Enriching Laser Powder Bed Fusion Part Data Using Category Theory

Abstract

1. Introduction

2. CT-Based Modelling

- For each morphism M in , there are two objects and in that are, respectively, called the domain and codomain of the morphism. The morphism is denoted as . The domain and codomain of the morphism are, respectively, denoted as and ;

- For any three objects , , and in and any two morphisms and in , if and , then there is a morphism called the composition of and ;

- For each object O in , there is an identity morphism that satisfies and for any two morphisms and in satisfying and .

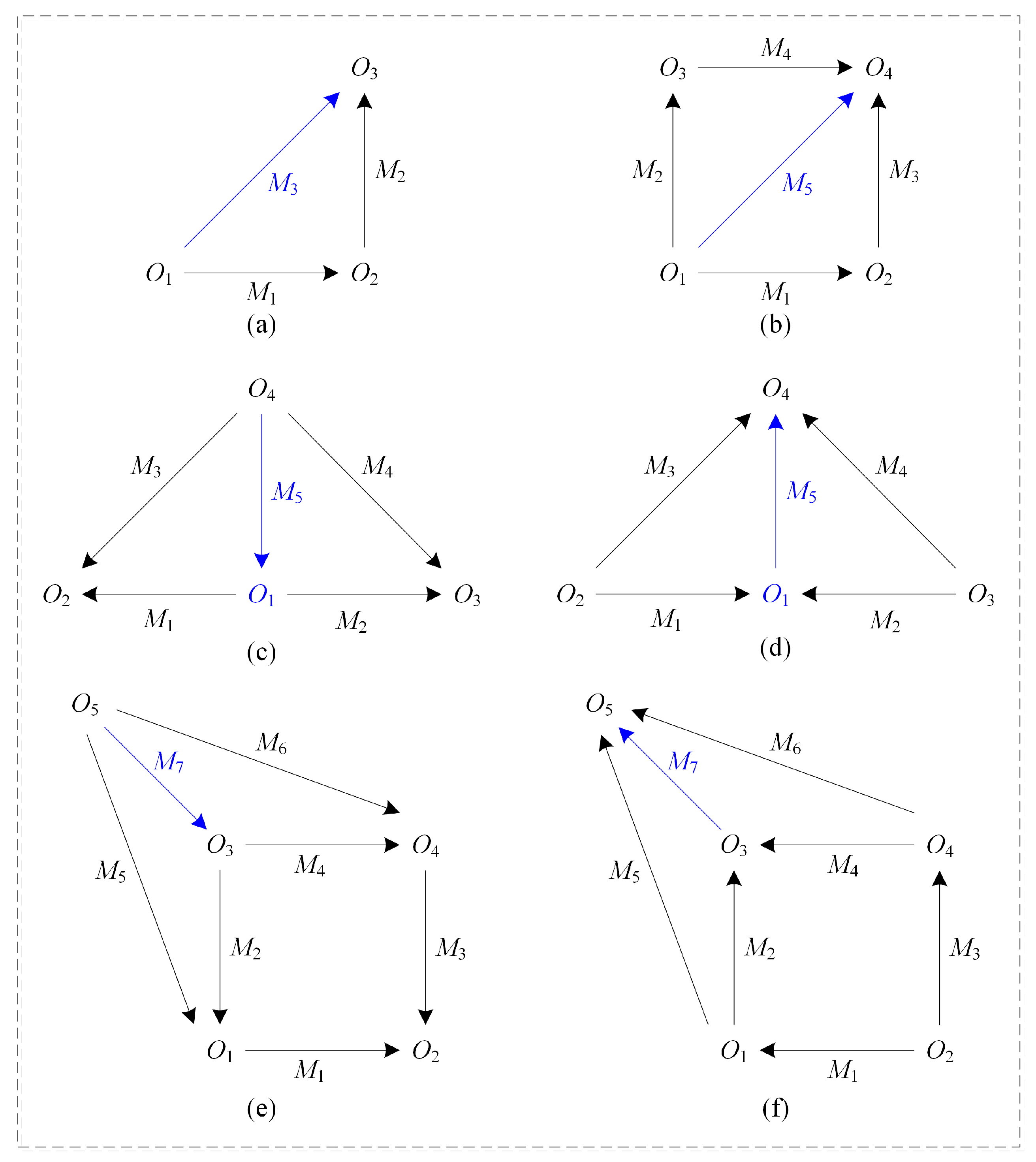

- Triangle structure: If there are two morphisms and among three objects , , and in a category , then a new morphism can be generated in (see Figure 1a);

- Rectangle structure: If there are four morphisms , , , and among four objects , , , and in a category , then a new morphism can be generated in (see Figure 1b);

- Product structure: If there are four morphisms , , , and among four objects , , , and in a category , then a new morphism can be generated in (see Figure 1c);

- Coproduct structure: If there are four morphisms , , , and among four objects , , , and in a category , then a new morphism can be generated in (see Figure 1d);

- Pullback structure: If there are six morphisms , , , , , and among five objects , , , , and in a category , then a new morphism can be generated in (see Figure 1e);

- Pushout structure: If there are six morphisms , , , , , and among five objects , , , , and in a category , then a new morphism can be generated in (see Figure 1f).

- Element: ;

- Object: ;

- Morphism: ;

- Category: ;

- Functor: ;

- Triangle structure: ;

- Rectangle structure: ;

- Product structure: ;

- Coproduct structure: ;

- Pullback structure: ;

- Pushout structure: .

