Simulation-Assisted Tool Design for Pulsed Electrochemical Machining of Magnetic Shape-Memory Alloys

Abstract

1. Introduction

2. Materials, Setup, and Methods

2.1. Material

2.2. Machine

2.3. Determination of Material Specific Dissolution Behavior

2.4. Measurement

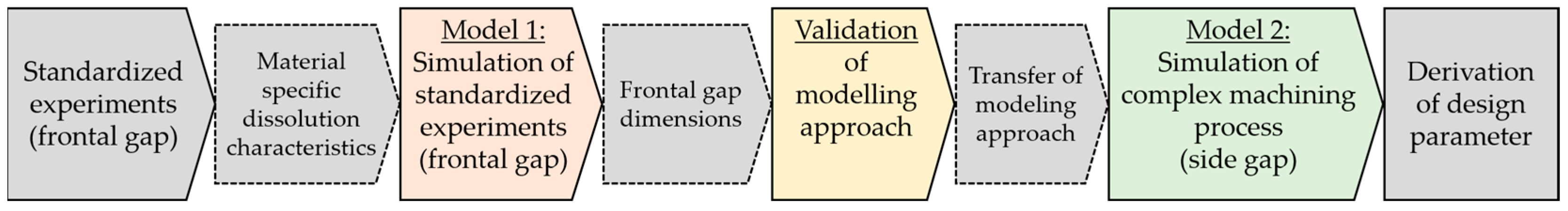

