Adaptation of Conventional Toolpath-Generation Software for Use in Curved-Layer Fused Deposition Modeling

Abstract

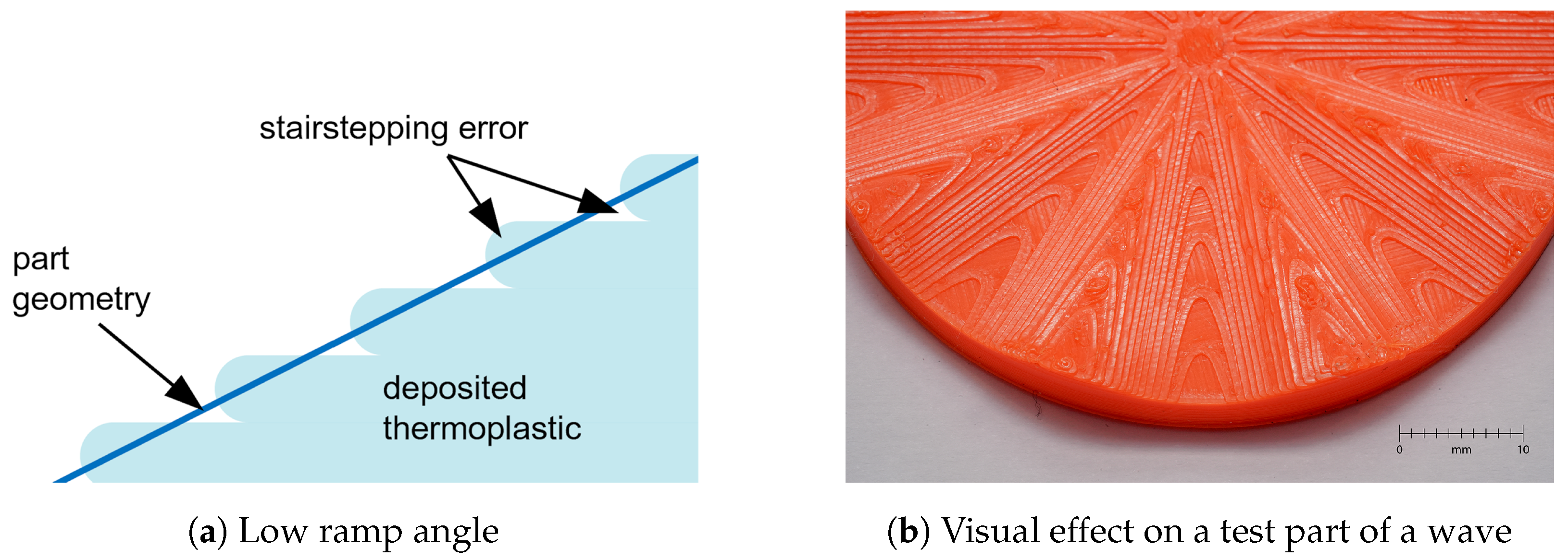

1. Introduction

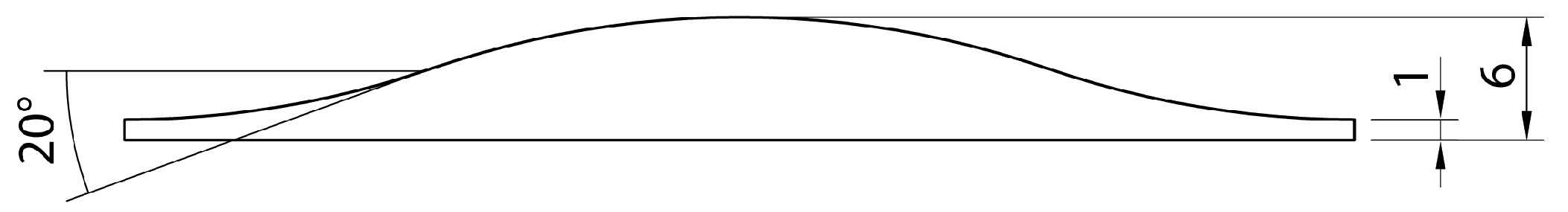

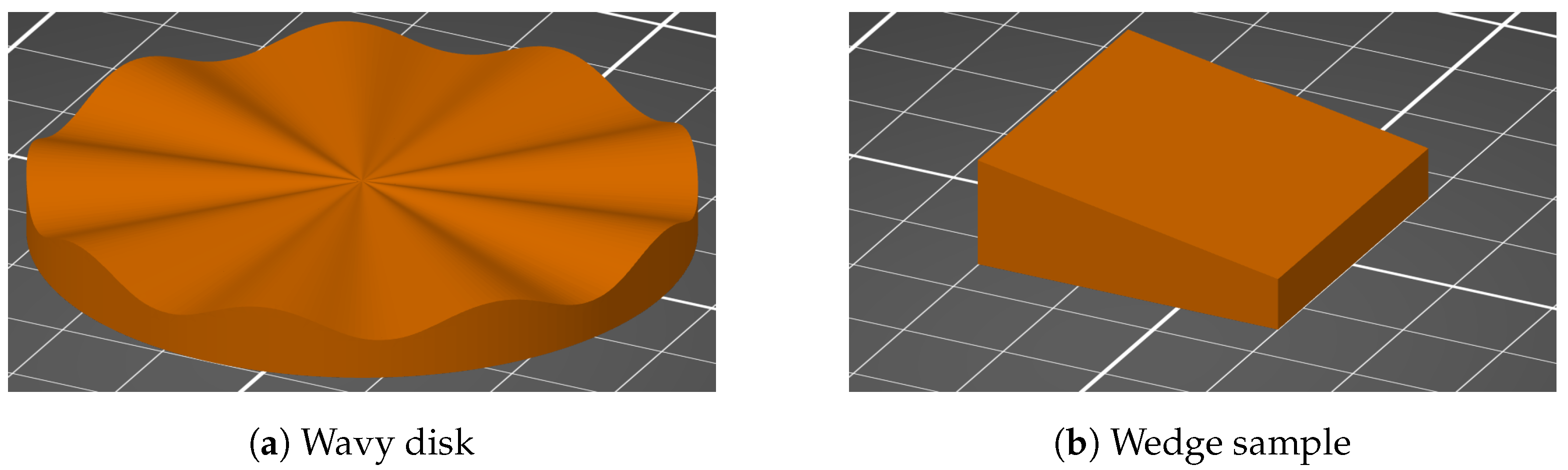

