Improved Machinability of Pockets in a Liquid-Silicon-Infiltrated Silicon Carbide Composite Using Ultrasonic Assistance

Abstract

1. Introduction

2. Materials and Methods

2.1. Silicon Carbide Composite Material and Grinding Tool

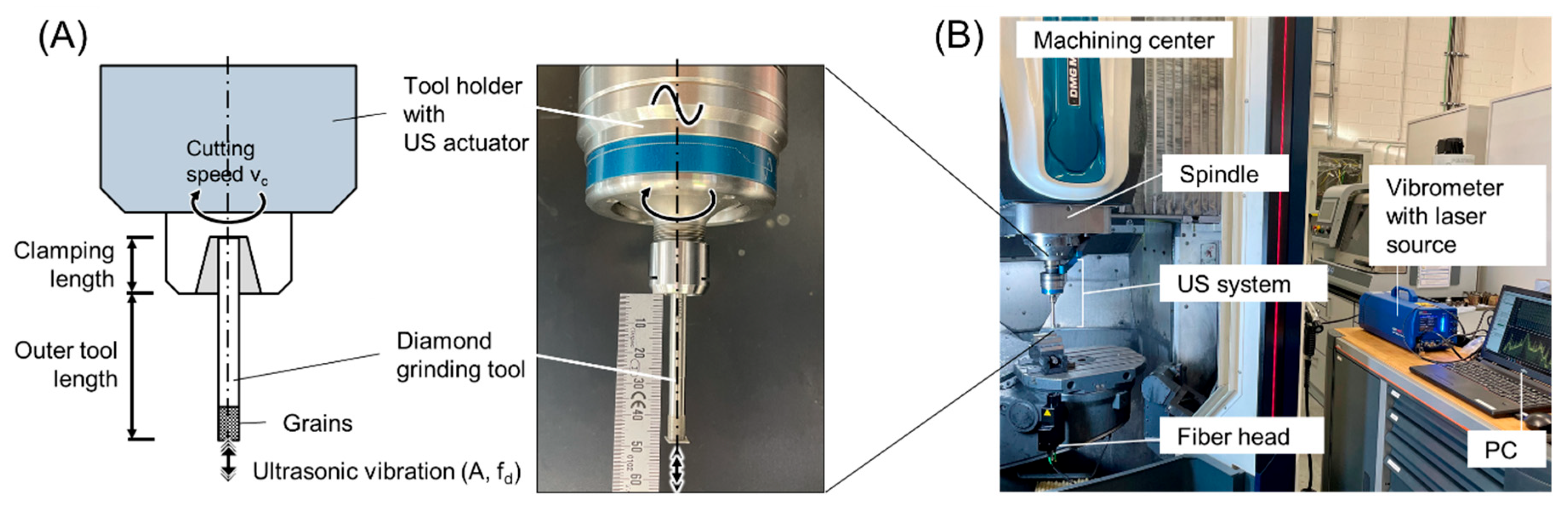

2.2. Ultrasonic Amplitude Measurement

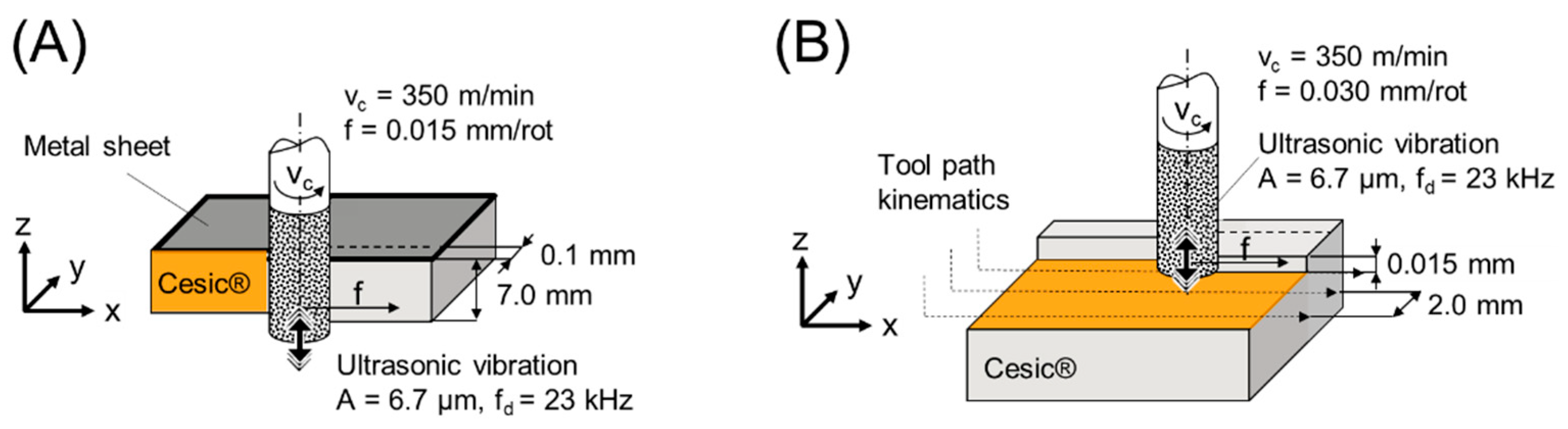

2.3. Machining Processes

2.4. Process and Workpiece Characterization

3. Results and Discussion

3.1. Dependence of Ultrasonic Amplitude on Excitation Frequency

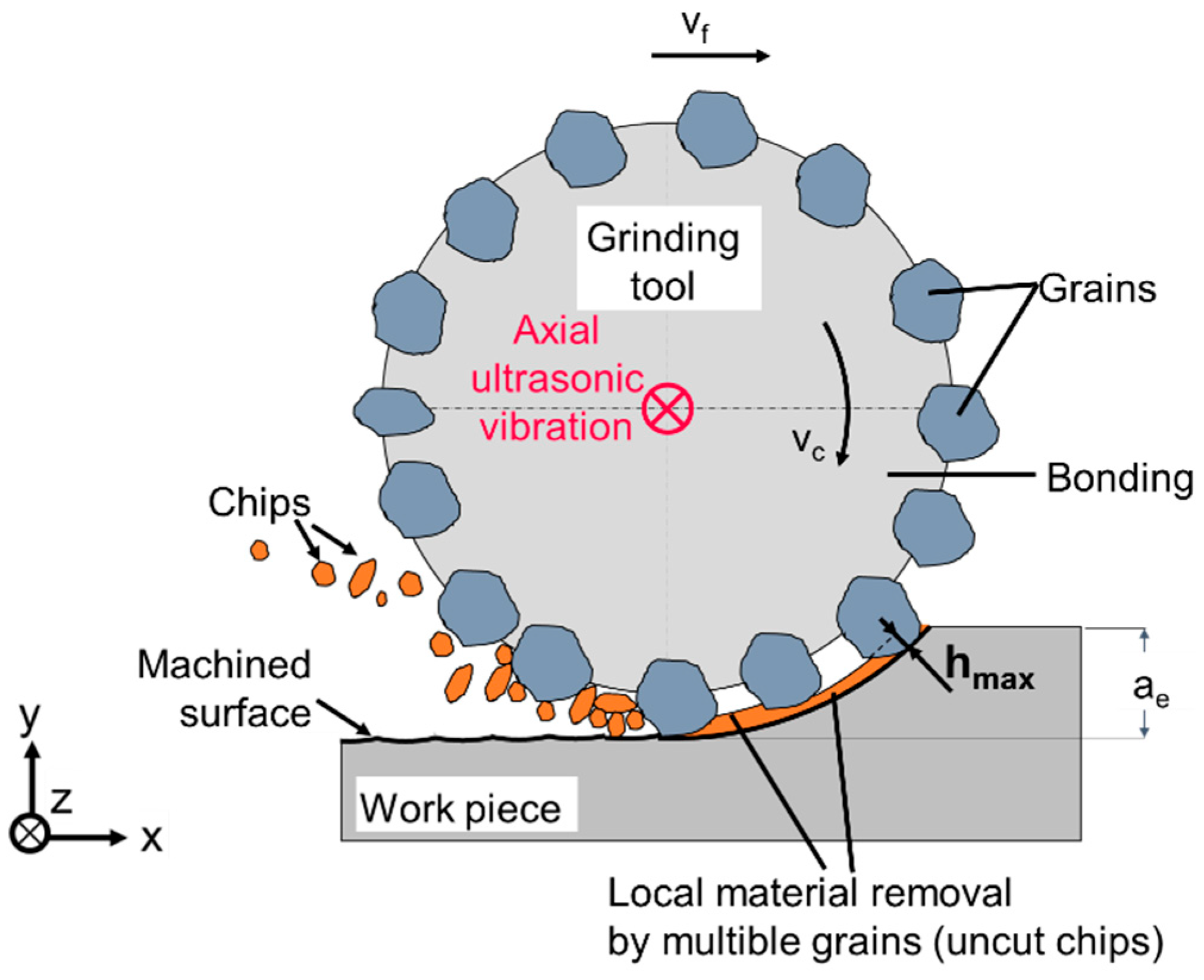

3.2. Principle of Material Removal and Verification of Ultrasonic Amplitude During Machining

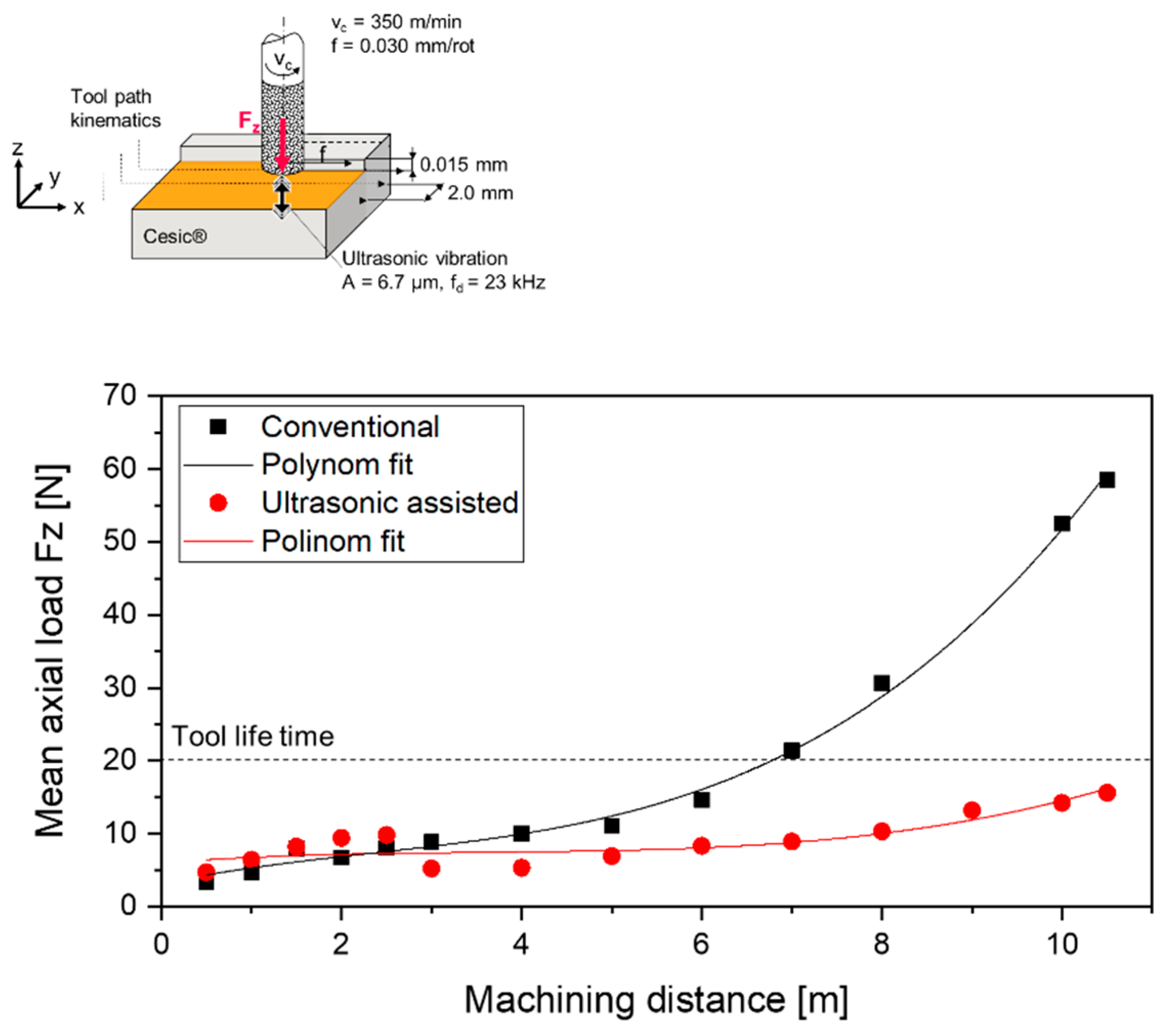

3.3. Influence of Ultrasonic Assistance on Grinding Load During Surface Grinding

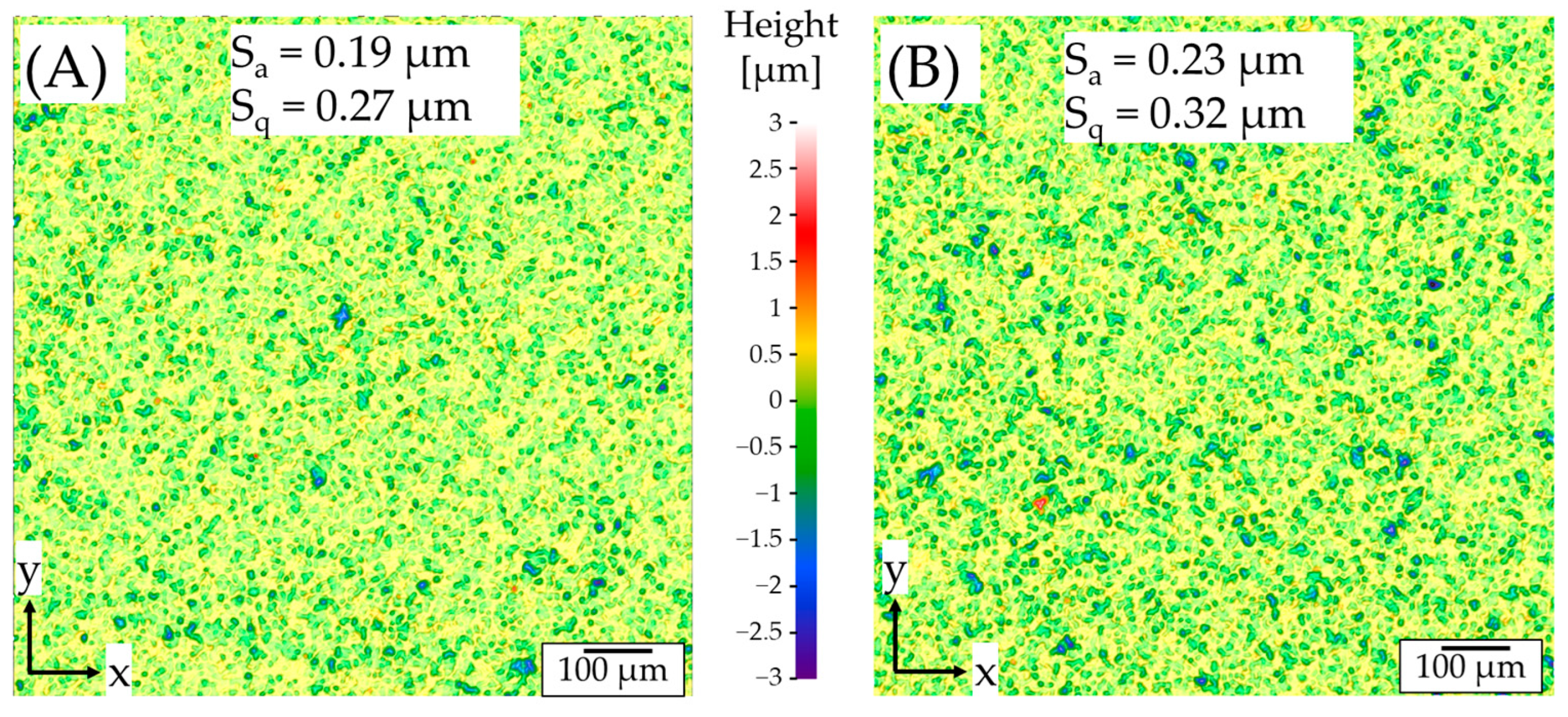

3.4. Influence of Ultrasonic Assistance on Surface Roughness of Pocket Machining