3. Simulation Methods

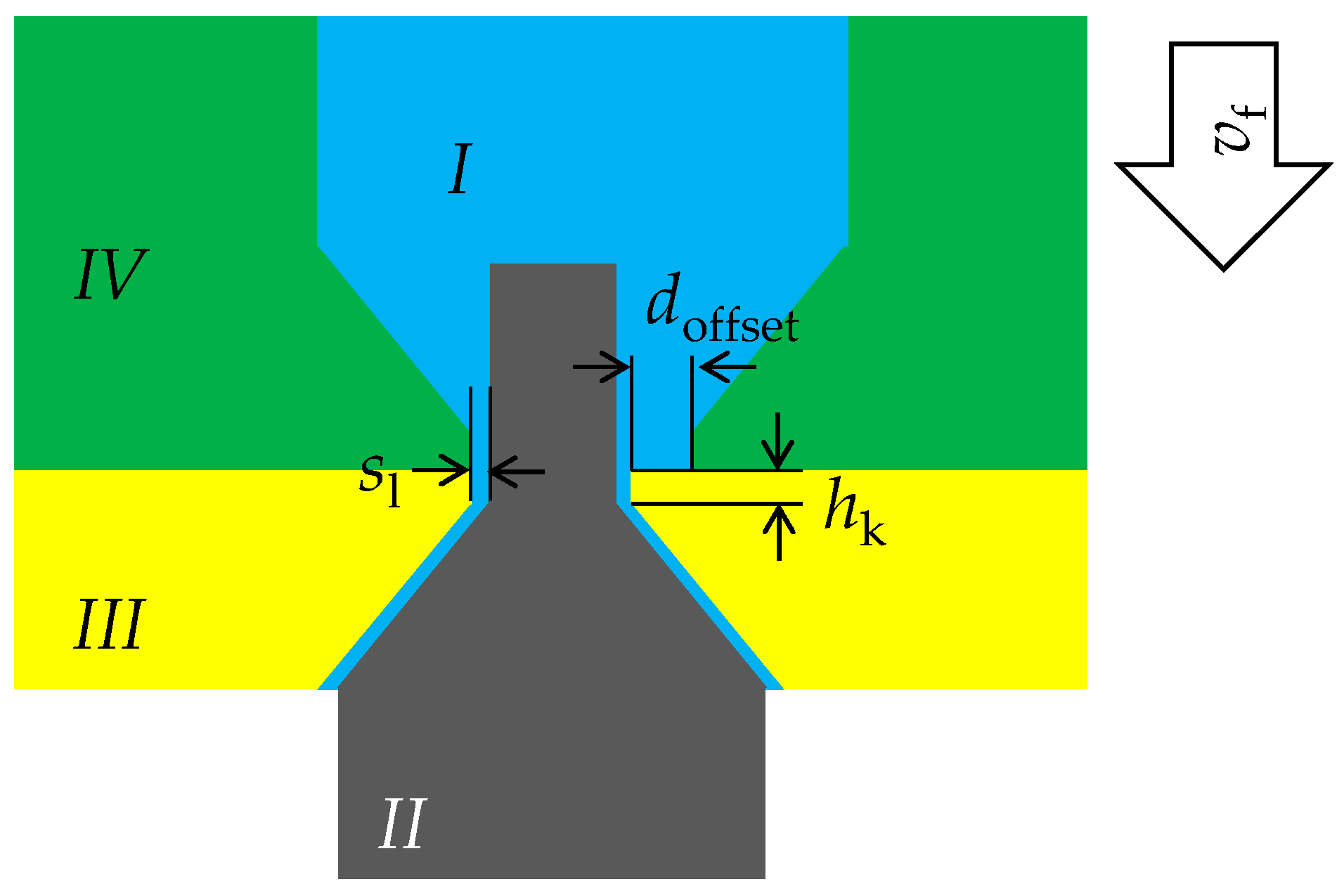

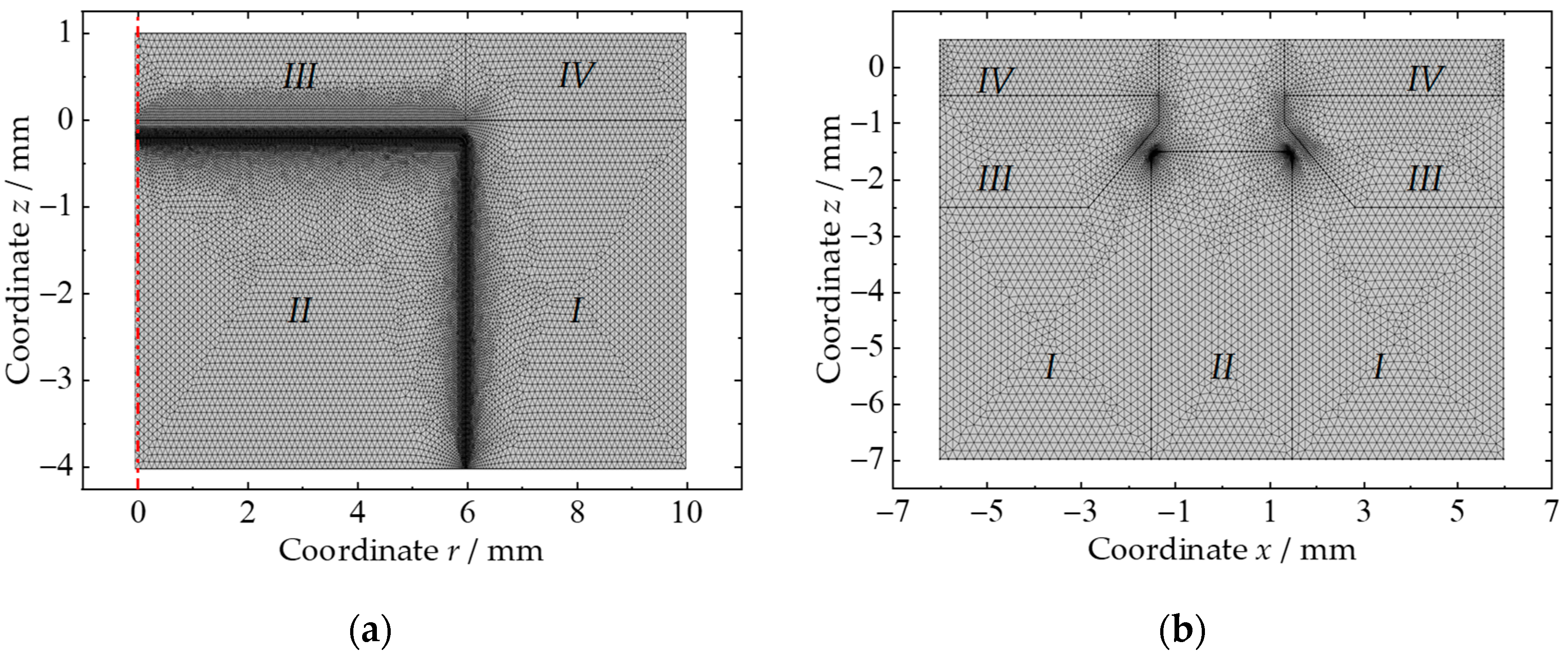

3.1. Model Geometries

3.2. Domain and Boundary Conditions

3.3. Meshing

4. Results and Discussion

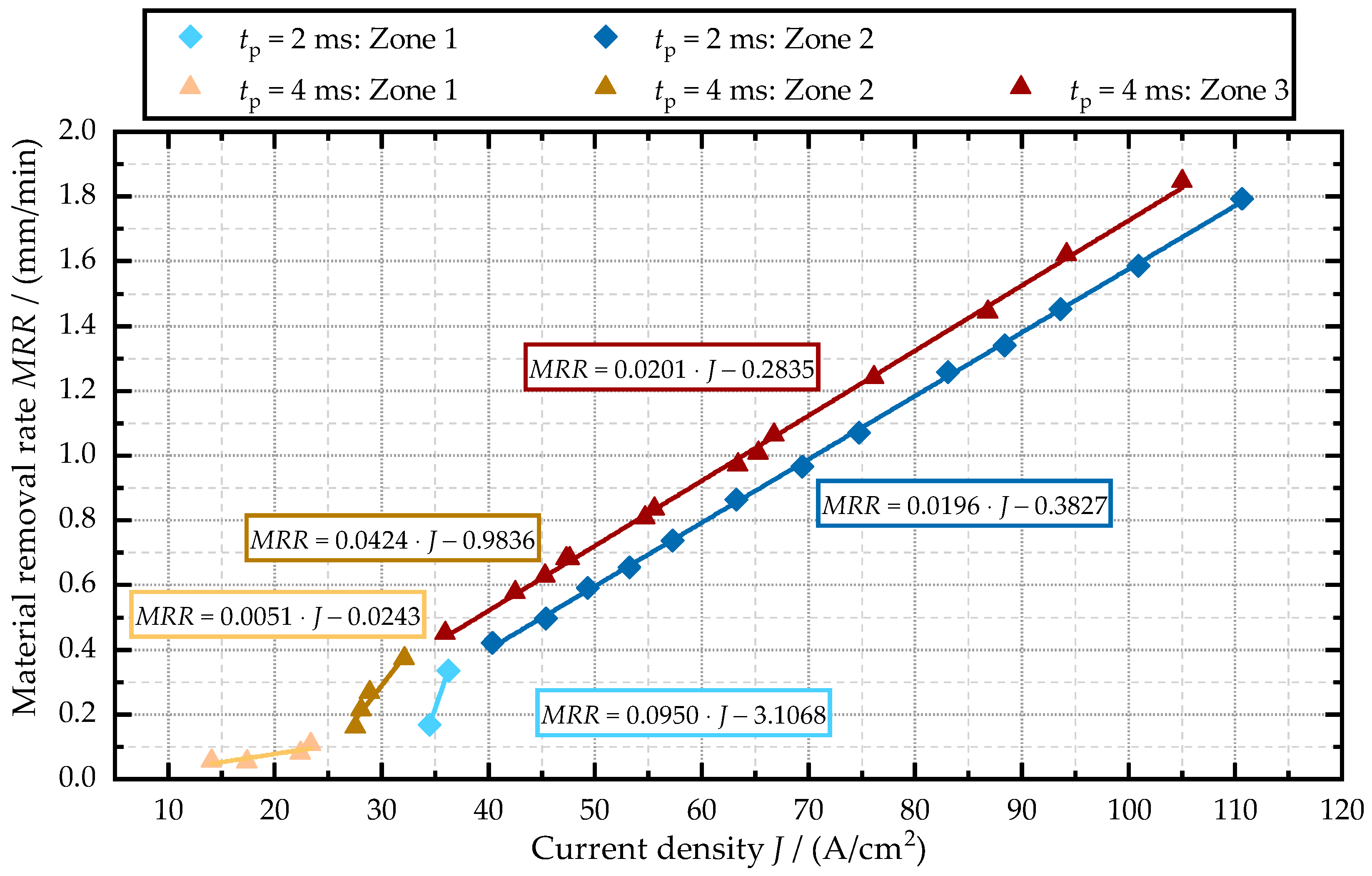

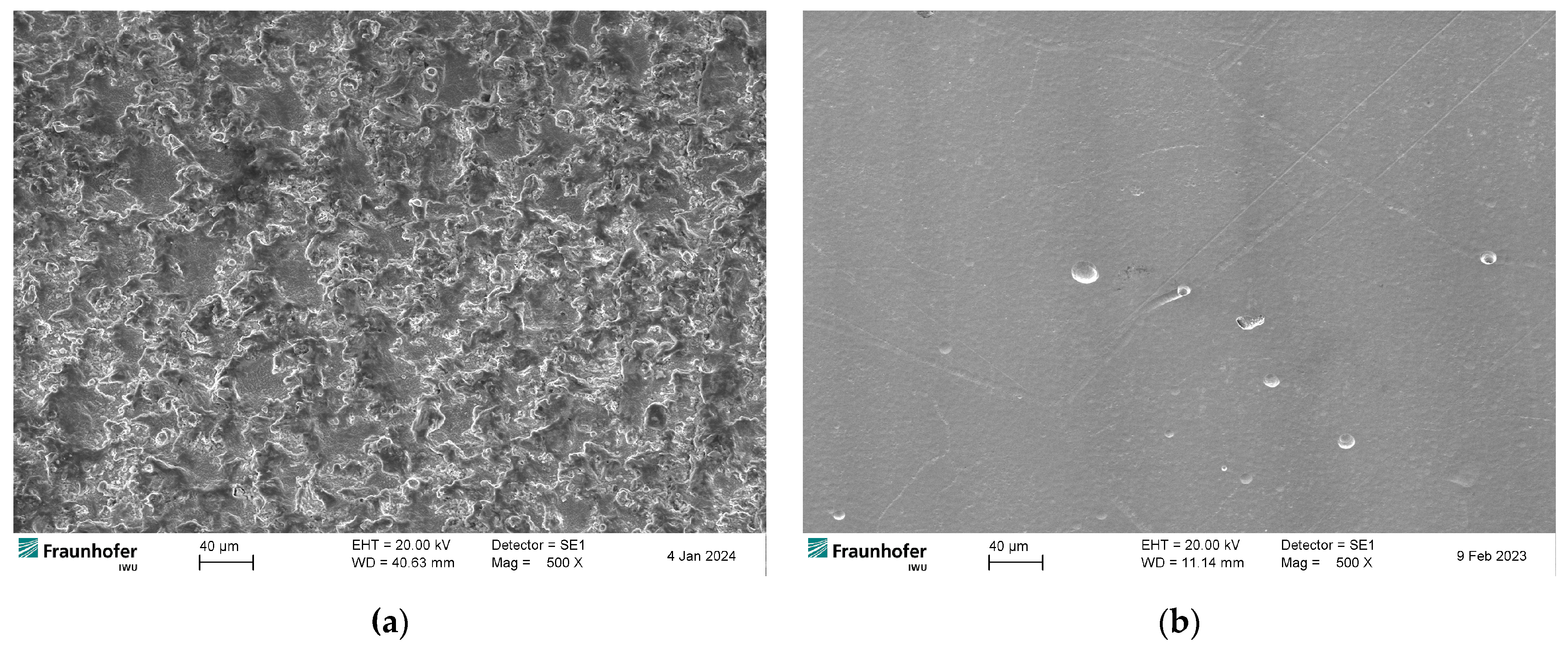

