Property Evaluation of AA2014 Reinforced with Synthesized Novel Mixture Processed through Squeeze Casting Technique

Abstract

1. Introduction

2. Materials and Methods

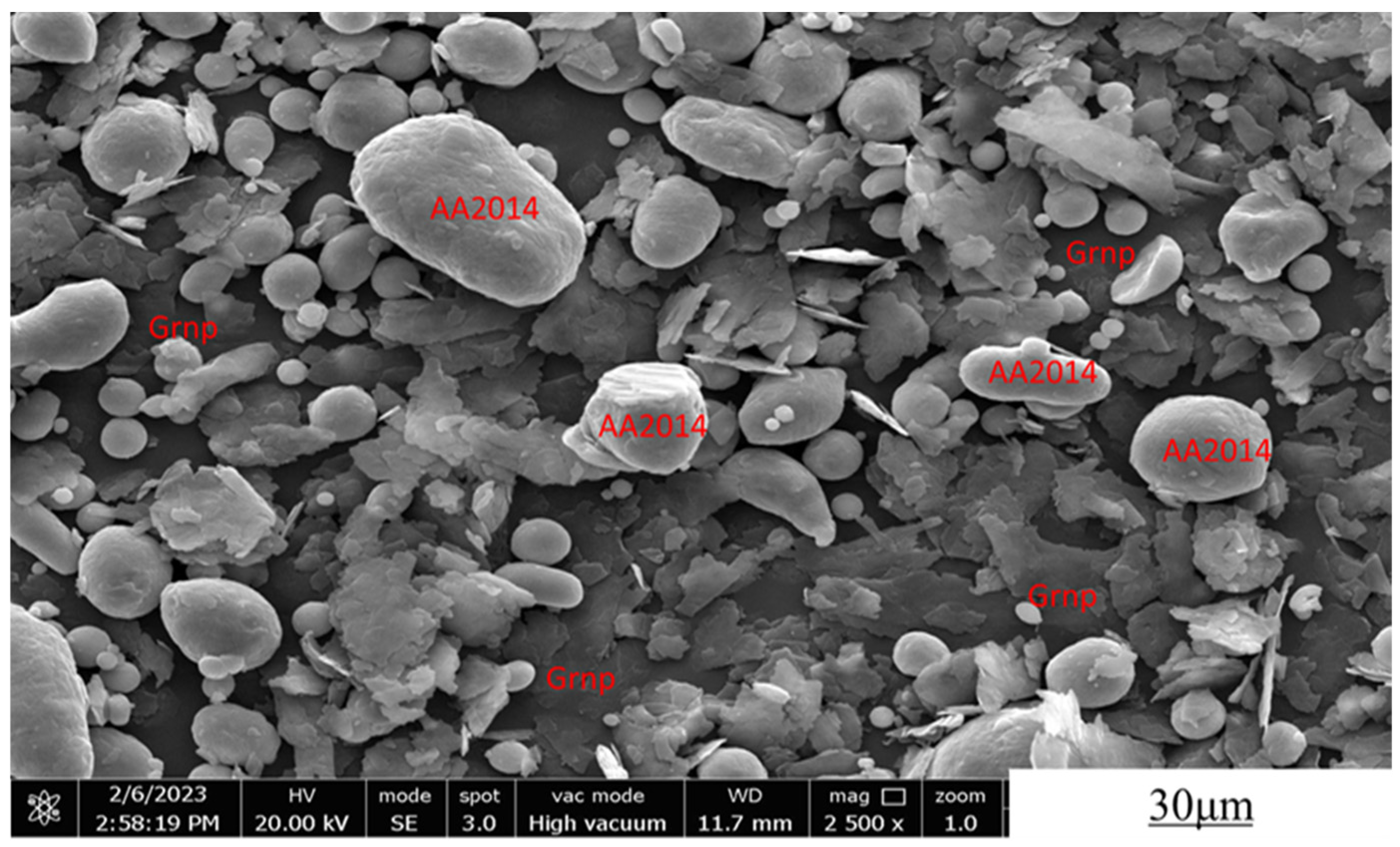

2.1. Synthesis of Novel Powder Mixture AA2014/Graphene Nanoparticles

2.2. Fabrication of Graphene/AA 2014 Composite

2.3. Hot Rolling Process for Novel Mixture-Reinforced AA2014 Matrix Composite

3. Results and Discussion

3.1. Strengthening Mechanism for AA2014 Graphene-Reinforced Casted Plate

- M—is the Taylor factor

- G—is the shear modulus

- b—is the Burgers vector

- ƒ—is a factor related to obstacles

- r—is a characteristic length related to obstacles

- L—is the obstacle spacing

- Dp—is likely the diameter or some dimension related to the precipitates or obstacles.