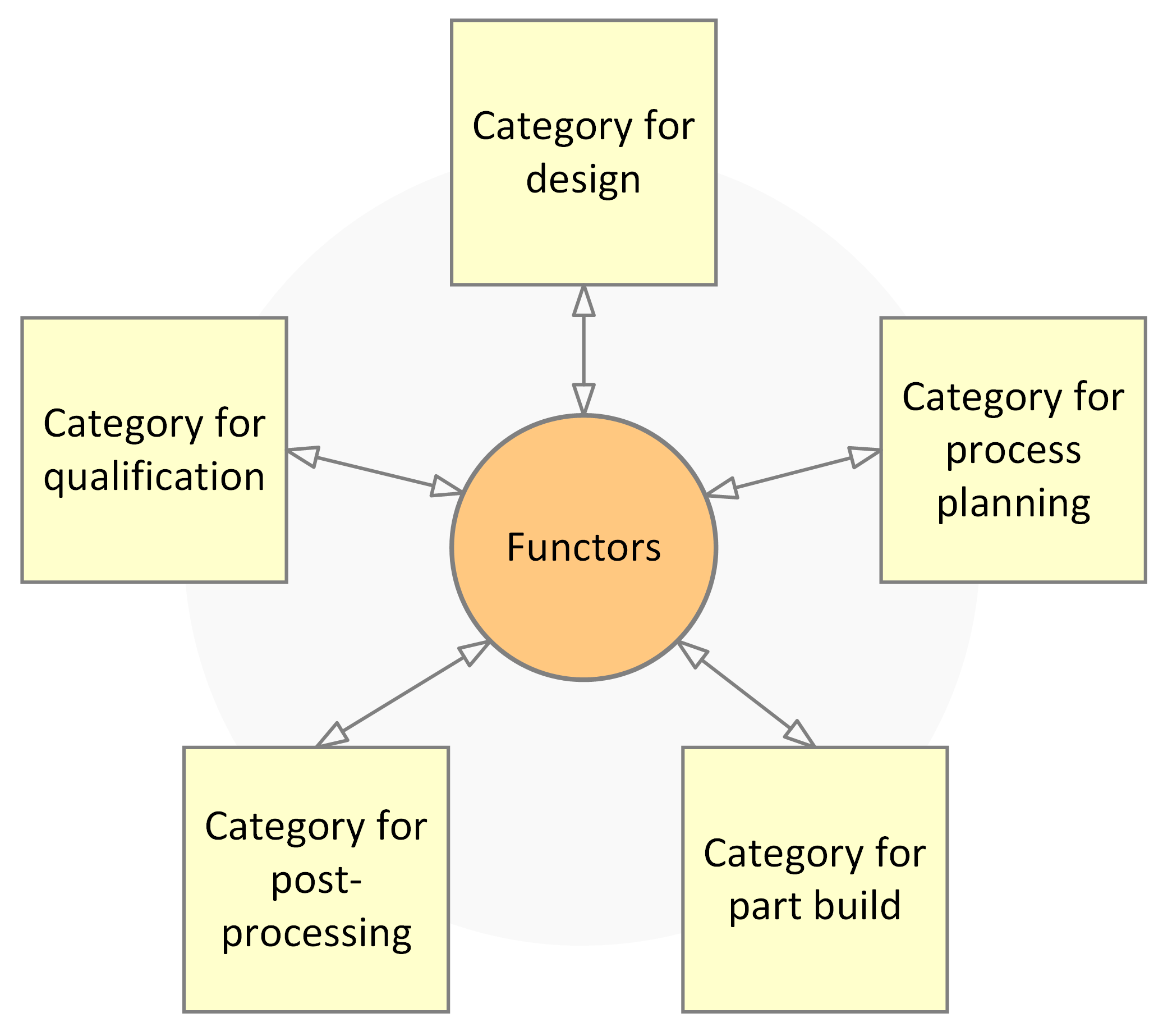

3. Semantically Enriched Model

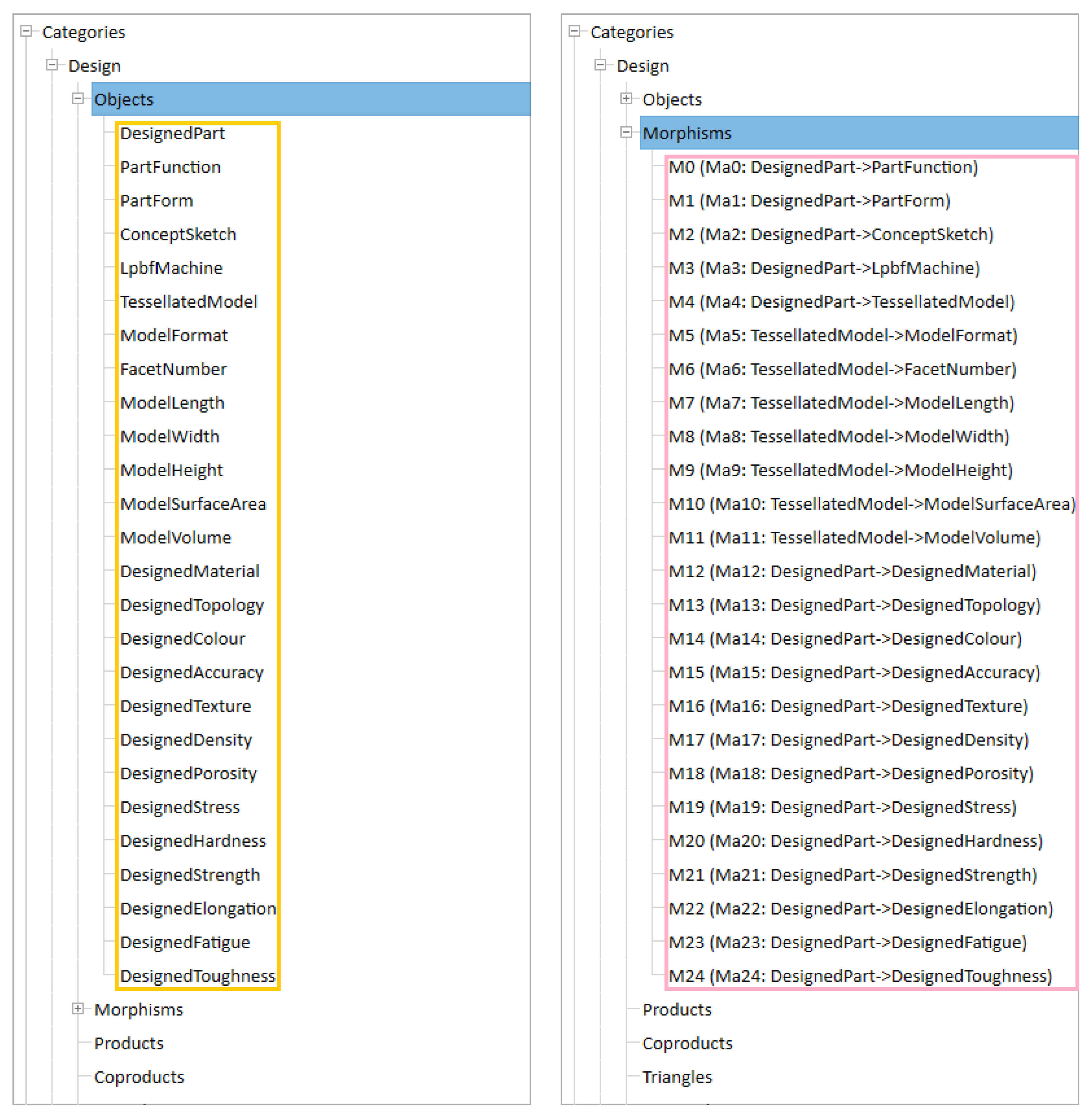

3.1. Category for Design

- Conceptual design: The definition of an LPBF product’s form and function is done in this initial task of the LPBF part realisation process. It describes the suggested LPBF product in concept sketches and entails the design of processes, strategies, interactions, and experiences [55];

