Abstract

Additive manufacturing (AM) is a field with both industrial and academic significance. Computer-aided optimisation has brought advances to this field over the years, but challenges and areas of improvement still remain. Design to execution inaccuracies, void formation, material anisotropy, and surface quality are examples of remaining challenges. These challenges can be improved via some of the trending optimisation topics, such as artificial intelligence (AI) and machine learning (ML); STL correction, replacement, or removal; slicing algorithms; and simulations. This paper reviews AM and its history with a special focus on the printing process and how it can be optimised using computer software. The most important new contribution is a survey of the present challenges connected with the prevailing optimisation topics. This can be seen as a foundation for future research. In addition, we suggest how certain challenges can be improved and show how such changes affect the printing process.

1. Introduction

Additive manufacturing (AM), also known as three-dimensional (3D) printing, is considered to be an essential component in the latest industrial revolution, Industry 4.0, where the integration of intelligent production systems and advanced information technologies is encouraged [1]. AM is a technique for the fabrication of a wide range of structures and complex geometries based on 3D computer-aided design (CAD) models. This technique builds a real physical object by stacking materials layer by layer [2,3,4].

There is an abundance of new and potentially revolutionary discoveries within the topic of computer-aided optimisation via software for AM. New research results and papers appear frequently, and researchers are in a race to solve AM’s many challenges. Due to this discovery rate, we seek to collect information concerning where computer-aided optimisation for AM stands from a research perspective.

In this paper, we survey the development of AM and its recent trends with an emphasis on computer-aided optimisation via software, focus on the challenges that the AM industry is currently facing, and suggest some topics for future research.

Section 1.1 starts by giving a brief description of the AM history with important key events that helped develop the research field as we know it today. Following this, Section 2 describes the printing process and the different printing methods. This information is further needed in the remainder of the paper due to the need to consider the context and intended use when dealing with optimisation. Section 3 builds on this by mentioning some of today’s optimisation topics, which may apply to different printing methods. A summary of the open general problems is given in Section 4. Section 5 connects Section 3 and Section 4, creating a basis for future research and development. The findings in Section 5 are then discussed and visualised in Section 6. Finally, in Section 7, some concluding remarks regarding the previous sections are given.

1.1. A Brief History of AM

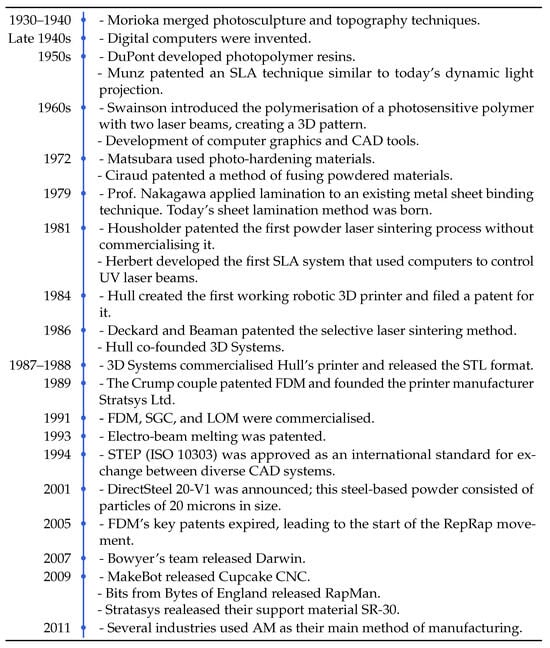

AM and 3D printing are relatively new fields of research. This makes their history traceable through patents and research papers. We opt to divide the AM history into four major parts, which are briefly addressed in Section 1.1.1, Section 1.1.2, Section 1.1.3 and Section 1.1.4. Within these different time periods, we collect some important events that developed the AM research field to its current state. Figure 1 illustrates the events addressed in this section as a timeline. These key events are collected from a number of research papers; see [5,6,7,8,9,10].

Figure 1.

A timeline of historical AM events.

1.1.1. Before 1980—The Beginning

AM and 3D printing are seen as recent fields of research, but their concepts, ideas, and fundamental exploration are considered to have started close to a century ago, when, between 1930 and 1940, Morioka started researching the combination of photosculpture and topography techniques. The technology available at that time was not mature enough to efficiently bring these ideas and concepts to life [5,6].

Throughout the 1950s and 1960s, the world developed rapidly and new technologies that would later be used for AM and 3D printing emerged. Some important events were the invention of digital computers in the late 1940s, DuPont’s development of photopolymer resins in the 1950s, commercially available laser technology in the 1960s, and the development of computer graphics and CAD in the 1960s. Even after these improvements and inventions, the 3D printing technology was still considered to be in its infancy, with no commercial market and little support for research and development activities [6].

Based on the previous advancements in combining photosculpture and topography, Munz filed a patent for an stereolithography (SLA) technique in 1951. This technique was very similar to the present dynamic light projection technique. By exposing a transparent photo-emulsion in a layer-wise manner, Munz was able to build a solid cylindrical object embedded with the image of the scanned object. This solid cylindrical object could then be carved, or chemically etched, to obtain a physical 3D model [5].

The accelerated development of primitive 3D printing systems began in the late 1960s and continued throughout the 1970s. Swainson was already employing the polymerisation of photosensitive polymers by 1968. This polymerisation was achieved by intersecting two laser beams to develop a 3D pattern. In 1971, a patent was filed for Swainson’s technique and the method termed photochemical machining. Shortly after, in 1972, Matsubara at Mitsubishi Motors made a technological leap when he used photo-hardening materials to shape a coherent solid sheet. This method became the foundation for many mature free-form fabrication techniques, including lithography and SLA, as we know them today [5,6].

At this point, the only explored 3D printing method was what today is known as vat photopolymerisation (VP). This changed when Ciraud, in 1972, patented a method of fusing powdered materials by partially melting the material using a thermal source like a laser, plasma, or an electron beam. What Ciraud had discovered was the start of today’s powder bed fusion (PBF) method. Then, in 1979, another method was invented. Prof. Nakagawa further developed a recently patented metal sheet binding technique by applying lamination and demonstrated the fabrication of different types of tools, such as banking, press forming, injection moulding, and punch tools. This marked the birth of today’s sheet lamination method [5,6,7].

1.1.2. The 1980s—The Rise of Modern 3D Printers

In the 1980s, the subject of AM and 3D printing started to truly gain traction, with some of the most important events in 3D printing history. In 1981, Housholder patented the first powder laser sintering process without having it commercialised; many consider this to be the first official 3D printer. During the same year, Herbert developed the earliest SLA system that used a computer to control the ultra violet (UV) laser beams [7].

In 1984, Hull filed a patent for his revolutionary SLA machine. This machine is generally credited as the first working robotic 3D printer. The patent for this robotic 3D printer was granted in 1986, the same year that Hull co-founded 3D Systems. During 1986, Deckard and Beaman patented another new printing method, selective laser sintering. In 1987–1988, 3D Systems commercialised Hull’s printer and released it and, at the same time, introduced the STL file format. Just a year later, in 1989, the Crump couple patented fused deposition modeling (FDM) and founded the printer manufacturer Stratasys, Ltd., Eden Prairie, Minnesota [7,8,9,10].

1.1.3. The 1990s and 2000s—A Period of Growth

The 3D printing research in the period between 1990 and 2010 seems to have mainly focused on improving the existing mechanical technologies. For this reason, there were not many specific historical events but rather steady growth, and technologies and ideas were patented and commercialised. In the early 1990s, various powder-based systems were patented. These systems were based on powder bed fusion but used a binder to glue the materials together, instead of melting them with a thermal source. This discovery offered the possibility for the usage of a variety of powder materials and is therefore considered to be the birth of binder jetting (BJ) [9].

In 1991, three different printing methods were commercialised, namely FDM, solid ground curing (SGC), and laminated object manufacturing (LOM). Two years later, in 1993, electro-beam melting was patented. Subsequently, all major printer companies released new printers and materials with slight differences and new improvements. One of the most noticeable was in 2001, when EOS announced its DirectSteel 20-V1. This product was a steel-based powder consisting of particles 20 microns (0.02 mm) in size. At the same time, EOS also introduced EOSINT 380, a laser sintering machine that offered speed improvements [8,10].

The physical printers and their technology were not the only part of AM that developed during the 1990s and 2000s. In 1994, a new standard for exchange between diverse CAD programs was approved; this was the birth of the Standard for the Exchange of Product Model Data (STEP). This data technology was further developed in the early 2000s, when the STEP extension, STEP-Compliant Numerical Control (STEP-NC), was introduced [11,12,13].