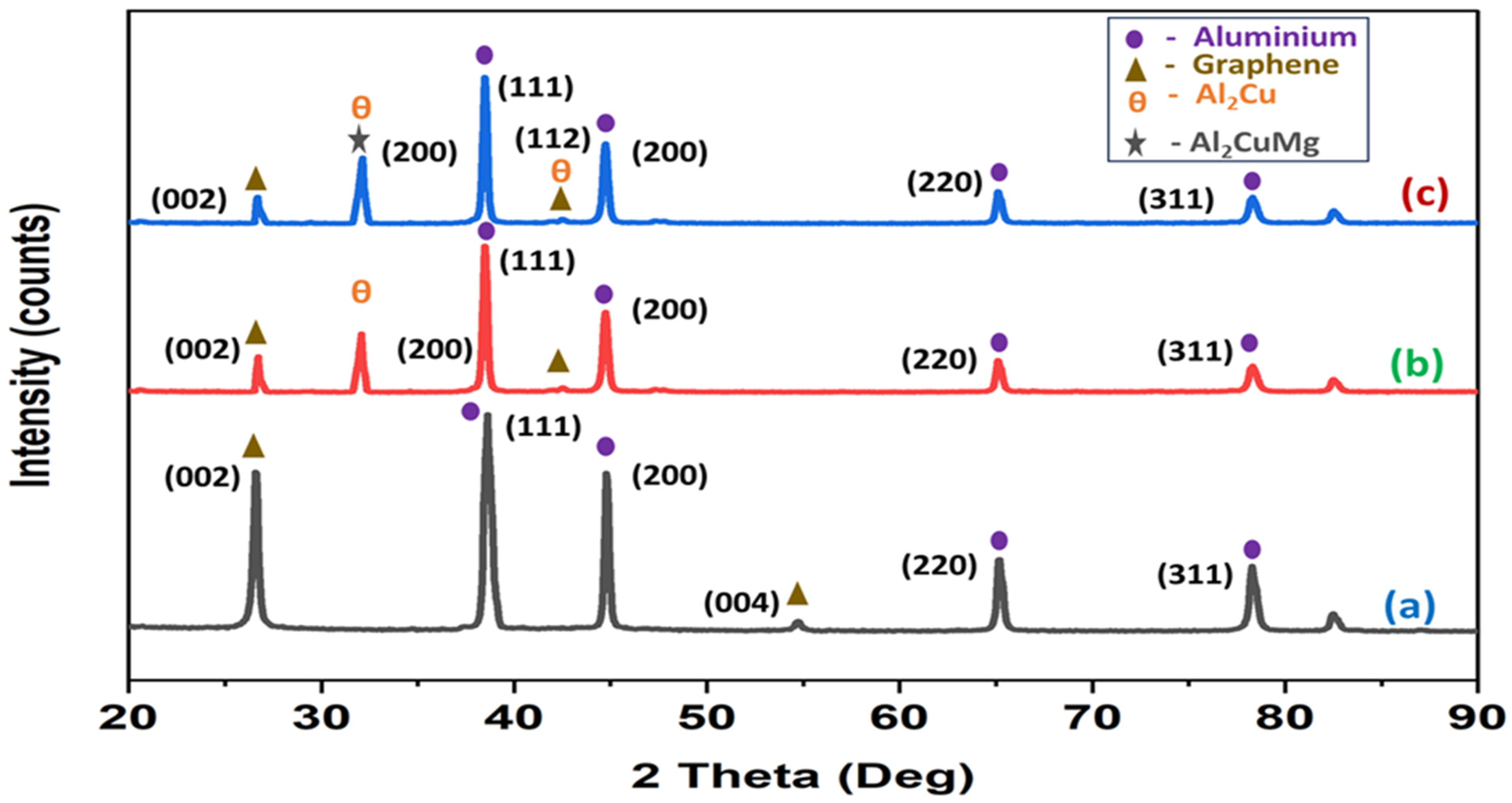

3.2. XRD Analysis

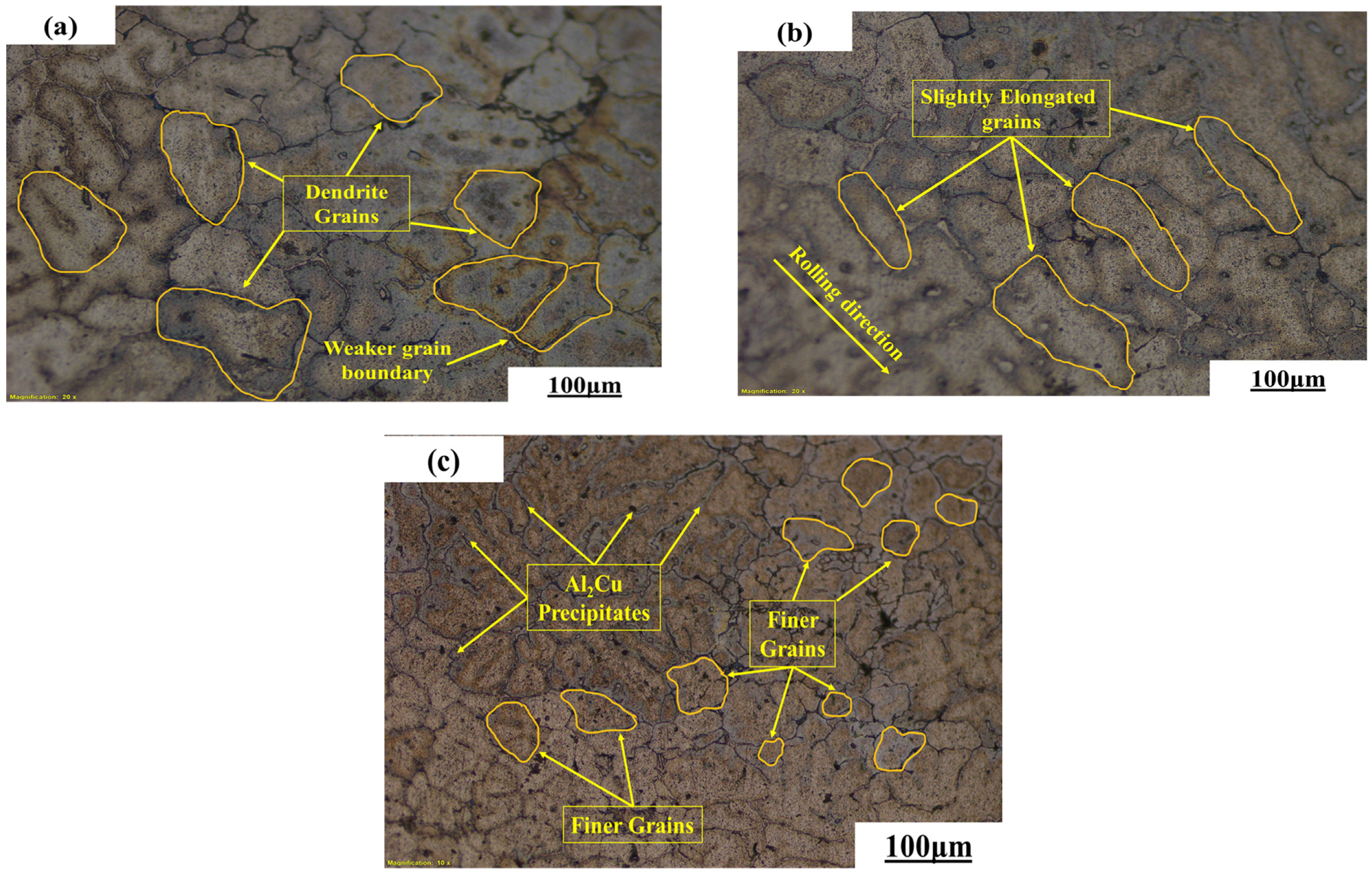

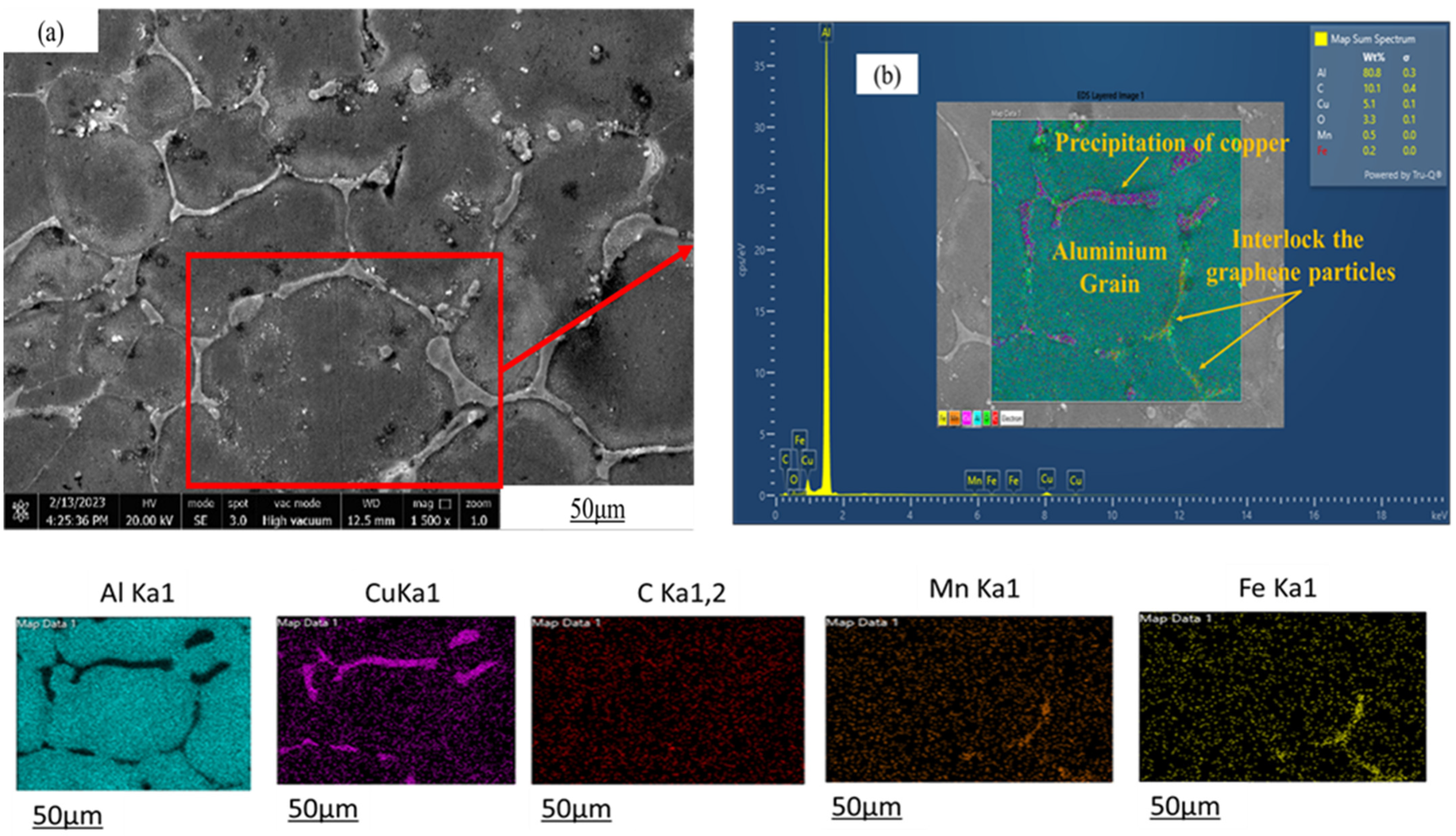

3.3. Microstructural Analysis

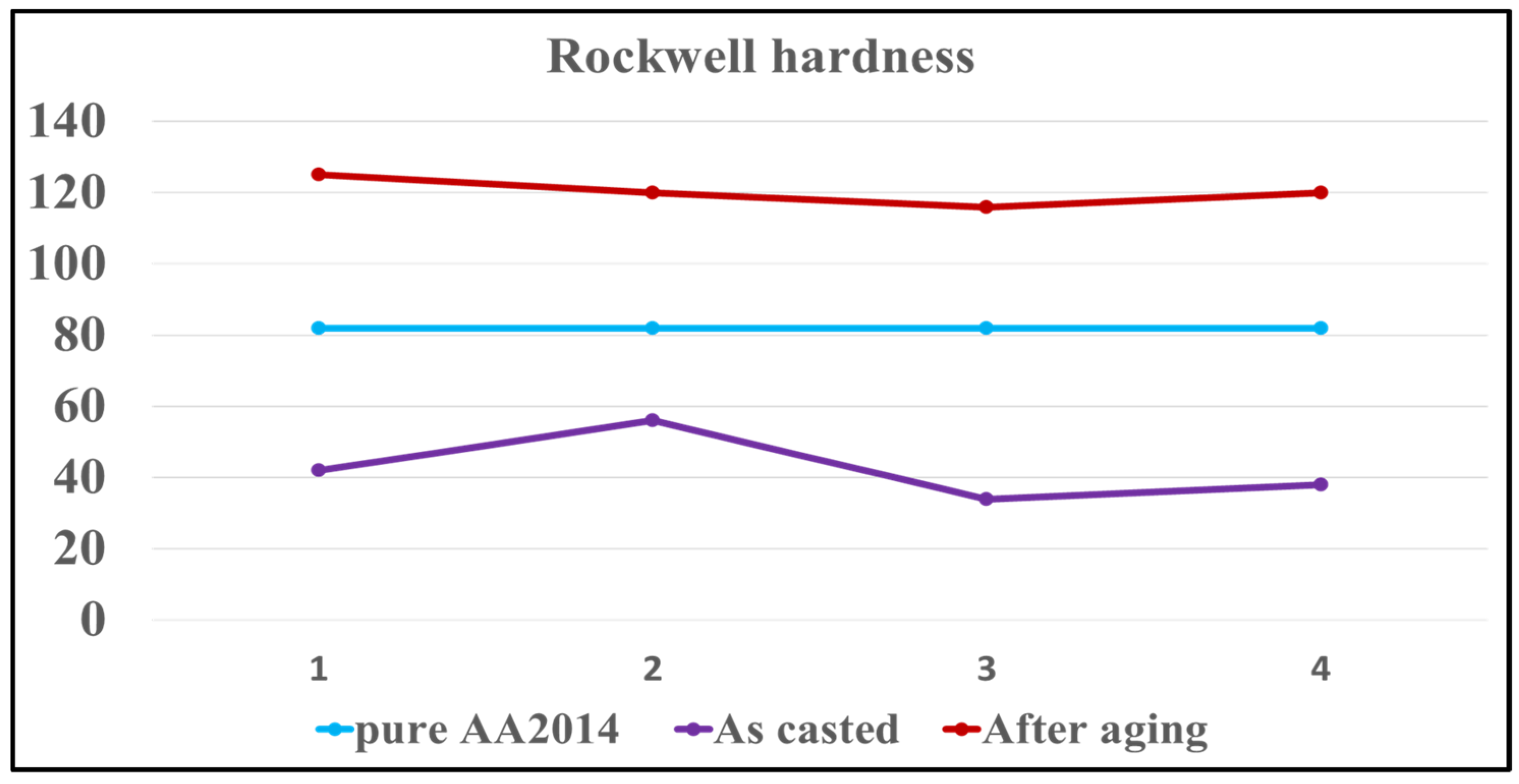

3.4. Rockwell Hardness Test

3.5. Tensile Behavior

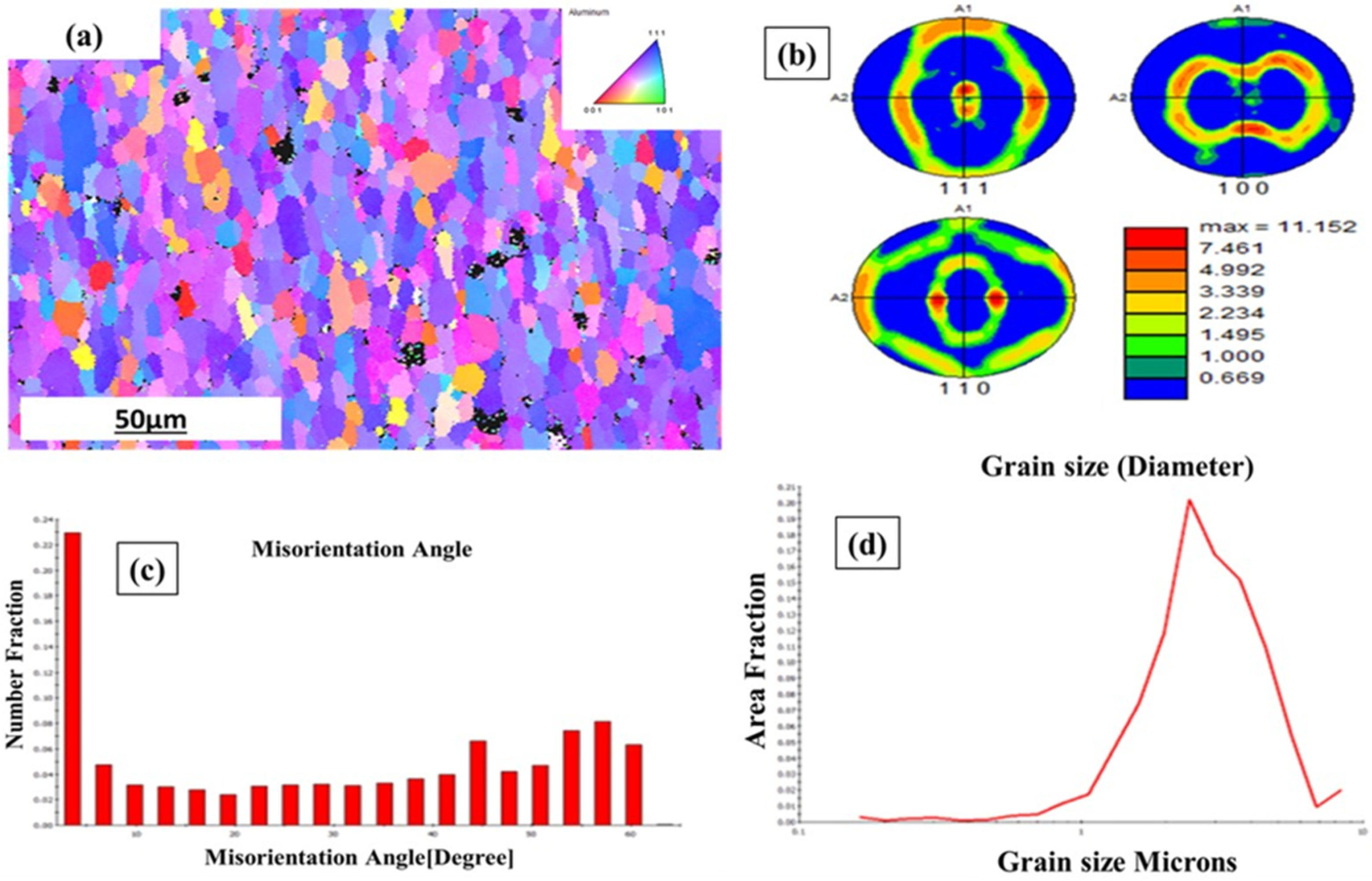

3.6. EBSD Analysis

4. Conclusions

- During the stirring process, AA2014 powder in the novel mixture acted as a transporting agent for graphene particles. This resulted in the uniform dispersion of graphene into the final cast.

- By analyzing the FESEM images, it was observed that graphene nanoparticles were homogenously dispersed in the AA2014 MMCs. The analysis also confirmed that the graphene particles were embedded and interlocked throughout the grain boundary of the AA2014 matrix.

