1. Introduction

Additive manufacturing (AM) has emerged as a transformative manufacturing paradigm with the potential to revolutionize the production of metallic components. By enabling layer-by-layer fabrication directly from digital models, AM provides unique advantages such as design freedom, reduced material waste, shortened lead times, and the capability to produce customized, complex geometries that are often unattainable by conventional subtractive methods [

1,

2]. These benefits have stimulated rapid growth in research and industrial demonstrations, particularly in aerospace, energy, automotive, and biomedical sectors, where lightweight structures and application-specific designs are increasingly in demand [

3].

Despite these advancements, the integration of AM into production lines remains constrained by persistent challenges, foremost among them the surface quality of as-built parts. Compared with conventionally manufactured components, AM surfaces often exhibit roughness, waviness, and geometrical deviations due to complex thermo-fluid phenomena during deposition. These irregularities not only degrade the mechanical performance of components by reducing fatigue resistance, wear behavior, and dimensional tolerances, but also necessitate extensive post-processing to meet industrial standards. Post-processing operations such as machining, rolling, peening, or polishing are routinely required to correct as-built surfaces, offsetting AM’s potential savings in cost and lead time [

4,

5]. For example, Rauch et al. [

6] reported that the as-built roughness of WAAM aluminum alloys exceeded 30 µm Ra, necessitating high-energy finishing techniques such as waterjet machining or laser polishing to achieve functional tolerances. Bankong et al. [

7] similarly emphasized that inter-pass rolling and peening are often indispensable to mitigate waviness and residual stresses in WAAM components. The dependence on such finishing methods highlights the centrality of surface quality as a bottleneck for AM’s industrial deployment.

Within the spectrum of AM technologies, Wire Arc Additive Manufacturing (WAAM) has attracted significant interest because of its high deposition rate, scalability, and cost efficiency, making it especially suitable for producing large-scale metallic structures [

8]. WAAM adapts arc welding processes such as Gas Metal Arc Welding (GMAW) to additive contexts, and is inherently sensitive to process parameters including voltage, current, wire feed speed, travel speed, inter-pass temperature, and the condition of previously deposited layers. Even minor variations in these parameters can lead to pronounced changes in melt pool behavior, bead geometry, and surface finish. Among the most characteristic surface defects of WAAM are visible undulations or “humps,” which arise from unstable molten pool flow and solidification. These instabilities are strongly linked to thermocapillary convection (Marangoni effect), where spatial variations in surface tension drive uneven redistribution of the molten metal [

9]. Such waviness increases post-processing demands, reduces structural integrity, and propagates variability across successive layers [

10].

Early investigations into WAAM and related AM processes have confirmed that process parameters strongly influence bead morphology and surface integrity. Studies on stainless steel WAAM demonstrated that increasing wire feed speed enhances bead height and waviness, whereas higher travel speeds flatten beads but risk incomplete fusion [

11]. Similar findings have been reported in optimization studies on 316L stainless steel and other alloys, where parameter balancing was shown to reduce roughness and irregularity, though not eliminate them entirely [

12,

13]. Laser-based AM investigations also highlighted the role of power input and scanning speed in governing surface roughness, underscoring the broader principle that surface texture in additive processes is governed by melt pool dynamics [

14,

15]. Collectively, this body of work establishes that while process parameters decisively shape surface quality, the majority of studies emphasize general roughness or bead geometry, with surface waviness as a distinct descriptor receiving limited attention.

This gap is significant because waviness is not only a surface feature but also a functional defect that influences fatigue resistance, dimensional accuracy, and layer-to-layer bonding. Although researchers have proposed post-processing solutions to mitigate waviness, a systematic understanding of how key WAAM parameters affect its formation is lacking. Addressing this knowledge gap is critical for advancing WAAM from laboratory demonstrations to industrial application, where surface integrity directly governs cost-effectiveness and part performance.

The present study addresses this issue by systematically investigating the effects of voltage, wire feed speed, and travel speed on surface waviness in WAAM. A factorial experimental design was employed to isolate the statistical contributions of each parameter, and Analysis of Variance (ANOVA) and regression modeling were used to quantify their effects. By identifying parameter combinations that minimize waviness, this work contributes to both the scientific understanding of WAAM surface formation mechanisms and the practical optimization of process windows to reduce post-processing requirements and improve component performance.

2. Materials and Methods

The material used in this study was aluminum, selected for its widespread industrial application due to its lightweight nature and ability to retain mechanical strength post-processing.

