Influence of Pre-Aging on the Hardness and Formability of a Thread Rolled 6056 Aluminum Alloy after Conventional Extrusion and Artificial Aging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Processing Route

2.2. Mechanical and Microstructural Characterization

2.3. FE-Simulation

3. Results

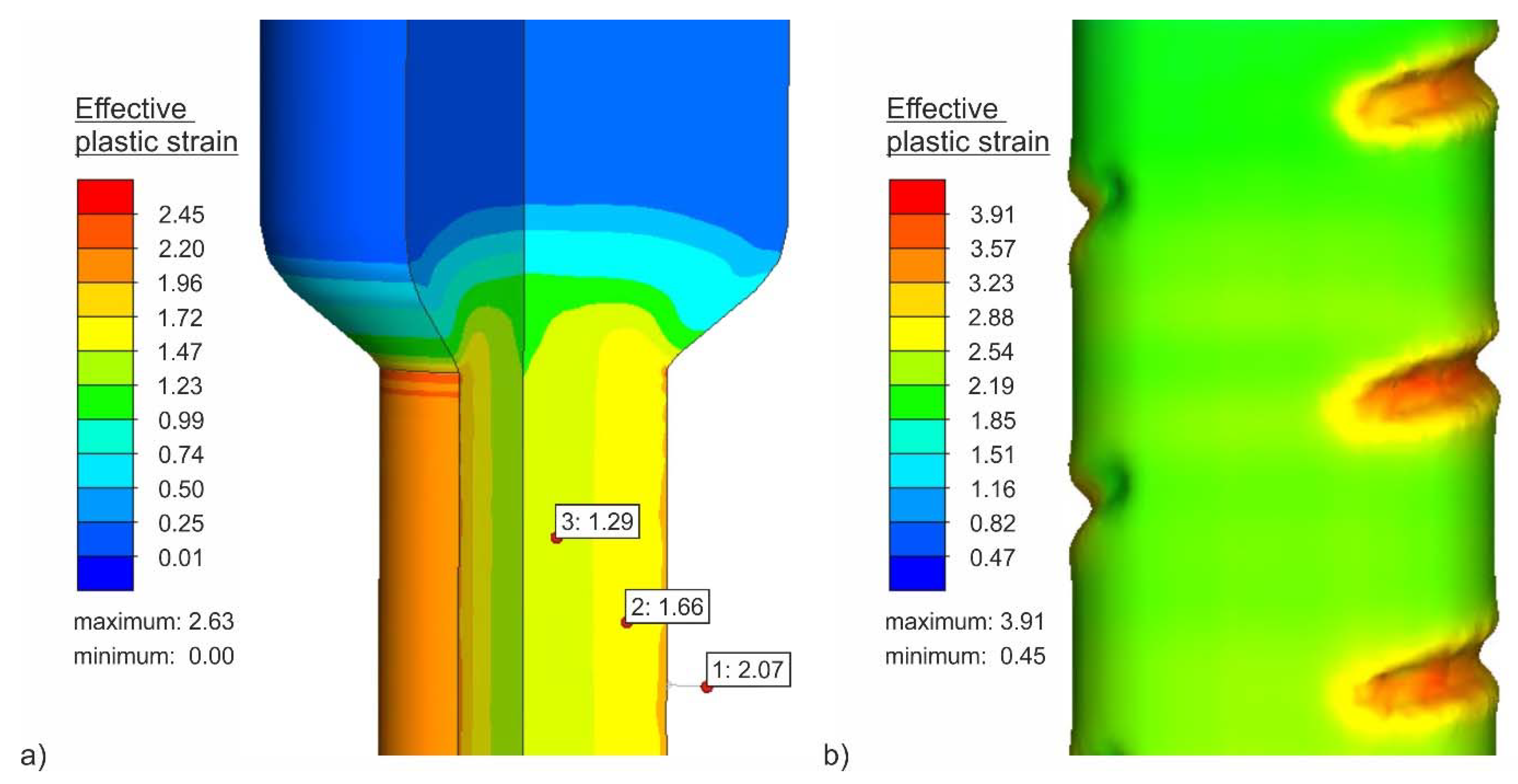

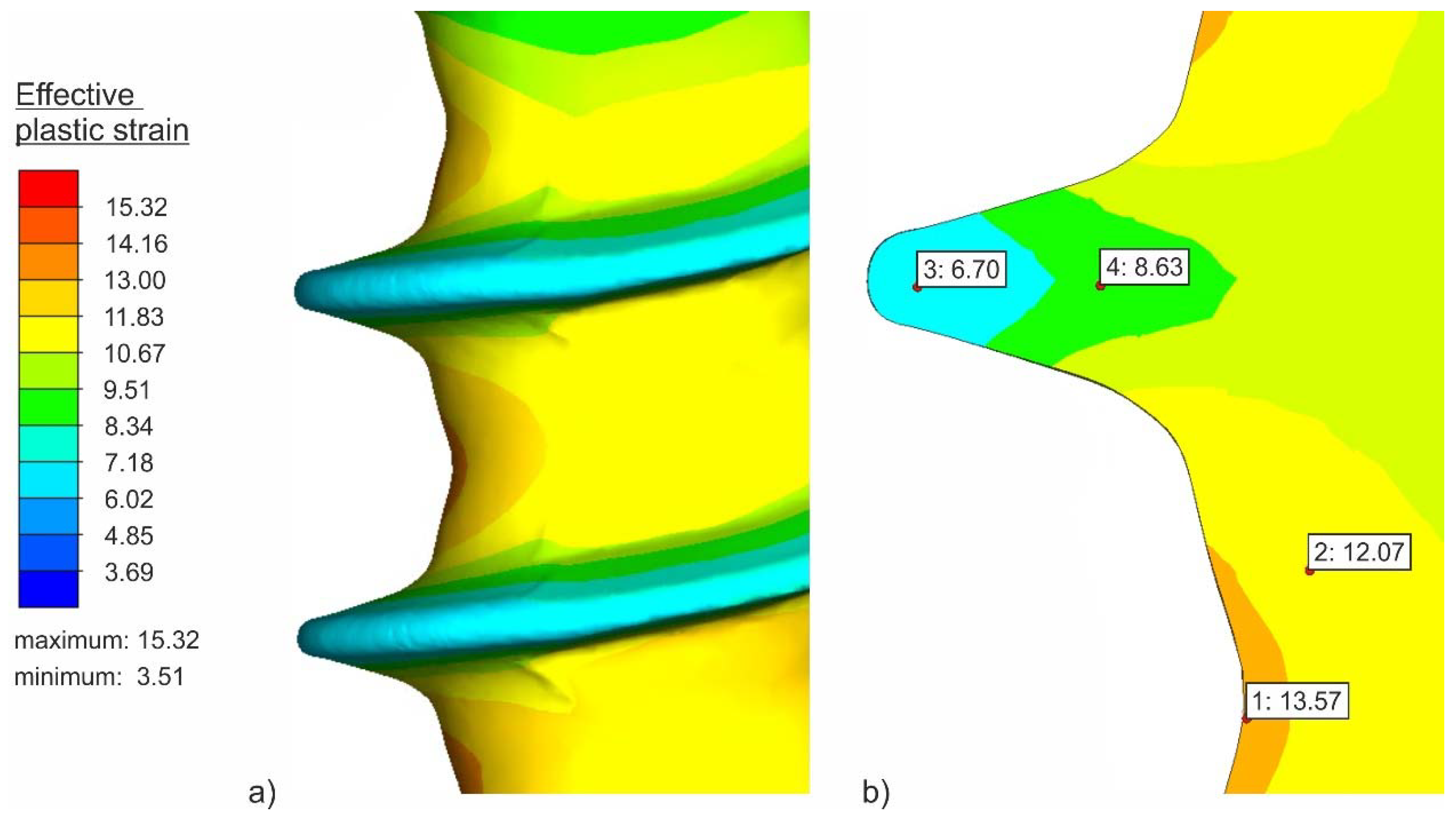

3.1. Process Simulation of Conventional Extrusion and Thread Rolling

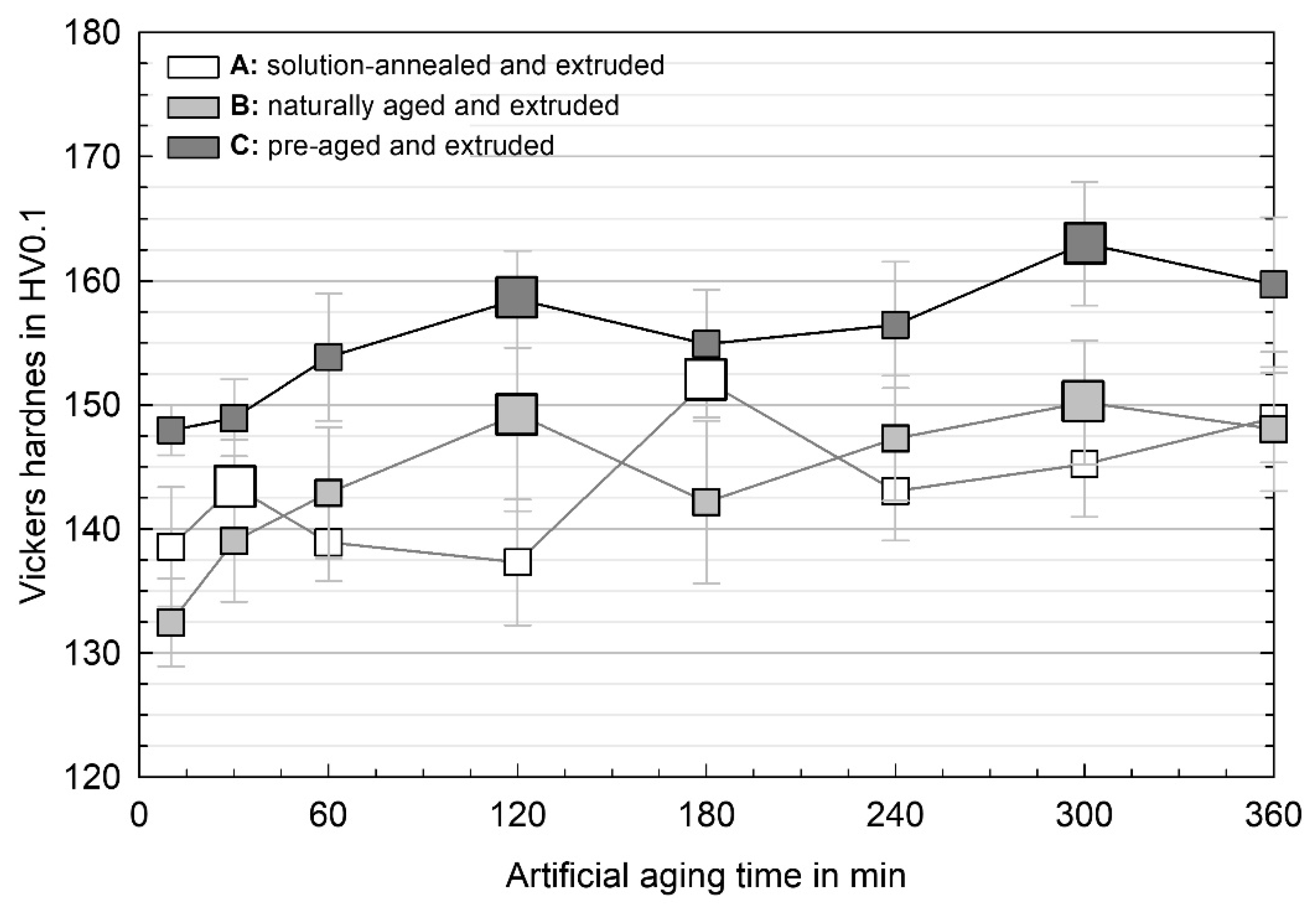