- During the hot rolling process, the aluminum grains were well-refined in the rolled plate, which enhanced the mechanical properties of the developed composite.

- The mechanical properties of 0.5 wt% graphene-reinforced AA2014 were exhibited. It was found that the Rockwell hardness increased from 82 to 120 HRB and UTS from 185 to 420 MPa after rolling and the T6 heat treatment process.

- EBSD data confirmed the dispersion of graphene particles and elongation of grains due to the rolling process. The addition of AA 2014/graphene mixture (reinforcement) to the matrix significantly inhibited crystallization during the post-deformation annealing process.

- The addition of graphene nanoplates resulted in a significant grain refinement, with the average grain size decreasing from 120 μm in the monolithic alloy to around 70 μm in the graphene-reinforced composite due to homogeneous dispersion of graphene particles.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hirsch, J. Aluminium in innovative light-weight car design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef]

- Haghparast, A.; Nourimotlagh, M.; Alipour, M. Effect of the strain-induced melt activation (SIMA) process on the tensile properties of a new developed super high strength aluminum alloy modified by Al5Ti1B grain refiner. Mater. Charact. 2012, 71, 6–18. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.J.; Dai, S.L.; Zhang, X.Y.; Yang, C.; Hong, Q.H.; Chen, J.Z.; Lin, Z.M. Investigating aluminum alloy reinforced by graphene nanoflakes. Mater. Sci. Eng. A 2014, 612, 440–444. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H. Fabrication and heat treatment of graphene nanoplatelets reinforced aluminium nanocomposites. Mater. Sci. Eng. A 2020, 791, 139657. [Google Scholar] [CrossRef]

- Ali, A.M.; Omar, M.Z.; Hashim, H.; Salleh, M.S.; Mohamed, I.F. Recent development in graphene-reinforced aluminium matrix composite: A review. Rev. Adv. Mater. Sci. 2021, 60, 801–817. [Google Scholar] [CrossRef]

- Pekok, M.A.; Setchi, R.; Ryan, M.; Gu, H.; Han, Q.; Gu, D. Al-Cu-Mg Alloy Powder Reinforced with Graphene Nanoplatelets: Morphology, Flowability and Discrete Element Simulation. J. Manuf. Mater. Process. 2022, 6, 148. [Google Scholar] [CrossRef]

- Naseer, A.; Ahmad, F.; Aslam, M.; Guan, B.H.; Harun, W.S.W.; Muhamad, N.; Raza, M.R.; German, R.M. A review of processing techniques for graphene-reinforced metal matrix composites. Mater. Manuf. Process. 2019, 34, 957–985. [Google Scholar] [CrossRef]

- Khanna, V.; Kumar, V.; Bansal, S.A. Mechanical properties of aluminium-graphene/carbon nanotubes (CNTs) metal matrix composites: Advancement, opportunities, and perspective. Mater. Res. Bull. 2021, 138, 111224. [Google Scholar] [CrossRef]

