Real-Time In-Process Evaluation of Spatter Area and Depth of Aluminium Surface in a Pulsed Laser Ablation Process Using Received Radio Frequency Power from Plasma Plumes

Abstract

1. Introduction

2. Materials and Methods

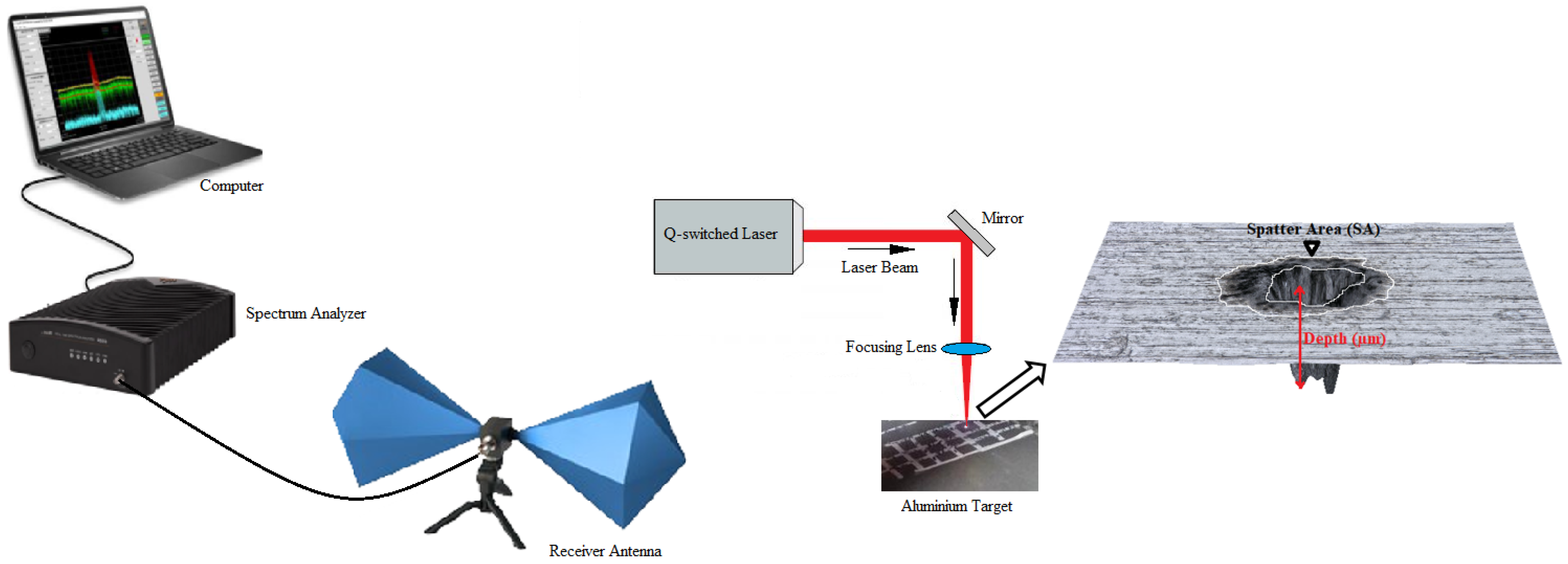

