Monitoring of the Weld Pool, Keyhole Morphology and Material Penetration State in Near-Infrared and Blue Composite Laser Welding of Magnesium Alloy

Abstract

1. Introduction

2. Materials and Methods

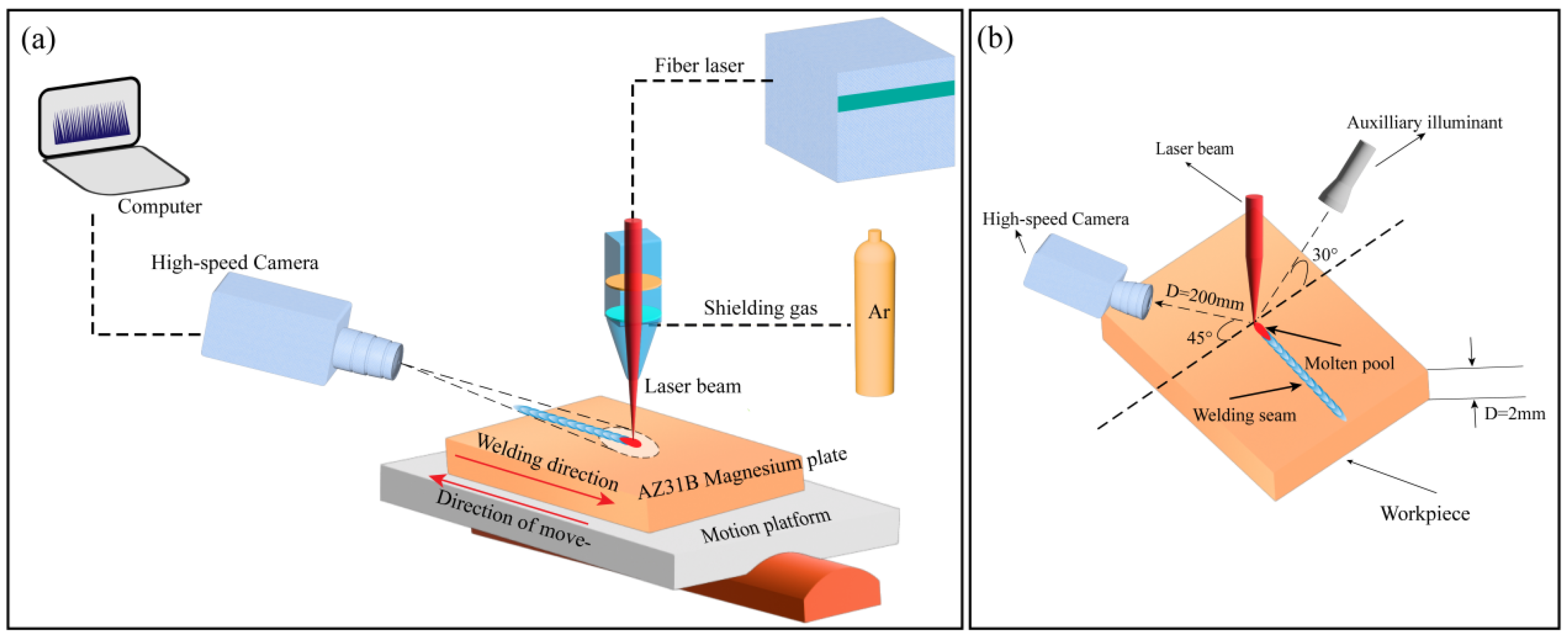

2.1. Experimental Setup

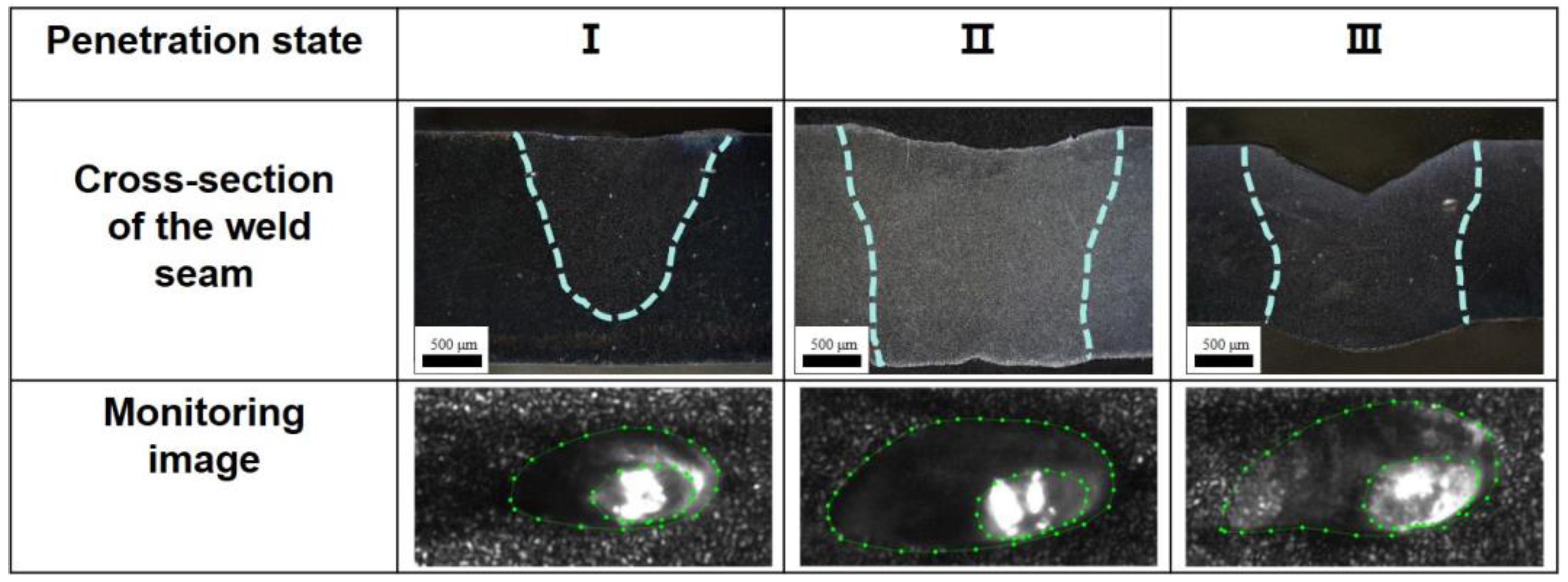

2.2. Penetration State Definition

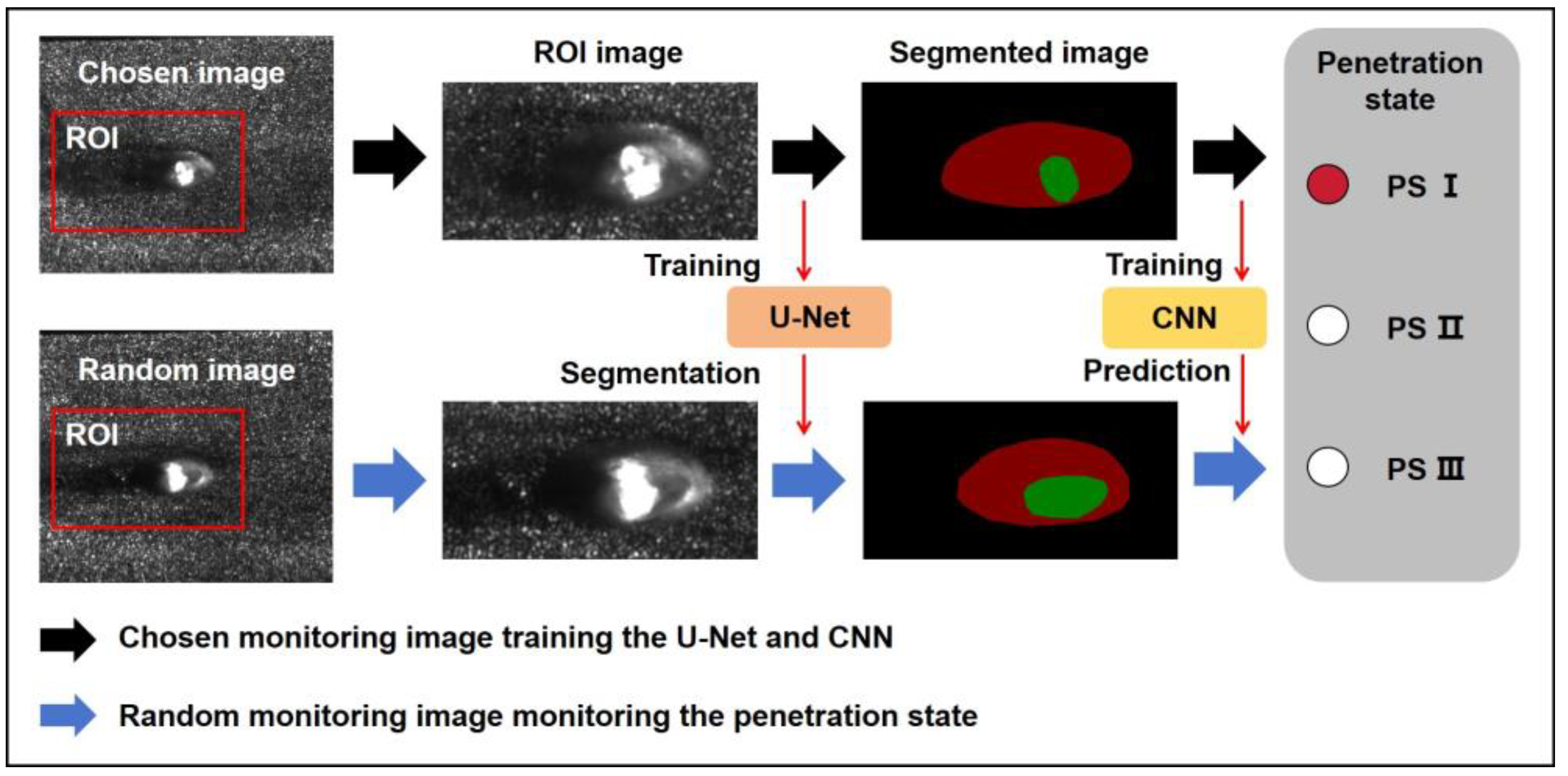

2.3. Overview of the Proposed Monitoring Architecture

3. Results and Discussion

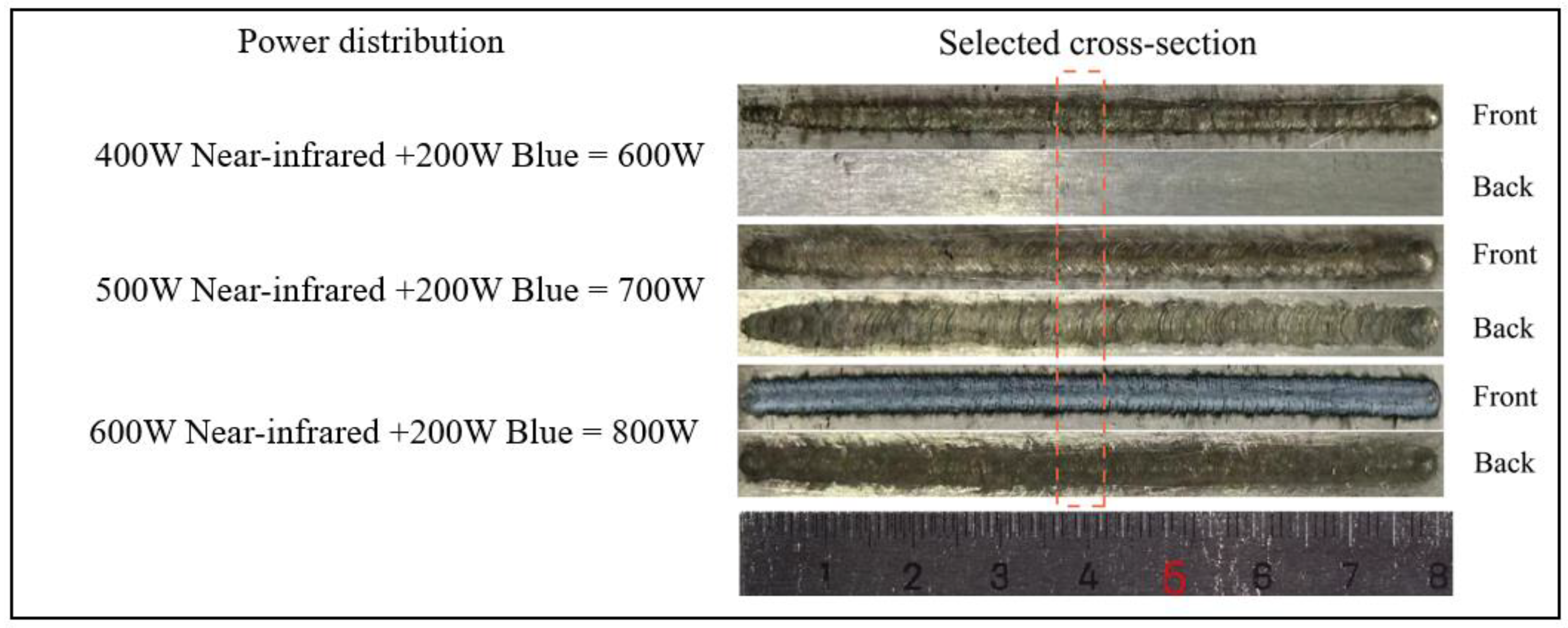

3.1. Weld Morphology at Different Laser Powers

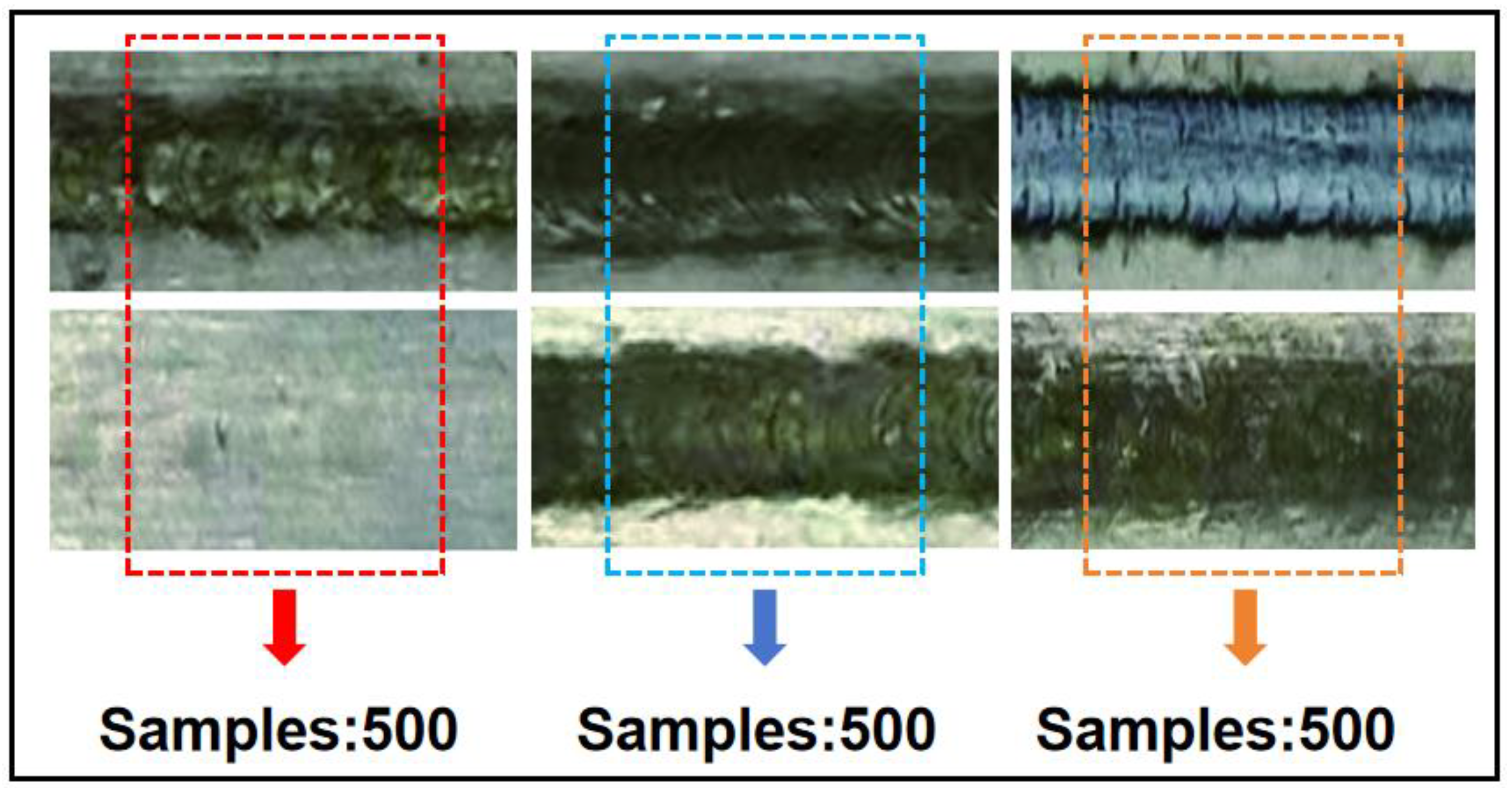

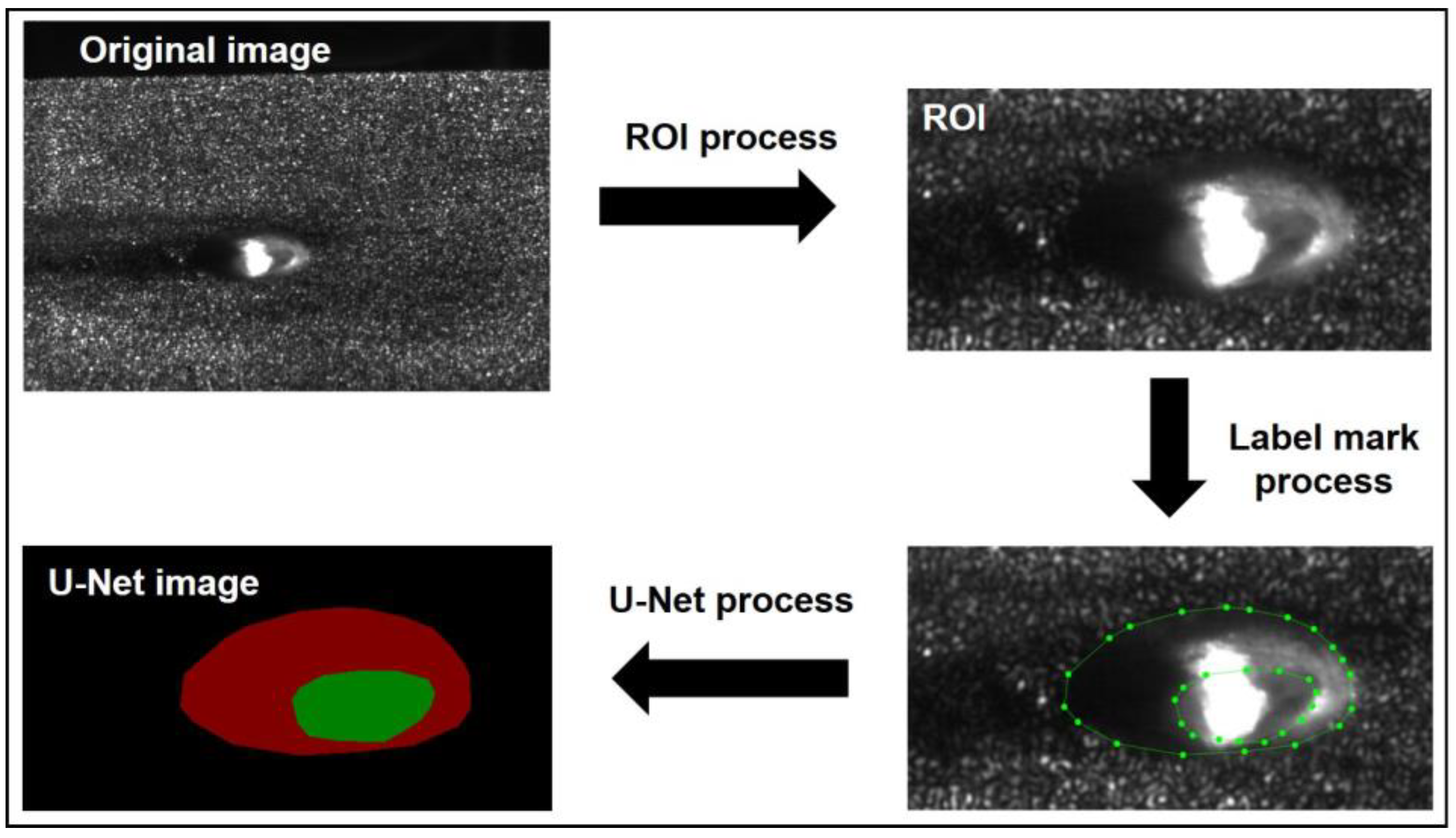