- Mertdinç-Ülküseven, S.; Savacı, U.; Onbasli, K.; Balcı-Çağıran, Ö.; Acar, H.Y.; Öveçoğlu, M.L.; Ağaoğulları, D. In-situ synthesis of graphene encapsulated Fe/Fe2O3 nanoparticles for possible biomedical applications. J. Mater. Res. Technol. 2022, 20, 2558–2577. [Google Scholar] [CrossRef]

- Liu, W.; Chen, Q.; Huang, Y.; Wang, D.; Li, L.; Liu, Z. In situ laser synthesis of Pt nanoparticles embedded in graphene films for wearable strain sensors with ultra-high sensitivity and stability. Carbon 2022, 190, 245–254. [Google Scholar] [CrossRef]

- Yehia, H.M.; Nouh, F.; El-Kady, O.A.; Abdelwahed, K.; El-Bitar, T. Homogeneous dispersion and mechanical performance of aluminum reinforced with high graphene content. J. Compos. Mater. 2022, 56, 29. [Google Scholar] [CrossRef]

- Alam, M.A.; Ya, H.B.; Azeem, M.; Mustapha, M.; Yusuf, M.; Masood, F.; Ansari, A.H. Advancements in aluminum matrix composites reinforced with carbides and graphene: A comprehensive review. Nanotechnol. Rev. 2023, 12, 20230111. [Google Scholar] [CrossRef]

- Kumar, L.D.; Kulkarni, S.S.; Deepu, J.N.; Subramani, N.; Sivaprakash, K. Investigation of mechanical & corrosion properties of graphene, R-glass fiber reinforced Aluminium 2024 hybrid composites. Mater. Today Proc. 2021, 43, 1684–1693. [Google Scholar]

- Zeng, X.; Teng, J.; Yu, J.G.; Tan, A.S.; Fu, D.F.; Zhang, H. Fabrication of homogeneously dispersed graphene/Al composites by solution mixing and powder metallurgy. Int. J. Miner. Metall. Mater. 2018, 25, 102–109. [Google Scholar] [CrossRef]

- Li, Z.; Fan, G.; Tan, Z.; Guo, Q.; Xiong, D.; Su, Y.; Zhang, D. Uniform dispersion of graphene oxide in aluminum powder by direct electrostatic adsorption for fabrication of graphene/aluminum composites. Nanotechnology 2014, 25, 325601. [Google Scholar] [CrossRef] [PubMed]

- Nellippallil, A.B.; De, P.S.; Gupta, A.; Goyal, S.; Singh, A.K. Hot Rolling of a Non-heat Treatable Aluminum Alloy: Ther-mo-Mechanical and Microstructure Evolution Model. Trans. Indian Inst. Met. 2016, 70, 1387–1398. [Google Scholar] [CrossRef]

- Dinaharan, I. Liquid metallurgy processing of intermetallic matrix composites. In Intermetallic Matrix Composites Properties and Applications; Woodhead Publishing: Johannesburg, South Africa, 2018; pp. 167–202. [Google Scholar]

- Kumar, U.K.A.V. Method of stir casting of Aluminum metal matrix Composites: A review. Mater. Today Proc. 2017, 4, 1140–1146. [Google Scholar] [CrossRef]

- Pazhani, A.; Venkatraman, M.; Xavior, M.A.; Moganraj, A.; Batako, A.; Paulsamy, J.; Bavan, J.S. Synthesis and characterization of graphene-reinforced AA 2014 MMC using squeeze casting method for lightweight aerospace structural applications. Mater. Des. 2023, 230, 111990. [Google Scholar] [CrossRef]

- Prabu, S.B.; Karunamoorthy, L.; Kathiresan, S.; Mohan, B. Influence of stirring speed and stirring time on dis-tribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 2006, 171, 268–273. [Google Scholar] [CrossRef]

- El-Bitar, T.; Nouh, F.; El-Kady, O.A.; Yehia, H.M. Impact of Graphene and Hot-Rolling on the Microstructure and Mechanical Properties of Aluminum Matrix Nano-Composite. Res. Sq. 2022. preprint version. [Google Scholar] [CrossRef]

- Chen, W.; Yang, T.; Dong, L.; Elmasry, A.; Song, J.; Deng, N.; Elmarakbi, A.; Liu, T.; Lv, H.B.; Fu, Y.Q. Advances in graphene reinforced metal matrix nanocomposites: Mechanisms, processing, modelling, properties, and applications. Nanotechnol. Precis. Eng. 2020, 3, 189–210. [Google Scholar] [CrossRef]

