A Review of Optimization and Measurement Techniques of the Friction Stir Welding (FSW) Process

Abstract

1. Introduction

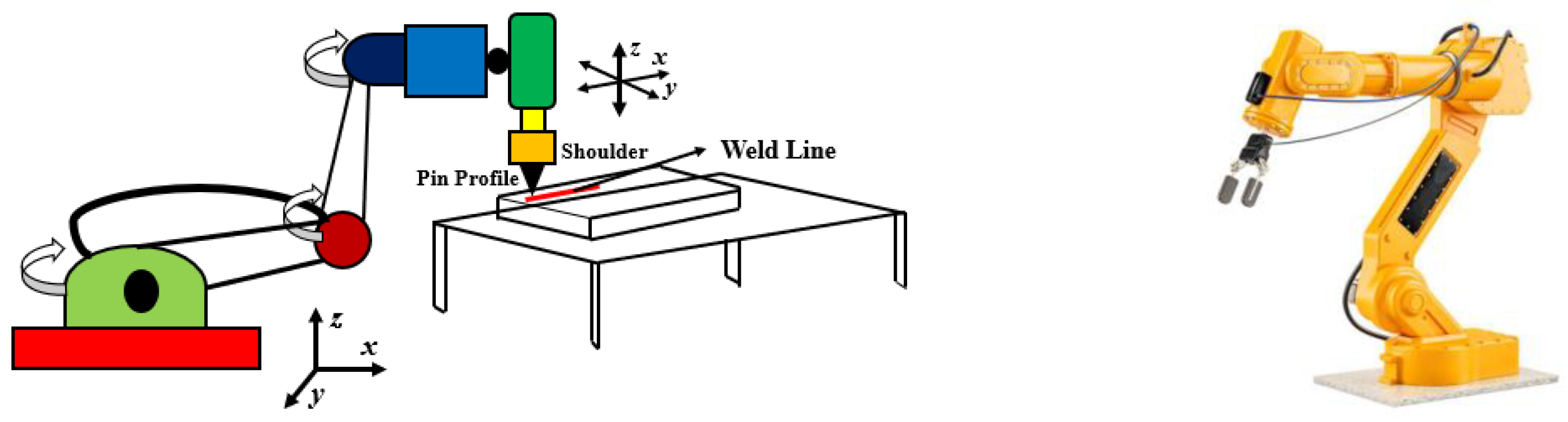

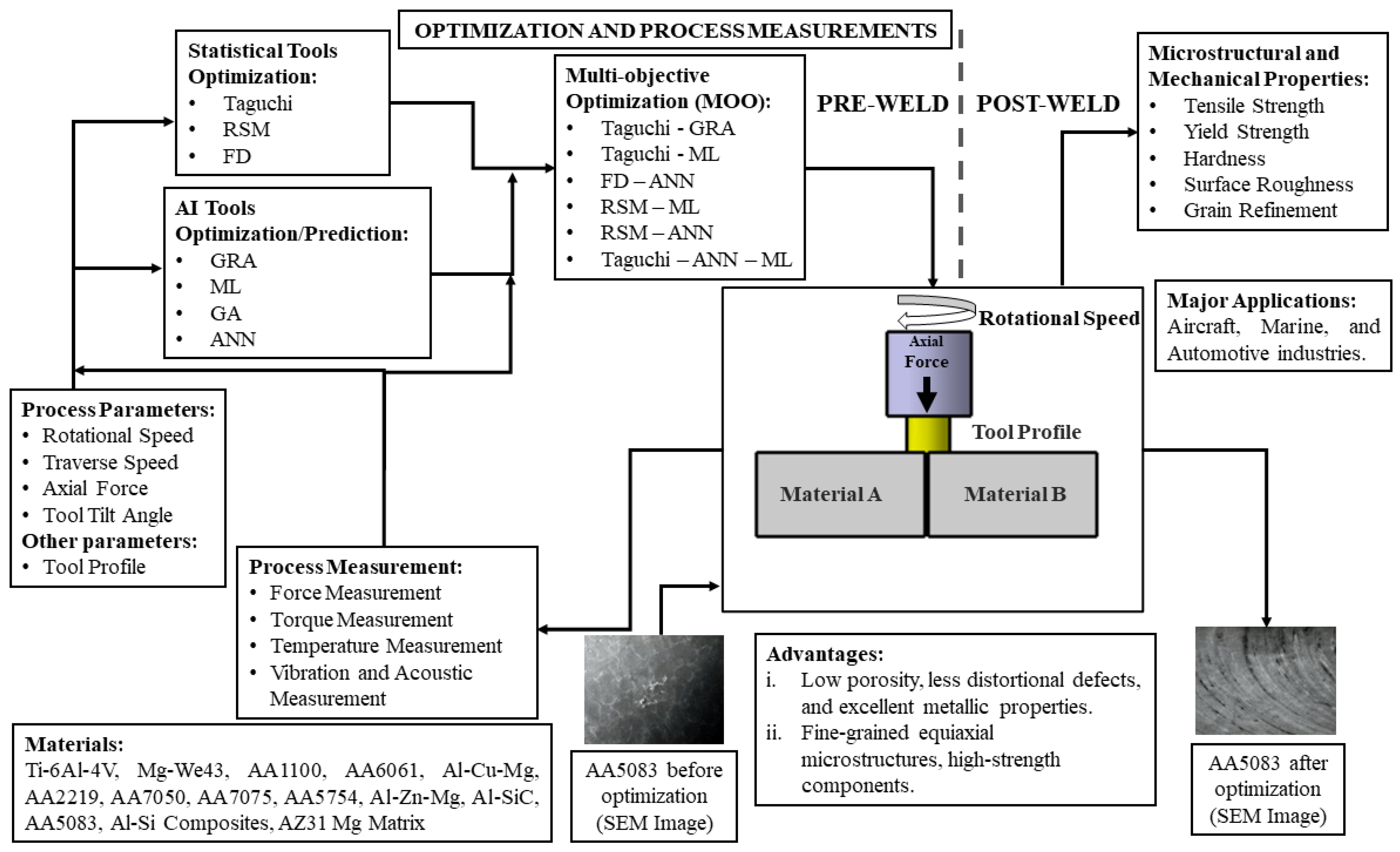

2. Friction Stir Welding (FSW)

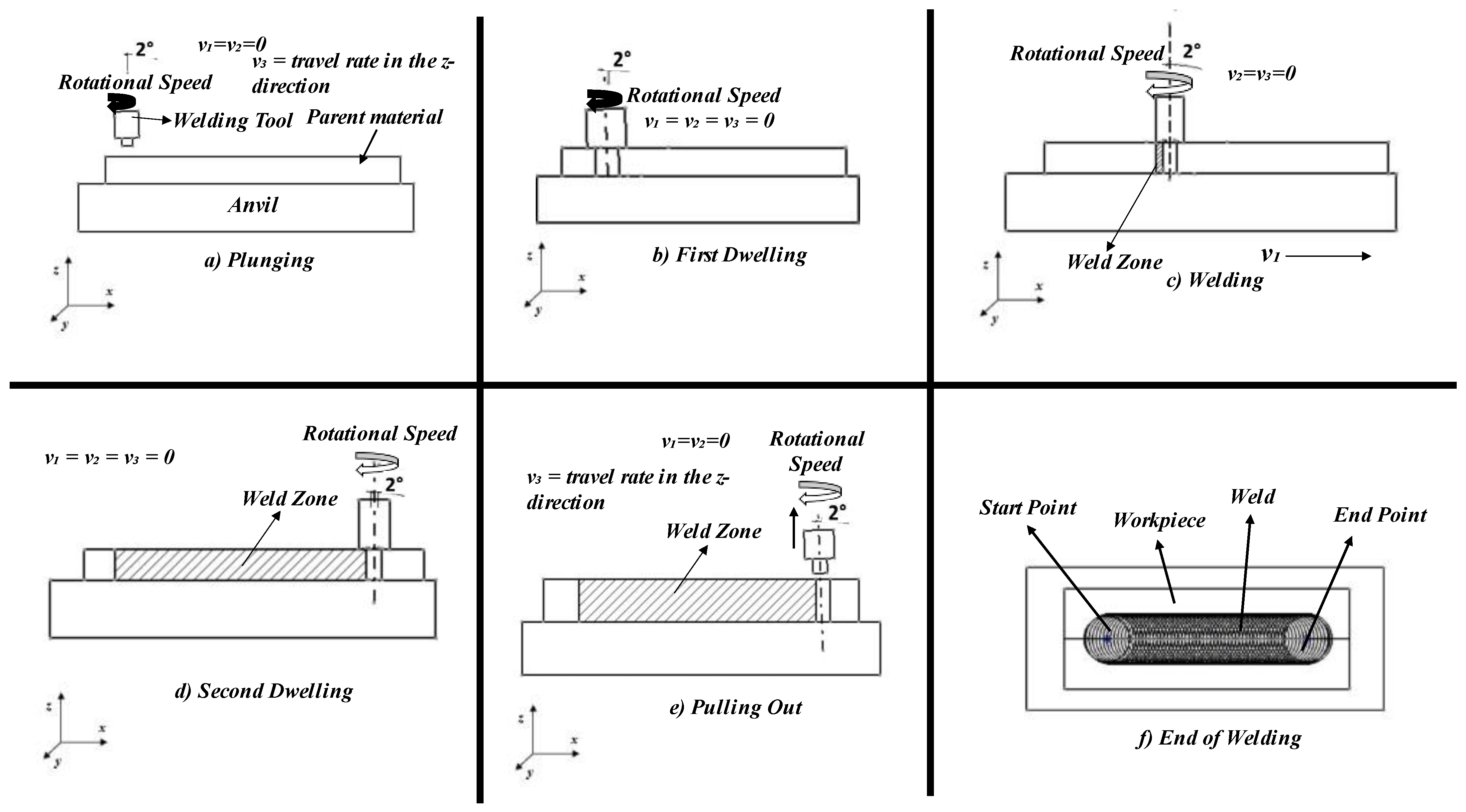

2.1. Process Description

- Plunge: the non-consumable tool thrusts into the workpiece at a specific RS up to a certain depth.

- Dwell: the tool stays in that position for some time.

- Traverse: The tool advances along the path at a specific speed.

- Tool Retract: the tool comes back from the BM to a certain height.

