Areal Analysis Investigation of Selective Laser Melting Parts

Abstract

:1. Introduction

2. Material and Methods

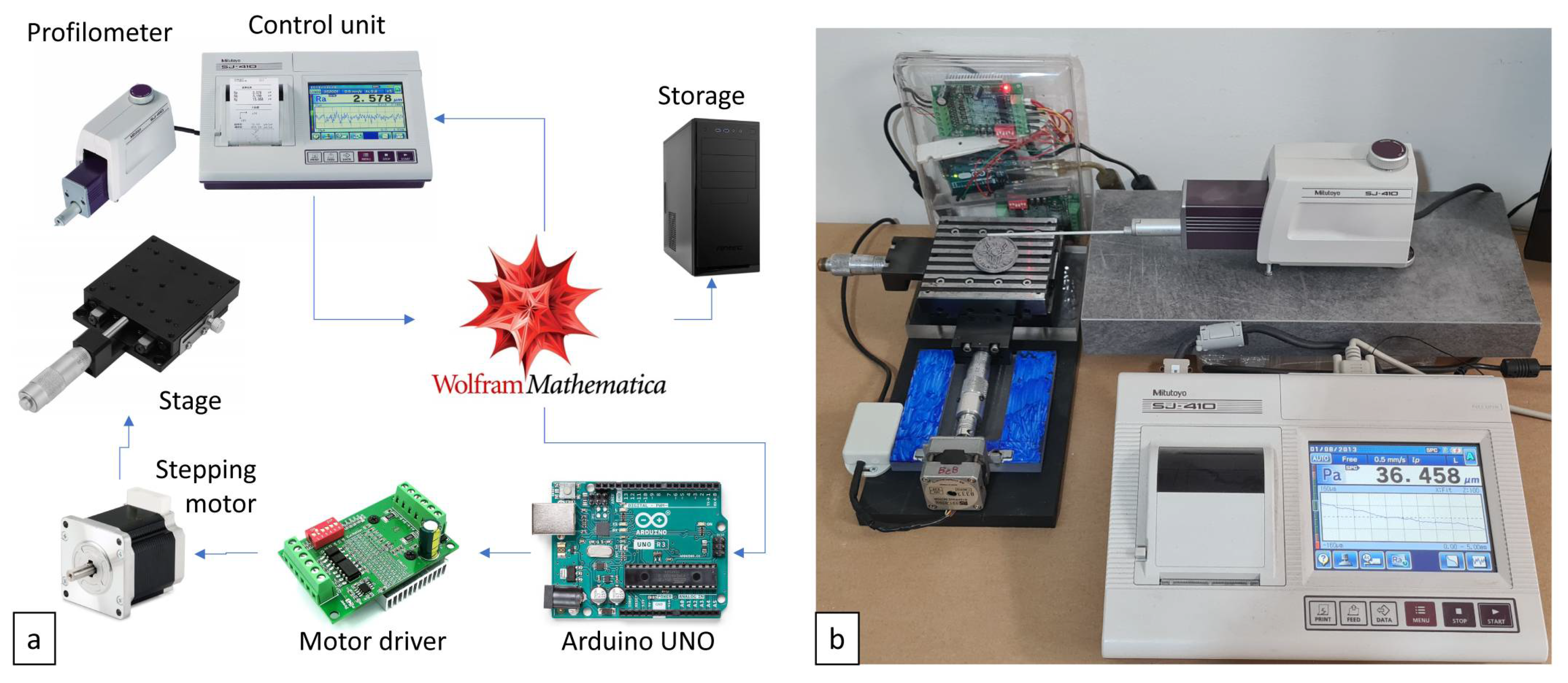

2.1. 3D-Map Measurement

- The stylus is positioned at the beginning of the measurement area;

- The profilometer starts measurement at 0.5 mm/s speed;

- The profile is cropped at the beginning and the end to eliminate starting and stopping dynamics;

- The data are acquired as an x-z temporary file;

- The stylus returns to its initial position at a 2 mm/s speed;

- The stage moves the part to the next y position;

- The operation pauses for 1 s to avoid vibration phenomena;

- Operation 2 is repeated until the y positioning is complete; and

- The map is built by composing all the temporary files in an x-y-z structure.