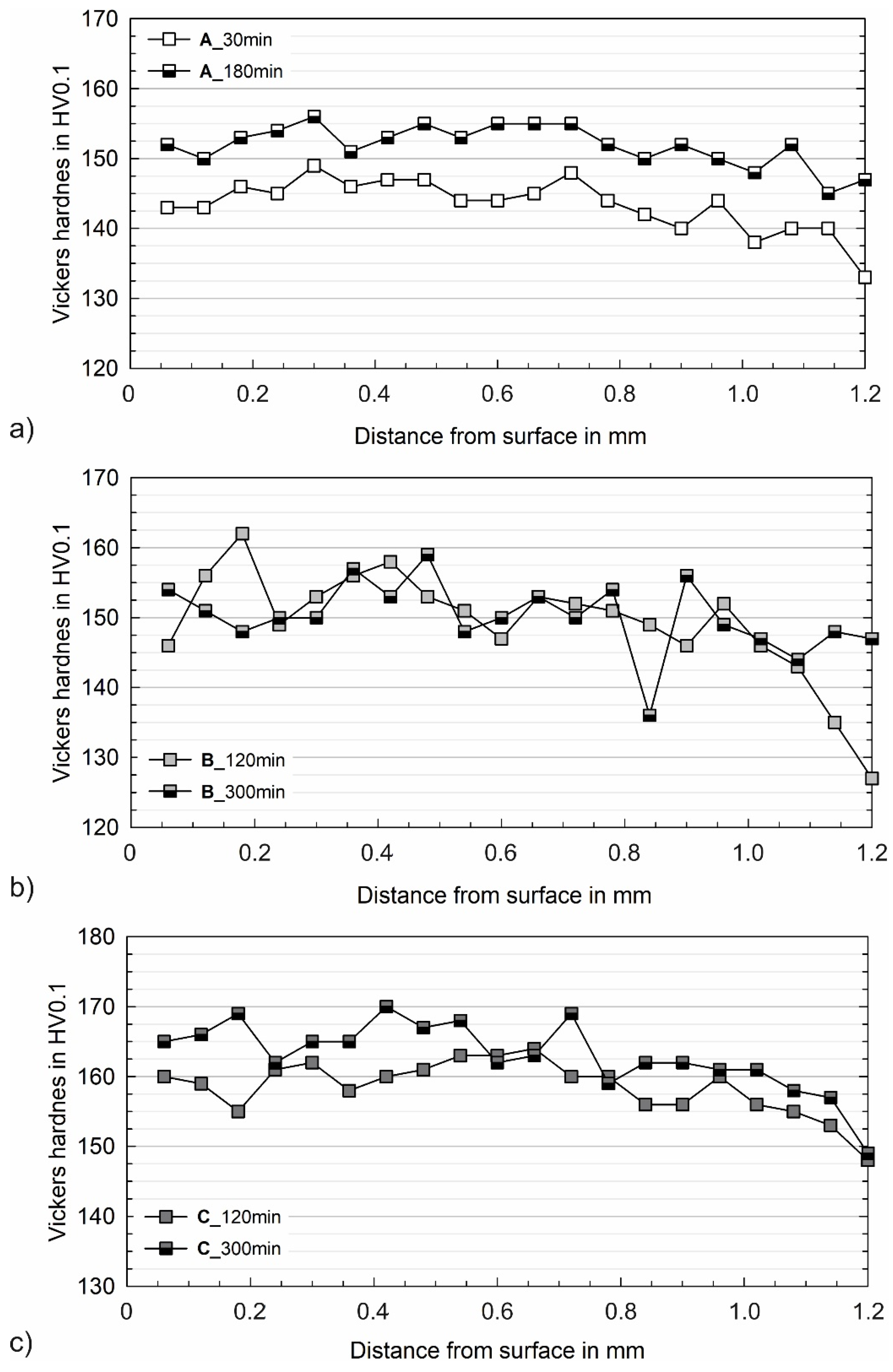

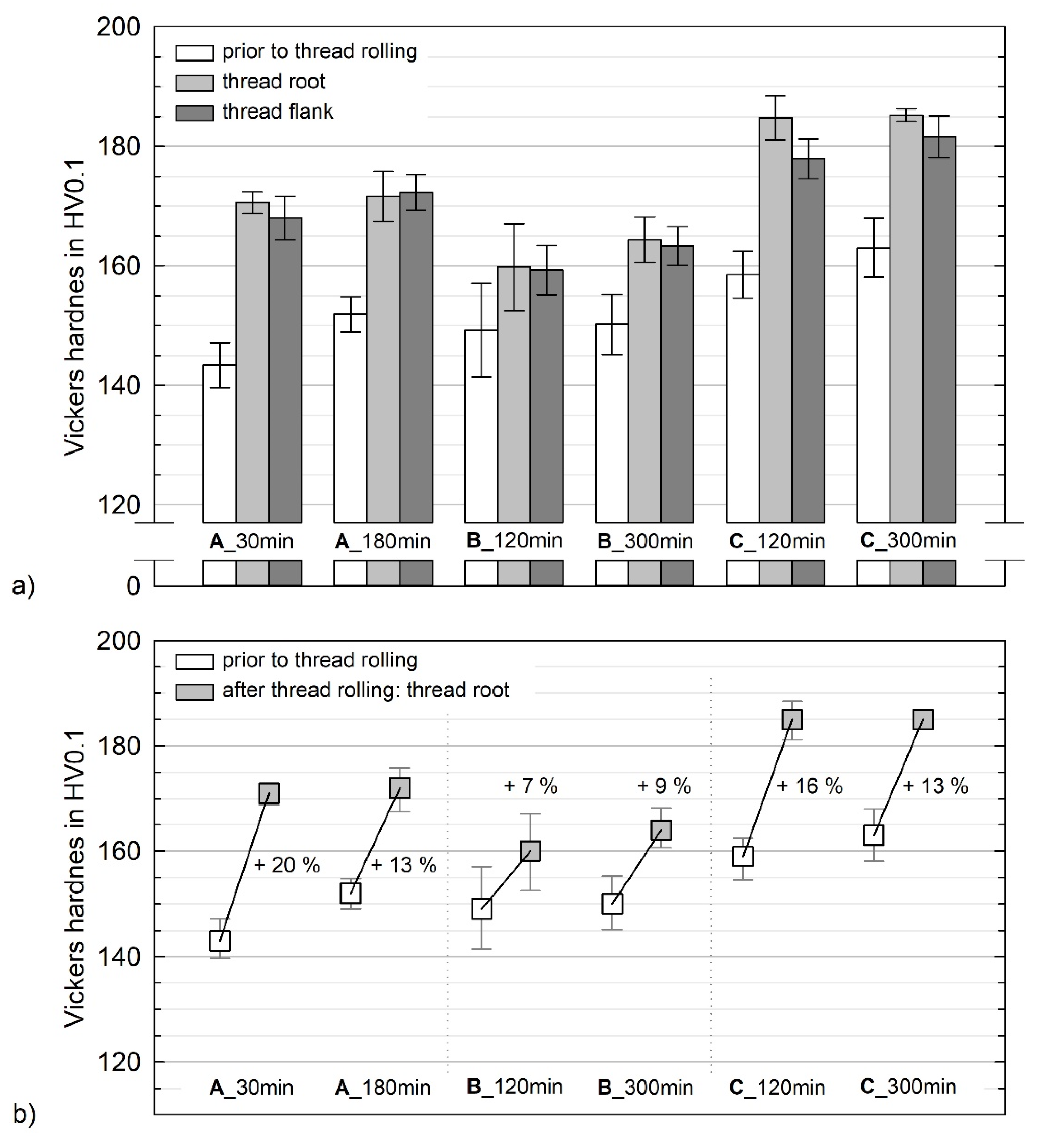

3.2. Hardness Prior to and after Thread Rolling

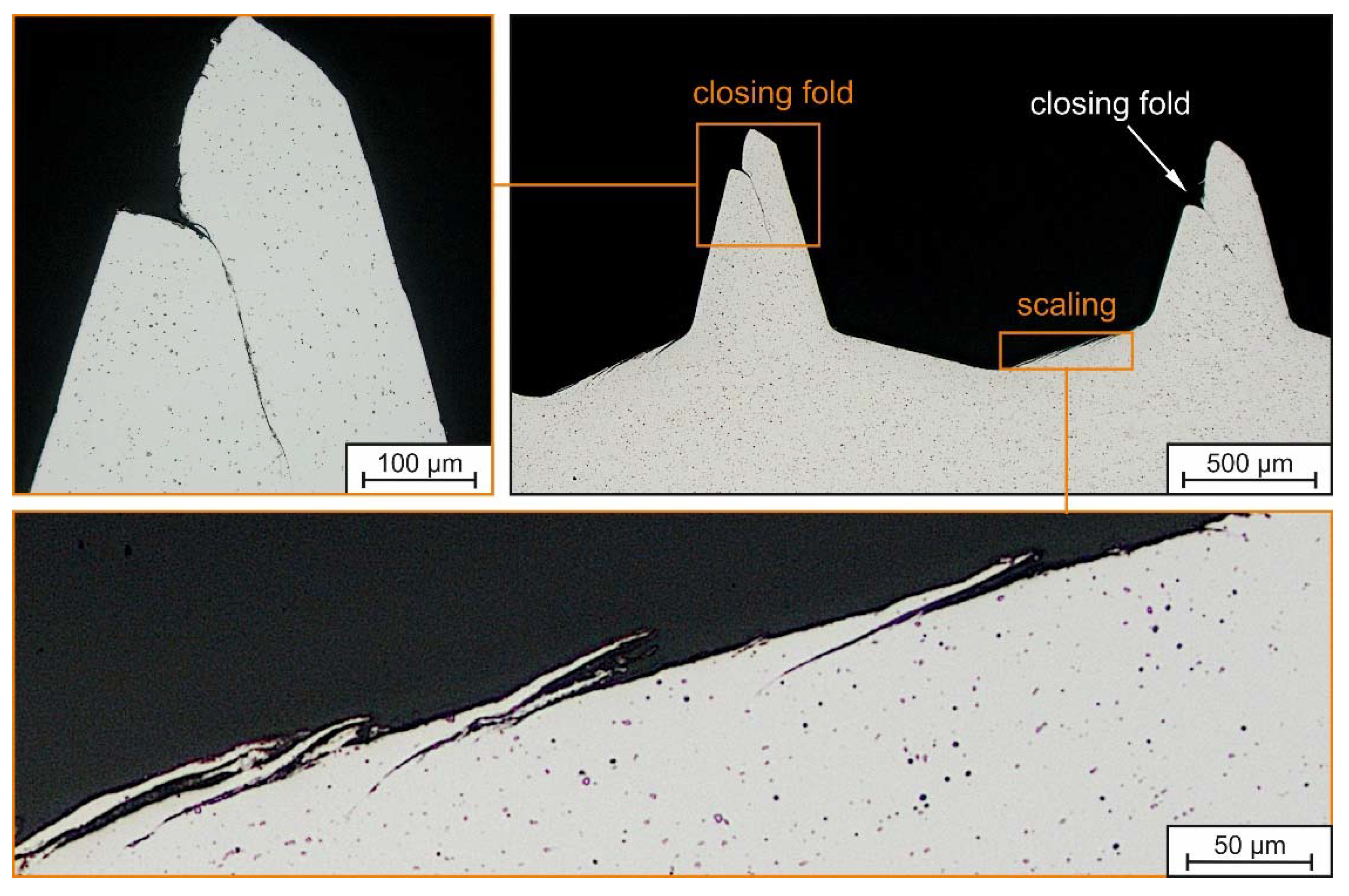

3.3. Surface of the Thread Rolled Parts

4. Discussion

4.1. Simulation

4.2. Evolution of Hardness Dependent on Processing Route

5. Conclusions

- Using a conventional 6056 aluminum alloy, it is possible to achieve an exceptional high hardness in a thread-formed product using a thermo-mechanical route containing a pre-aging