4.1. Electrochemical Characterization

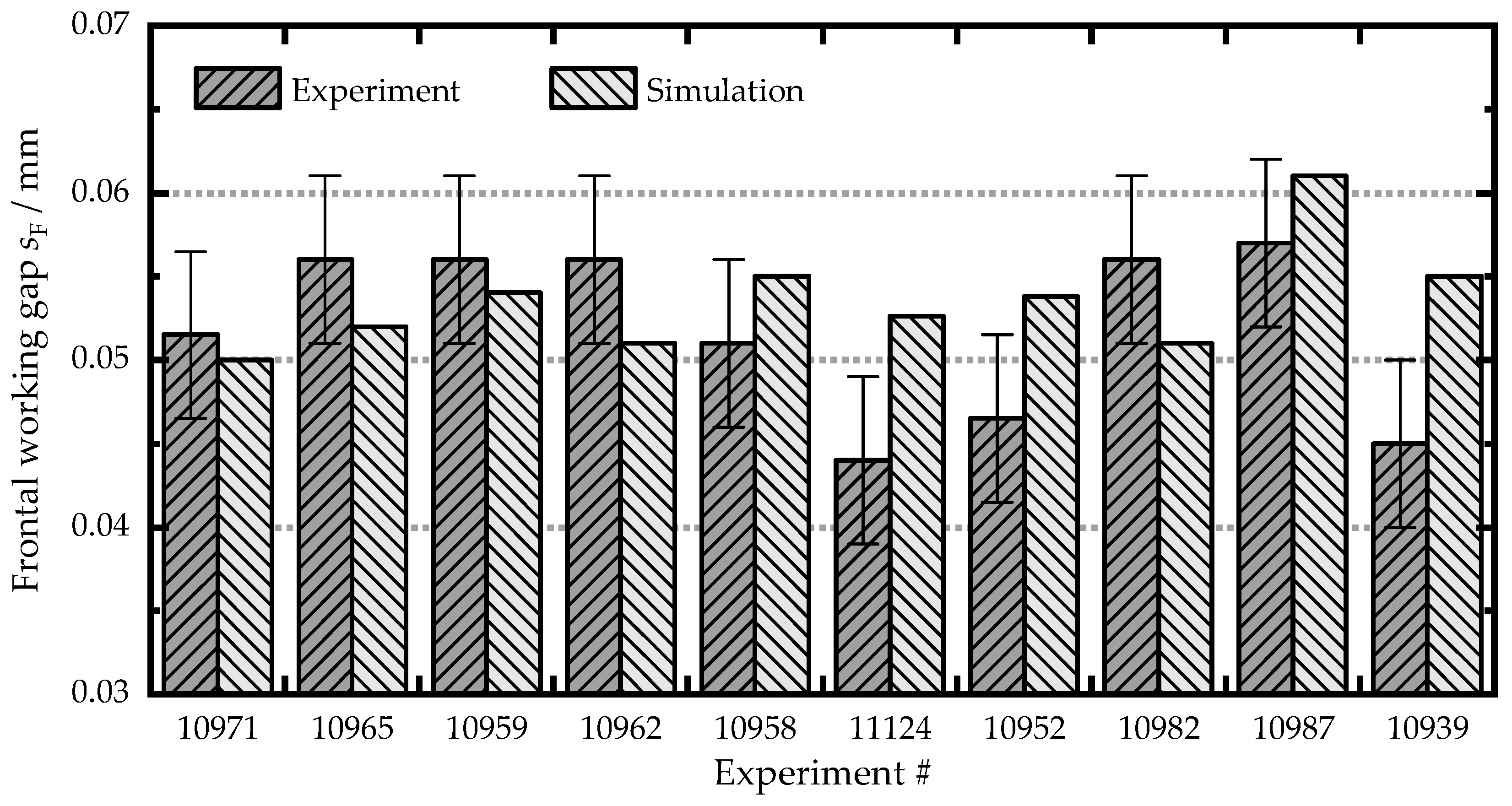

4.2. Validation of Simulation Approach

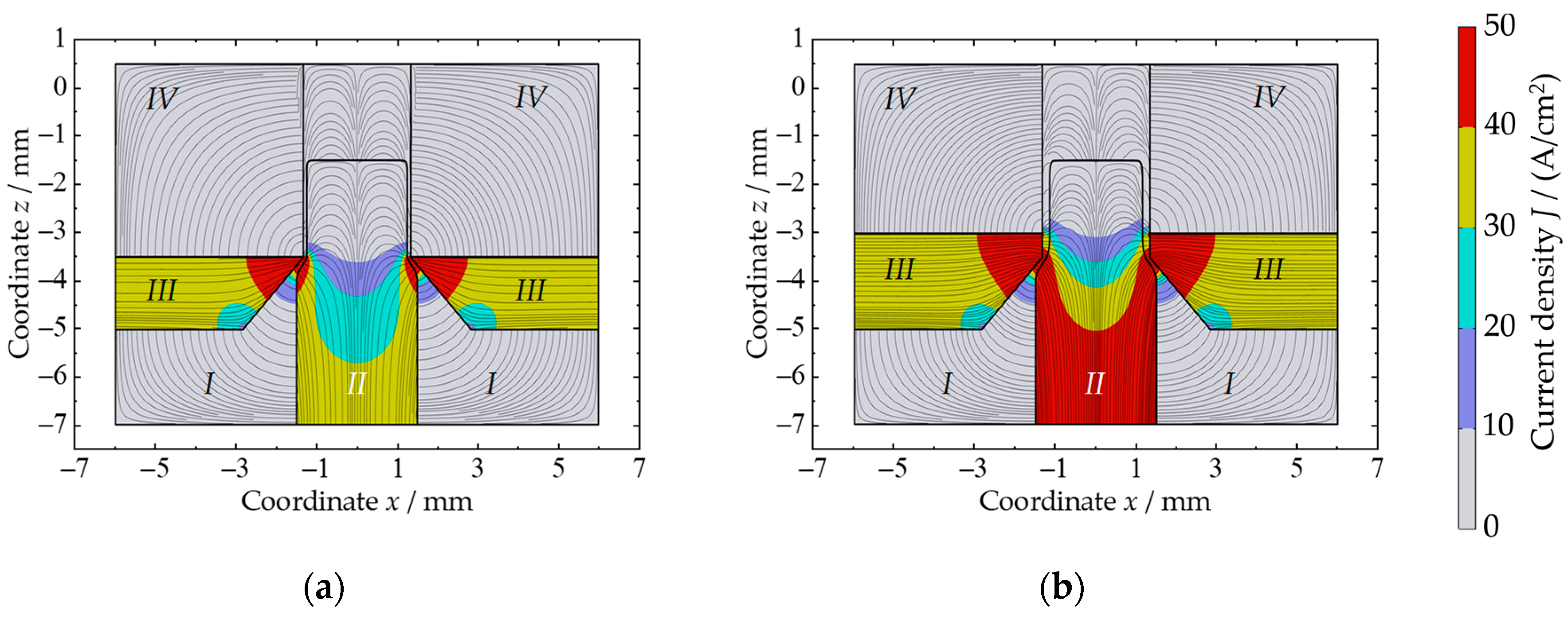

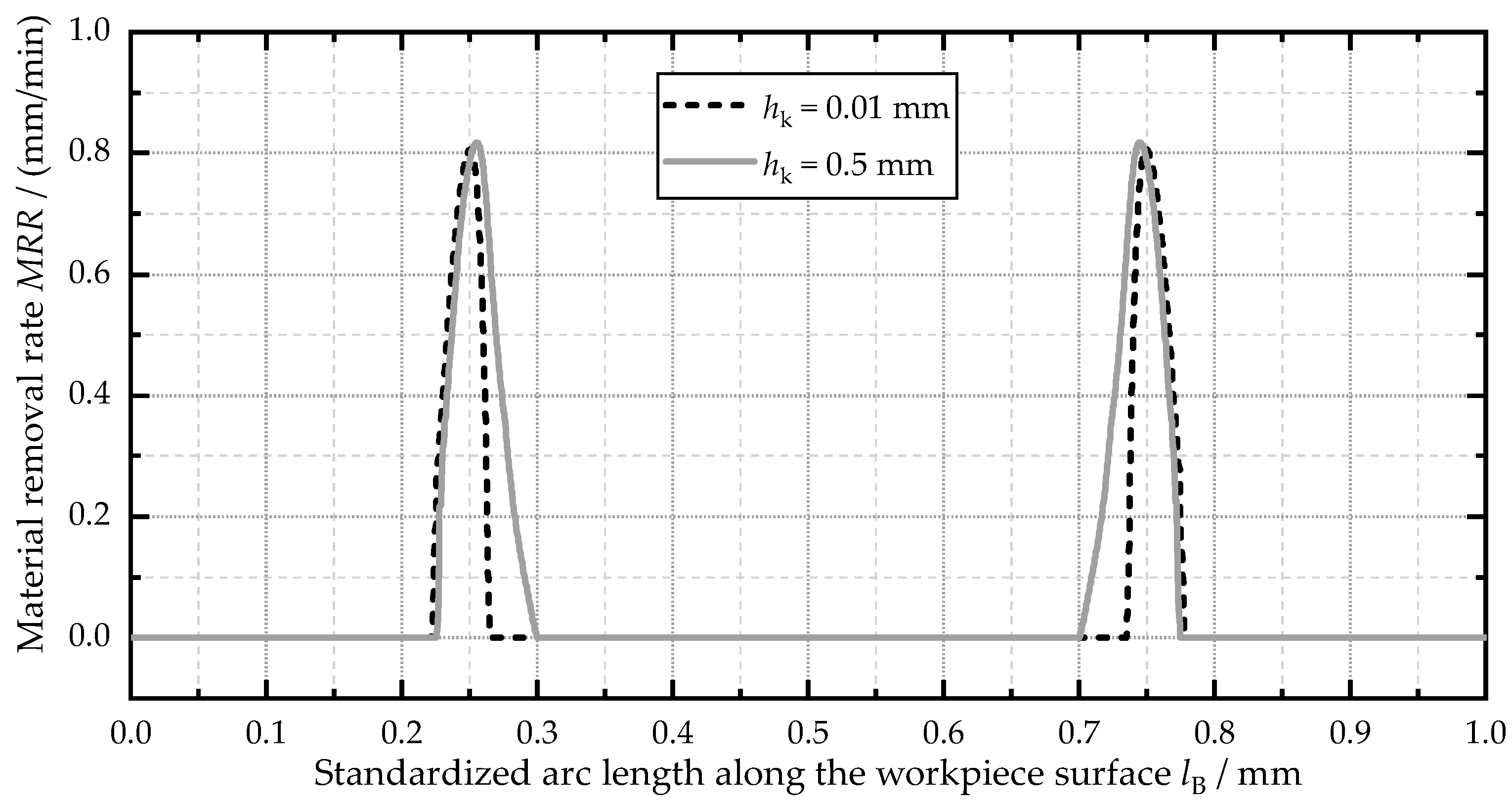

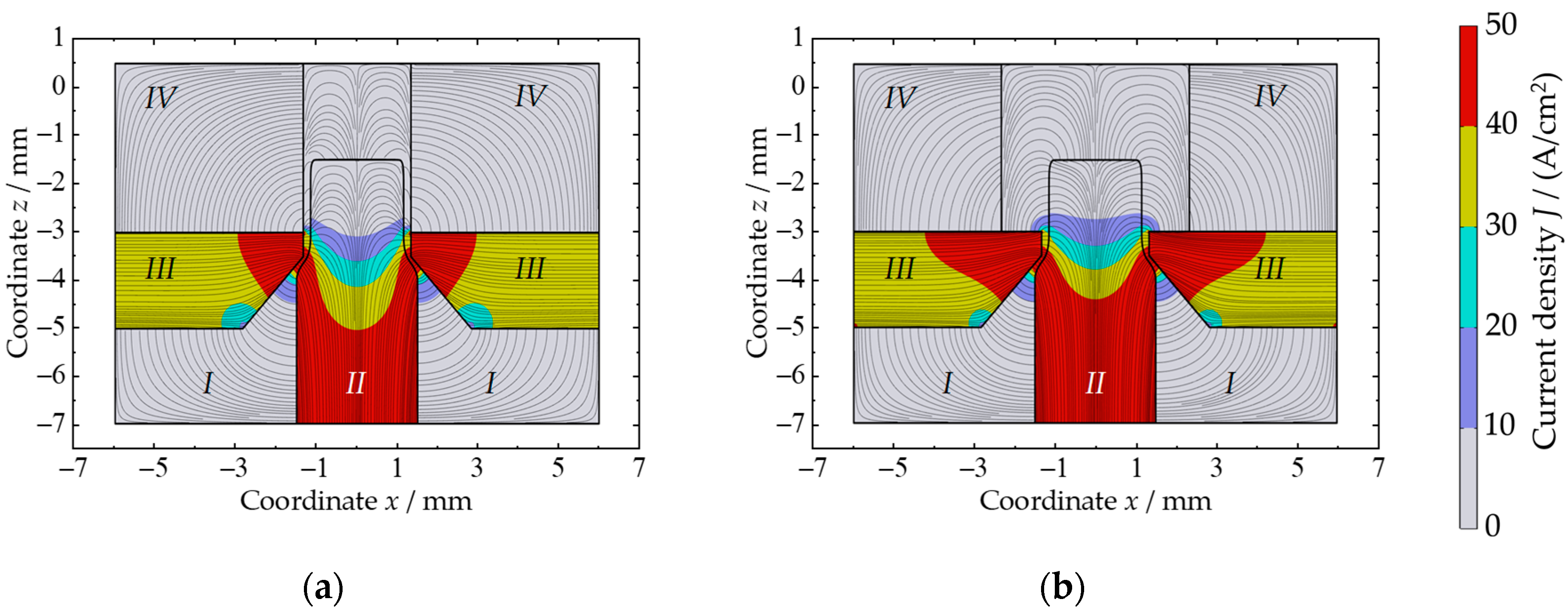

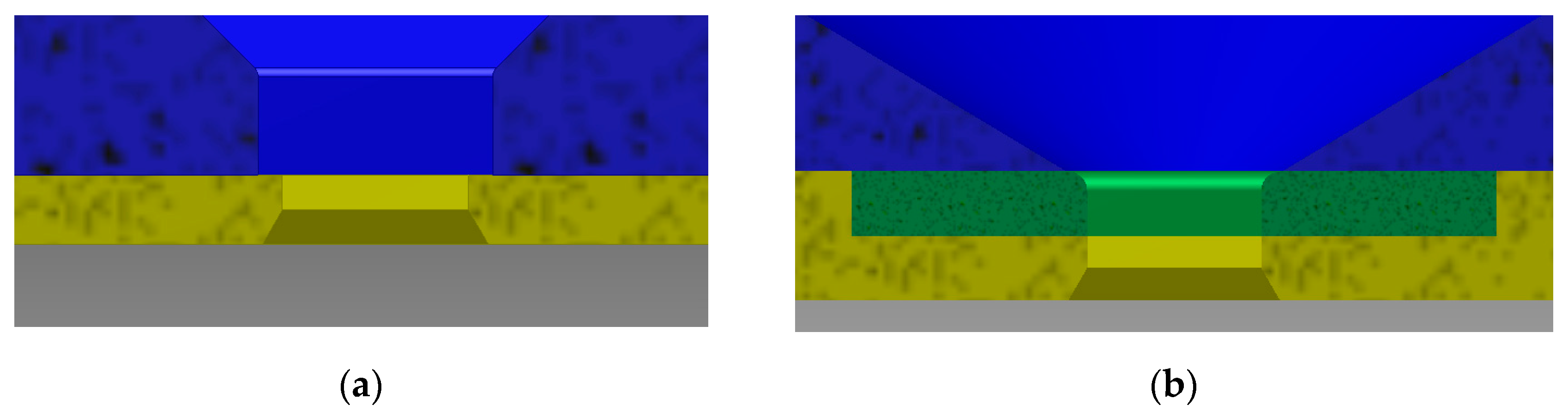