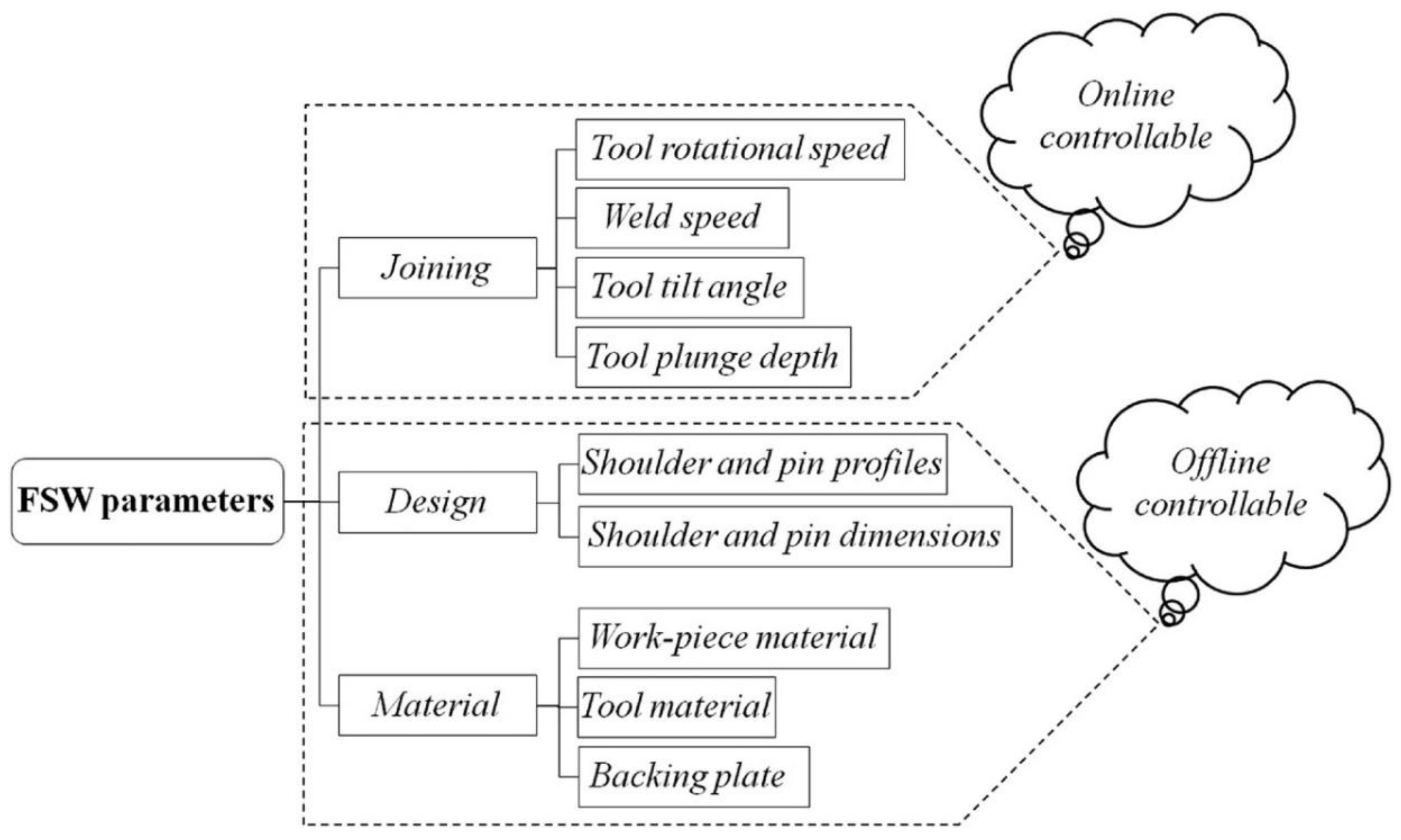

2.1.1. Process Parameters

Effect of Process Parameters

2.1.2. FSW Modelling

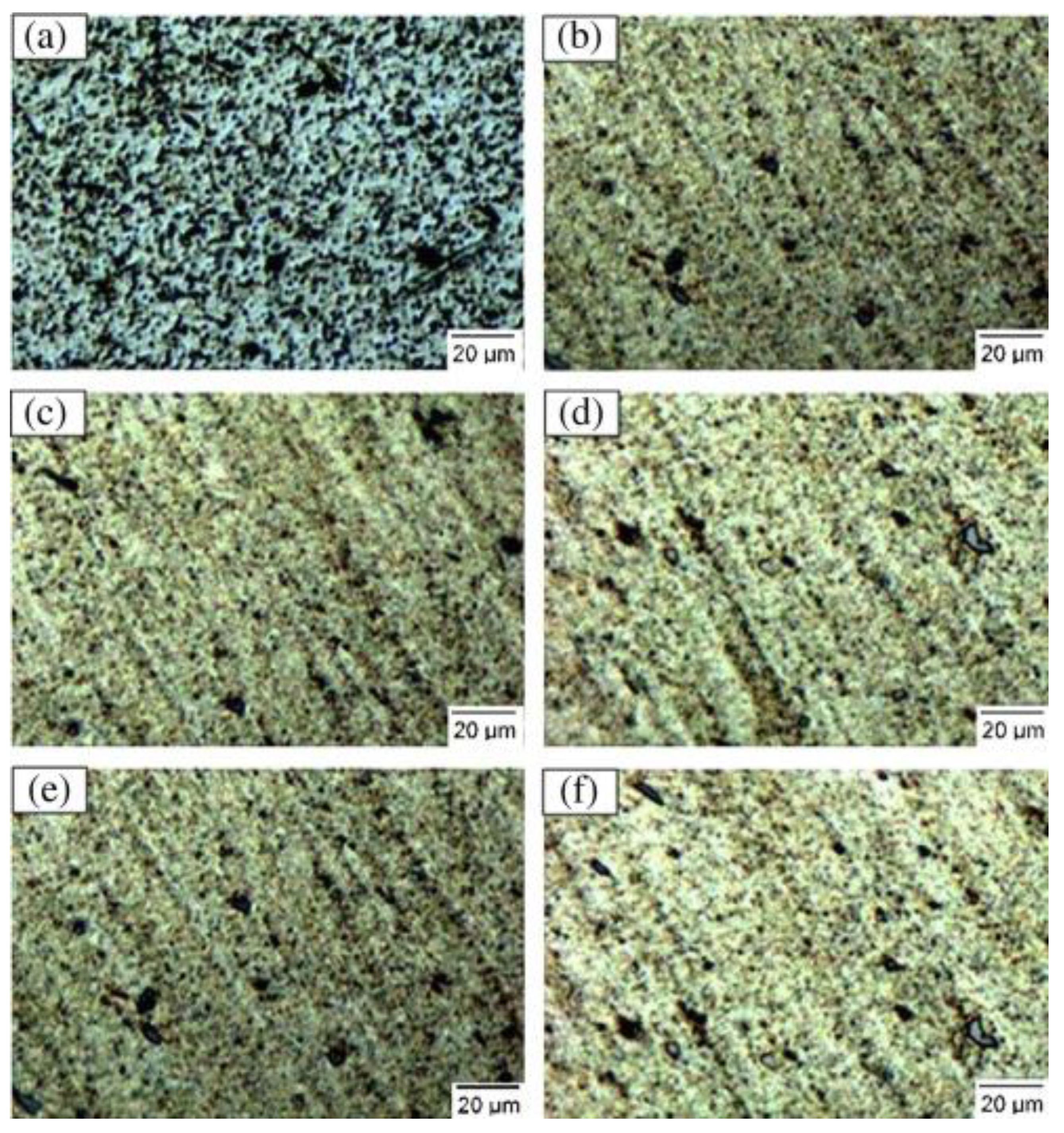

2.1.3. Microstructure

2.1.4. Materials (Alloys and Composites)

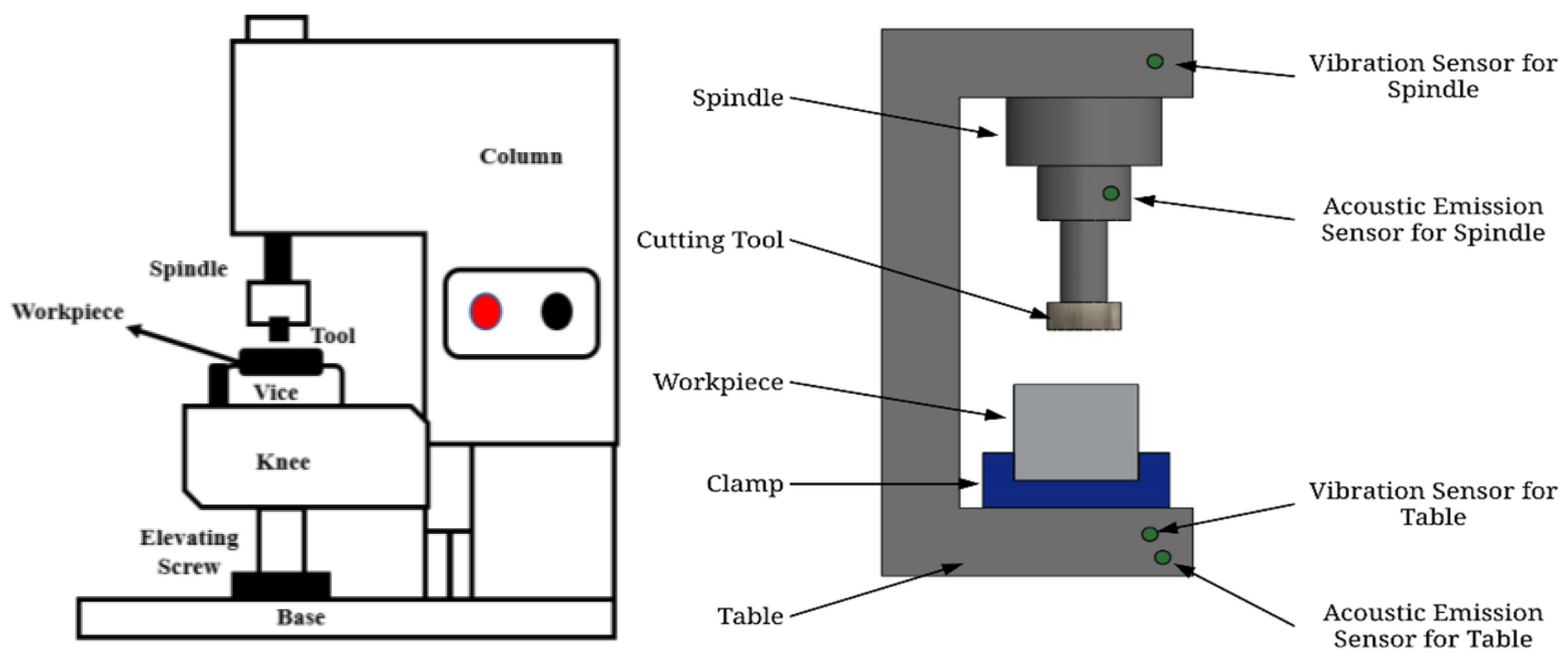

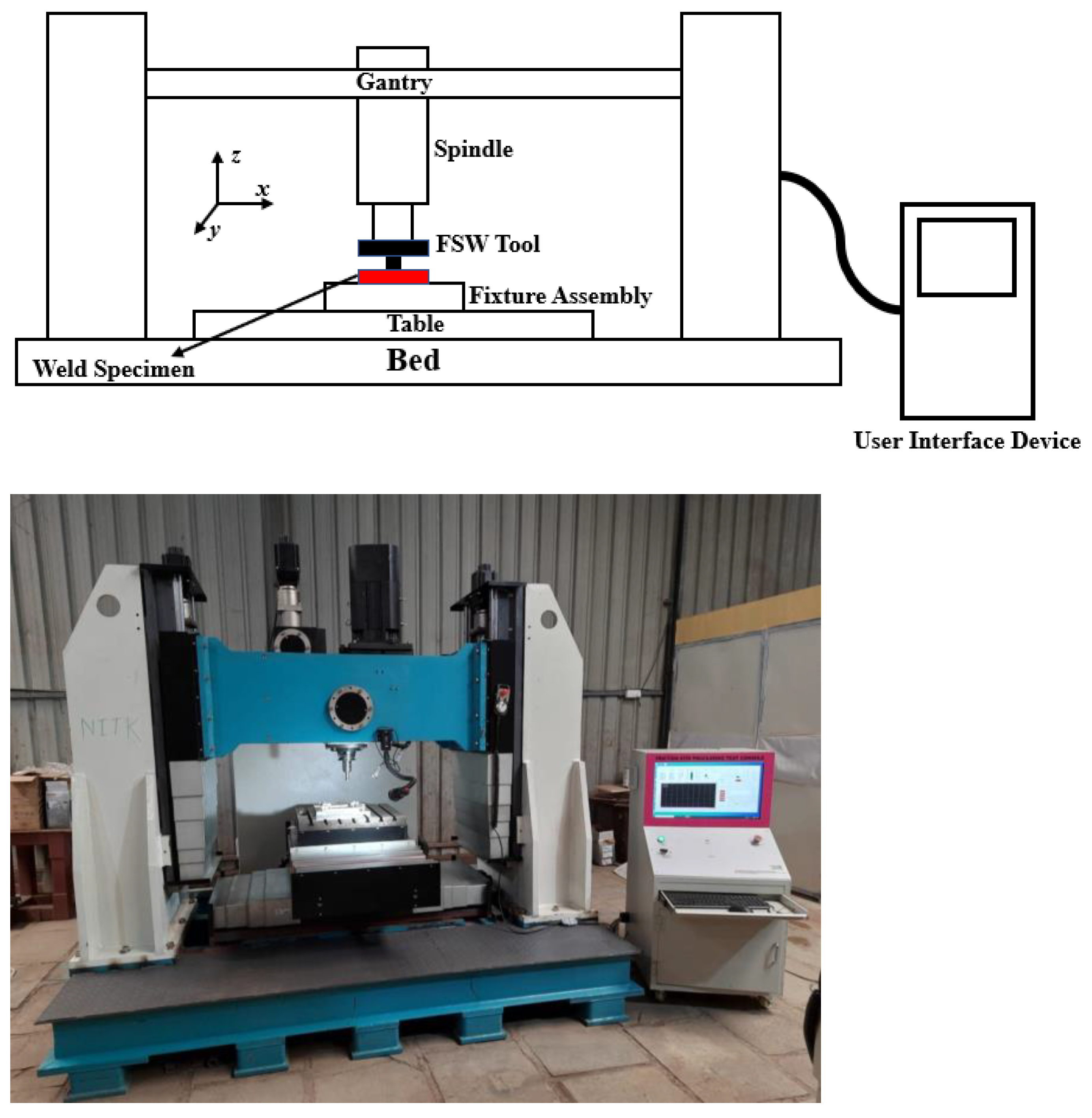

2.1.5. FSW Machines

- Conventional milling machines.

- Custom-made FSW machines.

- Specialized robots designed for FSW.

| Material | Tool Profile | Tool Material | Ref. |

|---|---|---|---|

| Al-SiC composite sheets | Cylindrical threaded | H-13 steel tool | [49] |

| Aluminium matrix composite | Cylindrical | M2 steel | [76] |

| AA6061-4.5Cu-5SiC (Wt.%) | Square | HSS M2 | [77] |

| Cast aluminum 359 + 20% SiC metal–matrix composite | Cylindrical threaded | 1/4–20, 01 AlSi oil-hardened | [78] |

| AA2009/SiCp composite | Cylindrical threaded | Steel | [79] |

| Aluminum 6092/SiC/25p/t6 metal matrix composite | Cylindrical | H13 tool steel | [80] |

| 2124Al/25vol%SiCp | Cylindrical threaded | H13 steel (48 HRc) and MP159 alloy | [81] |

| Boron carbide particulate reinforced AA6061 | Square profile | High-carbon high-chromium steel | [82] |

| Aluminium matrix nano-composite | Threaded taper | H13 steel | [83] |

| TiAl6V4 to AA2024-T3 | Threaded taper | Tool steel | [42] |

| 2024 and 7075 Al alloys | Cylindrical threaded | SKD61 | [84] |

| (AMg6, AD1) and steels (St3ps; 12Kh18N10T) | -- | -- | [2] |

| Ti-6Al-4V | -- | Tungsten carbide | [85] |

| Ti-6Al-4V | -- | Tungsten rhenium | [86] |

| Ti–1.5Al–1Mn | Conical | As-cast ZhS32 nickel superalloy | [87] |

| Ti–6Al–4V | -- | Tungsten rhenium | [88] |

| Titanium alloy T-joint | Cylindrical | W-25Re alloy | [89] |

| AZ31 magnesium alloy | Cylindrical stir | High-speed steel W18Cr4V | [90] |

| AZ31B magnesium alloy | Straight cylindrical, tapered cylindrical, threaded cylindrical, triangular and square | Mild steel, stainless steel, armour steel, high-carbon steel, high-speed steel | [91] |

| AZ31 magnesium alloy butt weld | -- | 65Mn steel | [92] |

| AZ80A and AZ91C Mg alloys | Cylindrical tapered | M35 high-speed steel | [93] |

| AZ31B magnesium alloy | Cylindrical threaded | H13 steel | [94] |

| Material | Tool Profile | Tool Material | Ref. |

|---|---|---|---|

| Al-Cu | Conical | Tool steel | [95] |

| Ti–6Al–4V to Al–6Mg | Tapered | WC–Co | [43] |

| AA7075-T651 to Ti-6Al-4V | Threaded taper | --- | [96] |

| Noryl™ GFN2 (Polyphenylene ether (PPE) + high impact polystyrene (HIPS) + 20 wt% of short glass-fiber-reinforced) and AA6082-T6 | Cylindrical threaded | Medium-carbon steel | [97] |

| AA6061-T6 and Ti6Al4V | Cylindrical and tapered | WC with 10% Co | [98] |

| Pure titanium (CP-Ti) and Ti6Al4V sheets | Truncated conical | [47] | |

| Al 6061-T6 to AISi 316 stainless steel | Cylindrical | WC-Co | [99] |

| AA1050 and AZ91 | Cylindrical | H13 steel | [100] |

| AA6061-T6 and pure Cu | Cylindrical | --- | [101] |

| Pure Al–pure Cu | Cylindrical, tapered, straight triangle, and straight square | W302 steel | [102] |

| Galvanized steel (GS) and mild steel Q235 | Conical tapered | WC | [103] |

| AZ31-AM60 | -- | Tool steel | [104] |

| Characteristics | FSW Processing Machines | |||

|---|---|---|---|---|

| Milling Machine | Customized Machine | Parallel Robot | Articulated Robot | |

| Capital investment | Low | High | High | Low |

| Stiffness | High | High | High | Low |

| Flexibility | Low | Medium | High | High |

| Setup Time | Low | High | Medium | Medium |

| Complex welds profiles | Low | Medium | High | High |

2.2. Summary

- Tool RS is related to heat generation, while TS relates to heat supply to the weld region.

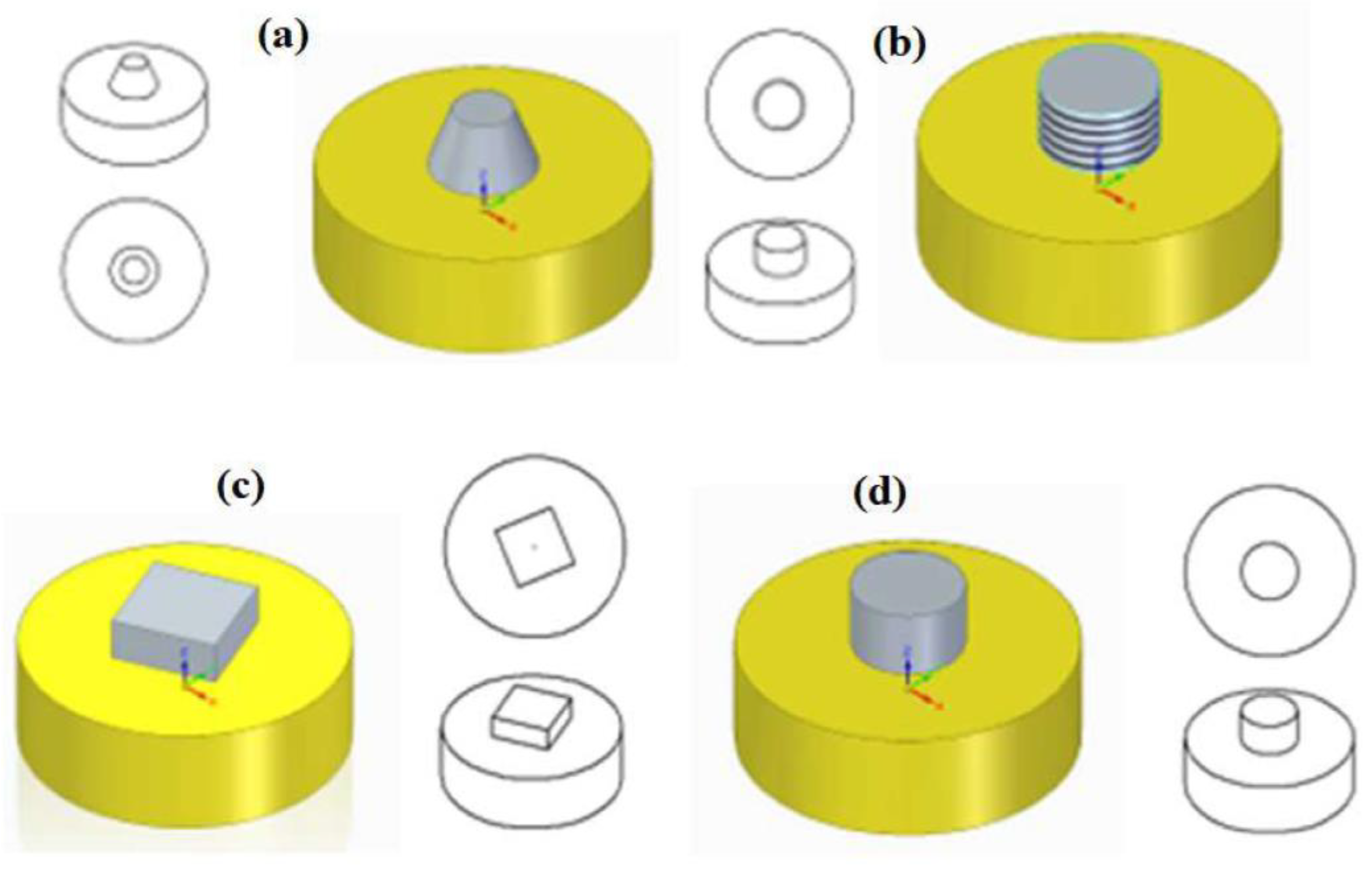

- For friction stir welding involving a tool pin, a threaded pin profile is preferred because threads allow the proper flow of material from the shoulder down to the bottom of the pin.

