Cost-Effective Surface Quality Measurement and Advanced Data Analysis for Reamed Bores

Abstract

1. Introduction

2. Materials and Methods

2.1. Reaming Process

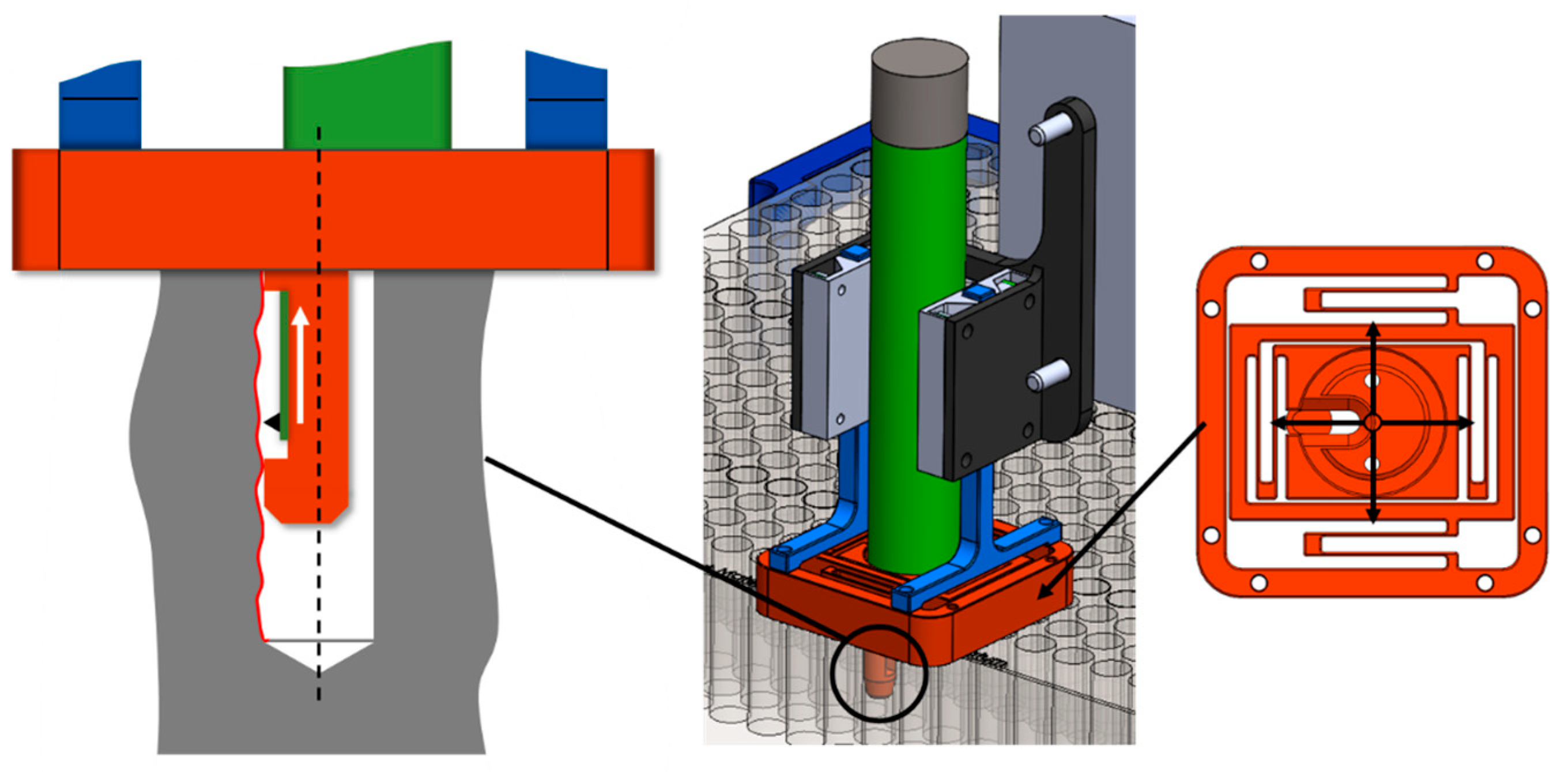

2.2. Automated Surface Measurement

3. Results

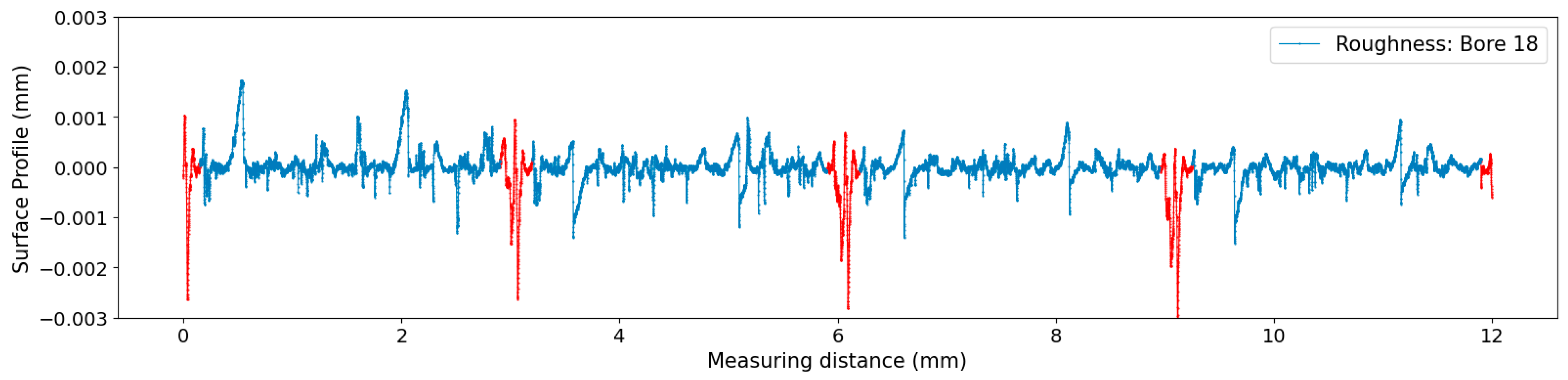