3.5. Influence of Ultrasonic Assistance on Cutting Tool Wear

4. Conclusions

- Amplitude Behavior: The magnitude of the ultrasonic amplitude varied with both the applied frequency and the tool’s protrusion length from the tool holder. Amplitude maxima had to be determined experimentally by identifying the natural frequencies of the complete tooling system (grinding tool, collet chuck, and tool holder). An ultrasonic amplitude of 6.7 µm was obtained for an excitation frequency of 23.0 kHz and an outer tool length of 40 mm.

- Verification of US Vibration: The presence of ultrasonic vibration during the contour machining of Cesic® was confirmed using a fine metal sheet, demonstrating effective transmission of ultrasonic energy.

- Grinding Forces and Tool Life: After a machining distance of 10.5 m, the mean axial load (Fz) in conventional grinding (58.5 N) reached nearly four times the value measured in ultrasonic-assisted grinding (15.6 N), respectively. Whereas during conventional grinding the grinding tool end-face was clogged by detached ceramic particles from the workpiece, ultrasonic vibration exhibited a 75% higher tool life, due to the continuous cooling effect and the improved removal of the ceramic chips out of the tool–workpiece contact zone.

- Surface Quality and Material Removal Rate: The ultrasonic-assisted grinding of pockets in Cesic® samples at a material removal rate of 16.7 mm3/min achieved an arithmetic mean roughness value of Sa = 0.23 µm; significantly lower than the more-than-1.05 µm obtained by EDM in previous studies on similar SiSiC materials and with lower material removal rates (0.01–3.6 mm3/min) [7].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CG | Conventional grinding |

| EDM | Electrical Discharge Machining |

