Overmolding of Hybrid Long and Short Carbon Fiber Polypropylene Composite: Optimizing Processing Parameters

Abstract

1. Introduction

2. Experimental

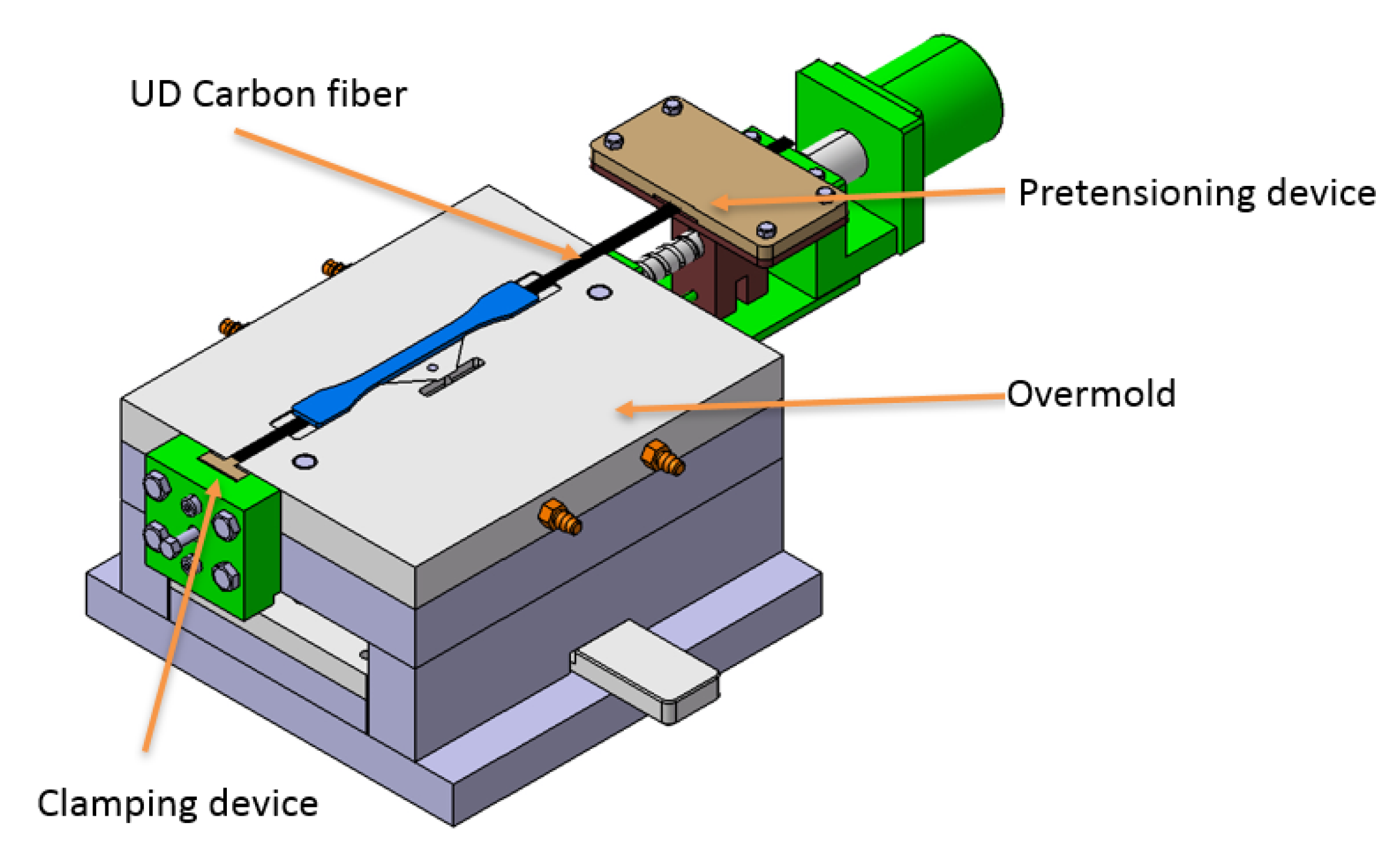

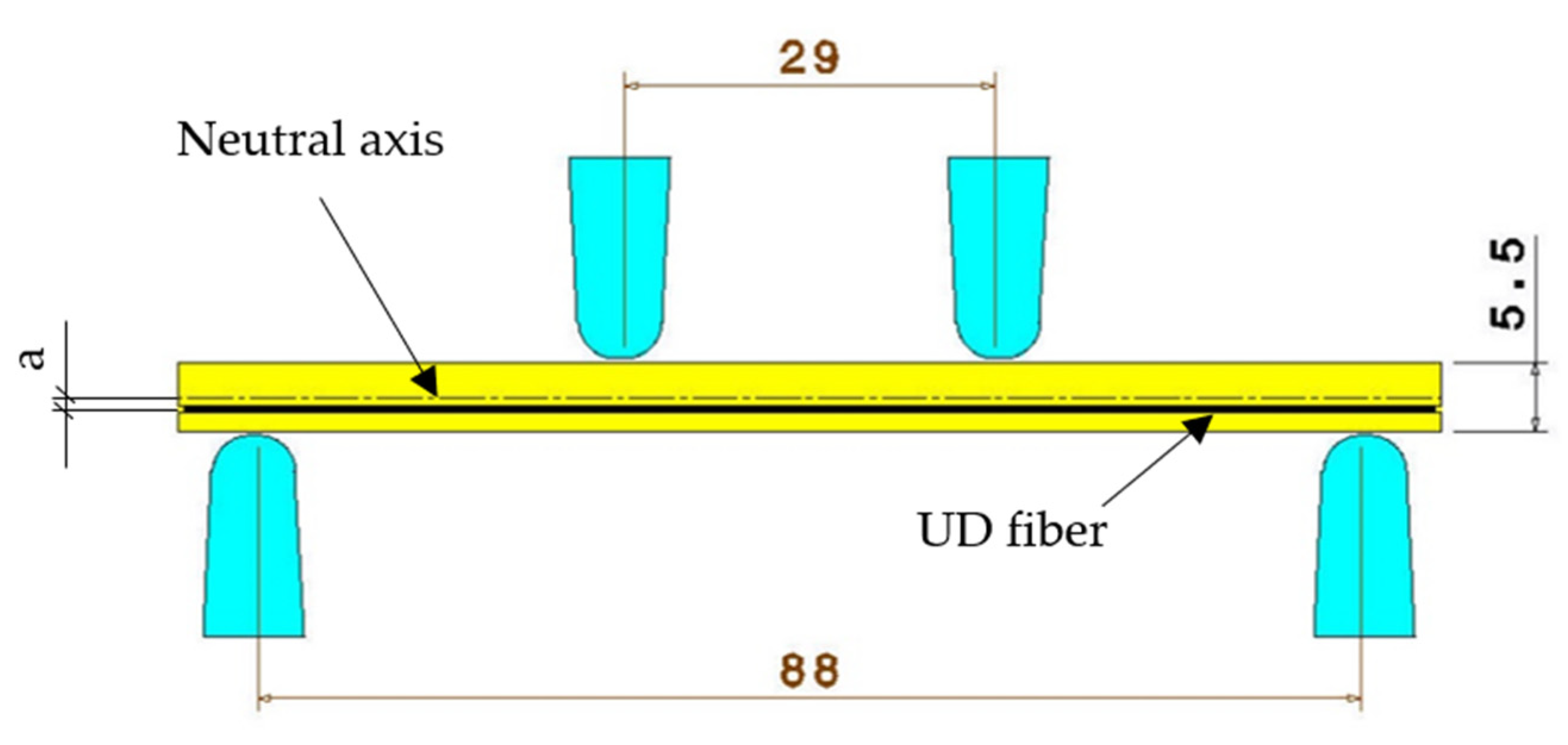