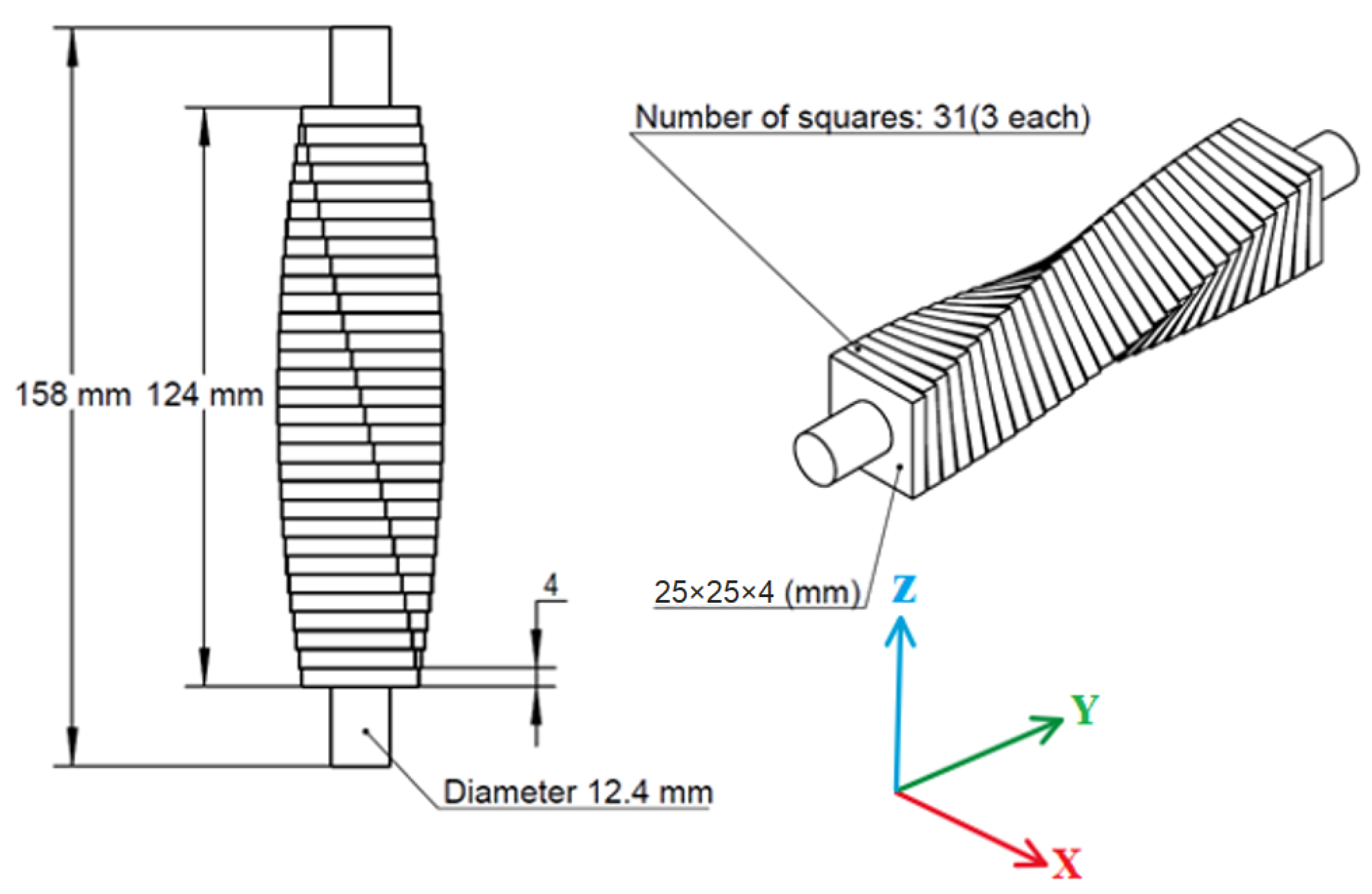

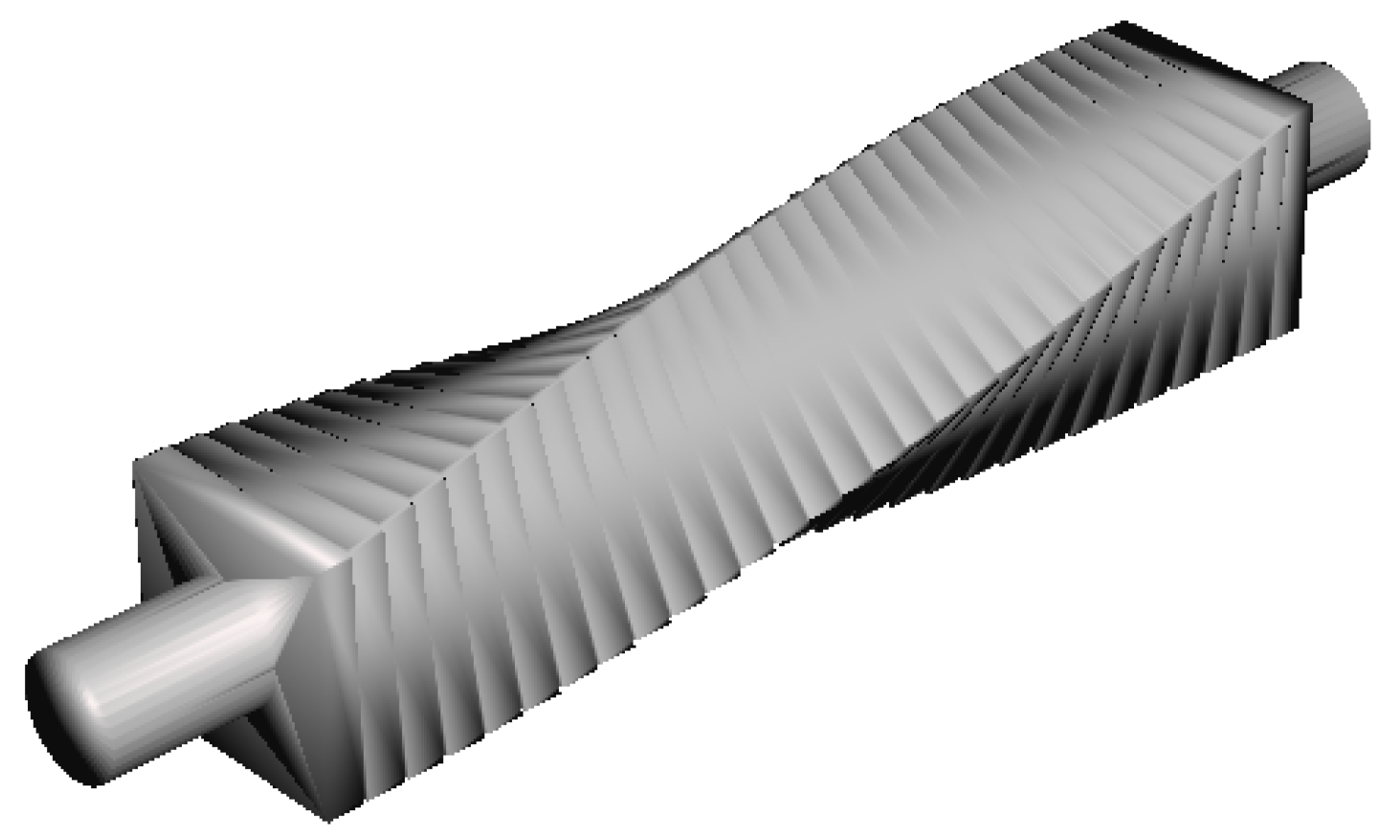

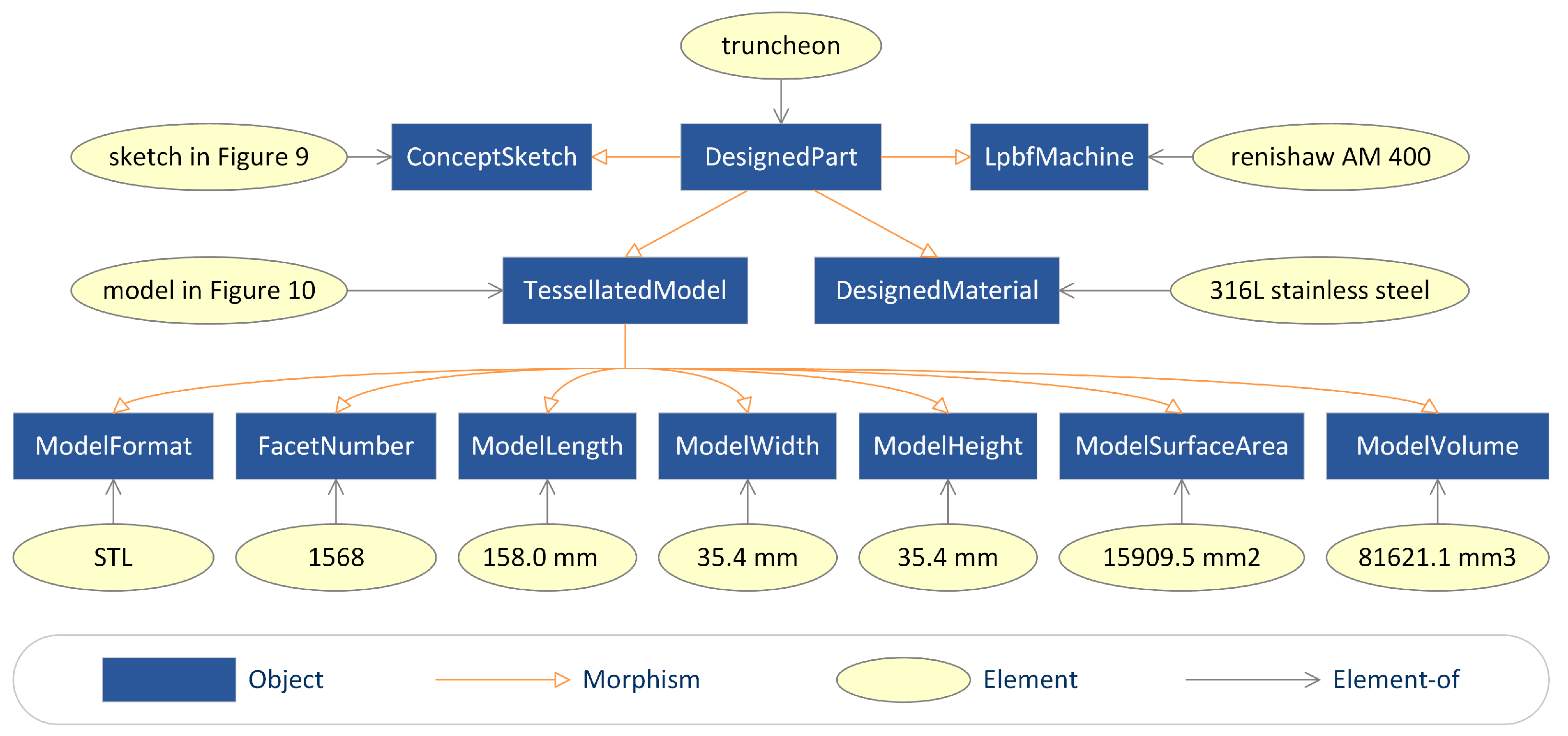

- Detailed design: This task involves creating plans, specifications, estimates, and refining the design. Choosing an LPBF machine to manufacture a product and designing its geometry and parameters are typically included in detailed design. Reverse engineering or computer-aided design (CAD) modelling are two methods for designing geometry. Based on the conceptual design results, CAD modelling is carried out in a CAD system, producing a tessellated 3D model of the product. Reverse engineering generates a tessellated 3D model of a component from its two-dimensional image or physical model. A tessellated 3D model is encoded in a specific format, such as the STL format, 3MF format, AMF format, and OBJ format. The basic geometric information of a tessellated 3D model include number of facets, length, width, height, surface area, and volume. The specifications to be designed could include material, topology, colour, accuracy, surface texture, density, porosity, residual stress, hardness, strength, elongation, fatigue, and toughness [56].

