Analysis of Tool Wear and Chip Morphology during Turning of AZ31B Magnesium Alloy under Dry Environment

Abstract

:1. Introduction

- Magnesium and its alloys are soft as well as highly flammable; so, the selection of the best machining combination and tool inserts is necessary to ensure their safe machining without any risk of fire ignition in a dry environment and to obtain good machinability.

- Hybrid machining processes such as laser- and vibration-assisted turning and machining in cryogenic and mist lubrication environments have also been used for magnesium alloy but they increase the overall machining cost.

- It has been observed that tool wear is a key performance indicator for machining magnesium alloy and has scarcely been investigated. Machining temperature, cutting forces, and surface roughness have been the main focuses of investigations.

- A gap exists to secure further improvement (in other words, lower value) in tool wear while machining AZ31B magnesium alloy in a dry environment.

- In most of the past work, the machining of magnesium has been conducted at low values of process parameter combinations (such as cutting speed ≤100 m/min and depth of cut ≤0.8 mm), which can further be increased and investigated to obtain better machinability indicators.

2. Materials and Methods

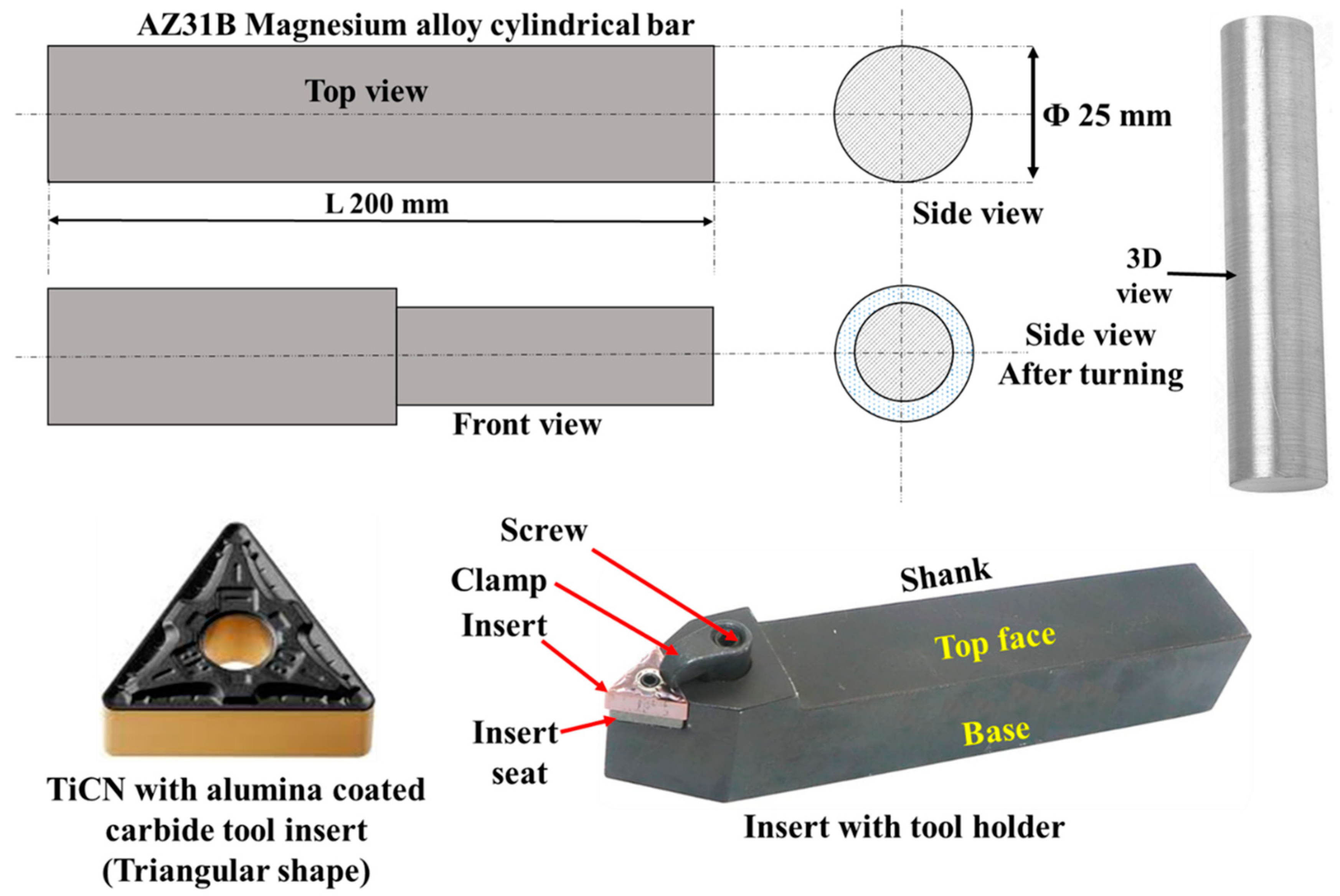

2.1. Work and Tool Insert Materials

2.2. Machine, Experimental Procedure, and Measurement

3. Results and Discussion

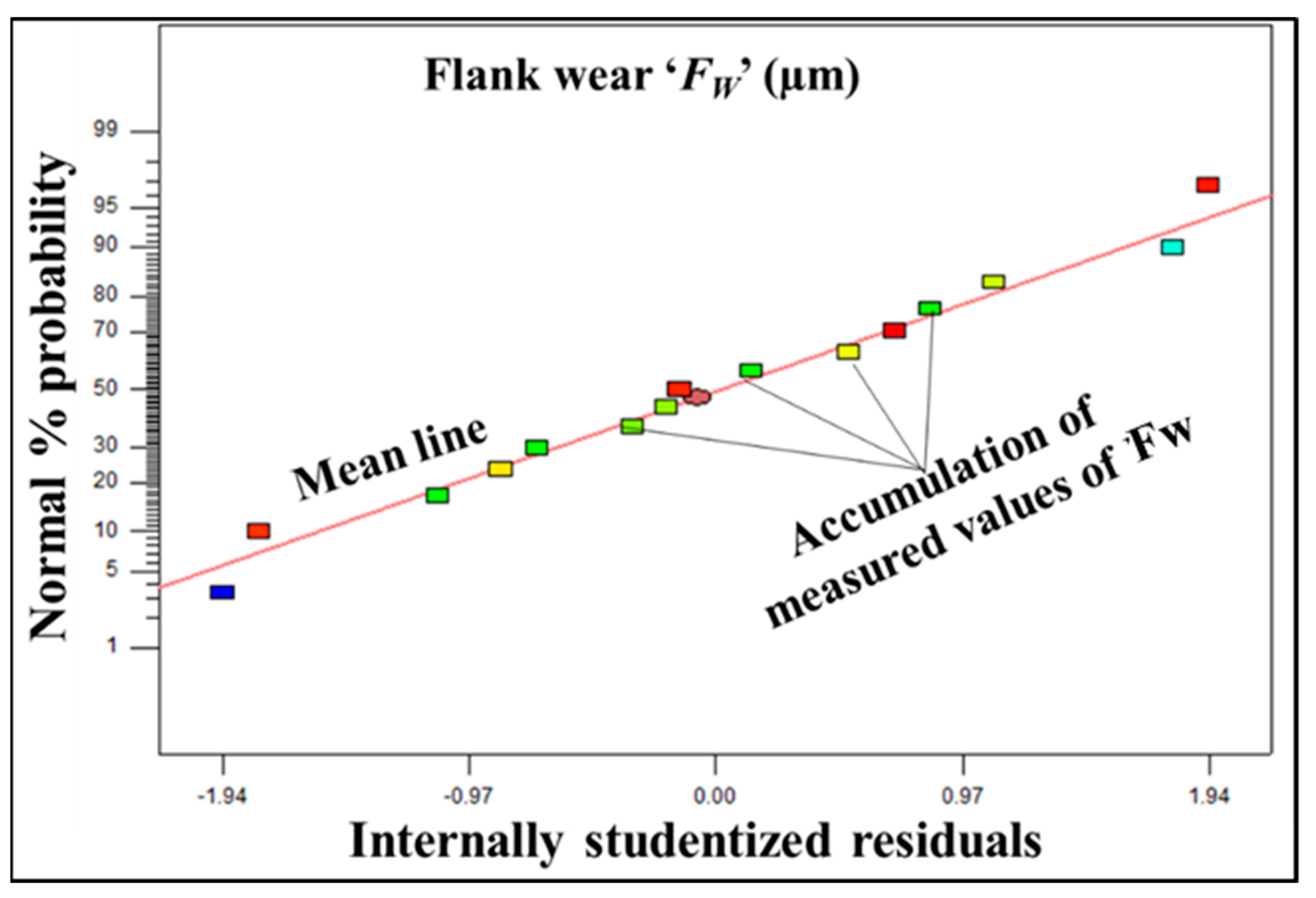

- The developed quadratic models for machining performance indicators are significant since their p-value is less than 0.05.

- Cutting speed and feed rate are found to be statistically significant for flank wear.

- The lack of fit is found to be non-significant for flank wear. A non-significant lack of fit indicates that developed models accurately fit the experimental data.

- The R-squared values of the developed response models are close to 1, thus confirming the adequacy of the developed response models.

- The value of adequate precision of the developed response model is 11.62, indicating an adequate signal.

- The following empirical equations are used to express the developed response models of machining performance indicators.

