Effect of Lubricated Liquid Carbon Dioxide (LCO2 + MQL) on Grinding of AISI 4140 Steel

Abstract

1. Introduction

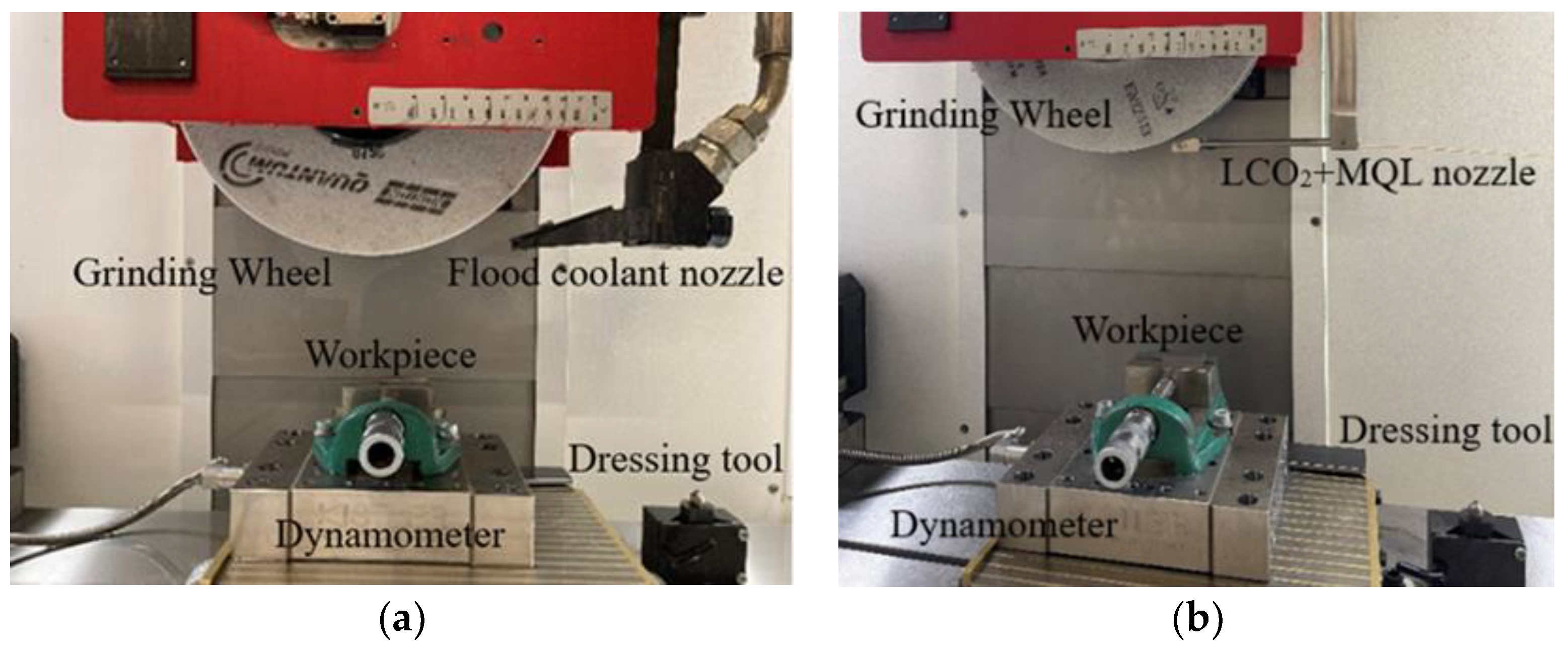

2. Materials and Methods

3. Results and Discussions

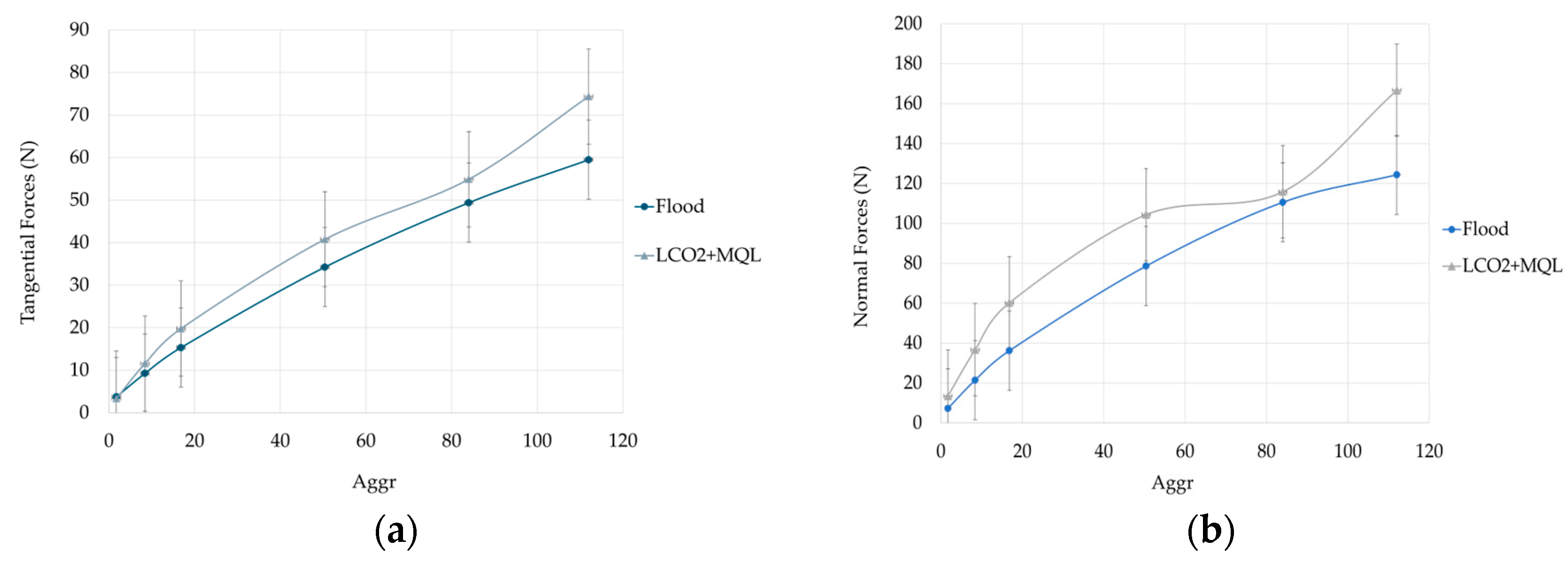

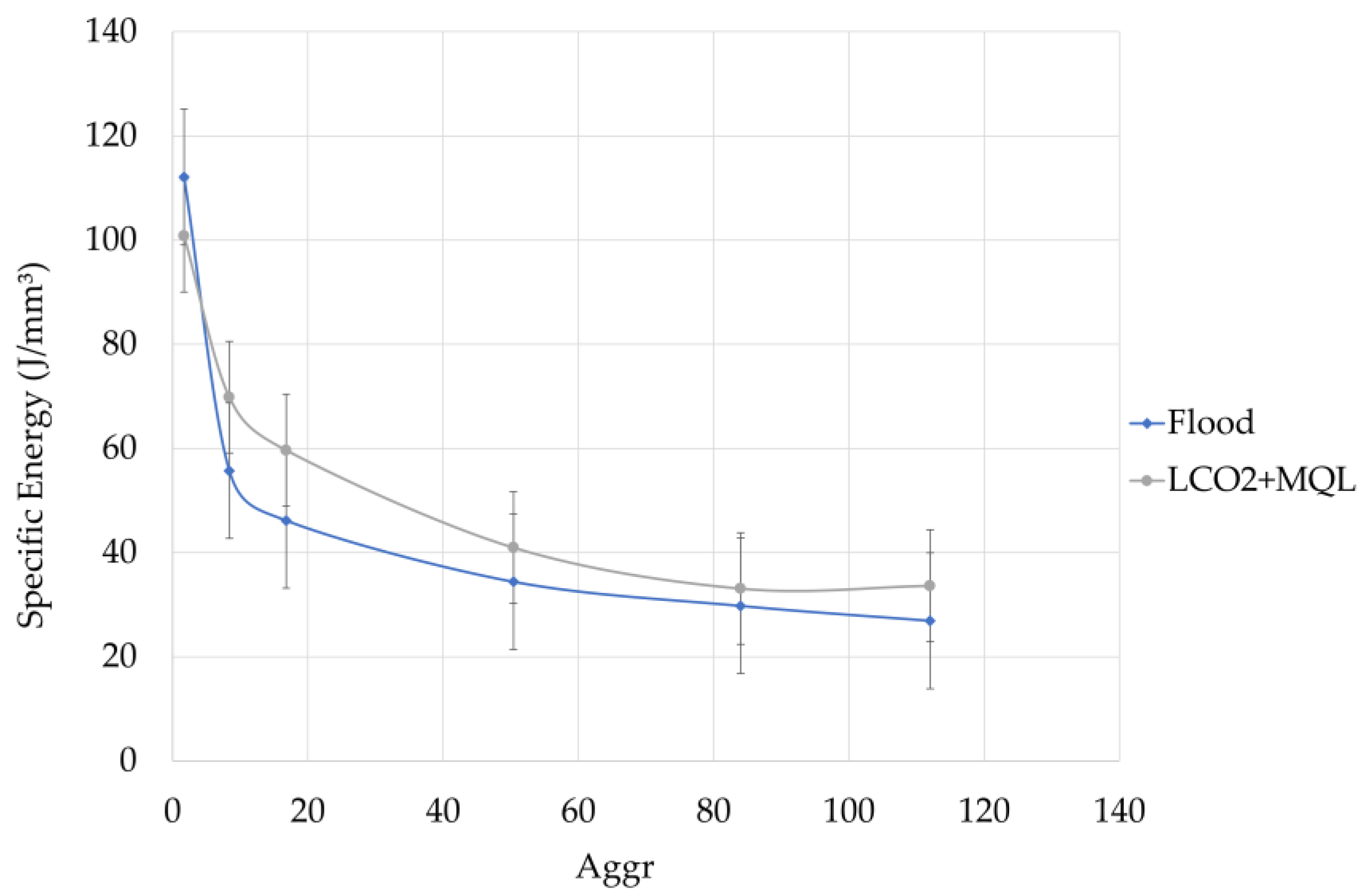

3.1. Grinding Forces

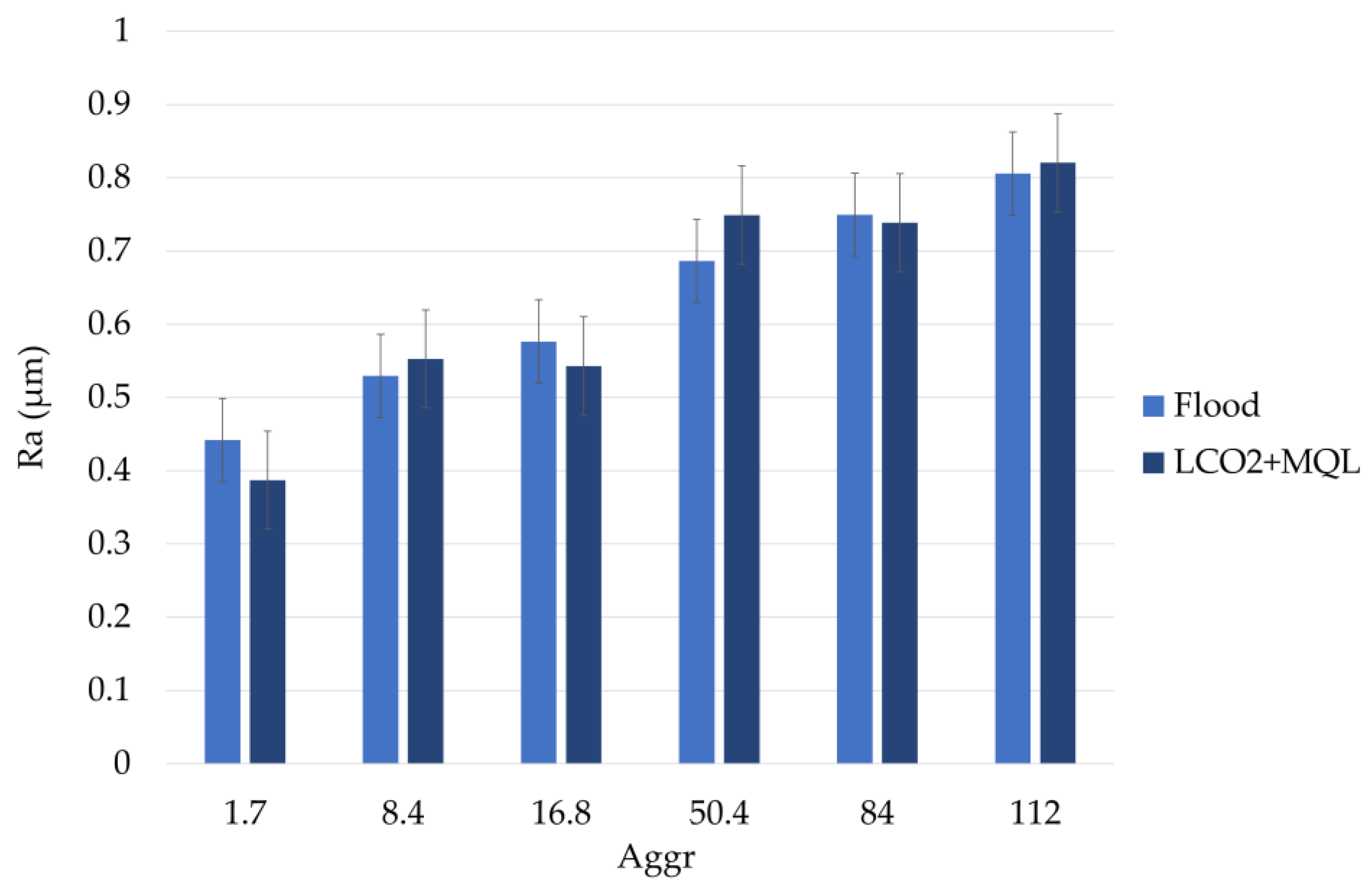

3.2. Surface Roughness

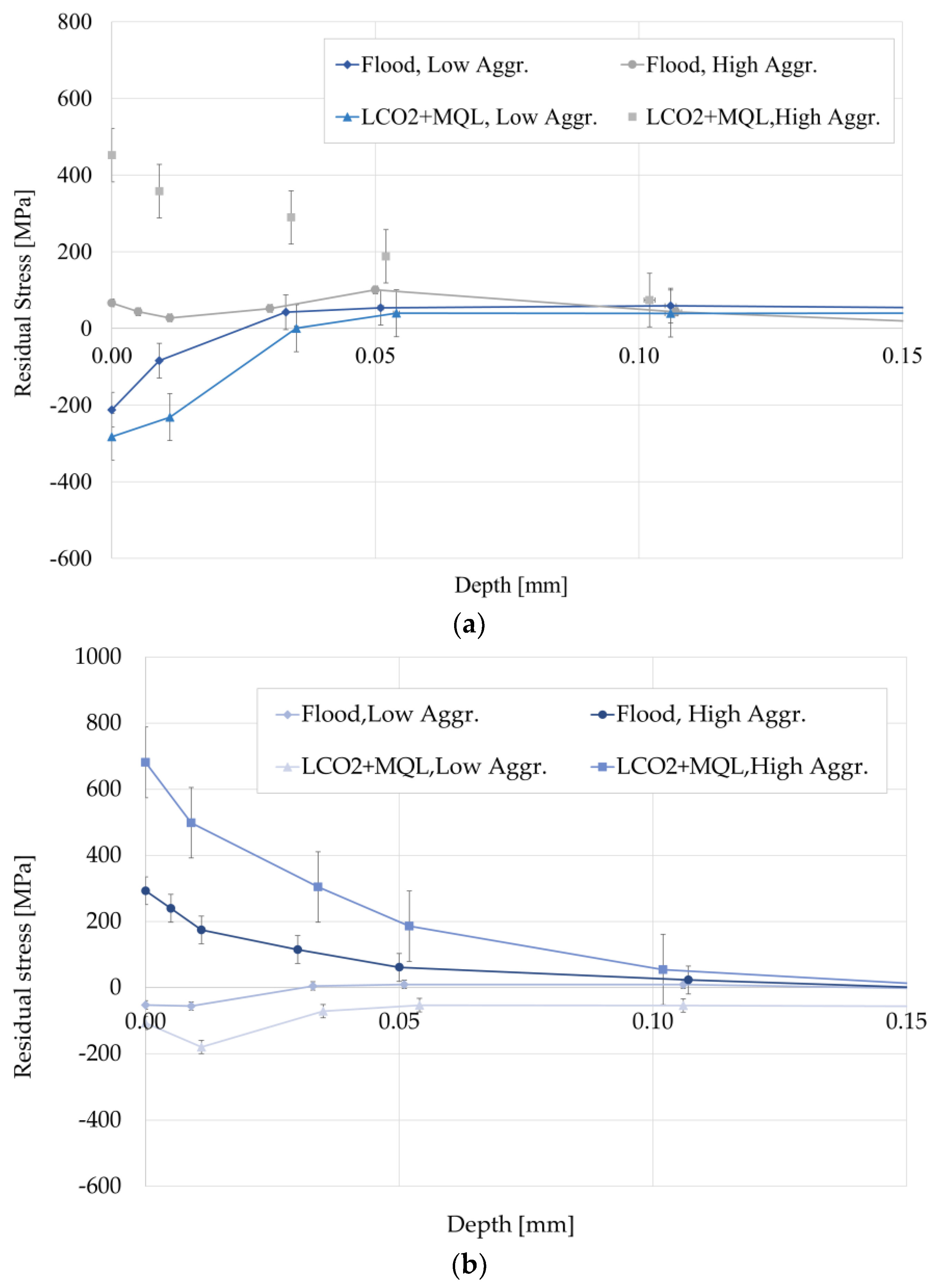

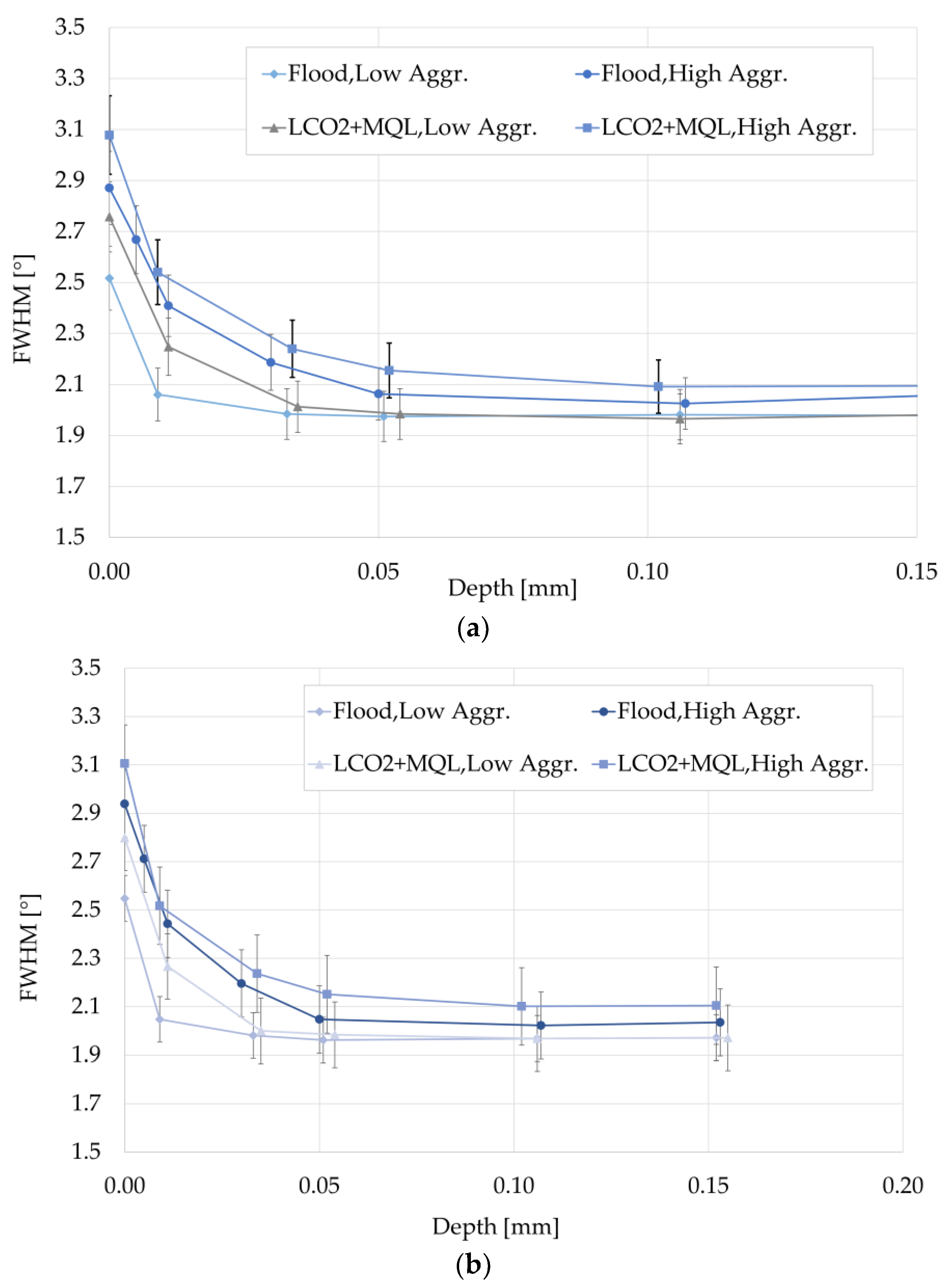

3.3. Residual Stresses

3.4. Microhardness Measurements

3.5. Cost-Effectiveness Analysis

4. Conclusions

- The normal grinding forces were 25% higher, tangential normal forces were 20% higher, and specific energies were 10–20% higher for LCO2 + MQL grinding at higher values. This increase can primarily be attributed to the inefficient cooling capability of LCO2 + MQL during rough grinding, likely due to the limited cooling