2.1. Fiber Pretension Principle

2.2. Materials

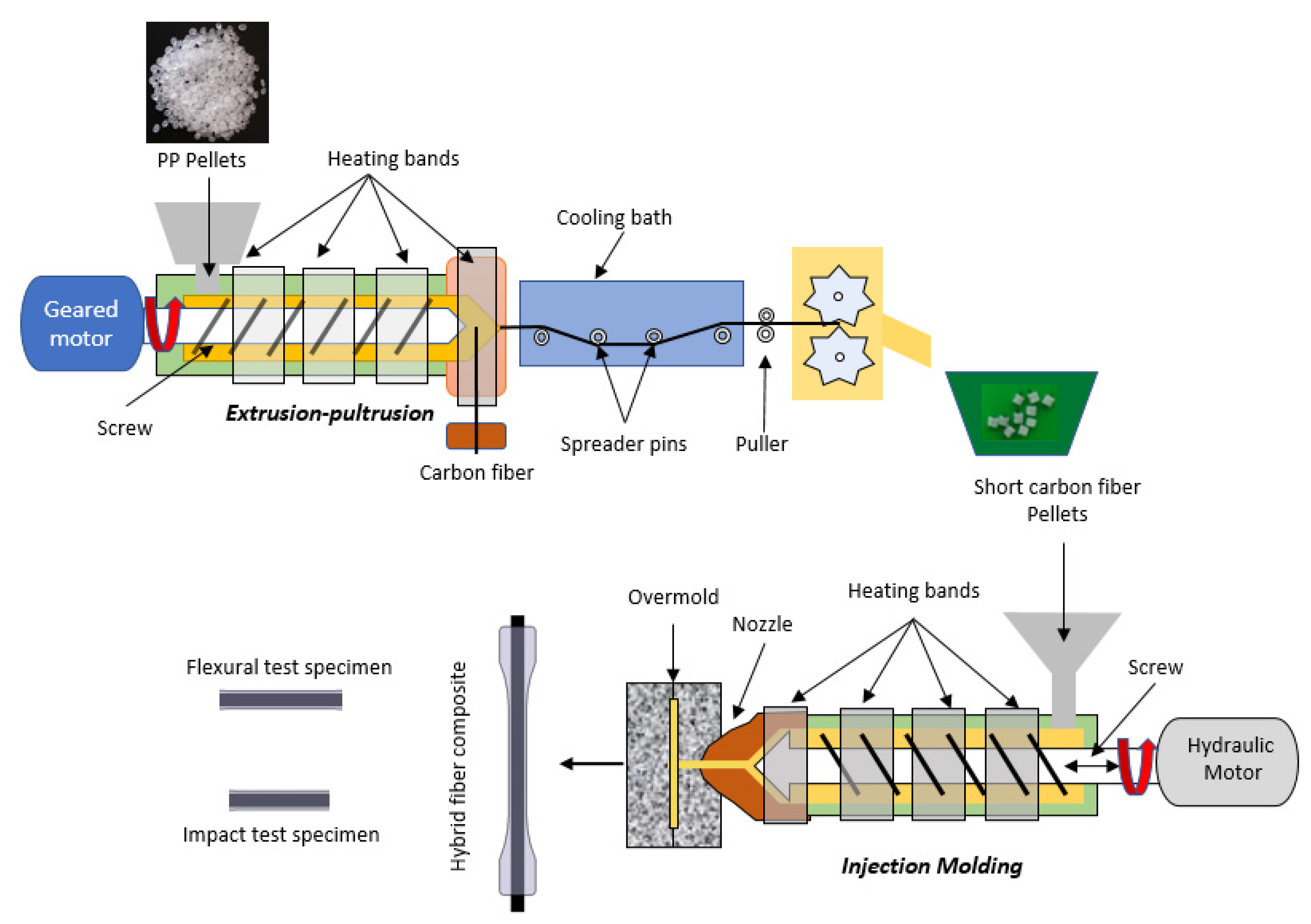

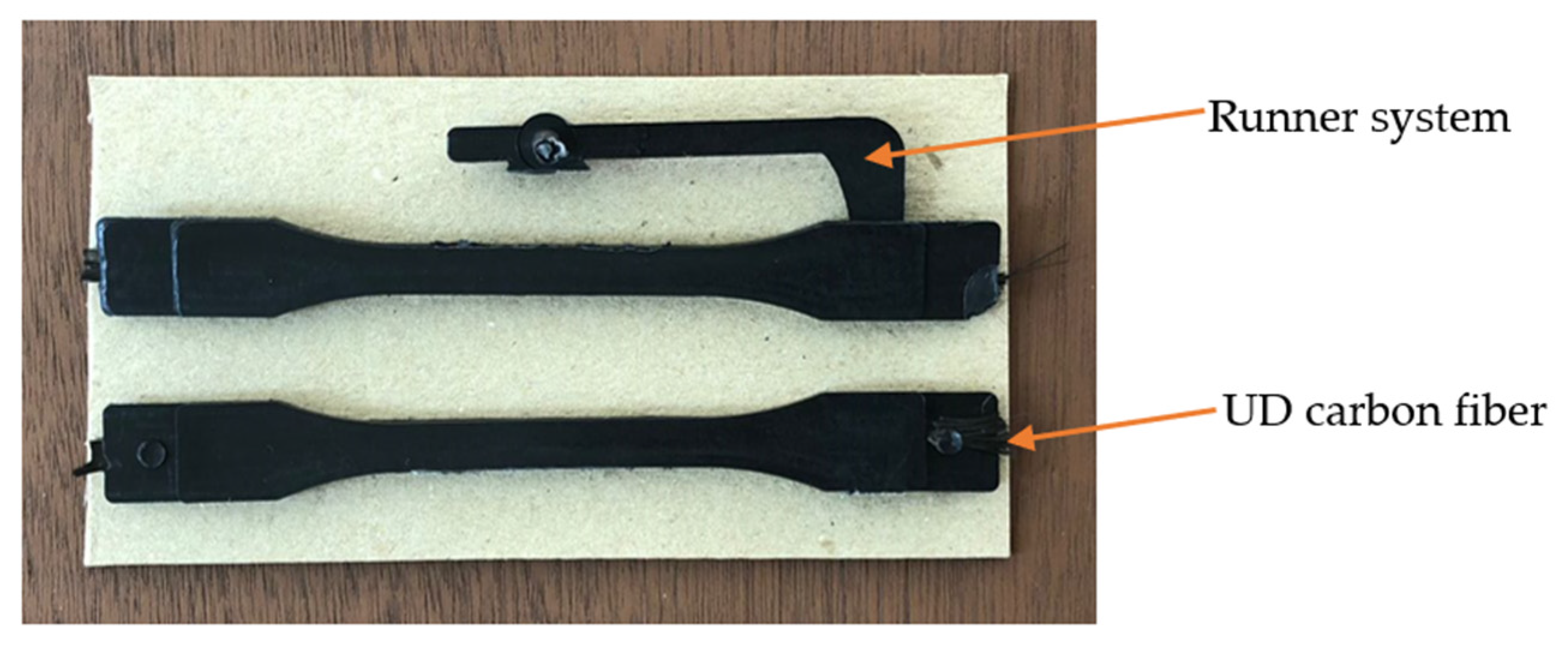

2.3. Preparation of Hybrid Overmolded Specimens

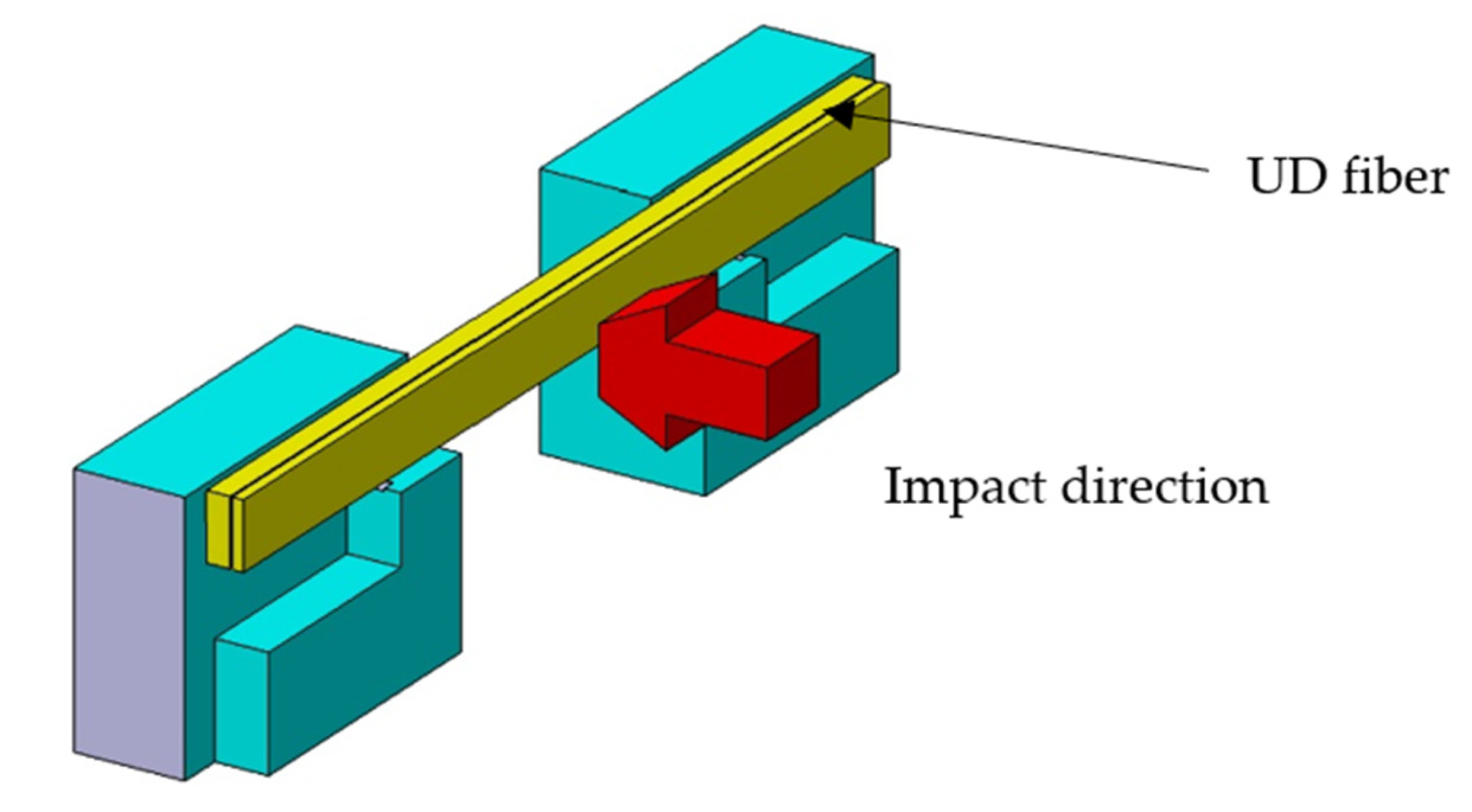

