Robustness Analysis of Pin Joining

Abstract

1. Introduction

2. Research Questions

3. Materials and Methods

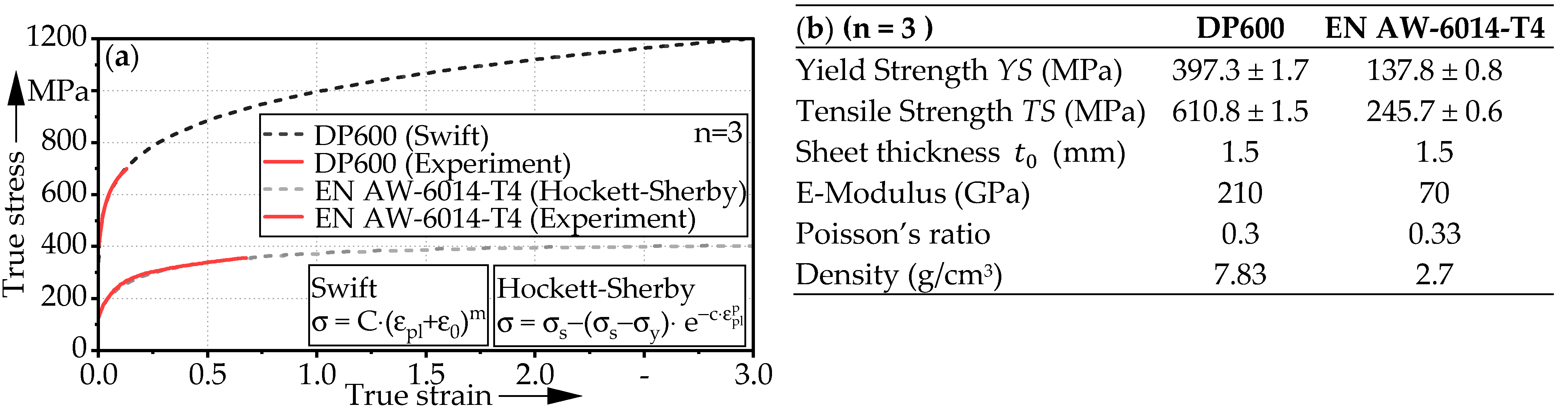

3.1. Materials

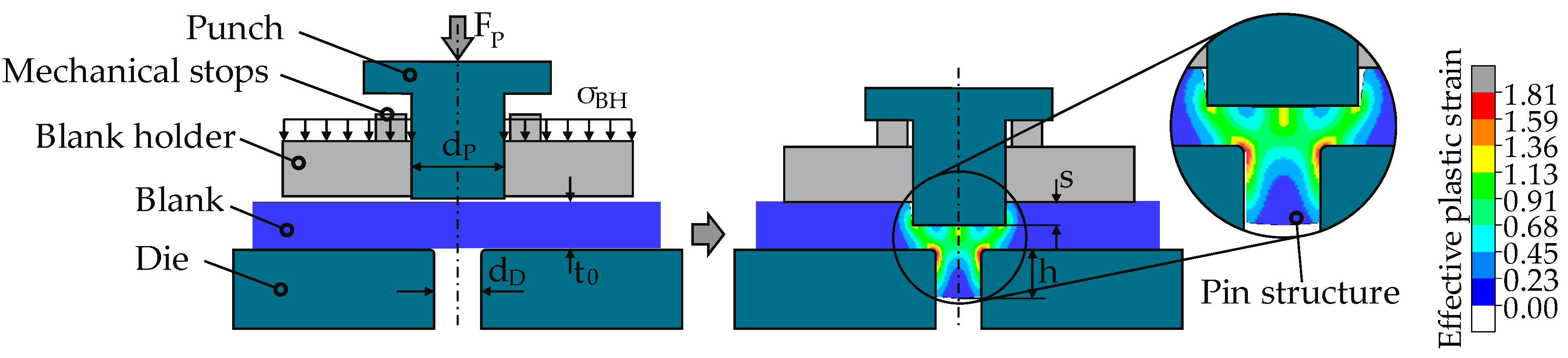

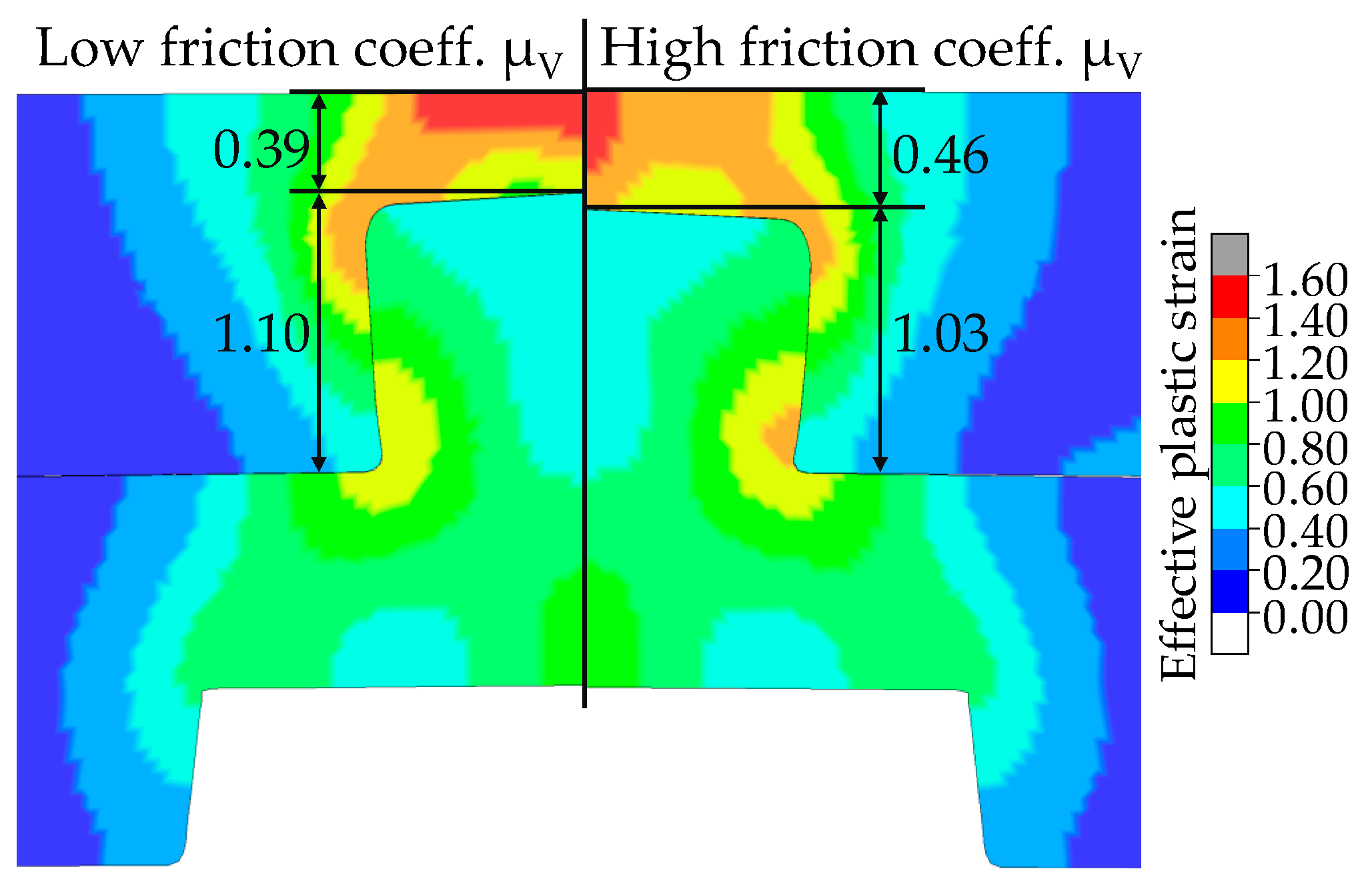

3.2. Cold Extrusion of Pin Structures