2.1. Experimental Setup and Materials

2.2. Experimental Procedure

2.3. Data Collecting and Analysis Method

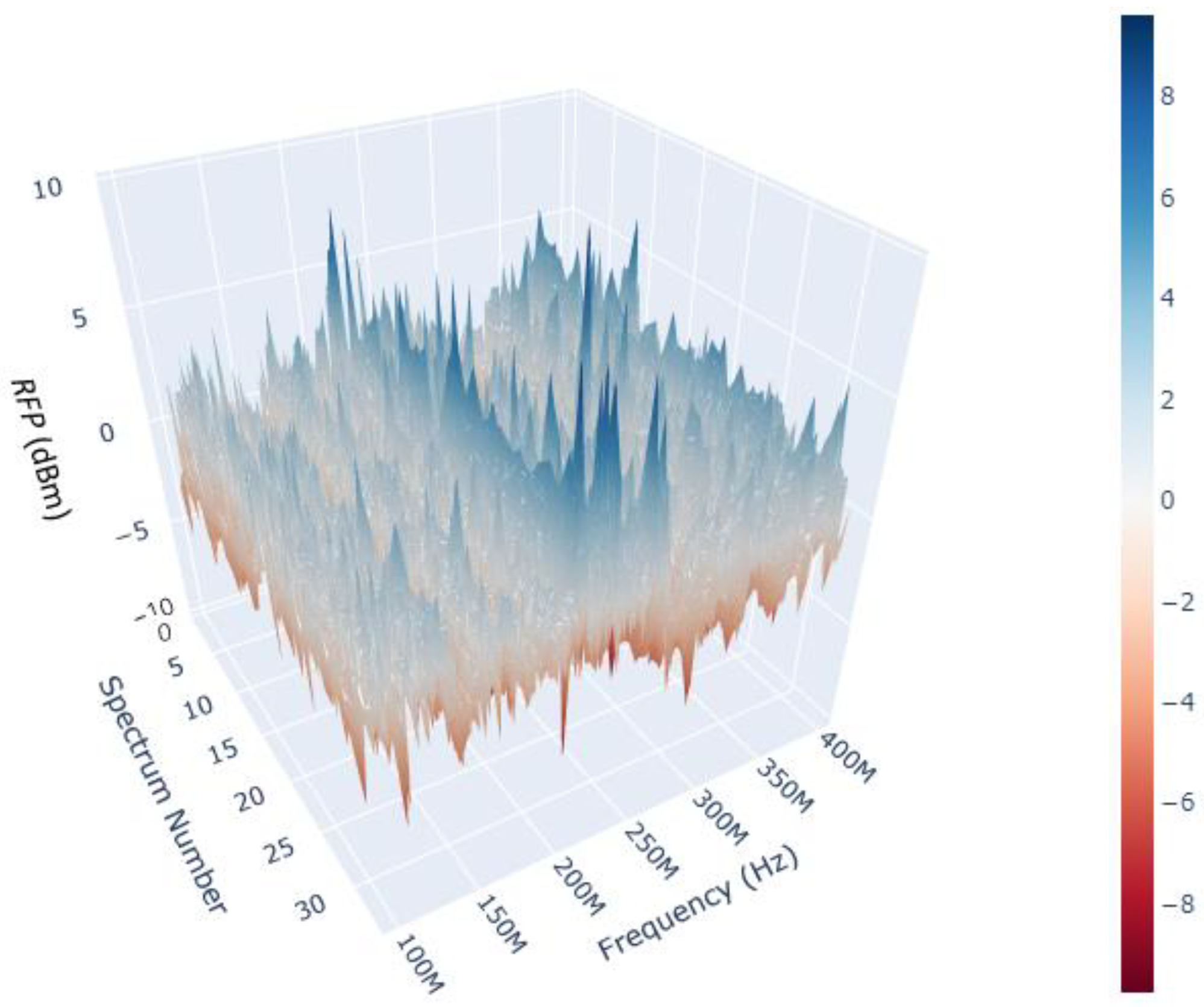

2.3.1. RF Spectra (In-Process) and Spectral Processing

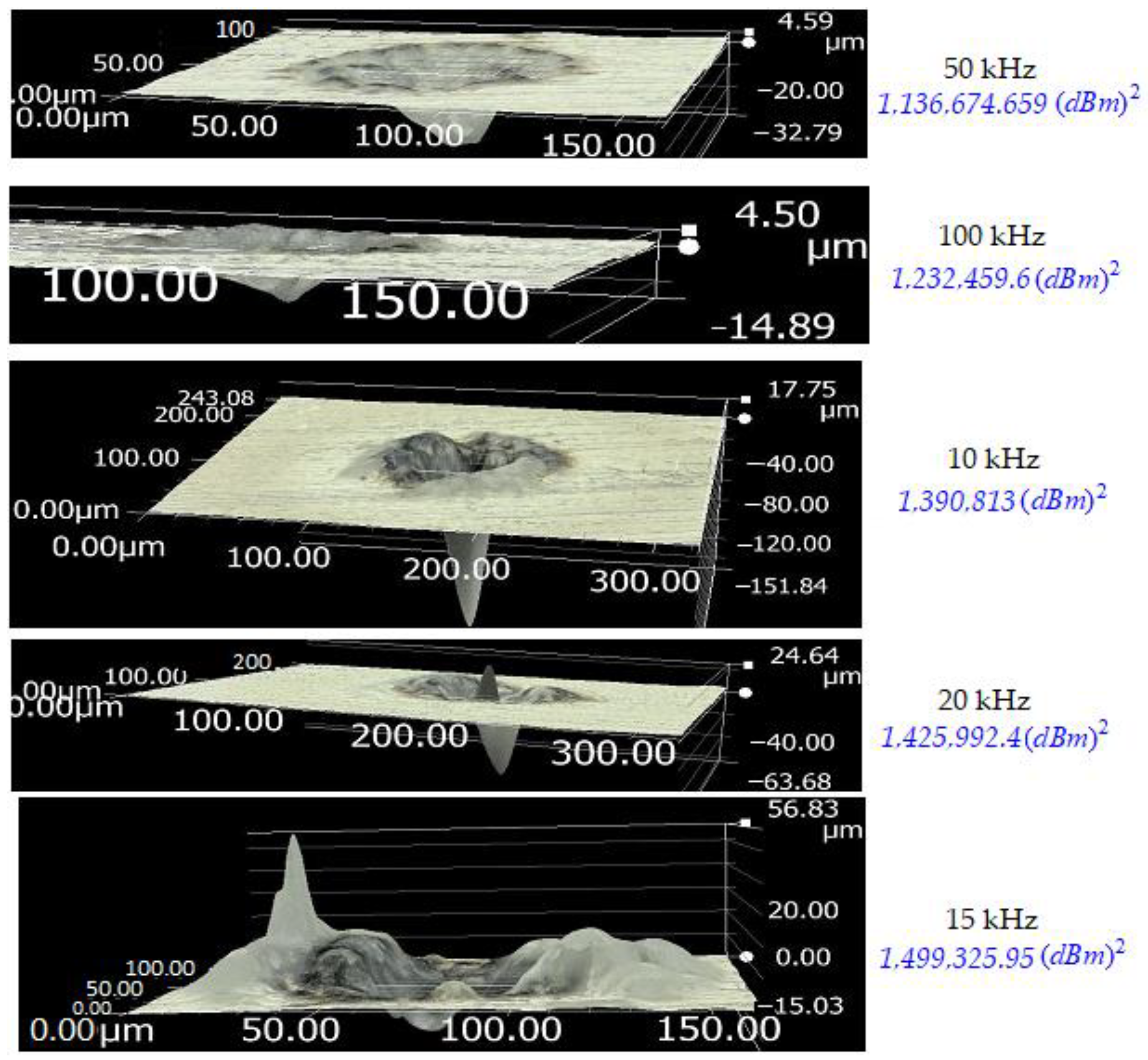

2.3.2. 3D Microscope (Post-Process)