capability of LCO2 + MQL, as the gaseous LCO2 is less effective at maintaining contact with the workpiece and evacuating heat, unlike the liquid MWF in flood cooling, which remains in contact longer and improves heat dissipation.

- The force ratio was significantly lower for LCO2 + MQL at lower , indicating insufficient lubrication. As increased, the force ratio for LCO2 + MQL improved, but it remained consistently lower than that of flood cooling, which provided better lubrication across all conditions.

- The study found that the average surface roughness achieved with LCO2 + MQL was comparable to that achieved with conventional flood cooling.

- Both cooling–lubrication methods resulted in residual tensile stresses at higher (rough grinding) and residual compressive stresses at lower (finish grinding). LCO2 + MQL induced more pronounced residual tensile stresses at higher , while at lower , more favorable residual stresses were observed. The analysis of the full width at half maximum (FWHM) profiles indicated higher values for LCO2 + MQL at higher , suggesting greater plastic deformation. At lower , LCO2 + MQL exhibited comparable FWHM results to flood cooling, likely due to the mechanical effects dominating over thermal ones.

- Microhardness measurements revealed negligible differences between the LCO2 + MQL and flood cooling, indicating similar effects on the workpiece subsurface. LCO2 + MQL proved effective in preventing the tempering (softening) of the work material under all of the grinding conditions tested.

- The preliminary cost-effectiveness analysis suggests that LCO2 + MQL is not only technologically feasible in terms of delivering comparable grindability results, but also demonstrates cost