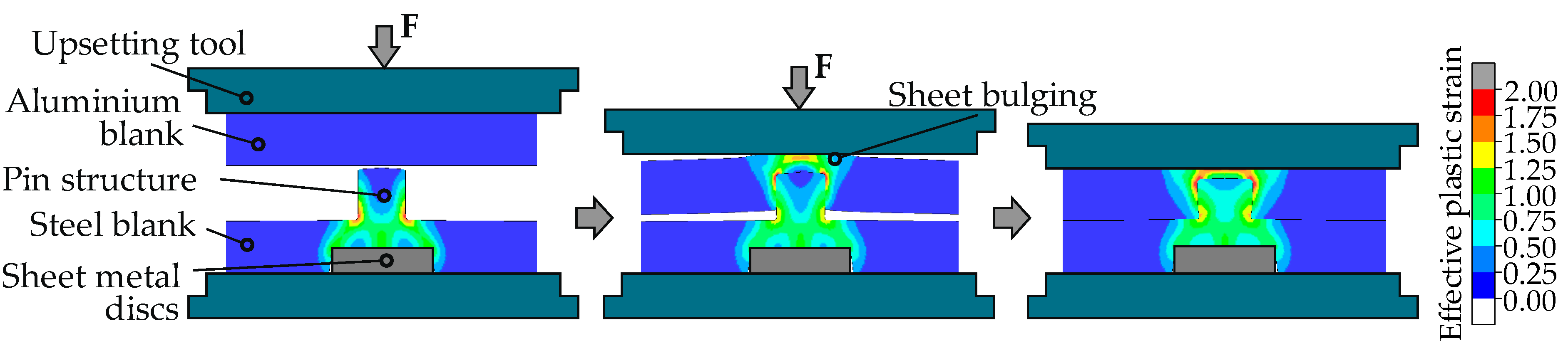

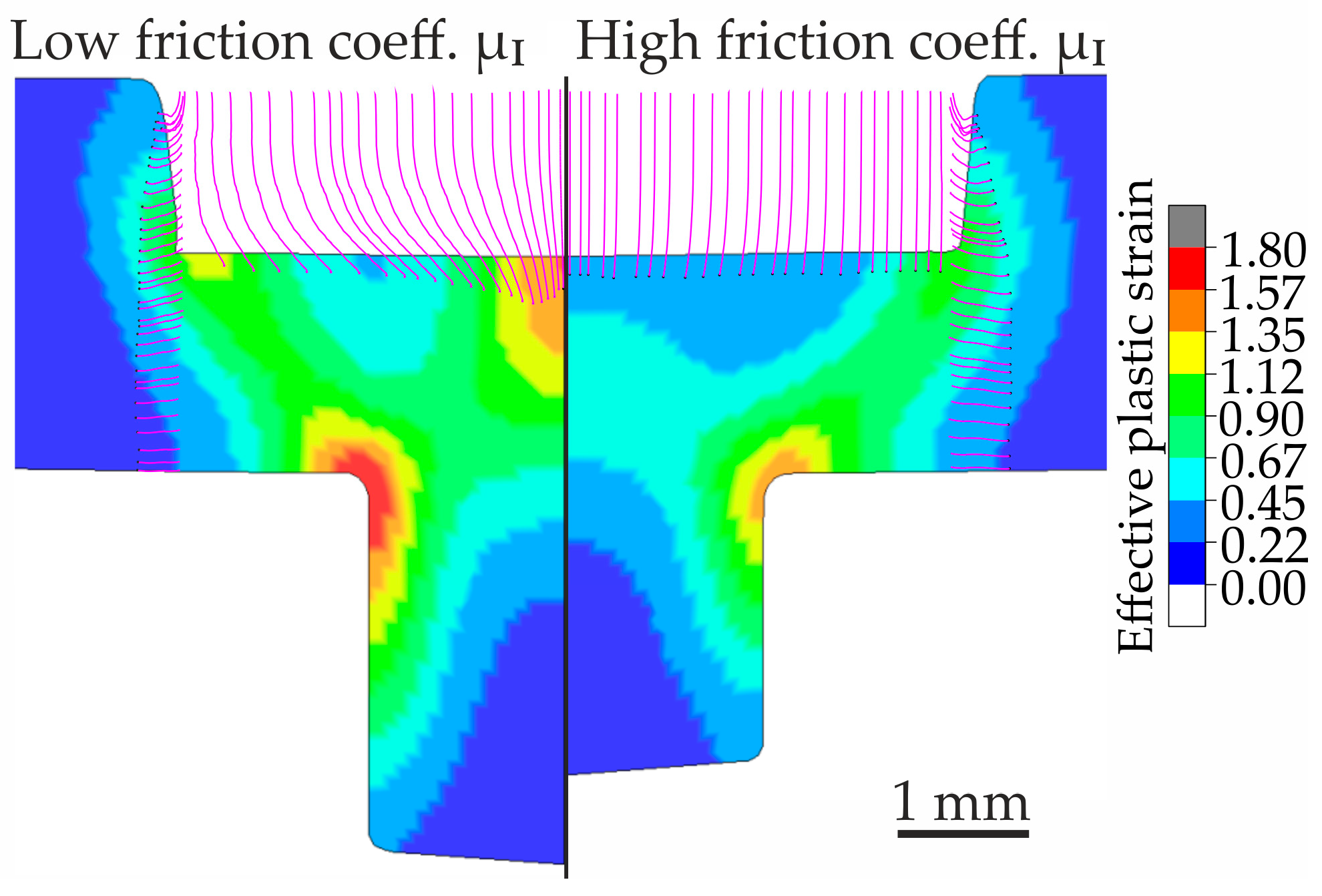

3.3. Joining by Direct Pin Pressing

3.4. Numerical Models of Pin Extrusion and Joining Processes

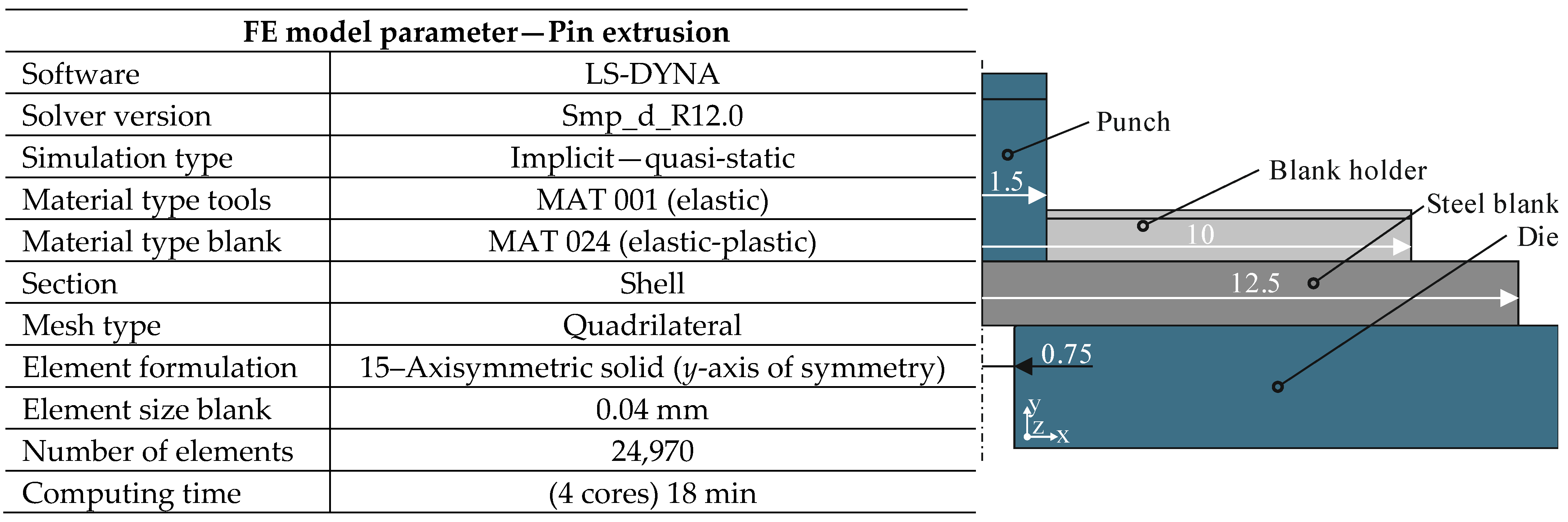

3.4.1. Pin Extrusion

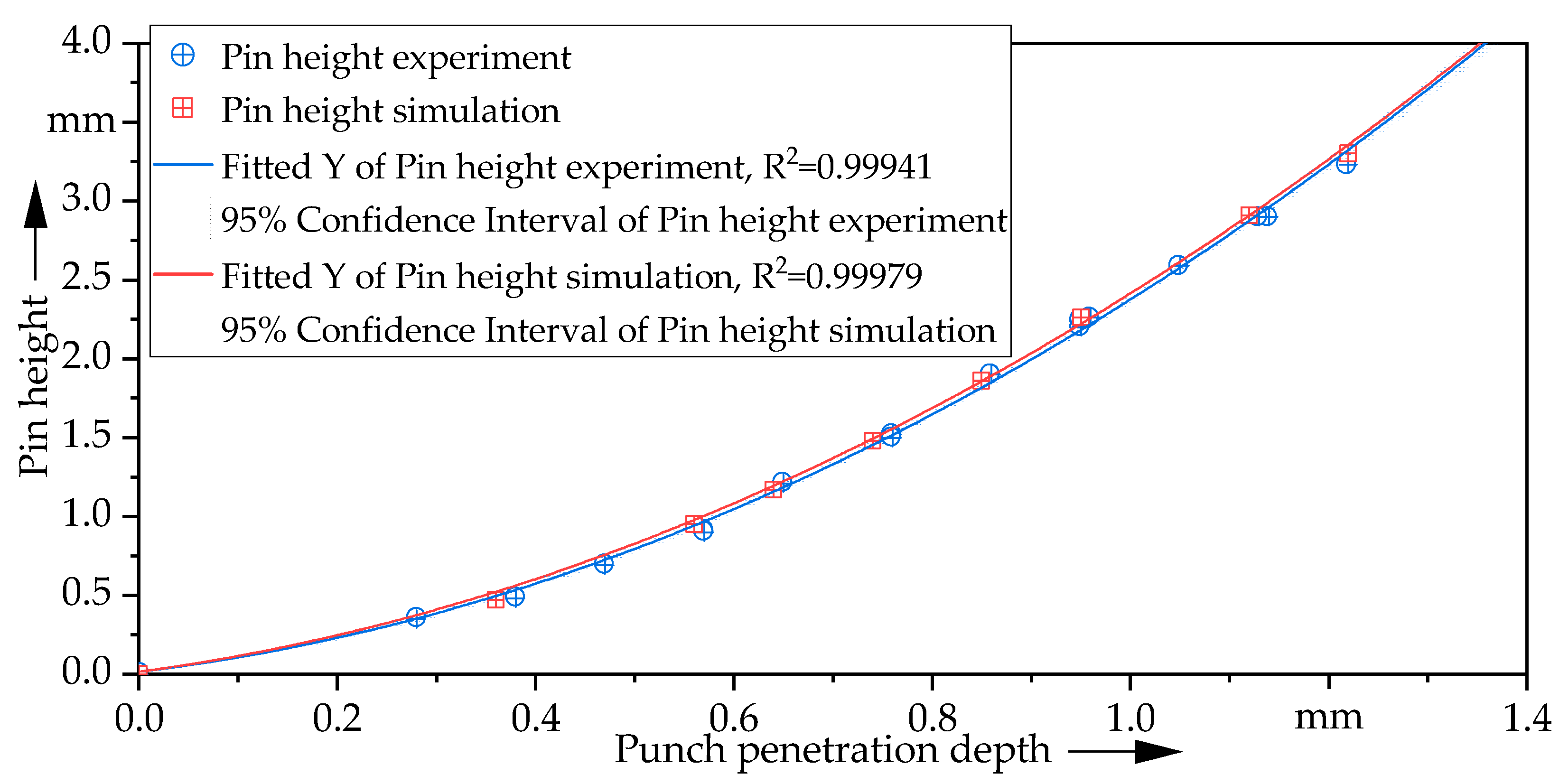

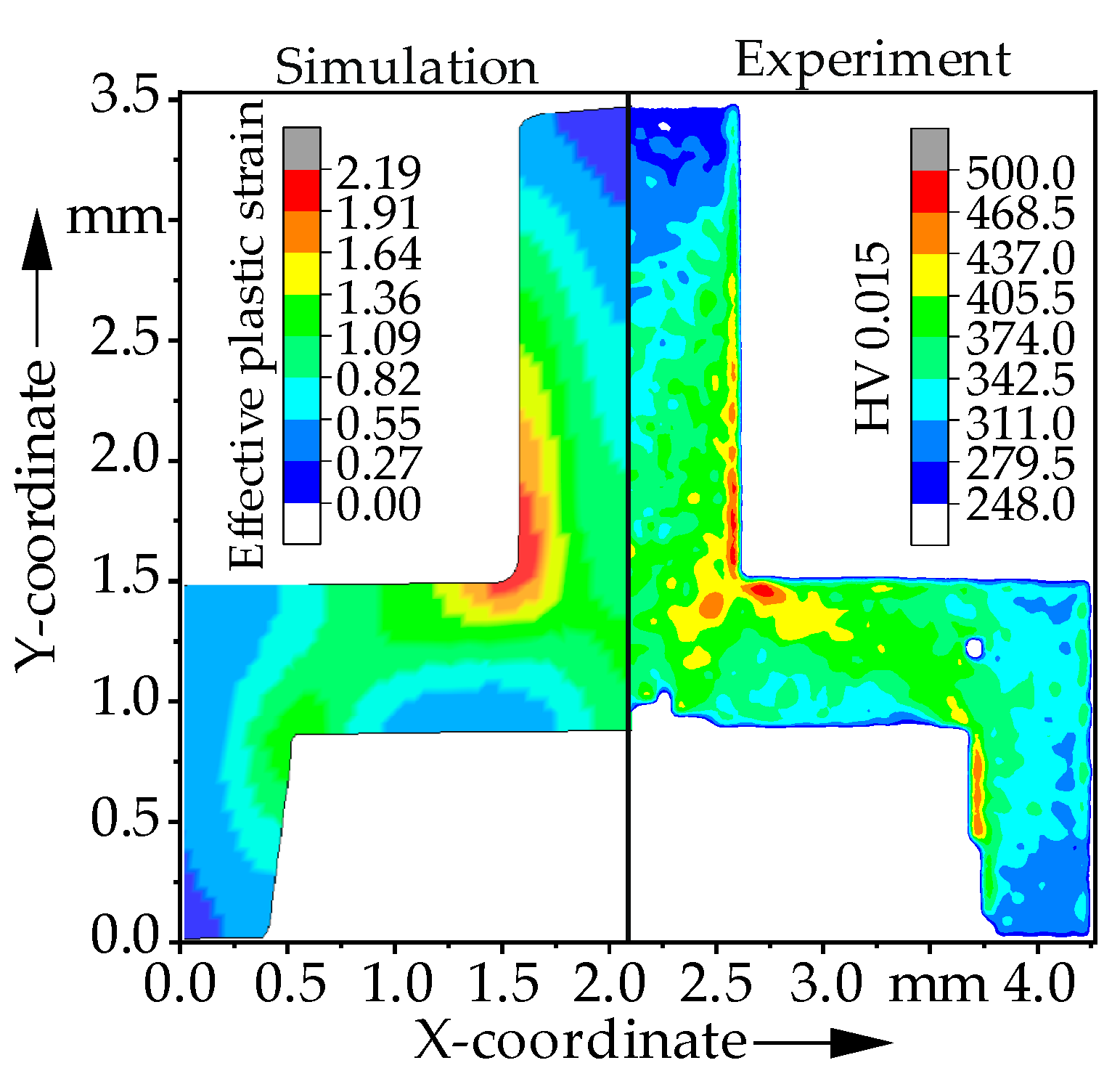