3. Results and Discussion

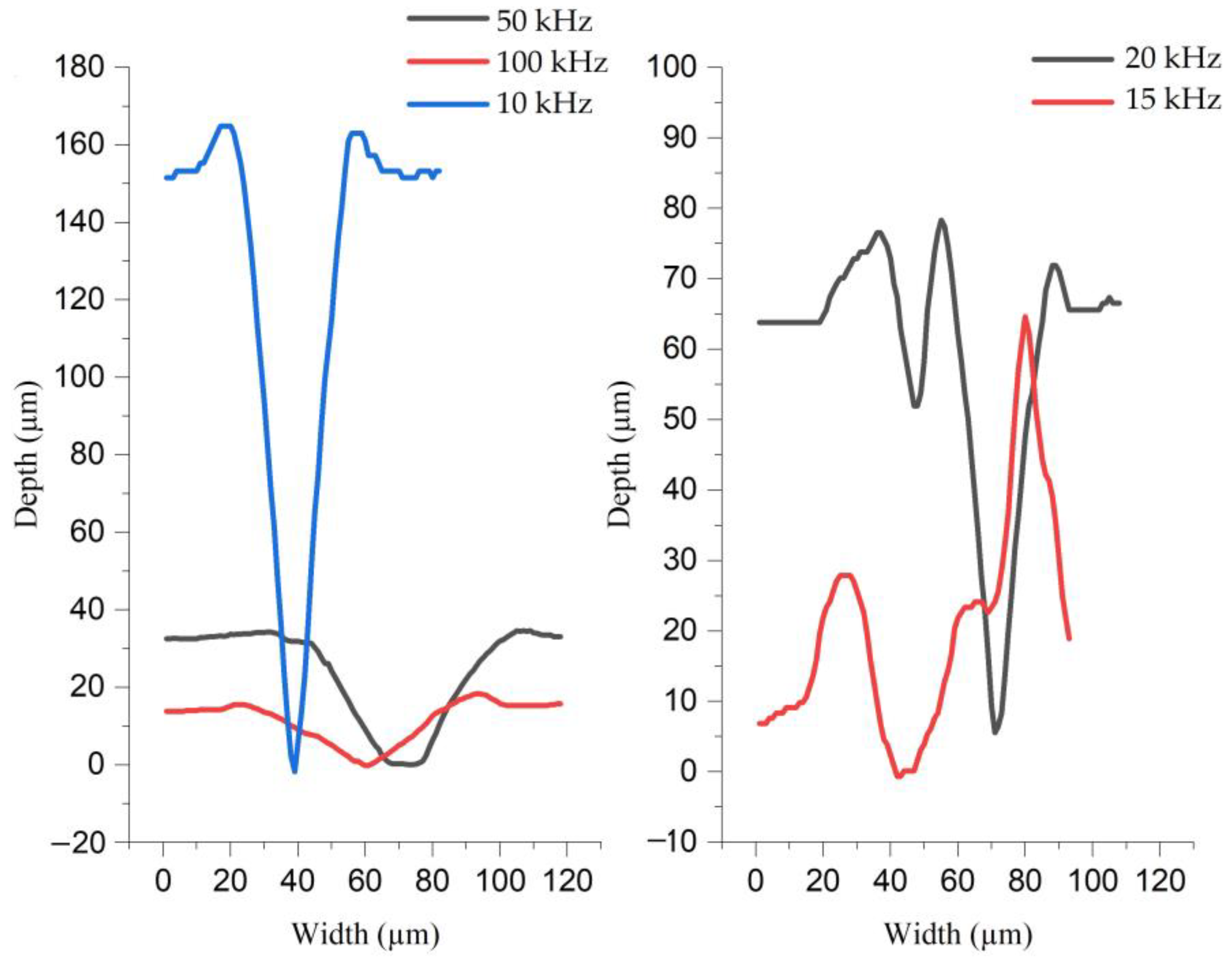

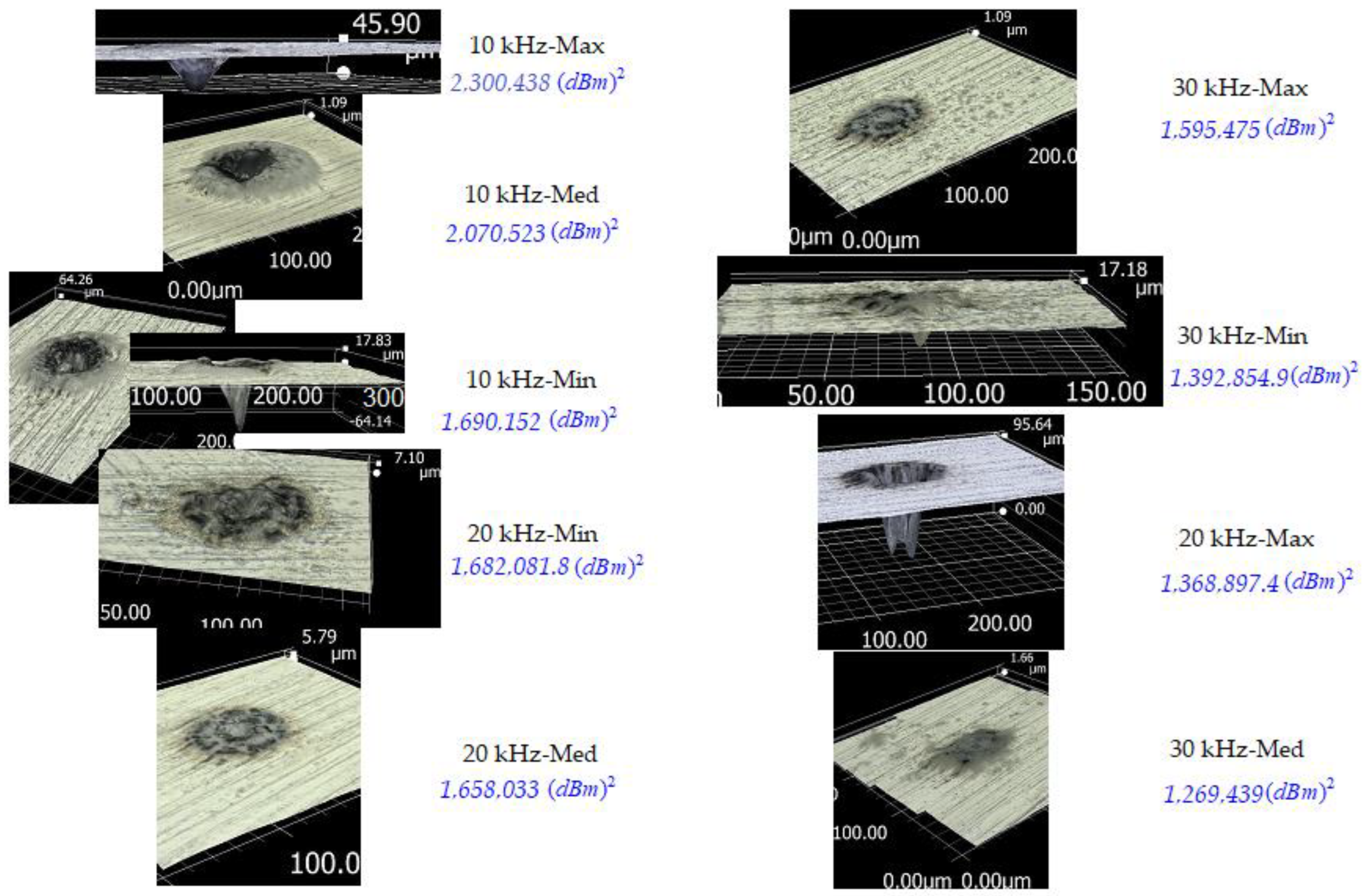

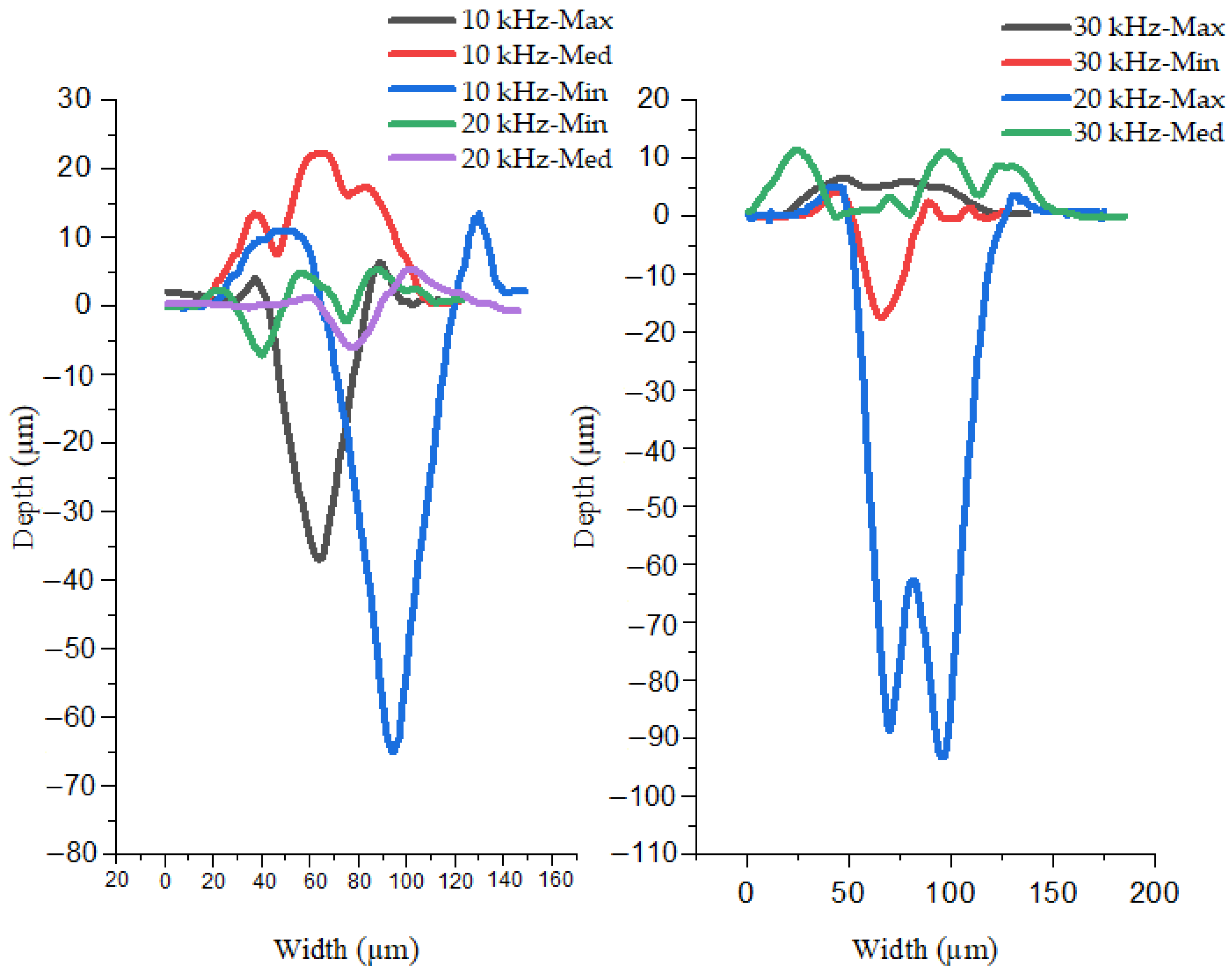

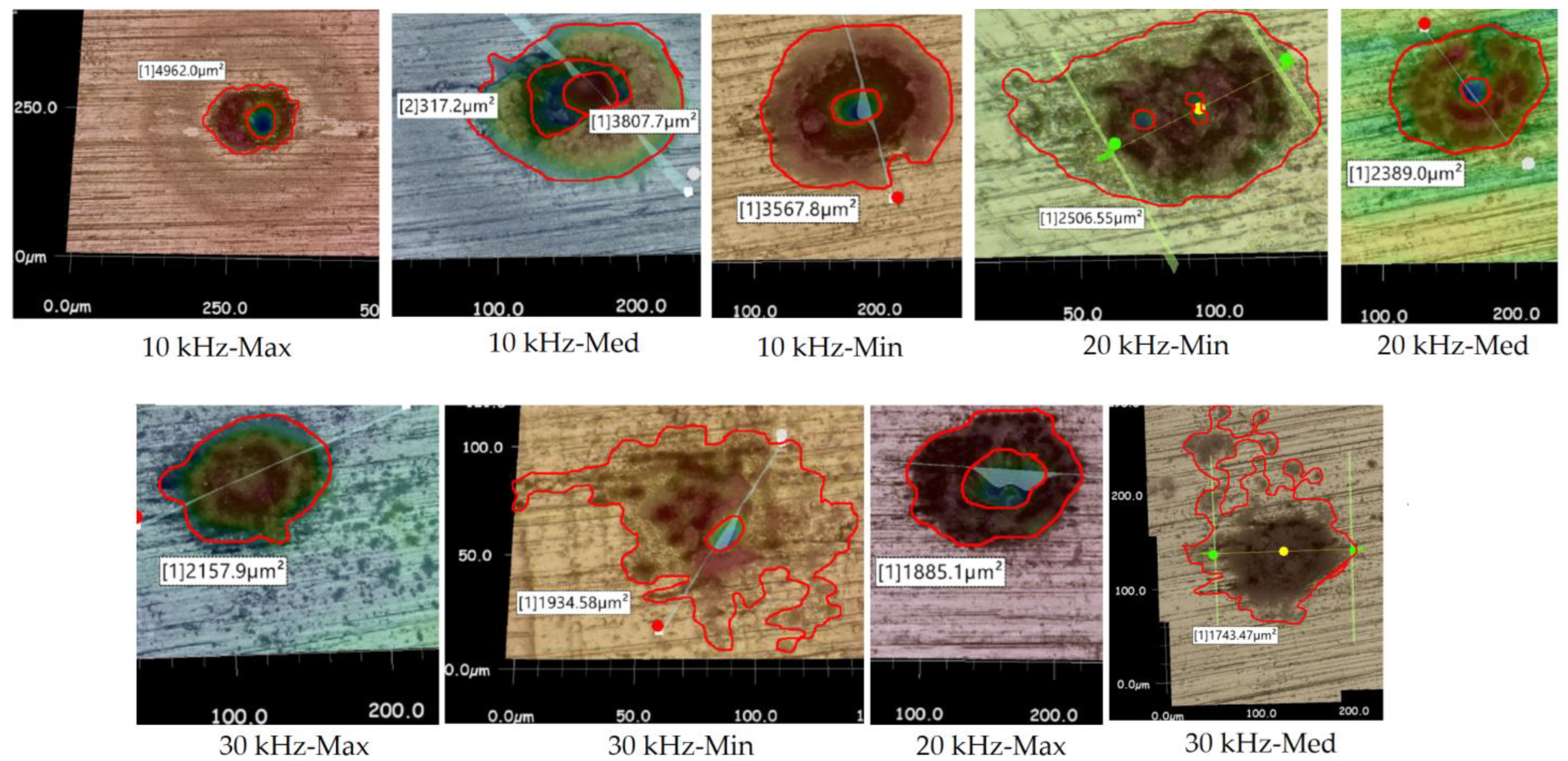

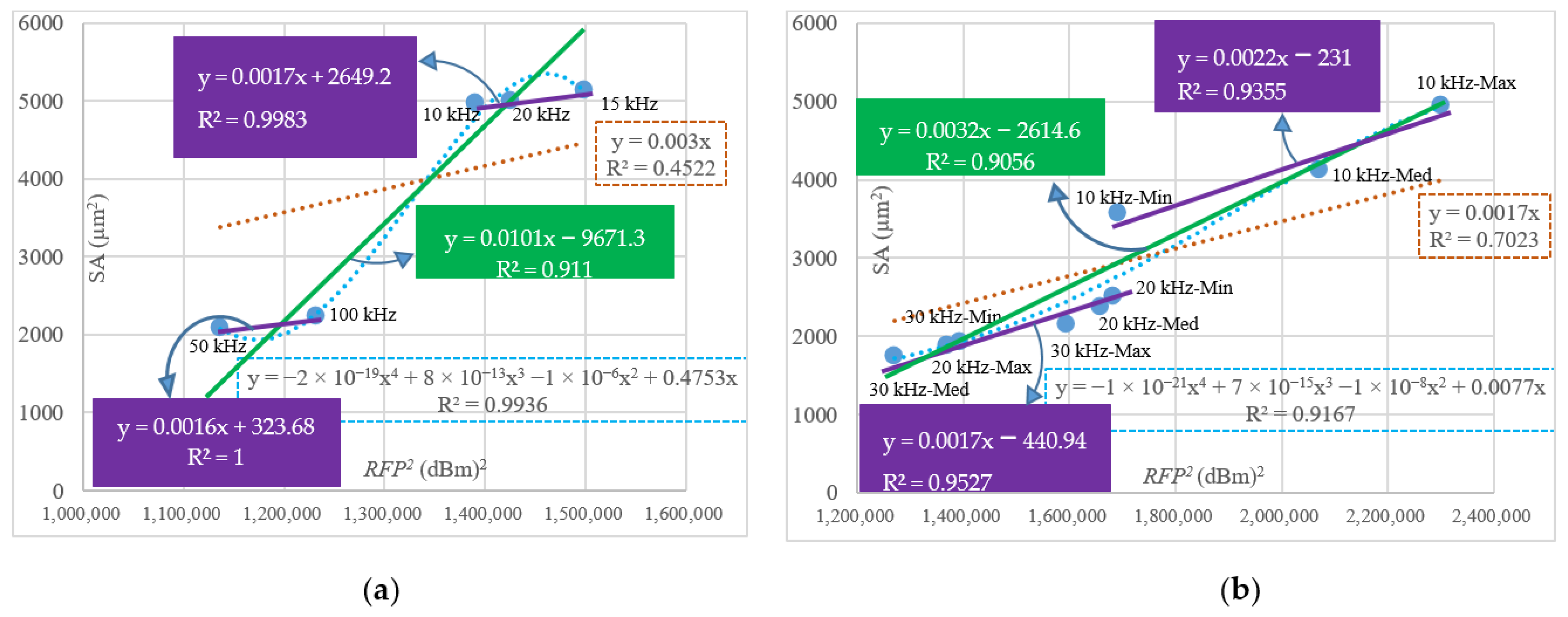

3.1. Received RF Power and Ablation Formation

3.2. Definition of RF Regulation (RFR) (%)

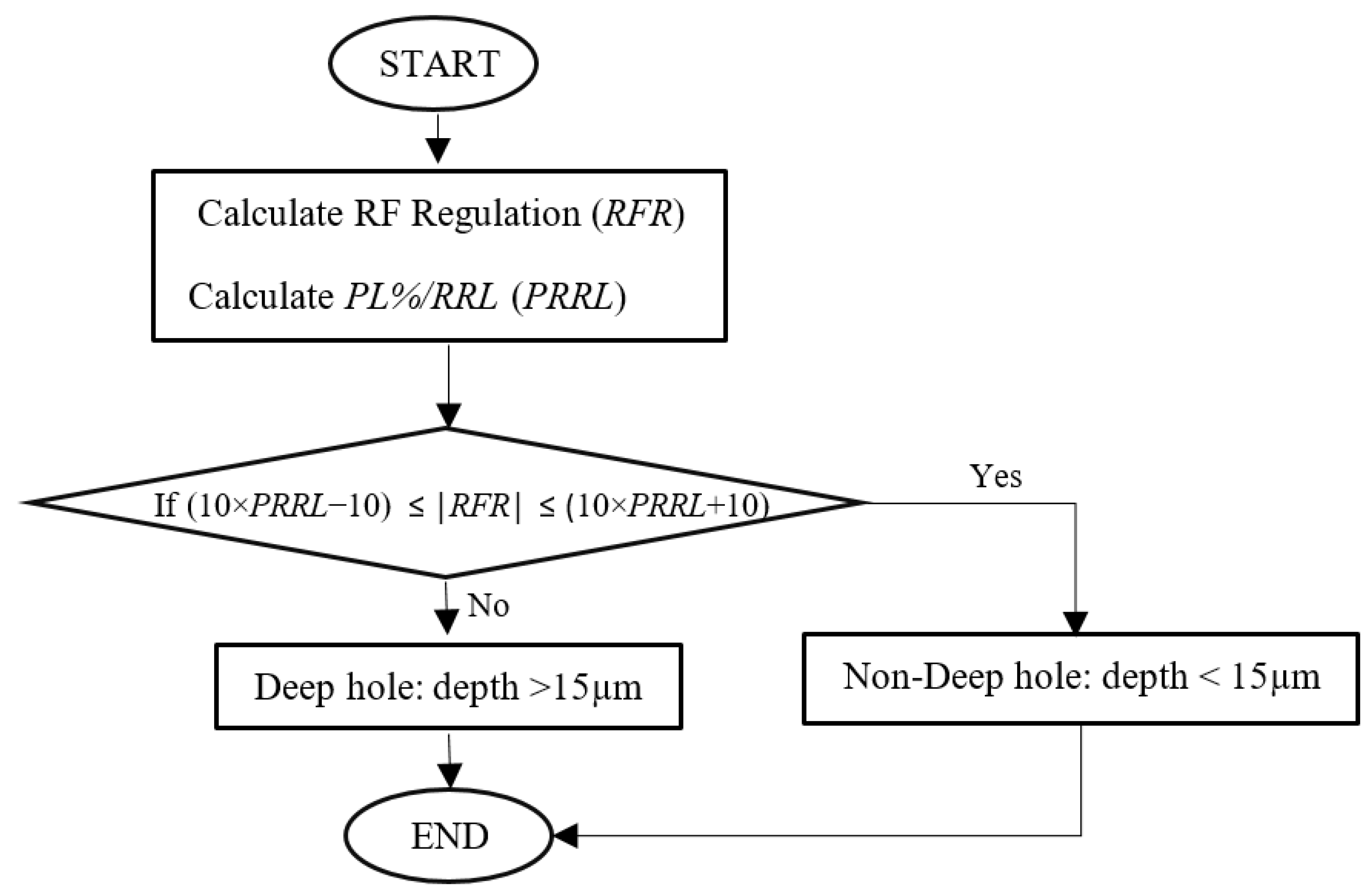

3.3. Diagnostic Process (Flowchart): How to Evaluate Depth of Ablation with RF Power by Considering Beam Characteristics (PL and RRL)

4. Conclusions

- (1)

- According to the experimental results, a relationship between RFP2 and spatter area (SA) was confirmed. It was observed that the greater the value of RFP2, the greater the extent of the SA formation. This leads to a real-time analysis factor to evaluate the SA in-process.

- (2)

- On the basis of (1), a calibration of the received RF data was conducted in order to define a factor called RF regulation % (RFR). In fact, RFR describes the SA variation on the surface. In another words, larger RFR values correspond to a larger SA.

- (3)

- Finally, by comparing the value of the PRRL (a factor of laser beam fluence) and RFR, a diagnostic process for real-time evaluation of the depth of ablation was proposed and experimentally confirmed. As a trial, this diagnostic process was tested based on whether the laser fluence for the ablation is large enough to form a hole depth greater than 15 µm, in aluminium. It was found that the received RFP will be less than an experimentally calibrated PRRL proportion (i.e., 10 × PL/RRL), which indicates that some RF power can escape from the deep hole with some interaction to the internal sidewall of the deeper ablated holes (i.e., received RF power decreases).