In 2005, another major event in AM history occurred. Several key patents regarding the Crump couple’s FDM technology expired. This gave the basis for the RepRap (a contraction of replicating rapid prototyper) movement and other open-source filament-based consumer printers [8,9].

The RepRap movement started when it occurred to Bowyer that it may be possible to produce a low-cost FDM printer and then print many of its own components and parts for another printer. Bowyer published the designs for the 3D printer parts on the Internet and encouraged others to further improve and update them. This open-source concept became the RepRap project. Bowyer’s team released their first printer, Darwin, in March 2007. The concept of improving files for printer parts evolved into producing complete printer kits available for purchase. Among the most well-known kits, we can mention the MakerBot Cupcake CNC, which was released in April 2009. At the same time, Bits from Bytes of England released their RapMan 3D printer kit. This kit was based on the RepRap open-source system, utilising an extrusion head similar to FDM, and included software for STL slicing and the transmission of the data to the machine in G-code format [9].

Another noteworthy event that occurred in 2009 was the release of Stratasys’ new SR-30 support material for their ABS M-30 build material. The SR-30 material dissolved about 50% faster than its predecessors, making the post-processing less time-consuming [10].

1.1.4. From 2010 to the Present

AM research in recent years has mainly focused on specialising and optimising solutions given a certain objective. An example of this optimisation is SMART Support, which was released with uPrint® Plus by Stratasys in January 2010 and could help to reduce the usage of support materials by up to 40%. Later in the same year, Stratasys extended its SMART Support capability to its entire line of Dimension and Fortus machines. This allowed the building time to be reduced by up to 14% [10].

Today, AM is used in various specialised fields, such as healthcare, biomedicine, aerospace, textiles, food, and construction [14]. By 2011, several industries were using AM as their main method of manufacturing. Manufacturers of in-the-ear hearing aids were the first to utilise AM in their industry for the production of custom-fit shells. The dental industry followed shortly after and began to experience the same pervasive growth in the usage of AM systems [10].

There is diverse industrial adoption of AM, including industries such as the aerospace, automotive, and medical industries [15]. With the different uses of the technology, many recently published AM research papers have focused on one specialised field or intended purpose [16,17,18,19,20,21,22]. Adaptations for specialisation are needed to further optimise AM technologies. For instance, the aerospace and automotive industries hold completely different standards for reliability and sturdiness than, for example, the healthcare sector.

Although the AM industry has grown massively over the last few years, it is expected to continue to grow, both in terms of usage and revenue [23,24]. The increased usage of AM has several benefits, as mentioned in [25]:

- AM can create topologically optimised structures, which are difficult to manufacture with traditional casting or forging processes;

- AM can be used to generate novel characteristics in materials, such as dislocation networks;

- AM greatly improves the material utilisation rate.

2. 3D Printing Process, Methods, and Optimisation

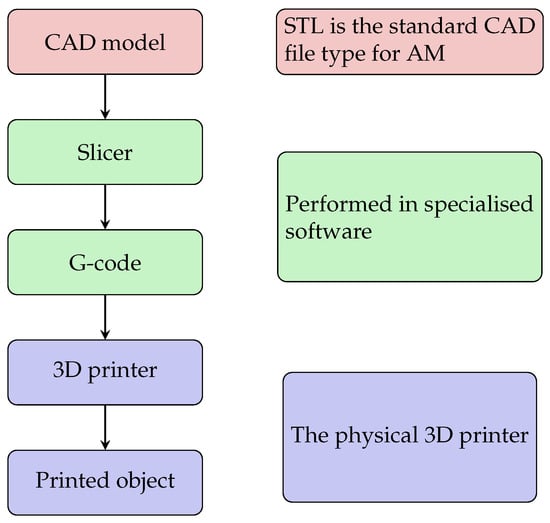

Regardless of the selected AM method (see Section 2.2), the basic 3D printing process remains the same. It is illustrated as a flowchart in Figure 2. There is a minimum of five consecutive main steps that are required for the printing process to be completed. The first step is to have a 3D CAD model. This model is exported to the slicer software, commonly as an STL file, which is today’s standard file type for AM.

Figure 2.

Flowchart illustrating the basic 3D printing process with the minimum number of steps needed. The steps are categorised by colour. Red indicates CAD software, green is usually specialised 3D printer software, and blue is the physical printer and the real world. The left side describe the workflow, while the right side gives additional information.

Slicing and G-code generation are usually performed by the same software. The slicer separates the CAD model into segments, while the G-code generator creates a code dictating the tool path for the given segments. Typically, these slicer segments are thin layers, which essentially makes each layer a two-dimensional (2D) problem. The G-code generator thus generates a tool path that creates the 2D layers.

The prepared G-code for the segments is then transferred to the physical 3D printer, which performs the specified actions, resulting in a printed physical object. Depending on the printer and the original CAD model, some cleaning and post-processing steps may be required. The finished product should be a physical realisation of the original CAD model, but deviations may occur due to errors and inaccuracies in the process.

2.1. From CAD to G-Code

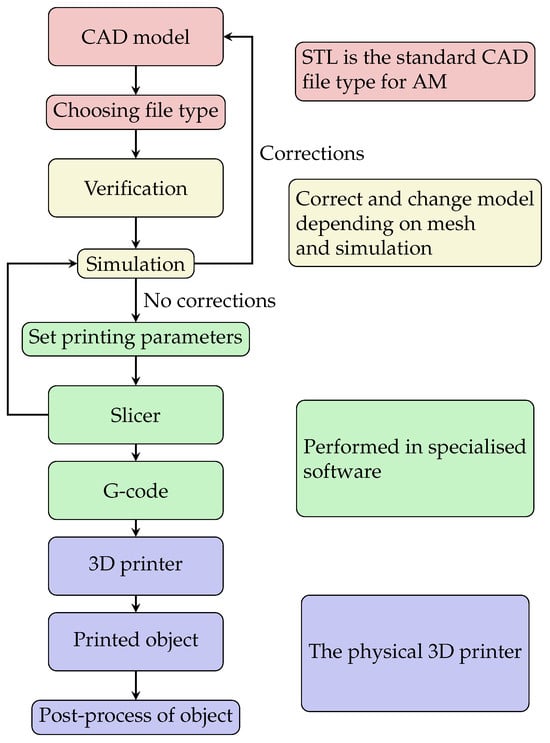

The basic 3D printing process, as depicted in Figure 2, can be expanded depending on the printer in question and the purpose of the printed object. The most common additional step is post-processing, but there are several other important details and optional steps between having a CAD model and sending the G-code to the printer.

As mentioned already, STL is the standard CAD file format for AM and 3D printing. In this case, the physical object needs to be designed as a geometric solid model. The solid model is then tessellated by creating a simple boundary representation that covers the entire surface with triangles. This list of triangular facet data is stored in the STL file. STL is the most common file type, but there are cases where other file types are needed and used. STEP, STEP-NC, additive manufacturing format (AMF), and 3D manufacturing format (3MF) are some promising researched alternatives to STL [26,27]. It is recommended to evaluate which file type to use for each project.

Due to problems related to exporting the model for use by the slicer, it is recommended to perform the verification of the 3D model. This verification step can, for example, consist of a simulation step, followed by corrections of defects and artifacts after file conversion [28].

After verification, the model enters the pre-slicer stage, which can include steps to adjust the printing parameters and try out their effects in a simulation. The printing parameters include the printing orientation, layer size, and material selection. After setting the initial parameters, support structures can be generated. The model is then ready for slicing and G-code generation. These pre-slicer steps may be limited by the software in question and their compatibility, if several software systems are used.

An expanded process flowchart, where the extra steps mentioned above are included, is presented in Figure 3. It is still a generic workflow that is common for the majority of printers. More steps can be added, depending on the specific printing method, desired object criteria, and properties.

Figure 3.

Flowchart illustrating an extended version of the basic 3D printing process. The steps are categorised by colour. Red concerns CAD software, yellow can be performed in software ranging from CAD to specialised simulation software, green is usually specialised 3D printer software, and blue is the physical printer and the real world. The left part constitutes the workflow, while the right part provides additional information. The smaller boxes are additional steps directly related to the taller boxes of the same colour.

2.2. AM Methods

Today’s AM techniques can be categorised into seven main methods: BJ, material extrusion (ME), direct energy deposition (DED), material jetting (MJ), PBF, sheet lamination (SL), and VP [29]. The various types of printer techniques have their own principles for the building of the model. This leads to differences in the available materials, advantages, and disadvantages for each printing technique [30]. ME is the most commonly available and affordable type of 3D printing technology [31]. We therefore focus especially on ME-based 3D printing. Table 1 gives a brief description of each printing method’s process.

Table 1.

A brief and systematic description of each printing method’s process.