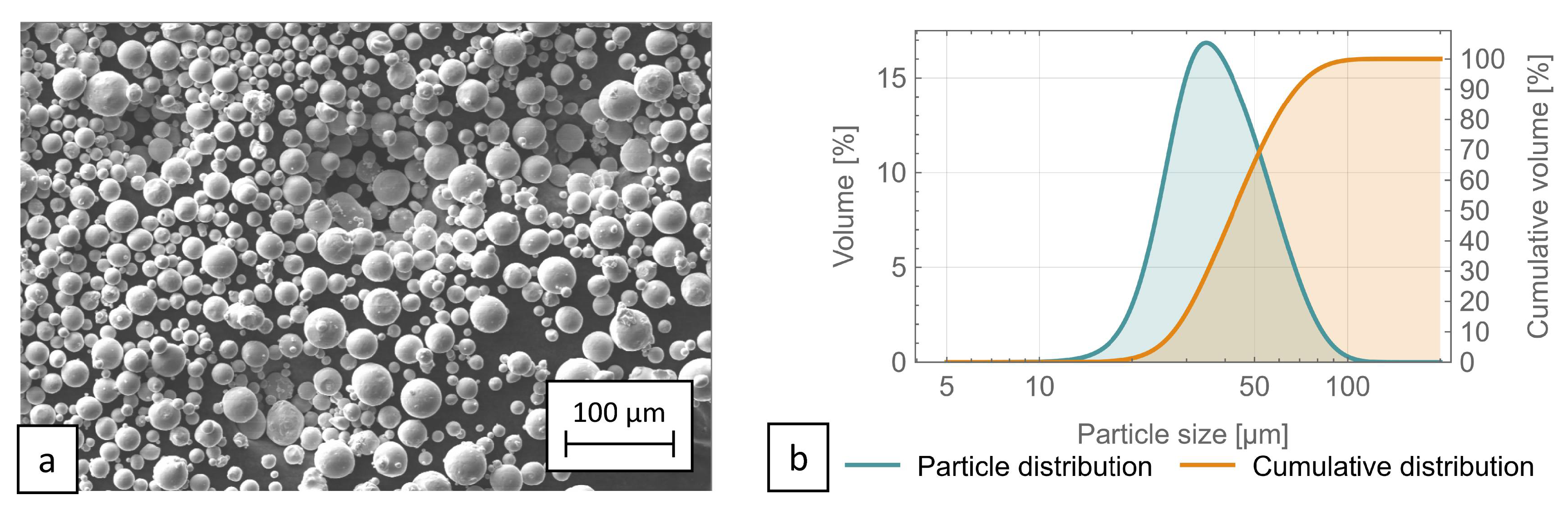

2.2. Fabrication Method

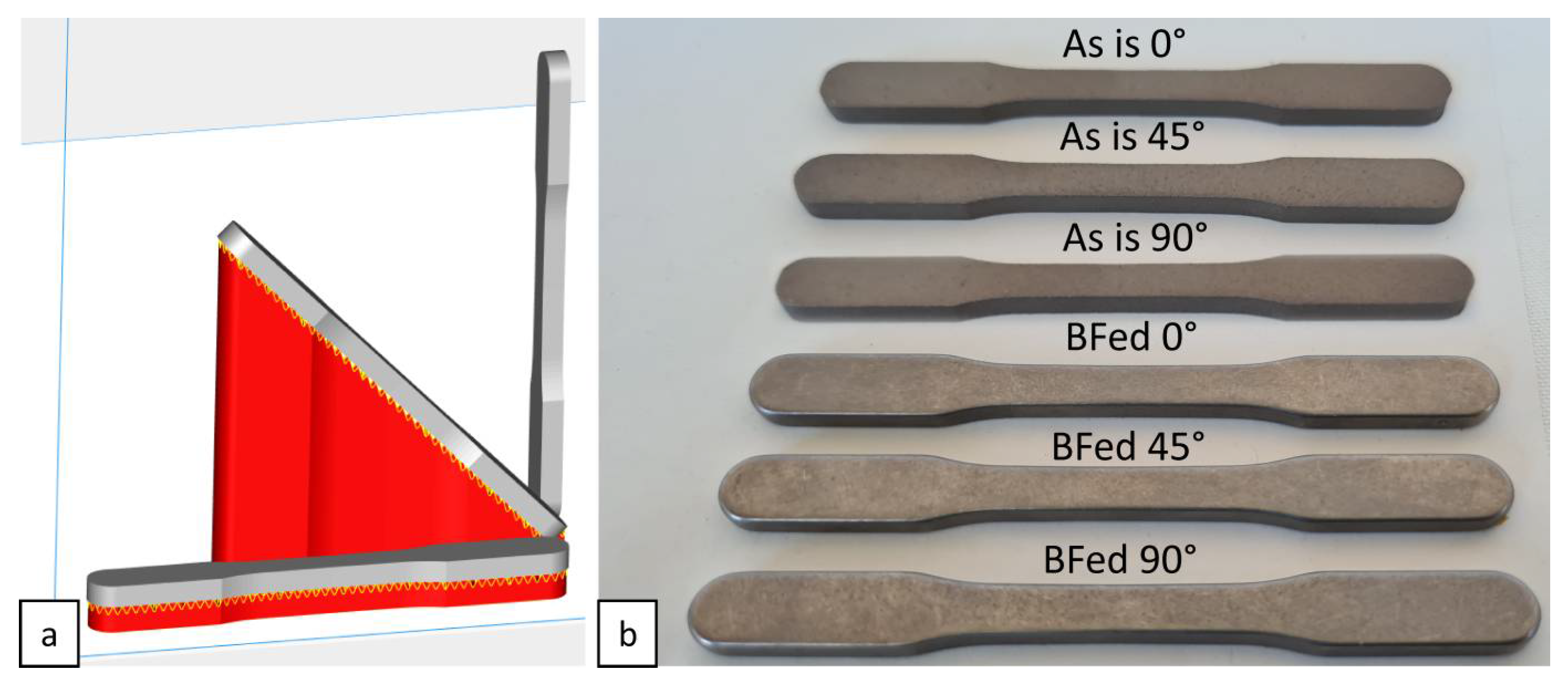

2.3. Secondary Finishing

3. Results

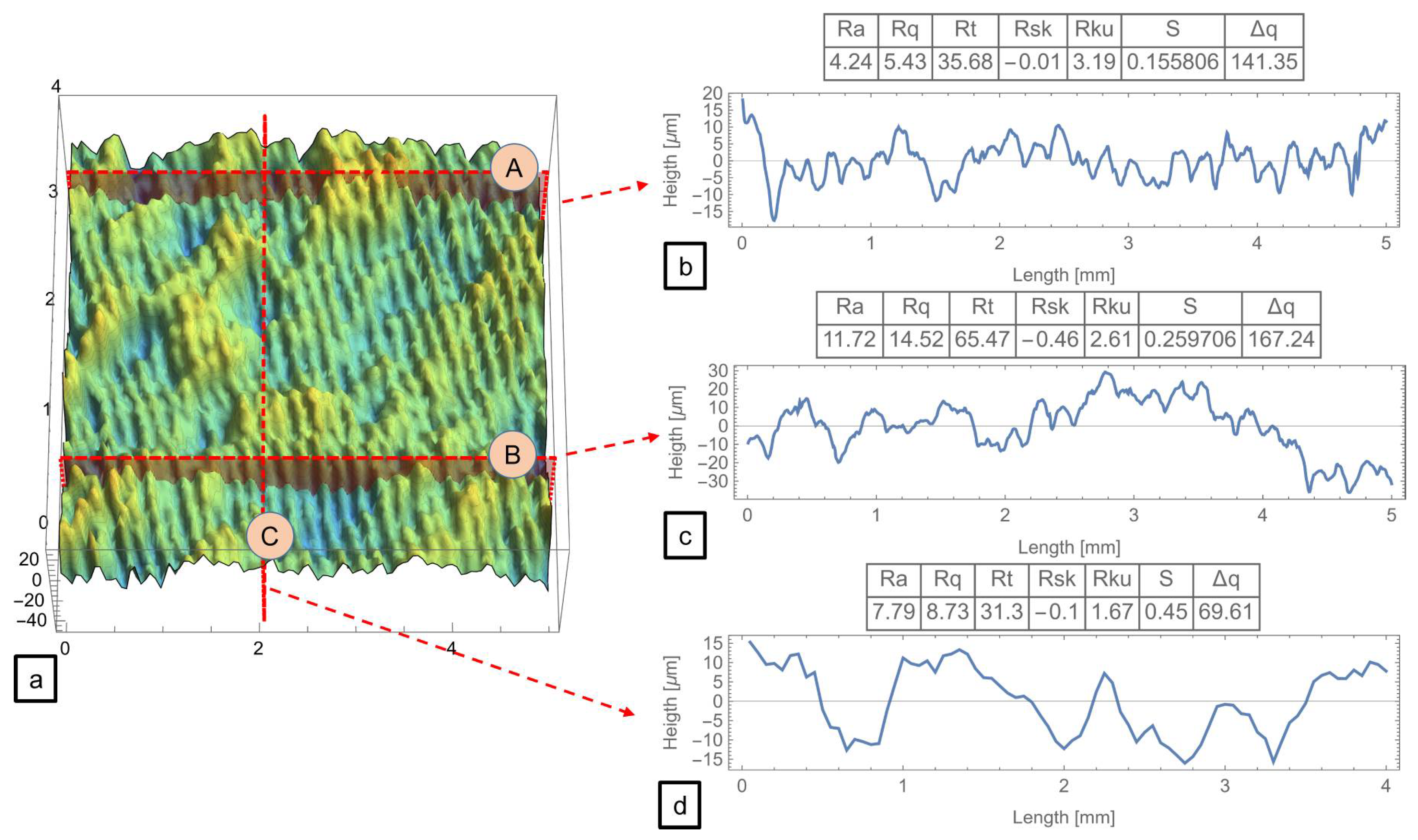

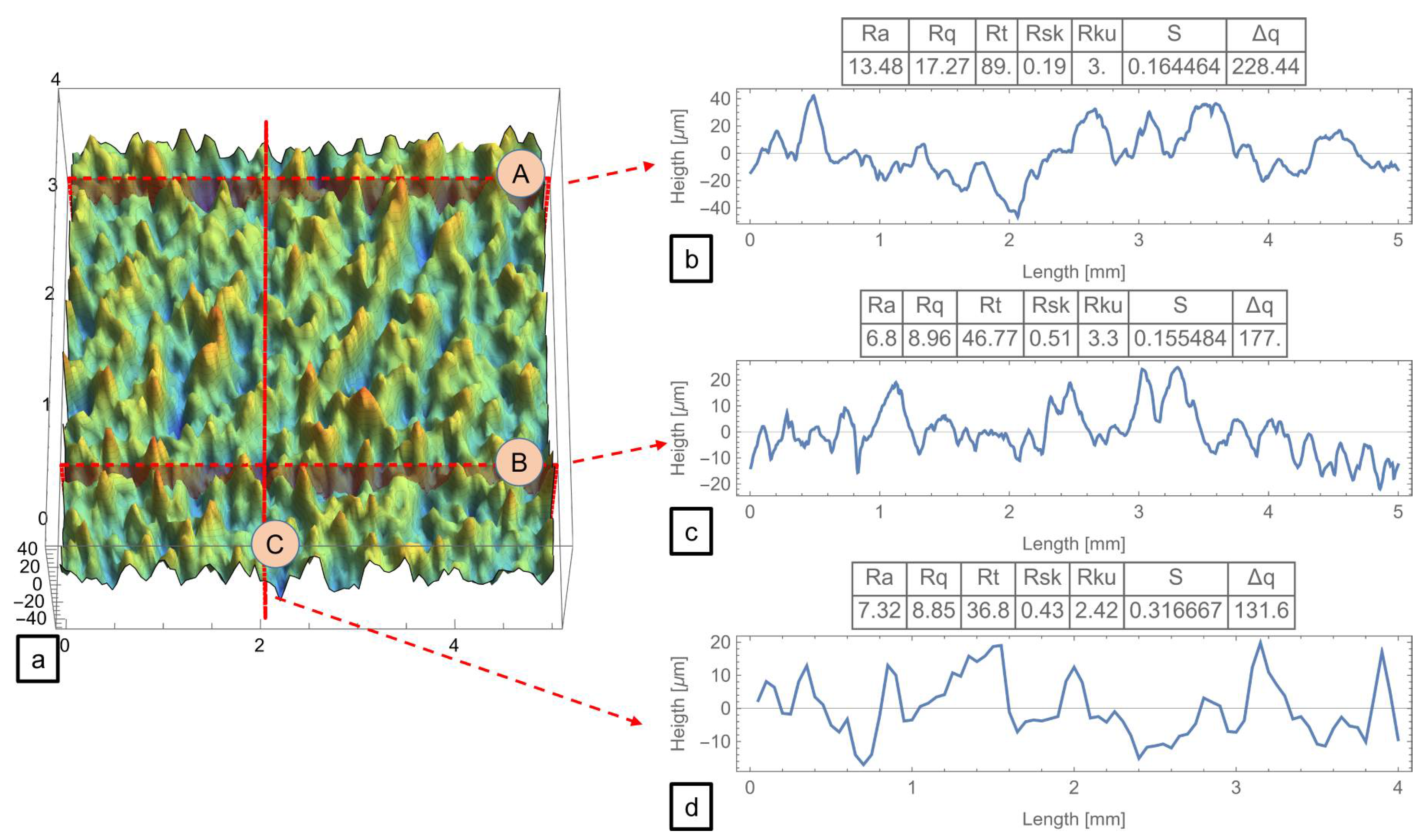

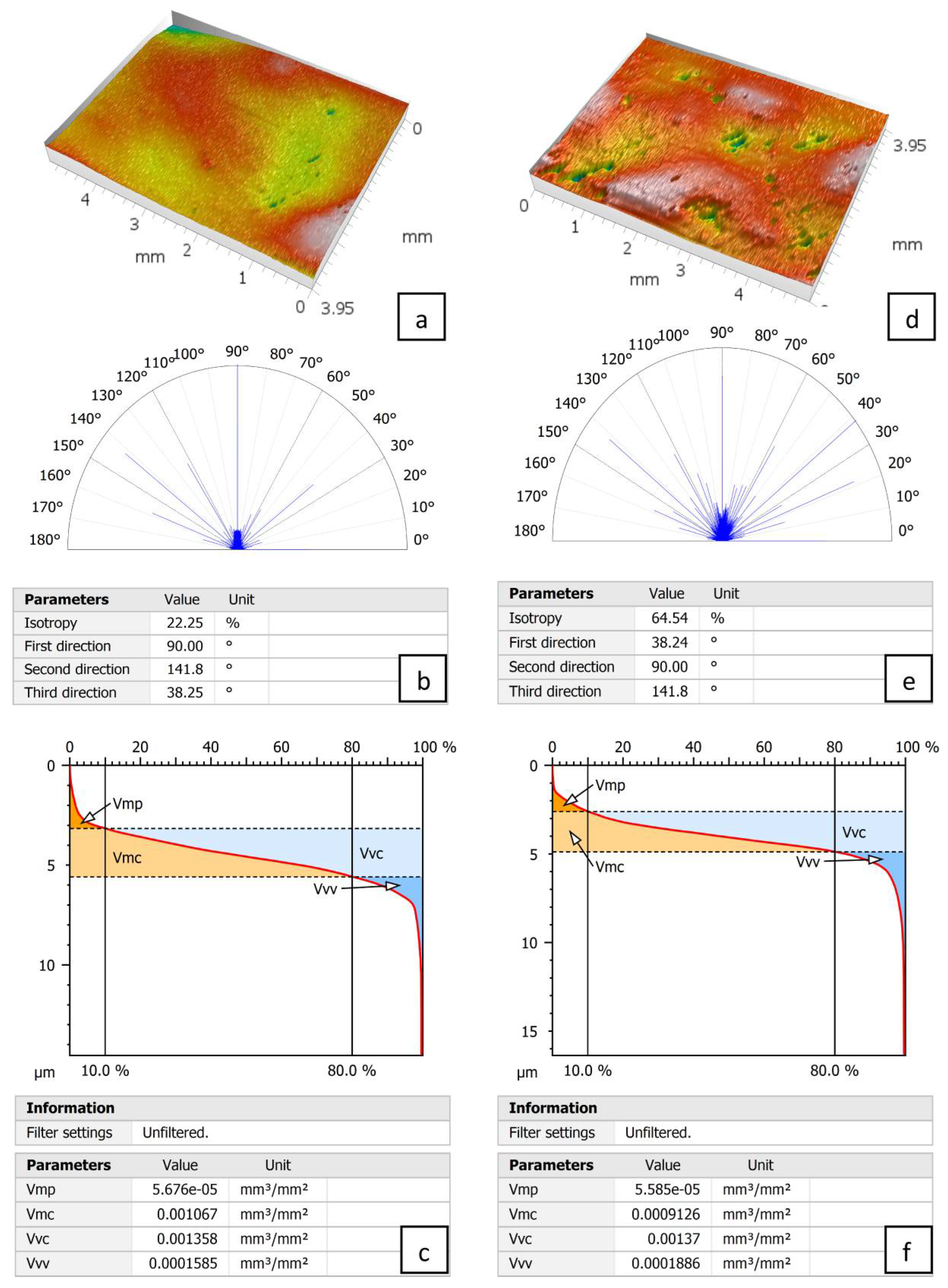

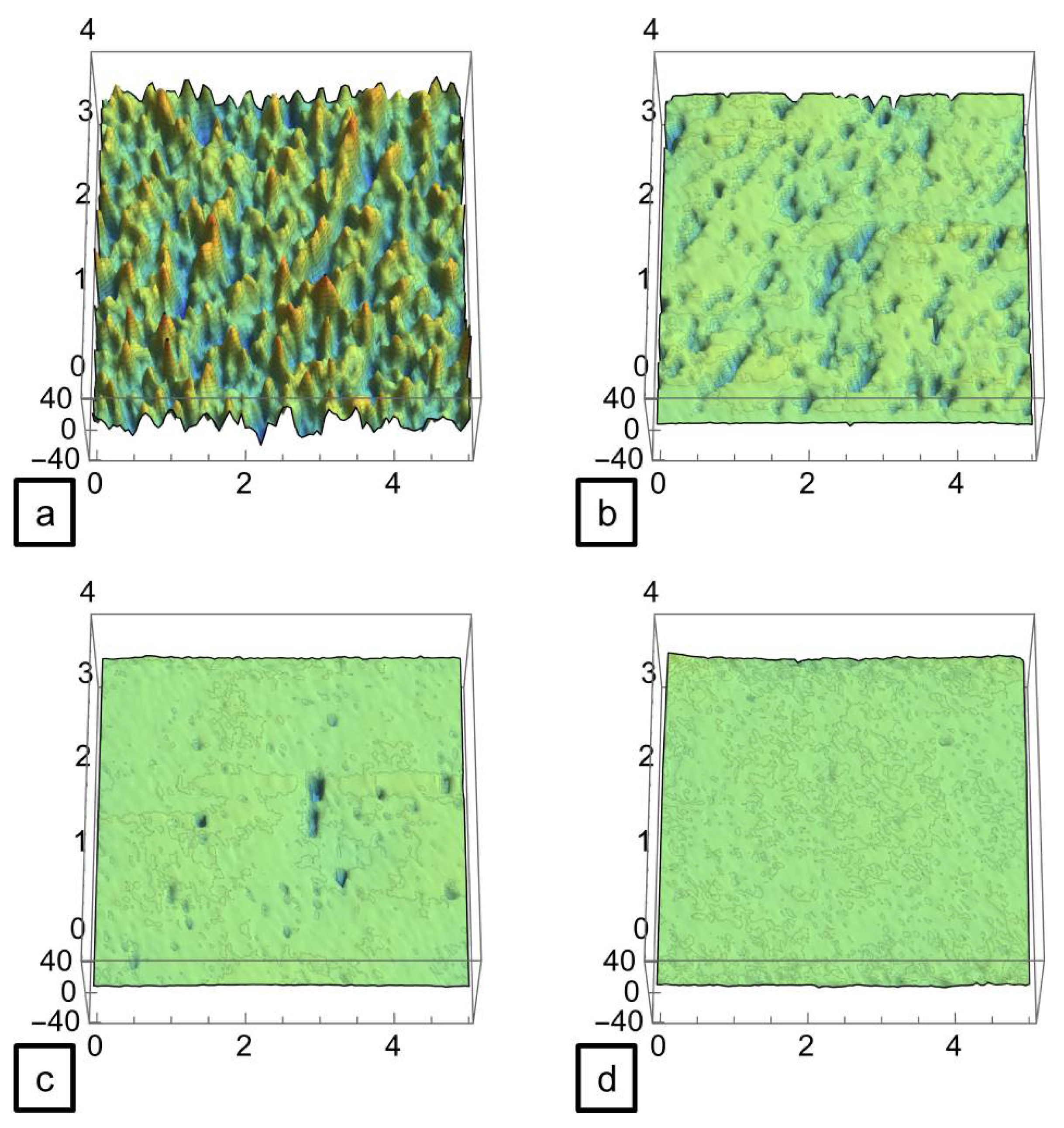

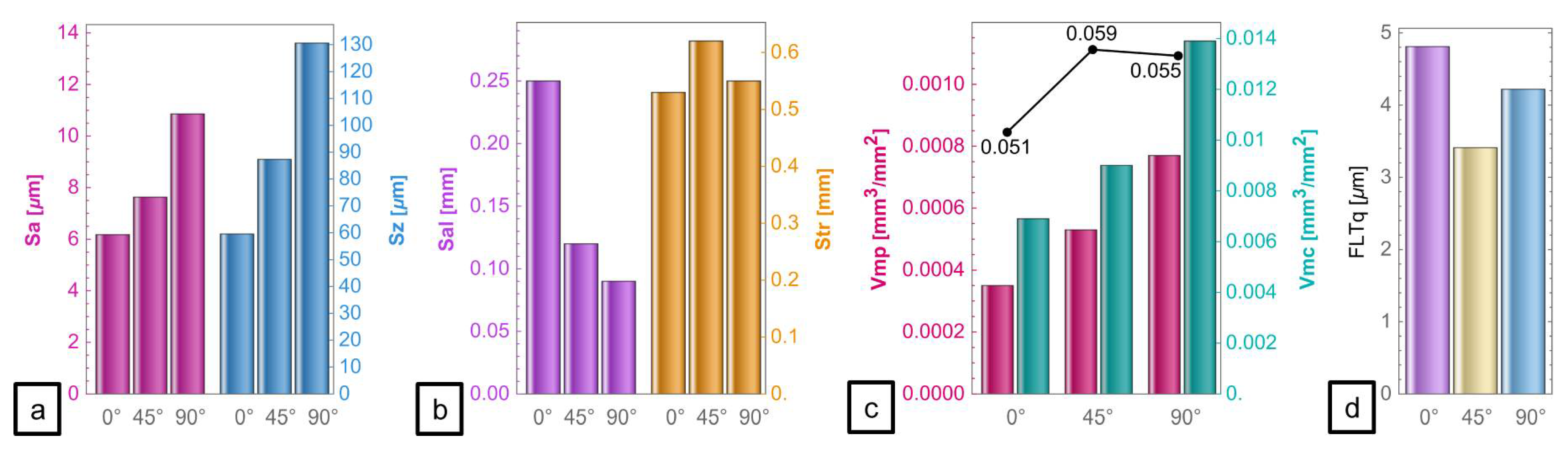

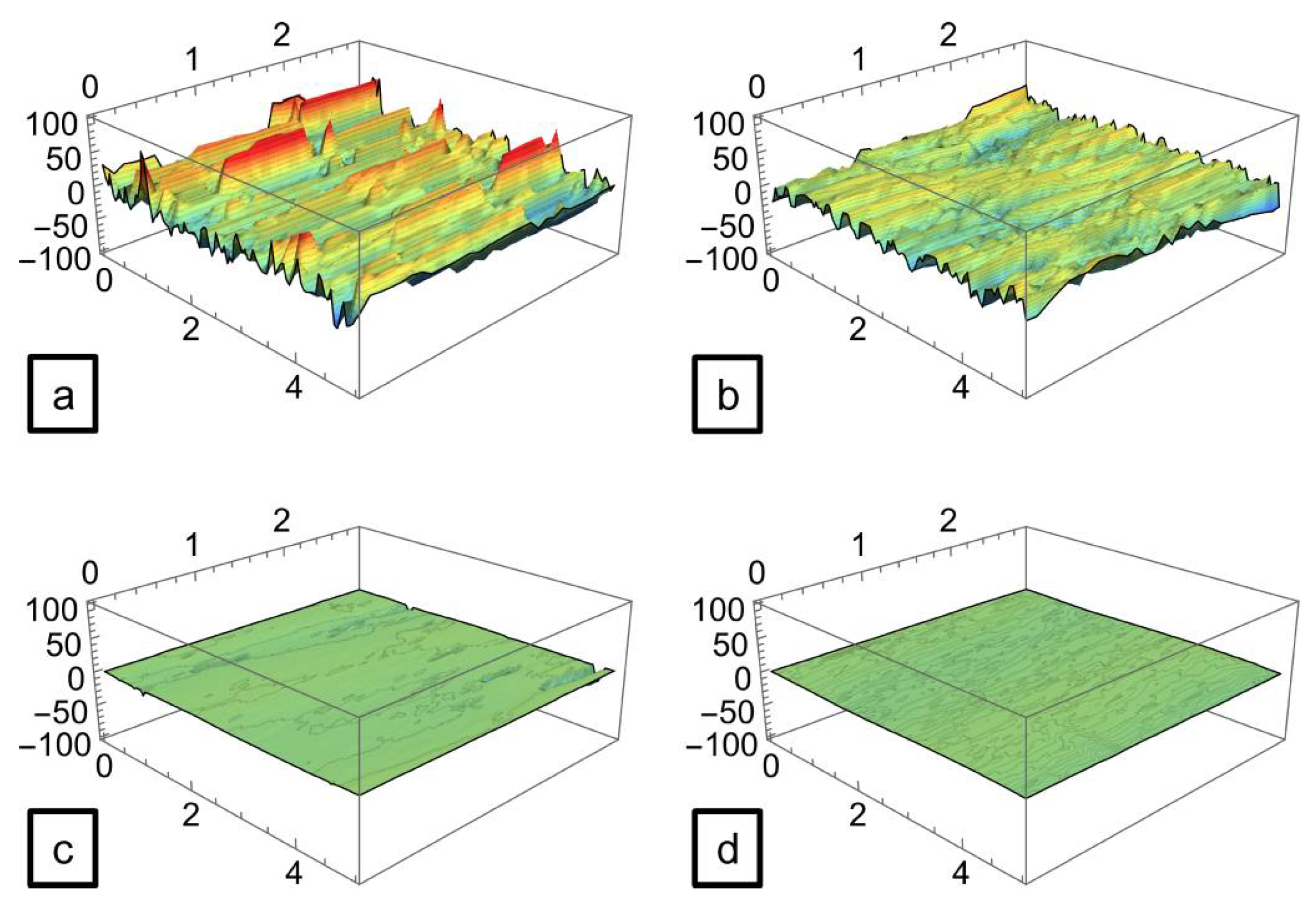

3.1. First Case Study

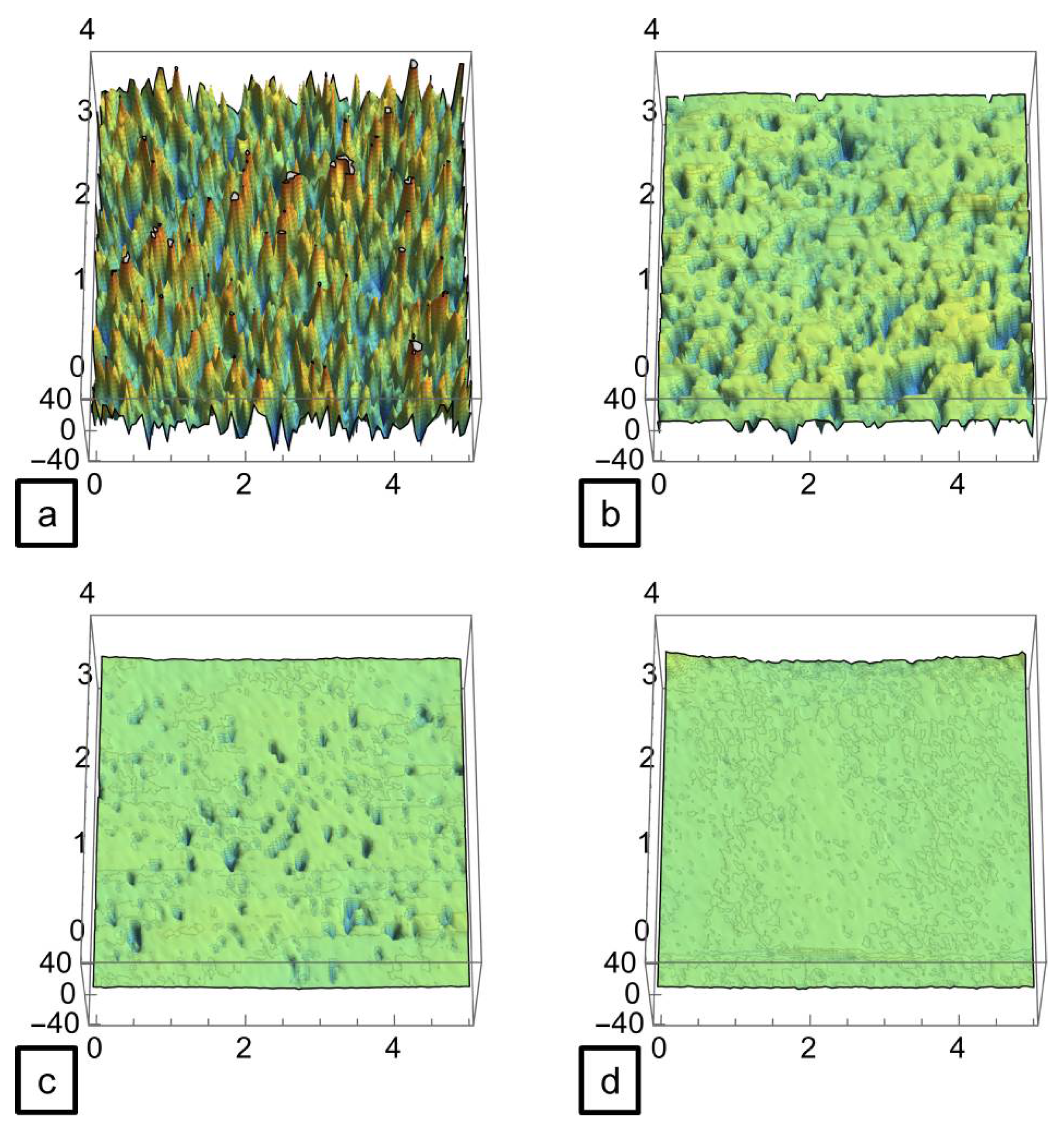

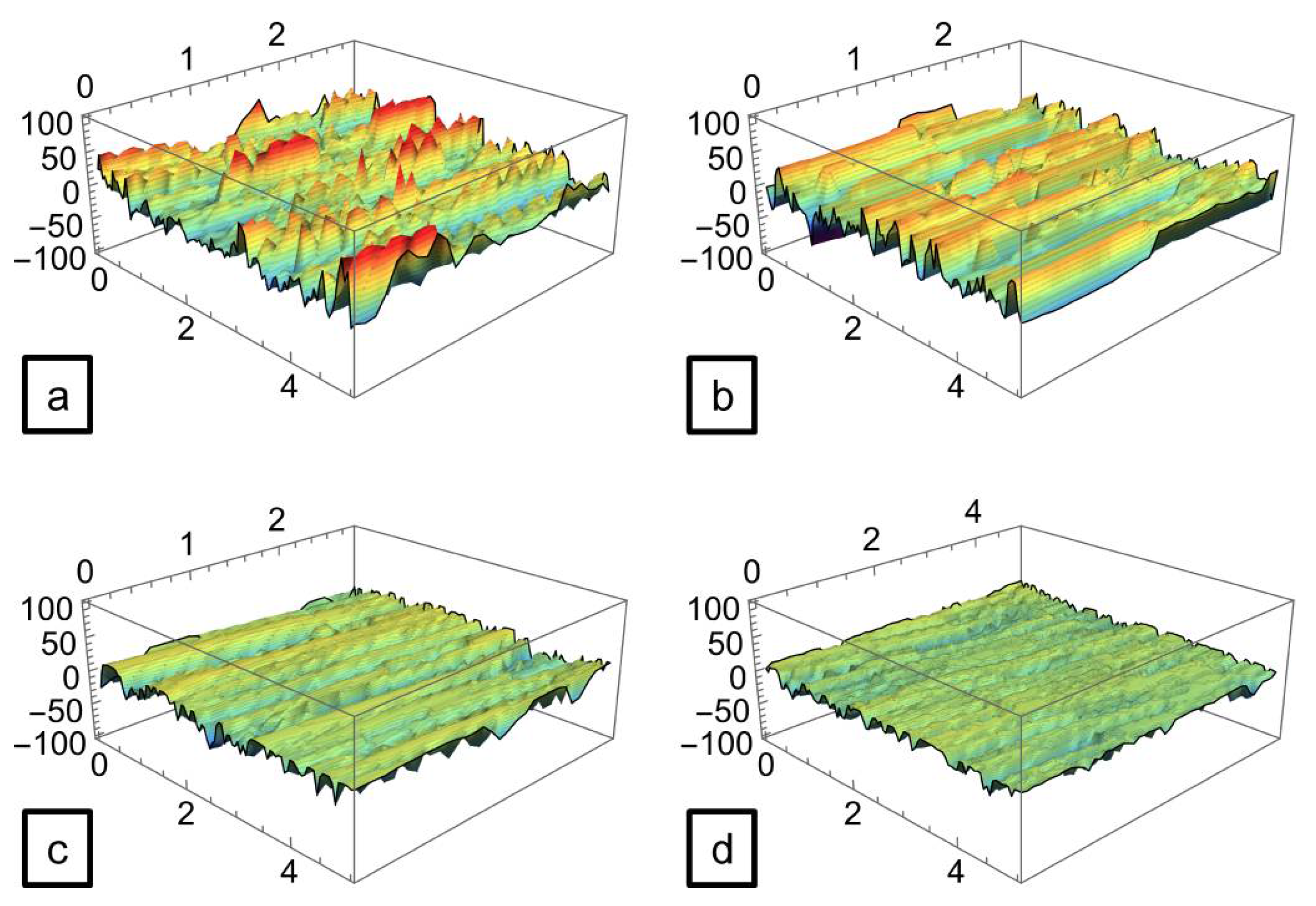

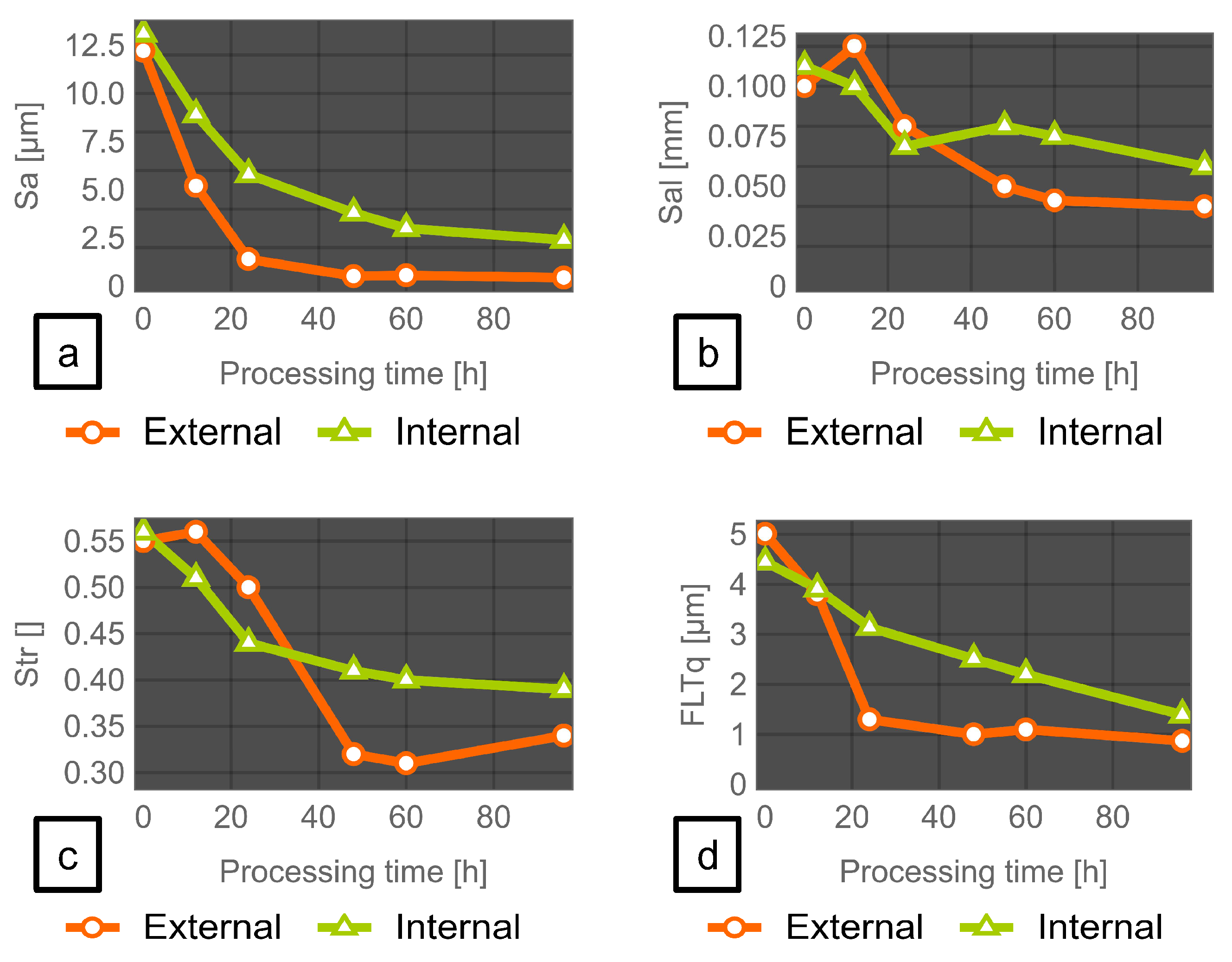

3.2. Second Case Study

4. Conclusions

- The use of 2D roughness analysis is not sufficient to describe the texture of SLMed surfaces, they exhibit non-homogeneities and anisotropies;

- The application of BF allows for improvement of the surface quality, but different building orientations result in differing starting surface textures with varying evoltions, as demonstrated by conditioning;

- Volume analysis confirms the BF mechanism, which is characterized by a marked reduction in the average peak volume, whereas the valleys are only slightly modified;