| UAG | Ultrasonic Assisted Grinding |

| US | Ultrasonic |

References

- Krödel, M.; Ozaki, T. Dynamic performance of HB-Cesic® under severe Conditions and its applications. In Proceedings of the 18th International Conference of Composite Materials, Jeju Island, Republic of Korea, 21–26 August 2011. [Google Scholar]

- Krenkel, W. Entwicklung eines Kostengünstigen Verfahrens zur Herstellung von Bauteilen aus Keramischen Verbundwerkstoffen. Ph.D. Thesis, Deutsches Zentrum für Luft- und Raumfahrt, Cologne, Germany, 2000. [Google Scholar]

- Krödel, M.; Ku, J.; Langton, J.B.; Schindler, R.H.; Wahl, B. The rigid and thermally stable all-ceramic LSST camera: Focal plane from design to assembly. In Ground-Based and Airborne Instrumentation for Astronomy VII; SPIE: Bellingham, WA, USA, 2018. [Google Scholar]

- Krödel, M.R.; Devilliers, C. SPIRALE: The first all-Cesic® telescopes orbiting earth. In Optical Materials and Structures Technologies IV; SPIE: Bellingham, WA, USA, 2009; p. 74250F. [Google Scholar]

- Krödel, M.; Ozaki, T.; Kume, M.; Yui, Y.Y.; Imai, H.; Katayama, H.; Tange, Y.; Nakagawa, T. Manufacturing and performance test of a 800 mm space optic. In Optical Manufacturing and Testing VIII; SPIE: Bellingham, WA, USA, 2009; Volume 7426, p. 74260K. [Google Scholar]

- Krödel, M.; Komadina, J.; Perrin, L.; Berill, M. MTG star tracker assembly bracket: A successful story of fabrication story of light-weighted structures. In Material Technologies and Applications to Optics, Structures, Components, and Sub-Systems IV; SPIE: Bellingham, WA, USA, 2019. [Google Scholar]

- Kliuev, M.; Maradia, U.; Boccadoro, M.; Perez, R.; Stirnimann, J.; Wegener, K. Experimental Study of EDM-Drilling and Shaping of SiSiC and SiC. Procedia CIRP 2016, 42, 191–196. [Google Scholar] [CrossRef]