2.3. Optimisation

Customisation and optimisation are trending and important topics in today’s AM research communities. According to the Oxford English Dictionary, optimisation is the action or process of making the best of something. There are many areas of AM that can be optimised, e.g., the material used for printing [40,41], the physical printer and its parts [42], and the printer software and its functionalities [43,44].

The purpose of optimisation is the most important aspect. When optimising 3D printers, it is therefore important to determine the usage and criteria of the printed object. For example, the criteria for 3D prints in the aerospace industry are different from, for example, those in healthcare. A printer optimised for the aerospace industry would therefore be less efficient in the healthcare industry. Refs. [45,46] focus on AM in the aerospace industry, while [47,48] focus on the healthcare industry. These papers display the different aspects of the industries that need to be taken into consideration when optimising the 3D printers.

This survey focuses on optimisation applied in the areas between the CAD model and G-code from the flowchart in Figure 3. These areas consist mainly of the use of different software, data conversion, calculation, and the transfer of important aspects.

3. Trending Optimisation Topics

As mentioned already, this survey focuses on computer-aided optimisation applied to the steps between the CAD model and G-code, as outlined in Figure 3. For each of these steps, there are certain main topics that have dominated the AM research community recently. Many papers considering improvements or changes to the slicing operation and the STL format have emerged. G-code generation improvements have been mentioned but not prioritised in the same way; however, this topic has started to gain traction in the last few years. Simulations specifically tailored to AM are a new topic that has started to gain momentum.

In parallel to these different areas of research, there is an increasing focus on exploring the usage of artificial intelligence (AI) in AM. The research is not limited to a specific area of AM, but rather concerns how to apply AI to any part of the AM process. In this section, we focus on the mentioned topics, provide some details, and refer to interesting and relevant research for each of them.

3.1. The Usage of AI in AM Today

After the introduction of Industry 4.0, the topic of utilising AI in general has gained tremendous traction. Many researchers strive to find new and innovative methods to use AI in their respected fields. Combining AI with 3D printing is an active area of research where the number of dedicated publications is growing; see, e.g., [49,50,51,52,53,54]. It is believed by many that AI has great potential for the future manufacturing industry.

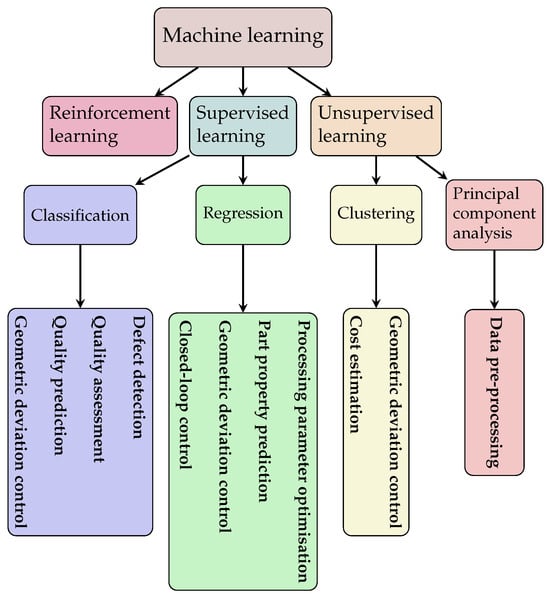

Machine learning (ML), which is a field of study in AI, can be divided into three main categories, namely supervised, unsupervised, and reinforcement learning. Figure 4, which is based on Figure 1 in [55], illustrates the taxonomy of ML with the corresponding applications within the AM field.

Figure 4.

Illustration of the taxonomy of ML with the corresponding applications within the AM field. This illustration is based on Figure 1 in [55]. ML is shown at the top, branching out into the three main types of ML, reinforcement, supervised, and unsupervised learning, respectively. From the main types follow some specific methods, each of which can help to solve the AM-related problems indicated below.

When it comes to the practical use of ML, neural network (NN) is the most widely used technique. It is classified as supervised, and it is suitable for AM due to AM’s clear targets and qualification methods [25]. NNs are classified as a supervised, layer-based ML technique [56], which means that the datasets need to be labelled [57].

3.2. STL

For the last few decades, the STL file format has been the industry standard for the transfer of information to additive manufacturing hardware. The STL file format does not include data about colour, texture, material, and there are no provisions for the definition of the physical units [58]. Due to these disadvantages, the current research involving STL in additive manufacturing mainly focuses on improving the post-processing tools to correct and improve the STL, while some suggest to simply replace or remove the usage of STL from the process. There is also a focus on analysing the inaccuracies that arise when converting data from the medical field, such as computed tomography (CT) and DICOM®—Digital Imaging and Communication in Medicine—into an STL file.

Refs. [59,60,61,62,63] all discuss additive manufacturing in the medical field. From this research, it seems that while additive manufacturing is used today, its full potential is far from being realised in this setting. One key issue is inaccuracies in conversion from DICOM® to STL. Refs. [59,61] especially mention this problem and state that a lot of post-processing is needed after conversion.

3.3. Slicer

Slicing is a crucial step in the AM process. The slicing software is highly unique and complicated due to its customisability. When choosing or creating slicer software, there are two important aspects that one needs to take into consideration: the software needs to be well suited for the 3D printing method, and the desired features of the printed product should be determined. For example, the tool path created for a ME printer should be different from one created for a VP printer. For the features of the printed product, the number of options is overwhelming. The study of specialised slicer algorithms to improve a certain problem or aspect dominates the slicer research.

Several papers present slicer algorithms that specialise in different areas. Ref. [64] deals with slicer algorithms that optimise the generation of support structures. Ref. [65] focuses on improving the slicer time for worst-case models, where a large percentage of triangles intersect with each slice plane for a triangulated model. Ref. [66] considers a helical slicing method that removes the seam defects found in the extrusion start–stop point. Ref. [67] investigates a slicer that avoids the creation of critical voids in the infill, since this can affect the mechanical properties of the parts.

G-code generation is directly connected to the slicing of the 3D model. The ongoing research that involves the G-code focuses on different solutions to a direct printing process. The idea of direct printing usually involves skipping the conversion to STL and directly slicing and/or creating the G-code. This type of process joins the slicing and G-code generation stages as a two-in-one process. Such simplification of the process could be useful in eliminating conversion errors, which are not unusual when converting data from one format to another. Refs. [68,69,70,71,72] are examples where various approaches to direct printing are explored.

3.4. Simulation

Simulations of the AM process can be applied to predict the result prior to printing. A simulation environment can also be used to test and improve the process, while the usage of time and material for physical tests is reduced. Most of the contemporary research that pertains to simulations in AM considers the usage of metal materials. These studies have distinct main targets, making the research unique despite their mutual focus on metal as a printing material. Refs. [22,73,74,75] explore the potential for reductions in cost, energy consumption, and carbon footprint in AM compared to conventional methods, and they connect the potential reduction to the minimisation of metallic material waste. With the principle that less material waste reduces the cost, energy consumption, and carbon footprint, a simulation with the potential to reduce faulty production steps can not only save time but also be cost-efficient and environmentally friendly.

Ref. [76] focuses on the simulation of flow and heat transfer in and around the molten pool formed as the powder bed is melted. Ref. [77] studies the usage of simulations to better understand the resultant microstructure from the rapid and directional solidification of metal materials. Being able to adjust specific microstructures offers the possibility to change the mechanical properties of the printed part. Ref. [78] investigates a similar challenge, with a focus on undesired distortions and crack initiation from the rapid solidification of melted powders in metal AM. In the mentioned work, the simulation requires the user to define even data, such as the element activation and heat input. Ref. [79] is an interesting work involving material deposition at the corners in extrusion AM. It focuses on investigating how smoothing the tool paths, material overextrusion on the corners, and rounding affect corner swelling. The paper suggests an optimal tool path achieved via a numerical simulation.

4. Challenges

Although AM is a versatile manufacturing method that has progressed significantly in recent years, there are still many remaining limitations and challenges with this type of manufacturing. The limitations and challenges can be divided into two groups: external issues and production- and process-related issues. External issues include high costs, material limitations, low manufacturing efficiency, a lack of test standards for printed objects, low suitability for mass production, and the low level of field maturity. Production- and process-related issues include part inaccuracy, void formation, anisotropic properties, appearance, under- and overextrusion, layer misalignment, and file format issues [80,81]. In this paper, we focus on production- and process-related challenges. The following five topics are chosen: the STL file format, design to execution inaccuracy, void formation, material anisotropy, and appearance. The selected challenges appear in most printing methods and materials, and they are not yet fully solved [2].

