co-29Cr-6Mo-0.14N [43] | hot rolling | - | 50.7 ± 5.3 | 1080 | 1415 | 20.6 |

| Co-27Cr-5Mo-0.16N [44] | reverse trans. | - | 20 to 25 | 700 | 1282 | 36 |

| ISO 5832-12 | Annealed | - | not be coarser grain size No 5 (62.5 µm) | 517.0 | 897.0 | 20.0 |

| Hot worked | - | 700.0 | 1000.0 | 12.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kin, T.; Gamin, Y.; Galkin, S.; Mahmoud Alhaj Ali, A.; Khakimova, A.; Skugorev, A. Evolution of Microstructure, Phase Composition, and Mechanical Properties During Thermomechanical Treatment of Co-Cr-Mo Alloy. J. Manuf. Mater. Process. 2025, 9, 110. https://doi.org/10.3390/jmmp9040110

Kin T, Gamin Y, Galkin S, Mahmoud Alhaj Ali A, Khakimova A, Skugorev A. Evolution of Microstructure, Phase Composition, and Mechanical Properties During Thermomechanical Treatment of Co-Cr-Mo Alloy. Journal of Manufacturing and Materials Processing. 2025; 9(4):110. https://doi.org/10.3390/jmmp9040110

Chicago/Turabian StyleKin, Tatiana, Yury Gamin, Sergei Galkin, Abdullah Mahmoud Alhaj Ali, Anna Khakimova, and Alexander Skugorev. 2025. "Evolution of Microstructure, Phase Composition, and Mechanical Properties During Thermomechanical Treatment of Co-Cr-Mo Alloy" Journal of Manufacturing and Materials Processing 9, no. 4: 110. https://doi.org/10.3390/jmmp9040110

APA StyleKin, T., Gamin, Y., Galkin, S., Mahmoud Alhaj Ali, A., Khakimova, A., & Skugorev, A. (2025). Evolution of Microstructure, Phase Composition, and Mechanical Properties During Thermomechanical Treatment of Co-Cr-Mo Alloy. Journal of Manufacturing and Materials Processing, 9(4), 110. https://doi.org/10.3390/jmmp9040110