4.3. Simulation-Assisted Tool Design

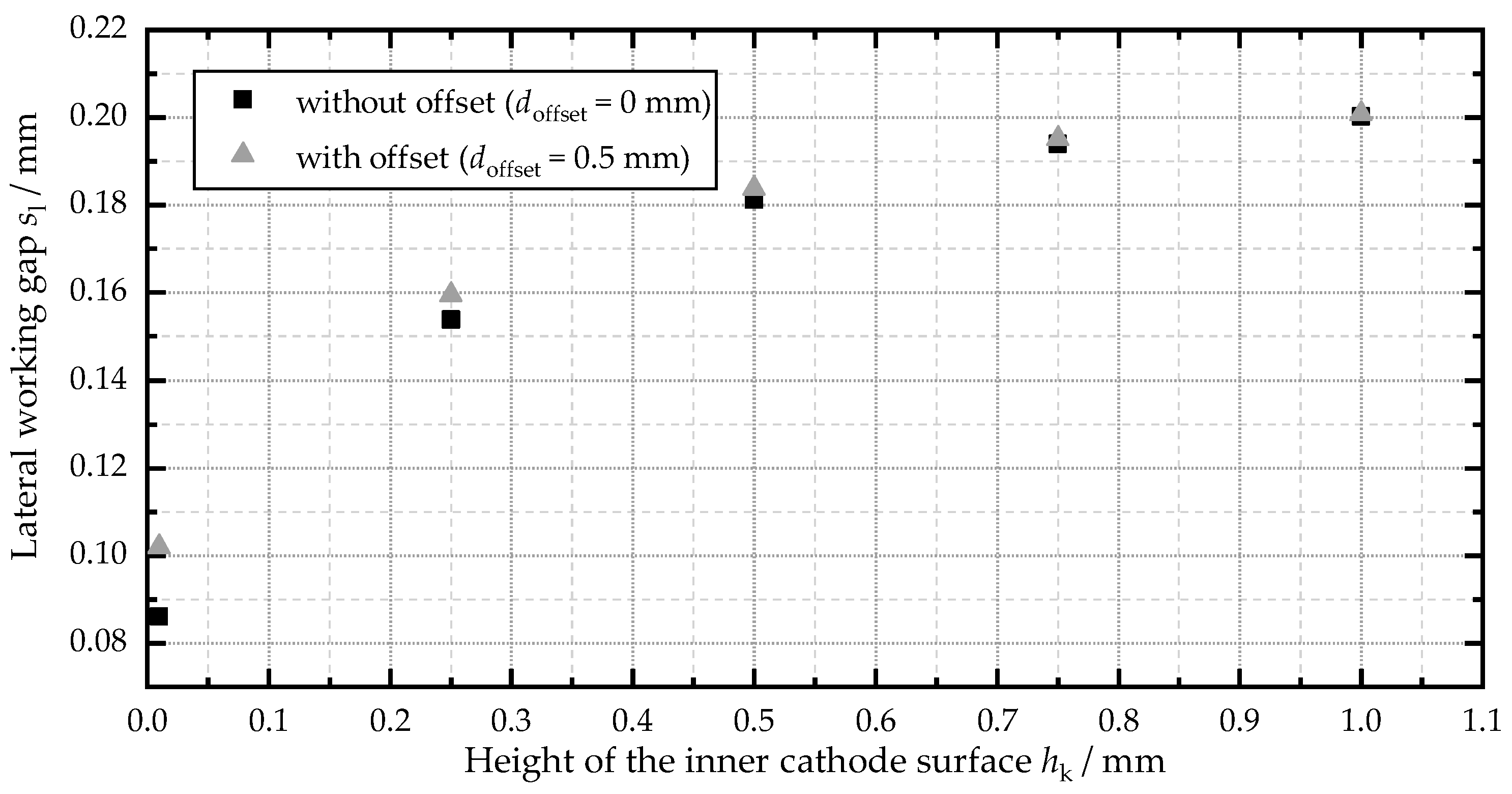

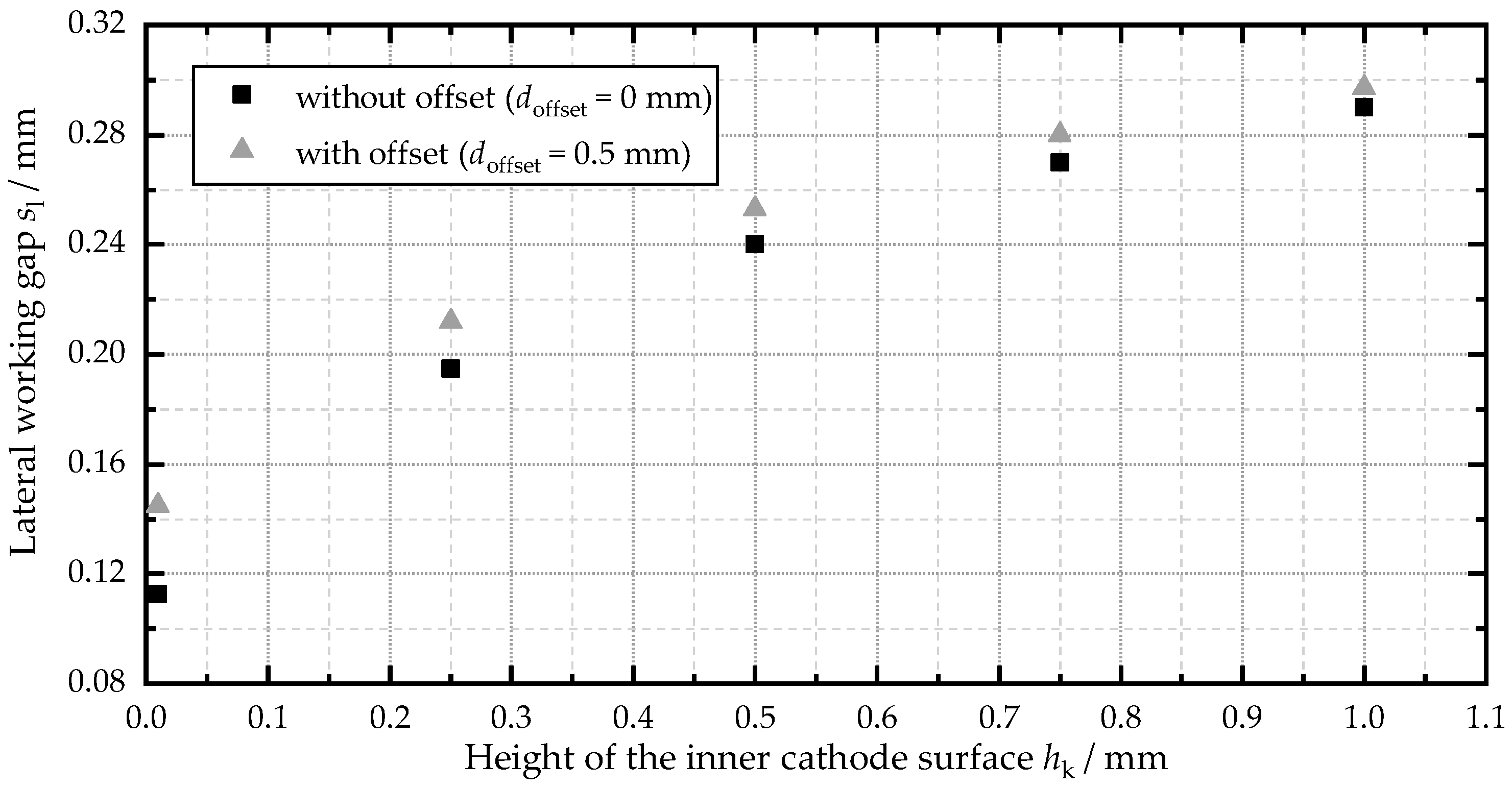

- The height of the inner cathode surface hk has a significant influence on the lateral working gap sl and the current density distribution J.

- The value of hk should be as small as possible to achieve a high accuracy.

- The influence of the offset of the insulation doffset is relatively small but is dependent on the height of the inner cathode surface and the machining parameters.

- The value of doffset should be as small as possible and homogenous around the top cathode surface.