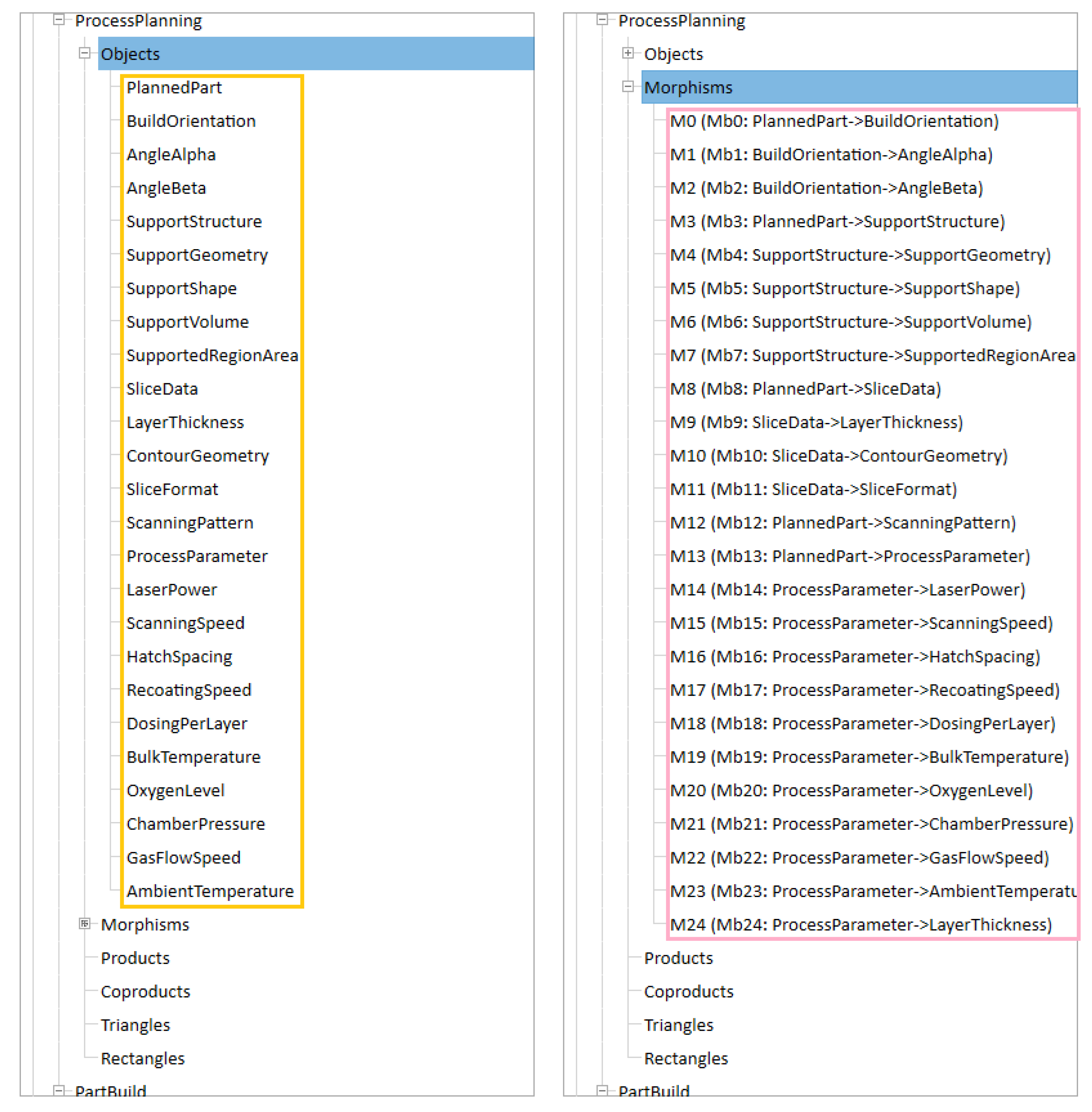

3.2. Category for Process Planning

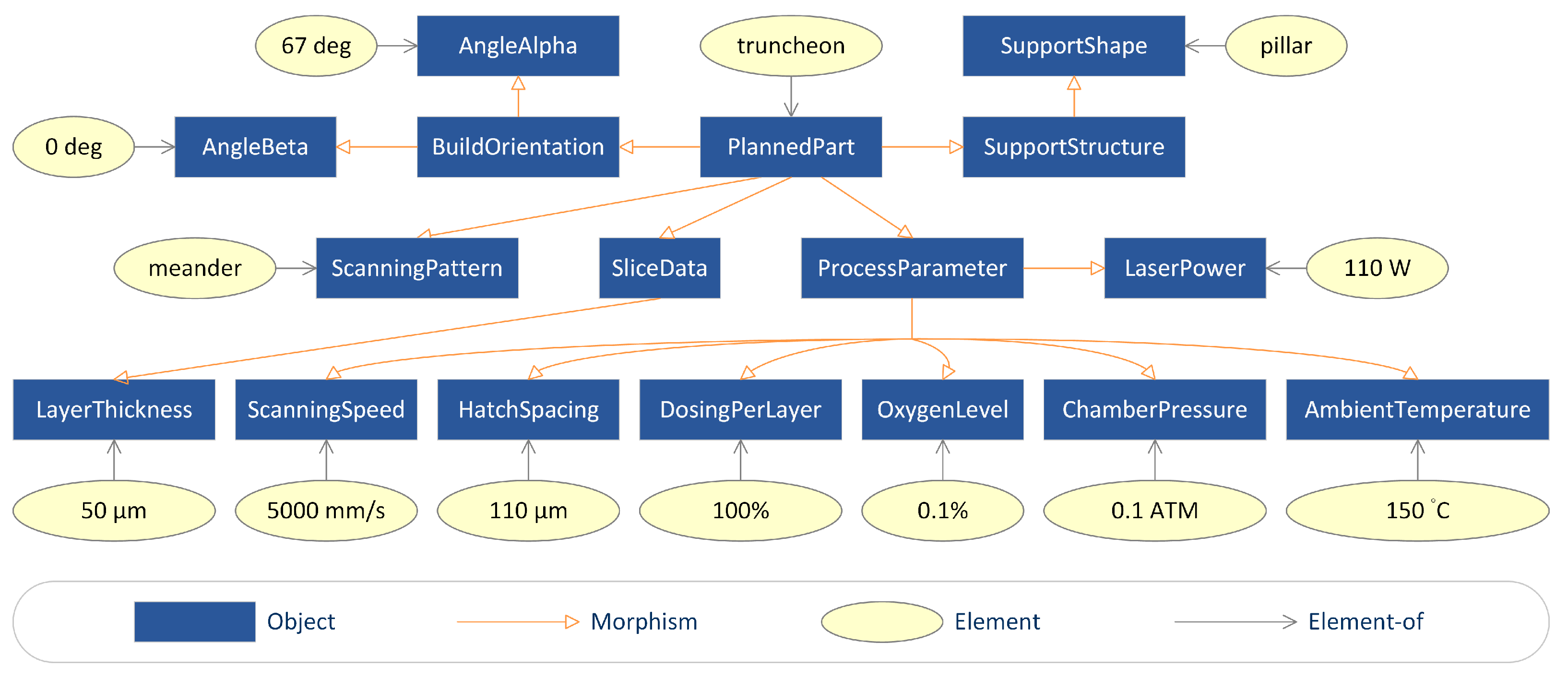

- Part orientation seeks to ascertain an appropriate build orientation based on the LPBF part’s tessellated 3D model and particular manufacturing constraints. The build orientation of an LPBF part is represented by two angles in the majority of the LPBF process planning tools currently in use: and . This ensures that, after rotating the tessellated 3D model around the X and Y axes by and , respectively, the build orientation lines up along the Z axis (the XOY plane is parallel to the build platform). The tessellated 3D model is the result of the design stage. The production requirements are specified based on several characteristics influenced by build orientation, which generally comprise hardness, strength, elongation, residual stress, fatigue, part accuracy, surface texture, support structure, build time, build cost, post-processing time, and post-processing cost [57];

- Support generation focuses on generating the minimum amount of support structure required for building the part on the basis of its tessellated 3D model in the determined build orientation. In LPBF, a support structure can be used to balance a building component to prevent shift or collapse, sustain the overhanging areas to prevent deformation or collapse, or lessen part distortion brought on by temperature gradients. Three importance indicators for describing support structure are geometry, shape, volume, and supported region area. The geometry is usually encoded in the same format as the tessellated 3D model. The shapes of support structures that are applicable for the LPBF process mainly include lattice shape, cellular shape, unit cell shape, tree shape, pin shape, Y shape, and IY shape [58]. The volume of the support structure can be calculated from its geometry. The area of supported region can be obtained from an analysis of the overhanging facets of the tessellated 3D model;

- 3D model slicing entails slicing a tessellated 3D model with the created support structure in the build orientation to ascertain the thickness of individual layers and the geometry of the contour to be gathered. A slice is each individual layer [59]. Typically, a proprietary file format, such as the stereo lithography contour format, the common layer interface format, or the Hewlett-Packard graphics language format [10], is used to encode the slice data, which consists of the layer thickness and contour geometry;

- Path planning focuses on planning the laser scanning path and process parameters to fabricate each layer from the identified slices. An important step in path planning is to select a proper scanning pattern. In general, alternative patterns mainly include tge raster pattern, zigzag pattern, grid pattern, spiral pattern, contour pattern and hybrid pattern [59,60]. Another important step is to specify a group of optimal process parameters. According to the study of Liu et al. [22], controllable process parameters mainly include laser power, scanning speed, hatch spacing, recoating speed, dosing per layer, bulk temperature, oxygen level, chamber pressure, gas flow speed, and ambient temperature.