The WAAM experiments were performed using a FANUC R1000iA articulated robot (FANUC America Corporation, Rochester Hills, MI, USA) integrated with a Lincoln PowerWave R450 welder and a Lincoln R420 auto-drive wire feeder (Lincoln Electric, Cleveland, OH, USA). Robotic motion and welding operations were programmed in Autodesk PowerMill, which enabled precise control of toolpaths and deposition parameters. Argon was employed as the shielding gas to ensure a stable arc and minimize oxidation during deposition. The build plate material consisted of a stainless steel plate with dimensions of 215 × 215 mm and a thickness of 10 mm, selected to provide adequate thermal mass and minimize substrate distortion under repeated thermal cycling. As the filler material, Hobart MaxalMig ER5356 aluminum alloy wire (Hobart Brothers LLC, Troy, OH, USA) with a diameter of 1.2 mm was used.

The choice of parameter levels was guided by preliminary trials and experimental evidence from earlier work in the same laboratory, and further validated against published WAAM optimization studies [

16]. Wire feed speed was varied between 175 and 200 in/min to capture the transition between underfill and excessive deposition regimes. Travel speed was selected within 3–5 mm/s to represent practical ranges where changes in heat input per unit length influence bead geometry without causing lack of fusion. Voltage was investigated in the range of 14–17.5 V, to have stable arc operation while avoiding excessive spatter or shallow penetration. These ranges provided a reliable basis for systematic analysis of surface waviness.