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Al | |

|---|---|---|---|---|---|---|---|---|

| Max. | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.07 | 0.05 | 99.5 |

| Min. | 0.14 | 0.18 | 0.001 | 0.001 | 0.001 | 0.003 | 0.012 | 99.64 |

References

- Breitling, D.; Ruf, A.; Dausinger, F. Fundamental aspects in machining of metals with short and ultrashort laser pulses. In Photon Processing in Microelectronics and Photonics III; SPIE: Bellingham, WA, USA, 2004; Volume 5339, pp. 49–63. [Google Scholar]

- Zhou, R.; Zhang, Z.; Hong, M. The art of laser ablation in aeroengine: The crown jewel of modern industry. J. Appl. Phys. 2020, 127, 080902. [Google Scholar]

- Zhao, W.; Wang, W.; Jiang, G.; Li, B.Q.; Mei, X. Ablation and morphological evolution of micro-holes in stainless steel with picosecond laser pulses. Int. J. Adv. Manuf. Technol. 2015, 80, 1713–1720. [Google Scholar] [CrossRef]

- Zhao, W.; Shen, X.; Liu, H.; Wang, L.; Jiang, H. Effect of high repetition rate on dimension and morphology of micro-hole drilled in metals by picosecond ultra-short pulse laser. Opt. Lasers Eng. 2020, 124, 105811. [Google Scholar] [CrossRef]

- Samimi, M.; Hosseinlaghab, H.; McCarthy, É.; McNally, P.J. Multi-Messenger Radio Frequency and Optical Diagnostics of Pulsed Laser Ablation Processes. J. Manuf. Mater. Process. 2022, 6, 106. [Google Scholar] [CrossRef]

- Mustafa, H.; Pohl, R.; Bor, T.C.; Pathiraj, B.; Matthews, D.T.A.; Römer, G. Picosecond-pulsed laser ablation of zinc: Crater morphology and comparison of methods to determine ablation threshold. Opt. Express 2018, 26, 18664–18683. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Z.; Zhou, J.; Xu, K.; Zhao, D.; Tangwarodomnukun, V. A computational study of heat transfer and material removal in picosecond laser micro-grooving of copper. Opt. Laser Technol. 2021, 137, 106792. [Google Scholar] [CrossRef]

- Cheng, J.; Cao, J.; Huang, Y.; Edwardson, S.; Perrie, W.; Dearden, G.; Liu, D. Metal ablation study with a 10 picosecond laser under low and median fluence. Opt. Laser Technol. 2020, 121, 105792. [Google Scholar] [CrossRef]

- Li, X.; Guan, Y. Theoretical fundamentals of short pulse laser–metal interaction: A review. Nanotechnol. Precis. Eng. 2020, 3, 105–125. [Google Scholar] [CrossRef]

- Döring, S.; Richter, S.; Nolte, S.; Tünnermann, A. In situ imaging of hole shape evolution in ultrashort pulse laser drilling. Opt. Express 2010, 18, 20395–20400. [Google Scholar] [CrossRef]

- He, X.; Chen, B.; Chen, Y.; Li, R.; Wang, F. Femtosecond laser-ablation spark-induced breakdown spectroscopy and its application to the elemental analysis of aluminum alloys. J. Anal. At. Spectrom. 2018, 33, 2203–2209. [Google Scholar] [CrossRef]

- Li, Q.; Yang, L.; Hou, C.; Adeyemi, O.; Chen, C.; Wang, Y. Surface ablation properties and morphology evolution of K24 nickel based superalloy with femtosecond laser percussion drilling. Opt. Lasers Eng. 2018, 114, 22–30. [Google Scholar] [CrossRef]

- Hopp, B.; Kresz, N.; Vass, C.; Toth, Z.; Smausz, T.; Ignacz, F. Spatial separation of fast and slow components of pulsed laser plumes. Appl. Surf. Sci. 2002, 186, 298–302. [Google Scholar] [CrossRef]

- Bittencourt, J.A. Fundamentals of Plasma Physics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Dendy, R.O. Plasma Physics: An Introductory Course; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Döring, S.; Szilagyi, J.; Richter, S.; Zimmermann, F.; Richardson, M.; Tünnermann, A.; Nolte, S. Evolution of hole shape and size during short and ultrashort pulse laser deep drilling. Opt. Express 2012, 20, 27147–27154. [Google Scholar] [CrossRef]

- Döring, S.; Ullsperger, T.; Heisler, F.; Richter, S.; Tünnermann, A.; Nolte, S. Hole formation process in ultrashort pulse laser percussion drilling. Phys. Procedia 2013, 41, 431–440. [Google Scholar] [CrossRef]

- Shen, N.; Bude, J.D.; Ly, S.; Keller, W.J.; Rubenchik, A.M.; Negres, R.; Guss, G. Enhancement of laser material drilling using high-impulse multi-laser melt ejection. Opt. Express 2019, 27, 19864–19886. [Google Scholar] [CrossRef]

- Kumar, L.V.; Manikanta, E.; Leela, C.; Kiran, P.P. Effect of laser intensity on radio frequency emissions from laser induced breakdown of atmospheric air. J. Appl. Phys. 2016, 119, 214904. [Google Scholar] [CrossRef]

- Consoli, F.; Tikhonchuk, V.T.; Bardon, M.; Bradford, P.; Carroll, D.C.; Cikhardt, J.; Cipriani, M.; Clarke, R.J.; Cowan, T.E.; Danson, C.N.; et al. Laser produced electromagnetic pulses: Generation, detection and mitigation. High Power Laser Sci. Eng. 2020, 8, e22. [Google Scholar] [CrossRef]