3.4.2. Validation of the Pin Extrusion Simulation

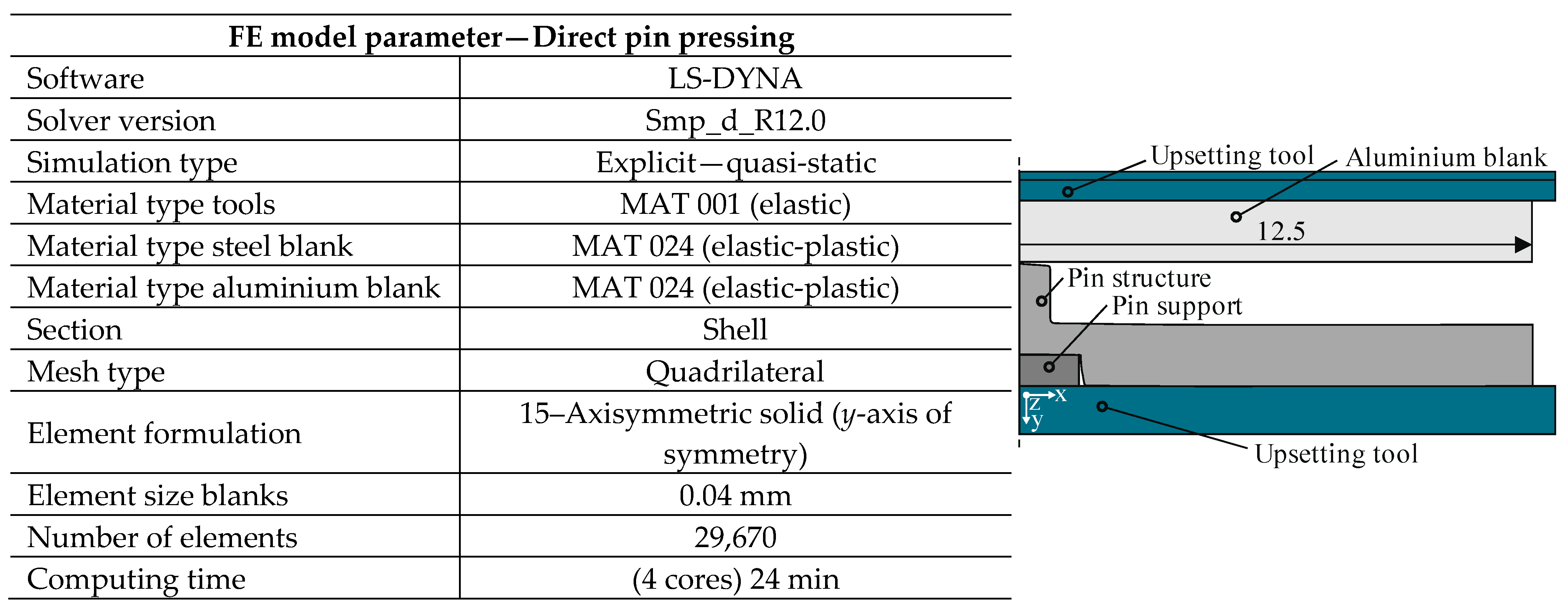

3.4.3. Pin Joining

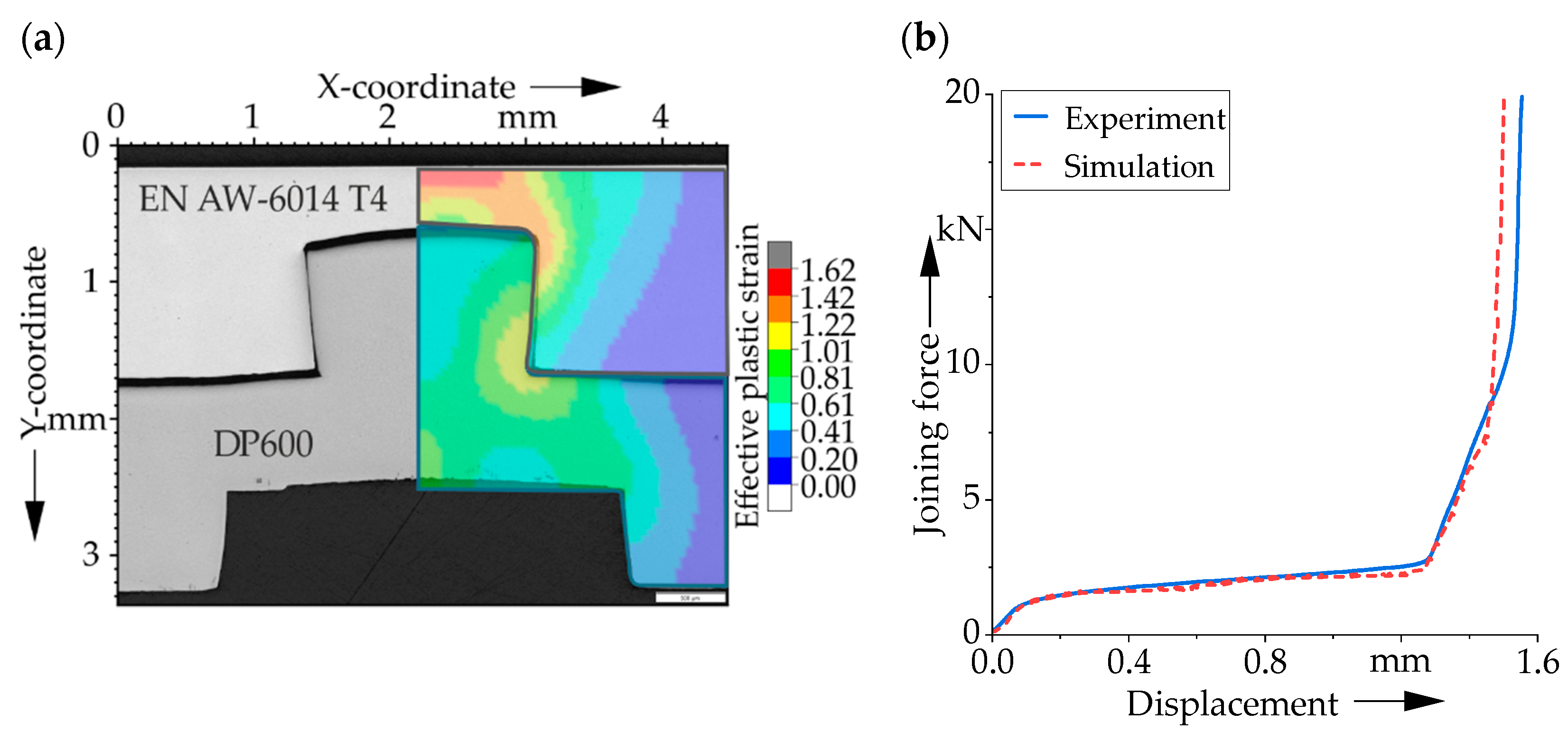

3.4.4. Validation of Pin Joining Simulation

3.5. Design of Experiment

4. Results

4.1. Data Sampling Process

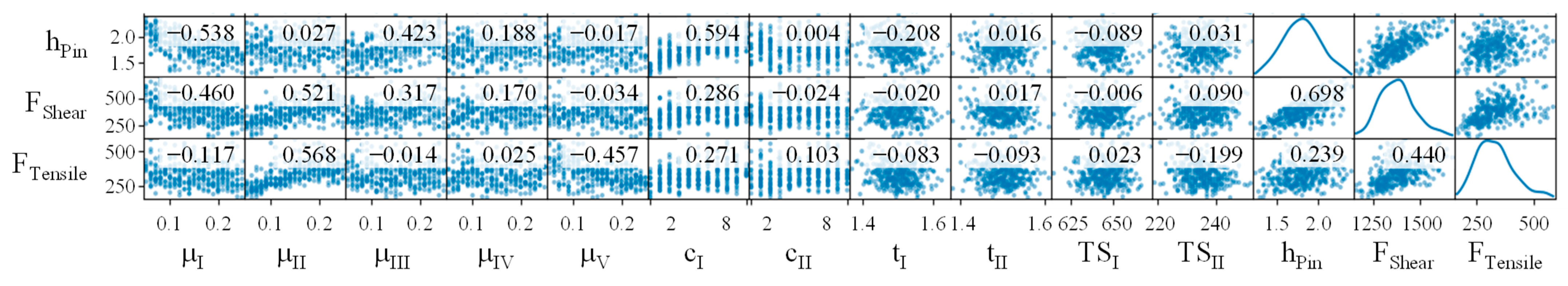