- Preheating the tool pin is advisable to reduce yield stress to prevent wear out of the tool. This makes welding easier.

- Conventional milling machines with structural enhancements to withstand heavy loads can be used for FSW.

- NZ has a higher strength due to fine, equiaxed grain structure formation.

- It was also observed that with an increase in RS, tensile strength increased to a specific value and then decreased with a further rise in RS.

- A decrease in heat input led to a reduction in workpiece temperature and increased vertical force due to welding speed.

- Higher values of RS, TS, and penetration depth and a lower tilt angle are required to enhance joint efficiency and increase microhardness.

3. Optimization

3.1. Statistical Tools

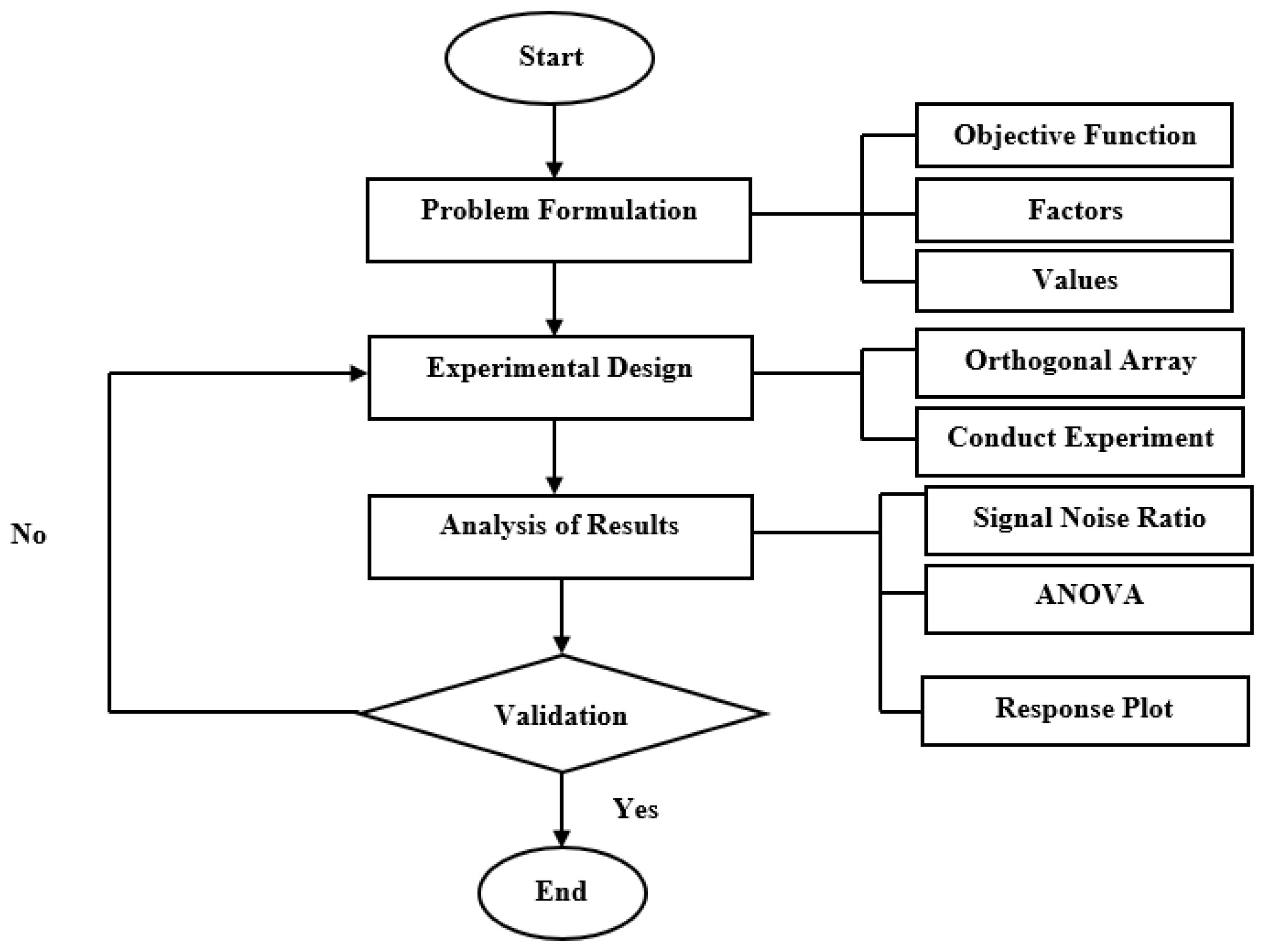

3.1.1. Taguchi Optimization

- Determine the primary function of any process.

- To find various noise factors, test conditions, and quality characteristics.

- Define the objective function.

- Categorize different elements and provide value to them.

- Select the correct orthogonal matrix for multiple experiments.

- Experimentation.

- Investigation of data and prediction of optimum level of performance.

- Verification of experiments conducted and plan of future action.

- The Taguchi matrix design for experimentation resulted in a cost-effective technique for parametric analysis and optimization.

- Taguchi designed different experimental matrices; therefore, individual matrix selection relies mainly on the investigator’s choice. The factors (individual, curvature, and interaction) and levels affecting the responses are to be considered by the investigator during the matrix or orthogonal array selection process.

- The Taguchi method optimizes only one response at once.

- The optimal setting for one response might not be true for the other.

- The optimal condition is different for different materials due to differences in material properties.

- The factors (RS, TS, axial load, pin profile, shoulder diameter, tool tilt angle, pin material, probe penetration, feed rate, tool vibration, etc.) critically affect the welded joint properties.

- Most of the literature neglected the interaction factor effects, probably due to reduced experimental trials or matrices selected.

- Taguchi determines the levels of factors that are the optimal conditions resulting in a local solution.

3.1.2. Advantages and Limitations

- Taguchi’s method focused on the performance value rather than the individual performance limit or range value.

- The Taguchi method is applied to narrow down the main process parameter (i.e., focused on reducing the process parameters by conducting limited experiments and analyzing the output performance).

- The Taguchi method enables conducting experimental trials to determine whether individual factors and interaction between process factors are less significant.

- The Taguchi method ensures studying both continuous and discontinuous responses.

- Taguchi’s OA does not test various combinations of process parameters, and the method does not consider the dynamic changes in the values.

- The Taguchi method can only optimize the process in offline mode.

- In many applications, the method is applied at the initial process development step.

- The matrices are limited in number and thus fail to test all factor interactions within the proposed experimental design.

- The Taguchi method limits the experimental trials and is treated as a one-time improvement technique, resulting in local or sub-optimal solutions.

- The Taguchi method only derives empirical equations with a mechanistic model, resulting in a local solution.

- Taguchi’s method refers to optimization without developing intrinsic empirical or mechanistic modeling, resulting in improper process insight.

- The Taguchi method requires the support of alternating optimization methods (say, GRA, TOPSIS, MOORA, AI and ML algorithms, etc.) to optimize multiple outputs simultaneously.

- The Taguchi method applied for multiple objective optimizations is based on judgmental and subjective methods, resulting in a less efficient model.

3.1.3. Response Surface Methodology (RSM)

- Collecting huge information with limited experiments.

- Collected data helps to build models and correlate input–outputs.

- Graphical representation of data that correlates input–outputs of any process.

- Help to analyze all individual, quadratic (nonlinear or linear), and interaction factor effects on responses.

- Optimize multiple responses by determining a set of input variables.

- The model does not explain the process mechanics.

- The models fit data corresponding to first- or second-order polynomials and do not explain all curvature information.

- An increase in independent variables increases the practical experiments, resulting in low prediction.

- The models are best suited to analyze and optimize a few independent variables.

3.1.4. Factorial Design (FD)

Advantages and Limitations of RSM

- The possibility of obtaining huge amounts of information in a limited number of experiments.

- It also provides build models and graphical data to correlate the relationship between the process parameters.

- It provides optimum response and optimal conditions from multiple responses.

- The RSM model provides detailed insight into full quadratic factor effects on response functions.

- The RSM model derives empirical equations that can be applied for prediction and optimization.

- The RSM method does not explain process mechanisms.

- It can fit data to first- or second-order order polynomials, so it cannot explain all systems containing curvature.

- If the number of independent variables increases, the number of experiments also increases, thus lowering the prediction capability. So, it is feasible with few parameters.

- The ML techniques discussed in Section 3.2 overcome these limitations.

- The RSM method is not an efficient technique for solving multiple objective functions that are nonlinear and multi-modal.

- RSM presents an unlimited saddle function in a quadratic model (response surface) possessing more than three responses and, therefore, is limited for responses ≤ 3.

- RSM may not be a cost-effective technique for many manufacturing sectors.

- RSM-derived response equations require continuous differentiable to locate optimal conditions.

- RSM-derived empirical equations predict only one output at a time.

3.2. Artificial Intelligence (AI)

3.2.1. Artificial Neural Networks (ANNs)

3.2.2. Machine Learning (ML)

Advantages and Limitations

- The storage of information in the whole network is the ability to work with missing data and parallel processing capability.

- ANNs can be applied to develop a process model relating linear or nonlinear relationships between responses.

- An ANN is an efficient tool to overcome the shortcomings of low-order polynomial equations and data containing noise or missing data for better predictions.

- The ANN model aims to predict multiple outputs simultaneously.

- ANNs can be applied for both online and offline process monitoring.

- An ANN uses weight between the network layers without knowing their physical inference while modeling.

- ANN models require tuning network architecture parameters (number of hidden layers and neurons, learning rate, momentum constants, transfer functions, bias) for accurate predictions.

- The major limitation is determining the neural net’s proper size and optimal structure.

- An ANN is a “black-box” model; determining the weight relationships between input-output parameters is not known, and hardware implementation of neural networks is costly [166].

3.3. Multi-Objective Optimization Techniques

Advantages and Limitations of ANFIS

3.4. Summary

- The main objective of RSM is to understand the topography of the response surface and find the region where optimal response occurs.

- The linear regression model gives a minimum percentage error between experimental and predicted values. It is based on supervised learning and assumes a linear relationship between variables. This is one of the disadvantages of a linear regression model. ANFIS can be used for nonlinear relationships.

- The backpropagation algorithm (BP) is the most extensively used ANN algorithm implemented online or in batch mode. Its accuracy is less than metaheuristic algorithms. Problems like determining the optimal number of neurons, the best learning rate in each hidden layer of an ANN, and the global optimum solution cannot be determined using the BP algorithm.

- Underfitting and overfitting in an ANN generate errors during the network training. Underfitting occurs when an ANN cannot accurately capture the relationship between input and output variables, resulting in high error. Overfitting refers to extra data generated along with noise from the training stage.

- The image processing technique has been predominantly used for detecting cracks and defects. Convolutional neural networks would yield better and optimized results.

- Taguchi and RSM have been widely used with ML techniques for determining/predicting more optimal values. These include Taguchi-GRA, RSM-ANN, Taguchi-PSO, and RSM-PSO-Firefly, to name a few.

4. Process Measurement

4.1. Force Measurement

4.2. Temperature Measurement

4.3. Vibration and Acoustic Measurement

4.4. Summary

- Workpiece material, tool material, and backing plate are material parameters that are kept constant.

- When the machine works in a force control mode, axial force should be monitored in a control mode position, and the tool PD should be monitored. For both control modes, the tool tilt angle and speed are common parameters to be monitored.

- The FSW tool experiences axial, longitudinal, and lateral forces. During the plunge state, when the tool starts rotating inside the workpiece, an axial force is generated, lifting the tool, which is opposed by the applied axial force via the tool’s shoulder. The linear motion of the tool results in a longitudinal force on the FSW tool. The combination of longitudinal and axial forces results in lateral force, leading to an asymmetric flow around the tool.

- It can be concluded that RS is the most important parameter for temperature measurement.

- The most common method of temperature measurement found in the literature was using embedded thermocouples inside the workpiece and near the rotating pin area.

- Spindle speed and thermal boundary conditions strongly affected the joint interface temperature.

5. Industry 5.0 and the Digital Twin Framework

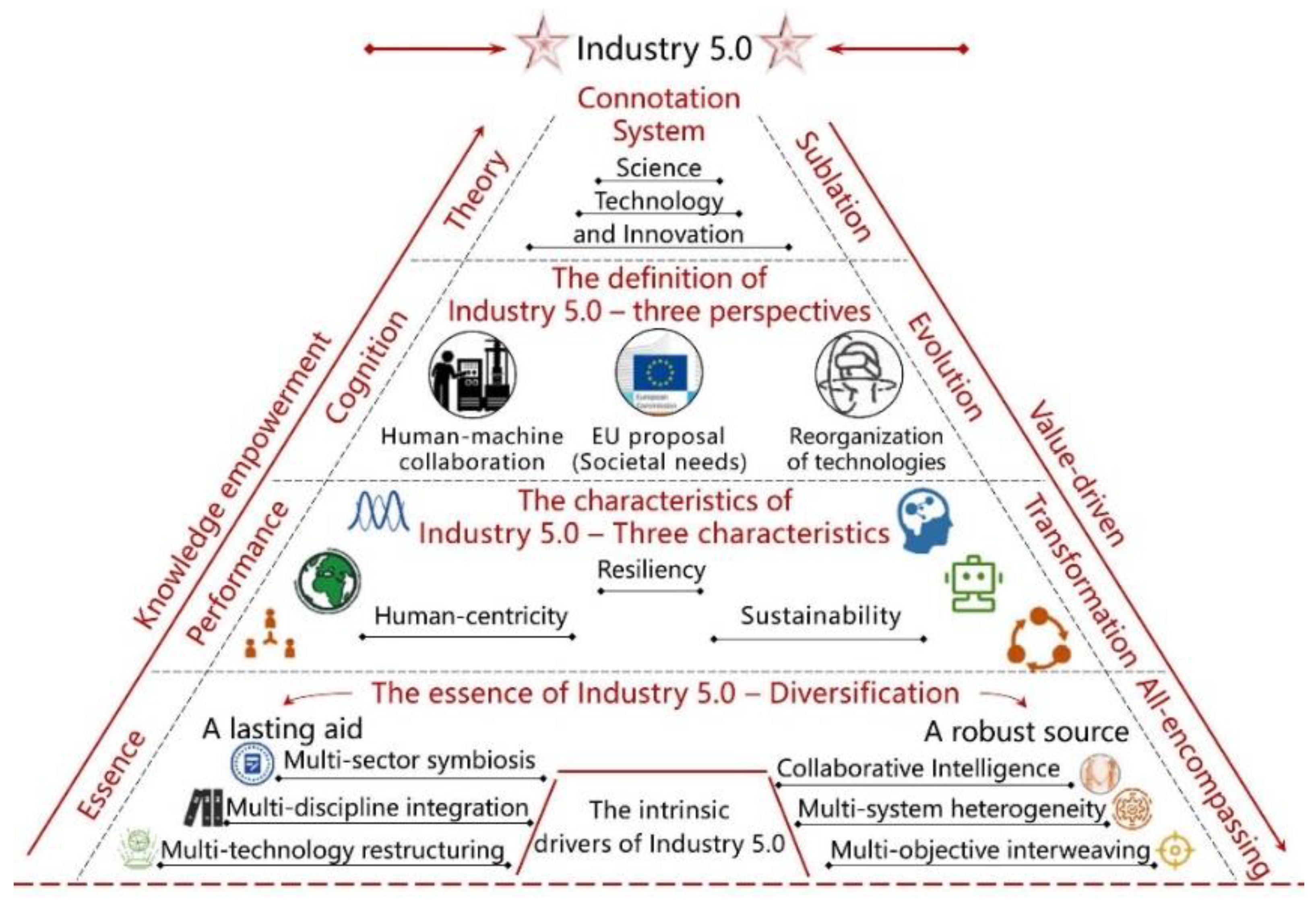

5.1. Industry 5.0

5.2. Digital Twin (DT) Technology

5.3. Summary

6. Conclusions and Future Scope

- FSW specimen evaluation of microstructure and mechanical characteristics regarding corrosion and wear resistance, fracture toughness, and fatigue strength is essential for widening the present applications.