- In the case of 0° surfaces, satisfactory isotropy and height parameters are obtained after 24 h. Beyond this time, functional analysis reveals that the valleys are altered, and new damage occurs. Flatness analysis reveals an increase in the FLTq parameter, suggesting that BF should be stopped at 24 h;

- Conversely, 45° and 90° surfaces require the longest investigated processing time to achieve good surface quality;

- The application of a slower BF rotational speed results in a more delicate action, as the rolling motion takes place within the barrel. Analysis indicates that the result after 48 h are the same as those achieved by BF at high speed after 24 h, making it a non-economic choice;

- The second case study involves a complex geometry. External surfaces confirm the results obtained for a simple geometry in terms of height parameters, volume analysis, and isotropy;

- The internal surfaces undergo slower decay of the areal parameters due to the reduced accessibility of the measured zone. As a consequence, the processing time must be extended for internal surfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Roson, D.; Stucke, B. Additive Manufacturing Technologies, 2nd ed.; Springer Science Business Media: New York, NY, USA, 2015; ISBN 978-1-4939-2113-3. [Google Scholar]

- ISO/ASTM 52900-15; Standard Terminology for Additive Manufacturing—General Principles—Terminology. ASTM International: West Conshohocken, PA, USA, 2015.

- Kunze, K.; Etter, T.; Grässlin, J.; Shoklover, V. Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2015, 620, 213–222. [Google Scholar] [CrossRef]

- Gu, D. Laser Additive Manufacturing of High-Performance Materials, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-662-46089-4. [Google Scholar]

- Yang, Y.; Loh, H.T.; Fuh, J.Y.H.; Wang, Y.G. Equidistant Path Generation for Improving Scanning Efficiency in Layered Manufacturing. Rapid Prototyping J. 2002, 8, 30–37. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, W.; Cheng, Y.; Huang, S. Compound Scan Mode Developed from Subarea and Contour Scan Mode for Selective Laser Sintering. Int. J. Mach. Tools Manuf. 2007, 47, 873–883. [Google Scholar] [CrossRef]