effectiveness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, S.; Yang, S.; Cheung, C.F.; Liu, T.; Duan, D.; Ho, L.T.; Jiang, Z. Study on the Surface Generation Mechanism during Ultra-Precision Parallel Grinding of SiC Ceramics. Crystals 2023, 13, 646. [Google Scholar] [CrossRef]

- Malkin, S.; Guo, C. Grinding Technology: Theory and Application of Machining with Abrasives, 2nd ed.; Industrial Press Inc.: New York, NY, USA, 2008. [Google Scholar]

- Kishore, K.; Sinha, M.K.; Singh, A.; Archana; Gupta, M.K.; Korkmaz, M.E. A Comprehensive Review on the Grinding Process: Advancements, Applications and Challenges. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2022, 236, 10923–10952. [Google Scholar] [CrossRef]

- Heep, T.; Bickert, C.; Abele, E. Application of Carbon Dioxide Snow in Machining of CGI Using an Additively Manufactured Turning Tool. J. Manuf. Mater. Process. 2019, 3, 15. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Deiab, I.; Eltaggaz, A. Sustainability Assessment during Machining Ti-6Al-4V with Nano-Additives-Based Minimum Quantity Lubrication. J. Manuf. Mater. Process. 2019, 3, 61. [Google Scholar] [CrossRef]

- Qian, N.; Chen, J.; Khan, A.M.; Zhao, B.; Chen, Y.; Ding, W.; Fu, Y.; Xu, J. Towards Sustainable Grinding of Difficult-to-Cut Alloys—A Holistic Review and Trends. Chin. J. Mech. Eng. 2024, 37, 23. [Google Scholar] [CrossRef]

- Liang, C.; Gong, Y.; Zhou, L.; Qi, Y.; Zhang, H.; Zhao, J. Tool Wear Mechanism and Grinding Performance for Different Cooling-Lubrication Modes in Grinding of Nickel-Based Superalloys. Materials 2023, 16, 3545. [Google Scholar] [CrossRef]

- Patil, A.S.; Sunnapwar, V.K.; S. Bhole, K.; Ray, M.P.; More, Y.S. Effective Cooling Methods for Ti6Al4V CNC Milling: A Review. Adv. Mater. Process. Technol. 2023, 9, 457–506. [Google Scholar] [CrossRef]