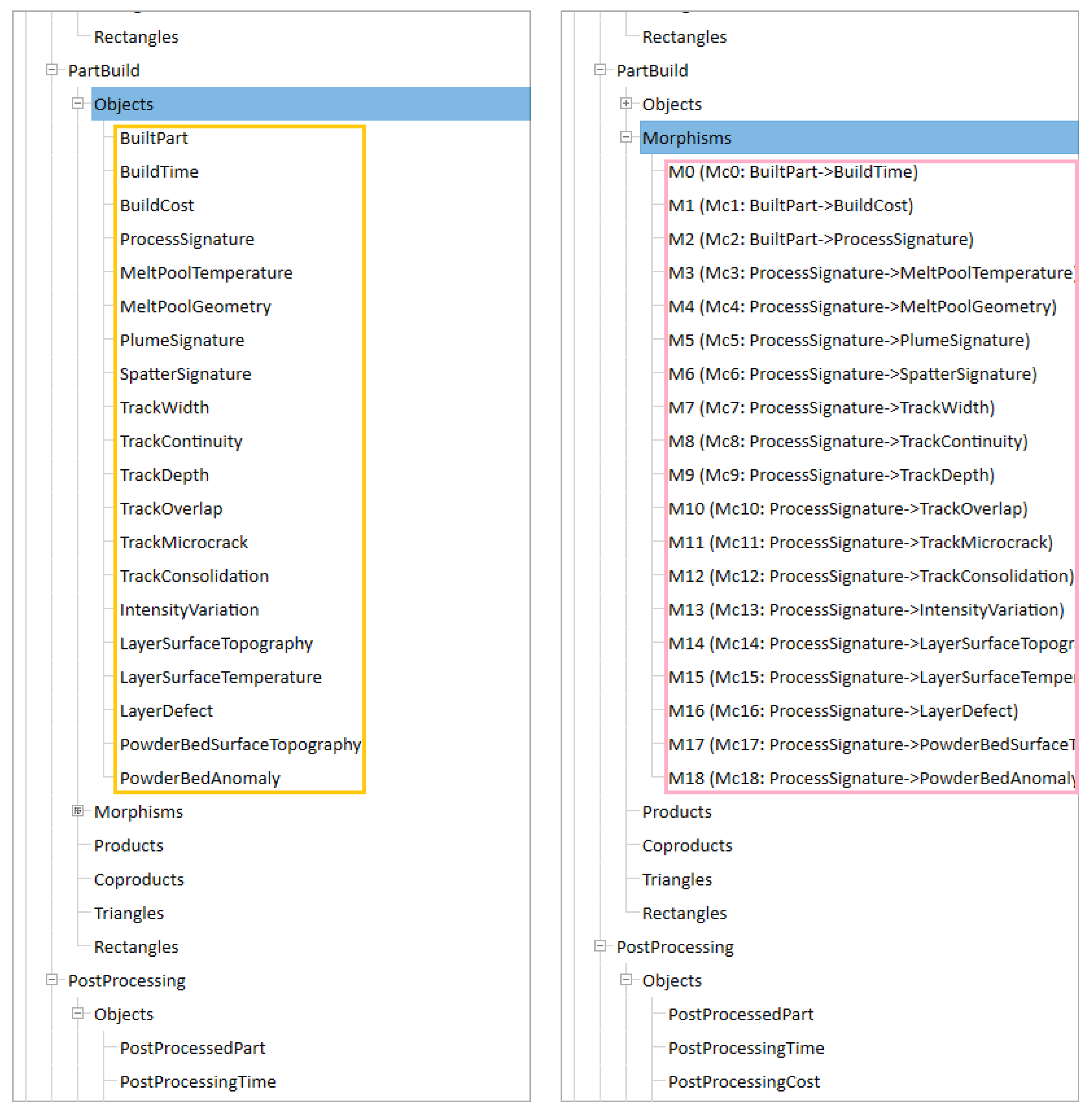

3.3. Category for Part Build

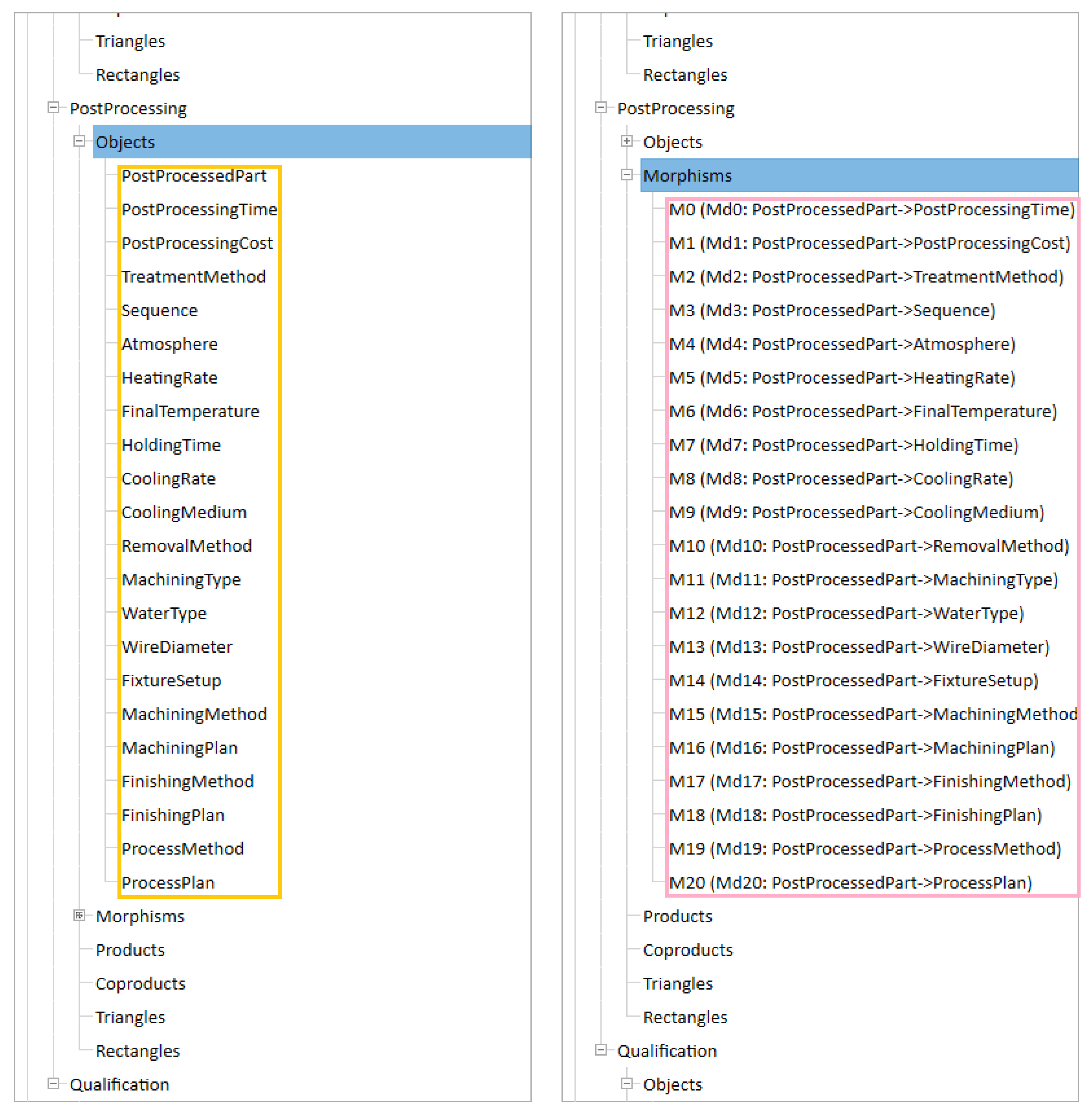

3.4. Category for Post-Processing

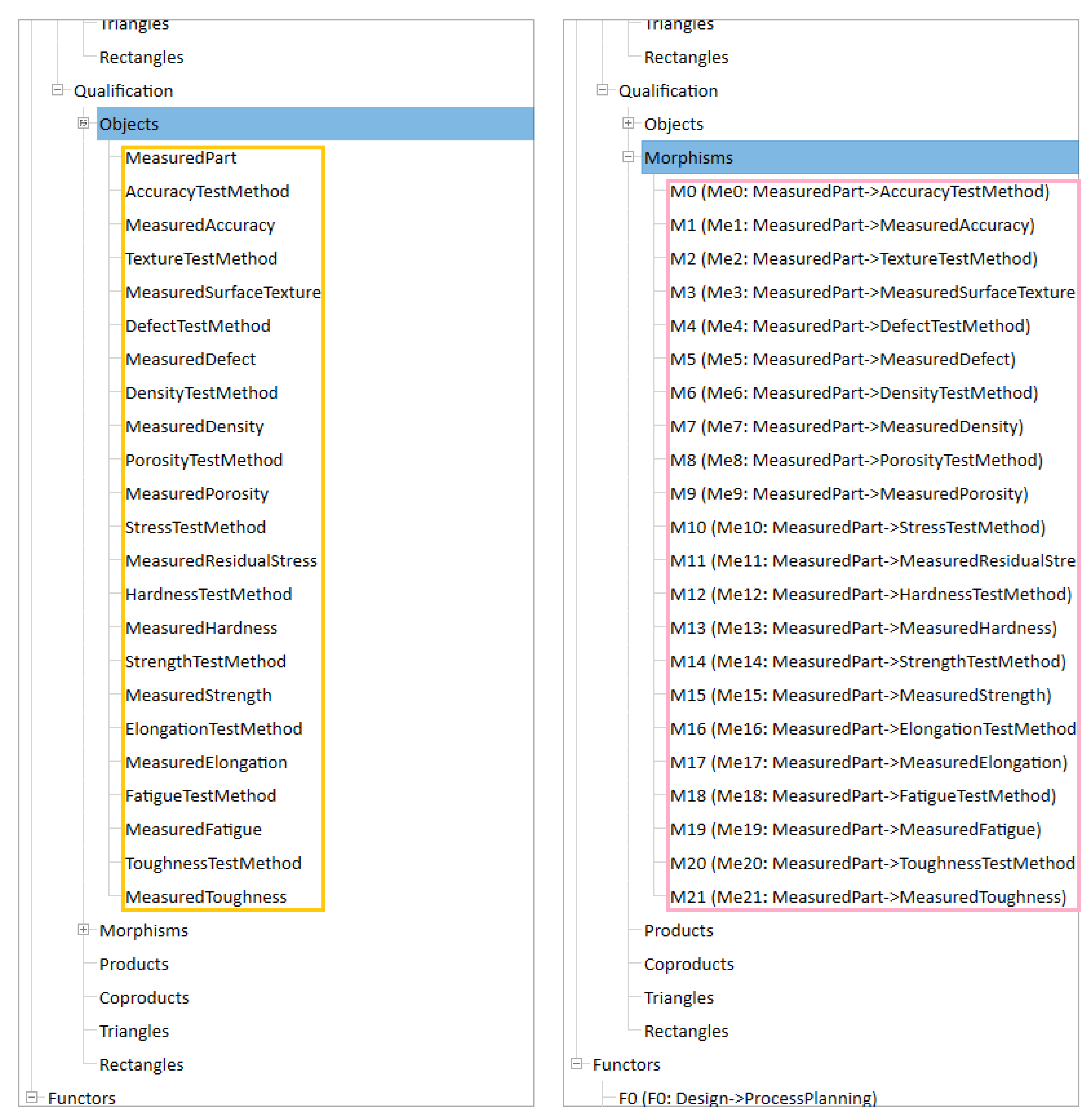

3.5. Category for Qualification

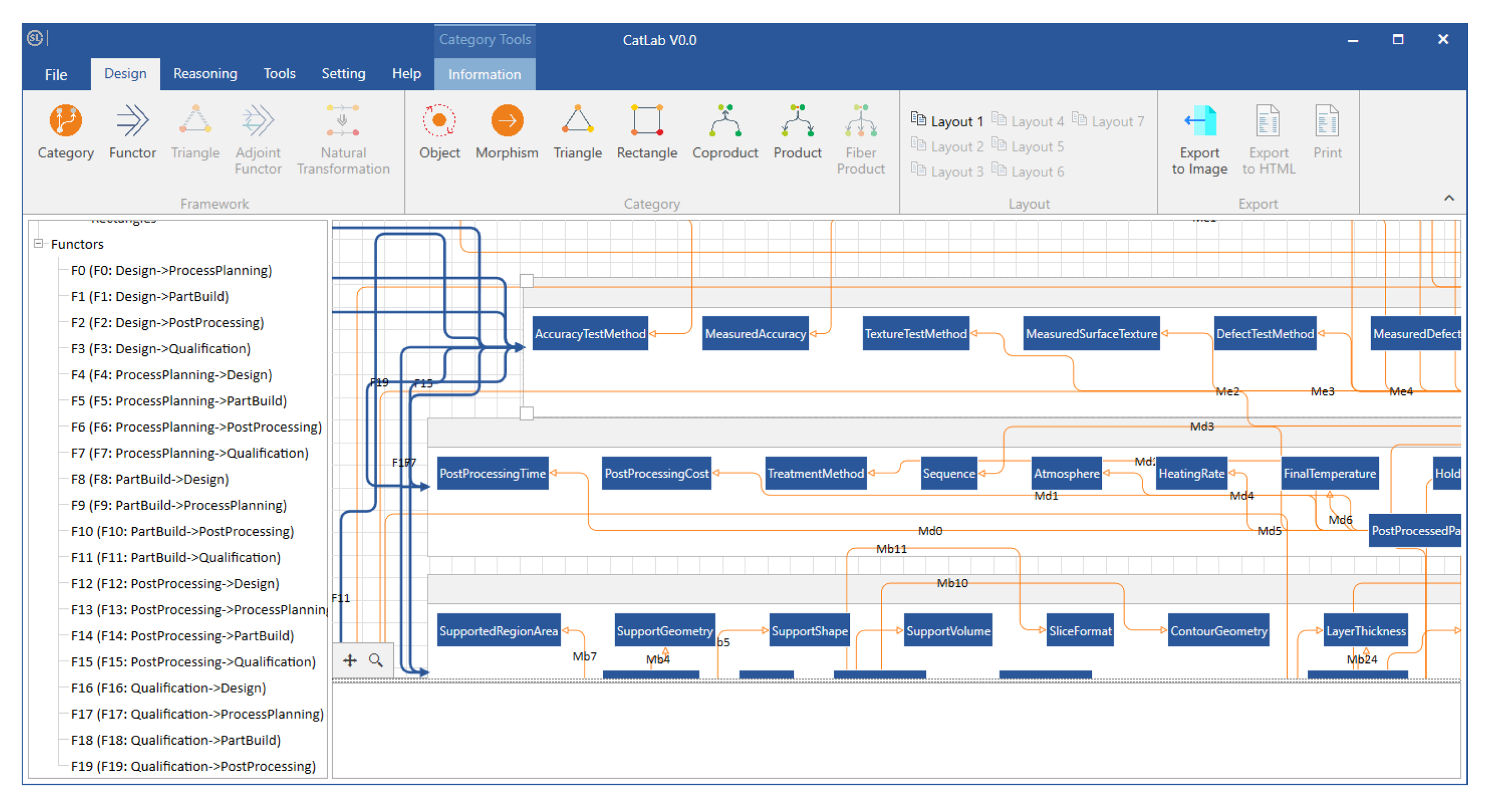

4. Implementation and Illustration

4.1. Implementation

4.2. Illustration

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015. [Google Scholar]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications (The 5th Edition of Rapid Prototyping: Principles and Applications); World Scientific Publishing: Singapore, 2017. [Google Scholar]

- Sing, S.L.; Yeong, W.Y. Laser powder bed fusion for metal additive manufacturing: Perspectives on recent developments. Virtual Phys. Prototyp. 2020, 15, 359–370. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372. [Google Scholar] [CrossRef] [PubMed]

- Dowling, L.; Kennedy, J.; O’shaughnessy, S.; Trimble, D. A review of critical repeatability and reproducibility issues in powder bed fusion. Mater. Des. 2020, 186, 108346. [Google Scholar] [CrossRef]

- Kim, D.B.; Witherell, P.; Lipman, R.; Feng, S.C. Streamlining the additive manufacturing digital spectrum: A systems approach. Addit. Manuf. 2015, 5, 20–30. [Google Scholar] [CrossRef]

- Mies, D.; Marsden, W.; Warde, S. Overview of Additive Manufacturing Informatics: “A Digital Thread”. Integr. Mater. Manuf. Innov. 2016, 5, 114–142. [Google Scholar] [CrossRef]

- Kim, D.B.; Witherell, P.; Lu, Y.; Feng, S. Toward a Digital Thread and Data Package for Metals-Additive Manufacturing. Smart Sustain. Manuf. Syst. 2017, 1, 75–99. [Google Scholar] [CrossRef]

- Qin, Y.; Qi, Q.; Scott, P.J.; Jiang, X. Status, comparison, and future of the representations of additive manufacturing data. Comput.-Aided Des. 2019, 111, 44–64. [Google Scholar] [CrossRef]

- Bonnard, R.; Hascoët, J.Y.; Mognol, P. Data model for additive manufacturing digital thread: State of the art and perspectives. Int. J. Comput. Integr. Manuf. 2019, 32, 1170–1191. [Google Scholar] [CrossRef]