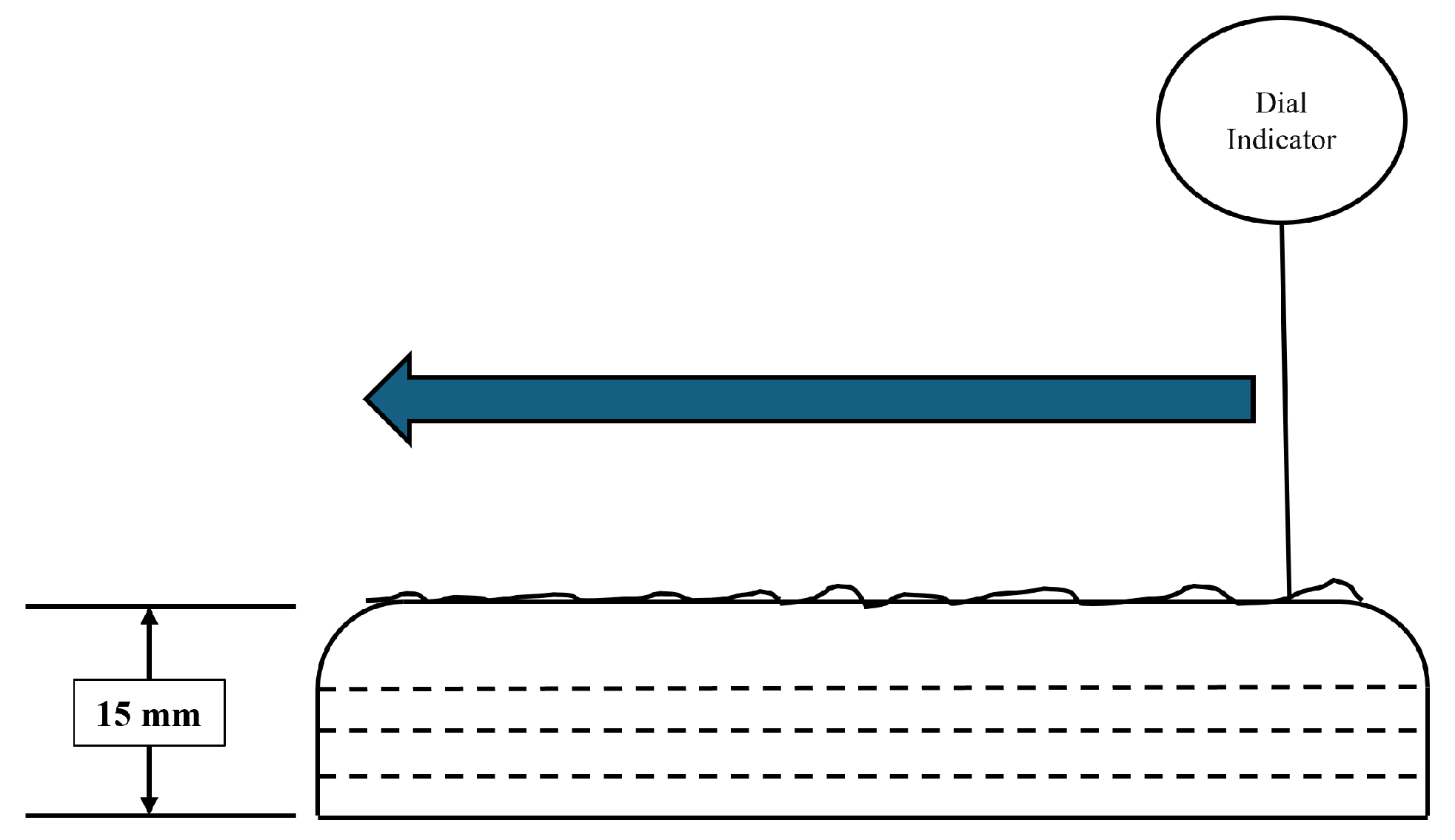

The deposition strategy was pre-programmed into the robot controller. The base layer was assigned a nominal thickness of 5 mm to promote metallurgical bonding with the substrate, followed by four subsequent layers at 2.5 mm each, yielding a total programmed wall height of 15 mm. This height was used as the reference baseline for waviness measurements. The build plate was clamped securely to the welding table to prevent distortion. Prior to the experimental runs, a calibration pass was conducted to confirm wall height, assess bead geometry, and validate correct toolpath execution. This ensured stable adhesion and reproducible deposition before the factorial experiments.

Following successful validation, five-layer walls were deposited under each experimental condition. Wire feed speed, travel speed, and voltage were kept constant within each run, while wire stick out was maintained at 19 mm. The robot executed the programmed deposition sequence using the settings outlined in

Table 1 and

Table 2. Each experimental condition was repeated five times in random order to ensure statistical reliability. A two-level factorial design was employed to evaluate the influence of process parameters on surface waviness as shown in

Table 3.