4.2. Correlation Analysis

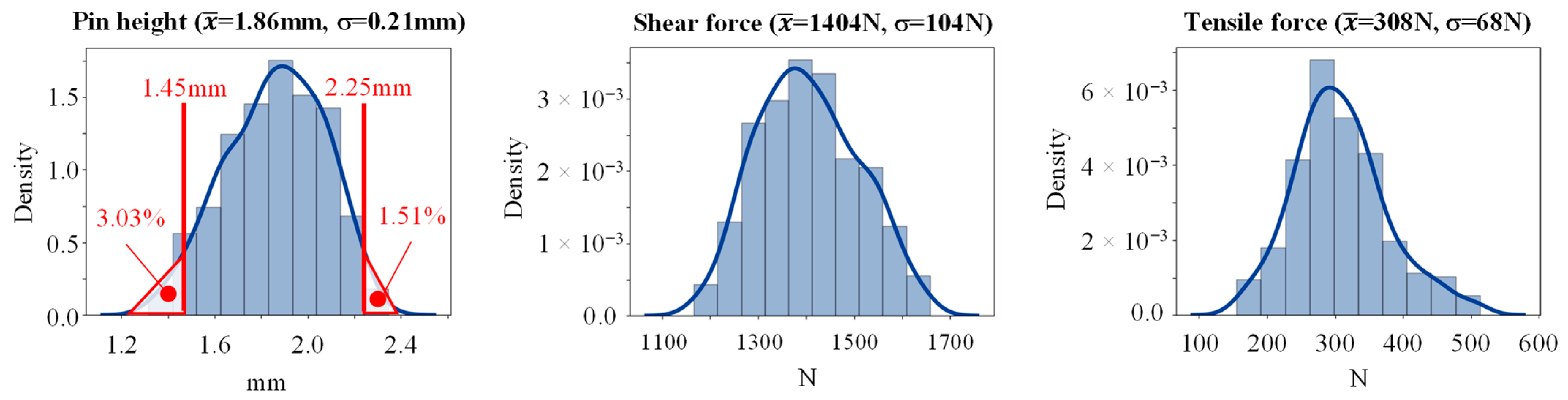

4.3. Robustness Analysis of Cold-Formed Pin Joints

4.4. Process Optimisation and Derivation of Process Windows

5. Discussion

6. Summary and Outlook

- The friction mechanics between the extrusion tools (punch and die) are highly relevant for the achievement of satisfying pin joint properties. In comparison to this, uncertainties within the materials, such as the ultimate tensile strength or the sheet thickness of the secondary joining part, are less relevant.

- The use of coated tools, especially for the punch, and the application of the pin joining process in areas including a small pre-straining level are recommended.

- However, a good balance between the adjustments of particular process parameters is highly important as even small changes can lead to a significant shift in the distribution of the resulting pin joint properties.