- Kumar, V.; Dutta, D. An approach to modeling & representation of heterogeneous objects. J. Mech. Des. 1998, 120, 659–667. [Google Scholar]

- Kou, X.Y.; Tan, S.T. A hierarchical representation for heterogeneous object modeling. Comput.-Aided Des. 2005, 37, 307–319. [Google Scholar] [CrossRef]

- Kou, X.Y.; Tan, S.T.; Sze, W.S. Modeling complex heterogeneous objects with non-manifold heterogeneous cells. Comput.-Aided Des. 2006, 38, 457–474. [Google Scholar] [CrossRef]

- Ingole, D.; Kuthe, A.; Deshmukh, T.; Bansod, S. Coding system for rapid prototyping industry. Rapid Prototyp. J. 2008, 14, 221–233. [Google Scholar] [CrossRef]

- Ko, H.; Moon, S.K.; Otto, K.N. Design knowledge representation to support personalised additive manufacturing. Virtual Phys. Prototyp. 2015, 10, 217–226. [Google Scholar] [CrossRef]

- Lu, Y.; Choi, S.; Witherell, P. Towards an Integrated Data Schema Design for Additive Manufacturing: Conceptual Modeling. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 57045, p. V01AT02A032. [Google Scholar]

- Prater, T. Database development for additive manufacturing. Prog. Addit. Manuf. 2017, 2, 11–18. [Google Scholar] [CrossRef]

- Feng, S.C.; Witherell, P.; Ameta, G.; Kim, D.B. Activity model for homogenization of data sets in laser-based powder bed fusion. Rapid Prototyp. J. 2017, 23, 137–148. [Google Scholar] [CrossRef]

- Wang, Y.; Blache, R.; Zheng, P.; Xu, X. A Knowledge Management System to Support Design for Additive Manufacturing Using Bayesian Networks. J. Mech. Des. 2018, 140, 051701. [Google Scholar] [CrossRef]

- Bonnard, R.; Hascoët, J.Y.; Mognol, P.; Zancul, E.; Alvares, A.J. Hierarchical object-oriented model (HOOM) for additive manufacturing digital thread. J. Manuf. Syst. 2019, 50, 36–52. [Google Scholar] [CrossRef]

- Liu, C.; Le Roux, L.; Körner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2022, 62, 857–874. [Google Scholar] [CrossRef]

- Barbau, R.; Krima, S.; Rachuri, S.; Narayanan, A.; Fiorentini, X.; Foufou, S.; Sriram, R.D. OntoSTEP: Enriching product model data using ontologies. Comput.-Aided Des. 2012, 44, 575–590. [Google Scholar] [CrossRef]