- High-temperature plastic flow behavior and mechanical properties for dissimilar welding can be studied further.

- Analyzing characteristics of FSW, namely, corrosion resistance, fatigue life, and residual stresses.

- Analyzing the impact of peak temperature on the microstructure and mechanical characteristics of hard materials using numerical and analytical methods.

- Further studies can be carried out in FSW of stainless steel to develop functions for variable friction and slip rate coefficients.

- Another topic to research is analyzing the impact of pre- and post-weld treatments for steels.

- More research must address the effects of various bobbin tool profiles on steel.

- In simulation modeling, the parameters connected to the tool pin, such as temperature, torque, and maximum shear stress, can reduce the incidence of poor welds by 4%. Techniques like ANNs and image processing enhance the procedure.

- Thick non-ferrous, ferrous, and metal-based composite materials can be manufactured using temperature simulation-based optimization techniques.

- Objective determination of the weights on each response should be included instead of subjectively choosing the values.

- Validation of datasets generated using ML models in the prediction of UTS.

- In situ data from the thermal camera generates temperature data during the welding process and sends it as an input to ML, and ANN models will drastically improve performance.

- Integration of FSW with AI and ML techniques for quality inspection and monitoring is another area to explore to obtain better quality and defect-free joints.

- The impact of welding conditions on the cost of the process can be another area to explore.

- Economic feasibility of research for FSW of steels and process commercialization.

- Multi-sensor feedback system coupled with multi-objective optimization techniques for better weld specimens and improved mechanical properties.

- Based on the work by [172], where the force model was developed for the square profile tool, similar works can be carried out for other tool profiles.

- Improvement in camera motion for better image extraction and processing.

- The determination of a relationship between measured data and weld quality can be further explored.

- An innovative ML-based model for determining tool conditioning monitoring systems (TCMSs) to predict tool wear and breakage measurement systems.

- Optimization of feature extraction, data reduction in void deduction, and defect identification in welded samples using image segmentation techniques.

- As most of the DRL work is simulation-based, implementing DRL into the FSW process by selecting an appropriate algorithm and defining guidelines is an important task.

- Implementing digital twin technology for in situ process monitoring and establishing a steady and stable production line for multiple FSW machines.

- Implementation of cloud-based platform controls.

- The design and deployment of 5G technologies into the FSW process is another area that can be explored.

- Integrate Industry 4.0 and 5.0 concepts and framework in the FSW process.

- Application of an online monitoring system for vibration, torque, and temperature measurement and converting the design into a digital system by implementing IoT.

- FSW of polymers can be explored. This can include the effect of PD or axial force on the morphology and strength of the joint, the relationship between physical properties and optimal parameters, and the quantification of the heat generated and its effect on the weld.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ABC: Artificial Bee Colony | MH: microhardness |

| ACO: Ant Colony Optimization | MI: maximum iterations |

| ANFIS: Artificial Neuro-fuzzy Inference System | ML: machine learning |

| ANN: artificial neural network | MR: mutation rate |

| ANOVA: Analysis of Variance | MSE: mean square error |

| AS: advancing side | NCGA: neighborhood cultivation genetic algorithm |

| BM: base metal | NZ: nugget zone |

| BPA: backpropagation algorithm | OA: orthogonal array |

| C1: correction factor | Pc: probability of crossover |

| CCD: central composite design | PA-FSW: plasma-assisted friction stir welding |

| CDR: continuous dynamic recrystallization | PCBN: polycrystalline cubic boron nitride |

| DDR: discontinuous dynamic recrystallization | PCD: polycrystalline diamond |

| DFA: desirability function approach | PD: plunge depth |

| DoE: design of experiment | PR: polynomial regression |

| DTR: decision tree regression | PS: population size |

| EBW: electron beam welding | PSO: particle swarm optimization |

| FEM: finite element model | PWHT: post-weld heat treatment |

| FSW: friction stir welding | RFR: random forest regression |

| GA: genetic algorithm | RS: rotational side |

| GPR: Gaussian progression regression | RSM: response surface methodology |

| GRA: Grey Relational Analysis | SA: simulated annealing |

| GTAW: gas–tungsten arc welding | SAW: submerged arc welding |

| HAZ: heat-affected zone | SEM: scanning electron microscope |

| HS: harmony search | SVM: support vector machine |

| IS: impact strength | SVR: support vector regression |

| IE: impact energy | SZ: stir zone SS: swarm size |

| JA: Jaya algorithm | TLBO: teaching–learning-based optimization |

| JE: joint efficiency | TMAZ: thermomechanical affected zone |

| L-M: Levenberg–Marquardtt | TS: tensile strength |

| LR: linear regression | UTS: ultimate tensile strength |

| MAE: mean absolute error |

References

- Mohan, D.G.; Wu, C.S. A Review on Friction Stir Welding of Steels. Chin. J. Mech. Eng. 2021, 34, 137. [Google Scholar] [CrossRef]

- Chularis, A.A.; Rzaev, R.A.; Valisheva, A.G.; Kogan, V.V. Joining of Steels to Aluminum and its Alloys by Friction Stir Welding. Met. Sci. Heat Treat. 2021, 62, 738–747. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Fydrych, D.; Cam, G. Friction stir welding in the aerospace industry: The current progress and state-of-the-art review. Materials 2023, 16, 2971. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Cam, G. Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J. Manuf. Process. 2018, 36, 571–600. [Google Scholar] [CrossRef]

- Cam, G.; Ipekoglu, G. Recent developments in joining of aluminium alloys. Int. J. Adv. Manuf. Technol. 2017, 91, 1851–1866. [Google Scholar] [CrossRef]

- Kavathia, K.; Badheka, V. Application of Friction Stir Welding (FSW) in Automotive and Electric Vehicle. In Recent Advances in Mechanical Infrastructure; Parwani, A.K., Ramkumar, P., Abhishek, K., Yadav, S.K., Eds.; Lecture Notes in Intelligent Transportation and Infrastructure Book Series; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Martin, J.; Wei, S. Friction Stir Welding Technology for Marine Applications. In Friction Stir Welding and Processing VIII; Mishra, R.S., Mahoney, M.W., Sato, Y., Hovanski, Y., Eds.; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- İpekoğlu, G.; Erim, S.; Kıral, B.G.; Çam, G. Investigation into the effect of temper condition on friction stir weldability of AA6061 Al-alloy plates. Kov. Mater. 2013, 51, 155–163. [Google Scholar] [CrossRef]

- Çam, G.; Javaheri, V.; Heidarzadeh, A. Advances in FSW and FSSW of dissimilar Al-alloy plates. J. Adhes. Sci. Technol. 2023, 37, 162–194. [Google Scholar] [CrossRef]

- El-Sayed, M.M.; Shash, A.Y.; Abd-Rabou, M.; ElSherbiny, M.G. Welding and processing of metallic materials by using friction stir technique: A review. J. Adv. Join. Process. 2011, 3, 100059. [Google Scholar] [CrossRef]

- Singh, K.; Singh, G.; Singh, H. Review on friction stir welding of magnesium alloys. J. Magnes. Alloys 2018, 6, 399–416. [Google Scholar] [CrossRef]

- Cui, L.; Peng, Z.; Chang, Y.; He, D.; Cao, Q.; Guo, X.; Zeng, Y. Porosity, microstructure and mechanical property of welded joints produced by different laser welding processes in selective laser melting AlSi10Mg alloys. Opt. Laser Technol. 2022, 150, 107952. [Google Scholar] [CrossRef]

- Ipekoglu, G.; Cam, G. Formation of weld defects in cold metal transfer arc welded 7075-T6 plates and its effect on joint performance. IOP Conf. Ser. Mater. Sci. Eng. 2019, 629, 012007. [Google Scholar] [CrossRef]

- Cam, G. Prospects of producing aluminum parts by wire arc additive manufacturing (WAAM). Mater. Today Proc. 2022, 62, 77–85. [Google Scholar] [CrossRef]

- Liu, F.; Dong, Y.; Tan, Z.; Wang, H.; Tan, C.; Chen, B.; Song, X. Mechanism analysis on suppressing porosity in laser-MIG hybrid welding of aluminum alloy via external magnetic field. J. Manuf. Process. 2023, 101, 1124–1135. [Google Scholar] [CrossRef]

- Deng, A.; Chen, H.; Zhang, Y.; Liu, Y.; Yang, X.; Zhang, B. Effect of filler materials on the porosity formation of aluminum alloy by laser welding with filler wire. Opt. Laser Technol. 2023, 159, 109000. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Yang, C.; Gao, M. Study of porosity suppression in oscillating laser-MIG hybrid welding of AA6082 aluminum alloy. J. Mater. Process. Technol. 2021, 292, 117053. [Google Scholar] [CrossRef]

- Chen, L.; Wang, C.; Xiong, L.; Zhang, X.; Mi, G. Microstructural, porosity and mechanical properties of lap joint laser welding for 5182 and 6061 dissimilar aluminum alloys under different place configurations. Mater. Des. 2020, 191, 108625. [Google Scholar] [CrossRef]

- Zhang, Y.N.; Cao, X.; Larose, S.; Wanjara, P. Review of tools for friction stir welding and processing. Can. Met. Q. 2012, 51, 250–261. [Google Scholar] [CrossRef]

- Simar, A.; Bréchet, Y.; de Meester, B.; Denquin, A.; Gallais, C.; Pardoen, T. Integrated modeling of friction stir welding of 6xxx series Al alloys: Process, microstructure and properties. Prog. Mater. Sci. 2012, 57, 95–183. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.K.; Herbert, M.A.; Gowdru, C.M.P.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Andrade, D.G.; Leitão, C.; Dialami, N.; Chiumenti, M.; Rodrigues, D.M. Analysis of contact conditions and its influence on strain rate and temperature in friction stir welding. Int. J. Mech. Sci. 2021, 191, 106095. [Google Scholar] [CrossRef]

- Andrade, D.G.; Leitão, C.; Dialami, N.; Chiumenti, M.; Rodrigues, D.M. Modelling torque and temperature in friction stir welding of aluminium alloys. Int. J. Mech. Sci. 2020, 182, 105725. [Google Scholar] [CrossRef]

- Leitãoa, C.; Louro, R.; Rodrigues, D.M. Using torque sensitivity analysis in accessing Friction Stir Welding/Processing conditions. J. Mater. Process. Technol. 2012, 212, 2051–2057. [Google Scholar] [CrossRef]

- Leal, R.M.; Leitãoa, C.; Loureiroa, A.; Rodrigues, D.M.; Vilaca, P. Material flow in heterogeneous friction stir welding of thin aluminium sheets: Effect of shoulder geometry. Mater. Sci. Eng. A 2008, 498, 384–391. [Google Scholar] [CrossRef]

- Simões, F.; Rodrigues, D.M. Material flow and thermo-mechanical conditions during Friction Stir Welding of polymers: Literature review, experimental results and empirical analysis. Mater. Des. 2014, 59, 344–351. [Google Scholar] [CrossRef]

- Kalita, K.; Burande, D.; Ghadai, R.K.; Chakraborty, S. Finite Element Modelling, Predictive Modelling and Optimization of Metal Inert Gas, Tungsten Inert Gas and Friction Stir Welding Processes: A Comprehensive Review. Arch. Comput. Methods Eng. 2023, 30, 271–299. [Google Scholar] [CrossRef]

- Shen, Z.; Ding, Y.; Gerlich, A.P. Advances in friction stir spot welding. Crit. Rev. Solid State Mater. Sci. 2020, 45, 457–534. [Google Scholar] [CrossRef]

- Ogunsemi, B.T.; Abioye, T.E.; Ogedengbe, T.I.; Zuhailawati, H. A review of various improvement strategies for joint quality of AA 6061-T6 friction stir weldments. J. Mater. Res. Technol. 2021, 11, 1061–1089. [Google Scholar] [CrossRef]

- Mofid, M.A.; Abdollah-Zadeh, A.; Ghaini, F.M. The effect of water cooling during dissimilar friction stir welding of Al alloy to Mg alloy. Mater. Des. 2012, 36, 161–167. [Google Scholar] [CrossRef]

- Eren, B.; Guvenc, M.A.; Mistikoglu, S. Artificial intelligence applications for friction stir welding: A review. Met. Mater. Int. 2021, 27, 193–219. [Google Scholar] [CrossRef]

- Smith, I.J.; Lord, D.D. FSW Patents-A Stirring Story; SAE Transactions; SAE International: Warrendale, PA, USA, 2007; pp. 772–780. [Google Scholar] [CrossRef]

- Birdi, A.; Procha, A.; Brar, A.S.; Kumar, R.; Kumar, S. Effect of tool pin profile on mechanical characteristics of friction stir welded al alloys: A critical review. Int. Res. J. Nat. Sci. 2019, 1, 15–21. Available online: https://www.scienceresearchjournals.org/IRJNST/volume-1%20issue-5.html (accessed on 2 February 2023).

- Kumar, A.; Raju, L.S. Influence of tool pin profiles on friction stir welding of copper. Mater. Manuf. 2012, 27, 1414–1418. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Kamal, S.; Parthiban, V.; Puthilibai, G.; Thirumal Azhagan, M.; Kamal, N.; Senthil, T.S.; Yishak, S. Investigation on tensile behaviour of different weld joints through Taguchi approach. Adv. Mater. Sci. Eng. 2022, 2022, 5258014. [Google Scholar] [CrossRef]

- Babalola, S.A.; Dutta, S.; Murmu, N.C.; Akinnuli, B.O. In-situ process reliability monitoring strategy for friction stir welding machine. Mater. Today Proc. 2022, 66, 3883–3889. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Purandare, Y.; Sugumaran, A.; Hovsepian, P.; Hatto, P.; de Backer, J. Improving the Quality of Friction Stir Welds in Aluminium Alloys. Coatings 2021, 11, 539. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding–process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- MohammadiSefat, M.; Ghazanfari, H.; Blais, C. Friction Stir Welding of 5052-H18 aluminum alloy: Modeling and process parameter optimization. J. Mater. Eng. Perform. 2021, 30, 1838–1850. [Google Scholar] [CrossRef]

- Mijajlović, M.; Milčić, D. Analytical model for estimating the amount of heat generated during friction stir welding: Application on plates made of aluminium alloy 2024 T351. In Welding Processes; IntechOpen: London, UK, 2012; pp. 247–274. [Google Scholar] [CrossRef]

- Dressler, U.; Biallas, G.; Mercado, U.A. Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater. Sci. Eng. A 2009, 526, 113–117. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Z.; Shen, Y.; Hu, W.; Luo, L. Dissimilar friction stir welding of Ti–6Al–4V alloy and aluminum alloy employing a modified butt joint configuration: Influences of process variables on the weld interfaces and tensile properties. Mater. Des. 2014, 53, 838–848. [Google Scholar] [CrossRef]

- Albannai, A.I. Review the Common Defects in Friction Stir Welding. Int. J. Sci. Technol. Res. 2020, 9, 318–329. [Google Scholar]

- Mao, Y.; Yang, P.; Zhang, W.; Li, N.; Nie, H.; Lin, D.; Ke, L. Improving tensile-shear properties of friction stir lap welded dissimilar Al/Mg joints by eliminating hook defect and controlling interfacial reaction. Chin. J. Aeronaut. 2022, 36, 257–267. [Google Scholar] [CrossRef]

- Wang, X.; Xiao, Y.; Shi, L.; Zhai, M.; Wu, C.; Chen, G. Revealing the mechanism of tool tilting on suppressing the formation of void defects in friction stir welding. J. Mater. Res. Technol. 2023, 25, 38–54. [Google Scholar] [CrossRef]