- Clijsters, S.; Liu, K.; Reynaerts, D.; Lauwers, B. EDM technology and strategy development for the manufacturing of complex parts in SiSiC. J. Mater. Process. Technol. 2010, 210, 631–641. [Google Scholar] [CrossRef]

- Yin, L.; Vancoille, E.; Lee, L.; Huang, H.; Ramesh, K.; Liu, X. High-quality grinding of polycrystalline silicon carbide spherical surfaces. Wear 2004, 256, 197–207. [Google Scholar] [CrossRef]

- Chen, S.; Cheung, C.; Zhao, C.; Zhang, F. Simulated and measured surface roughness in high-speed grinding of silicon carbide wafers. Int. J. Adv. Manuf. Technol. 2017, 91, 719–730. [Google Scholar] [CrossRef]

- Horvath, N.; Honeycutt, A.; Davies, M.A. Grinding of additively manufactured silicon carbide surfaces for optical applications. CIRP Ann. 2020, 69, 509–512. [Google Scholar] [CrossRef]

- Beaucamp, A.; Namba, Y.; Combrinck, H.; Charlton, P.; Freeman, R. Shape adaptive grinding of CVD silicon carbide. CIRP Ann. 2014, 63, 317–320. [Google Scholar] [CrossRef]

- Agarwal, S.; Rao, P.V. Grinding characteristics, material removal and damage formation mechanisms in high removal rate grinding of silicon carbide. Int. J. Mach. Tools Manuf. 2010, 50, 1077–1087. [Google Scholar] [CrossRef]

- Harrer, W.; Danzer, R.; Rendtel, A. Influence of the surface condition on the biaxial strength of a commercial silicon carbide. J. Eur. Ceram. Soc. 2016, 36, 3895–3900. [Google Scholar] [CrossRef]

- Uhlmann, E.G. Tiefschleifen Hochfester Keramischer Werkstoffe; Hanser: München, Germany, 1994. [Google Scholar]

- Teichert, C.; MacKay, J.F.; Savage, D.E.; Lagally, M.G.; Brohl, M.; Wagner, P. Comparison of surface roughness of polished silicon wafers measured by light scattering topography, soft-x-ray scattering, and atomic-force microscopy. Appl. Phys. Lett. 1995, 66, 2346–2348. [Google Scholar] [CrossRef]

- Zhao, Y.; Chang, L. A micro-contact and wear model for chemical–mechanical polishing of silicon wafers. Wear 2002, 252, 220–226. [Google Scholar]

- Ozturk, S.; Aydin, L.; Kucukdogan, N.; Celik, E. Optimization of lapping processes of silicon wafer for photovoltaic applications. Sol. Energy 2018, 164, 1–11. [Google Scholar] [CrossRef]

- Young, H.T.; Liao, H.T.; Huang, H.Y. Surface integrity of silicon wafers in ultra precision machining. Int. J. Adv. Manuf. Technol. 2006, 29, 372–378. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.; Reuben, R.L. Wear mechanism of diamond tools against single crystal silicon in single point diamond turning process. Tribol. Int. 2013, 57, 272–281. [Google Scholar] [CrossRef]

- Leung, T.; Lee, W.; Lu, X. Diamond turning of silicon substrates in ductile-regime. J. Mater. Process. Technol. 1998, 73, 42–48. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, Z.; Kuriyagawa, T. Mechanism for material removal in diamond turning of reaction-bonded silicon carbide. Int. J. Mach. Tools Manuf. 2009, 49, 366–374. [Google Scholar] [CrossRef]

- Chen, Y.; Su, H.; Qian, N.; He, J.; Gu, J.; Xu, J.; Ding, K. Ultrasonic vibration-assisted grinding of silicon carbide ceramics based on actual amplitude measurement: Grinding force and surface quality. Ceram. Int. 2021, 47, 15433–15441. [Google Scholar] [CrossRef]

- Churi, N.J.; Pei, Z.J.; Shorter, D.C.; Treadwell, C. Rotary ultrasonic machining of silicon carbide: Designed experiments. Int. J. Manuf. Technol. Manag. 2007, 12, 284–298. [Google Scholar] [CrossRef]