4.1. The STL File Format

STL is the file format most commonly used for 3D printing. The rationale behind the STL format is that the boundary of a CAD model can be approximated with triangles via tessellation [82]. The generation of triangles for the STL file has some disadvantages, since tessellation offers only an approximation of the original model and it contains only boundary information. Errors can occur from redundant triangles, missing geometry, ill-defined approximations, and a lack of technological information [82,83].

Although other file formats have been developed to store more information than the STL format, STL is still the de facto industry standard today, because of its simplicity and robustness [84]. A file format tailored to additive manufacturing, AMF, has been under development since 2011 by ISO/ASTM subcommittees. This format was developed to replace STL and solve many of the problems related to it. AMF contains more information than STL and has no process-specific information, which renders the format neutral and machine-independent. However, AMF is not well accepted in the market of additive manufacturing [84,85].

4.2. Design to Execution Inaccuracy

The main tool for the design of parts for 3D printing is CAD software. The process of designing these elements and printing the parts can introduce errors and inaccuracies that are not expected [2]. In [82], 3D printing errors are divided into three categories: data preparation, process, and material errors.

Data preparation errors are errors that occur leading up to the building of the part, in the pre-processing stage. Some of these errors originate from tessellation, slicing, path planning, and deciding on the orientation [82]. Since pre-processing happens before printing, there is great potential to minimise inaccuracies by changing the parameters and estimating the errors. Therefore, pre-processing has gained increased attention and is considered a key step in obtaining improved quality and performance [86]. One of the newest methods to minimise some of the pre-processing errors is the use of non-planar printing. However, although this topic is popular, its potential and efficient use are not yet fully apparent, and it has not been clarified whether these techniques have to be pre-loaded into the product and tolerance design [87].

In addition to errors in the pre-processing stage, errors can materialise in the physical printing process. Inaccuracy in this stage can come from speed variations in the machine tool, errors in the positioning system, or material errors [82]. Small errors that occur early in the printing process can propagate throughout the build time, and the printer has no means of recognising that an error has occurred. Sensors and cameras to monitor the process can help to detect certain errors. However, most 3D printers have yet to implement feedback systems, partially due to high costs and because the gathered data are insufficient to provide real-time feedback and correction [88,89].

Material errors are errors caused by variations in the material— for example, from differences between batches, improper storage, deterioration, shrinkage, and distortion [90,91]. These types of errors are challenging to predict and the current printers have no means of monitoring and correcting them [82].

4.3. Void Formation

Void formation between layers is one of the main disadvantages in 3D printing. It highly depends on the 3D printing method and the printed material. Voids are more common in methods that use filaments of materials, such as FDM or contour crafting [2]. Internal voids contribute to compromised mechanical properties, affect the visual quality and dimensional accuracy, and can lead to tearing, fractures, and fatigue in the printed part [92].

Because of the drawbacks of void formation, various methods to reduce voids have been given attention in research. For instance, diverse nozzle geometries have been tested [93,94]. Rectangular nozzles and star-shaped nozzles were found to reduce voids in concrete and polymers, respectively. Additional focus has been given to tool path optimisation techniques. Qiu and Langrana [95] created an adaptive tool path generation algorithm to locate and compute the sizes of voids in order to generate void-free tool paths. Kuipers et al. [96] minimised overfill and underfill by using contour-parallel tool paths with an adaptive bead width, while Lin et al. [97] examined maze-like path generation to optimise the mechanical features by reducing the gaps between filaments. Material modification has also been attempted by adding a low-molecular-weight additive to a polymer filament, which was proven to drastically increase the interlayer adhesion [98]. Heating and temperature-based methods have also shown promising results, e.g., using heated beds [99], a combination of heated beds and heated nozzles [100], or in-process laser heating [101]. Lastly, we note that a number of post-processing techniques have been examined. Yadollahi and Shamsaei [102] used pressure and temperature treatment on metal parts to fuse unmelted particles, thus decreasing the void size. Torres et al. [103] improved the infill density via post-process heat treatment. Meanwhile, Li et al. [104] strengthened the mechanical properties of 3D-printed parts by utilising ultrasonic vibrations.

4.4. Material Anisotropy

It is well known that AM materials suffer from anisotropic behaviour, because of the layer-by-layer manufacturing technique [105]. The printed parts are directionally dependent, and discontinuities can make the parts weak in the direction perpendicular to the print direction [106]. Multiple material properties can be affected by the direction of the printing [105,107], e.g., strength, elasticity, tensile properties, compression, and ductility. Anisotropy has been observed in different materials, such as polymers [108,109], ceramics [110,111,112], and alloys and metals [113,114,115]. However, the property is more significant in polymer components [105].

Because of the opportunities that come with additive manufacturing, efforts have been made to address the challenge of anisotropy in various materials. For polymers, it has been shown that exposing 3D-printed polymer blends to ionising radiation can increase both the ultimate tensile strength and strain capacity, which gives a dramatic reduction in anisotropy [107]. Another example is the use of a hybrid process consisting of a printing nozzle and foam-filling system. Here, the structure was toughened by an underlying soft polyurethane foam, which exhibited near-isotropic behaviour [116]. In additive manufacturing with ceramics, Li et al. [117] used a pore former and a triple sintering procedure to reduce the anisotropy when 3D printing ceramic cores. Moreover, in [118], the regulation of the lamellar structure of 3D-printed ceramic cores was suggested by optimising the slurry preparation process and improving the slurry spread system of the printer. Meanwhile, with metals and alloys, the anisotropy has been successfully reduced. For instance, inoculating AlSi10Mg powder with LaB6 nanoparticles gave it near-isotropic mechanical properties [119]; anisotropy in AlSi10Mg could also be effectively reduced with post-AM heat treatment [120]. Meanwhile, Hossain et al. [121] created isotropic stochastic porous structures in stainless steel and titanium alloys by overcoming the manufacturing limitations of low-angle struts in laser PBF.

4.5. Appearance

The appearance of printed parts has challenges when it comes to accuracy and surface quality. The 3D-printed models can exhibit a layer-by-layer appearance because of the layer-stacking nature of the printing process, and burrs can remain on the surface after support structure removal [122]. Some 3D printing methods are more likely to produce a layer-by-layer appearance than others. The methods that use a filament, like FDM, inkjet, and contour crafting, experience layer-by-layer appearances more often than powder bed or stereolithography methods [2].

To improve the appearance, different post-processing methods can be used, e.g., sanding, bead blasting, melting, acetone finishing, and polishing. However, these methods can create waste material, be damaging to the parts, take excessive time, and increase the cost [82]. Other methods to improve the appearance have been proposed in the literature, including optimising the building orientation to minimise part errors and support structures [123], reducing the number of layers and increasing the layer thickness [2], and increasing the number of layers and reducing the layer thickness [124]. All of these methods have their advantages and disadvantages, and the quality of the result varies.

5. Future Perspectives

Besides making a decision on a topic and its scope, several other aspects are important to consider for future development and research. Debating the idea and method employed to solve a problem, or to remove it, is crucial in the research and development of such processes as AM. In some extreme cases, improving or replacing a step in a process is simply not enough. It is possible that a previous error, misjudgement, or outdated practice biases the development in a negative way, where attempting to fix one problem leads to new problems. Moreover, in some rare and extreme cases, the development of an entirely new process from scratch may be necessary or desirable.

As established earlier, optimisation depends on the intended purpose and desired properties for the printing process and the resulting part. For AM, there are three highly sought properties: the printing time, the printed part’s accuracy, and its sturdiness. Depending on the purpose, the influence of these properties may vary from one project to another. In some instances, sturdiness and accuracy are very important, regardless of the printing time, while, in others, the printing time is of the essence.

The possibilities for future research within AM are numerous and seem to be unlimited. Solving or improving the challenges mentioned in Section 4 could be important for the industry, but any work aimed at optimising, shortening, or improving the steps described in Figure 3 could notably improve AM. The zones between the CAD model and the G-code are the most common areas of focus for computer-aided optimisation, and, with the aid of new and improved computers and algorithms, the possibilities for development and improvement are extensive. The topics mentioned in Section 3 can be considered as sources of inspiration for further research. In our opinion, addressing the challenges imposed by the STL file format, developing simulation steps, and considering customisations that combine AI and ML are intriguing topics with potential for future work.

5.1. STL

The challenges associated with the STL file format represent a clear example of why a debate on how to deal with a problem is needed. For example, one can ask whether future research should focus on fixing the errors caused by the STL conversion, or whether we should strive to remove or replace STL. STL is used and integrated in the industry, and it is simple and robust, which makes it difficult to find a suitable replacement. A potential new standard format must be thoroughly designed, tested, and documented. The results of these tests must unanimously state that the potential new standard is significantly better than the existing STL. In addition, such a new standard must be sustainable for the future, with the ability to be maintained and eventually updated.