2.4. Characterization

3. Results and Discussion

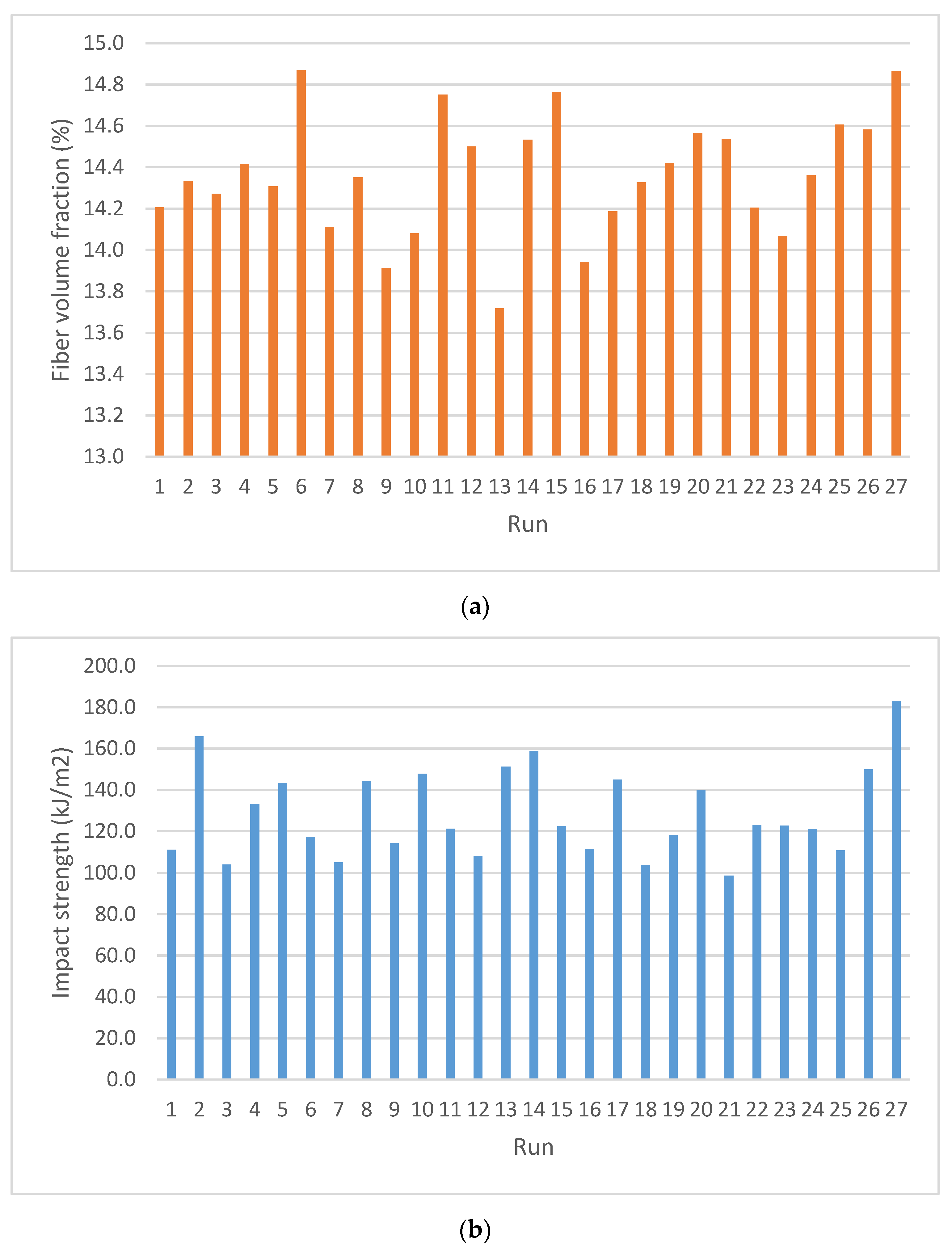

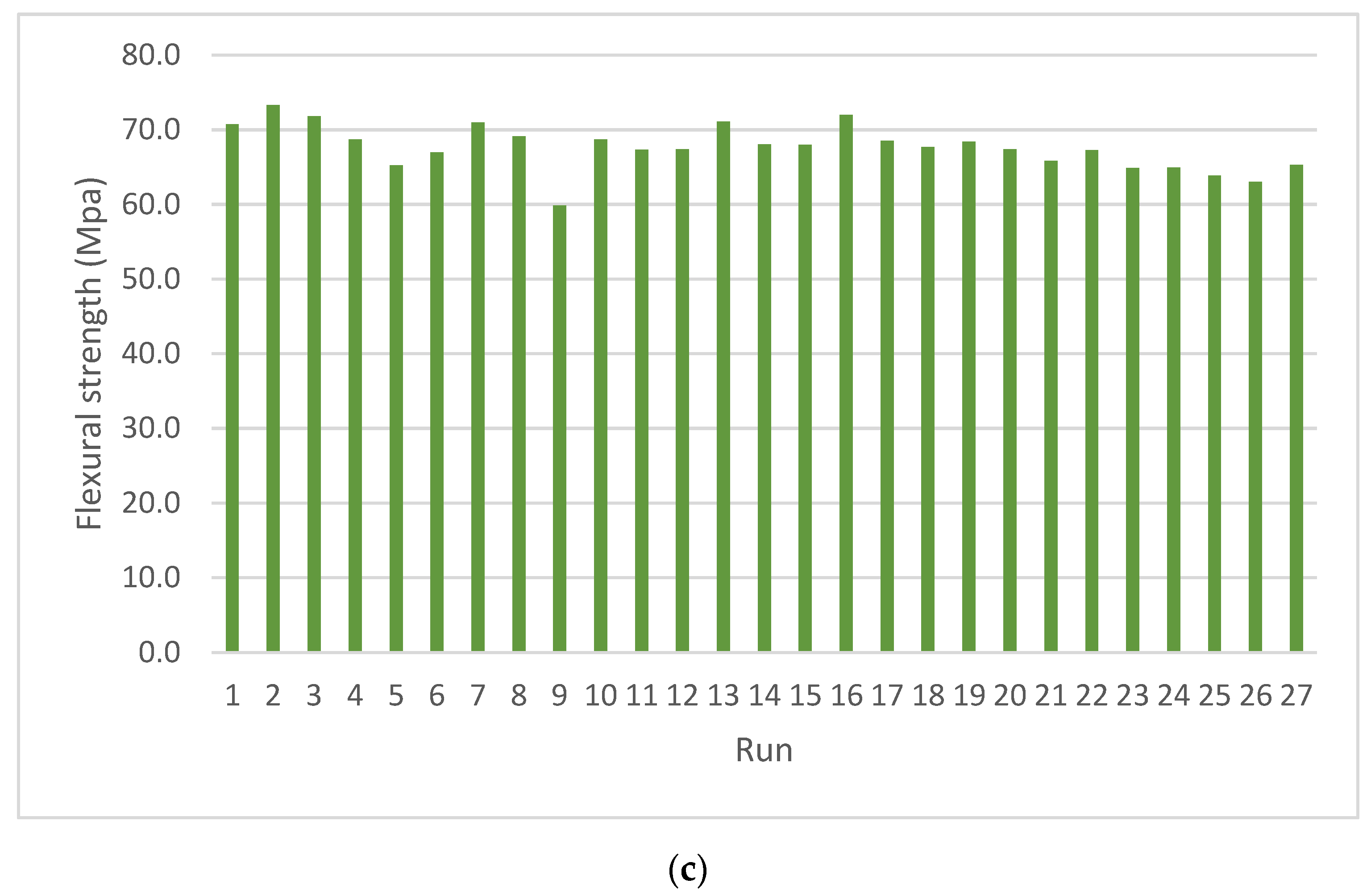

3.1. Responses

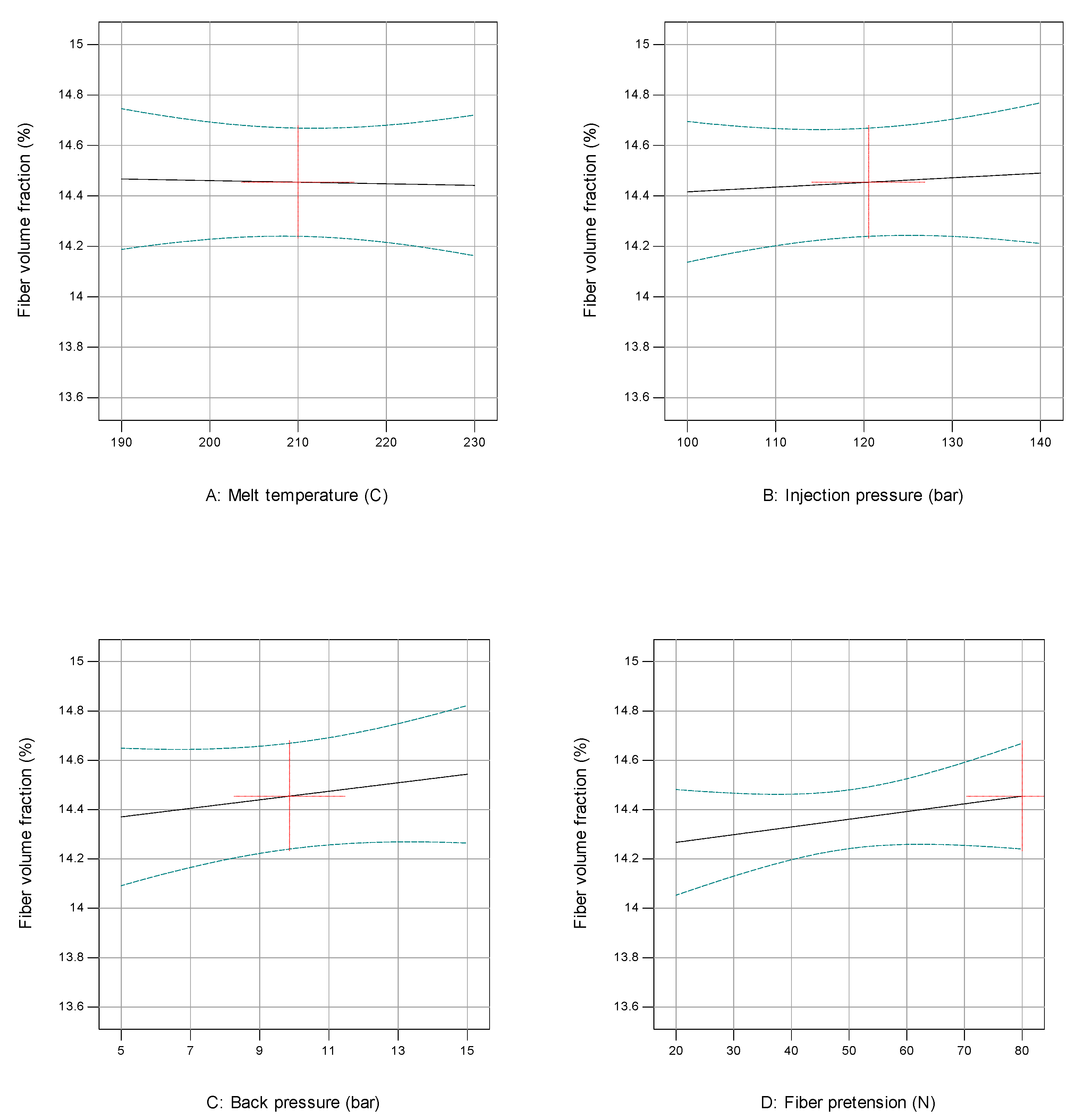

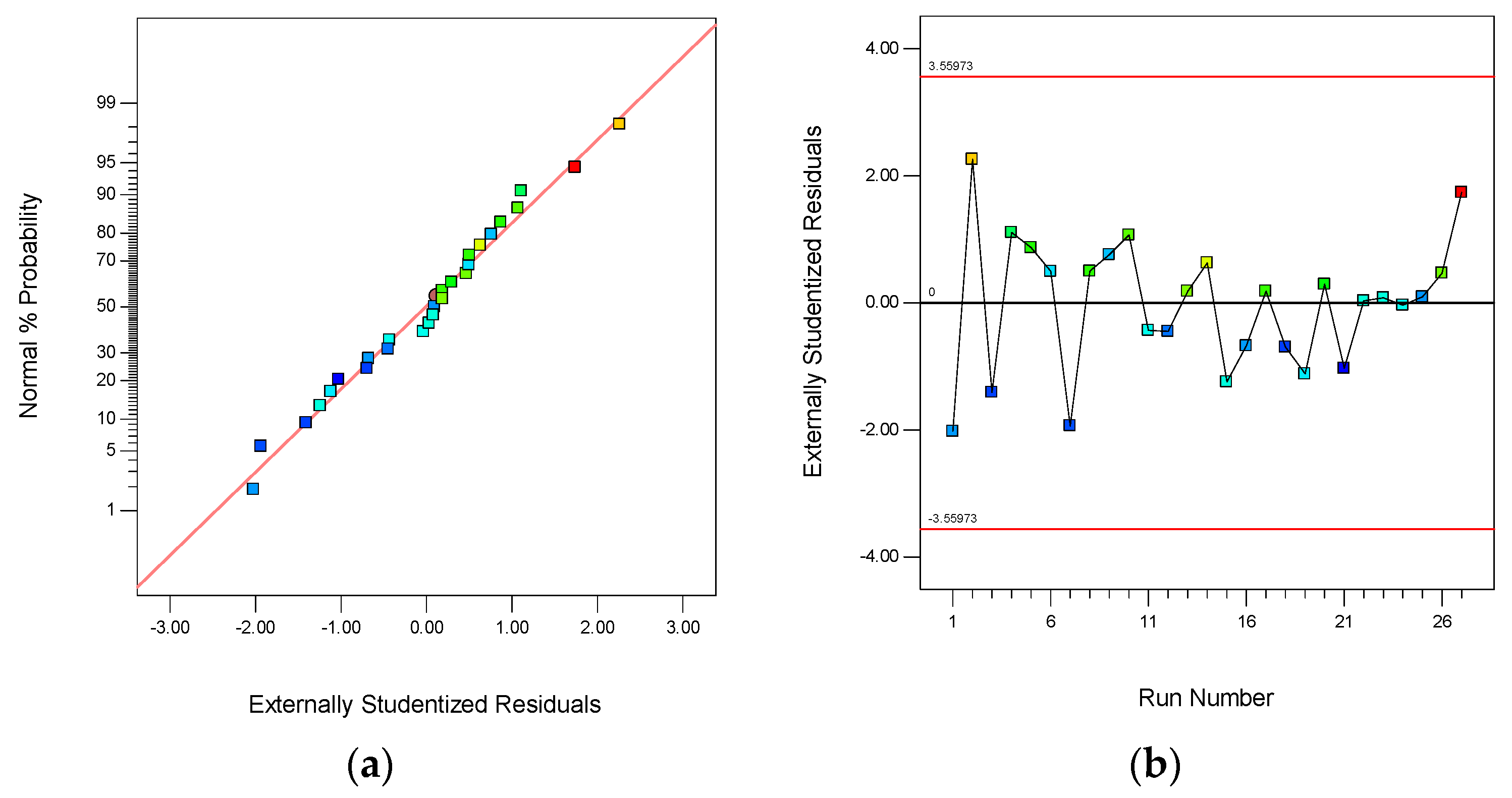