- Liu, X.; Rosen, D.W. Ontology Based Knowledge Modeling and Reuse Approach of Supporting Process Planning in Layer-Based Additive Manufacturing. In Proceedings of the 2010 International Conference on Manufacturing Automation, IEEE, Hong Kong, China, 13–15 December 2010; pp. 261–266. [Google Scholar]

- Witherell, P.; Feng, S.; Simpson, T.W.; Saint John, D.B.; Michaleris, P.; Liu, Z.K.; Chen, L.Q.; Martukanitz, R. Toward Metamodels for Composable and Reusable Additive Manufacturing Process Models. J. Manuf. Sci. Eng. 2014, 136, 061025. [Google Scholar] [CrossRef]

- Roh, B.M.; Kumara, S.R.; Simpson, T.W.; Michaleris, P.; Witherell, P.; Assouroko, I. Ontology-Based Laser and Thermal Metamodels for Metal-Based Additive Manufacturing. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 50077, p. V01AT02A043. [Google Scholar]

- Lu, Y.; Witherell, P.; Lopez, F.; Assouroko, I. Digital Solutions for Integrated and Collaborative Additive Manufacturing. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Charlotte, NC, USA, 21–24 August 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 50084, p. V01BT02A033. [Google Scholar]

- Dinar, M.; Rosen, D.W. A Design for Additive Manufacturing Ontology. J. Comput. Inf. Sci. Eng. 2017, 17, 021013. [Google Scholar] [CrossRef]

- Hagedorn, T.J.; Krishnamurty, S.; Grosse, I.R. A Knowledge-Based Method for Innovative Design for Additive Manufacturing Supported by Modular Ontologies. J. Comput. Inf. Sci. Eng. 2018, 18, 021009. [Google Scholar] [CrossRef]

- Liang, J.S. An ontology-oriented knowledge methodology for process planning in additive layer manufacturing. Robot. Comput.-Integr. Manuf. 2018, 53, 28–44. [Google Scholar] [CrossRef]

- Kim, S.; Rosen, D.W.; Witherell, P.; Ko, H. A Design for Additive Manufacturing Ontology to Support Manufacturability Analysis. J. Comput. Inf. Sci. Eng. 2019, 19, 041014. [Google Scholar] [CrossRef]

- Sanfilippo, E.M.; Belkadi, F.; Bernard, A. Ontology-based knowledge representation for additive manufacturing. Comput. Ind. 2019, 109, 182–194. [Google Scholar] [CrossRef]

- Ali, M.M.; Rai, R.; Otte, J.N.; Smith, B. A product life cycle ontology for additive manufacturing. Comput. Ind. 2019, 105, 191–203. [Google Scholar]

- Xiong, Y.; Dharmawan, A.G.; Tang, Y.; Foong, S.; Soh, G.S.; Rosen, D.W. A knowledge-based process planning framework for wire arc additive manufacturing. Adv. Eng. Inform. 2020, 45, 101135. [Google Scholar] [CrossRef]

- Ko, H.; Witherell, P.; Lu, Y.; Kim, S.; Rosen, D.W. Machine learning and knowledge graph based design rule construction for additive manufacturing. Addit. Manuf. 2021, 37, 101620. [Google Scholar] [CrossRef]

- Chen, R.; Lu, Y.; Witherell, P.; Simpson, T.W.; Kumara, S.; Yang, H. Ontology-Driven Learning of Bayesian Network for Causal Inference and Quality Assurance in Additive Manufacturing. IEEE Robot. Autom. Lett. 2021, 6, 6032–6038. [Google Scholar] [CrossRef]

- Roh, B.M.; Kumara, S.R.; Witherell, P.; Simpson, T.W. Ontology-based process map for metal additive manufacturing. J. Mater. Eng. Perform. 2021, 30, 8784–8797. [Google Scholar] [CrossRef]

- Mayerhofer, M.; Lepuschitz, W.; Hoebert, T.; Merdan, M.; Schwentenwein, M.; Strasser, T.I. Knowledge-Driven Manufacturability Analysis for Additive Manufacturing. IEEE Open J. Ind. Electron. Soc. 2021, 2, 207–223. [Google Scholar] [CrossRef]

- Li, Z.; Huang, M.; Zhong, Y.; Qin, Y. A Description Logic Based Ontology for Knowledge Representation in Process Planning for Laser Powder Bed Fusion. Appl. Sci. 2022, 12, 4612. [Google Scholar] [CrossRef]

- Roh, B.M.; Kumara, S.R.T.; Yang, H.; Simpson, T.W.; Witherell, P.; Jones, A.T.; Lu, Y. Ontology network-based in-situ sensor selection for quality management in metal additive manufacturing. J. Comput. Inf. Sci. Eng. 2022, 22, 060905. [Google Scholar] [CrossRef]

- Hasan, N.; Rahman, M.H.; Wessman, A.; Smith, T.; Shafae, M. Process Defects Knowledge Modeling in Laser Powder Bed Fusion Additive Manufacturing: An Ontological Framework. Manuf. Lett. 2023, 35, 822–833. [Google Scholar] [CrossRef]

- Park, H.; Ko, H.; Lee, Y.t.T.; Feng, S.; Witherell, P.; Cho, H. Collaborative knowledge management to identify data analytics opportunities in additive manufacturing. J. Intell. Manuf. 2023, 34, 541–564. [Google Scholar] [CrossRef]

- Wang, R.; Cheung, C.F. Knowledge graph embedding learning system for defect diagnosis in additive manufacturing. Comput. Ind. 2023, 149, 103912. [Google Scholar] [CrossRef]

- Wang, Y.; Peng, T.; Xiong, Y.; Kim, S.; Zhu, Y.; Tang, R. An ontology of eco-design for additive manufacturing with informative sustainability analysis. Adv. Eng. Inform. 2024, 60, 102430. [Google Scholar] [CrossRef]

- Eilenberg, S.; MacLane, S. General Theory of Natural Equivalences. Trans. Am. Math. Soc. 1945, 58, 231–294. [Google Scholar] [CrossRef]

- Spivak, D.I. Category Theory for the Sciences; MIT Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Qi, Q.; Pagani, L.; Jiang, X.; Scott, P.J. Enabling metrology-oriented specification of geometrical variability—A categorical approach. Adv. Eng. Inform. 2019, 39, 347–358. [Google Scholar] [CrossRef]

- Spivak, D.I.; Kent, R.E. Ologs: A Categorical Framework for Knowledge Representation. PLoS ONE 2012, 7, e24274. [Google Scholar] [CrossRef] [PubMed]

- Baez, J.C.; Fong, B. A compositional framework for passive linear networks. Theory Appl. Categ. 2018, 33, 1158–1222. [Google Scholar]

- Brown, K.S.; Spivak, D.I.; Wisnesky, R. Categorical data integration for computational science. Comput. Mater. Sci. 2019, 164, 127–132. [Google Scholar] [CrossRef]

- Baez, J.C.; Master, J. Open petri nets. Math. Struct. Comput. Sci. 2020, 30, 314–341. [Google Scholar] [CrossRef]

- Bakirtzis, G.; Fleming, C.H.; Vasilakopoulou, C. Categorical Semantics of Cyber-Physical Systems Theory. ACM Trans. Cyber-Phys. Syst. 2021, 5, 1–32. [Google Scholar] [CrossRef]

- Aguinaldo, A.; Bunker, J.; Pollard, B.; Shukla, A.; Canedo, A.; Quiros, G.; Regli, W. RoboCat: A Category Theoretic Framework for Robotic Interoperability Using Goal-Oriented Programming. IEEE Trans. Autom. Sci. Eng. 2021, 19, 2637–2645. [Google Scholar] [CrossRef]

- Rosen, D.W.; Seepersad, C.C.; Simpson, T.W.; Williams, C.B. Design for Additive Manufacturing: A Paradigm Shift in Design, Fabrication, and Qualification. J. Mech. Des. 2015, 137, 110301. [Google Scholar] [CrossRef]

- Williams, C.B.; Mistree, F.; Rosen, D.W. A Functional Classification Framework for the Conceptual Design of Additive Manufacturing Technologies. J. Mech. Des. 2011, 133, 121002. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Qin, Y.; Qi, Q.; Shi, P.; Scott, P.J.; Jiang, X. Status, issues, and future of computer-aided part orientation for additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 115, 1295–1328. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018, 2, 64. [Google Scholar] [CrossRef]

- Zhao, D.; Guo, W. Shape and Performance Controlled Advanced Design for Additive Manufacturing: A Review of Slicing and Path Planning. J. Manuf. Sci. Eng. 2020, 142, 010801. [Google Scholar] [CrossRef]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.K.; Taylor, J.S. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef]

- ISO/ASTM 52904; Additive manufacturing—Process Characteristics and Performance—Practice for Metal Powder Bed Fusion Process to Meet Critical Applications. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO/ASTM 52927; Additive Manufacturing—General Principles—Main Characteristics and Corresponding Test Methods. International Organization for Standardization: Geneva, Switzerland, 2024.