- Lunetto, V.; De Maddis, M.; Russo Spena, P. Similar and Dissimilar Lap Friction Stir Welding of Titanium Alloys: On the Elimination of the Hook Defect. Int. J. Adv. Manuf. Technol. 2023, 126, 3417–3435. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, H.; Jiang, X.; Yuan, T.; Han, Y.; Li, X. Mechanical properties of electric assisted friction stir welded 2219 aluminum alloy. J. Manuf. Process. 2019, 44, 197–206. [Google Scholar] [CrossRef]

- Zamani, S.M.M.; Behdinan, K.; Razfar, M.R.; Fatmehsari, D.H.; Mohandesi, J.A. Studying the effects of process parameters on the mechanical properties in friction stir welding of Al-SiC composite sheets. Int. J. Adv. Manuf. Technol. 2021, 113, 3629–3641. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater. Sci. Eng. 2007, 459, 7–18. [Google Scholar] [CrossRef]

- Sahali, M.A.; Aini, A.; Bouzit, L.; Himed, L.; Benaissa, B. Experimental modeling and multi-objective optimization of friction stir welding parameters of AA 3004 aluminum alloy. Int. J. Adv. Manuf. Technol. 2023, 124, 1229–1244. [Google Scholar] [CrossRef]

- Oakes, T.; Landers, R.G. Design, and implementation of a general tracking controller for friction stir welding processes. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 5576–5581. [Google Scholar] [CrossRef]

- Safeen, M.W.; Russo Spena, P.; Buffa, G.; Campanella, D.; Masnata, A.; Fratini, L. Effect of position and force tool control in friction stir welding of dissimilar aluminum-steel lap joints for automotive applications. Adv. Manuf. 2020, 8, 59–71. [Google Scholar] [CrossRef]

- Zhao, X.; Kalya, P.; Landers, R.G.; Krishnamurthy, K. Path force control for friction stir welding processes. Dyn. Syst. Control. Conf. 2008, 43352, 87–94. [Google Scholar]

- Jaffarullah, M.S.; Low, C.Y.; Shaari, M.S.B.; Jaffar, A. A review of force control techniques in friction stir process. Procedia Comput. Sci. 2015, 76, 528–533. [Google Scholar] [CrossRef]

- Shettigar, A.K.; Manjaiah, M. Friction Stir Welding—An Overview. In Advanced Manufacturing Technologies; Gupta, K., Ed.; Materials Forming, Machining and Tribology Book Series; Springer: Cham, Switzerlad, 2017. [Google Scholar] [CrossRef]

- Noreña, E.; Zuluaga, M.; Hoyos, E.; Montoya, Y. Model-based proposal of a control strategy for friction stir welding. In Proceedings of the 2019 IEEE 4th Colombian Conference on Automatic Control (CCAC), Medellin, Colombia, 15–16 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Zhao, S.; Bi, Q.; Wang, Y. An axial force controller with delay compensation for the friction stir welding process. Int. J. Adv. Manuf. Technol. 2016, 85, 2623–2638. [Google Scholar] [CrossRef]

- Teng, L.; Lu, X.; Luan, Y.; Sun, S. Predicting axial force in friction stir welding thick 2219 aluminum alloy plate. Int. J. Adv. Manuf. Technol. 2023, 126, 1025–1034. [Google Scholar] [CrossRef]

- Rabe, P.; Schiebahn, A.; Reisgen, U. Force feedback-based quality monitoring of the friction stir welding process utilizing an analytic algorithm. Weld. World 2021, 65, 845–854. [Google Scholar] [CrossRef]

- Guan, W.; Cui, L.; Liang, H.; Wang, D.; Huang, Y.; Li, M.; Li, X. The response of force characteristic to weld-forming process in friction stir welding assisted by machine learning. Int. J. Mech. Sci. 2023, 253, 108409. [Google Scholar] [CrossRef]

- Rabe, P.; Schiebahn, A.; Reisgen, U. Deep learning approaches for force feedback based void defect detection in friction stir welding. J. Adv. Join. Process. 2022, 5, 100087. [Google Scholar] [CrossRef]

- Karlsson, M.; Bagge Carlson, F.; Holmstrand, M.; Robertsson, A.; de Backer, J.; Quintino, L.; Johansson, R. Robotic friction stir welding–seam-tracking control, force control and process supervision. Ind. Robot. Int. J. Robot. Res. Appl. 2023, 50, 722–730. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, M.; Liu, H.; Liu, S.; Zhao, H.; Gao, J. A constant plunge depth control strategy for robotic FSW based on online trajectory generation. Robot. Comput. Integr. Manuf. 2023, 80, 102479. [Google Scholar] [CrossRef]

- Schmidt, H.; Hattel, J.; Wert, J. An analytical model for the heat generation in friction stir welding. Model. Simul. Mater. Sci. Eng. 2003, 12, 143. [Google Scholar] [CrossRef]

- Song, M.; Kovacevic, R. Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int. J. Mach. Tools Manuf. 2003, 43, 605–615. [Google Scholar] [CrossRef]

- Amara, K.; Badji, R.; Bouabdallah, M.; Cheniti, B.; Aissani, M.; Haddad, A.; Ziouche, A. Effect of PWHT on microstructure and corrosion resistance of the nugget zone in AZ31 friction stir weld. Int. J. Adv. Manuf. Technol. 2022, 123, 2757–2769. [Google Scholar] [CrossRef]

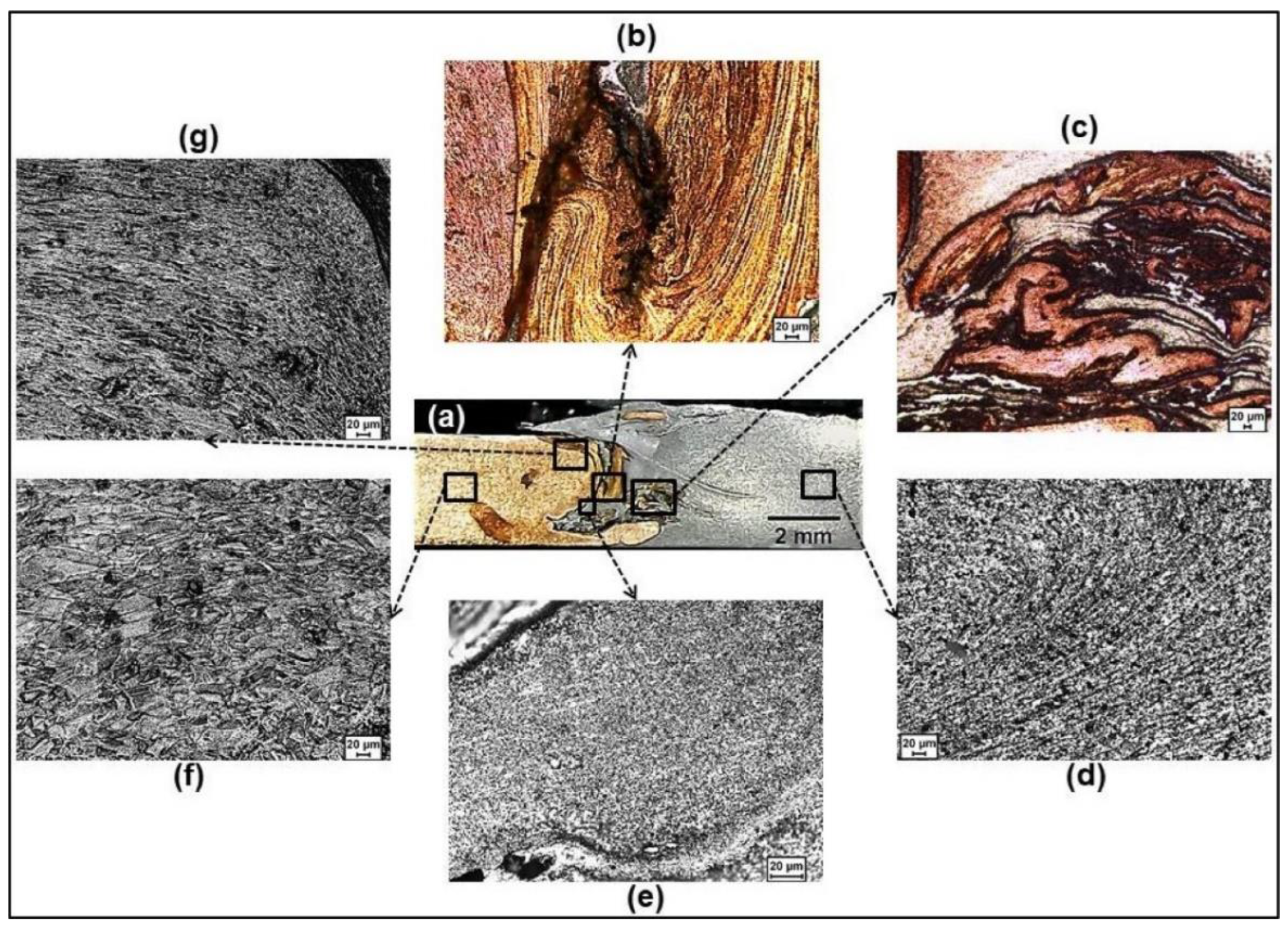

- Tiwari, A.; Pankaj, P.; Suman, S.; Singh, P.; Biswas, P.; Pal, S.; Rao, A.G. Effect of plasma preheating on weld quality and tool life during friction stir welding of DH36 steel. Proc. Inst. Mech. Eng. 2021, 235, 1458–1472. [Google Scholar] [CrossRef]

- Moshwan, R.; Yusof, F.; Hassan, M.A.; Rahmat, S.M. Effect of tool rotational speed on force generation, microstructure and mechanical properties of friction stir welded Al–Mg–Cr–Mn (AA 5052-O) alloy. Mater. Des. 2015, 66, 118–128. [Google Scholar] [CrossRef]

- Salloomi, K.N. Defect monitoring in dissimilar friction stir welding of aluminum alloys using Coupled Eulerian-Lagrangian (CEL) finite element model. Adv. Mater. Process. 2022, 16, 301. [Google Scholar] [CrossRef]

- West, P.; Shunmugasamy, V.C.; Usman, C.A.; Karaman, I.; Mansoor, B. Part I.: Friction stir welding of equiatomic nickel titanium shape memory alloy–microstructure, mechanical and corrosion behavior. J. Adv. Join. Process. 2021, 4, 100071. [Google Scholar] [CrossRef]

- Subramanya, P.; Amar, M.; Arun, S.; Mervin, H.; Shrikantha, R. Friction stir welding of Aluminium matrix composites–A Review. MATEC Web Conf. 2018, 144, 03002. [Google Scholar] [CrossRef][Green Version]

- Mendes, N.; Neto, P.; Loureiro, A.; Moreira, A.P. Machines and control systems for friction stir welding: A review. Mater. Des. 2016, 90, 256–265. [Google Scholar] [CrossRef]

- Sorensen, C.D.; Nelson, T.W. Friction stir welding of ferrous and nickel alloys. Frict. Stir Weld. Process. 2007, 44073, 111–121. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Prabhu, R.S.B.; Shettigar, A.K.; Patel, G.C.M.; Herbert, M.; Rao, S.S. Influence of process variables on joint attributes of friction stir welded aluminium matrix composite. Adv. Mater. Process. 2022, 8, 1550–1559. [Google Scholar] [CrossRef]

- Shettigar, A.K.; Salian, G.; Herbert, M.; Rao, S. Microstructural characterization and hardness evaluation of friction stir welded composite AA6061-4.5 Cu-5SiC (Wt.%). Def. Sci. J. 2013, 63, 429. [Google Scholar] [CrossRef]

- Fernandez, G.J.; Murr, L.E. Characterization of tool wear and weld optimization in the friction-stir welding of cast aluminum 359 + 20% SiC metal-matrix composite. Mater. Charact. 2004, 52, 65–75. [Google Scholar] [CrossRef]

- Feng, A.H.; Xiao, B.L.; Ma, Z.Y. Effect of microstructural evolution on mechanical properties of friction stir welded AA2009/SiCp composite. Compos. Sci. Technol. 2008, 68, 2141–2148. [Google Scholar] [CrossRef]

- Patthi, U.B.; Awang, M. Friction stir welding on aluminum 6092/sic/25p/t6 metal matrix composite: Its microstructure evolution and mechanical properties. In Proceedings of the 2011 National Postgraduate Conference, Perak, Malaysia, 19–20 September 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Cioffi, F.; Fernández, R.; Gesto, D.; Rey, P.; Verdera, D.; González-Doncel, G. Friction stir welding of thick plates of aluminum alloy matrix composite with a high-volume fraction of ceramicreinforcement. Compos.-A Appl. 2013, 54, 117–123. [Google Scholar] [CrossRef]

- Kalaiselvan, K.; Dinaharan, I.; Murugan, N. Characterization of friction stir welded boron carbide particulate reinforced AA6061 aluminum alloy stir cast composite. Mater. Des. 2014, 55, 176–182. [Google Scholar] [CrossRef]

- Bahrami, M.; Dehghani, K.; Givi, M.K.B. A novel approach to develop aluminum matrix nano-composite employing friction stir welding technique. Mater. Des. 2014, 53, 217–225. [Google Scholar] [CrossRef]

- Aonuma, M.; Nakata, K. Dissimilar metal joining of 2024 and 7075 aluminium alloys to titanium alloys by friction stir welding. Mater. Trans. 2011, 52, 948–952. [Google Scholar] [CrossRef]

- Nguyen, Q.M.; Do, T.V.; Nguyen, V.N. A study on the microstructure, mechanical properties, and corrosion behavior for friction stir welded Ti-6Al-4V alloys. Int. J. Mech. Eng. Robot. Res. 2021, 10, 163e8. [Google Scholar] [CrossRef]

- Han, Y.; Chen, S.; Jiang, X.; Bai, Y.; Yuan, T.; Wang, X. Effect of microstructure, texture and deformation behavior on tensile properties of electrically assisted friction stir welded Ti-6Al-4 V joints. Mater. Charact. 2021, 176, 111141. [Google Scholar] [CrossRef]

- Eliseev, A.; Amirov, A.; Kalashnikova, T.; Vorontsov, A.; Kolubaev, E. Production of Ti–1.5 Al–1Mn Titanium Alloy Butt Joints by Friction Stir Welding. Metals 2021, 11, 1566. [Google Scholar] [CrossRef]

- Liu, H.J.; Zhou, L.; Liu, Q.W. Microstructural characteristics and mechanical properties of friction stir welded joints of Ti–6Al–4V titanium alloy. Mater. Des. 2010, 31, 1650–1655. [Google Scholar] [CrossRef]

- Su, Y.; Li, W.; Gao, F.; Vairis, A. Effect of FSW process on anisotropic of titanium alloy T-joint. Mater. Manuf. 2022, 37, 25–33. [Google Scholar] [CrossRef]

- Wang, W.; Han, P.; Qiao, K.; Li, T.; Wang, K.; Cai, J.; Wang, L. Effect of the rotation rate on the low-cycle fatigue behavior of friction-stir welded AZ31 magnesium alloy. Eng. Fract. Mech. 2020, 228, 106925. [Google Scholar] [CrossRef]

- Padmanaban, G.; Balasubramanian, V. Selection of FSW tool pin profile, shoulder diameter and material for joining AZ31B magnesium alloy–an experimental approach. Mater. Des. 2009, 30, 2647–2656. [Google Scholar] [CrossRef]

- Xunhong, W.; Kuaishe, W. Microstructure and properties of friction stir butt-welded AZ31 magnesium alloy. Mater. Sci. Eng. A 2006, 431, 114–117. [Google Scholar] [CrossRef]

- Sevvel, P.; Jaiganesh, V. Influence of the arrangement of materials and microstructural analysis during FSW of AZ80A & AZ91C Mg alloys. Arch. Met. Mater. 2017, 62, 1795–1801. [Google Scholar] [CrossRef]

- Yang, J.; Wang, D.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. Effects of rotation rates on microstructure, mechanical properties, and fracture behavior of friction stir-welded (FSW) AZ31 magnesium alloy. Met. Mater. Trans. 2013, 44, 517–530. [Google Scholar] [CrossRef]

- Tan, C.; Jiang, Z.; Li, L.; Chen, Y.; Chen, X. Microstructural evolution and mechanical properties of dissimilar Al–Cu joints produced by friction stir welding. Mater. Des. 2013, 51, 466–473. [Google Scholar] [CrossRef]