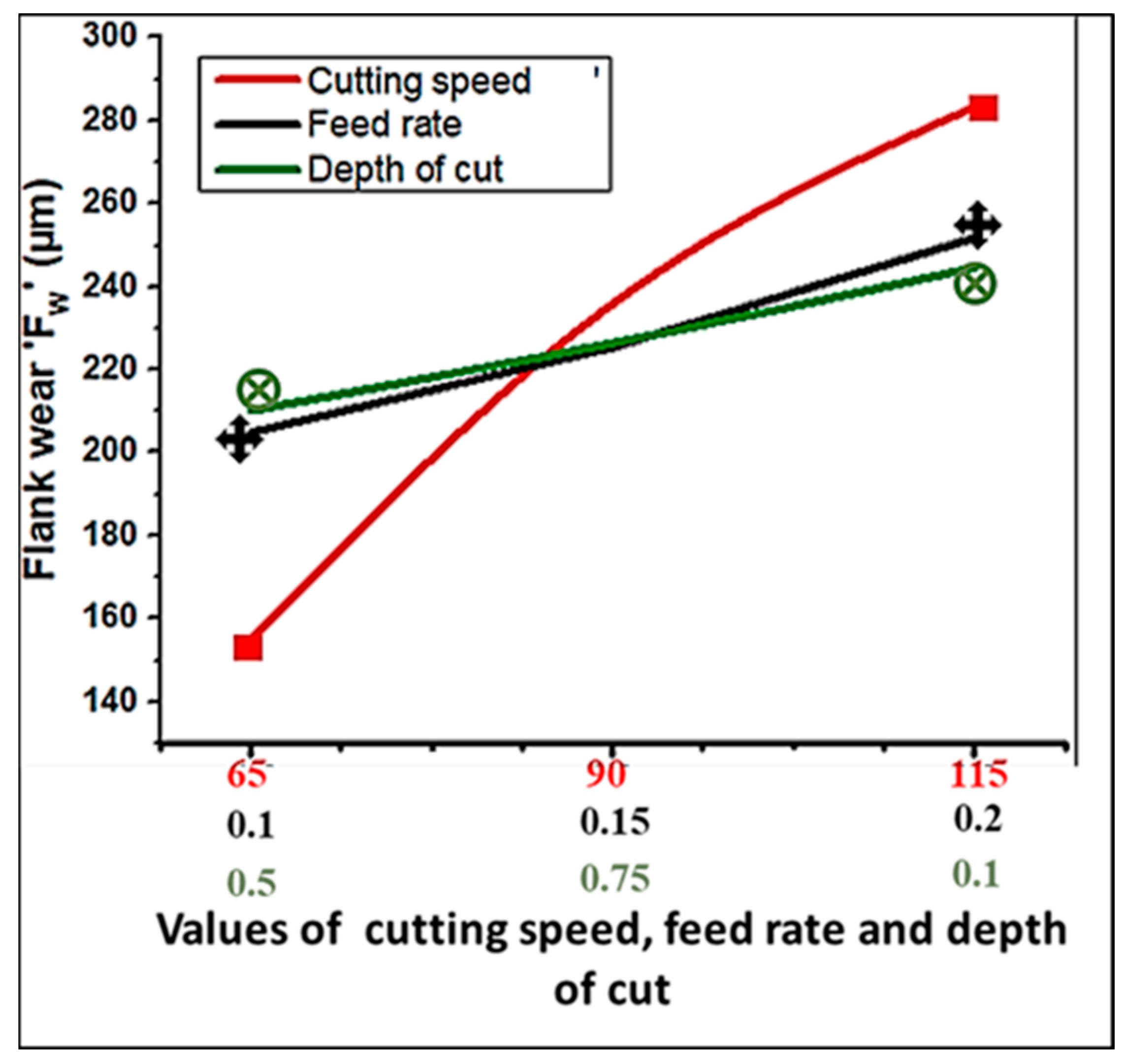

3.1. Variation in Performance Indicators with Turning Parameters

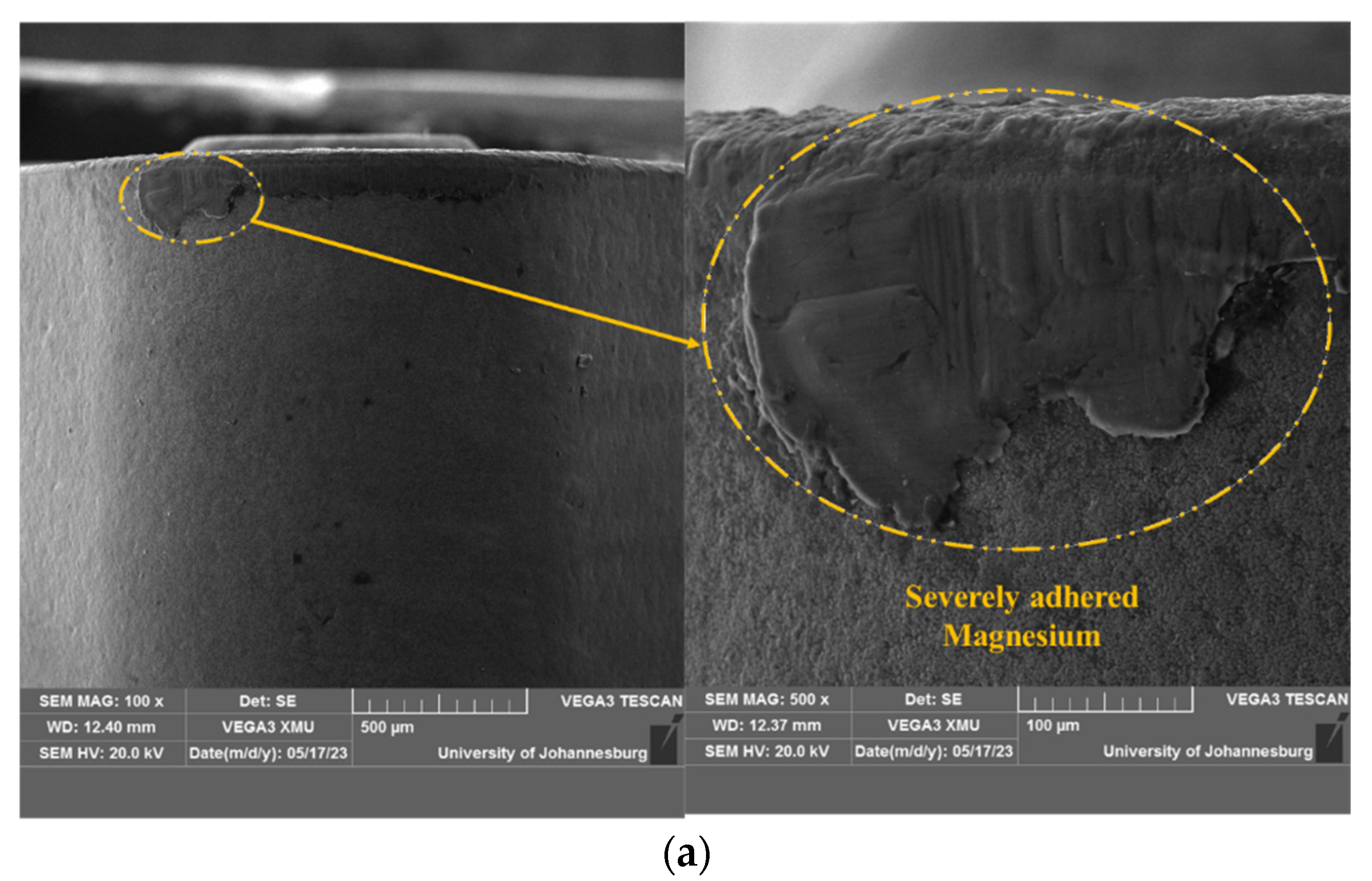

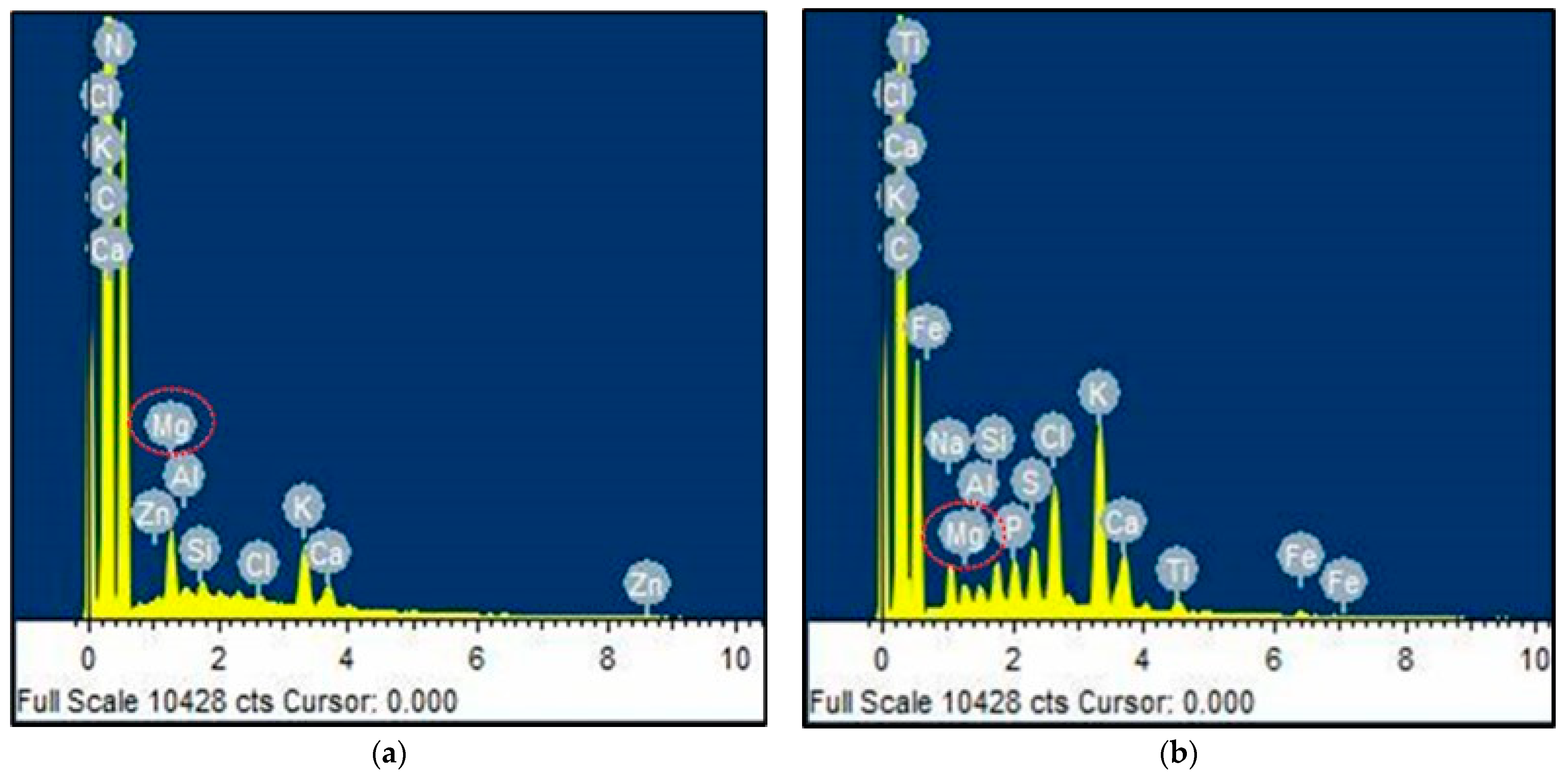

3.2. Tool Wear and Chip Morphology

4. Conclusions

- Cutting speed influenced the flank wear most significantly.

- Flank wear increased with the increase in cutting speed, feed rate, and depth of cut.

- The formation of continuous chips while machining at a high cutting speed, and discontinuous and small chips at a low cutting speed, was observed.

- The maximum flank wear value of 299.34 µm was obtained at a high cutting speed of 115 m/min and the minimum flank wear value of 89.56 µm at a low cutting speed of 65 m/min.

- The main reason behind the high flank wear is the adhesion of work material, i.e., magnesium particles on the tool face, due to their ignition and deposition at high temperatures corresponding to high speed.