- Hashmi, S.; Batalha, G.F.; van Tyne, C.J.; Yilbas, B.S. Comprehensive Materials Processing, 1st ed.; Elsevier Science Ltd.: Waltham, MA, USA, 2014; ISBN 978-0-080-96532-1. [Google Scholar]

- Tromme, E.; Kawamoto, A.; Guest, J.K. Topology optimization based on reduction methods with applications to multiscale design and additive manufacturing. Front. Mech. Eng. 2020, 15, 151–165. [Google Scholar] [CrossRef]

- Rombouts, M.; Kruth, J.P.; Froyen, L.; Mercelis, P. Fundamentals of Selective Laser Melting of alloyed steel powders. CIRP Ann. 2006, 55, 187–192. [Google Scholar] [CrossRef]

- Stempin, J.; Tausendfreund, A.; Stöbener, D.; Fischer, A. Roughness Measurements with Polychromatic Speckles on Tilted Surfaces. Nanomanuf. Metrol. 2021, 4, 237–246. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminum alloys: Additive Manufacturing of Aluminum alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Salak, A. Ferrous Powder Metallurgy, 10th ed.; Cambridge International Science Publishing: Cambridge, UK, 1995; ISBN 189-8-32603-7. [Google Scholar]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Brodin, H.; Andersson, O.; Johansson, S. Mechanical testing of a selective laser melted superalloy. Proceeding of the 13th International Conference on Fracture, Beijing, China, 16–21 June 2013; pp. 2573–2574. [Google Scholar]