- Dias, F.; Cipriano, G.; Correia, A.N.; Braga, D.F.O.; Moreira, P.; Infante, V. Joining of Aluminum Alloy AA7075 and Titanium Alloy Ti-6Al-4V through a Friction Stir Welding-Based Process. Metals 2023, 13, 249. [Google Scholar] [CrossRef]

- Correia, A.N.; Santos, P.A.; Braga, D.F.; Cipriano, G.P.; Moreira, P.M.; Infante, V. Effects of processing temperature on failure mechanisms of dissimilar aluminum-to-polymer joints produced by friction stir welding. Eng. Fail. Anal. 2023, 146, 107155. [Google Scholar] [CrossRef]

- Mustafa, S.E.; Rai, R.N.; Firoz, R. Enhancement of joint properties and reduction of intermetallics in FSW of highly dissimilar Al/Ti alloys. Weld. World 2023, 67, 1393–1410. [Google Scholar] [CrossRef]

- Newishy, M.; Jaskari, M.; Järvenpää, A.; Fujii, H.; Abdel-Aleem, H.A. Friction Stir Welding of Dissimilar Al 6061-T6 to AISI 316 Stainless Steel: Microstructure and Mechanical Properties. Materials 2023, 16, 4085. [Google Scholar] [CrossRef] [PubMed]

- Torabi, K.; Beygi, R.; Eisaabadi Bozchaloei, G.; da Silva, L.F.M. The Effect of Tool Rotation Speed on the Formation of Eutectic Structure during Friction Stir Welding of Aluminum to Magnesium. Appl. Sci. 2023, 13, 7133. [Google Scholar] [CrossRef]

- Tang, J.; Shi, L.; Wu, C.; Wu, M. Development of novel double-side friction stir Z shape butt-lap welding process for dissimilar joining of 12 mm medium-thick Al/Cu plates. Mater. Lett. 2023, 331, 133445. [Google Scholar] [CrossRef]

- Elmetwally, H.T.; Abdelhafiz, M.A.; El-Sheikh, M.N.; Abdullah, M.E. Effect of Friction Stir-Welding Tool Pin Geometry on the Characteristics of Al-Cu Joints. Appl. Eng. Lett. 2023, 8, 60–69. [Google Scholar] [CrossRef]

- Hu, J.; Cao, F.; Shen, Y.; Guo, C.; Yang, Z. Superior strength and ductility in friction stir welded dissimilar joint of galvanized steel and Q235 steel. CIRP J. Manuf. Sci. Technol. 2023, 45, 190–199. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Chen, X.; Li, Z.; Huang, G.; Pan, F. Improving joint performance of friction stir welded AZ31/ AM60 dissimilar Mg alloys by double-sided welding. Mater. Sci. Eng. A 2023, 882, 145444. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Maheshwari, S.; Noor Siddiquee, A.; Kundra, T.K. A review on recent progress in solid state friction-based metal additive manufacturing: Friction stir additive techniques. Crit. Rev. Solid State Mater. Sci. 2019, 44, 345–377. [Google Scholar] [CrossRef]

- Khusainov, R.M.; Sabirov, A.R.; Mubarakshin, I.I. Study of deformations field in the working zone of vertical milling machine. Procedia Eng. 2017, 206, 1069–1074. [Google Scholar] [CrossRef]

- Zhao, J.; Duan, Y.; Xie, B.; Zhang, Z. FSW robot system dimensional optimization and trajectory planning based on soft stiffness indices. J. Manuf. Process. 2021, 63, 88–97. [Google Scholar] [CrossRef]

- Yang, X.S. Optimization and metaheuristic algorithms in engineering. In Metaheuristics in Water, Geotechnical and Transport Engineering; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–23. [Google Scholar] [CrossRef]

- Modi, V.K.; Desai, D.A. Review of Taguchi Method, Design of Experiment (DOE) & Analysis Of Variance (ANOVA) For Quality Improvements through Optimization in Foundry. J. Emerg. Technol. Innov. Res. 2018, 5, 184–194. Available online: https://www.jetir.org/papers/JETIR1801035.pdf (accessed on 4 January 2023).

- Jagdev, H.S.; Browne, J.; Keogh, J. Manufacturing Process Optimisation—A Survey of Techniques. In Proceedings of the Twenty-Eighth International: Matador Conference, Macmillan Education, Manchester, UK, 18–19 April 1990; pp. 205–215. [Google Scholar] [CrossRef]

- Korgal, A.; Upadhyaya, S.; Anilkumar, T. Grain refinement of aluminium 4032 alloy with the impact of vibration using Taguchi technique and analysis of variance (ANOVA). Mater. Today Proc. 2022, 54, 507–512. [Google Scholar] [CrossRef]

- Chauhan, A.; Kumar, S. Optimization of Friction Stir Welding Parameters for Similar Base Material Combinations. In Advances in Engineering Materials: Select Proceedings of FLAME; Springer: Berlin/Heidelberg, Germany, 2021; pp. 665–675. [Google Scholar] [CrossRef]

- Krishna, G.G. Improving joint strength of the friction stir welding of dissimilar aluminium alloy by using coating technique. Sādhanā 2022, 47, 7. [Google Scholar] [CrossRef]

- Ismail, A.; Zulkipli, F.N.; Awang, M.; Ab Rahman, F.; Khalid, P.Z.M.; Baharudin, B.A. Optimum Welding Parameters for Friction Stir Welded AA6063 Pipe Butt Joint Using the Taguchi Method. Trans. Marit. Sci. 2021, 10, 404–413. [Google Scholar] [CrossRef]

- Tutum, C.C.; Hattel, J.H. Optimisation of process parameters in friction stir welding based on residual stress analysis: A feasibility study. Sci. Technol. Weld. Join. 2010, 15, 369–377. [Google Scholar] [CrossRef]

- Panwar, R.; Chandna, P. Parameter optimization of FSW aviation-grade AA8090 using Taguchi grey relational analysis. Aircr. Eng. Aerosp. Technol. 2023, 95, 715–724. [Google Scholar] [CrossRef]

- Seshu Kumar, G.S.V.; Kumar, A.; Rajesh, S.; Chekuri, R.B.R.; Ramakotaiah, K. An experimental study and parameter optimization of FSW for welding dissimilar 6061 and 7075 Al alloys. Int. J. Interact. Des. Manuf. 2023, 17, 215–223. [Google Scholar] [CrossRef]

- Delir Nazarlou, R.; Arghavanian, R.; Omidbakhsh, F. The effect of pin shape on the corrosion behaviour of friction stir welded 1080 aluminium alloy. Adv. Mater. Process. 2023, 9, 507–518. [Google Scholar] [CrossRef]

- El-Zathry, N.E.; Hassan, A.I.; El-Betar, A.A.; Sabry, I. Optimization of friction stir welding AA6082-T6 parameters using analysis of variance and grey relational analysis. J. Phys. Conf. Ser. 2022, 2299, 012015. [Google Scholar] [CrossRef]

- Sefene, E.M.; Tsegaw, A.A. Temperature-based optimization of friction stir welding of AA 6061 using GRA synchronous with Taguchi method. Int. J. Adv. Manuf. Technol. 2022, 119, 1479–1490. [Google Scholar] [CrossRef]

- Ubaid, M.; Bajaj, D.; Mukhopadhyay, A.K.; Siddiquee, A.N. Friction stir welding of thick AA2519 alloy: Defect elimination, mechanical and micro-structural characterization. Met. Mater. Int. 2020, 26, 1841–1860. [Google Scholar] [CrossRef]

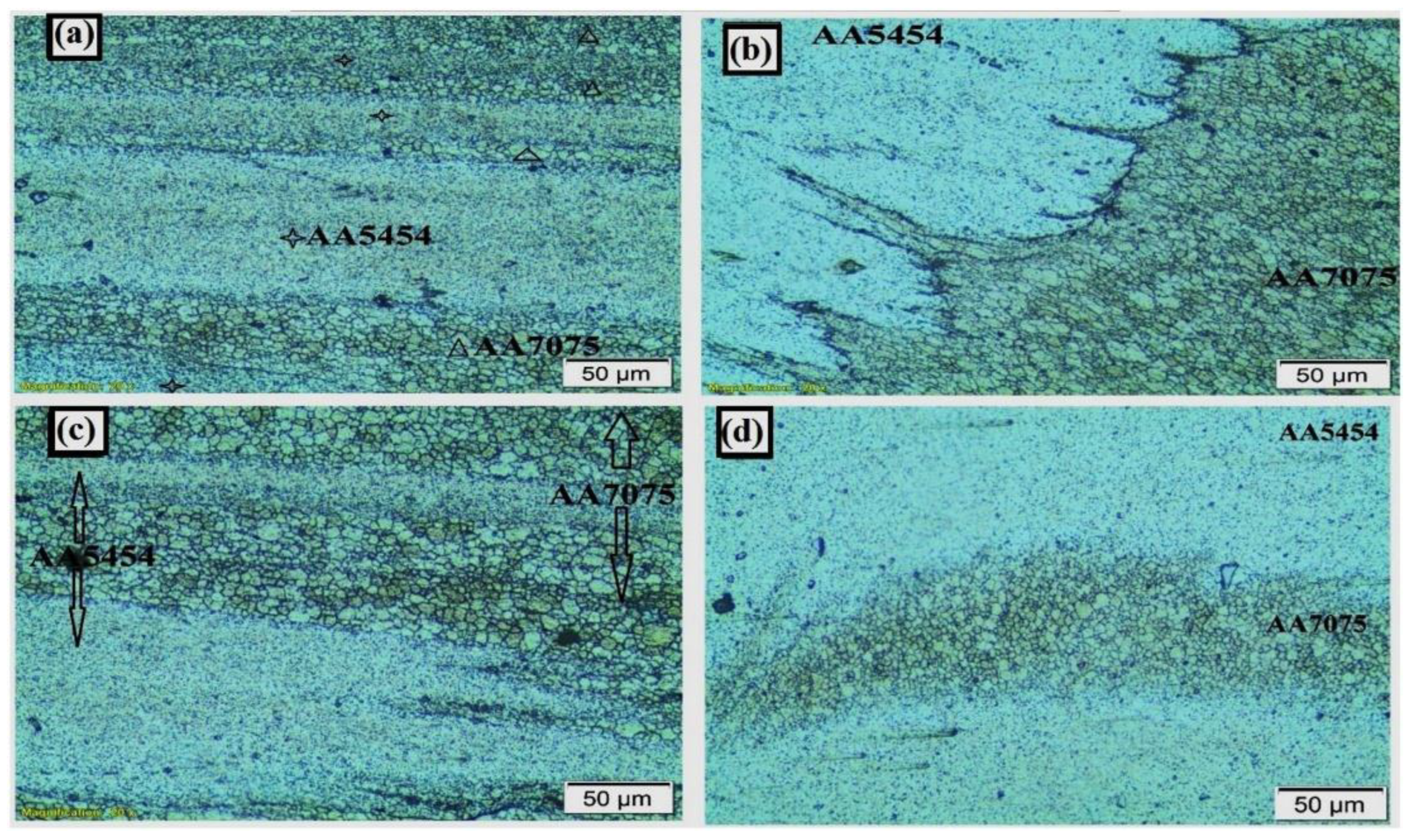

- Abd Elnabi, M.M.; Abdel-Mottaleb, M.M.; Osman, T.A.; El Mokadem, A. Influence of friction stir welding parameters on metallurgical and mechanical properties of dissimilar AA5454–AA7075 aluminum alloys. J. Mater. Res. Technol. 2019, 8, 1684–1693. [Google Scholar] [CrossRef]

- Vijayan, S.; Raju, R.; Subbaiah, K.; Sridhar, N.; Rao, S.R.K. Friction stir welding of Al–Mg alloy optimization of process parameters using Taguchi method. Exp. Tech. 2010, 34, 37–44. [Google Scholar] [CrossRef]

- Prasad, M.D.; Kumar Namala, K. Process parameters optimization in friction stir welding by ANOVA. Mater. Today Proc. 2018, 5, 4824–4831. [Google Scholar] [CrossRef]

- Khalkhali, A.; Sarmadi, M.; Sarikhani, E. Investigation on the best process criteria for lap joint friction stir welding of AA1100 aluminum alloy via Taguchi technique and ANOVA. Proc. Inst. Mech. Eng. 2017, 231, 329–342. [Google Scholar] [CrossRef]

- Kumar, G.S.V.S.; Kumar, A.; Rajesh, S.; Chekuri, R.B.R.; Sundaramurthy, V.P. Experimental and thermal investigation with optimization on friction stir welding of nylon 6A using Taguchi and microstructural analysis. Adv. Mech. Eng. 2021, 13, 16878140211050737. [Google Scholar] [CrossRef]

- Arof, S.; Diyanah, N.; Yaakop, N.; Mawby, P.; Arof, H. Advanced Engineering for Processes and Technologies. AIP Conf. Proc. 2019, 2195, 020032. [Google Scholar] [CrossRef]

- Balamurugan, S.; Jayakumar, K.; Subbaiah, K. Influence of friction stir welding parameters on dissimilar joints AA6061-T6 and AA5052-H32. Arab. J. Sci. Eng. 2021, 46, 11985–11998. [Google Scholar] [CrossRef]

- El-Wazery, M.S.; Mabrouk, O.M.; El Sissy, A.R. Optimization of ultrasonic-assisted friction stir welded using taguchi approach. Int. J. Eng. 2022, 35, 213–219. [Google Scholar] [CrossRef]

- Mahesha, C.R.; Suprabha, R.; Kumar, N.M.; Kosanam, K.; Anandaram, H.; Naidu, S.R.M.; Chakravarthi, M.K.; Govindarajan, V. Effect of Friction Stir Welding on the Mechanical and Microstructural Behaviour of AA7075 Aluminium Alloy. Adv. Mater. Sci. Eng. 2022, 2022, 2788479. [Google Scholar] [CrossRef]

- Kumar, R.R.; Singh, A.; Kumar, A.; Ansu, A.K.; Kumar, A.; Kumar, S.; Chakravarthi, M.K.; Singh, D. Enhancement of friction stir welding characteristics of alloy AA6061 by design of experiment methodology. Int. J. Interact. Des. Manuf. 2022, 16, 1–13. [Google Scholar] [CrossRef]

- Madhusudan, M.; Shanmuganatan, S.P.; Kurse, S. Optimization of Wear Parameters on Friction Stir Welded Dissimilar Aluminium Joints. J. Inst. Eng. (India) Ser. D 2022, 103, 1–16. [Google Scholar] [CrossRef]

- Vijayakumar, S.; Manickam, S.; Seetharaman, S.; Rao, T.; Pounraj, D.; Pydi, H.P. Examination of friction stir-welded AA 6262/5456 joints through the optimization technique. Adv. Mater. Sci. Eng. 2022, 2022, 4527595. [Google Scholar] [CrossRef]

- Muthurasu, P.; Kathiresan, M. Optimization and analysis of microstructural friction stir welded AA5083 grade aluminium alloy. J. Ceram. Process. Res. 2021, 22, 697–704. [Google Scholar] [CrossRef]

- Sivasubramaniam, S.; Ramanathan, T.; Shanmugham, N.; Sekar, K. Investigation of Welding Process Parameters in Friction Stir Welding of AA1100 Alloy Using Taguchi Technique. Chiang Mai J. Sci. 2022, 49, 1416–1427. [Google Scholar] [CrossRef]

- Ahmed, M.M.; Touileb, K.; El-Sayed Seleman, M.M.; Albaijan, I.; Habba, M.I. Bobbin Tool Friction Stir Welding of Aluminum: Parameters Optimization Using Taguchi Experimental Design. Materials 2022, 15, 2771. [Google Scholar] [CrossRef]

- Alam, M.P.; Sinha, A.N. Optimization of process parameters of friction stir welding using desirabilityfunction analysis. Weld. Int. 2022, 36, 129–143. [Google Scholar] [CrossRef]

- Raja, R.; Parthiban, A.; Nandha Gopan, S.; Degefa, D. Investigate the process parameter on the friction stir welding of dissimilar aluminium alloys. Adv. Mater. Sci. Eng. 2022, 2022, 4980291. [Google Scholar] [CrossRef]