Removing or finding an alternative for STL is a desirable first step in the direction of improvement. This could be achieved via direct slicing or simply by replacing STL with another file type, such as STEP or AMF. If these alternatives are unachievable for any reason, an additional validation program to correct and automatically adjust the STL file can be applied. We propose these alternatives for further exploration and comparison in future research.

5.2. Simulation

Simulations regarding the printing process have serious potential for further research and development. The usage of simulations is not only limited to the research topics mentioned in Section 3, but can be applied in new ways. As an example, simulation steps could be used to increase the sturdiness of a printed part, while reducing the time and material required for physical tests.

Infill structures are utilised for many printed parts. The infill structure could comprise solid overlapping layers, honeycombs, triangles, etc., and, in further research, a simulation could test these alternatives for a particular object. Simulations could indicate preferred infill settings for different desired part qualities, reduced printing times, improved sturdiness, and reduced material usage. A simulation could also contribute to improving the quality of the print and detect problematic and critical areas before the printing process starts. For example, detecting overhang, potential printer seams, and overextrusion near corners could improve extrusion-based AM tremendously and offer the opportunity for corrections and adjustments.

5.3. Customisation

One essential use of AM in the industry is to generate customised models and realise the desired parts. For this reason, it is necessary to have a wide variety of options, tools, and software available, to facilitate the customisation steps in the process. Customisation can be achieved in several ways—for example, by altering the printing process flow or via developing specialised tools.

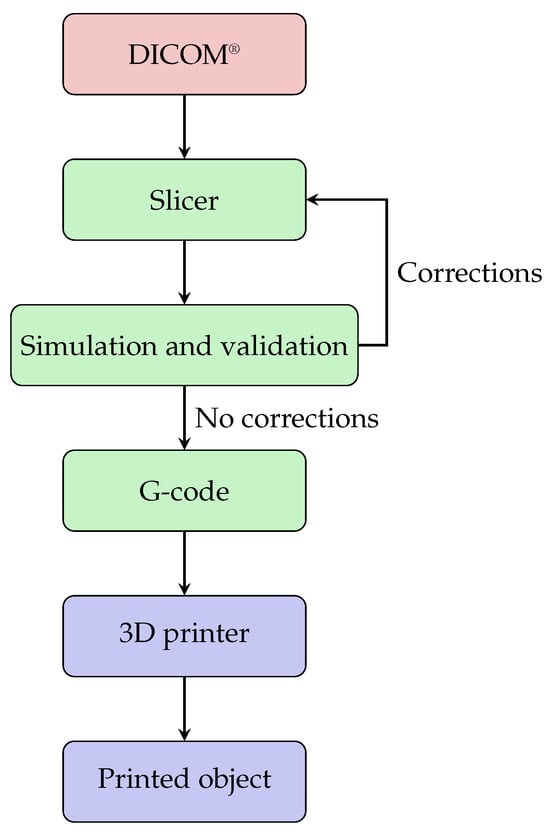

We note here that establishing a short and customised AM process for the medical field would be a major breakthrough. Figure 5 shows an example of a customised process that could work in the medical field. In this example, the slicer can accurately handle DICOM® directly, which removes the possibility of conversion errors related to the STL format.

Figure 5.

Flowchart representation of an alternative printing process customised for the the medical field. The steps are categorised by colour. Red involves medical software, green is specialised software, and blue is the physical printer and the real world.

5.4. The Future Usage of AI in AM

We consider AI to provide tools to support the process, rather than a “solution” or a challenge. Such techniques can be applied to any of the future research areas mentioned above. When working with AI, it is important to analyse the problem or system to be optimised. Such analysis can be used to find the most suitable algorithm or model. AI can be used to generate unique and efficient tool paths, find the optimal infill structure, or decide on the printing orientation depending on different properties, such as sturdiness or the printing time. ML is especially known for its usage in image recognition. One idea for research is to apply image recognition algorithms and adapt them to AM-related file formats, such as DICOM®, STEP, or AMF.

6. The Potential for Optimisation

As previously mentioned, the entire process and equipment intended to be used need to be taken into consideration when optimising. The individual steps of the 3D printing process in Figure 3 differ depending on the material and type of printing method used. In fact, the internal structure of the steps following the validation step in Figure 3 are completely different and unique for each printing method. Therefore, the optimised solutions and their effects and efficiency vary for different printers and their process. As mentioned earlier, Ref. [79] investigated how smoothing the tool paths and material overextrusion affected corner swelling. This research specifically targeted the optimisation of ME and the solution would have no effect for other printing methods, such as SL or VP. It is therefore important to note that each printing method has different printing processes and therefore also distinct aspects and methods associated with its optimisation, but some general suggestions for areas of improvement and their effects can be predicted regardless of the printing method.

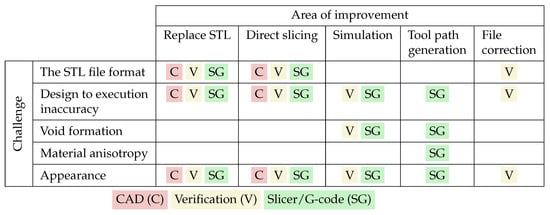

Figure 6, derived from Section 3 and Section 4, offers a short, comprehensive collection of general challenges and potential areas of improvement related to AM. The challenges and areas for improvement are based on their relevance to this paper and the authors’ personal research interests. Figure 6 is colour-coded according to Figure 3 such that the colours indicate the affected steps. We note here that the topics for future research are not limited to those mentioned in the table, whose main purpose is to systematise some possible alternatives; hence, it can be considered as a source of inspiration. Table 2 further connects the areas of improvement from Figure 6 to some of the potential optimisation aspects that may be achieved with said improvement.

Figure 6.

Table illustrating areas of improvement given different challenges. Each potential area of improvement is colour-coded according to which step in Figure 3 is affected. The colour categories are as follows: red for CAD, yellow for verification, and green for the slicer and G-code. All categories include additional steps, such as choosing the file type for CAD.

Table 2.

Table illustrating potential improved aspects depending on area of improvement. Areas of improvement are connected to Figure 6 and potential improved aspects are linked to the research previously mentioned.

7. Conclusions

A variety of interesting topics of research are trending within the field of computer-aided optimisation for AM. The use and adaptation of AI and ML techniques are very popular in many disciplines, including AM. Specialised slicers for a number of problems and challenges, such as infill structures, seam defects, time usage, and more, have caught the interest of many researchers and are constantly being explored. Simulations of the printing process can reduce the costs, energy consumption, and carbon footprint, due to the reductions in waste material and time resulting from the significant speed-up in the simulation when compared to real printing, as well as increased control and error handling during the process. In addition, simulations can also be used for testing and estimations of the final product.

Regardless of the continuous developments in AM, there remain many unresolved challenges. One of them is that STL is still the standard file format. There have been attempts to replace it with, for example, AMF or direct slicing, but none of the alternatives has gained significant interest from the community. Currently, many processes include the automatic and manual correction of the STL to compensate for the conversion errors. The problems with STL extend to two other well-known unresolved challenges, i.e., design to execution inaccuracies and appearance. When improving the data from the CAD system by replacing STL, or fixing or avoiding conversion errors, the design to execution inaccuracy and appearance can also be improved. Other options may be the verification and simulation of the printing parameters and tool paths. Void formation and material anisotropy are challenges with limited solutions regarding computer-aided optimisation; however, investigating the generation of tool paths may improve these aspects.

It is our hope that establishing this connection between trending optimisation topics and unresolved challenges will provide a foundation for new ideas, inspiration, and unexplored challenges that can be identified and considered for future research. Figure 6 is a considerable starting point as it encompasses the essence of this paper and its goals. This method of relating challenges to potential areas of improvement can be used further for specialised cases in future projects.