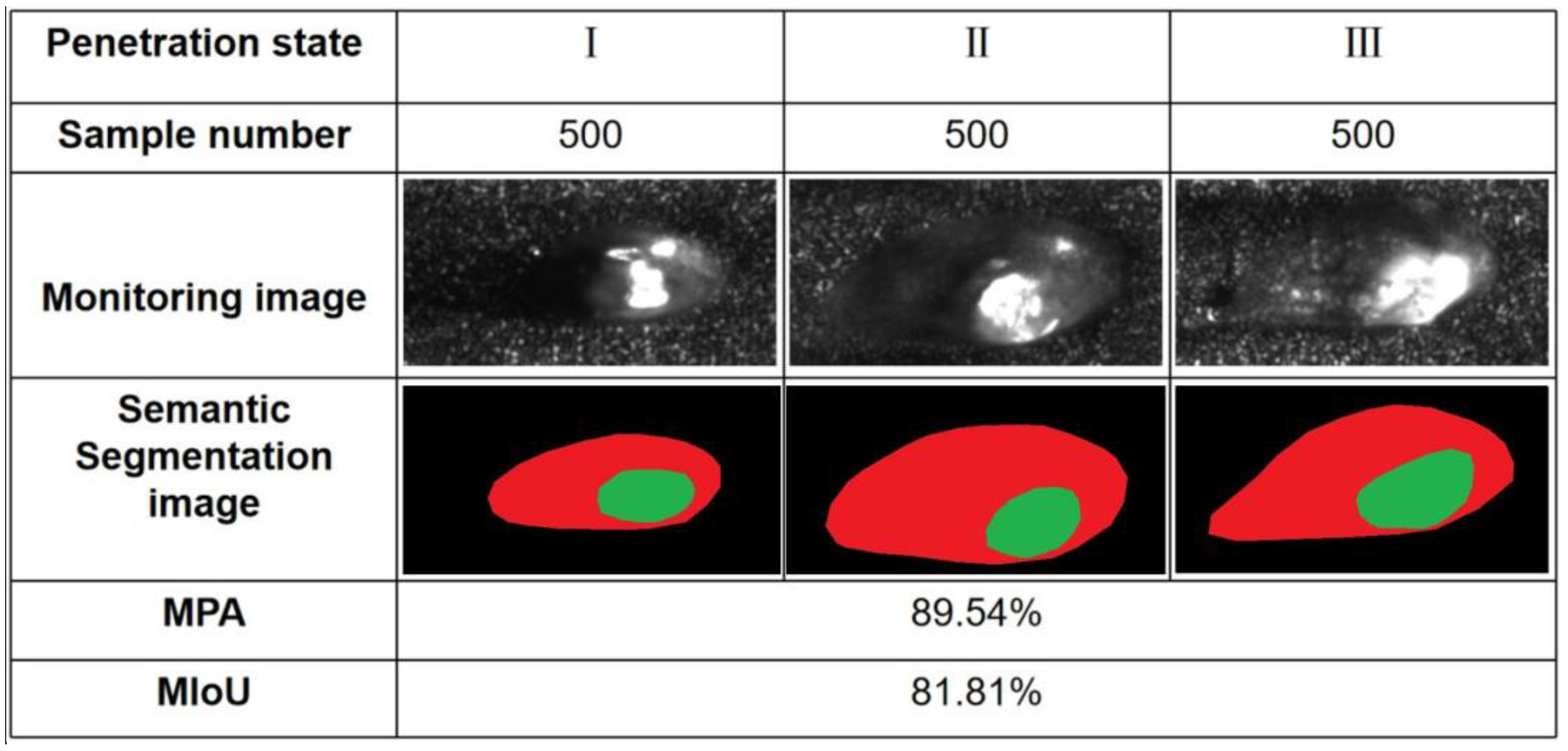

3.2. Data Processing

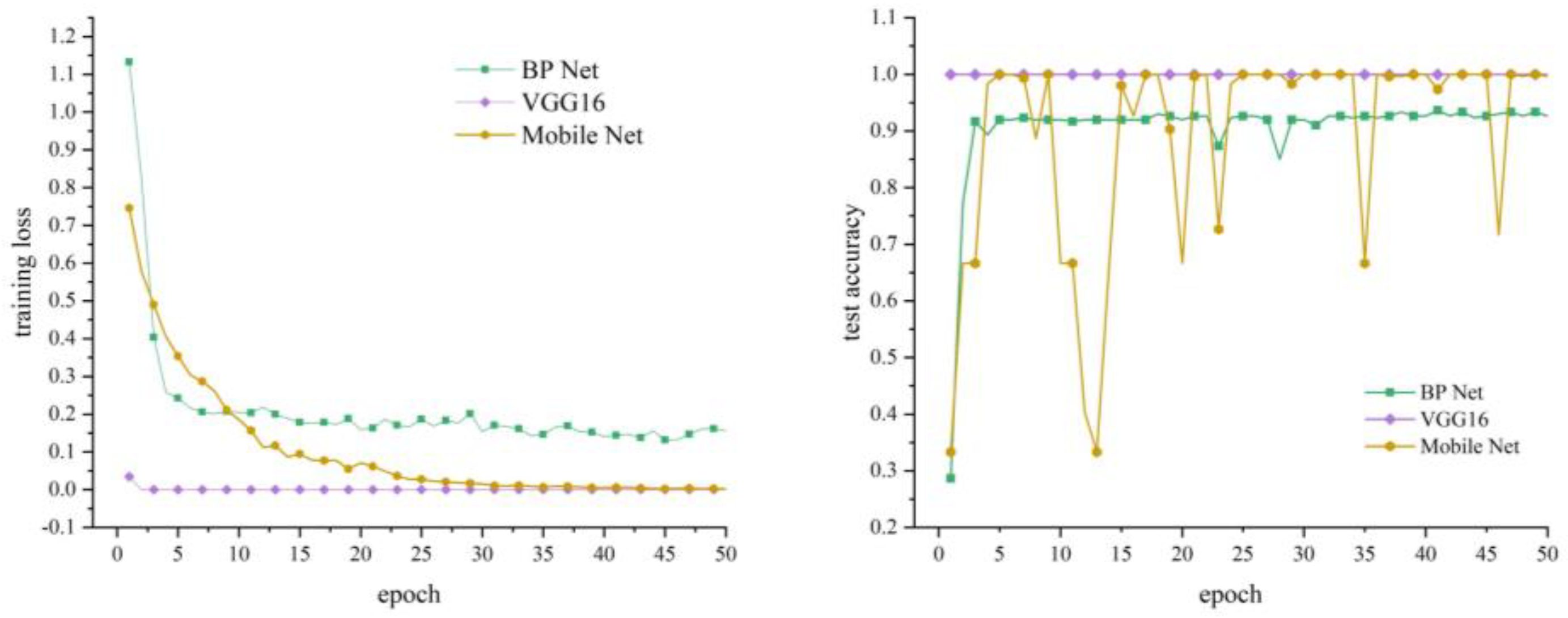

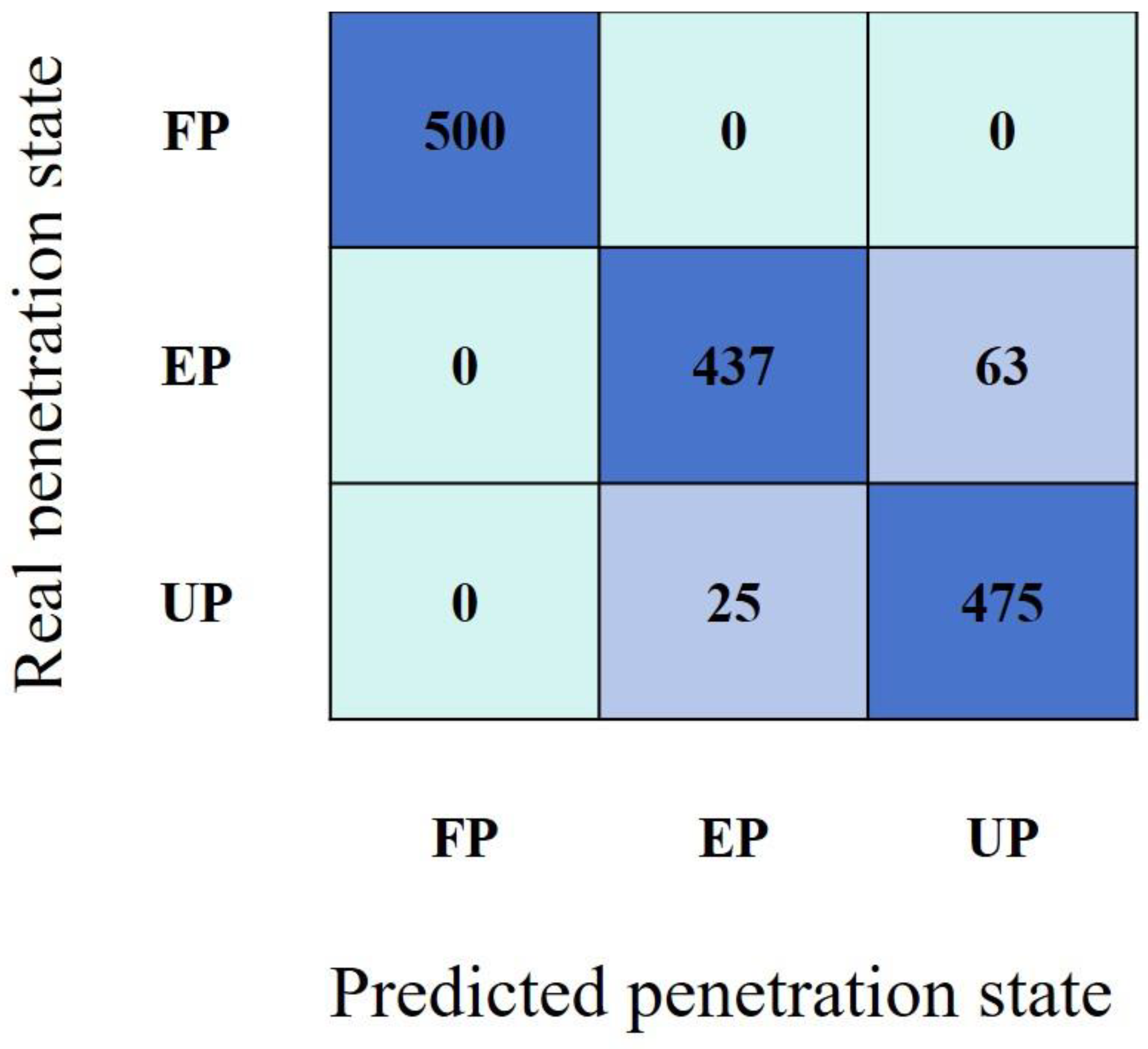

3.3. Penetration State Monitoring Based on CNN

4. Conclusions

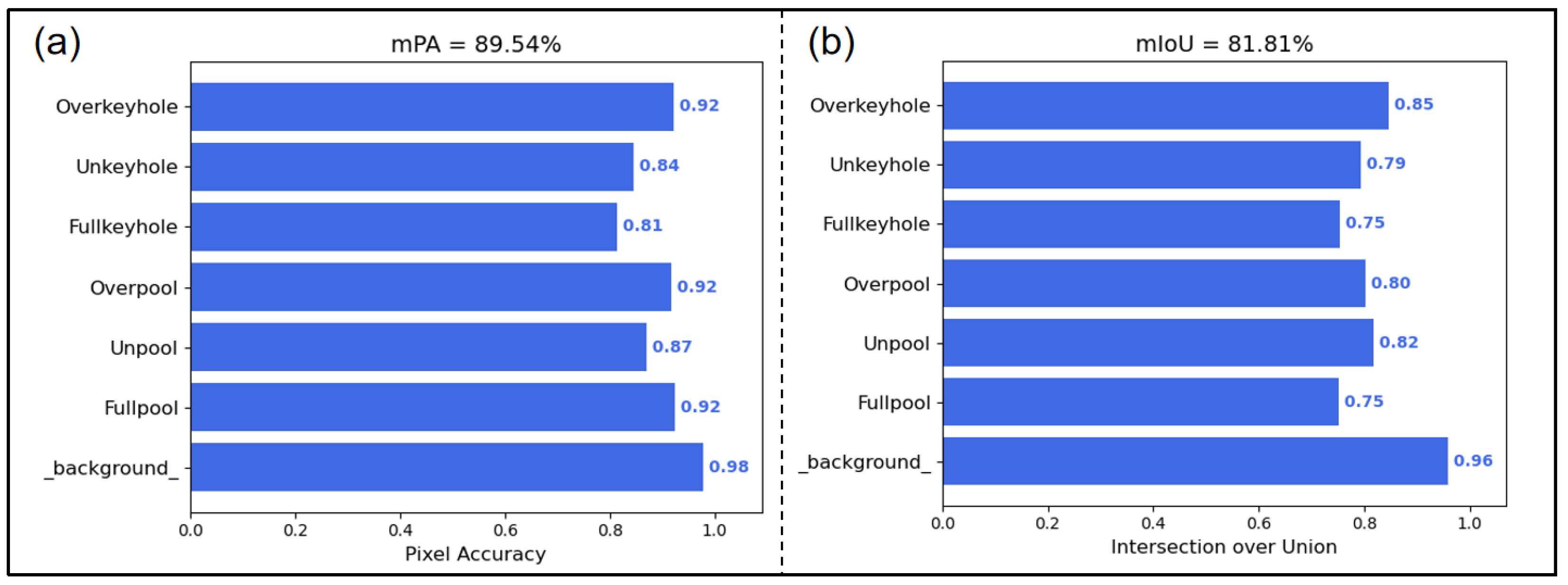

- The U-Net model constructed in this study can accurately extract the contours of the melt pool and keyholes from monitoring images with interference, demonstrating good model performance in the magnesium alloy welding field. The extracted images achieved MPA and MIoU values of 89.54% and 81.81%.

- The proposed image processing method using the VGG16 method can achieve 100% monitoring accuracy, meeting the stringent requirements for monitoring.