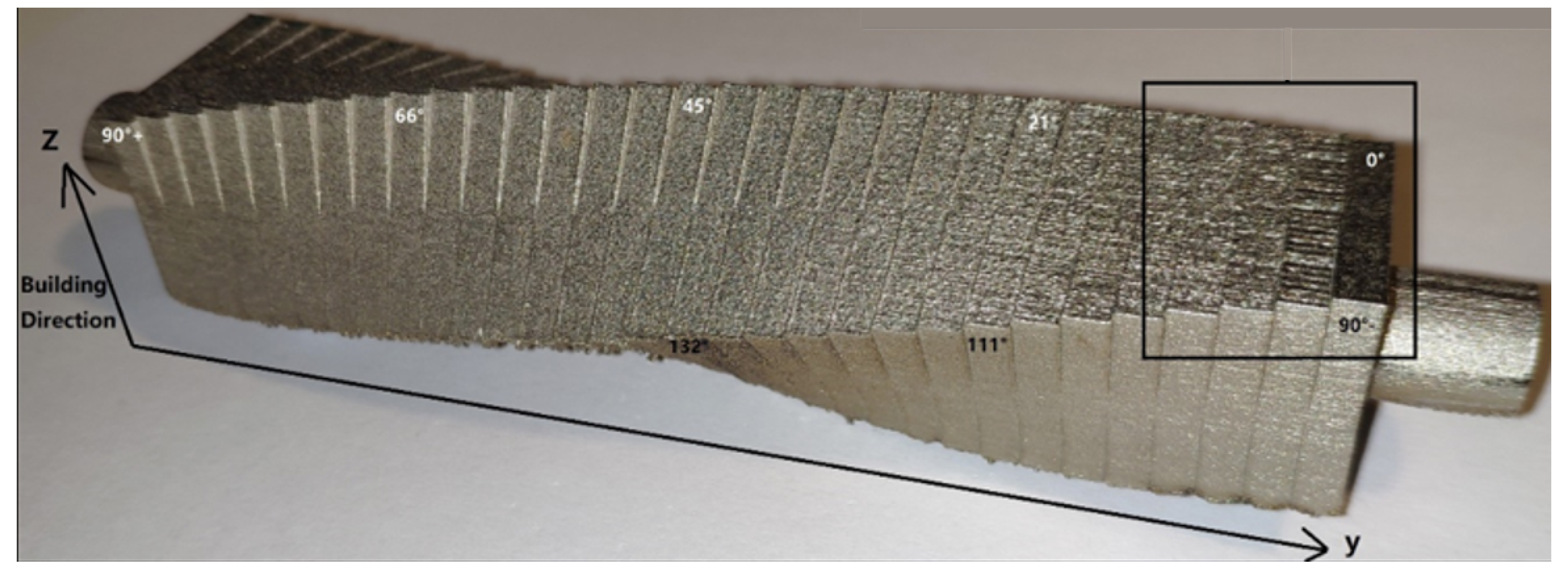

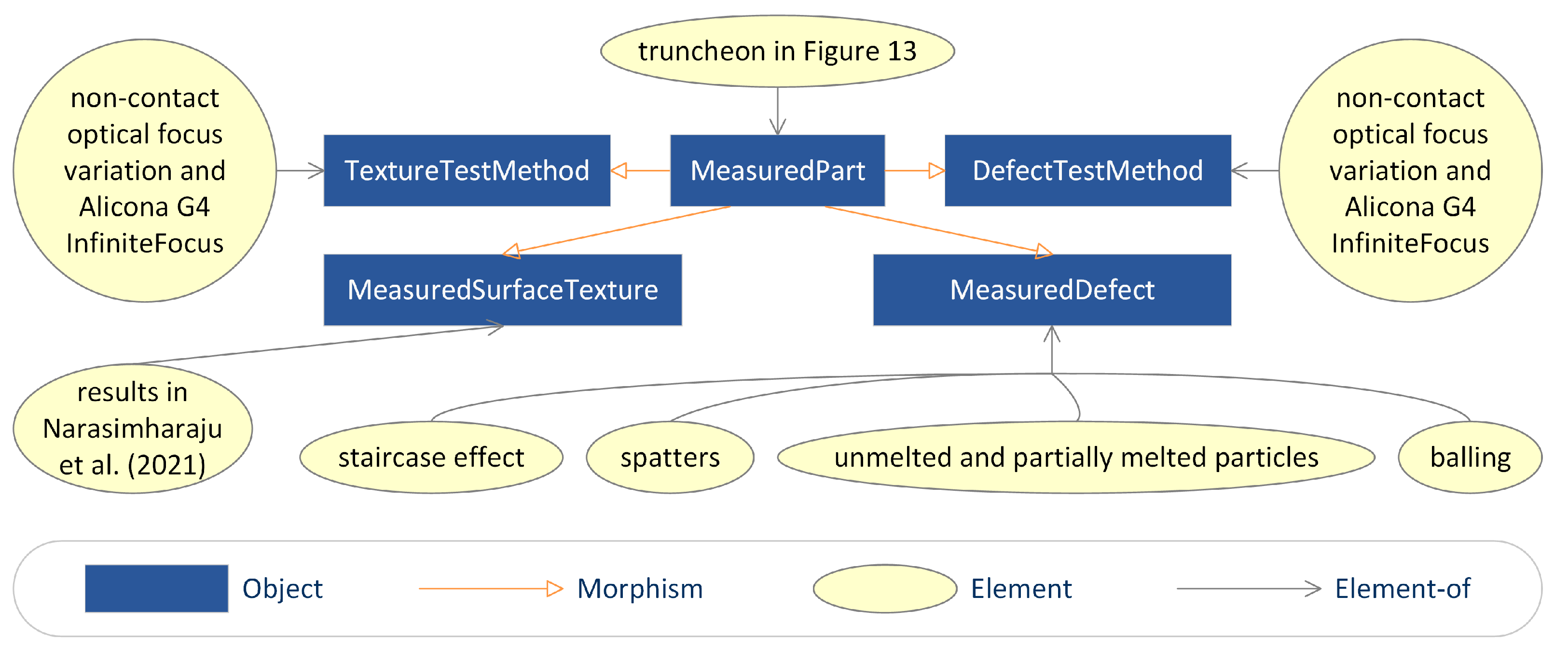

- Narasimharaju, S.R.; Liu, W.; Zeng, W.; See, T.L.; Scott, P.; Jiang, X.J.; Lou, S. Surface Texture Characterization of Metal Selective Laser Melted Part With Varying Surface Inclinations. J. Tribol. 2021, 143, 051106. [Google Scholar] [CrossRef]

| Laser Type | Laser Wavelength | Maximum Power | Build Area Dimension |

|---|---|---|---|

| Pulsed Nd:YAG | 1070 nm | 400 W | 250 × 250 × 300 mm |

| Powder Size | Fe | Cr | Ni | Mo | Mn |

|---|---|---|---|---|---|

| 15–45 m | Balance | 16–18% | 10–14% | 2–3% | ≤2% |

| Si | N | O | P | C | S |

| ≤1% | ≤0.1% | ≤0.1% | ≤0.045% | ≤0.03% | ≤0.03% |

| Magnification | Illumination | Lateral Resolution | Vertical Resolution | Sampling Distance | Measurement Dimension |

|---|---|---|---|---|---|

| 20× | Ring light | 1 m | 0.7 m | 0.878 m | 2.59 × 2.36 mm |

| Category | Parameter | Meaning |

|---|---|---|

| Height | (m) | Arithmetical mean height of the scale-limited surface |

| (m) | Root mean square height of the scale-limited surface | |

| Skewness of the scale-limited surface | ||

| Kurtosis of the scale-limited surface | ||

| Hybrid | Root mean square gradient of the scale-limited surface | |

| (%) | Developed interfacial area ratio of the scale-limited surface | |

| Functional | (%) | Material ratio related to the peak zone |

| (mm3/mm2) | Peak material volume of the scale-limited surface | |

| Spatial | (m) | Autocorrelation length (fastest decay to 0.2) |

| Texture aspect ratio | ||

| Feature | (1/mm2) | Density of peaks (number of peaks per unit area) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Narasimharaju, S.R.; Qi, Q.; Lou, S.; Zeng, W.; Scott, P.J.; Jiang, X. Enriching Laser Powder Bed Fusion Part Data Using Category Theory. J. Manuf. Mater. Process. 2024, 8, 130. https://doi.org/10.3390/jmmp8040130

Qin Y, Narasimharaju SR, Qi Q, Lou S, Zeng W, Scott PJ, Jiang X. Enriching Laser Powder Bed Fusion Part Data Using Category Theory. Journal of Manufacturing and Materials Processing. 2024; 8(4):130. https://doi.org/10.3390/jmmp8040130

Chicago/Turabian StyleQin, Yuchu, Shubhavardhan Ramadurga Narasimharaju, Qunfen Qi, Shan Lou, Wenhan Zeng, Paul J. Scott, and Xiangqian Jiang. 2024. "Enriching Laser Powder Bed Fusion Part Data Using Category Theory" Journal of Manufacturing and Materials Processing 8, no. 4: 130. https://doi.org/10.3390/jmmp8040130

APA StyleQin, Y., Narasimharaju, S. R., Qi, Q., Lou, S., Zeng, W., Scott, P. J., & Jiang, X. (2024). Enriching Laser Powder Bed Fusion Part Data Using Category Theory. Journal of Manufacturing and Materials Processing, 8(4), 130. https://doi.org/10.3390/jmmp8040130