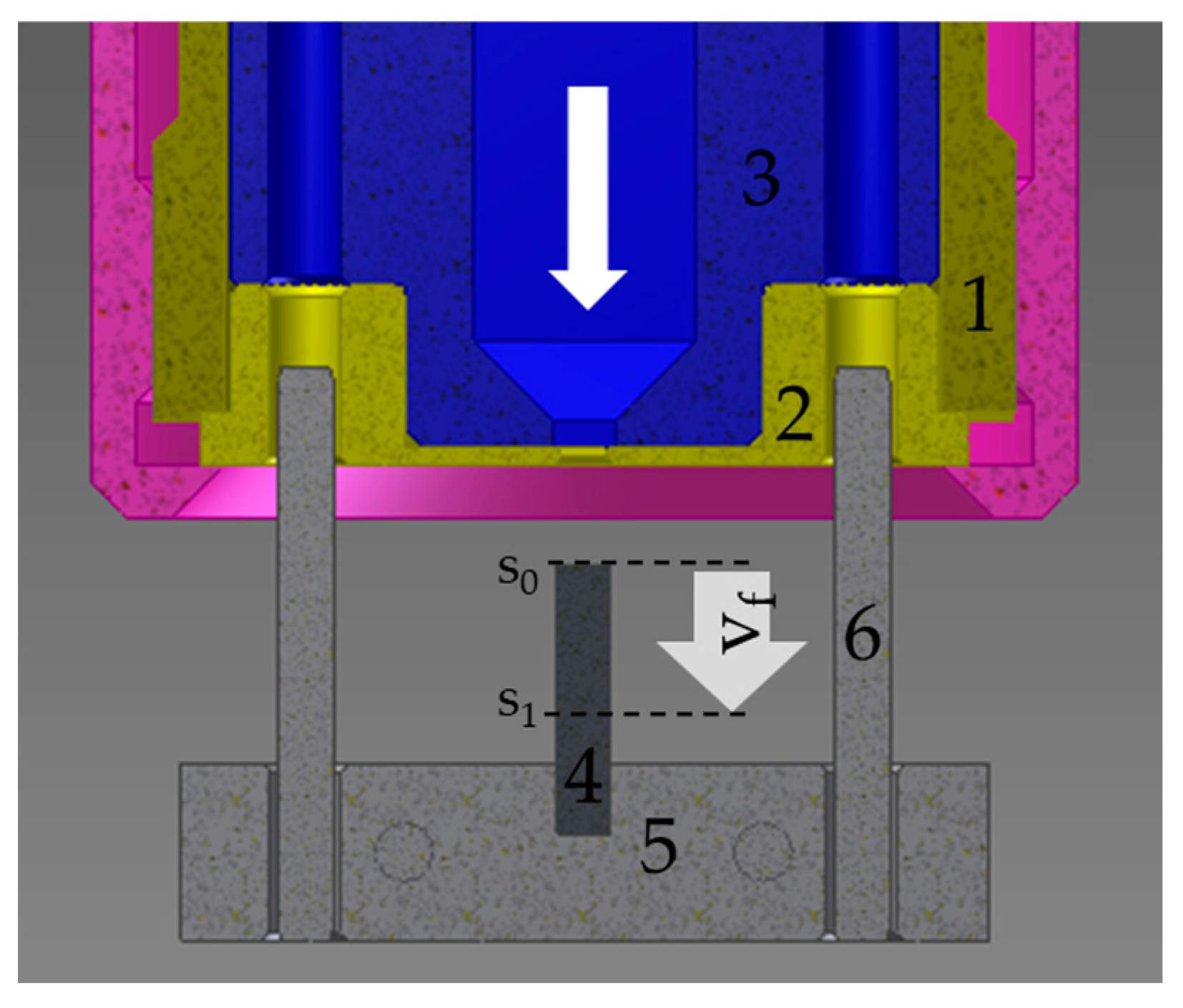

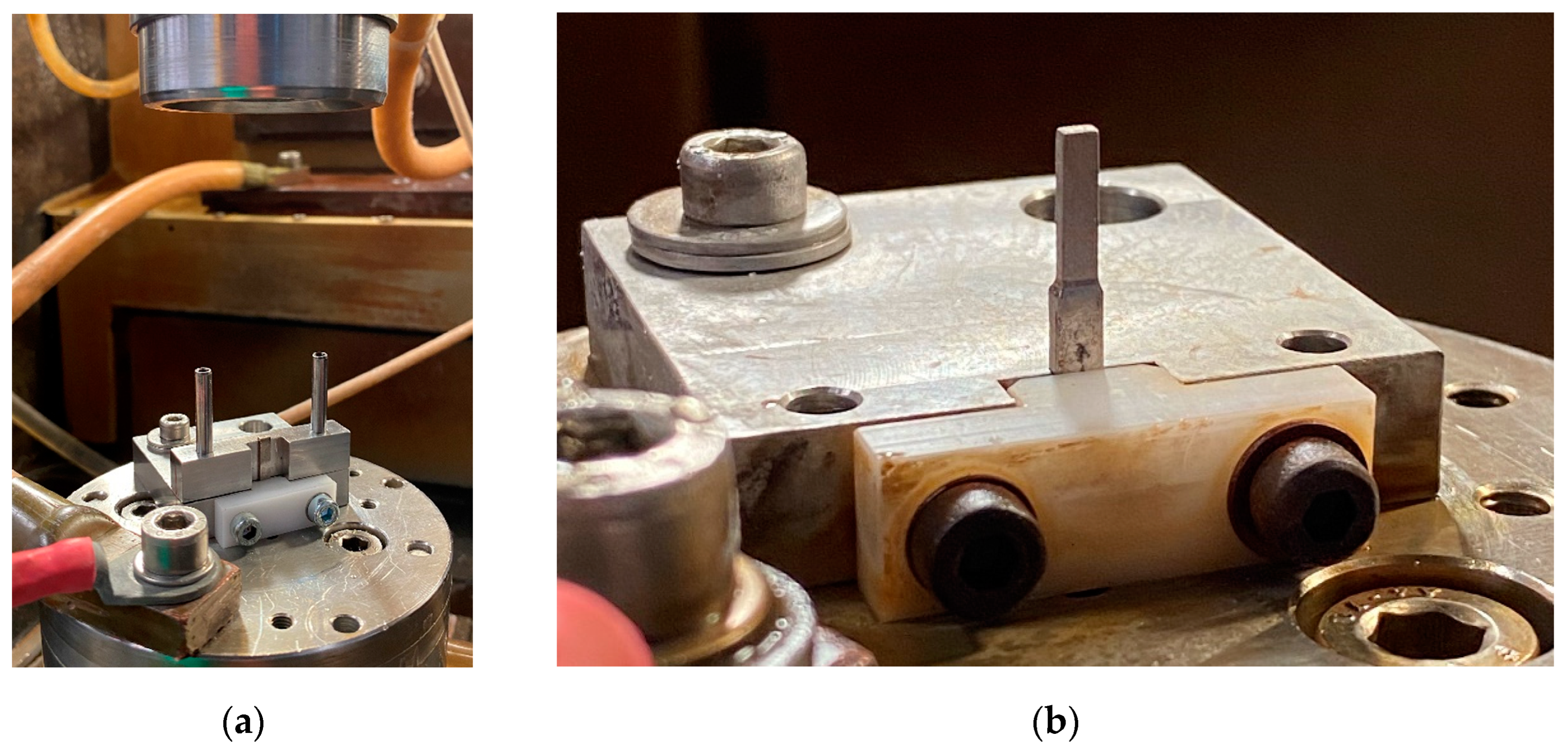

4.4. Fixture Development and Manufacturing

- Alignment mechanism between the tool unit and the workpiece unit;

- Stable, reproducible fastening of both electrodes (the cathodic poled tool and the anodic poled workpiece);

- Precisely manufactured cut-out for defined ablative shaping;

- Electrolyte guidance (in particular, a flow-optimized design of the electrolyte supply to ensure a uniform electrolyte flow at the process zone);

- Electrical insulation for spatial limitation of the electrical fields and thus localization of the possible material dissolution.