- Ahn, D.-G.; Jung, G.-W. Influence of process parameters on drilling characteristics of Al 1050 sheet with thickness of 0.2 mm using pulsed Nd:YAG laser. Trans. Nonferrous Met. Soc. China 2009, 19, s157–s163. [Google Scholar] [CrossRef]

- Tunna, L.; O’Neill, W.; Khan, A.; Sutcliffe, C. Analysis of laser micro drilled holes through aluminium for micro-manufacturing applications. Opt. Lasers Eng. 2005, 43, 937–950. [Google Scholar] [CrossRef]

- Al-Sayyad, A.; Bardon, J.; Hirchenhahn, P.; Vaudémont, R.; Houssiau, L.; Plapper, P. Influence of aluminum laser ablation on interfacial thermal transfer and joint quality of laser welded aluminum–polyamide assemblies. Coatings 2019, 9, 768. [Google Scholar] [CrossRef]

- Smijesh, N.; Rao, K.H.; Chetty, D.; Litvinyuk, I.V.; Sang, R.T. Plasma plumes produced by laser ablation of Al with single and double pulse schemes. Opt. Lett. 2018, 43, 6081–6084. [Google Scholar] [CrossRef] [PubMed]

- Yuan, B.-S.; Wang, D.; Dong, Y.; Zhang, W.; Jin, G.-Y. Experimental study of the morphological evolution of the millisecond–nanosecond combined-pulse laser ablation of aluminum alloy. Appl. Opt. 2018, 57, 5743–5748. [Google Scholar] [CrossRef] [PubMed]

- Marimuthu, S.; Dunleavey, J.; Liu, Y.; Smith, B.; Kiely, A.; Antar, M. Characteristics of hole formation during laser drilling of SiC reinforced aluminium metal matrix composites. J. Mater. Process. Technol. 2019, 271, 554–567. [Google Scholar] [CrossRef]

| Statues | RRL (kHz) | PL (W) | SDC (%) |

|---|---|---|---|

| 10 kHz | 10 (kHz) | 1.5 | 100% |

| 15 kHz | 15 (kHz) | 2 | 100% |

| 20 kHz | 20 (kHz) | 2.5 | 100% |

| 50 kHz | 50 (kHz) | 3.2 | 100% |

| 100 kHz | 100 (kHz) | 3.5 | 100% |

| Statues | RRL (kHz) | PL (W) | SDC (%) |

|---|---|---|---|

| 10 kHz-Max | 10 (kHz) | 1.5 | 100% |

| 20 kHz-Max | 20 (kHz) | 1.5 | 68% |

| 30 kHz-Max | 30 (kHz) | 1.5 | 60% |

| 10 kHz-Med | 10 (kHz) | 0.75 | 60% |

| 20 kHz-Med | 20 (kHz) | 0.75 | 49% |

| 30 kHz-Med | 30 (kHz) | 0.75 | 42% |

| 10 kHz-Min | 10 (kHz) | 0.35 | 41% |

| 20 kHz-Min | 20 (kHz) | 0.35 | 38% |

| 30 kHz-Min | 30 (kHz) | 0.35 | 34% |

| Correlation of Spatter Area (SA) and RFR | In-Process Depth Diagnostic Results | Post-Process Depth Measurement Results | |||

|---|---|---|---|---|---|

| Statue | SA (µm2) | RFR (%) | 10 × PRRL | If Depth < 15 µm (10 × PRRL−10) ≤ ∣RFR∣ ≤ (10 × PRRL + 10) | Depth (µm) |

| 10 kHz-Max | 4962 | 68 | 100 | No | 36.19 |

| 10 kHz-Med | 4124.9 | 51.2 | 60 | Yes | 0.78 |

| 10 kHz-Min | 3567.8 | 23.47 | 41 | No | 63.52 |

| 20 kHz-Min | 2506.55 | 22.88 | 19 | Yes | 6.73 |

| 20 kHz-Med | 2389 | 21.13 | 24.5 | Yes | 5.3 |

| 30 kHz-Max | 2157.9 | 16.56 | 20 | Yes | 0.79 |

| 30 kHz-Min | 1934.58 | 1.75 | 12 | No | 16.89 |

| 20 kHz-Max | 1885.1 | 0.00711 | 34 | No | 94.57 |

| 30 kHz-Med | 1743.47 | −7.25 | 14 | Yes | 0.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samimi, M.; Hosseinlaghab, H.; McNally, P.J. Real-Time In-Process Evaluation of Spatter Area and Depth of Aluminium Surface in a Pulsed Laser Ablation Process Using Received Radio Frequency Power from Plasma Plumes. J. Manuf. Mater. Process. 2023, 7, 56. https://doi.org/10.3390/jmmp7020056

Samimi M, Hosseinlaghab H, McNally PJ. Real-Time In-Process Evaluation of Spatter Area and Depth of Aluminium Surface in a Pulsed Laser Ablation Process Using Received Radio Frequency Power from Plasma Plumes. Journal of Manufacturing and Materials Processing. 2023; 7(2):56. https://doi.org/10.3390/jmmp7020056

Chicago/Turabian StyleSamimi, Mahdieh, Hassan Hosseinlaghab, and Patrick J. McNally. 2023. "Real-Time In-Process Evaluation of Spatter Area and Depth of Aluminium Surface in a Pulsed Laser Ablation Process Using Received Radio Frequency Power from Plasma Plumes" Journal of Manufacturing and Materials Processing 7, no. 2: 56. https://doi.org/10.3390/jmmp7020056

APA StyleSamimi, M., Hosseinlaghab, H., & McNally, P. J. (2023). Real-Time In-Process Evaluation of Spatter Area and Depth of Aluminium Surface in a Pulsed Laser Ablation Process Using Received Radio Frequency Power from Plasma Plumes. Journal of Manufacturing and Materials Processing, 7(2), 56. https://doi.org/10.3390/jmmp7020056