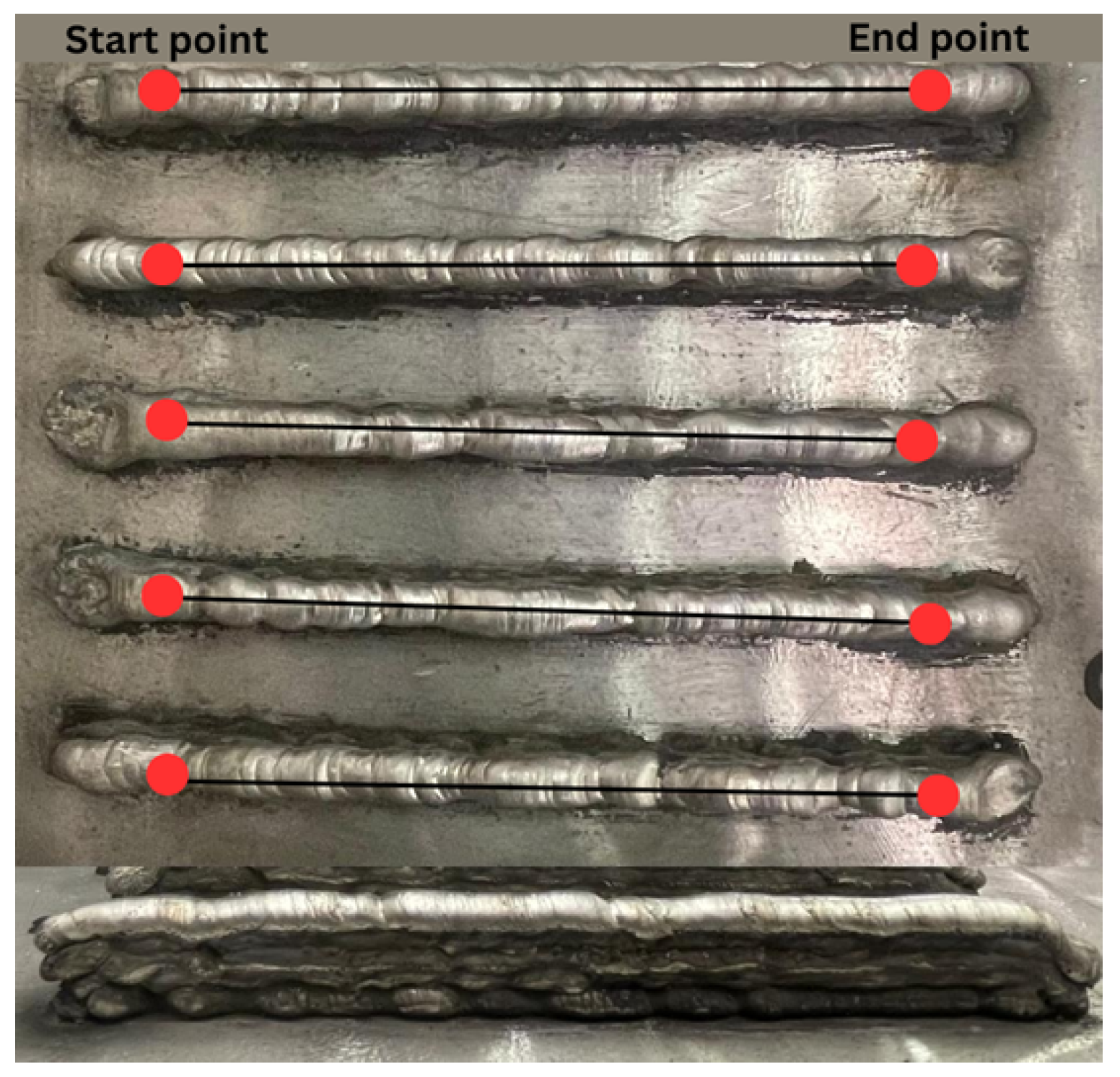

Surface waviness was measured using a dial drop indicator (INSIZE) mounted on a height gauge placed on a precision surface plate as shown in

Figure 1. The instrument was zeroed against the programmed reference height of 15 mm before use. Measurements were taken at fixed intervals along each bead, excluding the terminal regions to minimize edge effects, as shown in

Figure 2. For each plate, five beads were evaluated in this manner, and the results were averaged to obtain the mean surface waviness.

All statistical analyses and visualizations were performed in Python (version 3) which provided a comprehensive framework for data processing, regression modeling, and ANOVA calculations.

3. Results

A

factorial array was executed, with a total of 16 experiments. The mean surface waviness and standard deviation of each experiment are summarized in

Table 4. All waviness values were initially measured in millimeters (mm) and subsequently converted to micrometers (µm) for standardized reporting. Based on this convention, the overall mean waviness across all experiments was 104 µm, with a standard deviation of 14 µm.

3.1. Relationship Trends

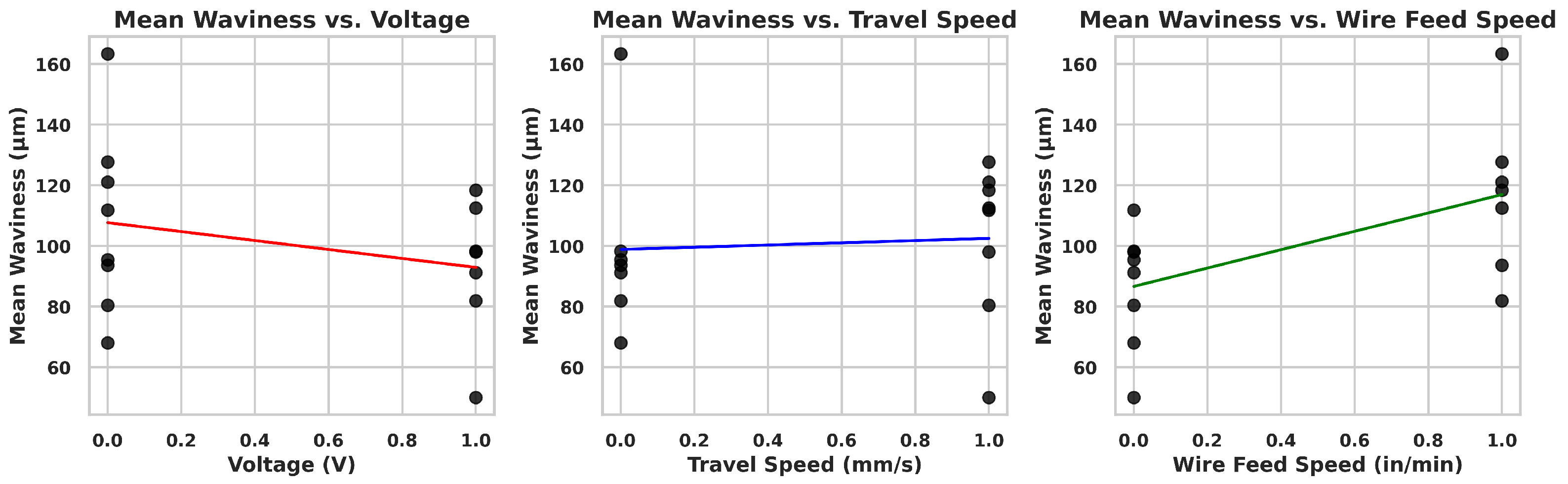

The relationship between process parameters and mean surface waviness is shown in

Figure 3. In the case of voltage, the regression line exhibits a slight negative slope, indicating that increasing voltage tends to reduce waviness. This behavior is consistent with previous reports that higher arc voltage stabilizes and elongates the arc, leading to more uniform heat distribution and smoother material deposition [

17].