Author Contributions

Conceptualisation, T.E.H., R.D., T.F.B. and A.P.; methodology, T.E.H. and R.D.; validation, T.E.H., R.D. and T.F.B.; investigation, T.E.H.; writing—original draft preparation, T.E.H. and T.F.B.; writing—review and editing, T.E.H., R.D. and T.F.B.; visualisation, T.E.H.; supervision, R.D., T.F.B. and A.P.; project administration, R.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ugur, M. Dilberoglu, Bahar Gharehpapagh, Ulas Yaman, and Melik Dolen. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3d printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Hong, Q.; Lin, L.; Li, Q.; Jiang, Z.; Fang, J.; Wang, B.; Liu, K.; Wu, Q.; Huang, C. A direct slicing technique for the 3d printing of implicitly represented medical models. Comput. Biol. Med. 2021, 135, 104534. [Google Scholar] [CrossRef]

- Kouraytem, N.; Li, X.; Tan, W.; Kappes, B.; Spear, A.D. Modeling process–structure–property relationships in metal additive manufacturing: A review on physics-driven versus data-driven approaches. J. Phys. Mater. 2021, 4, 032002. [Google Scholar] [CrossRef]

- Singh, S.; Mehla, S.; Bhargava, S.K.; Ramakrishna, S. History and Evolution of Additive Manufacturing; Springer Nature: Singapore, 2022; pp. 19–51. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for additive manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Zhai, Y.; Lados, D.A.; LaGoy, J.L. Additive manufacturing: Making imagination the major limitation. JOM 2014, 66, 808–816. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3d printing: State of the art and future perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Horvath, J. A Brief History of 3D Printing; Apress: Berkeley, CA, USA, 2014; pp. 3–10. [Google Scholar]

- Wohlers, T.; Gornet, T. History of Additive Manufacturing. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4474824 (accessed on 29 March 2024).

- Bonnard, R. An advanced step-nc platform for additive manufacturing. In Industrializing Additive Manufacturing—Proceedings of Additive Manufacturing in Products and Applications—AMPA2017; Meboldt, M., Klahn, C., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 127–136. [Google Scholar]

- Xu, X.W.; Wang, L.; Rong, Y. Step-nc and function blocks for interoperable manufacturing. IEEE Trans. Autom. Sci. Eng. 2006, 3, 297–308. [Google Scholar] [CrossRef][Green Version]

- Benthall, L.; Briggs, T.; Downie, B.; Gischner, B.; Kassel, B.; Wood, R. STEP for Shipbuilding: A Solution for Product Model Data Exchange. J. Ship Prod. 2003, 19, 44–52. [Google Scholar] [CrossRef]

- Sandeep, B.; Kannan, T.T.M.; Chandradass, J.; Ganesan, M.; Rajan, A.J. Scope of 3d printing in manufacturing industries—A review. Mater. Today Proc. 2021, 45, 6941–6945. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in metal additive manufacturing: A review of common processes, industrial applications, and current challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Tom, T.; Sreenilayam, S.P.; Brabazon, D.; Jose, J.P.; Joseph, B.; Madanan, K.; Thomas, S. Additive manufacturing in the biomedical field-recent research developments. Results Eng. 2022, 16, 100661. [Google Scholar] [CrossRef]

- Zocca, A.; Wilbig, J.; Waske, A.; Günster, J.; Widjaja, M.P.; Neumann, C.; Clozel, M.; Meyer, A.; Ding, J.; Zhou, Z.; et al. Challenges in the technology development for additive manufacturing in space. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100018. [Google Scholar] [CrossRef]

- Careri, F.; Khan, R.H.U.; Todd, C.; Attallah, M.M. Additive manufacturing of heat exchangers in aerospace applications: A review. Appl. Therm. Eng. 2023, 235, 121387. [Google Scholar] [CrossRef]

- Madhavadas, V.; Srivastava, D.; Chadha, U.; Raj, S.A.; Sultan, M.T.H.; Shahar, F.S.; Shah, A.U.M. A review on metal additive manufacturing for intricately shaped aerospace components. CIRP J. Manuf. Sci. Technol. 2022, 39, 18–36. [Google Scholar] [CrossRef]

- Goodacre, B.J.; Goodacre, C.J. Additive manufacturing for complete denture fabrication: A narrative review. J. Prosthodont. 2022, 31, 47–51. [Google Scholar] [CrossRef] [PubMed]

- Medvedev, A.E.; Maconachie, T.; Leary, M.; Qian, M.; Brandt, M. Perspectives on additive manufacturing for dynamic impact applications. Mater. Des. 2022, 221, 110963. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Metal additive manufacturing for electrical machines: Technology review and latest advancements. Energies 2022, 15, 1076. [Google Scholar] [CrossRef]

- Rouf, S.; Raina, A.; Haq, M.I.U.; Naveed, N.; Jeganmohan, S.; Kichloo, A.F. 3d printed parts and mechanical properties: Influencing parameters, sustainability aspects, global market scenario, challenges and applications. Adv. Ind. Eng. Polym. Res. 2022, 5, 143–158. [Google Scholar] [CrossRef]

- Xiong, Y.; Lu, H.; Li, G.; Xia, S.; Wang, Z.; Xu, Y. Game changer or threat: The impact of 3d printing on the logistics supplier circular supply chain. Ind. Mark. Manag. 2022, 106, 461–475. [Google Scholar] [CrossRef]

- Qi, X.; Chen, G.; Li, Y.; Cheng, X.; Li, C. Applying neural-network-based machine learning to additive manufacturing: Current applications, challenges, and future perspectives. Engineering 2019, 5, 721–729. [Google Scholar] [CrossRef]

- Bonnard, R.; Hascoët, J.Y.; Mognol, P. Data model for additive manufacturing digital thread: State of the art and perspectives. Int. J. Comput. Integr. Manuf. 2019, 32, 1170–1191. [Google Scholar] [CrossRef]

- Pei, E.; Ressin, M.; Campbell, R.I.; Eynard, B.; Xiao, J. Investigating the impact of additive manufacturing data exchange standards for re-distributed manufacturing. Prog. Addit. Manuf. 2019, 4, 331–344. [Google Scholar] [CrossRef]

- Nieto, D.M.; Sánchez, D.M. Design for additive manufacturing: Tool review and a case study. Appl. Sci. 2021, 11, 1571. [Google Scholar] [CrossRef]

- Lee, J.; An, J.; Chua, C.K. Fundamentals and applications of 3d printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Singh, T.; Kumar, S.; Sehgal, S. 3d printing of engineering materials: A state of the art review. Mater. Today Proc. 2020, 28, 1927–1931. [Google Scholar] [CrossRef]

- Schwaar, C. The 7 Main Types of 3d Printing Technology. Available online: https://all3dp.com/1/types-of-3d-printers-3d-printing-technology/ (accessed on 29 March 2024).

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Park, S.-I.; Rosen, D.W.; Choi, S.k.; Duty, C.E. Effective mechanical properties of lattice material fabricated by material extrusion additive manufacturing. Addit. Manuf. 2014, 1, 12–23. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Directed Energy Deposition Processes; Springer: New York, NY, USA, 2015; pp. 245–268. [Google Scholar]

- Gülcan, O.; Günaydın, K.; Tamer, A. The state of the art of material jetting—A critical review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Powder Bed Fusion; Springer International Publishing: Cham, Switzerland, 2021; pp. 125–170. [Google Scholar]

- Kong, C.Y.; Soar, R.C.; Dickens, P.M. Optimum process parameters for ultrasonic consolidation of 3003 aluminium. J. Mater. Process. Technol. 2004, 146, 181–187. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Sheet Lamination; Springer International Publishing: Cham, Switzerland, 2021; pp. 253–283. [Google Scholar]

- Al Rashid, A.; Ahmed, W.; Khalid, M.Y.; Koç, M. Vat photopolymerization of polymers and polymer composites: Processes and applications. Addit. Manuf. 2021, 47, 102279. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Method of optimisation for ambient temperature cured sustainable geopolymers for 3d printing construction applications. Materials 2019, 12, 902. [Google Scholar] [CrossRef] [PubMed]

- Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. Development and optimisation of novel polymeric compositions for sustained release theophylline caplets (printcap) via fdm 3d printing. Polymers 2020, 12, 27. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; He, Y.; Trindade, G.F.; Baumers, M.; Irvine, D.J.; Hague, R.J.M.; Ashcroft, I.A.; Wildman, R.D. Modelling the influence of uv curing strategies for optimisation of inkjet based 3d printing. Mater. Des. 2021, 208, 109889. [Google Scholar] [CrossRef]

- Heiden, B.; Alieksieiev, V.; Volk, M.; Tonino-Heiden, B. Framing artificial intelligence (ai) additive manufacturing (am). Procedia Comput. Sci. 2021, 186, 387–394. [Google Scholar] [CrossRef]

- Nguyen, P.D.; Nguyen, T.Q.; Tao, Q.B.; Vogel, F.; Nguyen-Xuan, H. A data-driven machine learning approach for the 3d printing process optimisation. Virtual Phys. Prototyp. 2022, 17, 768–786. [Google Scholar] [CrossRef]

- Tan, C.; Weng, F.; Sui, S.; Chew, Y.; Bi, G. Progress and perspectives in laser additive manufacturing of key aeroengine materials. Int. J. Mach. Tools Manuf. 2021, 170, 103804. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Khosravi, F.; Neisiany, R.E.; Singh, S.; Ramakrishna, S. Future of additive manufacturing in healthcare. Curr. Opin. Biomed. Eng. 2021, 17, 100255. [Google Scholar]