- Hanenkamp, N.; Amon, S.; Gross, D. Hybrid Supply System for Conventional and CO2/MQL-Based Cryogenic Cooling. Procedia CIRP 2018, 77, 219–222. [Google Scholar] [CrossRef]

- García, E.; Méresse, D.; Pombo, I.; Dubar, M.; Sánchez, J.A. Role of Frozen Lubricant Film on Tribological Behaviour and Wear Mechanisms in Grinding. Int. J. Adv. Manuf. Technol. 2016, 82, 1017–1027. [Google Scholar] [CrossRef]

- Mahata, S.; Mukhopadhyay, M.; Kundu, A.; Banerjee, A.; Mandal, B.; Das, S. Grinding Titanium Alloys Applying Small Quantity Lubrication. SN Appl. Sci. 2020, 2, 978. [Google Scholar] [CrossRef]

- Arafat, R.; Madanchi, N.; Thiede, S.; Herrmann, C.; Skerlos, S.J. Supercritical Carbon Dioxide and Minimum Quantity Lubrication in Pendular Surface Grinding—A Feasibility Study. J. Clean Prod. 2021, 296, 126560. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Yang, M.; Gao, T.; Wang, X.; Cui, X.; Zhang, Y.; Said, Z.; Sharma, S. Mechanism and enhanced grindability of cryogenic air combined with biolubricant grinding titanium alloy. Tribol. Int. 2023, 187, 108704. [Google Scholar] [CrossRef]

- Balan, A.S.; Vijayaraghavan, L.; Krishnamurthy, R.; Kuppan, P.; Oyyaravelu, R. An experimental assessment on the performance of different lubrication techniques in grinding of Inconel 751. J. Adv. Res. 2016, 7, 709–718. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Chaudhari, A.; Diwakar, V.; Awale, A.S.; Yusufzai, M.Z.; Vashista, M. Implementation of hybrid CryoMQL sustainable lubri-cooling to enhance the grindability and surface integrity of tool steel. J. Manuf. Process. 2024, 119, 16–31. [Google Scholar] [CrossRef]

- Bergs, T.; Pusavec, F.; Koch, M.; Grguras, D.; Dobbeler, B.; Klocke, F. Investigation of the Solubility of Liquid CO2 and Liquid Oil to Realize an Internal Single Channel Supply in Milling of Ti6Al4V. Procedia Manuf. 2019, 33, 200–207. [Google Scholar] [CrossRef]

- Grguraš, D.; Sterle, L.; Krajnik, P.; Pušavec, F. A Novel Cryogenic Machining Concept Based on a Lubricated Liquid Carbon Dioxide. Int. J. Mach. Tools Manuf. 2019, 145, 103456. [Google Scholar] [CrossRef]

- Santhosh, K.; Pušavec, F.; Krajnik, P. Grinding of Cemented Carbide Using a Vitrified Diamond Pin and Lubricated Liquid Carbon Dioxide. Stroj. Vestn.-J. Mech. Eng. 2023, 69, 435–443. [Google Scholar] [CrossRef]

- Ruiz-Trabolsi, P.A.; Chino-Ulloa, A.; Miranda-Hernández, J.G.; Tadeo-Rosas, R.; Carrera-Espinoza, R.; Velázquez, J.C.; Hernández-Sánchez, E. A Comparative Analysis of the Tribological Behavior of Hard Layers Obtained by Three Different Hardened-Surface Processes on the Surface of AISI 4140 Steel. Crystals 2022, 12, 298. [Google Scholar] [CrossRef]

- Özdemir, M.; Şahinoğlu, A.; Rafighi, M.; Yilmaz, V. Analysis and optimisation of the cutting parameters based on machinability factors in turning AISI 4140 steel. Can. Metall. Q. 2022, 61, 407–417. [Google Scholar] [CrossRef]

- Kohls, E.; Heinzel, C.; Eich, M. Evaluation of Hardness and Residual Stress Changes of AISI 4140 Steel Due to Thermal Load during Surface Grinding. J. Manuf. Mater. Process. 2021, 5, 73. [Google Scholar] [CrossRef]

- Grguraš, D.F.; Sterle, L.; Malneršič, A.; Kastelic, L.; Courbon, C.; Pušavec, F. Media Flow Analysis of Single-Channel Pre-Mixed Liquid CO2 and MQL in Sustainable Machining. Stroj. Vestn.-J. Mech. Eng. 2021, 67, 3–11. [Google Scholar]

- Drazumeric, R.; Badger, J.; Krajnik, P.; Kopac, J. Thermal Aspects and Grinding Aggressiveness in View of Optimizing High-Performance Grinding Operations in the Automotive Industry. In Proceedings of the International Manufacturing Science and Engineering Conference Detroit, Detroit, MI, USA, 9–13 June 2014; Volume 2. [Google Scholar]

- ISO 4287:1997 Geometrical Product Specifications (GPS) - Surface Texture: Profile Method - Terms, Definitions and Surface Texture Parameters. Available online: https://www.iso.org/standard/44475.html (accessed on 12 October 2024).

- BS EN ISO 21920-2:2022 - Geometrical Product Specifications (GPS). Surface Texture: Profile Terms, Definitions and Surface Texture Parameters. Available online: https://www.iso.org/obp/ui/#iso:std:iso:21920:-2:ed-1:v2:en (accessed on 12 October 2024).