In contrast, travel speed demonstrates only a marginal effect within the investigated range. The nearly horizontal trend line indicates that changes in travel speed produced minimal variation in surface waviness, suggesting that bead geometry and deposition dynamics were largely unaffected at the tested levels.

Wire feed speed, however, shows a distinct positive correlation with waviness. Higher feed rates increase the amount of material supplied per unit time, which can result in localized over-deposition and irregular bead buildup, thereby amplifying surface undulations.

Overall, among the three parameters, wire feed speed exerts the strongest influence on surface waviness, while voltage appears as a secondary factor and travel speed plays a negligible role. These trends suggest that minimizing waviness in WAAM requires maintaining relatively high voltage to stabilize the arc while carefully limiting wire feed speed to avoid excess deposition, thereby supporting smoother surface formation.

3.2. Analysis of Variance

The analysis of variance (ANOVA) partitions the total variation in surface waviness into contributions from each process parameter and residual error. The Sum of Squares (SS) quantifies the extent of variation in the response attributable to each factor, with larger values indicating a stronger contribution. The degrees of freedom (df) represent the number of independent comparisons, calculated as for each factor with k levels. Dividing SS by df yields the Mean Square (MS), which provides a normalized measure of variation. The F-statistic is computed as the ratio of a factor’s MS to the residual MS and indicates whether the factor effect is large relative to experimental noise. The p-value corresponds to the probability of observing such an F-ratio under the null hypothesis, thereby determining statistical significance. Finally, the Residual SS captures variation not explained by the model, arising from experimental error, uncontrolled variables, or inherent process fluctuations.

The ANOVA results in

Table 5 show that wire feed speed produced the highest F-statistic of 7.342 with a

p-value of 0.018 at

= 0.05, confirming it as the only statistically significant factor affecting surface waviness. Voltage yielded an F-statistic of 0.184 and a

p-value of 0.675. Although not statistically significant, voltage contributed more strongly than travel speed and aligns with the observed response trends, suggesting a secondary influence. Travel speed gave the lowest F-statistic of 0.119 with a

p-value of 0.735, indicating a negligible effect within the tested range. The residual variation was comparatively larger, reflecting the influence of unmeasured or uncontrolled factors such as arc stability or heat input fluctuations.

3.3. Analysis of Variance with Interactions

A factorial ANOVA (see

Table 6) was conducted to evaluate the main effects and interaction effects of the three input parameters, voltage, travel speed, and wire feed speed, on the surface waviness. This statistical method allowed for the assessment of whether the response variable was influenced not only by individual factors but also by their combined interactions.

The analysis revealed that no significant interaction effects were present among the factors. This suggests that the influence of each factor on surface waviness is independent of the others. In other words, the effect of one parameter on the waviness does not depend on the levels of the other parameter. The absence of interaction simplifies the interpretation of the results, allowing each factor’s impact to be considered in isolation.

This finding is consistent with the earlier observation from the main effects analysis, where wire feed speed emerged as the most significant parameter. The lack of interactions further reinforces that optimizing wire feed speed alone, irrespective of the specific voltage or travel speed setting, can result in noticeable improvements in surface finish.

3.4. Regression Analysis

A multiple linear regression was conducted to quantify the relationship between surface waviness Y and three process parameters: voltage (

), wire feed speed (

), and travel speed (

). Wire stick out was maintained constant at 19 mm and was therefore excluded from the model. The fitted model explained 0.389 of the variance in waviness, with an adjusted

of 0.236. At a significance level of 0.05, the overall regression test yielded

p = 0.105, indicating a modest but not statistically significant overall fit given the limited sample size. The estimated coefficients are provided in Equation (

1).

In this model, wire feed speed showed a positive association with waviness and was statistically significant with

p = 0.019, identifying it as the dominant predictor within the tested ranges. The positive coefficient indicates that increasing material feed increases bead build and raises waviness, consistent with deposition-rate physics in WAAM. Voltage had a small negative coefficient with

p = 0.675. Although not statistically significant, the negative coefficient points to a possible smoothing effect under higher arc energy, in line with trends reported in prior studies. Travel speed had a small negative coefficient with

p = 0.736, indicating a minimal effect under the present conditions. Taken together, these results are consistent with the ANOVA: wire feed speed governs waviness most strongly, voltage appears as a secondary influence, and travel speed contributes marginally.