- Ramola, M.; Yadav, V.; Jain, R. On the adoption of additive manufacturing in healthcare: A literature review. J. Manuf. Technol. Manag. 2019, 30, 48–69. [Google Scholar] [CrossRef]

- Castro, B.M.; Elbadawi, M.; Ong, J.J.; Pollard, T.; Song, Z.; Gaisford, S.; Pérez, G.; Basit, A.W.; Cabalar, P.; Goyanes, A. Machine learning predicts 3d printing performance of over 900 drug delivery systems. J. Control. Release 2021, 337, 530–545. [Google Scholar] [CrossRef]

- Yadav, D.; Chhabra, D.; Garg, R.K.; Ahlawat, A.; Phogat, A. Optimization of fdm 3d printing process parameters for multi-material using artificial neural network. Mater. Today Proc. 2020, 21, 1583–1591. [Google Scholar] [CrossRef]

- Sarabi, M.R.; Alseed, M.M.; Karagoz, A.A.; Tasoglu, S. Machine learning-enabled prediction of 3d-printed microneedle features. Biosensors 2022, 12, 491. [Google Scholar] [CrossRef]

- Zhu, H.S.P.Z.; Ng, D.W.H.; McAlpine, M.C. 3d-printed multifunctional materials enabled by artificial-intelligence-assisted fabrication technologies. Nat. Rev. Mater. 2021, 6, 27–47. [Google Scholar] [CrossRef]

- Elbadawi, M.; McCoubrey, L.E.; Gavins, F.K.H.; Ong, J.J.; Goyanes, A.; Gaisford, S.; Basit, A.W. Harnessing artificial intelligence for the next generation of 3d printed medicines. Adv. Drug Deliv. Rev. 2021, 175, 113805. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.P.; Tor, S.B.; Lim, C.S. Machine learning in additive manufacturing: State-of-the-art and perspectives. Addit. Manuf. 2020, 36, 101538. [Google Scholar] [CrossRef]

- Meng, L.; McWilliams, B.; Jarosinski, W.; Park, H.-Y.; Jung, Y.-G.; Lee, J.; Zhang, J. Machine learning in additive manufacturing: A review. JOM 2020, 72, 2363–2377. [Google Scholar] [CrossRef]

- Goldberg, Y. Neural network methods for natural language processing. Synth. Lect. Hum. Lang. Technol. 2017, 10, 1–309. [Google Scholar]

- Abiodun, O.I.; Jantan, A.; Omolara, A.E.; Dada, K.V.; Mohamed, N.A.; Arshad, H. State-of-the-art in artificial neural network applications: A survey. Heliyon 2018, 4, e00938. [Google Scholar] [CrossRef]

- Hiller, J.D.; Lipson, H. Stl 2.0: A proposal for a universal multi-material additive manufacturing file format. In Proceedings of the 2009 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 3–5 August 2009; University of Texas at Austin: Austin, TX, USA, 2009. [Google Scholar]

- van Eijnatten, M.; van Dijk, R.; Dobbe, J.; Streekstra, G.; Koivisto, J.; Wolff, J. Ct image segmentation methods for bone used in medical additive manufacturing. Med Eng. Phys. 2018, 51, 6–16. [Google Scholar] [CrossRef]

- Huotilainen, E.; Jaanimets, R.; Valášek, J.; Marcián, P.; Salmi, M.; Tuomi, J.; Mäkitie, A.; Wolff, J. Inaccuracies in additive manufactured medical skull models caused by the dicom to stl conversion process. J. Cranio-Maxillofac. Surg. 2014, 42, e259–e265. [Google Scholar] [CrossRef] [PubMed]

- Stoor, P.; Suomalainen, A.; Lindqvist, C.; Mesimäki, K.; Danielsson, D.; Westermark, A.; Kontio, R.K. Rapid prototyped patient specific implants for reconstruction of orbital wall defects. J. Cranio-Maxillofac. Surg. 2014, 42, 1644–1649. [Google Scholar] [CrossRef] [PubMed]

- D’Addazio, G.; Xhajanka, E.; Traini, T.; Santilli, M.; Rexhepi, I.; Murmura, G.; Caputi, S.; Sinjari, B. Accuracy of dicom–dicom vs. dicom–stl protocols in computer-guided surgery: A human clinical study. J. Clin. Med. 2022, 11, 2336. [Google Scholar] [CrossRef] [PubMed]

- Osti, F.; Santi, G.; Neri, M.; Liverani, A.; Frizziero, L.; Stilli, S.; Maredi, E.; Zarantonello, P.; Gallone, G.; Stallone, S.; et al. Ct conversion workflow for intraoperative usage of bony models: From dicom data to 3d printed models. Appl. Sci. 2019, 9, 708. [Google Scholar] [CrossRef]

- Allaire, G.; Bogosel, B. Optimizing supports for additive manufacturing. Struct. Multidiscip. Optim. 2018, 58, 2493–2515. [Google Scholar] [CrossRef]

- King, B.; Rennie, A.; Bennett, G. An efficient triangle mesh slicing algorithm for all topologies in additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 112, 1023–1033. [Google Scholar] [CrossRef]

- Yigit, I.E.; Lazoglu, I. Helical slicing method for material extrusion-based robotic additive manufacturing. Prog. Addit. Manuf. 2019, 4, 225–232. [Google Scholar] [CrossRef]

- Adams, D.; Turner, C.J. An implicit slicing method for additive manufacturing processes. Virtual Phys. Prototyp. 2018, 13, 2–7. [Google Scholar] [CrossRef]

- Alkadi, F.; Lee, K.; Bashiri, A.H.; Choi, J. Conformal additive manufacturing using a direct-print process. Addit. Manuf. 2020, 32, 100975. [Google Scholar] [CrossRef]

- Tan, W.S.; Juhari, M.A.B.; Shi, Q.; Chen, S.; Campolo, D.; Song, J. Development of a new additive manufacturing platform for direct freeform 3d printing of intrinsically curved flexible membranes. Addit. Manuf. 2020, 36, 101563. [Google Scholar] [CrossRef]

- Gupta, P.; Krishnamoorthy, B.; Dreifus, G. Continuous toolpath planning in a graphical framework for sparse infill additive manufacturing. Comput.-Aided Des. 2020, 127, 102880. [Google Scholar] [CrossRef]

- Xia, L.; Lin, S.; Ma, G. Stress-based tool-path planning methodology for fused filament fabrication. Addit. Manuf. 2020, 32, 101020. [Google Scholar] [CrossRef]

- Chacón, J.M.; Sanchez-Reyes, J.; Vallejo, J.; Núñez, P.J. G-code generation in a nurbs workflow for precise additive manufacturing. Rapid Prototyp. J. 2022, 28, 65–76. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Ukar, O.; Ostolaza, M.; Mugica, A. Study of the environmental implications of using metal powder in additive manufacturing and its handling. Metals 2020, 10, 261. [Google Scholar] [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Cook, P.S.; Murphy, A.B. Simulation of melt pool behaviour during additive manufacturing: Underlying physics and progress. Addit. Manuf. 2020, 31, 100909. [Google Scholar] [CrossRef]

- Körner, C.; Markl, M.; Koepf, J.A. Modeling and simulation of microstructure evolution for additive manufacturing of metals: A critical review. Metall. Mater. Trans. A 2020, 51, 4970–4983. [Google Scholar] [CrossRef]

- Song, X.; Feih, S.; Zhai, W.; Sun, C.; Li, F.; Maiti, R.; Wei, J.; Yang, Y.; Oancea, V.; Brandt, L.R.; et al. Advances in additive manufacturing process simulation: Residual stresses and distortion predictions in complex metallic components. Mater. Des. 2020, 193, 108779. [Google Scholar] [CrossRef]

- Comminal, R.; Serdeczny, M.P.; Pedersen, D.B.; Spangenberg, J. Motion planning and numerical simulation of material deposition at corners in extrusion additive manufacturing. Addit. Manuf. 2019, 29, 100753. [Google Scholar] [CrossRef]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive manufacturing: Challenges, trends, and applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Bhuvanesh Kumar, M.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A. Ten challenges in 3d printing: Engineering with computers. Compos. Part B Eng. 2016, 32, 135–148. [Google Scholar]

- Xiao, J.; Anwer, N.; Durupt, A.; Duigou, J.L.; Eynard, B. Information exchange standards for design, tolerancing and additive manufacturing: A research review. Int. J. Interact. Des. Manuf. 2018, 12, 495–504. [Google Scholar] [CrossRef]