3.2. Analysis of Fiber Volume Fraction

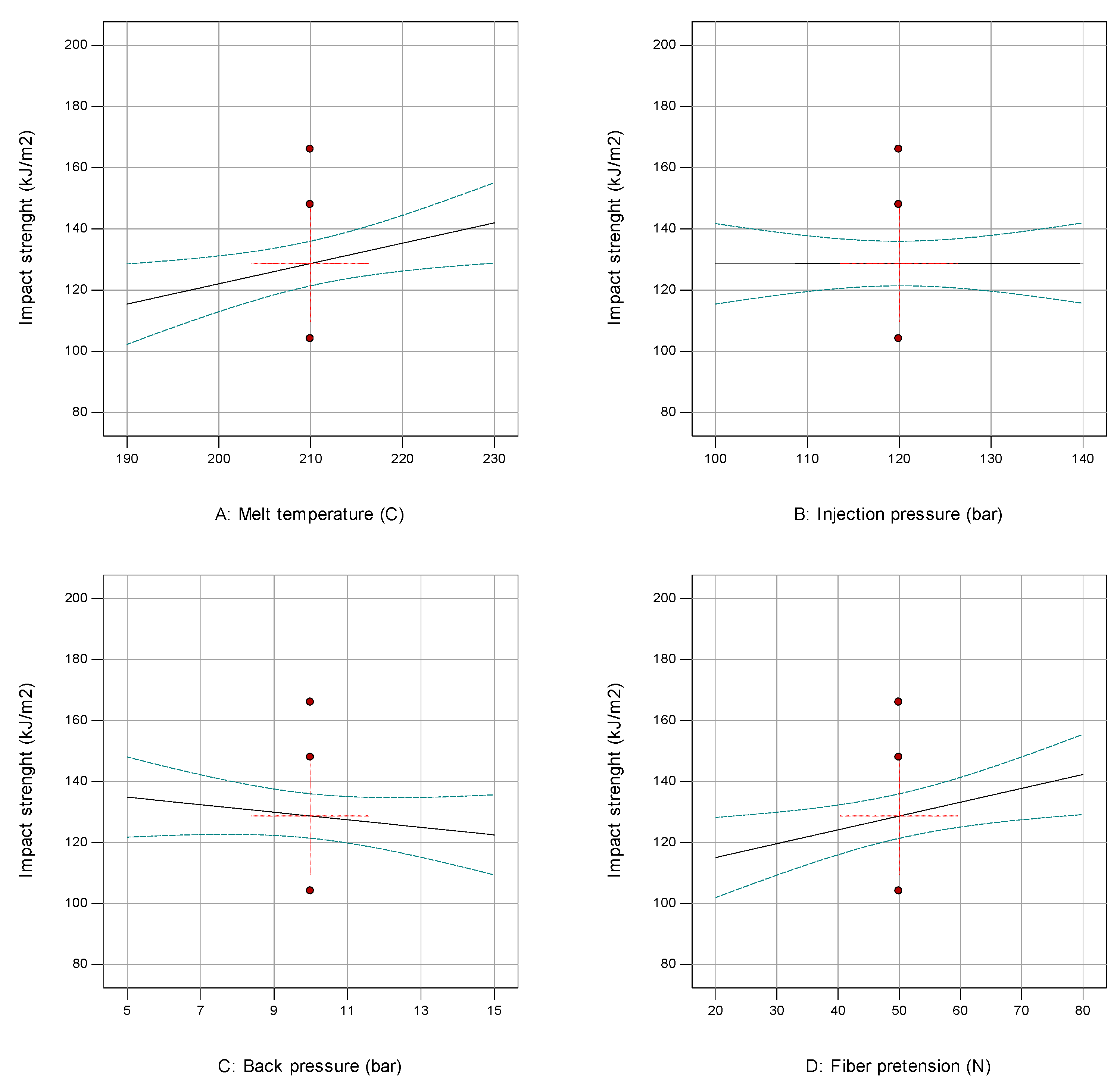

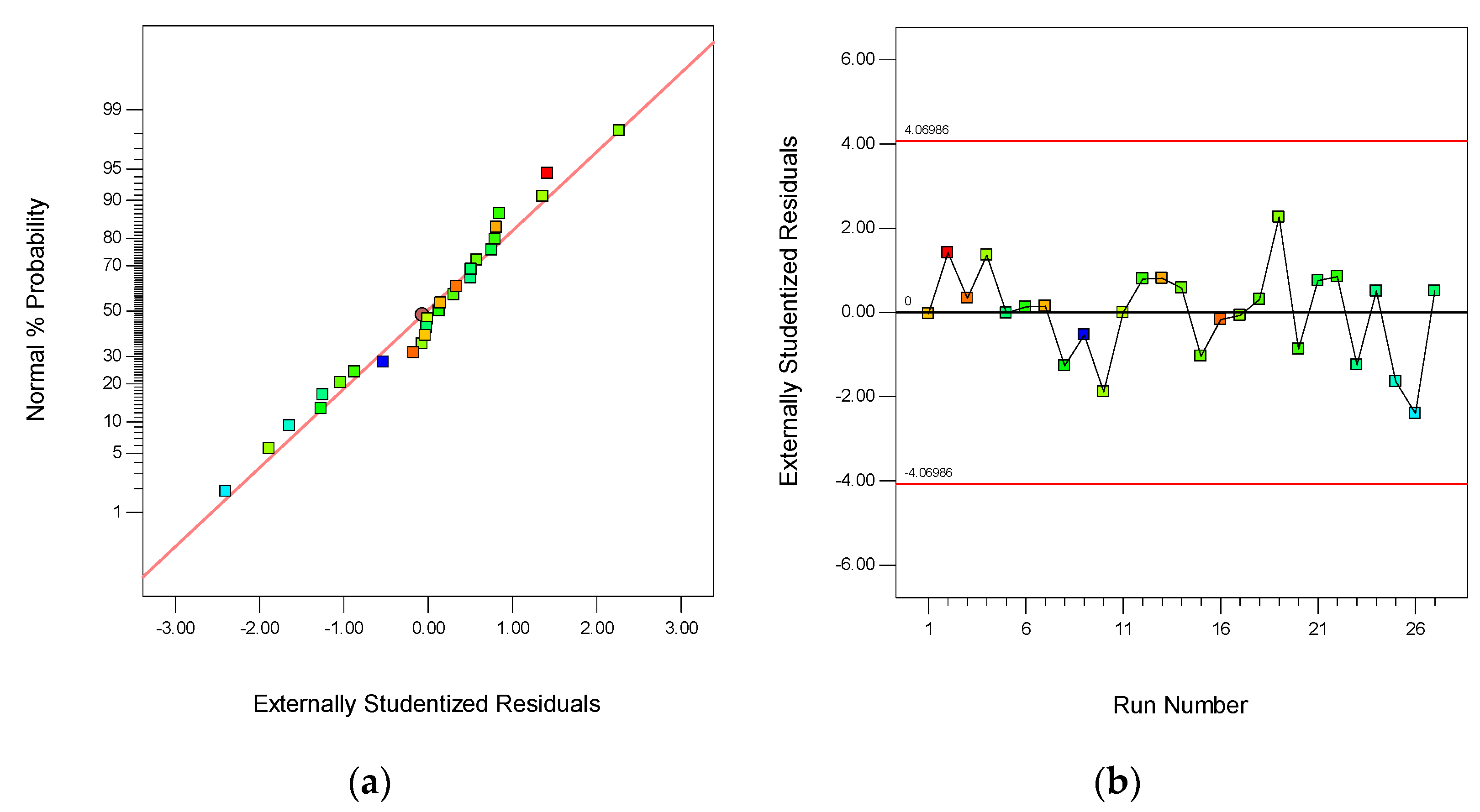

3.3. Analysis of Impact Strength

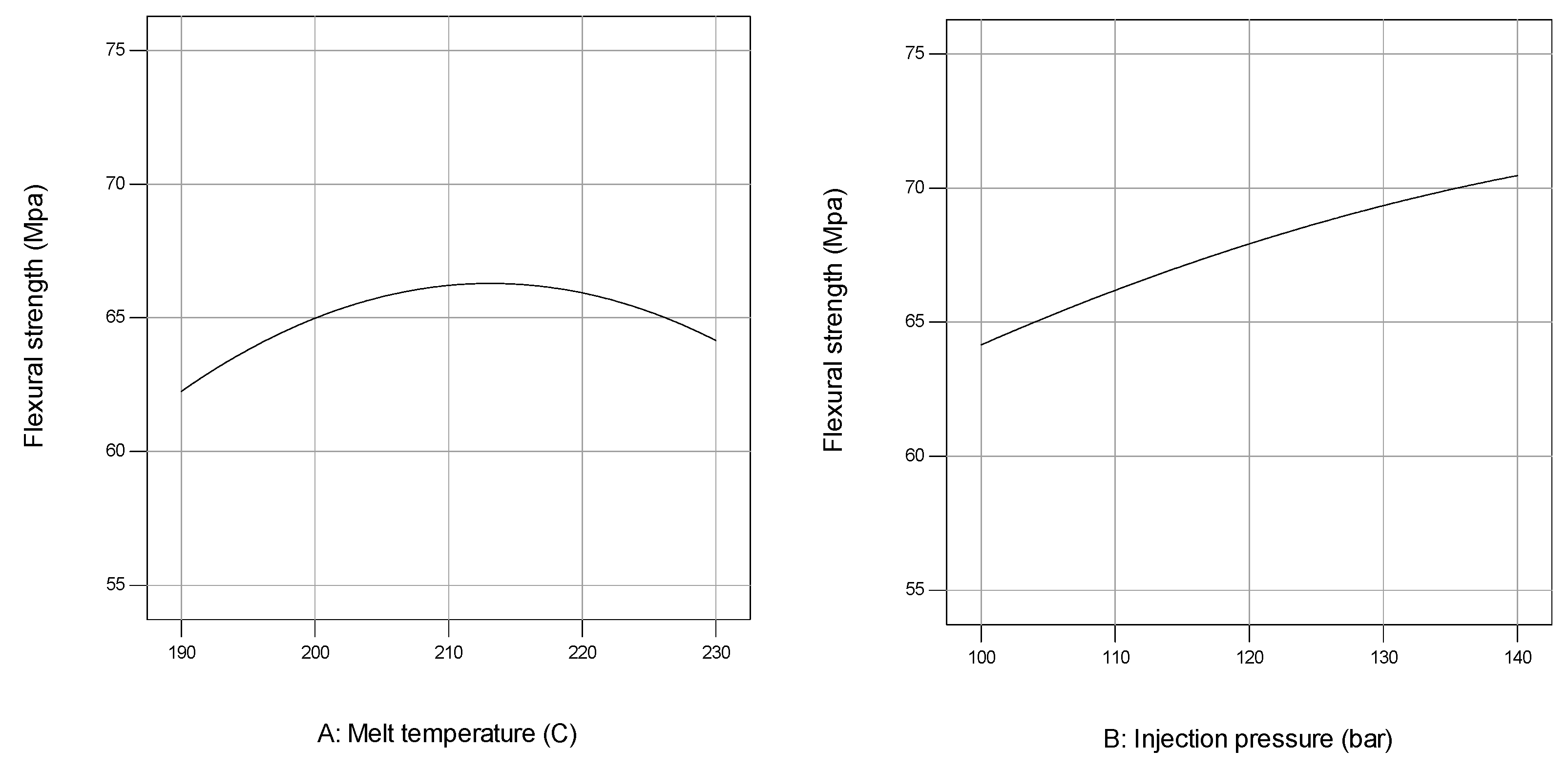

3.4. Analysis of Flexural Strength