To assess predictive accuracy, the model was evaluated at the chosen operating point used for validation. The prediction for waviness was 111 µm, while the measured value was 125 µm. The absolute difference was 14 µm, corresponding to an 11.2 percent difference computed using Equation (

2). This level of agreement is reasonable for a linear model in a thermal-deposition process and indicates that the model captures the dominant trend while leaving scope for refinement.

4. Discussion

Surface waviness is a critical factor in the quality of WAAM components, yet its dependence on process parameters has not been fully established, particularly for aluminum alloys. Previous studies have focused largely on bead geometry and deposition efficiency, while the mechanisms underlying surface morphology remain less understood. This study addressed that gap by isolating the effects of wire feed speed, voltage, and travel speed on surface waviness.

The results showed that wire feed speed was the only statistically significant predictor of surface waviness, emerging as the dominant control parameter. Voltage consistently appeared as the second-most influential factor, though not statistically significant within the tested window, while travel speed exerted no meaningful effect on waviness. Together, these findings establish a clear parameter hierarchy in aluminum WAAM: wire feed speed governs surface morphology, voltage provides secondary stabilization, and travel speed is comparatively negligible within narrow operating conditions.

4.1. Wire Feed Speed

The strong influence of wire feed speed is consistent with previous WAAM and GMAW studies. Remy et al. [

18] demonstrated that increasing wire feed speed directly increases bead height, width, and cross-sectional area, while Jorge et al. [

19] reported that it contributed the largest variance share in bead dimensions in ANOVA models. Roshan et al. [

20] showed that increasing wire feed speed transitions metal transfer from mixed modes to spray, narrows voltage and current probability distributions, and stabilizes the arc, while also increasing penetration and hardness through higher heat input and martensitic transformation. In terms of process behavior, beyond a critical deposition rate, the fluid flow and thermal diffusion of the melt pool become insufficient to maintain uniformity; thus, the localized overbuild forms and freezes into waviness. These findings reinforce the interpretation that wire feed speed governs both deposition supply and transfer stability, making it the primary lever for controlling surface morphology in WAAM. In addition to the nominal rate, the stability of wire feeding is also critical: even minor fluctuations in delivery can disturb arc length, alter current–voltage responses, and degrade weld consistency. Taken together, these results confirm that precise regulation of wire feed speed is central to minimizing surface waviness.

4.2. Voltage

Voltage, while secondary, remains important in process stability. Its influence is largely indirect, operating through arc length, heat input distribution, and droplet transfer dynamics. Wang et al. [

21] demonstrated that arc voltage fluctuations track pool oscillations and penetration states, while Zhao et al. [

22] showed that in aluminum WAAM, voltage modulates plasma distribution, current density, and droplet detachment frequency, with reduced fluctuations yielding smoother surfaces. Furthermore, studies have demonstrated that voltage fluctuations correlate directly with process instabilities such as porosity or burn-through [

23]. In practice, increases in wire feed speed typically require proportional increases in voltage to maintain arc stability and ensure consistent melting of the fed wire. Without this balance, deposition becomes irregular and surface waviness can worsen. Higher voltages also increase heat input and bead penetration, which can improve wetting and reduce surface irregularities, though excessive voltages may promote other defects. In the present study, the limited effect of voltage is best explained by the narrow operating range (14–17.5 V), which restricted variability. However, the negative slope observed suggests that higher voltages elongated and stabilized the arc, improving wetting and slightly reducing waviness. Voltage should therefore be viewed as a secondary stabilizer that enables deposition governed by wire feed speed to occur under consistent transfer conditions.

4.3. Travel Speed

Travel speed primarily governs bead formation through its effect on heat input per unit length. This relationship can be expressed as follows:

where

Q is the heat input per unit length,

P is the power, and

is the travel speed. Increasing travel speed reduces deposition per length and shortens melt pool lifetime, producing narrower beads [

24]. Rosli et al. [

25] reported that deposition remained stable at

, but increasing TS to

produced humping defects due to molten metal backflow, highlighting the narrow stability window in WAAM. Similarly, Nguyen et al. [

26] showed that travel speed strongly influenced grain size, underscoring its link to thermal history and microstructure. In the present study, however, travel speed was not statistically significant for surface waviness, most likely because the restricted range tested (4–

) kept

Q within a stable process envelope. Nevertheless, because travel speed directly shapes heat input and solidification behavior, its influence on grain refinement and microstructural evolution remains important and requires further investigation under broader parameter ranges.