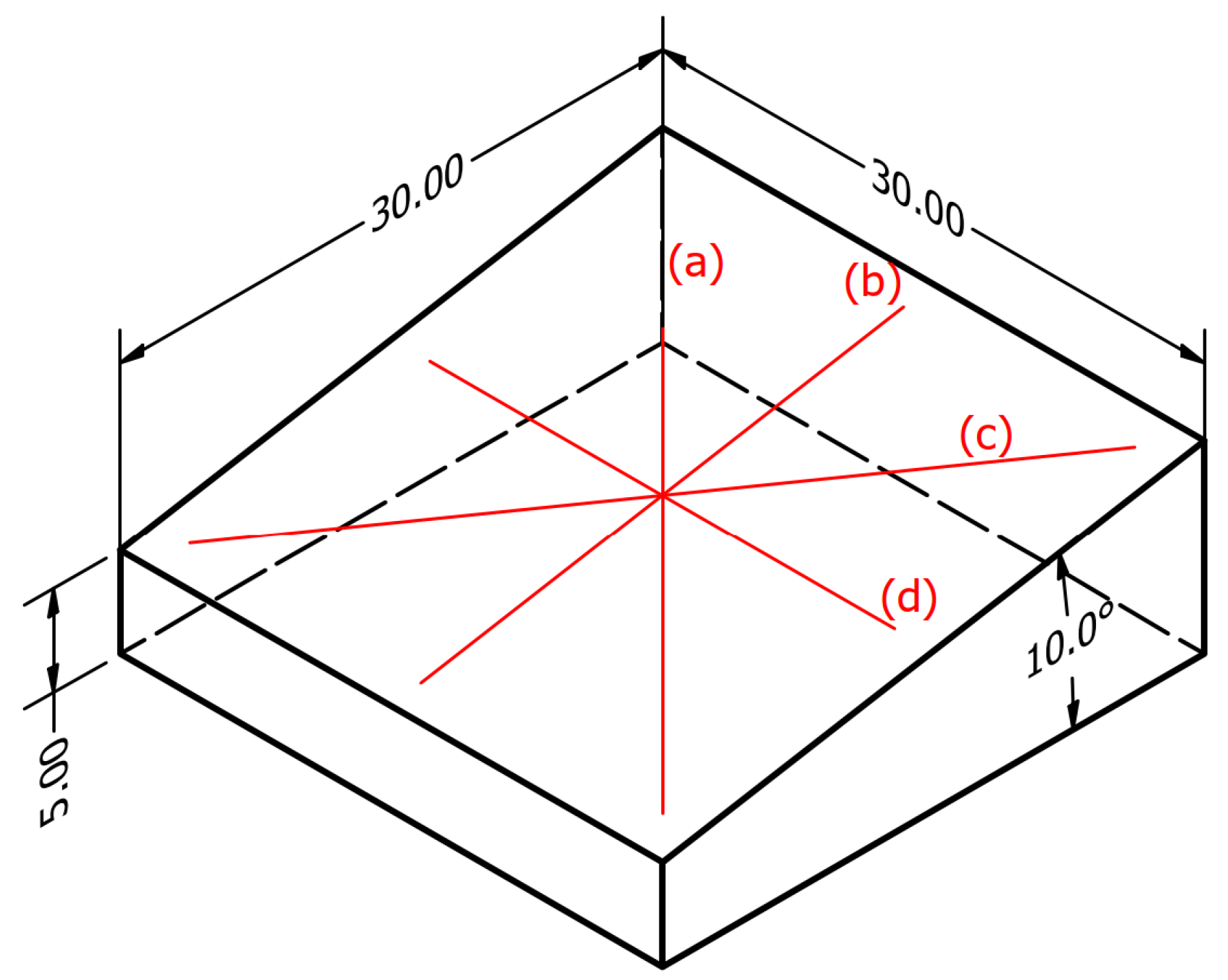

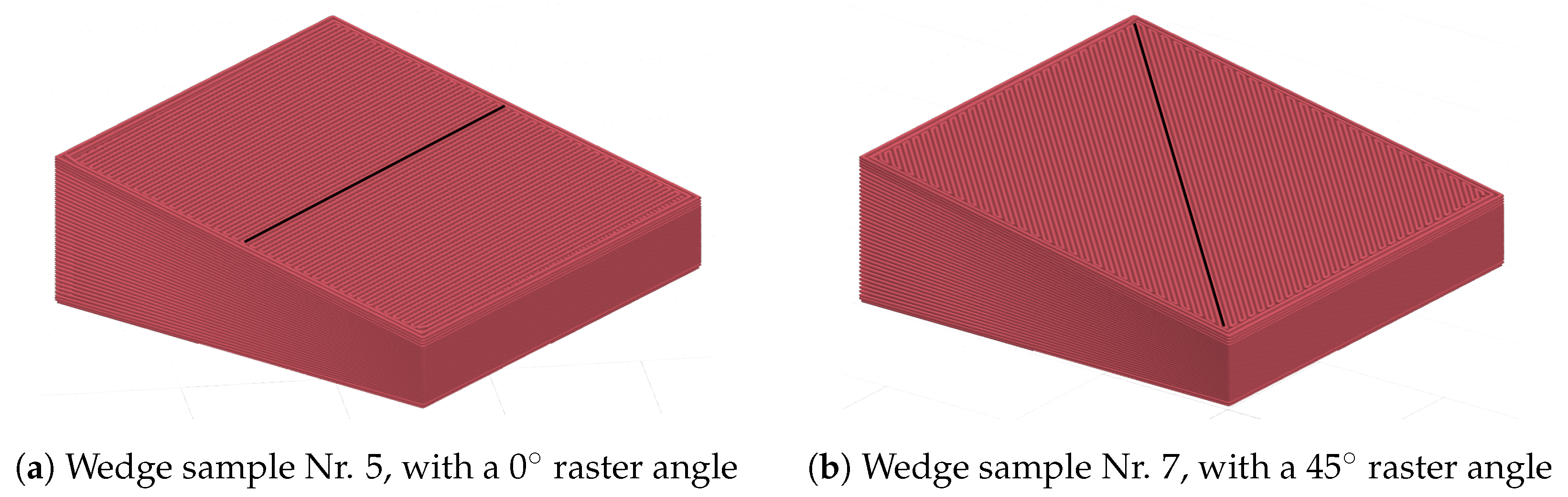

2. Methods

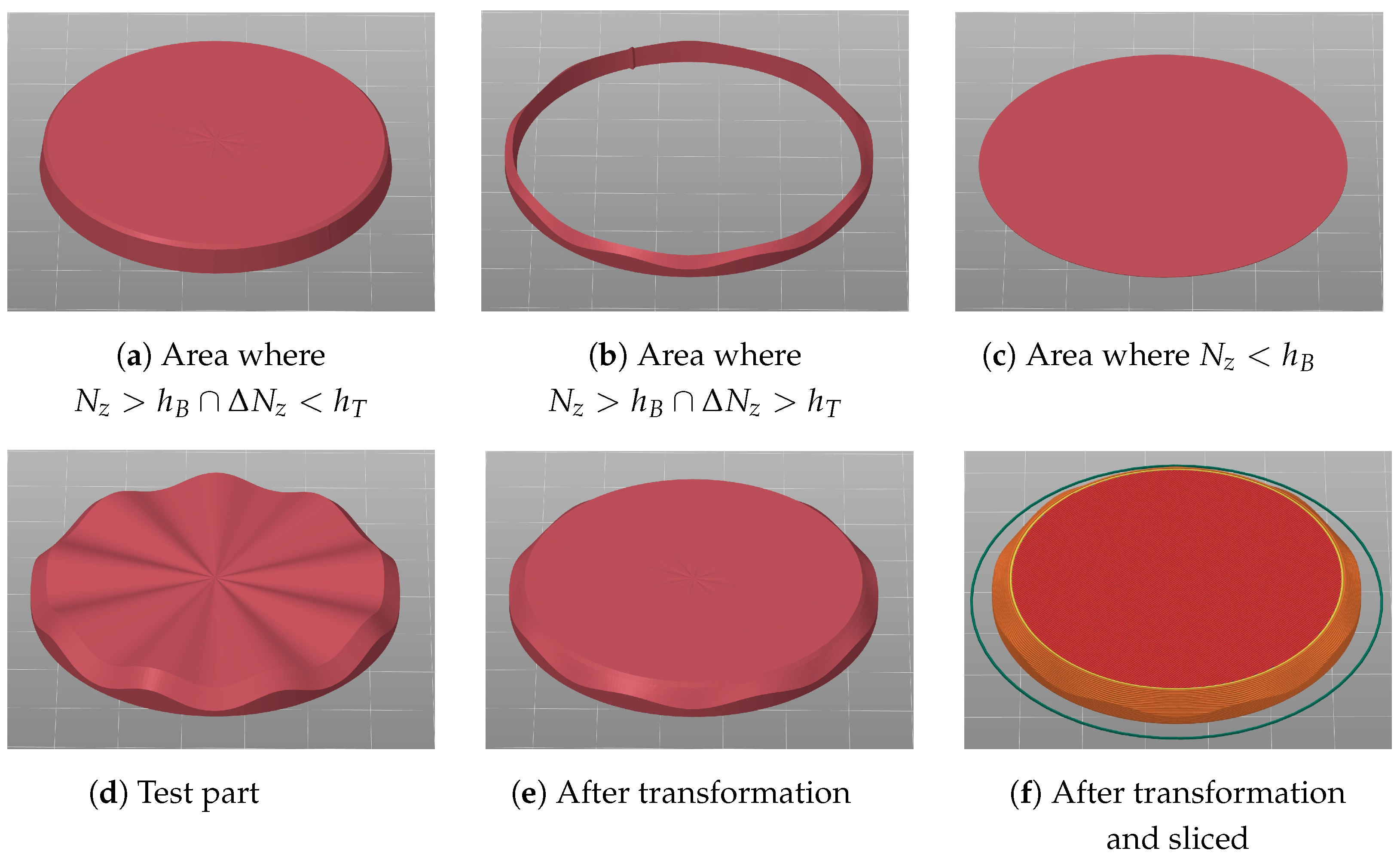

2.1. Detection of Non-Planar Surfaces

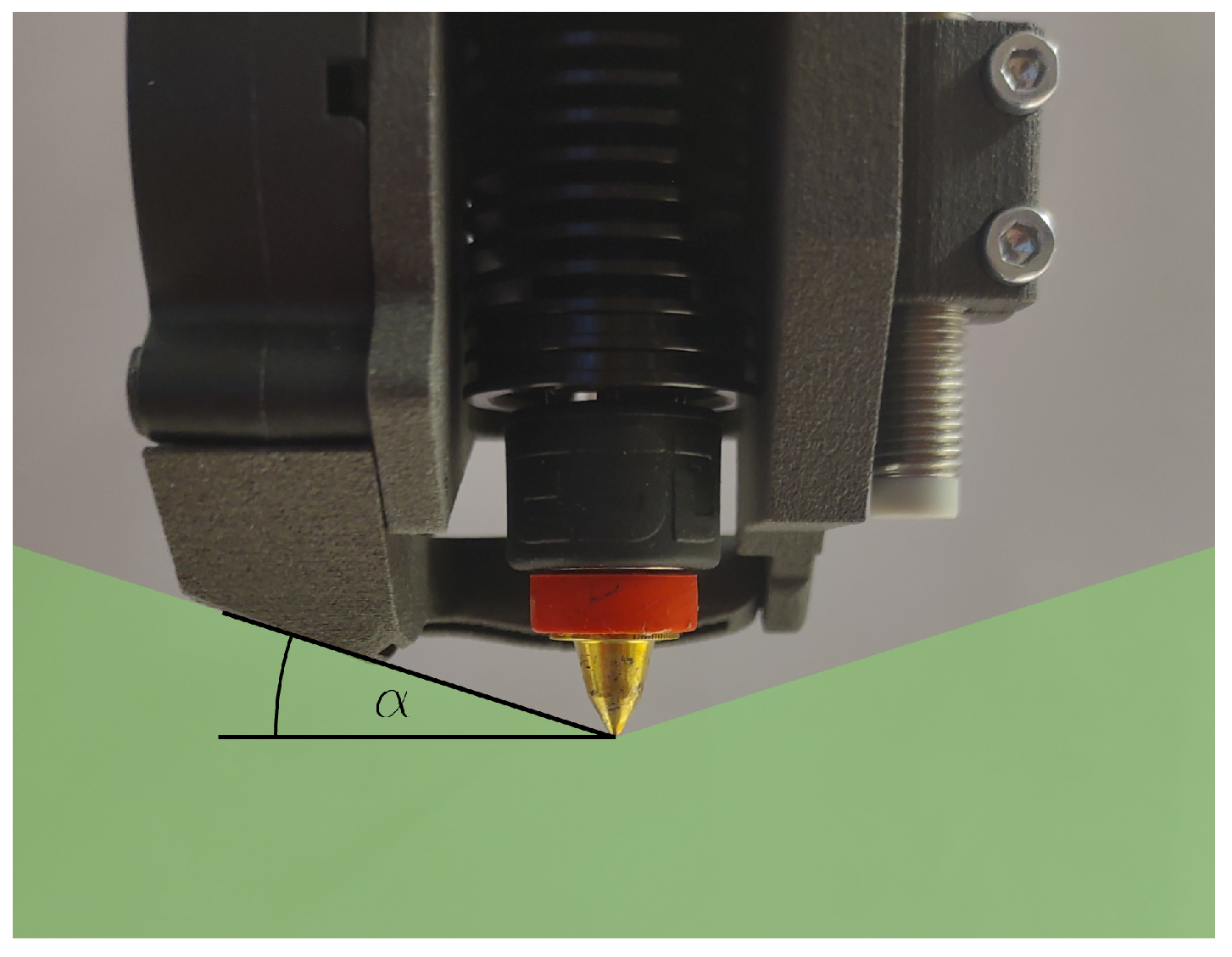