- An increase in the robustness of the pin joining process resulted from the described recommendations. In this context, the failure probability was reduced from 9.92% to 4.54%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Comission. The European Green Deal. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 14 July 2022).

- Eurostat. Greenhouse Gas Emissions by Source Sector. Available online: https://ec.europa.eu/eurostat/databrowser/bookmark/1ffd5837-18ba-4e68-9634-1eaf2d6d4023?lang=de (accessed on 21 September 2022).

- Meschut, G.; Merklein, M.; Brosius, A.; Drummer, D.; Fratini, L.; Füssel, U.; Gude, M.; Homberg, W.; Martins, P.A.F.; Bobbert, M.; et al. Review on mechanical joining by plastic deformation. J. Adv. Join. Process. 2022, 177, 100113. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Racine, D.; Zhang, Z.; Buiron, N.; Marceau, D.; Rachik, M. Magnetic pulse welding: Interface of Al/Cu joint and investigation of intermetallic formation effect on the weld features. J. Manuf. Process. 2014, 16, 427–434. [Google Scholar] [CrossRef]

- Kraus, M.; Merklein, M. Potential of Joining Dissimilar Materials by Cold Formed Pin-Structures. J. Mater. Process. Technology 2020, 283, 116697. [Google Scholar] [CrossRef]

- Ucsnik, S.A.; Kirov, G. New Possibility for the Connection of Metal Sheets and Fiber Reinforced Plastics. Mater. Sci. Forum 2011, 690, 465–468. [Google Scholar] [CrossRef]

- Parkes, P.N.; Butler, R.; Meyer, J.; de Oliveira, A. Static strength of metal-composite joints with penetrative reinforcement. Compos. Struct. 2014, 118, 250–256. [Google Scholar] [CrossRef]

- Römisch, D.; Popp, J.; Drummer, D.; Merklein, M. Joining of CFRT-steel hybrid parts via hole-forming and subsequent pin caulking. Prod. Eng. 2021, 16, 339–352. [Google Scholar] [CrossRef]

- Römisch, D.; Kraus, M.; Merklein, M. Investigation of the influence of formed, non-rotationally symmetrical pin geometries and their effect on the joint quality of steel and aluminium sheets by direct pin pressing. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 1187–1202. [Google Scholar] [CrossRef]

- Feistauer, E.E.; Santos, J.F.; Amancio-Filho, S.T. A review on direct assembly of through-the-thickness reinforced metal–polymer composite hybrid structures. Polym. Eng. Sci. 2019, 59, 661–674. [Google Scholar] [CrossRef]

- Graham, D.P.; Rezai, A.; Baker, D.; Smith, P.A.; Watts, J.F. The development and scalability of a high strength, damage tolerant, hybrid joining scheme for composite–metal structures. Compos. Part A Appl. Sci. Manuf. 2014, 64, 11–24. [Google Scholar] [CrossRef]

- Ucsnik, S.; Scheerer, M.; Zaremba, S.; Pahr, D.H. Experimental investigation of a novel hybrid metal–composite joining technology. Compos. Part A Appl. Sci. Manuf. 2010, 41, 369–374. [Google Scholar] [CrossRef]

- Feistauer, E.E.; dos Santos, J.F.; Amancio-Filho, S.T. An investigation of the ultrasonic joining process parameters effect on the mechanical properties of metal-composite hybrid joints. Weld. World 2020, 64, 1481–1495. [Google Scholar] [CrossRef]

- Smith, F. COMELD™: An innovation in composite to metal joining. Mater. Technol. 2005, 20, 91–96. [Google Scholar] [CrossRef]

- Ghassemali, E.; Tan, M.-J.; Jarfors, A.E.W.; Lim, S.C.V. Progressive microforming process: Towards the mass production of micro-parts using sheet metal. Int. J. Adv. Manuf. Technol. 2012, 66, 611–621. [Google Scholar] [CrossRef]

- Hirota, K. Fabrication of micro-billet by sheet extrusion. J. Mater. Process. Technol. 2007, 191, 283–287. [Google Scholar] [CrossRef]

- Stricker, N.; Lanza, G. The Concept of Robustness in Production Systems and its Correlation to Disturbances. Procedia CIRP 2014, 19, 87–92. [Google Scholar] [CrossRef]

- Romisch, D.; Zirngibl, C.; Schleich, B.; Wartzack, S.; Merklein, M. Data-driven analysis of cold-formed pin structure characteristics in the context of versatile joining processes. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1157, 012077. [Google Scholar] [CrossRef]

- Fonstein, N. Dual-phase steels. In Automotive Steels. Design, Metallurgy, Processing and Applications; Rana, R., Singh, S.B., Eds.; Woodhead Publishing: Duxford, UK, 2017; pp. 169–216. [Google Scholar]

- Novelis Inc. Data Sheet-Novelis AdvanzTM 6F-e170. 2019. Available online: https://www.novelis.com/wp-content/uploads/2019/02/Advanz-6F-e170-DataSheet-012119.pdf (accessed on 10 August 2022).

- DIN EN ISO 6892-1:2014-06; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature (ISO 6892-1:2014). Beuth Verlag: Berlin, Germany, 2014.

- Swift, H.W. Plastic instability under plane stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- 23. DIN EN ISO 16808:2014-1; Metallic Materials-Sheet and Strip-Determination of Biaxial Stress-Strain Curve by Means of Bulge Test with Optical Measuring Systems (ISO 16808:2014). Beuth Verlag: Berlin, Germany, 2014. [CrossRef]

- Hockett, J.E.; Sherby, O.D. Large strain deformation of polycrystalline metals at low homologous temperatures. J. Mech. Phys. Solids 1975, 23, 87–98. [Google Scholar] [CrossRef]

- Doege, E.; Behrens, B.-A. Handbuch Umformtechnik; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Kraus, M.; Lenzen, M.; Merklein, M. Contact pressure-dependent friction characterization by using a single sheet metal compression test. Wear 2021, 93, 203679. [Google Scholar] [CrossRef]

- Tekkaya, A.E. A guide for validation of FE-simulations in bulk metal forming. Arab. J. Sci. Eng. 2005, 30, 113–136. [Google Scholar]

- DIN EN ISO 14577-1:2015; Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. Beuth Verlag: Berlin, Germany, 2015.