- At low speeds, abrasion is the main wear mechanism with insignificant chipping of the work material.

- In essence, for dry machining, it is recommended to machine magnesium alloy material at lower values of machining parameters to obtain better machinability and longer tool life.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Expt. No. | Variable Machining Parameters | Responses | ||||

|---|---|---|---|---|---|---|

| Flank Wear ‘FW’ (µm) | ||||||

| Cutting Speed ‘Vc’ (m/min) | Feed ‘f’ (mm/rev) | Depth of Cut ‘ap’ (mm) | R1 | R2 | Avg. (R1 + R2) | |

| 1 | 90 (0) | 0.15 (0) | 0.75 (0) | 258 | 230 | 244 |

| 2 | 65 (−1) | 0.20 (1) | 0.75 (0) | 192.5 | 185.04 | 188.77 |

| 3 | 115 (1) | 0.15 (0) | 0.50 (−1) | 315.25 | 283.43 | 299.34 |

| 4 | 90 (0) | 0.10 (−1) | 1.00 (1) | 215.28 | 192.16 | 203.72 |

| 5 | 65 (−1) | 0.15 (0) | 1.00 (1) | 205.23 | 175.51 | 190.37 |

| 6 | 65 (−1) | 0.10 (−1) | 0.75 (0) | 137.26 | 164.1 | 150.68 |

| 7 | 90 (0) | 0.20 (1) | 0.50 (−1) | 252.32 | 226.46 | 239.39 |

| 8 | 115 (1) | 0.15 (0) | 1.00 (1) | 306.21 | 280.53 | 293.37 |

| 9 | 90 (0) | 0.20 (1) | 1.00 (1) | 296.25 | 285.21 | 290.73 |

| 10 | 90 (0) | 0.10 (−1) | 0.50 (−1) | 202.62 | 222.12 | 212.37 |

| 11 | 90 (0) | 0.15 (0) | 0.75 (0) | 245.23 | 213.45 | 229.34 |

| 12 | 65 (−1) | 0.15 (0) | 0.50 (−1) | 84.32 | 94.8 | 89.56 |

| 13 | 115 (1) | 0.20 (1) | 0.75 (0) | 294.4 | 282.12 | 288.26 |

| 14 | 115 (1) | 0.10 (−1) | 0.75 (0) | 232.63 | 272.31 | 252.47 |

| 15 | 90 (0) | 0.15 (0) | 0.75 (0) | 238.29 | 224.97 | 231.63 |

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Percentage Contribution | Remarks |