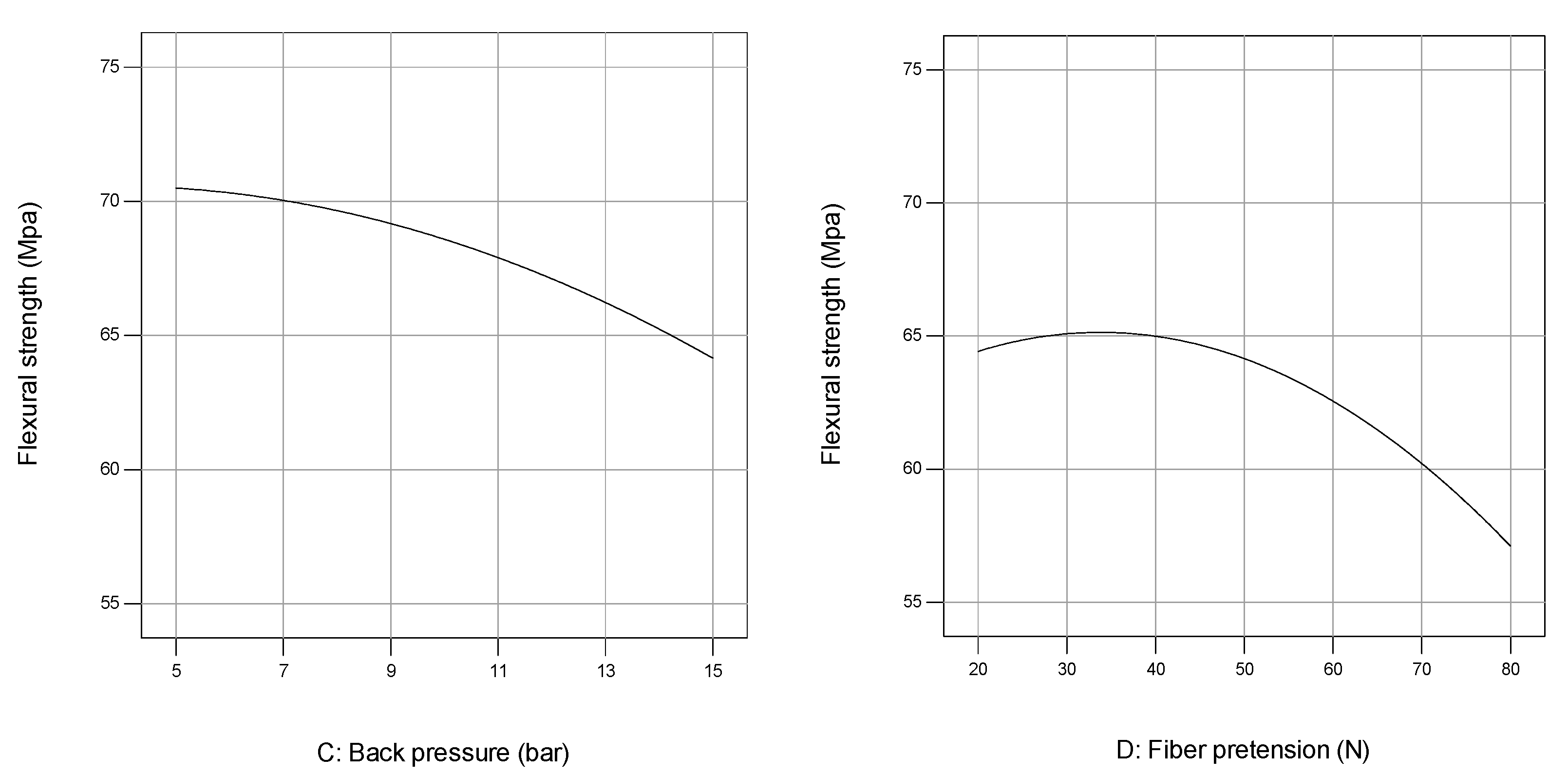

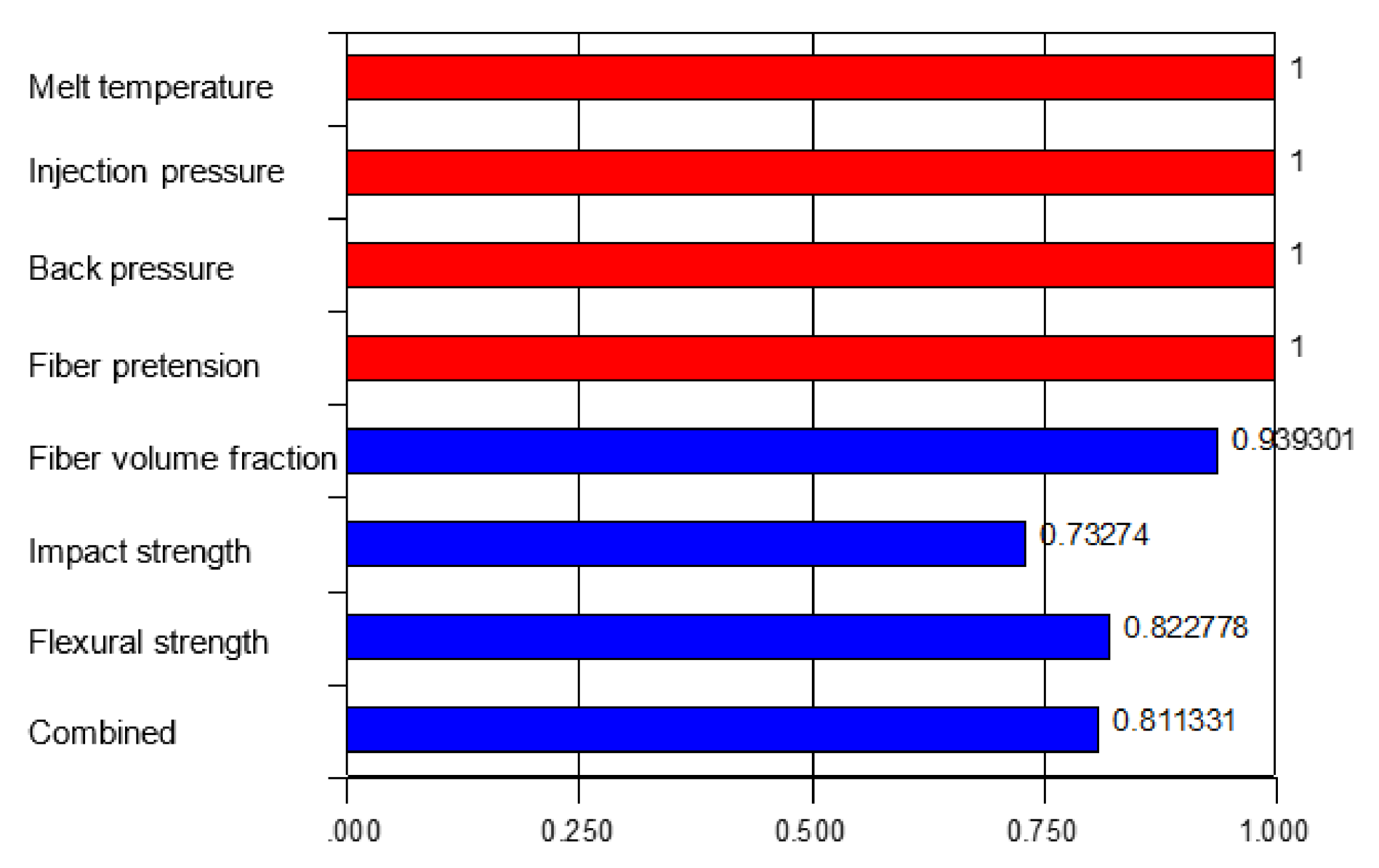

3.5. Optimizing All Responses

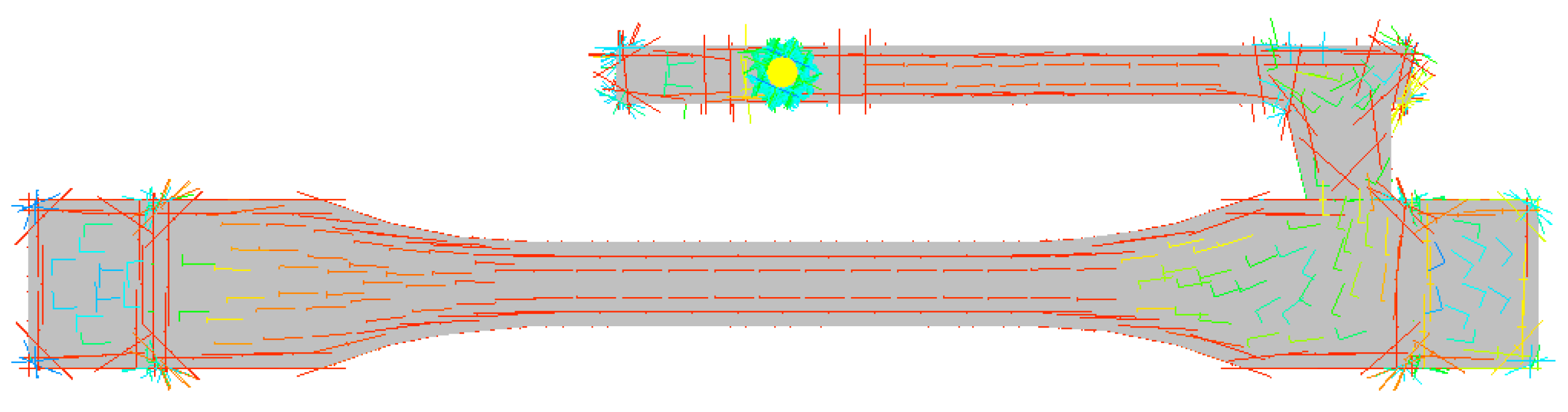

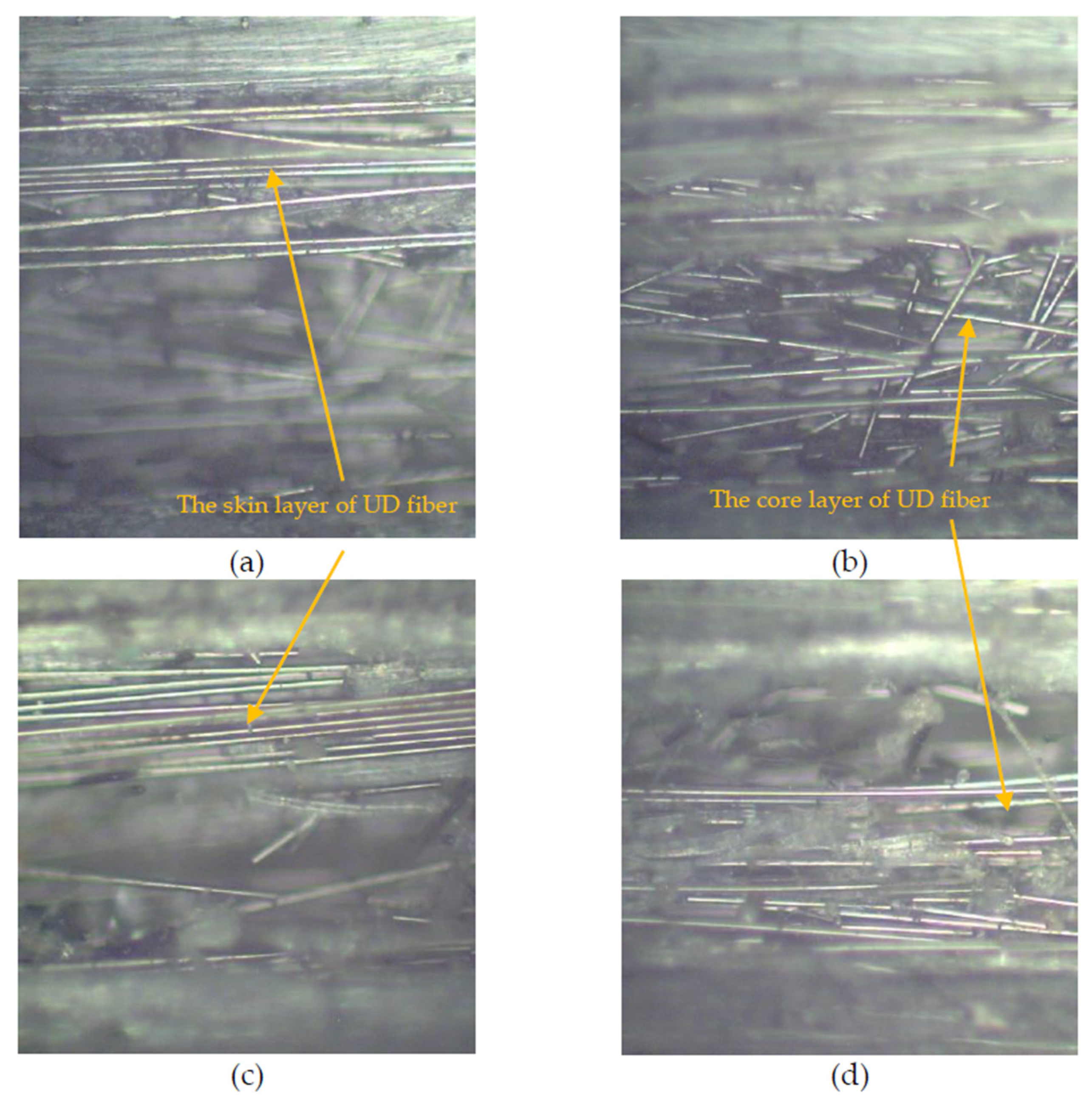

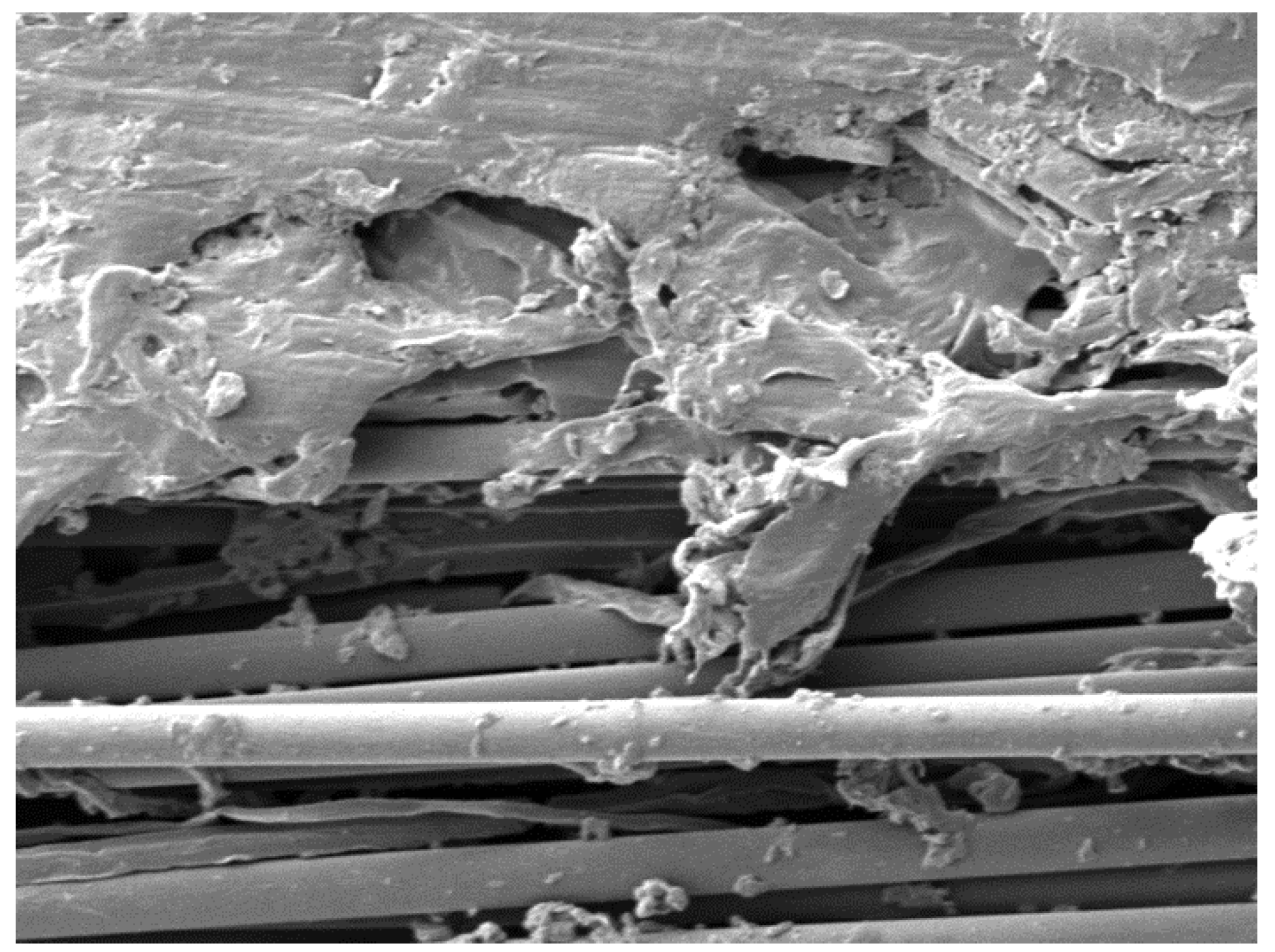