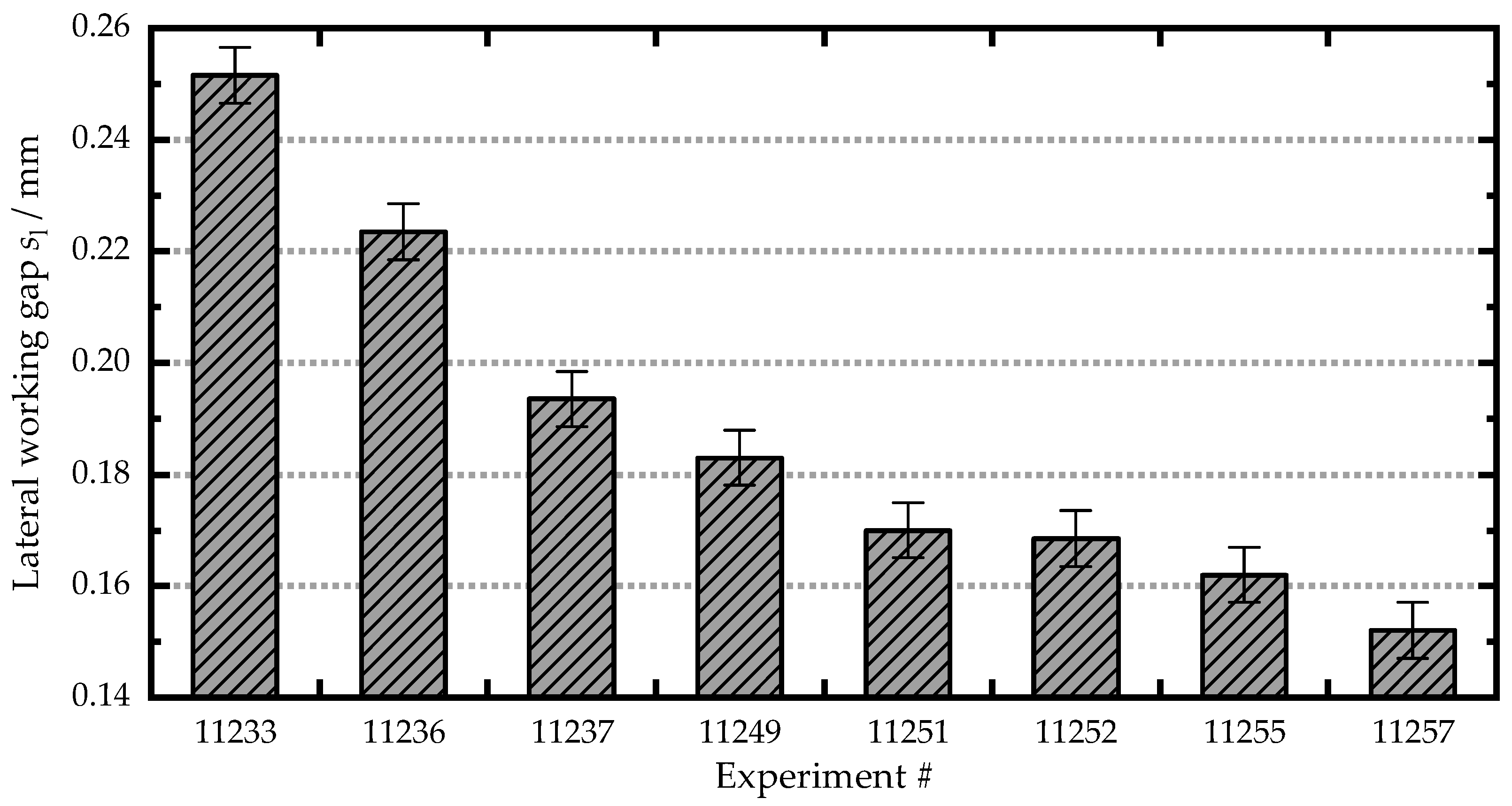

4.5. Experimental Results of Simulation Machining with Developed Fixture

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Experiment ID | Tool Velocity vf [mm/min] | Frequency f [s−1] | Electric Potential φ [V] | Pulse Duration tp [ms] |

|---|---|---|---|---|

| 10971 | 0.030 | 50 | 8.8 | 2 |

| 10965 | 0.060 | 50 | 10.5 | 2 |

| 10959 | 0.100 | 50 | 13.0 | 2 |

| 10962 | 0.126 | 50 | 14.0 | 2 |

| 10958 | 0.150 | 50 | 15.0 | 2 |

| 11124 | 0.020 | 50 | 6.3 | 4 |

| 10952 | 0.070 | 50 | 7.5 | 4 |

| 10982 | 0.130 | 50 | 9.9 | 4 |

| 10987 | 0.187 | 50 | 12.1 | 4 |

| 10939 | 0.280 | 50 | 15.0 | 4 |

Appendix B

| Experiment ID | Tool Velocity vf [mm/min] | Frequency f [s−1] | Electric Potential φ [V] | Pulse Duration tp [ms] |

|---|---|---|---|---|

| 1.1 (11233) | 0.158 | 50 | 14.0 | 4 |

| 1.2 (11236) | 0.280 | 50 | 15.0 | 4 |

| 2.1 (11237) | 0.140 | 50 | 15.0 | 2 |

| 2.2 (11249) | 0.170 | 50 | 15.0 | 2 |

| 2.3 (11251) | 0.290 | 50 | 15.0 | 2 |

| 2.4 (11252) | 0.205 | 50 | 15.0 | 2 |

| 2.5 (11255) | 0.240 | 50 | 15.0 | 2 |

| 2.6 (11257) | 0.300 | 50 | 15.0 | 2 |

References

- Vollmer, M.; Bauer, A.; Niendorf, T. Combined Shape Memory Alloy Phenomena: A Novel Approach to Extend Applications of Shape Memory Alloys. Mater. Lett. 2023, 347, 134643. [Google Scholar] [CrossRef]

- Molod, M.A.; Spyridis, P.; Barthold, F.-J. Applications of Shape Memory Alloys in Structural Engineering with a Focus on Concrete Construction—A Comprehensive Review. Constr. Build. Mater. 2022, 337, 127565. [Google Scholar] [CrossRef]

- Zhang, X.; Qian, M. Magnetic Shape Memory Alloys; Springer: Singapore, 2022; Volume 1200. [Google Scholar] [CrossRef]

- Behnken, H.; Hemes, S.; Pagounis, E.; Laufenberg, M. Thermal Stress and Local Crystallization Parameters in Single-Crystal Rods of Ni-Mn-Ga Ferromagnetic Shape Memory Alloys. J. Cryst. Growth 2020, 534, 125485. [Google Scholar] [CrossRef]

- Klocke, W.K.F. Fertigungsverfahren 3; Abtragen, Generieren und Lasermaterialbearbeitung; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Wilson, J. Practice and Theory of Electrochemical Machining; Wiley-Interscience: New York, NY, USA, 1982. [Google Scholar]

- DeBarr, A.E.; Oliver, D.A. Electrochemical Machining; American Elsevier Pub. Co.: New York, NY, USA, 1968. [Google Scholar]

- Lohrengel, M.M.; Rataj, K.P.; Münninghoff, T. Electrochemical Machining—Mechanisms of Anodic Dissolution. Electrochim. Acta 2016, 201, 348–353. [Google Scholar] [CrossRef]

- Yu, C.Y.; Liu, C.S.; Huang, Y.H.; Hsu, Y.C.; Peklenik, J. The Investigation of the Flow Characteristics of the Gap in the Pulse Electrochemical Machining (PECM). CIRP Ann. 1982, 31, 119–123. [Google Scholar] [CrossRef]

- Zhang, Z.; De Meter, E.; Basu, S. Use of Bidirectional Electrolyte Flow to Improve PECM Uniformity. Int. J. Adv. Manuf. Technol. 2023, 127, 2843–2859. [Google Scholar] [CrossRef]

- Sneddon, S.; De Silva, A.K.M.; Gomez-Gallegos, A.A.; Jayasinghe, P. Precision Improvements in ECM via Tool Insert Development by 3D Printing. Procedia CIRP 2022, 113, 459–464. [Google Scholar] [CrossRef]

- Guo, J.; Zhu, D.; Zhu, D.; Hou, Z. Investigation of the Stray Corrosion of Inconel 718 at Low Current Density in NaNO3 Solution. Int. J. Adv. Manuf. Technol. 2023, 128, 3149–3159. [Google Scholar] [CrossRef]

- Davydov, A.D.; Volgin, V.M.; Lyubimov, V.V. Electrochemical Machining of Metals: Fundamentals of Electrochemical Shaping. Russ. J. Electrochem. 2004, 40, 1230–1265. [Google Scholar] [CrossRef]

- Rebschläger, A.; Kollmannsperger, R.; Bähre, D. Video Based Process Observations of the Pulse Electrochemical Machining Process at High Current Densities and Small Gaps. Procedia CIRP 2014, 14, 418–423. [Google Scholar] [CrossRef][Green Version]

- Zong, Y.; Liu, J.; Zhu, D. Improving Blade Accuracy via Local Electrochemical Machining with Partial Insulated Cathodes. Precis. Eng. 2022, 76, 284–293. [Google Scholar] [CrossRef]

- Lu, J.; Riedl, G.; Kiniger, B.; Werner, E.A. Three-Dimensional Tool Design for Steady-State Electrochemical Machining by Continuous Adjoint-Based Shape Optimization. Chem. Eng. Sci. 2014, 106, 198–210. [Google Scholar] [CrossRef]

- Ernst, A.; Heib, T.; Hall, T.; Schmidt, G.; Bähre, D. Simulation of the Tool Shape Design for the Electrochemical Machining of Jet Engine Vanes. Procedia CIRP 2018, 68, 762–767. [Google Scholar] [CrossRef]

- Zhu, D.; Zhu, D.; Xu, Z. Optimal Design of the Sheet Cathode Using W-Shaped Electrolyte Flow Mode in ECM. Int. J. Adv. Manuf. Technol. 2012, 62, 147–156. [Google Scholar] [CrossRef]

- Li, Z.; Cao, B.; Dai, Y. Research on Multi-Physics Coupling Simulation for the Pulse Electrochemical Machining of Holes with Tube Electrodes. Micromachines 2021, 12, 950. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, D.; Fu, T.; Zhu, D. Evolution of the Interelectrode Gap during Co-Rotating Electrochemical Machining. Metals 2023, 13, 1771. [Google Scholar] [CrossRef]

- Bortels, L.; Purcar, M.; Van den Bossche, B.; Deconinck, J. A User-Friendly Simulation Software Tool for 3D ECM. J. Mater. Process. Technol. 2004, 149, 486–492. [Google Scholar] [CrossRef]

- Volgin, V.M.; Lyubimov, V.V.; Davydov, A.D. Modeling and Numerical Simulation of Electrochemical Micromachining. Chem. Eng. Sci. 2016, 140, 252–260. [Google Scholar] [CrossRef]