|---|---|---|---|---|---|---|---|

| Model | 44,624.33 | 9 | 4958.26 | 11.17 | 0.0081 | Significant | |

| Vc | 33,032.21 | 1 | 33,032.21 | 74.40 | 0.0003 | 70.52 | Significant |

| f | 4413.77 | 1 | 4413.77 | 9.94 | 0.0253 | 9.42 | Significant |

| ap | 2364.31 | 1 | 2364.31 | 5.33 | 0.0691 | 5.05 | Not significant |

| Vc f | 1.32 | 1 | 1.32 | 0.002979 | 0.9586 | 0.00 | Not significant |

| Vc ap | 2850.49 | 1 | 2850.49 | 6.42 | 0.0523 | 6.09 | Not significant |

| f ap | 899.70 | 1 | 899.70 | 2.03 | 0.2139 | 1.92 | Not significant |

| (Vc2) | 1025.90 | 1 | 1025.90 | 2.31 | 0.1890 | 2.19 | Not significant |

| (f2) | 10.97 | 1 | 10.97 | 0.025 | 0.8812 | 0.02 | Not significant |

| (ap2) | 0.096 | 1 | 0.096 | 0.0002162 | 0.9888 | 0.00 | Not significant |

| Residual | 2219.88 | 5 | 443.98 | ||||

| Lack of fit | 2095.49 | 3 | 698.50 | 11.23 | 0.0829 | Not significant | |

| Pure error | 124.39 | 2 | 62.20 | ||||

| Cor Total | 46,844.21 | 14 | |||||

| R-Squared = 0.9526, Adjusted R-Squared = 0.8673, Predicted R-Squared = 0.2783 | |||||||

| PRESS = 33,807.67, Adequate Precision = 11.62 | |||||||

References

- Dobrzanski, L.A.; Bamberger, M.; Totten, G.E. Magnesium and Its Alloys-Technology and Applications; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Moosbrugger, C. Engineering Properties of Magnesium Alloys; ASM International: Novelty, OH, USA, 2017. [Google Scholar]

- Thakur, B.; Barve, S.; Pesode, P. Investigation on mechanical properties of AZ31B magnesium alloy manufactured by stir casting process. J. Mech. Behav. Biomed. Mater. 2023, 13, 105641. [Google Scholar] [CrossRef] [PubMed]

- Abbas, A.; Huang, S.J.; Ballóková, B.; Sülleiová, K. Tribological effects of carbon nanotubes on magnesium alloy AZ31 and analyzing aging effects on CNTs/AZ31 composites fabricated by stir casting process. Tribol. Int. 2020, 142, 105982. [Google Scholar] [CrossRef]

- Dziubińskaa, A.; Gontarza, A.; Horzelskab, K.; Pieśko, P. The microstructure and mechanical properties of AZ31 magnesium alloy aircraft brackets produced by a new forging technology. Procedia Manuf. 2015, 2, 337–341. [Google Scholar] [CrossRef]

- Ugender, S.; Kumar, A.; Reddy, A.S. Microstructure and mechanical properties of AZ31B magnesium alloy by friction stir welding. Procedia Materi. Sci. 2014, 6, 1600–1609. [Google Scholar] [CrossRef]

- Zakaria, M.S.; Mustapha, M.; Azmi, A.I.; Khor, C.Y. Chip morphology and surface integrity in turning AZ31 magnesium alloy under dry machining and submerged convective cooling. Metals 2023, 13, 619. [Google Scholar] [CrossRef]

- Babe, I.B.; Gupta, K.; Chaubey, S.K. Sustainable dry machining of stainless steel with microwave-treated tungsten carbide cutting tools. Micromachines 2023, 14, 1148. [Google Scholar] [CrossRef] [PubMed]

- Wojtowicz, N.; Danis, I.; Monies, F.; Lamesle, P.; Chieragati, R. The influence of cutting conditions on surface integrity of a wrought magnesium alloy. Procedia Eng. 2023, 63, 20–28. [Google Scholar] [CrossRef]

- Viswanathan, R.; Ramesh, S. Optimization of machining parameters for magnesium alloy using Taguchi approach and RSM. Int. Conf. Adv. Des. Manuf. 2014, 2, 1–534. [Google Scholar]