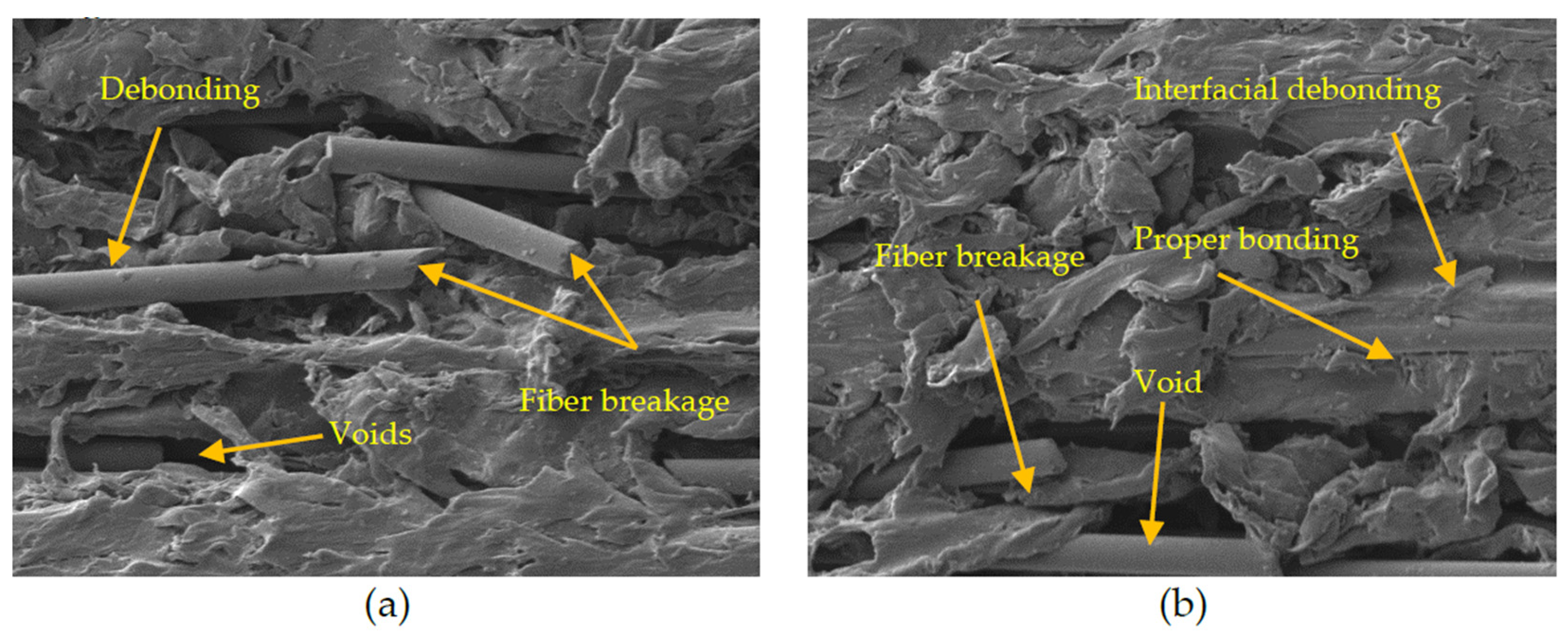

3.6. Morphology of Hybrid Fiber Polypropylene Composite

4. Conclusions

- The injection molding process parameters do not have a significant effect on fiber volume fraction.