- Sasikala, G.; Jothiprakash, V.M.; Pant, B.; Subalakshmi, R.; Thirumal Azhagan, M.; Arul, K.; Praveen Kumar, S. Optimization of process parameters for friction stir welding of different aluminum alloys AA2618 to AA5086 by Taguchi method. Adv. Mater. Sci. Eng. 2022, 2022, 3808605. [Google Scholar] [CrossRef]

- Thirumalai, R.; Karthick, S.; Giriraj, M. Microstructural analysis and optimization of welding parameters for AA1100 welded plates. J. Ceram. Process. Res. 2022, 23, 221–227. [Google Scholar] [CrossRef]

- Zhou, L.; Luo, L.Y.; Wang, R.; Zhang, J.B.; Huang, Y.X.; Song, X.G. Process parameter optimization in refill friction spot welding of 6061 aluminum alloys using response surface methodology. J. Mater. Eng. Perform. 2018, 27, 4050–4058. [Google Scholar] [CrossRef]

- Patel, G.C.M.; Krishna, P.; Parappagoudar, M.B. Squeeze casting process modeling by a conventional statistical regression analysis approach. Appl. Math. Model. 2016, 40, 6869–6888. [Google Scholar] [CrossRef]

- Patel, G.C.M.; Shettigar, A.K.; Parappagoudar, M.B. A systematic approach to model and optimize wear behaviour of castings produced by squeeze casting process. J. Manuf. Process. 2018, 32, 199–212. [Google Scholar] [CrossRef]

- Mallieswaran, K.; Padmanabhan, R.; Balasubramanian, V. Friction stir welding parameters optimization for tailored welded blank sheets of AA1100 with AA6061 dissimilar alloy using response surface methodology. Adv. Mater. Process. 2018, 4, 142–157. [Google Scholar] [CrossRef]

- Vignesh, S.; Dinesh Babu, P.; Nalla Mohamed, M.; Martin Vinoth, S.; Surya, G.; Dinesh, S. Investigation on the process parameters of double-sided friction stir welded AA6082-T 6 joints with different tool pins using response surface methodology. In Advances in Manufacturing Processes: Select Proceedings of ICEMMM 2018; Springer: Singapore, 2019; pp. 309–319. ISBN 978-981-13-1723-1. [Google Scholar]

- Akhai, S.; Srivastava, P.; Sharma, V.; Bhatia, A. Investigating weld strength of AA8011-6062 alloys joined via friction-stir welding using the RSM approach. J. Phys. Conf. Ser. 2021, 1950, 012016. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Chen, Q.D.; Jean, M.D. Optimization of the welding properties of friction stir weld butt joints using the response surface method based on taguchi’s design. Strength Mater. 2022, 54, 267–280. [Google Scholar] [CrossRef]

- Phanphet, S.; Sukprasert, N.; Wangmai, A.; Bangphan, S.; Bangphan, P. Application of factorial design to study the effect of moisture and rice of varieties on the production of Paddy Husker Machine. In Proceedings of the World Congress on Engineering, London, UK, 4–6 July 2018; Volume 2. [Google Scholar] [CrossRef]

- Medhi, T.; Hussain, S.A.I.; Roy, B.S.; Saha, S.C. An intelligent multi-objective framework for optimizing friction-stir welding process parameters. Appl. Soft Comput. 2021, 104, 107190. [Google Scholar] [CrossRef]

- Anand, R.; Sridhar, V.G. Microstructure and mechanical properties of interlock friction stir weld lap joint AA7475-T7 using fractional factorial design. Proc. Inst. Mech. Eng. Part C 2022, 236, 318–329. [Google Scholar] [CrossRef]

- Senapati, P.N.; Bhoi, R.K. Characterization of Friction-Stir Welded Joints of AA1100 by Factorial Design Based Hierarchical Regression Model. Ann. Chim. Sci. Mater. 2020, 44, 271–280. [Google Scholar] [CrossRef]

- Sahu, S.K.; Mishra, D.; Pal, K.; Pal, S.K. Multi-sensor-based strategies for accurate prediction of friction stir welding of polycarbonate sheets. Proc. Inst. Mech. Eng. Part C 2021, 235, 3252–3272. [Google Scholar] [CrossRef]

- Bector, K.; Tripathi, A.; Pandey, D.; Butola, R.; Singari, R.M. A review on the fabrication of surface composites via friction stir processing and its modeling using ANN. In Advances in Manufacturing and Industrial Engineering: Select Proceedings of ICAPIE 2019; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–11. [Google Scholar] [CrossRef]

- Patel, G.C.M.; Shettigar, A.K.; Krishna, P.; Parappagoudar, M.B. Back propagation genetic and recurrent neural network applications in modelling and analysis of squeeze casting process. Appl. Soft Comput. 2017, 59, 418–437. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks: A Comprehensive Foundation; Prentice Hall: Hoboken, NJ, USA, 1998. [Google Scholar]

- Patel, G.C.M.; Krishna, P.; Parappagoudar, M.B. An intelligent system for squeeze casting process—Soft computing-based approach. Int. J. Adv. Manuf. Technol. 2016, 86, 3051–3065. [Google Scholar]

- Shojaeefard, M.H.; Akbari, M.; Asadi, P. Multi-objective optimization of friction stir welding parameters using FEM and neural network. Int. J. Precis. Eng. Manuf. 2014, 15, 2351–2356. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Behnagh, R.A.; Akbari, M.; Givi, M.K.B.; Farhani, F. Modelling and Pareto optimization of mechanical properties of friction stir welded AA7075/AA5083 butt joints using neural network and particle swarm algorithm. Mater. Des. 2013, 44, 190–198. [Google Scholar] [CrossRef]

- Salhan, P.; Singh, R.; Jain, P.; Butola, R. Prediction of heat generation and microstructure of AA7075 friction stir welding using ANN: Effect of process parameters. Manuf. Lett. 2022, 32, 5–9. [Google Scholar] [CrossRef]

- Vangalapati, M.; Balaji, K.; Gopichand, A. ANN modeling and analysis of friction welded AA6061 aluminum alloy. Mater. Today Proc. 2019, 18, 3357–3364. [Google Scholar] [CrossRef]

- Senthilnathan, T.; Balachandar, K. Prediction of mechanical properties and optimization of process parameters in friction-stir-welded dissimilar aluminium alloys. World J. Eng. 2020, 17, 519–526. [Google Scholar] [CrossRef]

- Jamalian, H.M.; Eskandar, M.T.; Chamanara, A.; Karimzadeh, R.; Yousefian, R. An artificial neural network model for multi-pass tool pin varying FSW of AA5086-H34 plates reinforced with Al2O3 nanoparticles and optimization for tool design insight. CIRP J. Manuf. Sci. Technol. 2021, 35, 69–79. [Google Scholar] [CrossRef]

- D’Orazio, A.; Forcellese, A.; Simoncini, M. Prediction of the vertical force during FSW of AZ31 magnesium alloy sheets using an artificial neural network-based model. Neural. Comput. Appl. 2019, 31, 7211–7226. [Google Scholar] [CrossRef]

- Maleki, E. Artificial neural networks application for modeling of friction stir welding effects on mechanical properties of 7075-T6 aluminum alloy. IOP Conf. Ser. Mater. Sci. Eng. 2015, 103, 012034. [Google Scholar] [CrossRef]

- Ghetiya, N.D.; Patel, K.M. Prediction of tensile strength in friction stir welded aluminium alloy using artificial neural network. Proc. Technol. 2014, 14, 274–281. [Google Scholar] [CrossRef]

- Okuyucu, H.; Kurt, A.; Arcaklioglu, E. Artificial neural network application to the friction stir welding of aluminum plates. Mater. Des. 2007, 28, 78–84. [Google Scholar] [CrossRef]

- Dutt, A.K.; Sindhuja, K.; Reddy, S.V.N.; Kumar, P. Application of Artificial Neural Network to Friction Stir Welding Process of AA7050 Aluminum Alloy. In Advances in Industrial Automation and Smart Manufacturing; ICAIASM; Springer: Singapore, 2019; Volume 2021, pp. 407–414. [Google Scholar] [CrossRef]

- Dehabadi, V.M.; Ghorbanpour, S.; Azimi, G. Application of artificial neural network to predict Vickers microhardness of AA6061 friction stir welded sheets. J. Cent. South Univ. 2016, 23, 2146–2155. [Google Scholar] [CrossRef]

- Darzi Naghibi, H.; Shakeri, M.; Hosseinzadeh, M. Neural network and genetic algorithm based modeling and optimization of tensile properties in FSW of AA 5052 to AISI 304 dissimilar joints. Trans. Indian Inst. Met. 2016, 69, 891–900. [Google Scholar] [CrossRef]

- Verma, S.; Misra, J.P.; Singh, J.; Batra, U.; Kumar, Y. Prediction of tensile behavior of FS welded AA7039 using machine learning. Mater. Today Commun. 2021, 26, 101933. [Google Scholar] [CrossRef]

- Thapliyal, S.; Mishra, A. Machine learning classification-based approach for mechanical properties of friction stir welding of copper. Manuf. Lett. 2021, 29, 52–55. [Google Scholar] [CrossRef]

- Singh, R.; Kainthola, A.; Singh, T.N. Estimation of elastic constant of rocks using an ANFIS approach. Appl. Soft Comput. 2012, 12, 40–45. [Google Scholar] [CrossRef]

- Monostori, L.; Márkus, A.; van Brussel, H.; Westkämpfer, E. Machine learning approaches to manufacturing. CIRP Ann. 1996, 45, 675–712. [Google Scholar] [CrossRef]

- Chadha, U.; Selvaraj, S.K.; Gunreddy, N.; Sanjay Babu, S.; Mishra, S.; Padala, D.; Adefris, A. A survey of machine learning in friction stir welding, including unresolved issues and future research directions. Mater. Des. Process. Commun. 2022, 2022, 2568347. [Google Scholar] [CrossRef]

- Mishra, A.; Dutta, S.B. Detection of surface defects in friction stir welded joints by using a novel machine learning approach. Appl. Eng. Lett. 2020, 5, 16–21. [Google Scholar] [CrossRef]

- Mukherjee, I.; Ray, P.K. A review of optimization techniques in metal cutting processes. Comput. Ind. Eng. 2006, 50, 15–34. [Google Scholar] [CrossRef]

- Rao, R.V.; Rai, D.P. Optimisation of welding processes using quasi-oppositional-based Jaya algorithm. J. Exp. Theor. Artif. Intell. 2017, 29, 1099–1117. [Google Scholar] [CrossRef]

- Rambabu, G.; Naik, D.B.; Rao, C.V.; Rao, K.S.; Reddy, G.M. Optimization of friction stir welding parameters for improved corrosion resistance of AA2219 aluminum alloy joints. Def. Technol. 2015, 11, 330–337. [Google Scholar] [CrossRef]

- Saeidi, M.; Manafi, B.; Besharati Givi, M.K.; Faraji, G. Mathematical modeling and optimization of friction stir welding process parameters in AA5083 and AA7075 aluminum alloy joints. Proc. Inst. Mech. Eng. Part B 2016, 230, 1284–1294. [Google Scholar] [CrossRef]

- Kumar, A.K.; Surya, M.S.; Venkataramaiah, P. Performance evaluation of machine learning based-classifiers in friction stir welding of Aa6061-T6 alloy. Int. J. Interact. Des. Manuf. 2023, 17, 469–472. [Google Scholar] [CrossRef]

- Anandan, B.; Manikandan, M. Machine learning approach for predicting the peak temperature of dissimilar AA7050-AA2014A friction stir welding butt joint using various regression models. Mater. Lett. 2022, 325, 132879. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Peng, W.; Tabatabaei, M.; Kalogirou, S.A.; Soltanian, S.; Hosseinzadeh-Bandbafha, H.; Lam, S.S. Machine learning technology in biodiesel research: A review. Prog. Energy Combust. Sci. 2021, 85, 100904. [Google Scholar] [CrossRef]

- Sahu, P.K.; Kumari, K.; Pal, S.; Pal, S.K. Hybrid fuzzy-grey-Taguchi based multi weld quality optimization of Al/Cu dissimilar friction stir welded joints. Adv. Manuf. 2016, 4, 237–247. [Google Scholar] [CrossRef]

- Pitchipoo, P.; Muthiah, A.; Jeyakumar, K.; Manikandan, A. Friction stir welding parameter optimization using novel multi objective dragonfly algorithm. Int. J. Light. Mater. Manuf. 2021, 4, 460–467. [Google Scholar] [CrossRef]

- Nadikudi, B.K.B. Parametric optimization of friction stir welding process parameters of dissimilar welded joints using grey relational analysis and desirability function approach. World J. Eng. 2022, 20, 609–617. [Google Scholar] [CrossRef]

- Van, A.L.; Nguyen, T.T. Optimization of friction stir welding operation using optimal taguchi-based ANFIS and genetic algorithm. Stroj. Vestn./J. Mech. Eng. 2022, 68, 424–438. [Google Scholar] [CrossRef]

- Anjinappa, C.S.; Alamri, S.; Afzal, A.; Razak Kaladgi, A.; Saleel, C.A.; Hasan, N.; Saleh, B. Response surface, neural network, and experimental approach to optimize process parameters and characterization of Al-Mg alloy by friction stir welding. Adv. Mech. Eng. 2022, 14, 16878132221120460. [Google Scholar] [CrossRef]

- Ambekar, M.; Kittur, J. Multiresponse optimization of friction stir welding process parameters by an integrated WPCA-ANN-PSO approach. Mater. Today Proc. 2020, 27, 363–368. [Google Scholar] [CrossRef]

- Wakchaure, K.N.; Thakur, A.G.; Gadakh, V.; Kumar, A. Multi-objective optimization of friction stir welding of aluminium alloy 6082-T6 Using hybrid Taguchi-Grey relation analysis-ANN method. Mater. Today Proc. 2018, 5, 7150–7159. [Google Scholar] [CrossRef]

- Al-Mahasneh, M.; Aljarrah, M.; Rababah, T.; Alu’datt, M. Application of hybrid neural fuzzy system (ANFIS) in food processing and technology. Food Eng. Rev. 2016, 8, 351–366. [Google Scholar] [CrossRef]

- Wahid, M.A.; Masood, S.; Khan, Z.A.; Siddiquee, A.N.; Badruddin, I.A.; Algahtani, A. A simulation-based study on the effect of underwater friction stir welding process parameters using different evolutionary optimization algorithms. Proc. Inst. Mech. Eng. Part C 2020, 234, 643–657. [Google Scholar] [CrossRef]

- Gopalakrishnan, R.; Kanakaraj, D.A.; Dennis, B.P.R.; Rajendran, A.R. Multi-response Optimization of FSW Process Parameters of ZE42 Alloy Using RSM-Based Grey Relational Analysis. In Intelligent Manufacturing and Energy Sustainability: Proceedings of ICIMES; Springer: Singapore, 2020; pp. 125–133. [Google Scholar] [CrossRef]

- Ghangas, G.; Singhal, S. Modelling and optimization of process parameters for friction stir welding of armor alloy using RSM and GRA-PCA approach. Mater. Res. Express 2018, 6, 026553. [Google Scholar] [CrossRef]

- Chaluvaraju, B.V.; Afzal, A.; Vinnik, D.A.; Kaladgi, A.R.; Alamri, S.; Tirth, V. Mechanical and corrosion studies of friction stir welded nano Al2O3 reinforced Al-Mg matrix composites: RSM-ANN modelling approach. Symmetry 2021, 13, 537. [Google Scholar]

- Jaypuria, S.; Mahapatra, T.R.; Jaypuria, O. Metaheuristic tuned ANFIS model for input-output modeling of friction stir welding. Mater. Today Proc. 2019, 18, 3922–3930. [Google Scholar] [CrossRef]

- Kandavalli, S.R.; Khan, A.M.; Iqbal, A.; Jamil, M.; Abbas, S.; Laghari, R.A.; Cheok, Q. Application of sophisticated sensors to advance the monitoring of machining processes: Analysis and holistic review. Int. J. Adv. Manuf. Technol. 2023, 125, 989–1014. [Google Scholar] [CrossRef]