- Yalçın, B.; Özileri, E.D. Experimental investigation on turning of casted magnesium alloy used in manufacturing automotive parts. In Proceedings of the Advances in Materials & Processing Technologies Conferences, Madrid, Spain, 14–17 December 2015. [Google Scholar]

- Kolluru, U.K.; Narala, S.K.R.; Dutta, S. Optimization of cutting forces and surface roughness in dry turning of AM magnesium alloy using Taguchi method. Mater. Today Proc. 2021, 38, 2830–2838. [Google Scholar] [CrossRef]

- Gao, H.; Ma, B.; Singh, R.P.; Yang, H. Areal surface roughness of AZ31B magnesium alloy processed by dry face turning: An experimental framework combined with regression analysis. Materials 2020, 13, 2303. [Google Scholar] [CrossRef]

- Rubio, E.M.; Valencia, J.L.; Saá, A.J.; Carou, D. Experimental study of the dry facing of magnesium pieces based on the surface roughness. Int. J. Precis. Eng. Manuf. 2013, 14, 995–1001. [Google Scholar] [CrossRef]

- Guo, X.; Teng, L.; Wang, W.; Chen, T. Study on the cutting properties of magnesium alloy when dry turning with titanium cutting tools. Adv. Mater. Res. 2010, 102–104, 653–657. [Google Scholar] [CrossRef]

- Deswal, N.; Kant, R. Machinability and surface integrity analysis of magnesium AZ31B alloy during laser assisted turning. J. Manuf. Process. 2023, 101, 527–545. [Google Scholar] [CrossRef]

- Ali, S.; Pervaiz, S. Machinability analysis of AZ31 magnesium alloys using the Taguchi gray relational analysis. Int. J. Adv. Manuf. Technol. 2023, 126, 4171–4190. [Google Scholar] [CrossRef]

- Deshwal, N.; Kant, R. Experimental investigation on magnesium AZ31B alloy during ultrasonic vibration assisted turning process. Mater. Manuf. Process. 2022, 37, 1–7. [Google Scholar] [CrossRef]

- Zakaria, M.S.; Mustapha, M.; Azmi, A.I.; Ahmad, A.; Danish, M.; Rubaiee, S. Machinability investigations of AZ31 magnesium alloy via submerged convective cooling in turning process. J. Mater. Res. Technol. 2022, 19, 3685–3698. [Google Scholar] [CrossRef]

- Ijaz, H.; Asad, M.; Danish, M.; Gupta, M.K.; Siddiqui, M.E. Al-Zahrani, Numerical investigations of cutting temperature and cutting forces in cryogenic assisted turning of magnesium alloy. Int. J. Adv. Manuf. Technol. 2021, 114, 1991–2001. [Google Scholar] [CrossRef]

- Viswanathan, R.; Ramesh, S.; Maniraj, S.; Subburam, V. Measurement and multi-response optimization of turning parameters for magnesium alloy using hybrid combination of Taguchi-GRA-PCA technique. Measurement 2020, 159, 107800. [Google Scholar] [CrossRef]

- Dutta, S.; Narala, S.K.R. Optimizing turning parameters in the machining of AM alloy using Taguchi methodology. Measurement 2021, 169, 108340. [Google Scholar] [CrossRef]

- Asal, O. Optimization of Surface Roughness in Turning of AZ31 Magnesium Alloys with Taguchi Method. Gazi Univ. J. Sci. Part A Eng. Innov. 2019, 6, 25–32. [Google Scholar]

- Tibrewal, V.; Dak, K.; Himanshu, A.; Kumar, H.; Kuppan, P.; Balan, A.S.S. Cryogenic Machining of AZ31B Magnesium Alloy for Bio-implant Applications. In Advances in Forming, Machining and Automation. AIMTDR 2018. Lecture Notes on Multidisciplinary Industrial Engineering; Shunmugam, M.S., Kanthababu, M., Eds.; Springer: Singapore, 2019. [Google Scholar] [CrossRef]

- Danish, M.; Ginta, T.L.; Habib, K.; Carou, D.; Rani, A.M.A.; Saha, B.B. Thermal analysis during turning of AZ31 magnesium alloy under dry and cryogenic conditions. Int. J. Adv. Manuf. Technol. 2017, 91, 2855–2868. [Google Scholar] [CrossRef]

- Urbikain, G.; Olvera, D.; de Lacalle, L.N.L.; Elías-Zúñiga, A. Stability and vibrational behaviour in turning processes with low rotational speeds. Int. J. Adv. Manuf. Technol. 2015, 80, 871–885. [Google Scholar] [CrossRef]