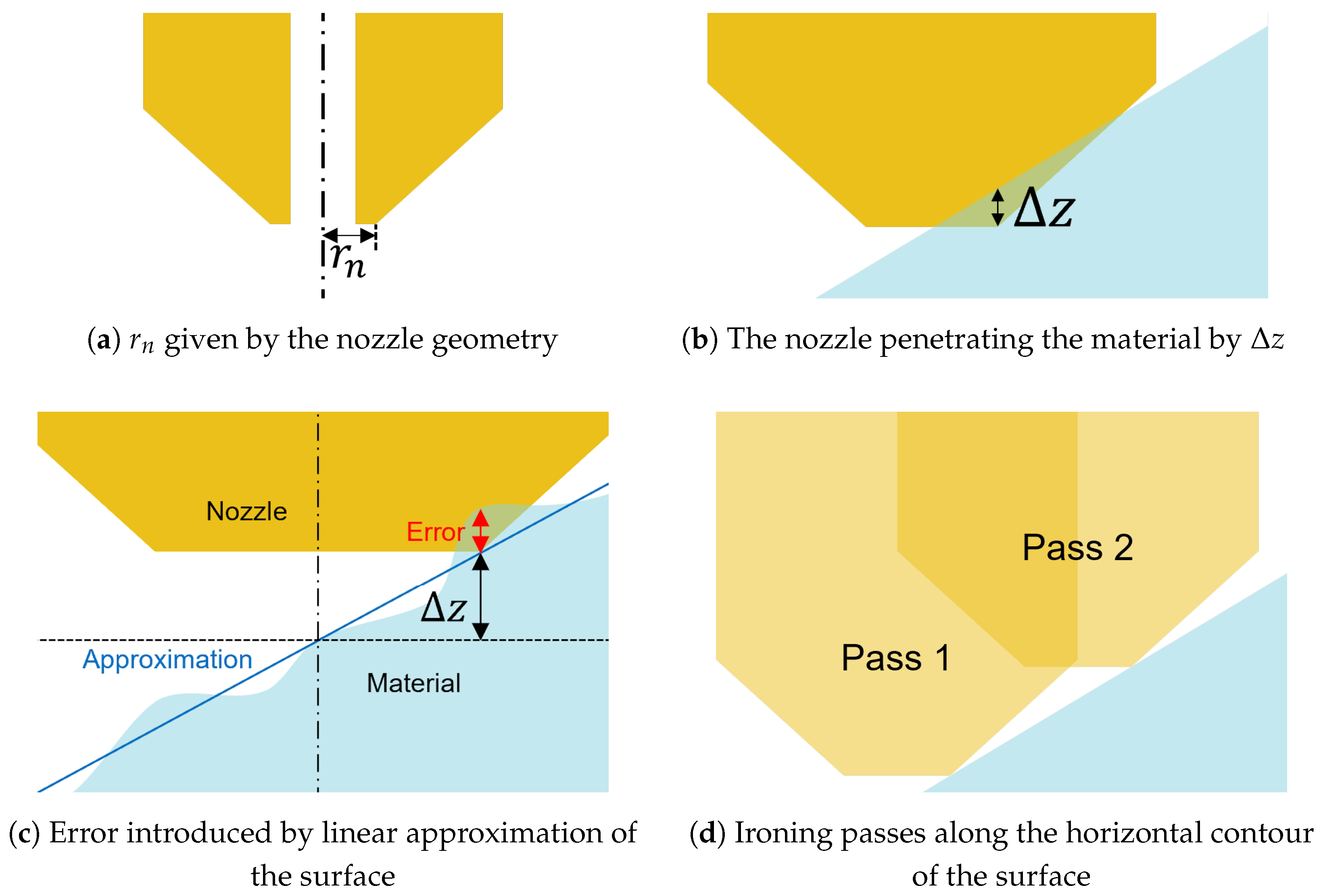

2.1.1. Physical Manufacturability

2.1.2. Evaluation of Triangles

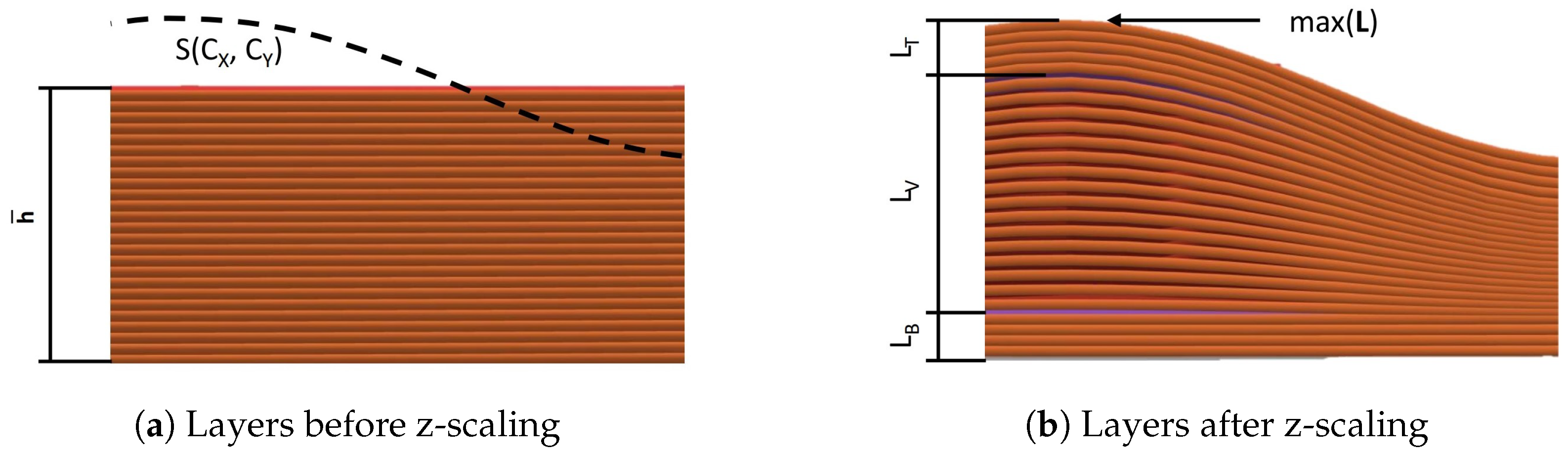

2.2. Method 1: Adapting Layer Heights

2.2.1. Adapting the Part Surface

2.2.2. Slicing with a Conventional Slicer