- Krueckemeier, S.; Anderl, R.; Schleich, B. File format selection for efficient digital process chains in additive manufacturing. Proc. Des. Soc. 2023, 3, 1875–1884. [Google Scholar] [CrossRef]

- Godec, D.; Gonzalez-Gutierrez, J.; Nordin, A.; Pei, E.; Ureña, J. A Guide to Additive Manufacturing; Springer Nature: Cham, Switzerland, 2022. [Google Scholar]

- Zhao, D.; Guo, W. Shape and performance controlled advanced design for additive manufacturing: A review of slicing and path planning. J. Manuf. Sci. Eng. 2020, 142, 010801. [Google Scholar] [CrossRef]

- Schaechtl, P.; Schleich, B.; Wartzack, S. On the potential of slicing algorithms in additive manufacturing for the optimization of geometrical part accuracy. Procedia CIRP 2022, 114, 215–220. [Google Scholar] [CrossRef]

- Brion, D.A.J.; Pattinson, S.W. Generalisable 3d printing error detection and correction via multi-head neural networks. Nat. Commun. 2022, 13, 4654. [Google Scholar] [CrossRef] [PubMed]

- Wylie, B.; Moore, C. Optical methods of error detection in additive manufacturing: A literature review. J. Manuf. Mater. Process. 2023, 7, 80. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Strucker, B. Post-Processing, 2nd ed.; Springer: New York, NY, USA, 2010. [Google Scholar]

- Lekas, S.; Drummond, R.; Grant, P.; Duncan, S.R. Control of additive manufacturing for radio-frequency devices with spatially varying dielectric properties. IEEE Trans. Control. Syst. Technol. 2024. [Google Scholar] [CrossRef]

- Sun, X.; Mazur, M.; Cheng, C. A review of void reduction strategies in material extrusion-based additive manufacturing. Addit. Manuf. 2023, 67, 103463. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3d printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A.; Sharif, M. Numerical study for the improvement of bead spreading architecture with modified nozzle geometries in additive manufacturing of polymers. Rapid Prototyp. J. 2021, 27, 518–529. [Google Scholar] [CrossRef]

- Qiu, D.; Langrana, N. Void eliminating toolpath for extrusion-based multi-material layered manufacturing. Rapid Prototyp. J. 2002, 8, 38–45. [Google Scholar] [CrossRef]

- Kuipers, T.; Doubrovski, E.L.; Wu, J.; Wang, C.C.L. A framework for adaptive width control of dense contour-parallel toolpaths in fused deposition modeling. Comput.-Aided Des. 2020, 128, 102907. [Google Scholar] [CrossRef]

- Lin, S.; Xia, L.; Ma, G.; Zhou, S.; Xie, Y.M. A maze-like path generation scheme for fused deposition modeling. Int. J. Adv. Manuf. Technol. 2019, 104, 1509–1519. [Google Scholar] [CrossRef]

- Levenhagen, N.P.; Dadmun, M.D. Interlayer diffusion of surface segregating additives to improve the isotropy of fused deposition modeling products. Polymer 2018, 152, 35–41. [Google Scholar] [CrossRef]

- Wang, L.; Gramlich, W.; Gardner, D. Improving the impact strength of poly(lactic acid) (pla) in fused layer modeling (flm). Polymer 2017, 114, 242–248. [Google Scholar] [CrossRef]

- Aliheidari, N.; Christ, J.; Tripuraneni, R.; Nadimpalli, S.; Ameli, A. Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process. Mater. Des. 2018, 156, 351–361. [Google Scholar] [CrossRef]

- Ravi, A.; Deshpande, A.; Hsu, K.H. An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing. J. Manuf. Process. 2016, 24, 179–185. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef]

- Torres, J.; Cotelo, J.; Karl, J.; Gordon, A.P. Mechanical property optimization of fdm pla in shear with multiple objectives. JOM 2015, 67, 1183–1193. [Google Scholar] [CrossRef]

- Li, G.; Zhao, J.; Jiang, J.; Jiang, H.; Wu, W.; Tang, M. Ultrasonic strengthening improves tensile mechanical performance of fused deposition modeling 3d printing. Int. J. Adv. Manuf. Technol. 2018, 96, 2747–2755. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, J.; To, A.C. Role of anisotropic properties on topology optimization of additive manufactured load bearing structures. Scr. Mater. 2017, 135, 148–152. [Google Scholar] [CrossRef]

- Zohdi, N.; Yang, R. Material anisotropy in additively manufactured polymers and polymer composites: A review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef]

- Shaffer, S.; Yang, K.; Vargas, J.; Di Prima, M.A.; Voit, W. On reducing anisotropy in 3d printed polymers via ionizing radiation. Polymer 2014, 55, 5969–5979. [Google Scholar] [CrossRef]

- Cooke, W.; Tomlinson, R.; Burguete, R.; Johns, D.; Vanard, G. Anisotropy, homogeneity and ageing in an sls polymer. Rapid Prototyp. J. 2011, 17, 269–279. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H.; Ben Hassana, O. Anisotropic damage inferred to 3d printed polymers using fused deposition modelling and subject to severe compression. Eur. Polym. J. 2016, 85, 324–340. [Google Scholar] [CrossRef]

- Muhler, T.; Gomes, C.M.; Heinrich, J.; Günster, J. Slurry-based additive manufacturing of ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 18–25. [Google Scholar] [CrossRef]

- Manière, C.; Kerbart, G.; Harnois, C.; Marinel, S. Modeling sintering anisotropy in ceramic stereolithography of silica. Acta Mater. 2020, 182, 163–171. [Google Scholar] [CrossRef]

- Wu, X.; Xu, C.; Zhang, Z.; Guo, C. Modeling and visualization of layered curing conversion profile in ceramic mask projection stereolithography process. Ceram. Int. 2020, 46, 25750–25757. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Zhu, Y.; Tian, X.; Li, J.; Wang, H. The anisotropy of laser melting deposition additive manufacturing Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater. Des. 2015, 67, 538–542. [Google Scholar] [CrossRef]

- Körner, C.; Helmer, H.; Bauereiß, A.; Singer, R. Tailoring the grain structure of IN718 during selective electron beam melting. MATEC Web Conf. 2014, 14, 08001. [Google Scholar] [CrossRef]

- Prajapati, M.J.; Kumar, A.; Lin, S.; Jeng, J. Reducing mechanical anisotropy in material extrusion process using bioinspired architectured lattice structures. Addit. Manuf. 2023, 66, 103480. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Colombo, P.; Li, W.; Liu, Y.; Hu, K.; Lu, Z. The influence of sintering procedure and porosity on the properties of 3d printed alumina ceramic cores. Ceram. Int. 2021, 47, 27668–27676. [Google Scholar] [CrossRef]

- Li, Q.; Hou, W.; Liang, J.; Zhang, C.; Li, J.; Zhou, Y.; Sun, X. Controlling the anisotropy behaviour of 3d printed ceramic cores: From intralayer particle distribution to interlayer pore evolution. Addit. Manuf. 2022, 58, 103055. [Google Scholar] [CrossRef]

- Tan, Q.; Zhang, J.; Mo, N.; Fan, Z.; Yin, Y.; Bermingham, M.; Liu, Y.; Huang, H.; Zhang, M. A novel method to 3d-print fine-grained alsi10mg alloy with isotropic properties via inoculation with lab6 nanoparticles. Addit. Manuf. 2020, 32, 101034. [Google Scholar] [CrossRef]

- Chen, S.; Tan, Q.; Gao, W.; Wu, G.; Fan, J.; Feng, Z.; Huang, T.; Godfrey, A.W.; Zhang, M.; Huang, X. Effect of heat treatment on the anisotropy in mechanical properties of selective laser melted alsi10mg. Mater. Sci. Eng. A 2022, 858, 144130. [Google Scholar] [CrossRef]

- Hossain, U.; Ghouse, S.; Nai, K.; Jeffers, J.R.T. Controlling and testing anisotropy in additively manufactured stochastic structures. Addit. Manuf. 2021, 39, 101849. [Google Scholar] [CrossRef]

- Ahn, D.; Kim, H.; Lee, S. Fabrication direction optimization to minimize post-machining in layered manufacturing. Int. J. Mach. Tools Manuf. 2007, 47, 593–606. [Google Scholar] [CrossRef]

- Das, P.; Chandran, R.; Samant, R.; Anand, S. Optimum part build orientation in additive manufacturing for minimizing part errors and support structures. Procedia Manuf. 2015, 1, 343–354. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Revolutionary Additive Manufacturing: An Overview; University of Johannesburg Institutional Repository (UJIR): Johannesburg, South Africa, 2014. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).