- Pathak, S. Intelligent Manufacturing, 1st ed.; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Montgomery, D.G. Design and Analysis of Experiments, 7th ed.; John Willey and Sons: New York, NY, USA, 2009. [Google Scholar]

- Kant, G.; Sangwan, K.S. Prediction and optimization of machining parameters for minimizing power consumption and surface roughness in machining. J. Clean. Prod. 2014, 83, 151–164. [Google Scholar] [CrossRef]

- Sahoo, S.P.; Datta, S. Dry machining of Ti–6Al–4V using PVD Si-doped TiAlxN super nitride (HSN2) coated WC–Co tool. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 1–23. [Google Scholar] [CrossRef]

- Ramachandran, K.; Yeesvaran, B.; Kadirgama, K.; Ramasamy, D.; Ghani, S.A.C.; Anamalai, K. State of art of cooling method for dry machining. MATEC Web Conf. 2016, 90, 1–8. [Google Scholar] [CrossRef]

- Suresh, R.; Basavarajappa, S.; Gaitonde, V.N. Experimental studies on the performance of multilayer coated carbide tool in hard turning of high strength low alloy steel. J. Mater. Res. 2015, 30, 3056–3064. [Google Scholar] [CrossRef]

- Kotiba, H. Highly-Ductile Magnesium Alloys: Atomistic-Flow Mechanisms and Alloy Designing. Materials 2019, 12, 1934. [Google Scholar]

- Yuan, J.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Control of tribofilm formation in dry machining of hardened AISI D2 steel by tuning the cutting speed. Wear 2018, 402–403, 30–37. [Google Scholar] [CrossRef]

| Parameters Varied during the Turning | Machining Performance Indicators/Responses | ||||

|---|---|---|---|---|---|

| Parameters, Symbols, and (Unit) | Levels (Actual and (Coded)) | ||||

| Low (−1) | Medium (0) | High (1) | |||

| Cutting speed ‘Vc’ (m/min) | 65 (−1) | 90 (0) | 115 (1) | Flank wear (FW) Chip morphology | |

| Feed rate ‘f’ (mm/rev) | 0.1 (−1) | 0.15 (0) | 0.2 (1) | ||

| Depth of cut ‘ap’ (mm) | 0.5 (−1) | 0.75 (0) | 1.0 (1) | ||

| Constant machining factors | |||||

| Workpiece diameter, materials of inserts and workpiece; cutting tool inserts; tool geometry; turning time (15 min); Mode of machining: dry | |||||

| Details of the machine, workpiece, and cutting tool | |||||

| Machine details | Make: Colchester, Model: Mascot 1600, Country of origin: UK; Power: 12.5 HP; Maximum RPM: 1600 | ||||

| Workpiece details | Material: Magnesium alloy (AZ31B); Shape: Cylindrical bar; Cross-section: Round; Dimensions: diameter (ф)—25 mm, Length (l)—200 mm | ||||

| Cutting tool details | Material: Tungsten carbide; Type: Insert; Shape: Triangular; Cutting edges: 3, Type: Single point (Negative); Hardness: 3000 HV | ||||

| Chemical composition (% wt.) of Mg work material | Mg: 96.5%; Al: 2.5; Zn: 0.6; Mn: 0.2; Si: 0.1; Cu: 0.05; Ca: 0.04; Fe: 0.005; Ni: 0.005 | ||||

| Physical and Mechanical properties of the magnesium alloy bar | Density: 1.77 g/cm3; Tensile strength: 260 MPa; Compressive strength: 97 MPa; Elastic modulus: 44.8 GPa; Poisson’s ratio: 0.35 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thobane, T.M.; Chaubey, S.K.; Gupta, K. Analysis of Tool Wear and Chip Morphology during Turning of AZ31B Magnesium Alloy under Dry Environment. J. Manuf. Mater. Process. 2023, 7, 187. https://doi.org/10.3390/jmmp7050187

Thobane TM, Chaubey SK, Gupta K. Analysis of Tool Wear and Chip Morphology during Turning of AZ31B Magnesium Alloy under Dry Environment. Journal of Manufacturing and Materials Processing. 2023; 7(5):187. https://doi.org/10.3390/jmmp7050187

Chicago/Turabian StyleThobane, Thabiso Moral, Sujeet Kumar Chaubey, and Kapil Gupta. 2023. "Analysis of Tool Wear and Chip Morphology during Turning of AZ31B Magnesium Alloy under Dry Environment" Journal of Manufacturing and Materials Processing 7, no. 5: 187. https://doi.org/10.3390/jmmp7050187

APA StyleThobane, T. M., Chaubey, S. K., & Gupta, K. (2023). Analysis of Tool Wear and Chip Morphology during Turning of AZ31B Magnesium Alloy under Dry Environment. Journal of Manufacturing and Materials Processing, 7(5), 187. https://doi.org/10.3390/jmmp7050187