2.2.3. Scaling z-Axis and Material Extrusion

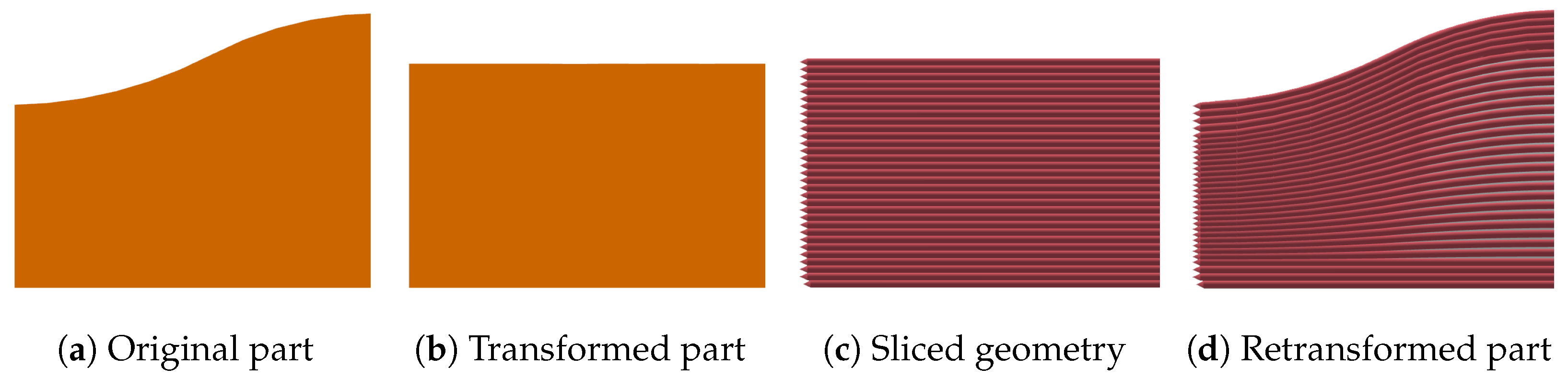

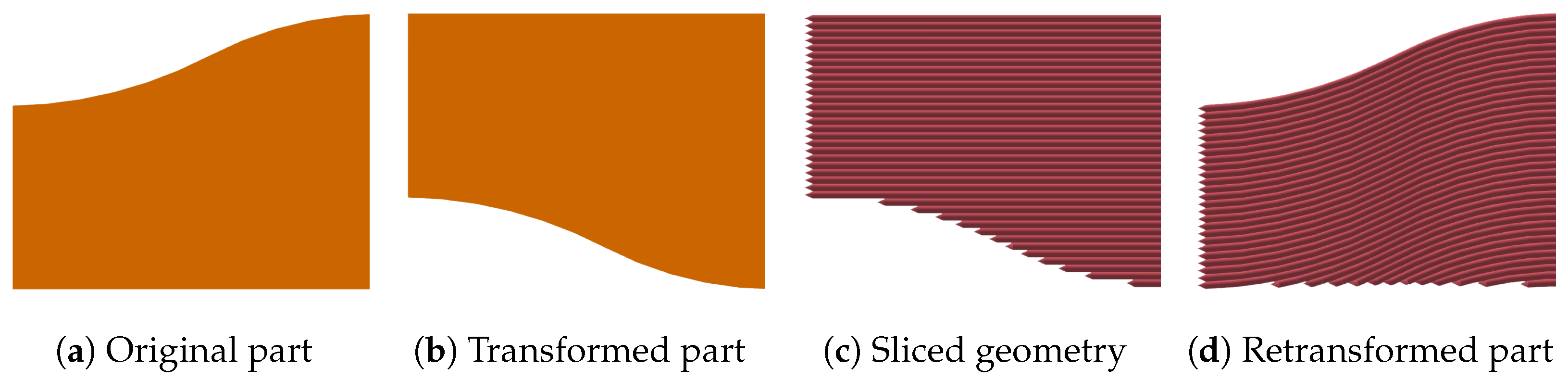

2.3. Method 2: Transforming Part

2.3.1. Transformation of the Part

2.3.2. Retransformation of the GCode