- Brodova, I.; Yolshina, L.; Razorenov, S.; Rasposienko, D.; Petrova, A.; Shirinkina, I.; Shorokhov, E.; Muradymov, R.; Garkushin, G.; Savinykh, A. Effect of Grain Size on the Properties of Aluminum Matrix Composites with Graphene. Metals 2022, 12, 1054. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, X.X.; Li, J.C.; Zhang, X.X.; Muhammad, I.; Lin, G.E.N.G. Preparation and properties of graphene nanoplatelets reinforced aluminum MMCs. Trans. Nonferrous Met. Soc. China 2021, 31, 878–886. [Google Scholar] [CrossRef]

- Liu, H.; Papadimitriou, I.; Lin, F.X.; LLorca, J. Precipitation during high temperature aging of Al−Cu alloys: A multiscale analysis based on first principles calculations. Acta Mater. 2019, 167, 121–135. [Google Scholar] [CrossRef]

- Hu, Z.; Wu, Z.; Luo, S.; Wang, X.; Nian, Q.; Chen, Y.; Nagaumi, H. Large-scale production of graphene aluminum composites by stir casting: Process, microstructure and properties. J. Mater. Res. Technol. 2023, 27, 681–691. [Google Scholar] [CrossRef]

- Neuser, M.; Schaper, M.; Grydin, O. Mechanical and Microstructure Characterisation of the Hypoeutectic Cast Aluminium Alloy AlSi10Mg Manufactured by the Twin-Roll Casting Process. J. Manuf. Mater. Process. 2023, 7, 132. [Google Scholar] [CrossRef]

- Manjunath Naik, H.R.; Manjunath, L.H.; Vinayak, M.; Manjunath Patel, G.C.M.; Saxena, K.K.; Lakshmikanthan, A. Effect of microstructure, mechanical and wear on Al-CNTs/graphene hybrid MMC’S. Adv. Mater. Process. Technol. 2022, 8 (Suppl. 2), 366–379. [Google Scholar]

- Cui, X.; Cai, X.; Wang, Q.; Zhu, X. Preparation and Properties of Modified Graphene Reinforced Aluminum Matrix Composites. Integer. Ferroelectric. 2021, 218, 17–26. [Google Scholar] [CrossRef]

- Du, X.M.; Chen, R.Q.; Liu, F.G. Investigation of Graphene Nanosheets Reinforced Aluminum Matrix Composites. Dig. J. Nanometer. Biostructures 2017, 12, 37–45. [Google Scholar]

- Zheng, Z.; Zhang, X.; Li, J.; Geng, L. Achieving homogeneous distribution of high-content graphene in aluminum alloys via high-temperature cumulative shear deformation. Mater. Des. 2020, 193, 108796. [Google Scholar] [CrossRef]

- Su, J.; Teng, J. Recent progress in graphene-reinforced aluminum matrix composites. Front. Mater. Sci. 2021, 15, 79–97. [Google Scholar] [CrossRef]

- Sadhu, K.K.; Mandal, N.; Sahoo, R.R. SiC/graphene reinforced aluminum metal matrix composites prepared by powder metallurgy: A review. J. Manuf. Process. 2023, 91, 10–43. [Google Scholar] [CrossRef]

| Sample Direction | Procured AA2014 | As-Casted Condition | Hot-Rolled and T6 |

|---|---|---|---|

| Rolling Direction | 185 MPa | 220 MPa | 420 MPa |

| Transverse Direction | 185 MPa | 220 MPa | 338 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manokaran, V.; Michael, A.X. Property Evaluation of AA2014 Reinforced with Synthesized Novel Mixture Processed through Squeeze Casting Technique. J. Manuf. Mater. Process. 2024, 8, 153. https://doi.org/10.3390/jmmp8040153

Manokaran V, Michael AX. Property Evaluation of AA2014 Reinforced with Synthesized Novel Mixture Processed through Squeeze Casting Technique. Journal of Manufacturing and Materials Processing. 2024; 8(4):153. https://doi.org/10.3390/jmmp8040153

Chicago/Turabian StyleManokaran, Venkatraman, and Anthony Xavior Michael. 2024. "Property Evaluation of AA2014 Reinforced with Synthesized Novel Mixture Processed through Squeeze Casting Technique" Journal of Manufacturing and Materials Processing 8, no. 4: 153. https://doi.org/10.3390/jmmp8040153

APA StyleManokaran, V., & Michael, A. X. (2024). Property Evaluation of AA2014 Reinforced with Synthesized Novel Mixture Processed through Squeeze Casting Technique. Journal of Manufacturing and Materials Processing, 8(4), 153. https://doi.org/10.3390/jmmp8040153