- Jinhui, L.; Ruidi, L.; Wenxian, Z.; Liding, F.; Huashan, Y. Study on formation of surface and microstructure of stainless-steel part produced by selective laser melting. Mater. Sci. Technol. 2010, 26, 1259–1264. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Laleh, M.; Hughes, A.E.; Yang, S.; Li, Y.; Xu, W.; Gibson, I.; Tan, M.Y. Two and three-dimensional characterization of localized corrosion affected by lack-of-fusion pores in 316L stainless steel produced by selective laser melting. Corros. Sci. 2020, 156, 108394. [Google Scholar] [CrossRef]

- Kumar, L.J.; Pandey, P.M.; Wimpenny, D.I. (Eds.) 3D Printing and Additive Manufacturing Technologies, 1st ed.; Springer: Berlin, Germany, 2019; ISBN 978-981-13-0305-0. [Google Scholar]

- Sefene, E.M. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Pilone, D. Effect of laser remelting on surface roughness and microstructure of AlSi10Mg selective laser melting manufactured parts. Int. J. Adv. Manuf. Technol. 2021, 113, 2739–2759. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskerya, I.; Tucka, C.; Ashcroft, I.; Everitt, N.M. On the formation of AlSi10Mg single tracks and layers in selective laser melting: Microstructure and nano-mechanical properties. J. Mater. Process. Technol. 2016, 230, 88–98. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Roughness modeling of AlSi10Mg parts fabricated by selective laser melting. J. Mater. Process. Technol. 2017, 241, 154–163. [Google Scholar] [CrossRef]

- Zaleski, K.; Skoczylas, A.; Brzozowska, M. The effect of the conditions of shot peening the Inconel 718 nickel alloy on the geometrical structure of the surface. Adv. Sci. Technol. Res. J. 2017, 11, 205–211. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Martinez, S.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Lamikiz, A.; Prokopenko, G.I. Post-processing of the Inconel 718 alloy parts fabricated by selective laser melting: Effects of mechanical surface treatments on surface topography, porosity, hardness and residual stress. Surf. Coat. Technol. 2020, 381, 125136. [Google Scholar] [CrossRef]