- ISO 6507-1:2018-Metallic Materials-Vickers Hardness Test-Part 1: Test Method. Available online: https://www.en-standard.eu/iso-6507-1-2018-metallic-materials-vickers-hardness-test-part-1-test-method/ (accessed on 12 October 2024).

- BS EN 15305:2008 Non-Destructive Testing. Test Method for Residual Stress Analysis by X-ray Diffraction. Available online: https://knowledge.bsigroup.com/products/non-destructive-testing-test-method-for-residual-stress-analysis-by-x-ray-diffraction?version=standard. (accessed on 12 October 2024).

- Liu, M.; Li, C.H.; An, Q.; Zhang, Y.; Yang, M.; Cui, X.; Gao, T.; Dambatta, Y.S.; Li, R. Atomized Droplets Liquid Film Thickness Model and Verification in Sustainable Hybrid Lubrication (Cryo-Mql) Grinding. SSRN 2024. [Google Scholar] [CrossRef]

- Sanchez, J.A.; Pombo, I.; Alberdi, R.; Izquierdo, B.; Ortega, N.; Plaza, S.; Martinez-Toledano, J. Machining Evaluation of a Hybrid MQL-CO2 Grinding Technology. J. Clean Prod. 2010, 18, 1840–1849. [Google Scholar] [CrossRef]

- Hoier, P.; Azarhoushang, B.; Lundin, P.; Malakizadi, A.; Badger, J.; Stormvinter, A.; Björk, T.; Klement, U.; Hashimoto, F.; Krajnik, P. Influence of batch-to-batch material variations on grindability of a medium-carbon steel. J. Manuf. Process. 2022, 73, 463–470. [Google Scholar] [CrossRef]

- Hoier, P.; Kareepadath Santhosh, D.; Hryha, E.; Krajnik, P. An investigation into the grindability of additively manufactured 42CrMo4 steel. CIRP Ann. 2024, 73, 257–260. [Google Scholar] [CrossRef]

- Ding, W.; Xu, J.; Chen, Z.; Su, H.; Fu, Y. Grindability and Surface Integrity of Cast Nickel-Based Superalloy in Creep Feed Grinding with Brazed CBN Abrasive Wheels. Chin. J. Aeronaut. 2010, 23, 501–510. [Google Scholar]

- Osman, M.; Malkin, S. Lubrication by Grinding Fluids at Normal and High Wheel Speeds. A S L E Trans. 1972, 15, 261–268. [Google Scholar] [CrossRef]

- Mao, C.; Zhang, J.; Huang, Y.; Zou, H.; Huang, X.; Zhou, Z. Investigation on the Effect of Nanofluid Parameters on MQL Grinding. Mater. Manuf. Process. 2013, 28, 436–442. [Google Scholar] [CrossRef]

- Singh, P.K.; Kumar, S.; Jain, P.K. Effect of Cryogenic Grinding on Surface Characteristics of Additively Manufactured Ti-6Al-4V Alloy. Surf. Topogr. Metrol. Prop. 2023, 11, 015014. [Google Scholar] [CrossRef]

- Li, C.H.; Lu, B.H.; Ding, Y.C.; Cai, G.Q. Innovative Technology Investigation into Cryogenic Cooling Green Grinding Using Liquid Nitrogen Jet. In Proceedings of the 2009 International Conference on Management and Service Science, Beijing, China, 20–22 September 2009. [Google Scholar]

- Manimaran, G.; Pradeep kumar, M.; Venkatasamy, R. Surface Modifications in Grinding AISI D3 Steel Using Cryogenic Cooling. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 1357–1363. [Google Scholar] [CrossRef]

- Setti, D.; Yadav, N.K.; Ghosh, S. Grindability Improvement of Ti-6Al-4V Using Cryogenic Cooling. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2014, 228, 1131–1137. [Google Scholar] [CrossRef]

- Balan, A.S.S.; Chidambaram, K.; Kumar, A.V.; Krishnaswamy, H.; Pimenov, D.Y.; Giasin, K.; Nadolny, K. Effect of Cryogenic Grinding on Fatigue Life of Additively Manufactured Maraging Steel. Materials 2021, 14, 1245. [Google Scholar] [CrossRef] [PubMed]

- Yaqoob, S.; Ghani, J.A.; Juri, A.Z.; Muhamad, S.S.; Haron, C.H.C.; Jouini, N. A Review of Sustainable Hybrid Lubrication (Cryo-MQL) Techniques in Machining Processes. Int. J. Adv. Manuf. Technol. 2024, 131, 151–169. [Google Scholar] [CrossRef]

- Abedrabbo, F.; Soriano, D.; Madariaga, A.; Fernández, R.; Abolghasem, S.; Arrazola, P.J. Experimental Evaluation and Surface Integrity Analysis of Cryogenic Coolants Approaches in the Cylindrical Plunge Grinding. Sci. Rep. 2021, 11, 20952. [Google Scholar] [CrossRef] [PubMed]

- Pušavec, F.; Grguraš, D.; Koch, M.; Krajnik, P. Cooling capability of liquid nitrogen and carbon dioxide in cryogenic milling. CIRP Ann. 2019, 68, 73–76. [Google Scholar] [CrossRef]