- Temur, R.; Coole, T.; Bocking, C. Simulation of The Electrochemical Machining Process. In Proceedings of the 2001 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2001; pp. 486–496. [Google Scholar]

- Deconinck, D.; Van Damme, S.; Deconinck, J. A Temperature Dependent Multi-Ion Model for Time Accurate Numerical Simulation of the Electrochemical Machining Process. Part I: Theoretical Basis. Electrochim. Acta 2012, 60, 321–328. [Google Scholar] [CrossRef]

- Deconinck, D.; Van Damme, S.; Deconinck, J. A Temperature Dependent Multi-Ion Model for Time Accurate Numerical Simulation of the Electrochemical Machining Process. Part II: Numerical Simulation. Electrochim. Acta 2012, 69, 120–127. [Google Scholar] [CrossRef]

- Deconinck, D.; Hoogsteen, W.; Deconinck, J. A Temperature Dependent Multi-Ion Model for Time Accurate Numerical Simulation of the Electrochemical Machining Process. Part III: Experimental Validation. Electrochim. Acta 2013, 103, 161–173. [Google Scholar] [CrossRef]

- Ming, W.; Zhongninga, G.; Junfeng, H.; Xiaolei, C. Modeling and Simulation of the Material Removal Process in Electrolyte Jet Machining of Mass Transfer in Convection and Electric Migration. Procedia CIRP 2018, 68, 488–492. [Google Scholar] [CrossRef]

- Volgin, V.M.; Lyubimov, V.V.; Gnidina, I.V. Simulation of Ion Transfer during Electrochemical Shaping by Ultrashort Pulses; Springer International Publishing: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- DIN SPEC 91399; Methode zur Bestimmung von Prozesseingangsgrößen für Das Elektrochemische Präzisionsabtragen—Anforderungen, Kriterien, Festlegungen. Deutsches Institut für Normung e.V.: Berlin, Germany, 2018.

- Meichsner, G.; Hackert-Oschätzchen, M.; Krönert, M.; Edelmann, J.; Schubert, A.; Putz, M. Fast Determination of the Material Removal Characteristics in Pulsed Electrochemical Machining. In Proceedings of the CIRP Conference on High Performance Cutting—HPC 2016, Chemnitz, Germany, 31 May–2 June 2016; Elsevier B.V.: Amsterdam, The Netherlands, 2016; Volume 46, pp. 123–126. [Google Scholar] [CrossRef]

- Xu, C.; Fang, X.; Han, Z.; Zhu, D. Wire Electrochemical Machining with Pulsating Radial Electrolyte Supply and Preparation of Its Tube Electrode with Micro-Holes. Appl. Sci. 2020, 10, 331. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Z.; Wang, J.; Zhu, D. Electrochemical Machining on Blisk Channels with a Variable Feed Rate Mode. Chin. J. Aeronaut. 2021, 34, 151–161. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, D.; Li, J.; Gu, Z. Flow Field Research on Electrochemical Machining with Gas Film Insulation. J. Mater. Process. Technol. 2019, 267, 247–256. [Google Scholar] [CrossRef]

- Meichsner, G. Entwicklung und Realisierung Einer Methode zur Bestimmung von Prozesseingangsgrößen für Das Elektrochemische Präzisionsabtragen; Technische Universität Chemnitz: Chemnitz, Germany, 2018. [Google Scholar]

- Lee, E.-S.; Shin, T.-H.; Kim, B.-K.; Baek, S.-Y. Investigation of Short Pulse Electrochemical Machining for Groove Process on Ni-Ti Shape Memory Alloy. Int. J. Precis. Eng. Manuf. 2010, 11, 113–118. [Google Scholar] [CrossRef]

- Rosenkranz, C. Elektrochemische Prozesse an Eisenoberflächen Bei Extremen Anodischen Stromdichten; Heinrich Heine Universität Düsseldorf: Düsseldorf, Germany, 2005. [Google Scholar]

- Ghasemiansafaei, M.; Schaefer, F.; Hall, T.; Baehre, D. Analysis of Mechanisms Affecting the Tool in Pulsed Electrochemical Machining. J. Electrochem. Soc. 2023, 170, 063504. [Google Scholar] [CrossRef]

- Bashkatov, A.; Hossain, S.S.; Mutschke, G.; Yang, X.; Rox, H.; Weidinger, I.M.; Eckert, K. On the Growth Regimes of Hydrogen Bubbles at Microelectrodes. Phys. Chem. Chem. Phys. 2022, 24, 26738–26752. [Google Scholar] [CrossRef] [PubMed]

- Böttcher, F. Investigations on the Surface Texture after Pulsed Electrochemical Machining (PECM) of the Magnetic Shape Memory Alloy NiMnGa. In Proceedings of the International Symposium on Electrochemical Machining Technology—INSECT, Saarbrücken, Germany, 13–14 November 2023. [Google Scholar]

- Oßwald, K.; Schneider, S.; Klink, A.; Bergs, T. White Layer Thickness Variation in Die Sinking EDM. Procedia CIRP 2022, 113, 5–9. [Google Scholar] [CrossRef]

- Liu, J.F.; Guo, Y.B.; Butler, T.M.; Weaver, M.L. Crystallography, Compositions, and Properties of White Layer by Wire Electrical Discharge Machining of Nitinol Shape Memory Alloy. Mater. Des. 2016, 109, 1–9. [Google Scholar] [CrossRef]

- Mwangi, J.W. Micro-Electrical Discharge Machining of Nitinol for Medical Applications; Chemnitz University of Technology: Chemnitz, Germany, 2019. [Google Scholar]

| Element | Ni | Mn | Ga |

|---|---|---|---|

| Volume content | 50.9% | 29.5% | 19.6% |

| Oxidation status | 2 | 2 | 3 |

| Constant Parameter | Value |

|---|---|

| Electrolyte solution | Sodium nitrate NaNO3 |

| pH value | 7.0 |

| Temperature | 20.5 °C ± 1.0 °C |

| Electric conductivity | 72.0 mS/cm ± 0.5 mS/cm |

| Tool oscillation | On |

| Amplitude | 0.35 mm |

| Pulse frequency | 50 Hz |

| Start working gap | 0.05 mm |

| Variable Parameter | Value |

|---|---|

| Voltage | 6 V to 17 V |

| Feed rate | 0.015–0.355 mm/min |

| Pulse length | 2 ms; 4 ms |

| Material | Domain | Condition |

|---|---|---|

| Electrolyte | I | σ = 7.2 S/m |

| NiMnGa | II | σ = 106 S/m |

| AISI 304 Steel | III | σ = 106 S/m |

| Polyoxymethylene | IV | σ = 10−10 S/m |

| Condition | Boundary | Condition |

|---|---|---|

| Electric potential | 1 | φ = φi − 5 V 1 |

| Electric insulation | 4, 5, 6, 7 | - |

| Electric potential | 2 | φ = 0 V |

| Axial symmetry | 10 | - |

| Condition | Boundary | Condition |

|---|---|---|

| Mesh Velocity | 8, 9 | vz = vz;i 1 |

| Mesh Velocity | 3 | vn = va(Jn) 2 |

| Mesh Displacement | 1, 2, 4, 5, 6, 7 | s = 0 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Böttcher, F.; Schaarschmidt, I.; Edelmann, J.; Schubert, A. Simulation-Assisted Tool Design for Pulsed Electrochemical Machining of Magnetic Shape-Memory Alloys. J. Manuf. Mater. Process. 2024, 8, 46. https://doi.org/10.3390/jmmp8020046

Böttcher F, Schaarschmidt I, Edelmann J, Schubert A. Simulation-Assisted Tool Design for Pulsed Electrochemical Machining of Magnetic Shape-Memory Alloys. Journal of Manufacturing and Materials Processing. 2024; 8(2):46. https://doi.org/10.3390/jmmp8020046

Chicago/Turabian StyleBöttcher, Falko, Ingo Schaarschmidt, Jan Edelmann, and Andreas Schubert. 2024. "Simulation-Assisted Tool Design for Pulsed Electrochemical Machining of Magnetic Shape-Memory Alloys" Journal of Manufacturing and Materials Processing 8, no. 2: 46. https://doi.org/10.3390/jmmp8020046

APA StyleBöttcher, F., Schaarschmidt, I., Edelmann, J., & Schubert, A. (2024). Simulation-Assisted Tool Design for Pulsed Electrochemical Machining of Magnetic Shape-Memory Alloys. Journal of Manufacturing and Materials Processing, 8(2), 46. https://doi.org/10.3390/jmmp8020046