- ANOVA provides a predictive mathematical model that can be used to calculate a response if factor values are determined.

- Factors that have a significant effect on impact strength are melt temperature and fiber pretension, respectively.

- The maximum impact strength of 168.03 kJ/m2 can be obtained from a combination of parameters: melt temperature of 230 °C, injection pressure of 100 bar, backpressure of 10 bar, and fiber pretension of 50 N.

- Sequentially, factors that significantly affect flexural strength are melt temperature, quadratic melt temperature, melt temperature interaction with fiber pretension, and injection pressure interaction with backpressure.

- The maximum flexural strength value of 71.3 Mpa can be obtained from a combination of parameters: melt temperature of 210 °C, the injection pressure of 120 bar, backpressure of 10 bar, and fiber pretension of 50 N.

- In order to optimize the responses simultaneously, individual and combined desirability functions were derived. The overall desirability was 0.81, individual desirability for fiber volume fraction was 0.94, impact strength was 0.73, and flexural strength was 0.82.

- Finally, for optimizing multiple responses, the recommended factors are as follows: melt temperature of 223 °C, the injection pressure of 140 bar, backpressure of 10.7 bar, and fibre pretension of 65.82 N. The combination of these factors resulted in an optimum fibre volume fraction of 14.45%, impact strength of 143.58 kJ/m2, and flexural strength of 70.67 Mpa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Wan, Y.; Takahashi, J. Tensile properties and aspect ratio simulation of transversely isotropic discontinuous carbon fiber reinforced thermoplastics. Compos. Sci. Technol. 2016, 137, 167–176. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing Aspects of Advanced Polymer Composites for Automotive Applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Jiang, B.; Fu, L.; Zhang, M.; Weng, C. Effect of thermal gradient on interfacial behavior of hybrid fiber reinforced polypropylene composites fabricated by injection overmolding technique. Polym. Compos. 2020, 41, 4064–4073. [Google Scholar] [CrossRef]

- Akkerman, R.; Bouwman, M.; Wijskamp, S. Analysis of the thermoplastic composite overmolding process: Interface strength. Front. Mater. 2020, 7, 27. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Przyszczypkowski, P.; Szostak, M. Development and characterization of poly (ethylene terephthalate) based injection molded self-reinforced composites. Direct reinforcement by overmolding the composite inserts. Mater. Des. 2018, 153, 273–286. [Google Scholar] [CrossRef]

- Gupta, S.K.; Saini, S.K.; Spranklin, B.W. Incorporating Manufacturability Considerations during Design of Injection Molded Multi-Material Objects. Mech. Eng. 2005, 37, 207–231. [Google Scholar]

- Huang, P.W.; Peng, H.-S.; Hwang, S.-J.; Huang, C.-T. The Low Breaking Fiber Mechanism and Its Effect on the Behavior of the Melt Flow of Injection Molded Ultra-Long Glass Fiber Reinforced Polypropylene Composites. Polymers 2021, 13, 2492. [Google Scholar] [CrossRef]

- Rosato, D.V. Plastics Processing Data Handbook, 2nd ed.; Chapman & Hall: London, UK, 1997. [Google Scholar]

- Rohde, M.; Ebel, A. Influence of Processing Parameters on the Fiber Length and Impact Properties of Injection Molded Long Glass Fiber Reinforced Polypropylene. Intern. Polym. Process. 2011, 26, 292–303. [Google Scholar] [CrossRef]

- Garnich, M.; Karami, G. Localized Fiber Waviness and Implications for Failure in Unidirectional Composites. J. Compos. Mater. 2005, 39, 1225–1244. [Google Scholar] [CrossRef]

- Allison, B.D.; Evans, J.L. Effect of fiber waviness on the bending behavior of S-glass/epoxy composites. Mater. Des. 2012, 36, 316–322. [Google Scholar] [CrossRef]

- Mertiny, P.; Ellyin, F. Influence of the filament winding tension on physical and mechanical properties of reinforced composites. Compos. Part A 2002, 33, 1615–1622. [Google Scholar] [CrossRef]

- Hörrmann, S.; Adumitroaie, A.; Viechtbauer, C. The effect of fiber waviness on the fatigue life of CFRP materials. Int. J. Fatigue J. 2016, 90, 139–147. [Google Scholar] [CrossRef]

- Krishnamurthy, S. Prestressed Advanced Fibre Reinforced Composites: Fabrication and Mechanical Performance. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2006. [Google Scholar]

- Moallemzadeh, A.R.; Sabet, S.A.R.; Abedini, H. Preloaded composite panels under high velocity impact. Int. J. Impact Eng. 2018, 114, 153–159. [Google Scholar] [CrossRef]

- Pickett, A.K.; Fouinneteau, M.R.C.; Middendorf, P. Test and Modelling of Impact on Pre-Loaded Composite Panels. Appl. Compos. Mater. 2009, 16, 225–244. [Google Scholar] [CrossRef]

- Whittingham, B.; Marshall, I.H.; Mitrevski, T.; Jones, R. The response of composite structures with pre-stress subject to low velocity impact damage. Compos. Struct. 2004, 66, 685–698. [Google Scholar] [CrossRef]

- Schlichting, L.H.; de Andrada, M.A.C.; Vieira, L.C.C. Composite resin reinforced with pre-tensioned glass fibers. Influence of prestressing on flexural properties. Dent. Mater. 2010, 26, 118–125. [Google Scholar] [CrossRef]

- Mostafa, N.H.; Ismarrubie, Z.N.; Sapuan, S.M. Fibre prestressed polymer-matrix composites: A review. J. Compos. Mater. 2017, 51, 39–66. [Google Scholar] [CrossRef]

- Schuite, K.; Marissen, R. Influence of artificial pre-stressing during curing of CFRP laminates on interfibre transverse cracking. Compos. Sci. Technol. 1992, 44, 361–367. [Google Scholar] [CrossRef]

- Tuttle, M.E.; Koehler, R.; Keren, D. Controlling Thermal Stresses in Composite by Means of Fiber Prestress. J. Compos. Mater. 1995, 30, 486–502. [Google Scholar] [CrossRef]

- Motahhari, S.; Cameron, J. Measurement of Micro-Residual Stresses in Fiber-Prestressed Composite. J. Reinf. Plast. Compos. 1997, 16, 1129–1136. [Google Scholar] [CrossRef]

- Mostafa, N.H.; Ismarrubie, Z.N.; Sapuan, S.M.; Sultan, M.T.H. Fibre prestressed composites: Theoretical and numerical modelling of unidirectional and plain-weave fibre reinforcement forms. Compos. Struct. 2017, 159, 410–423. [Google Scholar] [CrossRef]

- Sumitomo, C. Cosmoplene® AW564 Technical Data Sheet; The Polyolefin Company: Singapore, 2019. [Google Scholar]

- Torayca. T700S Data Sheet No. CFA-005; Toray Carbon Fibers: Santa Ana, CA, USA, 2018. [Google Scholar]

- Budiyantoro, C.; Rochardjo, H.S.B.; Nugroho, G. Design, Manufacture, and Performance Testing of Extrusion–Pultrusion Machine for Fiber-Reinforced Thermoplastic Pellet Production. Machines 2021, 9, 42. [Google Scholar] [CrossRef]

- Budiyantoro, C.; Rochardjo, H.S.B.; Nugroho, G. Effects of Processing Variables of Extrusion—Pultrusion Method on the Impregnation Quality of Thermoplastic Composite Filaments. Polymers 2020, 12, 2833. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.K.F.; Abdullah, O.A. New methodology for prestressing fiber composites. Univers. J. Mech. Eng. 2015, 3, 252–261. [Google Scholar] [CrossRef][Green Version]

- Wong, K.H.; Mohammed, D.S.; Pickering, S.J.; Brooks, R. Effect of coupling agents on reinforcing potential of recycled carbon fibre for polypropylene composite. Compos. Sci. Technol. 2012, 72, 835–844. [Google Scholar] [CrossRef]

- Standard, B. ISO 178—Plastic, Determination of Flexural Properties; BSI: London, UK, 2005. [Google Scholar]

- Czél, G.; Jalalvand, M.; Wisnom, M.R. Hybrid specimens eliminating stress concentrations in tensile and compressive testing of unidirectional composites. Compos. Part A 2016, 16, 436–447. [Google Scholar] [CrossRef]

- Meng, M.; Le, H.; Jahir, R.; Grove, S. The effects of unequal compressive/tensile moduli of composites. Compos. Struct. 2015, 126, 207–215. [Google Scholar] [CrossRef]

- ISO. ISO 179—Determination of Charpy Impact Properties; ISO: Brussels, Belgium, 2013. [Google Scholar]

- Shokri, P.; Bhatnagar, N. Effect of the Post-Filling Stage on Fiber Orientation at the Mid-Plane in Injection Molding of Reinforced Thermoplastics. Phys. Procedia 2012, 25, 79–85. [Google Scholar] [CrossRef]

- Dupuis, A.; Pesce, J.; Ferreira, P.; Gilles, R. Fiber Orientation and Concentration in an Injection-Molded Ethylene-Propylene Copolymer Reinforced by Hemp. Polymers 2020, 12, 2771. [Google Scholar] [CrossRef]

- Tzeng, C.; Yang, Y.; Lin, Y. A study of optimization of injection molding process parameters for SGF and PTFE reinforced PC composites using neural network and response surface methodology. Int. J. Adv. Manuf. Technol. 2012, 63, 691–704. [Google Scholar] [CrossRef]