From a process optimization perspective, minimizing waviness requires prioritizing precise feed regulation, complemented by voltage tuning for arc stability and penetration control, while adjusting travel speed primarily to balance heat input per unit length and deposition efficiency. Addressing these aspects will refine predictive capability and advance process control toward consistent, high-quality surfaces in WAAM.

5. Conclusions

This study systematically investigated the influence of key process parameters such as voltage, travel speed, and wire feed speed on surface waviness in WAAM. Through factorial experiments and statistical analysis, wire feed speed was identified as the dominant factor contributing to increased waviness due to excess material deposition, while voltage showed a secondary stabilizing effect and travel speed exerted only a minor influence within the tested range. These results highlight the importance of carefully balancing deposition rate and arc stability to minimize surface irregularities and thereby reduce post-processing requirements.

It should be noted that the present work was limited to surface waviness characterization. Future studies should extend the analysis to account for external disturbances such as arc instability, shielding gas variations, and environmental fluctuations, which may alter melt pool behavior. Additionally, the accumulation of heat during multi-layer deposition and variations in inter-pass temperature warrant detailed investigation, as these thermal effects are likely to intensify surface undulations. Understanding how increasing heat input influences process stability could enable adaptive parameter control strategies, allowing voltage, wire feed speed, and travel speed to be dynamically adjusted in real time. Such approaches would not only optimize surface finish but also further reduce the reliance on post-processing, thereby advancing WAAM toward broader industrial adoption.

Author Contributions

S.M.S.: Conceptualizing, Investigation, Software, Validation, Investigation, Data curation, Visualization, Writing—original draft; A.F.: Conceptualizing, Methodology, Resources, Review and editing, Supervision; N.V.H.: Conceptualizing, Methodology, Resources, Supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors would like to express sincere gratitude to the Department of Manufacturing and Mechanical Engineering Technology at Michigan Technological University for its academic and infrastructural support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Armstrong, M.; Mehrabi, H.; Naveed, N. An overview of modern metal additive manufacturing technology. J. Manuf. Process. 2022, 84, 1001–1029. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021; Volume 17. [Google Scholar]

- Stavropoulos, P.; Foteinopoulos, P.; Papacharalampopoulos, A.; Bikas, H. Addressing the challenges for the industrial application of additive manufacturing: Towards a hybrid solution. Int. J. Lightweight Mater. Manuf. 2018, 1, 157–168. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Rauch, M.; Hascoet, J.Y. A comparison of post-processing techniques for Additive Manufacturing components. Procedia CIRP 2022, 108, 442–447. [Google Scholar] [CrossRef]

- Bankong, B.; Abioye, T.; Olugbade, T.; Zuhailawati, H.; Gbadeyan, O.; Ogedengbe, T. Review of post-processing methods for high-quality wire arc additive manufacturing. Mater. Sci. Technol. 2023, 39, 129–146. [Google Scholar] [CrossRef]

- Dinovitzer, M.; Chen, X.; Laliberte, J.; Huang, X.; Frei, H. Effect of wire and arc additive manufacturing (WAAM) process parameters on bead geometry and microstructure. Addit. Manuf. 2019, 26, 138–146. [Google Scholar] [CrossRef]

- Nguyen, T.C.; Weckman, D.C.; Johnson, D.A.; Kerr, H.W. The humping phenomenon during high speed gas metal arc welding. Sci. Technol. Weld. Join. 2005, 10, 447–459. [Google Scholar] [CrossRef]

- Cunningham, C.; Wikshåland, S.; Xu, F.; Kemakolam, N.; Shokrani, A.; Dhokia, V.; Newman, S. Cost Modelling and Sensitivity Analysis of Wire and Arc Additive Manufacturing. Procedia Manuf. 2017, 11, 650–657. [Google Scholar] [CrossRef]

- Zmarzły, P.; Gogolewski, D.; Kozior, T. Assessment of surface waviness of casting patterns made using 3D printing technologies. Bull. Pol. Acad. Sci. Tech. Sci. 2023, 71, e144585. [Google Scholar] [CrossRef]

- Le, V.T.; Doan, Q.T.; Mai, D.S.; Bui, M.C.; Tran, H.S.; Van Tran, X.; Nguyen, V.A. Prediction and optimization of processing parameters in wire and arc-based additively manufacturing of 316L stainless steel. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 394. [Google Scholar] [CrossRef]

- Kozior, T.; Bochnia, J.; Zmarzły, P.; Gogolewski, D.; Mathia, T.G. Waviness of freeform surface characterizations from austenitic stainless steel (316L) manufactured by 3D printing-selective laser melting (SLM) technology. Materials 2020, 13, 4372. [Google Scholar] [CrossRef]