2.4. Choosing Between Methods 1 and 2

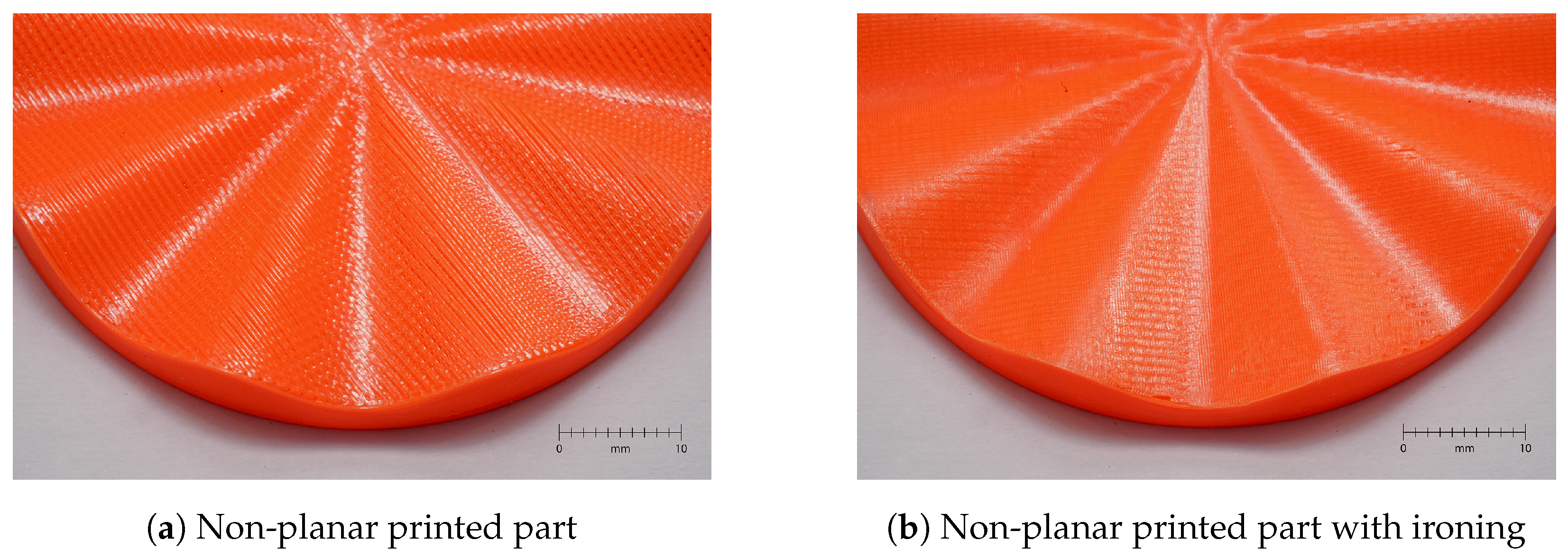

2.5. Ironing

‘Ironing is the process of passing the topmost layer with the heated nozzle again while extruding (or not extruding) a low amount of material.’