- Ginghtong, T.; Nakpathomkun, N.; Pechyen, C. Effect of injection parameters on mechanical and physical properties of super ultra-thin wall propylene packaging by Taguchi method. Results Phys. 2018, 9, 987–995. [Google Scholar] [CrossRef]

| Material | Properties | Values |

|---|---|---|

| Carbon fiber (T700SC 12K) | Filament diameter (µm) | 7 |

| Density (g/cm3) | 1.8 | |

| Tensile strength (Mpa) | 4900 | |

| Cosmoplene AW564-PP | Density (g/cm3) | 0.9 |

| Cylinder temperature (°C) | 190–230 | |

| Tensile strength at yield (Mpa) | 27.5 | |

| Tensile strength at break (Mpa) | 23 | |

| Melt Flow Index (g/10 min) | 10 | |

| Liquid nitrogen | Boiling point (°C) | −196 |

| Density, Liquid @ BP, 1 atm (Kg/m3) | 808.5 | |

| Specific Gravity, Liquid (water = 1) @ 20 °C, 1 atm | 0.808 |

| Parameters | Values | Unit |

|---|---|---|

| Charging time | 3.5 | s |

| Shot size | 83 | mm |

| Injection speed | 80 | mm/s |

| Filling time | 0.6 | s |

| Velocity Transfer Pressure | 35 | mm |

| Packing pressure | 70 | bar |

| Screw speed | 40 | rpm |

| Packing time | 5 | s |

| Cooling temperature | 40 | °C |

| Cooling time | 15 | s |

| Factors | Coding | Actual Level | ||

|---|---|---|---|---|

| Low (−1) | Middle (0) | High (+1) | ||

| Melting temperature (°C) | A | 190 | 210 | 230 |

| Injection pressure (bar) | B | 100 | 120 | 140 |

| Backpressure (bar) | C | 5 | 10 | 15 |

| Fiber Pre-tension (N) | D | 20 | 50 | 80 |

| Run | Code | Actual | ||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | A | B | C | D | |

| 1 | 1 | 1 | 0 | 0 | 230 | 140 | 10 | 50 |

| 2 | 0 | 0 | 0 | 0 | 210 | 120 | 10 | 50 |

| 3 | 0 | 0 | 0 | 0 | 210 | 120 | 10 | 50 |

| 4 | 0 | 1 | 0 | −1 | 210 | 140 | 10 | 20 |

| 5 | −1 | 0 | 0 | 1 | 190 | 120 | 10 | 80 |

| 6 | 0 | 0 | 1 | −1 | 210 | 120 | 15 | 20 |

| 7 | 0 | −1 | −1 | 0 | 210 | 100 | 5 | 50 |

| 8 | 1 | 0 | 1 | 0 | 230 | 120 | 15 | 50 |

| 9 | −1 | 0 | 0 | −1 | 190 | 120 | 10 | 20 |

| 10 | 0 | 0 | 0 | 0 | 210 | 120 | 10 | 50 |

| 11 | 1 | 0 | 0 | −1 | 230 | 120 | 10 | 20 |

| 12 | −1 | 1 | 0 | 0 | 190 | 140 | 10 | 50 |

| 13 | 1 | 0 | −1 | 0 | 230 | 120 | 5 | 50 |

| 14 | 0 | 0 | −1 | 1 | 210 | 120 | 5 | 80 |

| 15 | 0 | 1 | 0 | 1 | 210 | 140 | 10 | 80 |

| 16 | 0 | 1 | 1 | 0 | 210 | 140 | 15 | 50 |

| 17 | 1 | −1 | 0 | 0 | 230 | 100 | 10 | 50 |

| 18 | 0 | −1 | 0 | −1 | 210 | 100 | 10 | 20 |

| 19 | 0 | 0 | 1 | 1 | 210 | 120 | 15 | 80 |

| 20 | 0 | 1 | −1 | 0 | 210 | 140 | 5 | 50 |

| 21 | −1 | −1 | 0 | 0 | 190 | 100 | 10 | 50 |

| 22 | 0 | −1 | 1 | 0 | 210 | 100 | 15 | 50 |

| 23 | 0 | 0 | −1 | −1 | 210 | 120 | 5 | 20 |

| 24 | −1 | 0 | −1 | 0 | 190 | 120 | 5 | 50 |

| 25 | −1 | 0 | 1 | 0 | 190 | 120 | 15 | 50 |

| 26 | 0 | −1 | 0 | 1 | 210 | 100 | 10 | 80 |

| 27 | 1 | 0 | 0 | 1 | 230 | 120 | 10 | 80 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Note |

|---|---|---|---|---|---|---|

| Model | 0.21 | 4 | 0.053 | 0.60 | 0.6652 | not significant |

| A-Melt temperature | 1.919 × 10−3 | 1 | 1.919 × 10−3 | 0.022 | 0.8845 | |

| B-Injection pressure | 0.017 | 1 | 0.017 | 0.19 | 0.6707 | |

| C-Back pressure | 0.090 | 1 | 0.090 | 1.01 | 0.3253 | |

| D-Fiber pretension | 0.11 | 1 | 0.11 | 1.19 | 0.2874 | |

| Residual | 1.95 | 22 | 0.089 | |||

| Lack of Fit | 1.92 | 20 | 0.096 | 5.78 | 0.1575 | not significant |

| Pure Error | 0.033 | 2 | 0.017 | |||

| Cor Total | 2.17 | 26 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Note |

|---|---|---|---|---|---|---|

| Model | 4796.90 | 4 | 1199.23 | 3.59 | 0.0212 | significant |

| A-Melt temperature | 2113.25 | 1 | 2113.25 | 6.33 | 0.0197 | significant |

| B-Injection pressure | 0.19 | 1 | 0.19 | 5.541 × 10−4 | 0.9814 | |

| C-Back pressure | 459.81 | 1 | 459.81 | 1.38 | 0.2531 | |

| D-Fiber pretension | 2223.66 | 1 | 2223.66 | 6.66 | 0.0171 | significant |

| Residual | 7345.45 | 22 | 333.88 | |||

| Lack of Fit | 5318.92 | 20 | 265.95 | 0.26 | 0.9604 | not significant |

| Pure Error | 2026.53 | 2 | 1013.27 | |||

| Cor Total | 12,142.35 | 26 | ||||

| Pred R-Squared | 0.1429 | |||||

| Adj R-Squared | 0.2851 | |||||

| Adeq Precision | 6.838 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Note |

|---|---|---|---|---|---|---|

| Model | 4796.72 | 3 | 1598.91 | 5.01 | 0.0081 | significant |

| A-Melt temperature | 2113.25 | 1 | 2113.25 | 6.62 | 0.0170 | significant |

| C-Back pressure | 459.81 | 1 | 459.81 | 1.44 | 0.2424 | |

| D-Fiber pretension | 2223.66 | 1 | 2223.66 | 6.96 | 0.0147 | significant |

| Residual | 7345.63 | 23 | 319.38 | |||

| Lack of Fit | 5319.10 | 21 | 253.29 | 0.25 | 0.9663 | not significant |

| Pure Error | 2026.53 | 2 | 1013.27 | |||

| Cor Total | 12,142.35 | 26 | ||||

| Pred R-Squared | 0.2190 | |||||

| Adj R-Squared | 0.3161 | |||||

| Adeq Precision | 7.816 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value Prob > F | Note |

|---|---|---|---|---|---|---|

| Model | 194.27 | 14 | 13.88 | 4.09 | 0.0096 | significant |

| A-Melt temperature | 48.52 | 1 | 48.52 | 14.31 | 0.0026 | significant |

| B-Injection pressure | 10.09 | 1 | 10.09 | 2.98 | 0.1102 | |

| C-Back pressure | 0.43 | 1 | 0.43 | 0.13 | 0.7277 | |

| D-Fiber pretension | 0.039 | 1 | 0.039 | 0.012 | 0.9158 | |

| AB | 0.10 | 1 | 0.10 | 0.030 | 0.8649 | |

| AC | 3.25 | 1 | 3.25 | 0.96 | 0.3469 | |

| AD | 21.09 | 1 | 21.09 | 6.22 | 0.0282 | significant |

| BC | 17.33 | 1 | 17.33 | 5.11 | 0.0431 | significant |

| BD | 3.83 | 1 | 3.83 | 1.13 | 0.3086 | |

| CD | 0.77 | 1 | 0.77 | 0.23 | 0.6416 | |

| A2 | 48.32 | 1 | 48.32 | 14.25 | 0.0026 | significant |

| B2 | 1.99 | 1 | 1.99 | 0.59 | 0.4588 | |

| C2 | 8.50 | 1 | 8.50 | 2.51 | 0.1393 | |

| D2 | 61.19 | 1 | 61.19 | 18.05 | 0.0011 | significant |

| Residual | 40.68 | 12 | 3.39 | |||

| Lack of Fit | 29.59 | 10 | 2.96 | 0.53 | 0.7963 | not significant |

| Pure Error | 11.09 | 2 | 5.54 | |||

| Cor Total | 234.95 | 26 |

| Factors or Responses | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance | Target |

|---|---|---|---|---|---|---|---|

| Melt temperature | In range | 190 | 230 | 1 | 1 | 3 | |

| Injection pressure | In range | 100 | 140 | 1 | 1 | 3 | |

| Backpressure | In range | 5 | 15 | 1 | 1 | 3 | |

| Fiber pretension | In range | 20 | 80 | 1 | 1 | 3 | |

| Fiber volume fraction | Maximize | 13.72 | 14.87 | 1 | 1 | 3 | 14.5 |

| Impact strength | Maximize | 98.56 | 182.717 | 1 | 1 | 3 | 150 |

| Flexural strength | Maximize | 59.86 | 73.32 | 1 | 1 | 3 | 73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Budiyantoro, C.; Rochardjo, H.S.B.; Nugroho, G. Overmolding of Hybrid Long and Short Carbon Fiber Polypropylene Composite: Optimizing Processing Parameters. J. Manuf. Mater. Process. 2021, 5, 132. https://doi.org/10.3390/jmmp5040132

Budiyantoro C, Rochardjo HSB, Nugroho G. Overmolding of Hybrid Long and Short Carbon Fiber Polypropylene Composite: Optimizing Processing Parameters. Journal of Manufacturing and Materials Processing. 2021; 5(4):132. https://doi.org/10.3390/jmmp5040132

Chicago/Turabian StyleBudiyantoro, Cahyo, Heru S. B. Rochardjo, and Gesang Nugroho. 2021. "Overmolding of Hybrid Long and Short Carbon Fiber Polypropylene Composite: Optimizing Processing Parameters" Journal of Manufacturing and Materials Processing 5, no. 4: 132. https://doi.org/10.3390/jmmp5040132

APA StyleBudiyantoro, C., Rochardjo, H. S. B., & Nugroho, G. (2021). Overmolding of Hybrid Long and Short Carbon Fiber Polypropylene Composite: Optimizing Processing Parameters. Journal of Manufacturing and Materials Processing, 5(4), 132. https://doi.org/10.3390/jmmp5040132