3.1. Preprocessing: Filtering According to Standards

3.2. Analysis of Retraction Grooves in the Roughness Profile

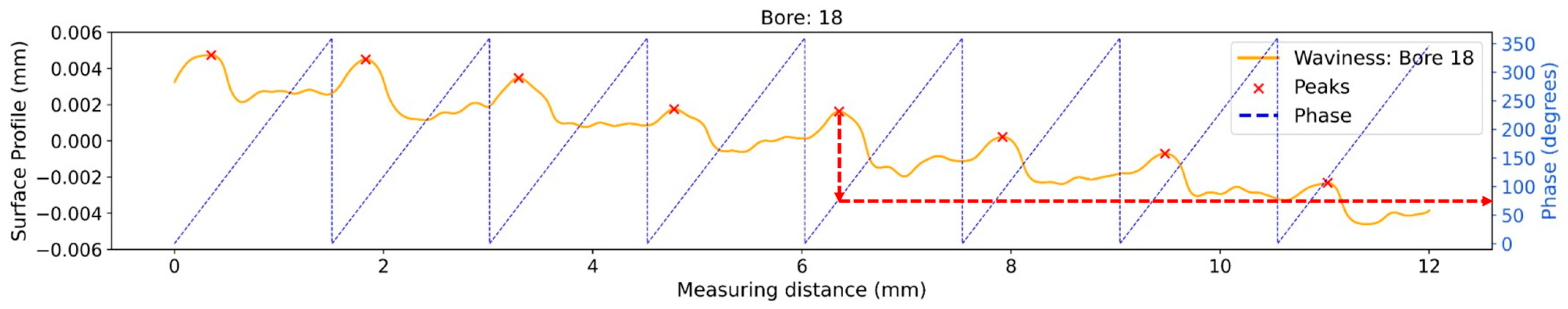

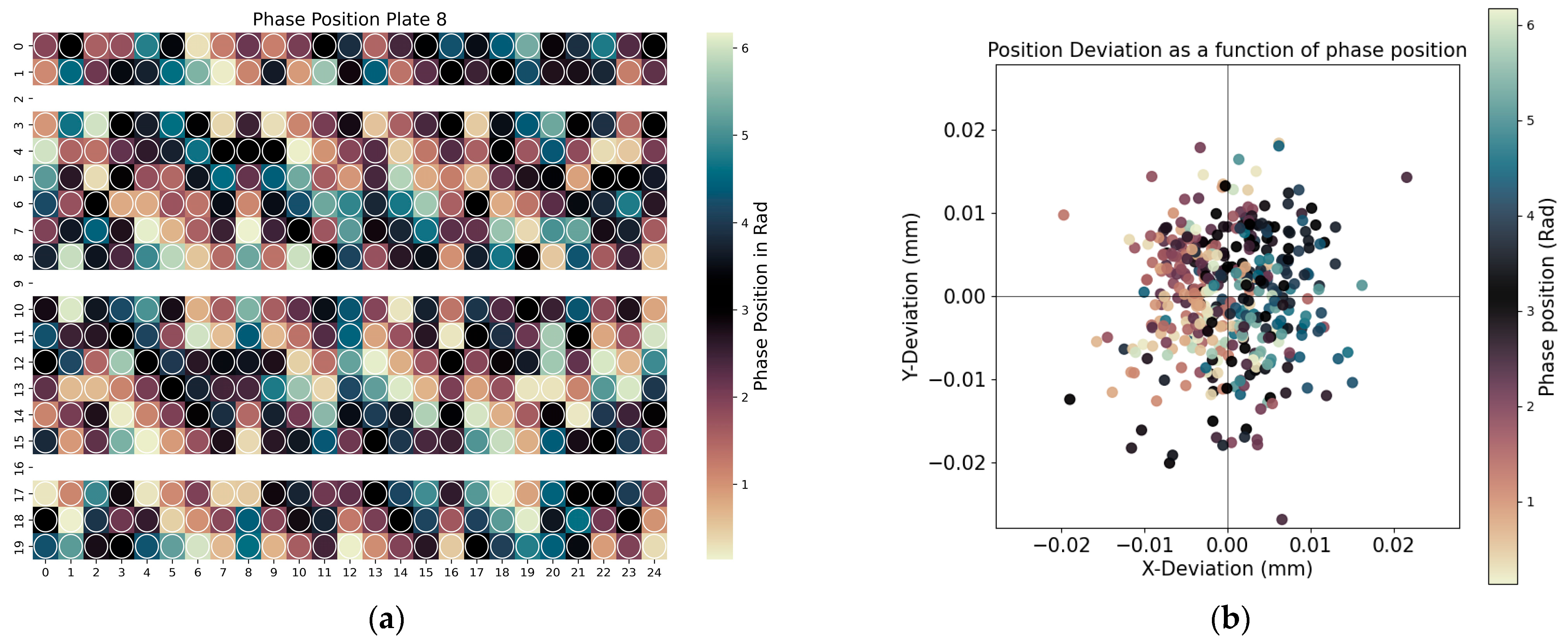

3.3. Analysis of Phase Position in Waviness