- Avanzini, A.; Battini, D.; Gelfi, M.; Girelli, L.; Petrogalli, C.; Pola, A.; Tocci, M. Investigation on fatigue strength of sand-blasted DMLS-AlSi10Mg alloy. Procedia Struct. Integr. 2019, 18, 119–128. [Google Scholar] [CrossRef]

- Löber, L.; Flache, C.; Petters, R.; Kühn, U.; Eckert, J. Comparison of different post processing technologies for SLM generated 316l steel parts. Rapid Prototyp. J. 2013, 19, 173–179. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. The effect of post-processing operations on surface characteristics of 316L stainless steel produced by selective laser melting. Addit. Manuf. 2019, 26, 84–93. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Macera, L.; Veniali, F. Post-Processing of Complex SLM Parts by Barrel Finishing. Appl. Sci. 2020, 10, 1382. [Google Scholar] [CrossRef] [Green Version]

- Boschetto, A.; Bottini, L.; Veniali, F. Surface roughness and radiusing of Ti6Al4V selective laser melting-manufactured parts conditioned by barrel finishing. Int. J. Adv. Manuf. 2018, 94, 2773–2790. [Google Scholar] [CrossRef]

- Leach, R. (Ed.) Characterization of Aerial Texture; Springer: Berlin/Heidelberg, Germany, 2013; Chapter 1; ISBN 978-3-642-36457-0. [Google Scholar]

- ISO 4287:2000; Geometrical Product Specification (GPS), Surface texture: Profile Method, Terms, Definitions and Surface Texture Parameters. International Organization of Standardization: Geneva, Switzerland, 2000.

- ISO 4288:1996; Geometrical Product Specifications (GPS), Surface Texture: Profile Method, Rules and Procedures for the Assessment of Surface Texture. International Organization of Standardization: Geneva, Switzerland, 1996.

- ISO 25178-2:2012; Geometrical Product Specifications (GPS), Surface Texture: Aerial, Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 1011:2004; Geometric Product Specification (GPS), Geometrical Tolerancing, Tolerances of Form, Orientation, Location and Run-Out. International Organization for Standardization: Geneva, Switzerland, 2004.

- ISO 12781-1:2011; Geometrical Product Specification (GPS), Flatness, Part 1: Vocabulary and Parameters of Flatness. International Organization for Standardization: Geneva, Switzerland, 2011.

- ISO 16610-21:2012; Geometrical Product Specifications (GPS), Filtration, Part 21: Linear Profile Filters: Gaussian Filters. International Organization for Standardization: Geneva, Switzerland, 2012.

- Material Data Sheet EOS TitaniumTi4Al6V. Available online: https://www.eos.info/03_system-related-assets/material-related-contents/metal-materials-and-examples/metal-material-datasheet/titan/ti64/material_datasheet_eos_titanium_ti64_grade5_en_web.pdf (accessed on 15 July 2022).

- Tulinski, E.H. Mass finishing. In ASM Metals Handbook: Surface Engineering, 9th ed.; ASM International: Materials Park, OH, USA, 1994; Volume 5, pp. 261–277. ISBN 978-0-871-70011-7. [Google Scholar]

- Nalli, F.; Bottini, L.; Boschetto, A.; Cortese, L.; Veniali, F. Effect of Industrial Heat Treatment and Barrel Finishing on the Mechanical Performance of Ti6Al4V Processed by Selective Laser Melting. Appl. Sci. 2020, 10, 2280. [Google Scholar] [CrossRef] [Green Version]

- Gillespie, L.K. Mass Finishing Handbook, 1st ed.; Industrial Press Inc.: New York, NY, USA, 2007; ISBN 9780831132576. [Google Scholar]

- Henein, H.; Brimacombe, J.K.; Watkinson, A.P. Experimental study of transverse bed motion in rotary kilns. Metall. Trans. B 1983, 14, 91–205. [Google Scholar] [CrossRef]

- Gadelmawla, E.S.; Koura, M.M.; Maksoud, T.M.A.; Elewa, I.M.; Soliman, H.H. Roughness parameters. J. Mater. Process. Technol. 2002, 123, 133–145. [Google Scholar] [CrossRef]

| Vertical Height | Vertical Precision | Tip Radius | Travel Speed | Vertical Force | Travelling Distance |

|---|---|---|---|---|---|

| 2400 µm | 16 nm | 2 µm | 0.5–2 mm/s | 0.75 mN | 50 mm |

| Chemical Composition | AL | V | Fe | C | N | H | O | Ti |

|---|---|---|---|---|---|---|---|---|

| Ti6Al4V (wt.%) | 5.5–6.8 | 3.5–4.5 | ≤0.30 | ≤0.08 | ≤0.05 | ≤0.015 | ≤0.20 | Balanced |

| Power (W) | Scan Speed (mm/s) | Hatch Distance (mm) | Contour Offset (mm) | |

|---|---|---|---|---|

| Hatch infill | 280 | 1200 | 0.14 | - |

| Hatch upskin | 280 | 1200 | 0.14 | - |

| Hatch downskin | 120 | 1000 | 0.10 | - |

| Contour | 150 | 1250 | - | 0.02 |

| Height Parameters | Spatial Parameters | |||||||

|---|---|---|---|---|---|---|---|---|

| Sa | Sq | Ssk | Sku | Sp | Sv | Sz | Sal | Str |

| 6.182 | 7.809 | −0.04568 | 3.105 | 28.11 | 31.43 | 59.54 | 0.2529 | 0.5294 |

| µm | µm | µm | µm | µm | mm | |||

| Vm | Vv | Vmp | Vmc | Vvc | Vvv |

|---|---|---|---|---|---|

| 0.0003533 | 0.01045 | 0.0003533 | 0.006908 | 0.009534 | 0.0009182 |

| mm³/mm² | mm³/mm² | mm³/mm² | mm³/mm² | mm³/mm² | mm³/mm² |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boschetto, A.; Bottini, L.; Ghanadi, N. Areal Analysis Investigation of Selective Laser Melting Parts. J. Manuf. Mater. Process. 2022, 6, 83. https://doi.org/10.3390/jmmp6040083

Boschetto A, Bottini L, Ghanadi N. Areal Analysis Investigation of Selective Laser Melting Parts. Journal of Manufacturing and Materials Processing. 2022; 6(4):83. https://doi.org/10.3390/jmmp6040083

Chicago/Turabian StyleBoschetto, Alberto, Luana Bottini, and Nahal Ghanadi. 2022. "Areal Analysis Investigation of Selective Laser Melting Parts" Journal of Manufacturing and Materials Processing 6, no. 4: 83. https://doi.org/10.3390/jmmp6040083

APA StyleBoschetto, A., Bottini, L., & Ghanadi, N. (2022). Areal Analysis Investigation of Selective Laser Melting Parts. Journal of Manufacturing and Materials Processing, 6(4), 83. https://doi.org/10.3390/jmmp6040083