- When the focus of the welding process monitoring is solely on determining normality, utilizing the LBP feature + BP neural network approach offers advantages in terms of computational efficiency and model size.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Haferkamp, H.; Niemeyer, M.; Dilthey, U.; Trager, G. Laser and electron beam welding of magnesium materials. Weld. Cutt. 2000, 52, 178–180. [Google Scholar]

- Sanders, P.G.; Keske, J.S.; Leong, K.H.; Kornecki, G. High power Nd:YAG and CO2 laser welding of magnesium. J. Laser Appl. 1999, 11, 96–103. [Google Scholar] [CrossRef]

- Dziubińska, A.; Gontarz, A.; Horzelska, K.; Pieśko, P. The Microstructure and Mechanical Properties of Az31 Magnesium Alloy Aircraft Brackets Produced by a New Forging Technology. Procedia Manuf. 2015, 2, 337–341. [Google Scholar] [CrossRef]

- Nie, P.; Zhi, G.; Lin, H.; Chen, Y.; Xu, Q.; Zhou, J.; Long, Y. Metallurgical analysis of laser welded AZ31/5A06 lap joints with Ti–Ni interlayer. Mater. Sci. Eng. A 2024, 901, 146344. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, C.; Zhou, Z.; Long, H.; Jia, J.; He, L.; Long, Y. Dissimilar laser lap welding of Mg and Al alloys using a CoCrFeNi medium-entropy alloy interlayer. Opt. Laser Technol. 2023, 157, 108639. [Google Scholar] [CrossRef]