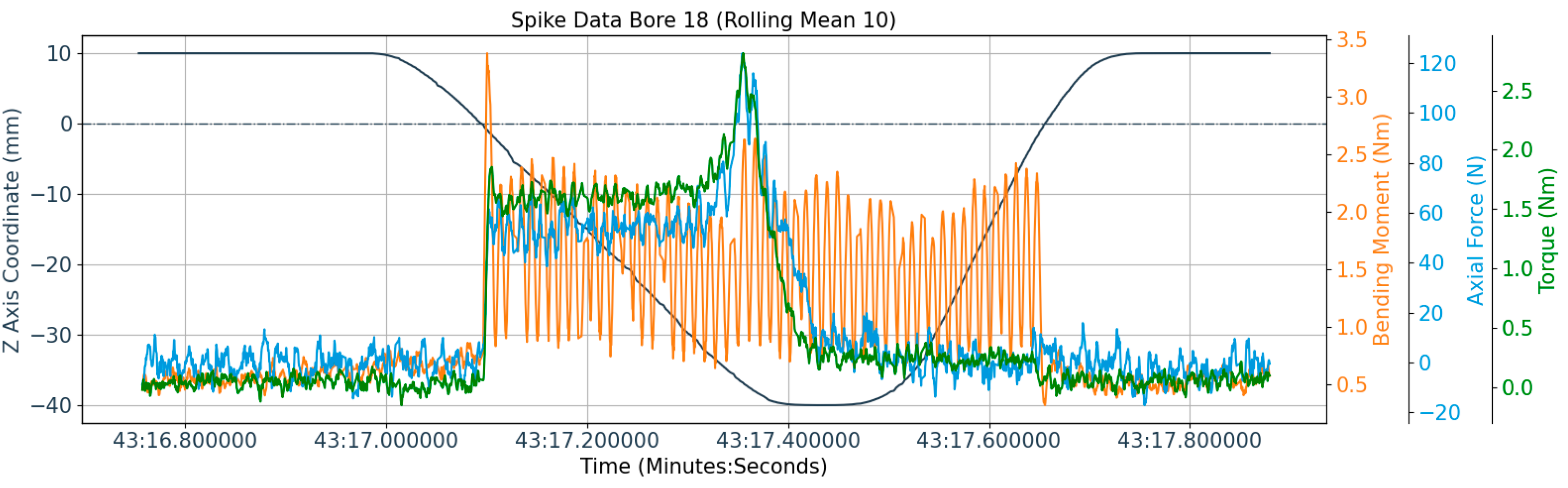

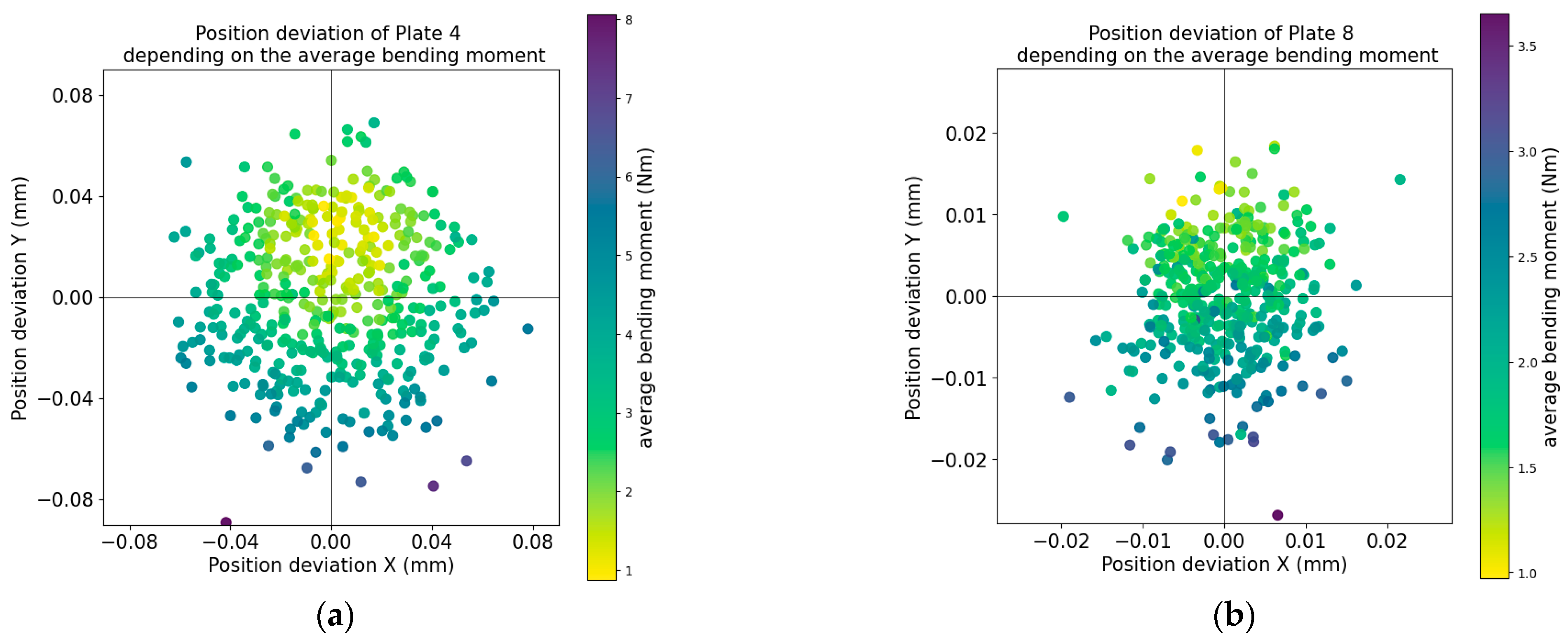

3.4. Analysis of Cutting Forces

4. Discussion

5. Conclusions

- An automated and cost-effective system for measuring surface quality in reamed bores was demonstrated, utilizing an NC-controlled gantry and a mobile stylus profilometer.

- The analysis of the profile data, and in particular the separation of surface profiles into roughness and waviness components according to the demanding DIN EN ISO standards, enabled a more targeted analysis of process-specific issues.