- Ding, K.; Fu, Y.; Su, H.; Cui, F.; Li, Q.; Lei, W.; Xu, H. Study on surface/subsurface breakage in ultrasonic assisted grinding of C/SiC composites. Int. J. Adv. Manuf. Technol. 2017, 91, 3095–3105. [Google Scholar] [CrossRef]

- Uhlmann, E.; Daus, N.-A. Ultraschallunterstütztes Schleifen–Einsatzvorteile Durch ein Innovatives Schleifverfahren, Universitätsbibliothek u. Technische Informationsbibliothek; Institut für Werkzeugmaschinen und Fabrikbetrieb: Berlin, Germany, 2001. [Google Scholar]

- Rösiger, A. Einfluss der Schleif- und Fräsbearbeitung auf die Oberflächenqualität und die Mechanischen Eigenschaften von Kohlenstofffaserverstärktem Siliziumcarbid. Ph.D. Thesis, Cuvillier Verlag, Göttingen, Germany, 2022. [Google Scholar]

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- Malkin, S. Grinding Technology: Theory and Applications of Machining with Abrasives, 2nd ed.; Industrial Press: New York, NY, USA, 2008. [Google Scholar]

- Chen, J.; An, Q.; Ming, W.; Chen, M. Investigation on machined surface quality in ultrasonic-assisted grinding of Cf/SiC composites based on fracture mechanism of carbon fibers. Int. J. Adv. Manuf. Technol. 2020, 109, 1583–1599. [Google Scholar] [CrossRef]

- Rösiger, A.; Schukraft, J.; Goller, R.; Weidenmann, K.A. Investigation of the mechanical machinability of an interpenetrating metal-ceramic composite using diamond grinding. Int. J. Adv. Manuf. Technol. 2025, 136, 5625–5639. [Google Scholar] [CrossRef]

- Wdowik, R.; Porzycki, J.; Magdziak, M. Measurements of Surface Texture Parameters After Ultrasonic Assisted and Conventional Grinding of ZrO2 Based Ceramic Material Characterized by Different States of Sintering. Procedia CIRP 2017, 62, 293–298. [Google Scholar] [CrossRef]

- Ding, K.; Fu, Y.; Su, H.; Gong, X.; Wu, K. Wear of diamond grinding wheel in ultrasonic vibration-assisted grinding of silicon carbide. Int. J. Adv. Manuf. Technol. 2014, 71, 1929–1938. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Density [g/cm3] | 2.97 |

| Bending strength [MPa] | 320 |

| Young’s modulus [GPa] | 350 |

| Fracture toughness Kic [MPa·m1/2] | 3.7 |

| Poisson’s ratio | 0.18 |

| Coefficient of thermal expansion 313 K-293 K [10−6/K] | 2.3 |

| Thermal conductivity RT [W/(m·K)] | 125 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rösiger, A.; León-Pérez, P.; Macken, J.; Goller, R. Improved Machinability of Pockets in a Liquid-Silicon-Infiltrated Silicon Carbide Composite Using Ultrasonic Assistance. J. Manuf. Mater. Process. 2025, 9, 346. https://doi.org/10.3390/jmmp9110346

Rösiger A, León-Pérez P, Macken J, Goller R. Improved Machinability of Pockets in a Liquid-Silicon-Infiltrated Silicon Carbide Composite Using Ultrasonic Assistance. Journal of Manufacturing and Materials Processing. 2025; 9(11):346. https://doi.org/10.3390/jmmp9110346

Chicago/Turabian StyleRösiger, Achim, Patricia León-Pérez, Joshua Macken, and Ralf Goller. 2025. "Improved Machinability of Pockets in a Liquid-Silicon-Infiltrated Silicon Carbide Composite Using Ultrasonic Assistance" Journal of Manufacturing and Materials Processing 9, no. 11: 346. https://doi.org/10.3390/jmmp9110346

APA StyleRösiger, A., León-Pérez, P., Macken, J., & Goller, R. (2025). Improved Machinability of Pockets in a Liquid-Silicon-Infiltrated Silicon Carbide Composite Using Ultrasonic Assistance. Journal of Manufacturing and Materials Processing, 9(11), 346. https://doi.org/10.3390/jmmp9110346