3. Results and Discussion

3.1. Computing Time

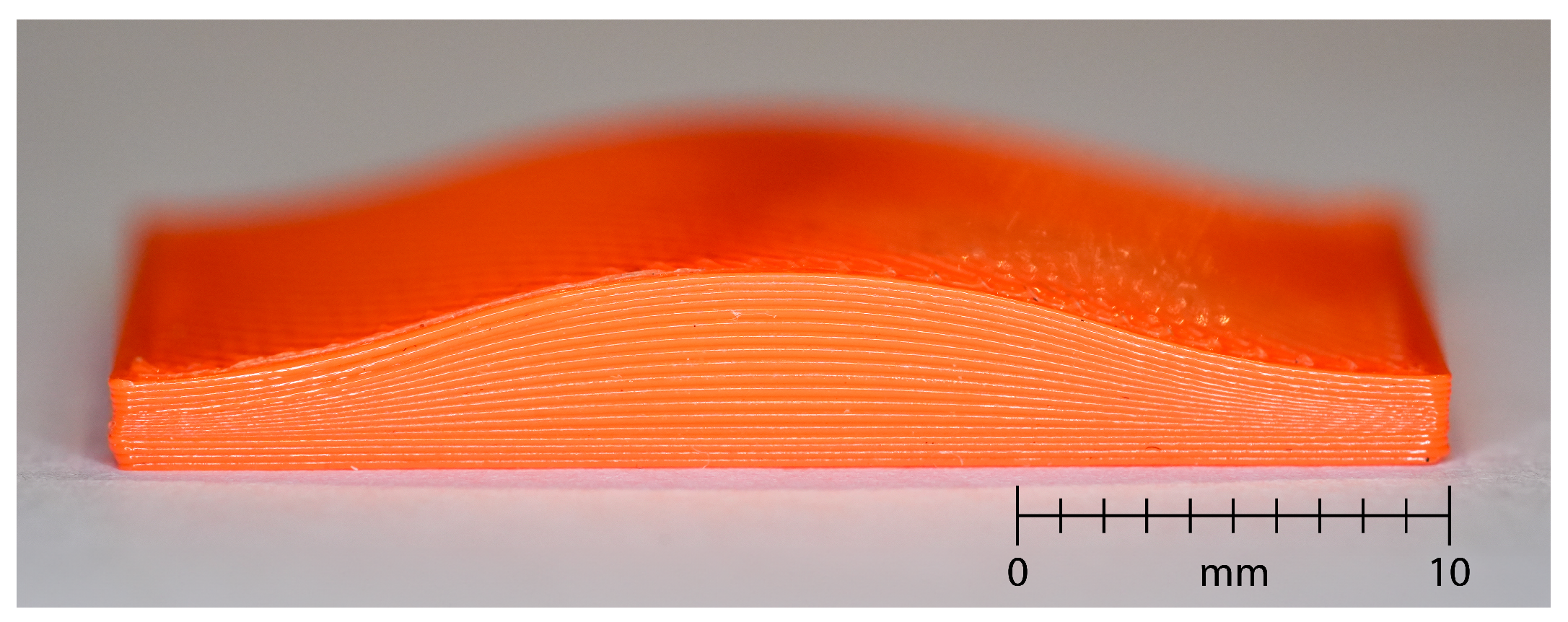

3.2. Printability

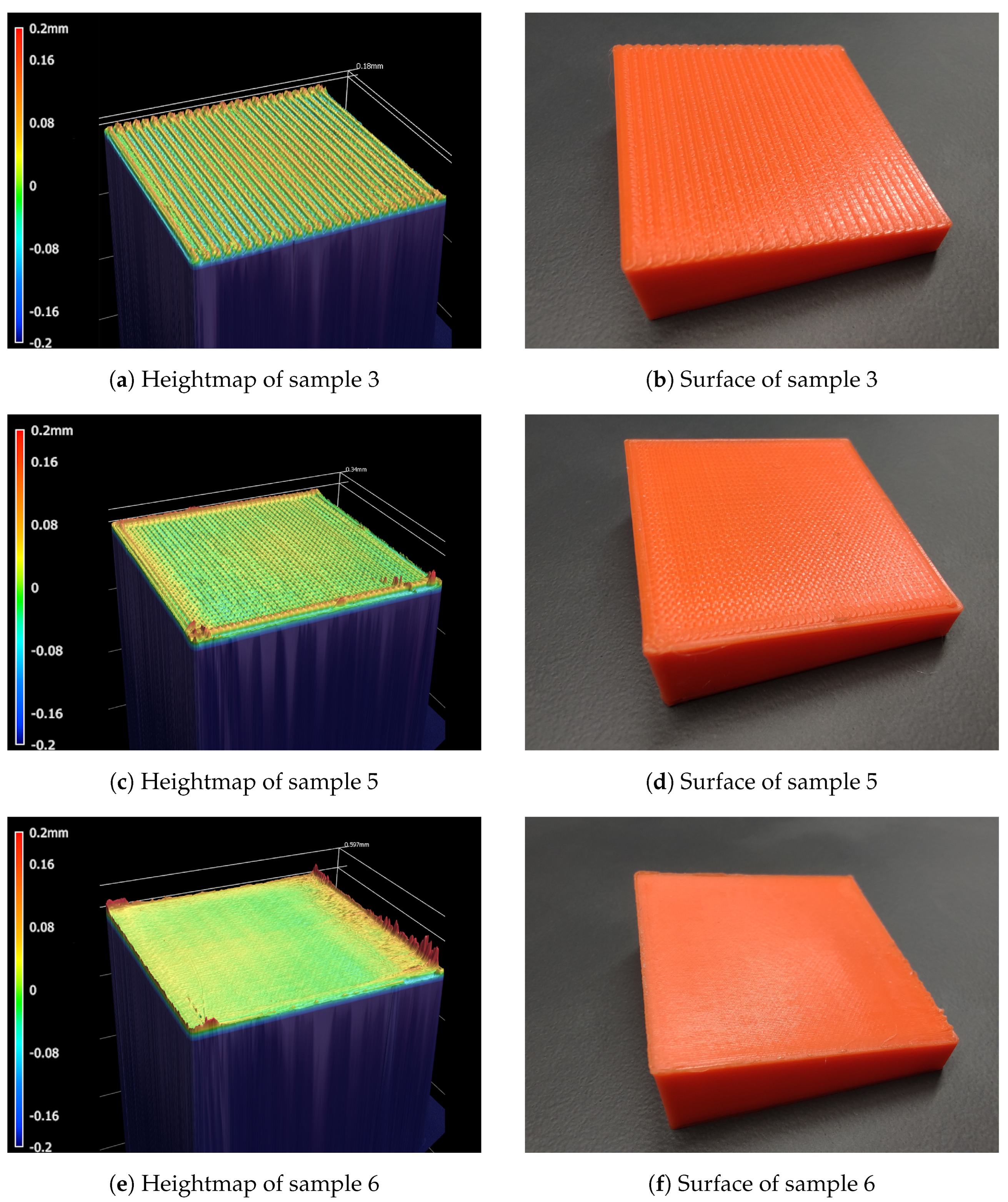

3.3. Surface Roughness

3.4. Limitations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CLFDM | Curved-Layer Fused Deposition Modeling |

| FDM | Fused Deposition Modeling |

| STL | Stereolithography file format |

| CAD | Computer-Aided Design |

| DOF | Degree Of Freedom |

| CLI | Command Line Interface |

| PLA | Polylactic acid |

References

- Kumar, S.A.; Prasad, R. Chapter 2—Basic principles of additive manufacturing: Different additive manufacturing technologies. In Additive Manufacturing; Woodhead Publishing Reviews: Mechanical Engineering Series; Woodhead Publishing: Sawston, UK, 2021; pp. 17–35. [Google Scholar]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 1–10. [Google Scholar] [CrossRef]

- Hu, J. Study on STL-Based Slicing Process for 3D Printing. In Proceedings of the 2017 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Ahlers, D.; Wasserfall, F.; Hendrich, N.; Zhang, J. 3D Printing of Nonplanar Layers for Smooth Surface Generation. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019. [Google Scholar]

- Kiński, W.; Pietkiewicz, P. Influence of the Print Layer Height in FDM Technology on the Rolling Force Value and the Print Time. Agric. Eng. 2019, 23, 1–9. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Gonabadi, H.; Hosseini, S.F.; Chen, Y.; Bull, S. Structural analysis of small-scale 3D printed composite tidal turbine blades. Ocean Eng. 2024, 306, 118057. [Google Scholar] [CrossRef]

- Wang, W.; Chao, H.; Tong, J.; Yang, Z.; Tong, X.; Li, H.; Liu, X.; Liu, L. Saliency-Preserving Slicing Optimization for Effective 3D Printing. Comput. Graph. Forum 2015, 34, 148–160. [Google Scholar] [CrossRef]

- Delfs, P.; Toews, M.; Schmid, H.J. Surface roughness optimized alignment of parts for additive manufacturing processes. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015; Volume 26, pp. 1334–1344. [Google Scholar]

- Chakraborty, D.; Aneesh Reddy, B.; Roy Choudhury, A. Extruder path generation for Curved-Layer Fused Deposition Modeling. Comput.-Aided Des. 2008, 40, 235–243. [Google Scholar] [CrossRef]