- Shao, Y.; Fergani, O.; Ding, Z.; Li, B.; Liang, S.Y. Experimental Investigation of Residual Stress in Minimum Quantity Lubrication Grinding of AISI 1018 Steel. J. Manuf. Sci. Eng. Trans. ASME 2016, 138, 011009. [Google Scholar] [CrossRef]

- Zhou, N.; Peng, R.L.; Pettersson, R. Surface Characterization of Austenitic Stainless Steel 304l after Different Grinding Operations. Int. J. Mech. Mater. Eng. 2017, 12, 6. [Google Scholar] [CrossRef]

- Pušavec, F.; Hamdi, H.; Kopac, J.; Jawahir, I.S. Surface Integrity in Cryogenic Machining of Nickel Based Alloy—Inconel 718. J. Mater. Process. Technol. 2011, 211, 773–783. [Google Scholar] [CrossRef]

- Ganesh, M.; Arunkumar, N.; Kumar, N.A.; Sathish, R. Investigation of Surface Grinding on Inconel under Distinct Cooling Conditions. Mater. Manuf. Process. 2023, 38, 1823–1836. [Google Scholar] [CrossRef]

| Chemical Composition (Weight %) | |||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Mo | Ni |

| 0.448 | 0.264 | 0.735 | 0.012 | 0.002 | 1.09 | 0.244 | 0.2 |

| Experiment No. | Feed Rate (mm/s) | Wheel Speed (m/s) | Depth of Cut (mm) | - | Q’w (mm3/mm/s) |

|---|---|---|---|---|---|

| 1 | 10 | 30 | 0.01 | 1.7 | 0.1 |

| 2 | 50 | 30 | 0.01 | 8.4 | 0.5 |

| 3 | 100 | 30 | 0.01 | 16.8 | 1 |

| 4 | 300 | 30 | 0.01 | 50.4 | 3 |

| 5 | 500 | 30 | 0.01 | 84 | 5 |

| 6 | 667 | 30 | 0.01 | 112 | 6.7 |

| Inputs | Value | Outputs | Value |

|---|---|---|---|

| Mass flow rate of CO2 | 170 g/min | Consumption of CO2 | 26,010 kg/year |

| Cost of CO2 | 1 EUR/kg | Annual cost of CO2 | 26,010 EUR/year |

| MQL flow rate | 35 mL/h | Annual MQL consumption | 179 L/year |

| Cost of MQL oil | 20 EUR/L | Annual cost of MQL oil | 3570 EUR/year |

| Utilization of LCO2-MQL | 50% | ||

| LCO2-MQL equipment investment | 60,000 EUR | ||

| Equipment cost (5-year depreciation) | 12,000 EUR/year | ||

| Total for LCO2-MQL→41,580 EUR/year | |||

| Inputs | Value | Outputs | Value |

|---|---|---|---|

| Grinding fluid volume | 1400 L | Daily MWF loss | 140 L/day |

| Solution concentration | 8% | Annual MWF loss | 35,000 L/year |

| Cost of grinding fluid | 15 EUR/L | Volume of MWF loss | 2800 L/year |

| Cost of water | 1.7 EUR/1000 L | Volume of water lost | 32,200 L/year |

| Electricity cost | 0.03 EUR/kWh | Cost of lost MWF | 42,000 EUR/year |

| Daily MWF loss | 10% | Cost of lost water | 55 EUR/year |

| Pump power | 1.3 kW | Annual energy use (pump) | 6630 kWh |

| Electricity emissions factor | 0.09 kg CO2/kWh | Pump energy cost | 199 EUR/year |

| CO2 emission cost | 122 EUR/ton | CO2 emissions from electricity | 597 kg CO2/year |

| Annual CO2 emission cost | 73 EUR/year | ||

| Water cost for conventional cooling | 57 EUR/year | ||

| Total for flood cooling→42,329 EUR/year | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kareepadath Santhosh, D.; Hoier, P.; Pušavec, F.; Krajnik, P. Effect of Lubricated Liquid Carbon Dioxide (LCO2 + MQL) on Grinding of AISI 4140 Steel. J. Manuf. Mater. Process. 2024, 8, 230. https://doi.org/10.3390/jmmp8050230

Kareepadath Santhosh D, Hoier P, Pušavec F, Krajnik P. Effect of Lubricated Liquid Carbon Dioxide (LCO2 + MQL) on Grinding of AISI 4140 Steel. Journal of Manufacturing and Materials Processing. 2024; 8(5):230. https://doi.org/10.3390/jmmp8050230

Chicago/Turabian StyleKareepadath Santhosh, Deepa, Philipp Hoier, Franci Pušavec, and Peter Krajnik. 2024. "Effect of Lubricated Liquid Carbon Dioxide (LCO2 + MQL) on Grinding of AISI 4140 Steel" Journal of Manufacturing and Materials Processing 8, no. 5: 230. https://doi.org/10.3390/jmmp8050230

APA StyleKareepadath Santhosh, D., Hoier, P., Pušavec, F., & Krajnik, P. (2024). Effect of Lubricated Liquid Carbon Dioxide (LCO2 + MQL) on Grinding of AISI 4140 Steel. Journal of Manufacturing and Materials Processing, 8(5), 230. https://doi.org/10.3390/jmmp8050230