- It was demonstrated that a 360° scan allows for clear visualization of retraction grooves. An autocovariance-based approach proved helpful in evaluating these grooves, offering a more specific assessment than standard metrics.

- The phase position of the waviness profile on the reamed surface correlated with tool entry angle and position deviation. By putting this phase position into context with the bore position in the workpiece, patterns associated with tool wear were identified, allowing for potential process improvements to reduce positional deviations.

- Process forces were measured and analyzed to link bending moments with bore position deviations, revealing that bending moments increase significantly with larger positional deviations.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Unsin, S.; Dorer, C.; Müller, B.; Jung, T.; Limmer, A.; Schirmeier, F. Schritt für Schritt zur Zerspanungs-Ki. Maschinenbau 2024, 4, 10–15. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Han, Z. Study on Characteristics for Reaming Titanium Alloy Ti6Al4V with Two Kinds of Cemented-Carbide Groove Reamers. Materials 2022, 15, 5027. [Google Scholar] [CrossRef] [PubMed]

- Lagoa Melo, T.F.; Ribeiro Filho, S.L.M.; Arruda, É.M.; Brandão, L.C. Analysis of the surface roughness, cutting efforts, and form errors in bore reaming of hardened steel using a statistical approach. Measurement 2019, 134, 845–854. [Google Scholar] [CrossRef]

- Bezerra, A.A.; Machado, A.R.; Souza, A.M.; Ezugwu, E.O. Effects of machining parameters when reaming aluminium-silicon (SAE 322) alloy. J. Mater. Process. Technol. 2001, 112, 185–198. [Google Scholar] [CrossRef]

- Zheleznov, G.S.; Andreeva, S.G. Final Surface Roughness in Reaming Holes. Russ. Eng. Res. 2013, 33, 522–524. [Google Scholar] [CrossRef]

- Müller, P.; Genta, G.; Barbato, G.; De Chiffre, L.; Levi, R. Reaming process improvement and control: An application of statistical engineering. CIRP J. Manuf. Sci. Technol. 2012, 5, 196–201. [Google Scholar] [CrossRef][Green Version]

- Müller, P.; De Chiffre, L. Reproducibility of surface roughness in reaming. In Proceedings of the 4th Swedish Production Symposium, Göteborg, Sweden, 3–5 May 2011. [Google Scholar]

- De Chiffre, L.; Tosello, G.; Píška, M.; Müller, P. Investigation on Capability of Reaming Process using Minimal Quantity Lubrication. CIRP J. Manuf. Sci. Technol. 2009, 2, 47–54. [Google Scholar] [CrossRef]

- Rodriguez, M.A.; Moreira, L.T.S. Tool wear and surface roughness evaluation of the reaming process for the 15-5 precipitation hardening stainless steel. In Proceedings of the COBEM 2009, 20th International Congress of Mechanical Engineering, Gramado, RS, Brazil, 15–20 November 2009. [Google Scholar]

- Wang, Y.; Cui, X.; Xu, H.; Jiang, K. Cutting force analysis in reaming of ZL102 aluminium cast alloys by PCD reamer. Int. J. Adv. Manuf. Technol. 2013, 67, 1509–1516. [Google Scholar] [CrossRef]

- Bretz, A.; Abele, E.; Weigold, M. Measuring the bore straightness during reaming with sensoric tools. Prod. Eng. Res. Dev. 2020, 14, 535–544. [Google Scholar] [CrossRef]

- Bhattacharyya, O.; Jun, M.B.; Kapoor, S.G.; DeVor, R.E. The effects of process faults and misalignments on the cutting force system and hole quality in reaming. Int. J. Mach. Tools Manuf. 2006, 46, 1281–1290. [Google Scholar] [CrossRef]

- Kamath, R.C.; Bekinal, S.; Bhat, R.; Naik, N.; Kuttan, A. Dynamic Force Modelling and Experimental Analysis of Reaming. Eng. Sci. 2021, 15, 166–176. [Google Scholar] [CrossRef]

- Rakshith, M.C.; Kamath, R.C.; Vijay, G.S. Prediction of the Reaming Torque Using Artificial Neural Network and Random Forest Algorithm: Comparative Performance Analysis. Eng. Proc. 2023, 59, 97. [Google Scholar] [CrossRef]

- Voina, I.-D.; Sattel, S.; Contiu, G.; Faur, A.; Luca, B. Reamers cutting edge preparation for improvement the GGG 40 machining. MATEC Web Conf. 2018, 178, 01014. [Google Scholar] [CrossRef]