- Li, G.; Xu, W.; Jin, X.; Liu, L.; Ding, S.; Li, C. The machinability of stainless steel 316 L fabricated by selective laser melting: Typical cutting responses, white layer and evolution of chip morphology. J. Mater. Process. Technol. 2023, 315, 117926. [Google Scholar] [CrossRef]

- Li, G.; Ye, J.; Xu, W.; Wei, W.; Li, C.; Ding, S. Investigation of coatings with in-situ TiX reinforcements fabricated by additive-subtractive manufacturing: Hardness, microstructure and machinability. Surf. Coat. Technol. 2024, 467, 130271. [Google Scholar] [CrossRef]

- Chen, C.; Jia, J.; Xu, Q.; Zhang, J.; Long, Y. Study on laser welding of Cu/Ti dissimilar materials using a hybrid light source with wavelengths of 455/1080 nm. J. Manuf. Process. 2024, 115, 94–107. [Google Scholar] [CrossRef]

- Yang, H.; Wu, J.; Wei, Q.; Tang, Z.; Wang, A.; Jin, X.; Li, X.; Wu, Y.; Lu, G.; Wang, H.; et al. Stable cladding of high reflectivity pure copper on the aluminum alloy substrate by an infrared-blue hybrid laser. Addit. Manuf. Lett. 2022, 3, 100040. [Google Scholar] [CrossRef]

- Tang, Z.; Wan, L.; Yang, H.; Zhu, C.; Wu, Y.; Wang, H.; Wang, H. Stable conduction mode welding of conventional high-reflectivity metals with 2000 W blue laser. Opt. Laser Technol. 2024, 168, 109971. [Google Scholar] [CrossRef]

- Yuan, G.; Zhou, Z.; Li, X.; Long, Y. Blue laser welding of 7075-T6 aluminum alloy and carbon fiber reinforced polyetheretherketone. Opt. Laser Technol. 2022, 155, 108440. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, Z.; Chen, C.; Long, Y. Comparison study of 6082 Al alloy laser welding using 455 nm blue laser and 1080 nm near-infrared laser. Optik 2023, 272, 170224. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, M.; Tang, H.; Zeng, X. Characterization of AZ31B wrought magnesium alloy joints welded by high power fiber laser. Mater. Charact. 2011, 62, 943–951. [Google Scholar] [CrossRef]