- Shan, Y.; Gan, D.; Mao, H. Curved Layer Slicing based on Isothermal Surface. Procedia Manuf. 2021, 53, 484–491. [Google Scholar] [CrossRef]

- Feng, X.; Cui, B.; Liu, Y.; Li, L.; Shi, X.; Zhang, X. Curved-layered material extrusion modeling for thin-walled parts by a 5-axis machine. Rapid Prototyp. J. 2021, 27, 1378–1387. [Google Scholar] [CrossRef]

- Nayyeri, P.; Zareinia, K.; Bougherara, H. Planar and nonplanar slicing algorithms for fused deposition modeling technology: A critical review. Int. J. Adv. Manuf. Technol. 2022, 119, 2785–2810. [Google Scholar] [CrossRef]

- Prusa Research. PrusaSlicer. Available online: https://www.prusa3d.com/en/prusaslicer/ (accessed on 27 November 2024).

- Ultimaker. Cura. Available online: https://ultimaker.com/software/ultimaker-cura/ (accessed on 27 November 2024).

- Wüthrich, M.; Gubser, M.; Elspass, W.J.; Jaeger, C. A Novel Slicing Strategy to Print Overhangs without Support Material. Appl. Sci. 2021, 11, 8760. [Google Scholar] [CrossRef]

- Maissen, S.; Zürcher, S. GitHub Repository. Available online: https://github.com/RotBotSlicer/Nonplanar_Slicing/ (accessed on 27 November 2024).

- Jin, Y.; Du, J.; He, Y.; Fu, G. Modeling and process planning for Curved-Layer Fused Deposition. Int. J. Adv. Manuf. Technol. 2016, 91, 273–285. [Google Scholar] [CrossRef]

- Huang, B.; Singamneni, S. Curved-Layer Adaptive Slicing (CLAS) for fused deposition modelling. Rapid Prototyp. J. 2015, 21, 354–367. [Google Scholar] [CrossRef]

- Singamneni, S.; Roychoudhury, A.; Diegel, O.; Huang, B. Modeling and evaluation of Curved-Layer Fused Deposition. J. Mater. Process. Technol. 2012, 212, 27–35. [Google Scholar] [CrossRef]

- Alfeld, P. A trivariate clough—Tocher scheme for tetrahedral data. Comput. Aided Geom. Des. 1984, 1, 169–181. [Google Scholar] [CrossRef]

- Parker, J.A.; Kenyon, R.V.; Troxel, D.E. Comparison of Interpolating Methods for Image Resampling. IEEE Trans. Med Imaging 1983, 2, 31–39. [Google Scholar] [CrossRef]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef]

- SciPy Griddata. Available online: https://docs.scipy.org/doc/scipy/reference/generated/scipy.interpolate.griddata.html (accessed on 27 November 2024).