- MAPAL Fabrik für Präzisionswerkzeuge Dr. Kress KG. Mehrschneidige Reibahle. Deutsches Patent-und Markenamt DE102017208017B4, 21 February 2019. [Google Scholar]

- Kumar, A. Design and Analysis of Reaming Tool by Finite Element Modeling and Simulation. In Advances in Engineering Design, Lecture Notes in Mechanical Engineering; Joshi, P., Gupta, S.S., Shukla, A.K., Gautam, S.S., Eds.; Springer: Singapore, 2021; pp. 465–472. [Google Scholar] [CrossRef]

- Leveille, T.; Valiorgue, F.; Dumas, M.; Masciantonio, U.; Brosse, A.; Karaouni, H.; Rech, J. 3D numerical modelling of residual stresses induced by reaming. J. Manuf. Process. 2024, 114, 47–60. [Google Scholar] [CrossRef]

- Eckstein, M.; Breitkopf, G.; Huber, R.; Jäger, T. Spannfutter-Integriertes Kraftmesssystem. European Patent Office EP2103379B2, 16 November 2016. [Google Scholar]

- Schörghofer, P.; Pauker, F.; Leder, N.; Mangler, J.; Ramsauer, C.; Bleicher, F. Using sensory tool holder data for optimizing production processes. J. Mach. Eng. 2019, 19, 43–55. [Google Scholar] [CrossRef]

- Schuster, A.; Rentzsch, H.; Ihlenfeldt, S. Energy self-sufficient, multi-sensory tool holder for sensitive monitoring of milling processes. Procedia CIRP 2023, 117, 80–85. [Google Scholar] [CrossRef]

- Bleicher, F.; Schörghofer, P.; Habersohn, C. In-process control with a sensory tool holder to avoid chatter. J. Mach. Eng. 2018, 18, 16–27. [Google Scholar] [CrossRef]

- Sollapur, S.B.; Waghmare, P.M.; Patil, M.S.; Deshmukh, S.P. Design and Validation of XY Flexure Mechanism. J. Eng. Sci. Technol. 2021, 16, 1416–1425. [Google Scholar]

- Jagtap, S.P.; Deshmukh, B.B.; Pardeshi, S. Applications of compliant mechanism in today’s world—A review. J. Phys. Conf. Ser. 2021, 1969, 012013. [Google Scholar] [CrossRef]

- ISO 16610-31; Geometrical Product Specification (GPS)—Filtration—Part 31: Robust Profile Filters: Gaussian Regression Filters. International Organization for Standardization (ISO): Geneva, Switzerland, 2023. [CrossRef]

- ISO 13565-2; Geometrical Product Specification (GPS)—Surface texture—Part 2: Height characterization using the linear material ratio curve. German Institute for Standardisation: Berlin, Germany, 1998. [CrossRef]

- Kreiß, J.-P.; Neuhaus, G. Die Differenzengleichung für die Autokovarianzen. In Einführung in die Zeitreihenanalyse; Springer: Berlin/Heidelberg, Germany, 2006; pp. 128–133. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jäkel, T.; Unsin, S.; Müller, B.; Schirmeier, F. Cost-Effective Surface Quality Measurement and Advanced Data Analysis for Reamed Bores. J. Manuf. Mater. Process. 2025, 9, 99. https://doi.org/10.3390/jmmp9030099

Jäkel T, Unsin S, Müller B, Schirmeier F. Cost-Effective Surface Quality Measurement and Advanced Data Analysis for Reamed Bores. Journal of Manufacturing and Materials Processing. 2025; 9(3):99. https://doi.org/10.3390/jmmp9030099

Chicago/Turabian StyleJäkel, Thomas, Sebastian Unsin, Benedikt Müller, and Frank Schirmeier. 2025. "Cost-Effective Surface Quality Measurement and Advanced Data Analysis for Reamed Bores" Journal of Manufacturing and Materials Processing 9, no. 3: 99. https://doi.org/10.3390/jmmp9030099

APA StyleJäkel, T., Unsin, S., Müller, B., & Schirmeier, F. (2025). Cost-Effective Surface Quality Measurement and Advanced Data Analysis for Reamed Bores. Journal of Manufacturing and Materials Processing, 9(3), 99. https://doi.org/10.3390/jmmp9030099