- Tekkaya, A.E.; Martins, P.A.F. Accuracy, reliability and validity of finite element analysis in metal forming: A user’s perspective. Eng. Comput. 2009, 26, 1026–1055. [Google Scholar] [CrossRef]

- Wituschek, S.; Lechner, M. Friction Characterisation for a Tumbling Self-Piercing Riveting Process. Key Eng. Mater. 2021, 883, 27–34. [Google Scholar] [CrossRef]

- Römisch, D.; Kraus, M.; Merklein, M. Experimental Study on Joining by Forming of HCT590X + Z and EN-AW 6014 Sheets Using Cold Extruded Pin Structures. J. Manuf. Mater. Process. 2021, 5, 25. [Google Scholar] [CrossRef]

- Bielak, C.R.; Böhnke, M.; Beck, R.; Bobbert, M.; Meschut, G. Numerical analysis of the robustness of clinching process considering the pre-forming of the parts. J. Adv. Join. Process. 2021, 3, 100038. [Google Scholar] [CrossRef]

- Martin, S.; Bielak, C.R.; Bobbert, M.; Tröster, T.; Meschut, G. Numerical investigation of the clinched joint loadings considering the initial pre-strain in the joining area. Prod. Eng. 2022, 16, 261–273. [Google Scholar] [CrossRef]

- Siebertz, K.; van Bebber, D.; Hochkirchen, T. Statistische Versuchsplanung; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Zirngibl, C.; Schleich, B.; Wartzack, S. Approach for the Automated and Data-Based Design of Mechanical Joints. Proc. Des. Soc. 2021, 1, 521–530. [Google Scholar] [CrossRef]

- Zirngibl, C.; Schleich, B. Approach for the Automated Analysis of Geometrical Clinch Joint Characteristics. Key Eng. Mater. 2021, 883, 105–110. [Google Scholar] [CrossRef]

- Kraus, M.; Hufnagel, T.; Merklein, M. Accuracy of Conventional Finite Element Models in Bulk-Forming of Micropins from Sheet Metal. J. Micro Nano-Manuf. 2019, 7, 010902. [Google Scholar] [CrossRef]

- DIN EN 485-4:2019-05; Aluminium and Aluminium Alloys-Sheet, Strip and Plate-Part 4: Tolerances on Shape and Dimensions for Cold-Rolled Products. Beuth Verlag: Berlin, Germany, 1993. [CrossRef]

- DIN EN ISO 9445-1:2010-06; Continuously Cold-Rolled Stainless Steel-Tolerances on Dimensions and Form-Part 1: Narrow Strip and Cut Lengths (ISO 9445-1:2009). Beuth Verlag: Berlin, Germany, 2010. [CrossRef]

- Zirngibl, C.; Kügler, P.; Popp, J.; Bielak, C.R.; Bobbert, M.; Drummer, D.; Meschut, G.; Wartzack, S.; Schleich, B. Provision of cross-domain knowledge in mechanical joining using ontologies. Prod. Eng. 2022, 16, 327–338. [Google Scholar] [CrossRef]

| Input Parameter | A. | Unit | Spaces | |

|---|---|---|---|---|

| min. | max. | |||

| Pin extrusion | ||||

| Friction punch/ primary sheet | 0.05 | 0.25 | ||

| Friction die/ primary sheet | 0.05 | 0.25 | ||

| Friction primary sheet/blank holder | 0.05 | 0.25 | ||

| Pre-straining primary sheet | % * | 0 | 10 | |

| Pin joining | ||||

| Friction primary/secondary sheet | 0.05 | 0.25 | ||

| Friction secondary sheet/upsetting tool | 0.05 | 0.25 | ||

| Pre-straining secondary sheet | % * | 0 | 10 | |

| Input Parameter | A. | Unit | Distribution | ||

|---|---|---|---|---|---|

| Materials | |||||

| Thickness primary sheet | mm | 1.5 | 0.033 | 0.1 | |

| Thickness secondary sheet | mm | 1.5 | 0.033 | 0.1 | |

| Tensile strength primary sheet | MPa | 645 | 16.67 | 55 | |

| Tensile strength secondary sheet | MPa | 235 | 11.67 | 35 | |

| Input Parameter | Initial Parameter Space | Adapted Parameter Space |

|---|---|---|

| (punch and primary joining part) | = 0.05–0.25 | = 0.05–0.15 |

| (die and primary joining part) | = 0.05–0.25 | = 0.15–0.25 |

| (pre-straining primary joining part) | = 0–10% | = 0–5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Römisch, D.; Zirngibl, C.; Schleich, B.; Wartzack, S.; Merklein, M. Robustness Analysis of Pin Joining. J. Manuf. Mater. Process. 2022, 6, 122. https://doi.org/10.3390/jmmp6050122

Römisch D, Zirngibl C, Schleich B, Wartzack S, Merklein M. Robustness Analysis of Pin Joining. Journal of Manufacturing and Materials Processing. 2022; 6(5):122. https://doi.org/10.3390/jmmp6050122

Chicago/Turabian StyleRömisch, David, Christoph Zirngibl, Benjamin Schleich, Sandro Wartzack, and Marion Merklein. 2022. "Robustness Analysis of Pin Joining" Journal of Manufacturing and Materials Processing 6, no. 5: 122. https://doi.org/10.3390/jmmp6050122

APA StyleRömisch, D., Zirngibl, C., Schleich, B., Wartzack, S., & Merklein, M. (2022). Robustness Analysis of Pin Joining. Journal of Manufacturing and Materials Processing, 6(5), 122. https://doi.org/10.3390/jmmp6050122