- Pelzer, L.; Hopmann, C. Additive manufacturing of non-planar layers with variable layer height. Addit. Manuf. 2021, 37, 101697. [Google Scholar] [CrossRef]

- Zhao, G.; Ma, G.; Feng, J.; Xiao, W. Nonplanar slicing and path generation methods for robotic additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 3149–3159. [Google Scholar] [CrossRef]

- Chohan, J.; Singh, R. Pre and post processing techniques to improve surface characteristics of FDM parts: A state of art review and future applications. Rapid Prototyp. J. 2017, 23, 495–513. [Google Scholar] [CrossRef]

- Caputo, M.; Rashwan, O.; Waryoba, D.; McDade, K. Surface texture and thermo-mechanical properties of material extruded and ironed polylactic acid. Addit. Manuf. 2022, 59, 103084. [Google Scholar] [CrossRef]

- Keyence. Keyence VR-6000. Available online: https://www.keyence.com/products/microscope/macroscope/vr-6000/ (accessed on 27 November 2024).

- Wüthrich, M. Trilab Mod. Available online: https://www.printables.com/model/798333-trilab-deltiq2-printhead-modification-to-gain-clea (accessed on 27 November 2024).

- Gonabadi, H.; Hosseini, S.F.; Chen, Y.; Bull, S. Size effects of voids on the mechanical properties of 3D printed parts. Int. J. Adv. Manuf. Technol. 2024, 132, 5439–5456. [Google Scholar] [CrossRef]

| Part/ (Scale) | Vol [cm3] | Trans. STL [s] | Slice STL [s] | Retrans. GCode [s] | Total Time [s] 1 | Total Time per Volume [s cm3] |

|---|---|---|---|---|---|---|

| Disk (0.5) | 1.8 | 0.08 | 0.14 | 0.38 | 0.61 | 0.345 |

| Disk (1) | 14.1 | 0.06 | 0.19 | 2.37 | 2.64 | 0.187 |

| Disk (2) | 113.1 | 0.09 | 0.41 | 16.78 | 17.31 | 0.153 |

| Disk (4) | 904.8 | 0.08 | 1.94 | 135.24 | 137.27 | 0.152 |

| Wedge (0.5) | 0.8 | 0.01 | 0.07 | 0.17 | 0.29 | 0.344 |

| Wedge (1) | 6.7 | 0.01 | 0.08 | 0.97 | 1.1 | 0.163 |

| Wedge (2) | 54.0 | 0.02 | 0.15 | 8.0 | 8.17 | 0.151 |

| Wedge (4) | 432.0 | 0.02 | 0.71 | 64.87 | 65.61 | 0.152 |

| Sample Nr. | Slicing and Printing | Layer Height [mm] | Raster Angle [°] | Printing Time [min] |

|---|---|---|---|---|

| 1 | Cube, planar | 0.2 | 45 | 13 |

| 2 | Cube, planar + ironing | 0.2 | 45 | 23 |

| 3 | Wedge, planar | 0.05 | 0 | 62 (392) |

| 4 | Wedge, planar | 0.1 | 0 | 32 (251) |

| 5 | Wedge, planar | 0.2 | 0 | 19 |

| 6 | Wedge, planar | 0.3 | 0 | 17 |

| 7 | Wedge, non-planar | 0.2 | 0 | 19 |

| 8 | Wedge, non-planar + ironing | 0.2 | 0 | 29 |

| 9 | Wedge, non-planar | 0.2 | 45 | 19 |

| 10 | Wedge, non-planar + ironing | 0.2 | 45 | 29 |

| Sample Nr. | Measurement Angle [°] | Ra [μm] | Rz [μm] |

|---|---|---|---|

| (a) Measurements for planar reference samples (cube) | |||

| 1 | −45° | 13.673 | 91.082 |

| 0° | 12.673 | 86.512 | |

| 45° | 10.795 | 67.466 | |

| 90° | 14.051 | 84.248 | |

| 2 | −45° | 7.362 | 64.860 |

| 0° | 5.959 | 47.001 | |

| 45° | 6.397 | 49.242 | |

| 90° | 5.983 | 58.725 | |

| (b) Measurements for planar samples (wedge) | |||

| 3 | −45° | 9.903 | 74.235 |

| 0° | 9.737 | 62.009 | |

| 45° | 9.251 | 70.622 | |

| 90° | 4.115 | 35.207 | |

| 4 | −45° | 19.364 | 130.754 |

| 0° | 17.484 | 99.633 | |

| 45° | 17.329 | 108.070 | |

| 90° | 4.243 | 32.850 | |

| 5 | −45° | 37.685 | 190.306 |

| 0° | 34.949 | 178.347 | |

| 45° | 37.462 | 200.418 | |

| 90° | 10.728 | 62.341 | |

| 6 | −45° | 59.269 | 320.549 |

| 0° | 59.068 | 277.89 | |

| 45° | 60.197 | 298.219 | |

| 90° | 13.871 | 83.965 | |

| (c) Measurements for non-planar samples (wedge) | |||

| 7 | −45° | 13.728 | 86.994 |

| 0° | 11.737 | 75.676 | |

| 45° | 12.504 | 77.960 | |

| 90° | 9.443 | 47.863 | |

| 8 | −45° | 6.557 | 40.907 |

| 0° | 6.617 | 56.073 | |

| 45° | 6.946 | 74.983 | |

| 90° | 4.018 | 27.513 | |

| 9 | −45° | 22.189 | 101.425 |

| 0° | 20.567 | 98.123 | |

| 45° | 8.129 | 58.368 | |

| 90° | 20.810 | 106.219 | |

| 10 | −45° | 10.117 | 51.010 |

| 0° | 6.194 | 35.794 | |

| 45° | 9.244 | 48.962 | |

| 90° | 5.693 | 35.741 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maissen, S.; Zürcher, S.; Wüthrich, M. Adaptation of Conventional Toolpath-Generation Software for Use in Curved-Layer Fused Deposition Modeling. J. Manuf. Mater. Process. 2024, 8, 270. https://doi.org/10.3390/jmmp8060270

Maissen S, Zürcher S, Wüthrich M. Adaptation of Conventional Toolpath-Generation Software for Use in Curved-Layer Fused Deposition Modeling. Journal of Manufacturing and Materials Processing. 2024; 8(6):270. https://doi.org/10.3390/jmmp8060270

Chicago/Turabian StyleMaissen, Samuel, Severin Zürcher, and Michael Wüthrich. 2024. "Adaptation of Conventional Toolpath-Generation Software for Use in Curved-Layer Fused Deposition Modeling" Journal of Manufacturing and Materials Processing 8, no. 6: 270. https://doi.org/10.3390/jmmp8060270

APA StyleMaissen, S., Zürcher, S., & Wüthrich, M. (2024). Adaptation of Conventional Toolpath-Generation Software for Use in Curved-Layer Fused Deposition Modeling. Journal of Manufacturing and Materials Processing, 8(6), 270. https://doi.org/10.3390/jmmp8060270