- Xu, Y.; Qian, P.; Qiao, Y.; Li, J.; Zhang, J. Study on laser welding process, microstructure and properties of AZ31B magnesium alloy. Trans. Indian Inst. Met. 2022, 75, 2905–2912. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, J.; Mao, C.; Cheng, B.; Shakhawat, H.M.; Li, H.; Wang, K.; Zhang, J.; Hu, Y.; Bi, Z. Impact of power modulation on weld appearance and mechanical properties during laser welding of AZ31B magnesium alloy. Opt. Laser Technol. 2022, 156, 108490. [Google Scholar] [CrossRef]

- Jiang, P.; Dong, H.; Cai, Y.; Gao, M. Effects of laser power modulation on keyhole behavior and energy absorptivity for laser welding of magnesium alloy AZ31. Int. J. Adv. Manuf. Technol. 2023, 125, 563–576. [Google Scholar] [CrossRef]

- Ning, J.; Na, S.-J.; Zhang, L.J.; Wang, X.; Long, J.; Cho, W.I. Improving thermal efficiency and stability of laser welding process for magnesium alloy by combining power modulation and subatmospheric pressure environment. J. Magnes. Alloys 2022, 10, 2788–2800. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, M.; Chen, X.; Chen, A.; Ma, S.; Jiang, N.; Zhang, S.; Wang, Z.; Lei, Z.; Chen, Y. Vacuum laser beam welding of AZ31 magnesium alloy: Weld formability, microstructure and mechanical properties. Opt. Laser Technol. 2024, 169, 110115. [Google Scholar] [CrossRef]

- Hinton, G.E.; Osindero, S.; Teh, Y.W. A fast learning algorithm for deep belief nets. Neural Comput. 2006, 18, 1527–1554. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Commun. Acm 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Silver, D.; Huang, A.; Maddison, C.J.; Guez, A.; Sifre, L.; Van Den Driessche, G.; Schrittwieser, J.; Antonoglou, I.; Panneershelvam, V.; Lanctot, M.; et al. Mastering the game of Go with deep neural networks and tree search. Nature 2016, 529, 484–489. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Wei, W.; He, G.; Yang, J.; Li, G.; Ding, S. Tool Wear Monitoring Based on the Gray Wolf Optimized Variational Mode Decomposition Algorithm and Hilbert–Huang Transformation in Machining Stainless Steel. Machines 2023, 11, 806. [Google Scholar] [CrossRef]

- Zhao, Y.; Ren, H.; Zhang, Y.; Wang, C.; Long, Y. Layer-wise multi-defect detection for laser powder bed fusion using deep learning algorithm with visual explanation. Opt. Laser Technol. 2024, 174, 110648. [Google Scholar] [CrossRef]

- Cai, W.; Jiang, P.; Shu, L.; Geng, S.; Zhou, Q. Real-time identification of molten pool and keyhole using a deep learning-based semantic segmentation approach in penetration states monitoring. J. Manuf. Process. 2022, 76, 695–707. [Google Scholar] [CrossRef]

- Ai, Y.; Han, S.; Lei, C.; Cheng, J. The characteristics extraction of weld seam in the laser welding of dissimilar materials by different image segmentation methods. Opt. Laser Technol. 2023, 167, 109740. [Google Scholar] [CrossRef]

- Liu, S.; Wu, D.; Luo, Z.; Zhang, P.; Ye, X.; Yi, Z. Measurement of pulsed laser welding penetration based on keyhole dynamics and deep learning approach. Measurement 2022, 199, 111579. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. arXiv 2015, arXiv:1505.04597. [Google Scholar]

- He, G.; Gao, X.; Li, L.; Gao, P. OCT monitoring data processing method of laser deep penetration welding based on HDBSCAN. Opt. Laser Technol. 2024, 179, 111303. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Si | Fe | Cu | Ni | Mg |

|---|---|---|---|---|---|---|---|

| 3.2 | 0.82 | 0.27 | 0.006 | 0.002 | 0.008 | 0.007 | Bal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, W.; Liu, Y.; Deng, H.; Wei, Z.; Wang, T.; Li, G. Monitoring of the Weld Pool, Keyhole Morphology and Material Penetration State in Near-Infrared and Blue Composite Laser Welding of Magnesium Alloy. J. Manuf. Mater. Process. 2024, 8, 150. https://doi.org/10.3390/jmmp8040150

Wei W, Liu Y, Deng H, Wei Z, Wang T, Li G. Monitoring of the Weld Pool, Keyhole Morphology and Material Penetration State in Near-Infrared and Blue Composite Laser Welding of Magnesium Alloy. Journal of Manufacturing and Materials Processing. 2024; 8(4):150. https://doi.org/10.3390/jmmp8040150

Chicago/Turabian StyleWei, Wei, Yang Liu, Haolin Deng, Zhilin Wei, Tingshuang Wang, and Guangxian Li. 2024. "Monitoring of the Weld Pool, Keyhole Morphology and Material Penetration State in Near-Infrared and Blue Composite Laser Welding of Magnesium Alloy" Journal of Manufacturing and Materials Processing 8, no. 4: 150. https://doi.org/10.3390/jmmp8040150

APA StyleWei, W., Liu, Y., Deng, H., Wei, Z., Wang, T., & Li, G. (2024). Monitoring of the Weld Pool, Keyhole Morphology and Material Penetration State in Near-Infrared and Blue Composite Laser Welding of Magnesium Alloy. Journal of Manufacturing and Materials Processing, 8(4), 150. https://doi.org/10.3390/jmmp8040150