- Garg, A.; Lam, J.S.L.; Savalani, M.M. Laser power based surface characteristics models for 3-D printing process. J. Intell. Manuf. 2018, 29, 1191–1202. [Google Scholar] [CrossRef]

- Hajjaji, I.; Khalifa, A.B.; Ftoutou, E.; Said, M.B.; Trigui, M. Experimental investigations on Wall Geometry and Waviness. In Proceedings of the 9th Scientific and Technical Days in Mechanics and Materials: Innovative Materials and Processes for Industrial and Biomedical Applications (JSTMM 2024), MATEC Web of Conferences, EDP Sciences, Hammamet, Tunisia, 20–22 December 2024; Volume 414, p. 01005. [Google Scholar]

- Hendrickson, N.; Sotubadi, S.V.; Nguyen, V. Improving the Efficiency of WAAM-Based Hybrid Manufacturing Through Selective In-Situ Machining Based on Height Error Prediction. In Proceedings of the ASME 2024 19th International Manufacturing Science and Engineering Conference, Additive Manufacturing, Advanced Materials Manufacturing, Biomanufacturing, Life Cycle Engineering, Knoxville, TN, USA, 17–21 June 2024; Volume 1. Available online: https://asmedigitalcollection.asme.org/MSEC/proceedings-pdf/MSEC2024/88100/V001T01A028/7367476/v001t01a028-msec2024-124647.pdf (accessed on 15 November 2024). [CrossRef]

- Diao, Z.; Yang, F.; Chen, L.; Wang, R.; Zhang, Y.; Sun, J.; Wu, Y.; Rong, M. Effects of deposition height stability of CuCrZr alloy based on arc voltage sensing: Influence of materials and energy saving on wire arc additive manufacturing. J. Clean. Prod. 2023, 425, 138665. [Google Scholar] [CrossRef]

- Remy, A.; Nwankpa, U.V.; Rauch, M.; Hascoët, J.Y.; Ruckert, G. Impact of a variation in Wire Feed Speed on deposits from the wire arc additive manufacturing (WAAM). J. Mach. Eng. 2024, 24, 117–128. [Google Scholar] [CrossRef]

- Jorge, V.L.; Scotti, F.M.; Reis, R.P.; Scotti, A. The potential of wire feed pulsation to influence factors that govern weld penetration in GMA welding. Int. J. Adv. Manuf. Technol. 2020, 110, 2685–2701. [Google Scholar] [CrossRef]

- Roshan, R.; Kumar Naik, A.; Kumar Saxena, K.; Arora, K.S.; Shajan, N.; Msomi, V.; Mehdi, H. Effect of welding speed and wire feed rate on arc characteristics, weld bead and microstructure in standard and pulsed gas metal arc welding. J. Adhes. Sci. Technol. 2023, 37, 3297–3314. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Z.; Hu, S.; Bai, P.; Lu, T.; Cao, Y. Weld pool surface fluctuations sensing in pulsed GMAW. Weld J. 2018, 97, 327S–337S. [Google Scholar]

- Zhao, W.; Tashiro, S.; Murphy, A.B.; Tanaka, M.; Liu, X.; Wei, Y. Deepening the understanding of arc characteristics and metal properties in GMAW-based WAAM with wire retraction via a multi-physics model. J. Manuf. Process. 2023, 97, 260–274. [Google Scholar] [CrossRef]

- Sumesh, A.; Rameshkumar, K.; Raja, A.; Mohandas, K.; Santhakumari, A.; Shyambabu, R. Establishing correlation between current and voltage signatures of the arc and weld defects in GMAW process. Arab. J. Sci. Eng. 2017, 42, 4649–4665. [Google Scholar] [CrossRef]

- Vora, J.; Parikh, N.; Chaudhari, R.; Patel, V.K.; Paramar, H.; Pimenov, D.Y.; Giasin, K. Optimization of bead morphology for GMAW-based wire-arc additive manufacturing of 2.25 Cr-1.0 Mo steel using metal-cored wires. Appl. Sci. 2022, 12, 5060. [Google Scholar] [CrossRef]

- Rosli, N.A.; Alkahari, M.R.; Ramli, F.R.; Sudin, M.N.; Maidin, S. Influence of process parameters in wire and arc additive manufacturing (WAAM) process. J. Mech. Eng. JMechE 2020, 17, 69–78. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Minh, P.S.; Uyen, T.M.T.; Do, T.T.; Ngoc, H.V.T.; Le, M.T.; Tien Nguyen, V.T. WAAM technique: Process parameters affecting the mechanical properties and microstructures of low-carbon steel. Metals 2023, 13, 873. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).