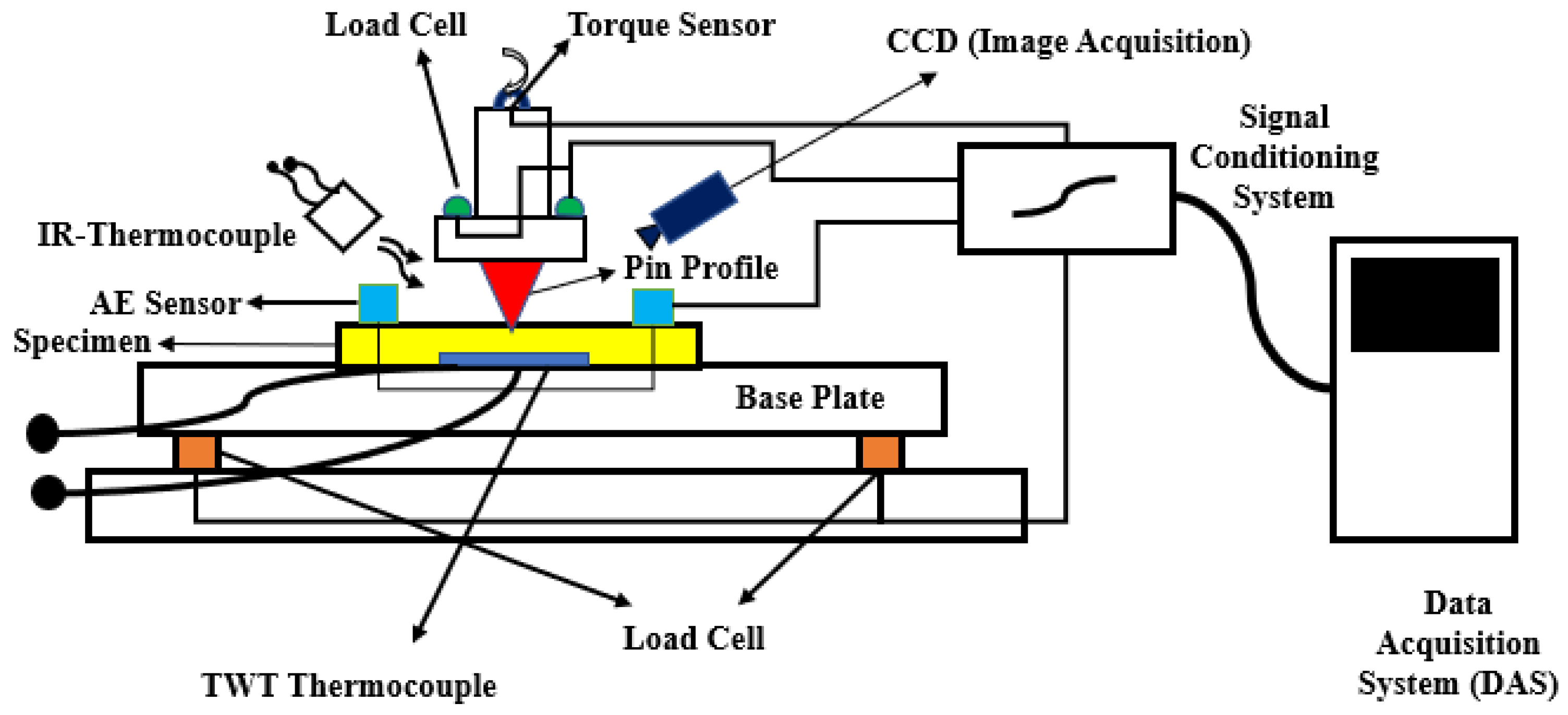

- Mishra, D.; Roy, R.B.; Dutta, S.; Pal, S.K.; Chakravarty, D. A review on sensor-based monitoring and control of friction stir welding process and a roadmap to Industry 4.0. J. Manuf. Process. 2018, 36, 373–397. [Google Scholar] [CrossRef]

- Murthy, V.; Ullegaddi, K.; Mahesh, B.; Rajaprakash, B.M. Application of image processing and acoustic emission technique in monitoring of friction stir welding process. Mater. Today Proc. 2017, 4, 9186–9195. [Google Scholar] [CrossRef]

- Balachandar, K.; Jegadeeshwaran, R.; Gandhikumar, D. Condition monitoring of FSW tool using vibration analysis–A machine learning approach. Mater. Today Proc. 2020, 27, 2970–2974. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, K.; Pandey, S. Process forces and heat input as function of process parameters in AA5083 friction stir welds. Trans. Nonferrous Met. Soc. China 2012, 22, 288–298. [Google Scholar] [CrossRef]

- Atharifar, H.; Lin, D.; Kovacevic, R. Numerical and experimental investigations on the loads carried by the tool during friction stir welding. J. Mater. Eng. Perform. 2009, 18, 339–350. [Google Scholar] [CrossRef]

- Das, B.; Pal, S.; Bag, S. Design and development of force and torque measurement setup for real time monitoring of friction stir welding process. Measurement 2017, 103, 186–198. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lammlein, D.H.; Prater, T.J.; Longhurst, W.R.; Cox, C.D.; Ballun, M.C.; Strauss, A.M. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Zuluaga-Posada, M.; Hoyos, E.; Montoya, Y. Performance evaluation of a novel force measuring device for Friction Stir Welding (FSW) of aluminum alloys. DYNA 2019, 86, 150–155. [Google Scholar] [CrossRef]

- Fleming, P.A.; Lammlein, D.H.; Wilkes, D.M.; Cook, G.E.; Strauss, A.M.; DeLapp, D.R.; Hartman, D.A. Misalignment detection and enabling of seam tracking for friction stir welding. Sci. Technol. Weld. Join. 2009, 14, 93–96. [Google Scholar] [CrossRef]

- Das, B.; Pal, S.; Bag, S. Monitoring of friction stir welding process through signals acquired during the welding. In Proceedings of the AIMTDR 2014, Guwahati, India, 12–14 December 2014; pp. 12–14. [Google Scholar]

- Kumar, U.; Yadav, I.; Kumari, S.; Kumari, K.; Ranjan, N.; Kesharwani, R.K.; Pal, S.K. Defect identification in friction stir welding using discrete wavelet analysis. Adv. Eng. Softw. 2015, 85, 43–50. [Google Scholar] [CrossRef]

- Arya, H.K.; Jaiswal, D. Parametric Study and Force Analysis of Friction Stir Welded Aa-6063 Joint. Int. J. Mech. Eng. 2022, 7, 756–768. Available online: https://kalaharijournals.com/ijme-vol7-issue-jan2022.php (accessed on 16 January 2023).

- Terra, C.S.; Silveira, J.L.L. Models for FSW forces using a square pin profile tool. J. Manuf. Process. 2021, 68, 1395–1404. [Google Scholar] [CrossRef]

- Fehrenbacher, A.; Duffie, N.A.; Ferrier, N.J.; Pfefferkorn, F.E.; Zinn, M.R. Toward automation of friction stir welding through temperature measurement and closed-loop control. J. Manuf. Sci. Eng. 2011, 133, 051008. [Google Scholar] [CrossRef]

- De Backer, J.; Bolmsjö, G.; Christiansson, A.K. Temperature control of robotic friction stir welding using the thermoelectric effect. Int. J. Adv. Manuf. Technol. 2014, 70, 375–383. [Google Scholar] [CrossRef]

- Silva, A.C.F.; de Backer, J.; Bolmsjö, G. Temperature measurements during friction stir welding. Int. J. Adv. Manuf. Technol. 2017, 88, 2899–2908. Available online: https://link.springer.com/article/10.1007%2Fs00170-016-9007-4 (accessed on 12 February 2023). [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Schmale, J.; Fehrenbacher, A.; Shrivastava, A.; Pfefferkorn, F.E. Calibration of dynamic tool–workpiece interface temperature measurement during friction stir welding. Measurement 2016, 88, 331–342. [Google Scholar] [CrossRef]

- D’Errico; Calzavarini, R.; Settineri, L. Experiments on self-tuning regulation of cutting temperature in turning process. In Proceedings of the 1994 Proceedings of IEEE International Conference on Control and Applications, Glasgow, UK, 24–26 August 1994; pp. 1165–1169. [Google Scholar] [CrossRef]

- de Backer, J.; Bolmsjö, G. Thermoelectric method for temperature measurement in friction stirwelding. Sci. Technol. Weld. Join. 2013, 18, 558–565. [Google Scholar] [CrossRef]

- Fehrenbacher, A.; Duffie, N.A.; Ferrier, N.J.; Pfefferkorn, F.E.; Zinn, M.R. Effects of tool—Workpiece interface temperature on weld quality and quality improvements through temperature control in friction stir welding. Int. J. Adv. Manuf. Technol. 2014, 71, 165–179. [Google Scholar] [CrossRef]

- Campanella, D.; Casavola, C.; Cazzato, A.; Fratini, L.; Moramarco, V.; Pappalettere, C. Residual Stress Measurement in Innovative Friction Stir Welding Processes. Key Eng. Mater. 2017, 754, 391–394. [Google Scholar] [CrossRef]

- Brauer, H.; Otterbach, J.M.; Ziolkowski, M.; Toepfer, H.; Graetzel, M.; Bergmann, J.P. Friction stir weld inspection using the motion induced eddy current testing technique. AIP Conf. Proc. 2019, 2102, 080004. [Google Scholar] [CrossRef]

- García Ruano, S.A.; Bertelli, F.; dos Santos, A.A., Jr. Evaluation of 7050 Aluminum Plates Joined by Friction Stir Welding Using Acoustoelastic. ASME Int. Mech. Eng. Congr. Expo. 2017, 58356, V002T02A089. [Google Scholar] [CrossRef]

- Sevvel, P.; Babu, S.D.; Kumar, R.S. Peak Temperature Correlation and Temperature Distribution during Joining of AZ80A Mg Alloy by FSW-A Numerical and Experimental Investigation. Stroj. Vestn./J. Mech. Eng. 2020, 66, 395–407. [Google Scholar] [CrossRef]

- da Silva, Y.C.; Oliveira Junior, F.J.; dos Santos, J.F.; Marcondes, F.; Silva, C. Numerical investigation of the influence of FSW parameters on the heat and mass transfer of austenitic stainless steels. Weld. World 2020, 64, 2019–2032. [Google Scholar] [CrossRef]

- Subramaniam, S. Acoustic emission–based monitoring approach for friction stir welding of aluminum alloy AA6063-T6 with different tool pin profiles. Proc. Inst. Mech. Eng. Part B 2013, 227, 407–416. [Google Scholar] [CrossRef]

- Soundararajan, V.; Atharifar, H.; Kovacevic, R. Monitoring and processing the acoustic emission signals from the friction-stir-welding process. Proc. Inst. Mech. Eng. Part B 2006, 220, 1673–1685. [Google Scholar] [CrossRef]

- Chen, C.; Kovacevic, R.; Jandgric, D. Wavelet transform analysis of acoustic emission in monitoring friction stir welding of 6061 aluminum. Int. J. Mach. Tools Manuf. 2003, 43, 1383–1390. [Google Scholar] [CrossRef]

- Mishra, D.; Gupta, A.; Raj, P.; Kumar, A.; Anwer, S.; Pal, S.K.; Pal, S. Sensor based real-time information for monitoring and control of a manufacturing process. Eng. Res. Express 2021, 3, 025040. [Google Scholar] [CrossRef]

- Mishra, D.; Gupta, A.; Raj, P.; Kumar, A.; Anwer, S.; Pal, S.K.; Misra, S. Real-time monitoring and control of friction stir welding process using multiple sensors. CIRP J. Manuf. Sci. Technol. 2020, 30, 1–11. [Google Scholar] [CrossRef]

- Silva-Magalhães, A.; de Backer, J.; Martin, J.; Bolmsjö, G. In-situ temperature measurement in friction stir welding of thick section aluminium alloys. J. Manuf. Process. 2019, 39, 12–17. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Bajaj, D.; Ubaid, M. Understanding the dissimilar friction stir welding through force and temperature evolution. Mater. Today Proc. 2018, 5, 17125–17131. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. 2022, 11, 40. [Google Scholar] [CrossRef] [PubMed]

- Noor-A-Rahim, M.; John, J.; Firyaguna, F.; Sherazi, H.H.R.; Kushch, S.; Vijayan, A.; Armstrong, E. Wireless communications for smart manufacturing and industrial IoT: Existing technologies, 5G and beyond. Sensors 2022, 23, 73. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Lv, L.; Li, X.; Li, H.; Leng, J.; Zhang, Y.; Thomson, V.; Liu, G.; Wen, X.; Sun, C.; et al. A safety management approach for Industry 5.0′ s human-centered manufacturing based on digital twin. J. Manuf. Syst. 2023, 66, 1–12. [Google Scholar] [CrossRef]

- del Real Torres, A.; Andreiana, D.S.; Ojeda Roldán, Á.; Hernández Bustos, A.; Acevedo Galicia, L.E. A review of deep reinforcement learning approaches for smart manufacturing in industry 4.0 and 5.0 framework. Appl. Sci. 2022, 12, 12377. [Google Scholar] [CrossRef]

- Mincă, E.; Filipescu, A.; Cernega, D.; Șolea, R.; Filipescu, A.; Ionescu, D.; Simion, G. Digital Twin for a Multifunctional Technology of Flexible Assembly on a Mechatronics Line with Integrated Robotic Systems and Mobile Visual Sensor—Challenges towards Industry 5.0. Sensors 2022, 22, 8153. [Google Scholar] [CrossRef]

- Chen, G.; Zhu, J.; Zhao, Y.; Hao, Y.; Yang, C.; Shi, Q. Digital twin modeling for temperature field during friction stir welding. J. Manuf. Process. 2021, 64, 898–906. [Google Scholar] [CrossRef]

- Roy, R.B.; Mishra, D.; Pal, S.K.; Chakravarty, T.; Panda, S.; Chandra, M.G.; Chakravarty, D.; Misra, S. Digital twin: Current scenario and a case study on a manufacturing process. Int. J. Adv. Manuf. Technol. 2020, 107, 3691–3714. [Google Scholar] [CrossRef]

| Process Parameters | The Objective of the Work | Ref. |

|---|---|---|

| L9 experiments (three levels) RS: 500,650,800 rp; TS: 115, 135, 155 mm/s; Axial load: 9, 13, 17 kN; Cylindrical tapered column threaded tool | Process optimization of Al-Mg alloy | [123] |

| L9 experiments (three levels) RS: 800, 1200, 1600 rpm; Tool tilt angle: 0°, 1°, 2°; TS: 20, 50, 80 mm/min; H13 tool steel with taper cylindrical pin profile | Process optimization of FSW of AA5083 and AA6061 | [124] |

| L16 experiments (four levels) RS: 400, 800, 1250, 1600 rpm; TS: 20, 50, 80, 125 mm/min; Pin profile: square, pentagonal, hexagonal, circular; TA: 90°, 108°, 120° and 180° tool internal angle. | Process optimization of friction stir lap welding joint parameters of AA1100 alloy | [125] |

| L27 experiments (four levels) RS: 500, 1000, 1500 rpm; Feed rate: 30, 40, 50 mm/min; Pitch: 1, 2, 3 mm; HCHCr tool with taper threaded profile | Optimizing process parameters of FSW of Nylon 6A | [126] |

| L9 experiments (three levels) RS: 910, 1280, 1700 rpm; Pin profile: square, cylindrical, triangle; Joint type: butt, stepped, and scarf | Optimizing FSW process parameters of self-supporting AA6063 pipe joints | [127] |

| L27 experiments (three levels) RS: 800, 950, 1100 rpm; TS: 30, 60, 90 mm/min; Pin profile: square, cylindrical, triangle | Process optimization of dissimilar joints of AA6061-T6 and AA5052-H32 alloy | [128] |

| L16 experiments (four levels) Vibration amplitude: 20–80µm; TS = 40–160 mm/min; RS: 630–1200 rpm | Optimizing ultrasonic-assisted FSW parameters for AA6082-T61 joints | [129] |

| L18 experiments (four levels) RS: 500, 600, 700 rpm; Axial load: 10, 15, 20 kN; Feed rate: 16, 20, 24 mm/min; Tilt angle: 0°, 1.5° | Optimizing mechanical and microstructural behavior of AA7075 | [130] |

| L16 experiments (four levels) RS: 400, 630, 1000, 1600 rpm; TS: 10, 25, 40, 63 mm/min; Tool profile: square, cylindrical, triangular, and tapered | Optimization characteristics for AA6061 alloy | [131] |