treatment. The maximum hardness, which is obtained after thread rolling, depends on the initial combination of heat treatment and extrusion.

- Pre-ageing seems to be an appropriate process to achieve a high hardness after extrusion, which cannot be obtained by natural ageing. Followed by artificial ageing of the extruded parts, the differences of pre-aged and naturally aged parts become even more pronounced.

- The hardness increase by thread rolling of a pre-aged condition is higher, when compared to a naturally aged condition. Furthermore, threaded parts made of pre-aged conditions exhibit much less scale at the thread roots where the highest deformation is observed due to a better formability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Arz, U.; Weber, J.O.; Marx, T.; Berger, C. Mechanical behaviour of aluminum screws Part 1—Static load capacity. Mater. Werkst. 2010, 41, 213–217. [Google Scholar] [CrossRef]

- Reinhold, B.; Klose, S.G.; Kopp, J. Schutzsysteme für Verschraubungselemente in Kontakt mit Leichtmetall. Mater. Werkst. 1998, 29, 1–8. [Google Scholar] [CrossRef]

- Sieber, M.; Scharf, I.; Härtel, M.; Hellmig, R.J.; Lampke, T. Influence of anodic oxide coatings on screwing behaviour and susceptibility to stress corrosion cracking of self-tapping aluminium screws. Mater. Werkst. 2012, 43, 661–667. [Google Scholar] [CrossRef]

- Gröber, D.; Georgi, W.; Sieber, M.; Scharf, I.; Hellmig, R.J.; Leidich, E.; Lampke, T.; Mayr, P. The effect of anodising on the fatigue performance of self-tapping aluminium screws. Int. J. Fatigue 2015, 75, 108–114. [Google Scholar] [CrossRef]

- Brendler, G.; Scharf, I.; Härtel, M.; Nickel, D.; Hellmig, R.J.; Alisch, G.; Lampke, T. Vergleich des Anodisierens von Aluminiumschrauben mittels Direkt- bzw. Flüssigkontaktierung. Mater. Werkst. 2011, 42, 672–679. [Google Scholar] [CrossRef]

- Rao, A.C.U.; Vasu, V.; Govindaraju, M.; Srinadh, K.V.S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review. Trans. Nonferrous Met. Soc. China 2016, 26, 1447–1471. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Jansen, J.; Zandbergen, H.W. The influence of temperature and storage time at RT on nucleation of the β″ phase in a 6082 Al-Mg-Si alloy. Acta Mater. 2003, 51, 789–796. [Google Scholar] [CrossRef]

- Saga, M.; Sasaki, Y.; Kikuchi, M.; Yan, Z.; Matsuo, M. Effect of Pre-Aging Temperature on the Behavior in the Early Stage of Aging at High Temperature for Al-Mg-Si Alloy. Mater. Sci. Forum 1996, 217–222, 821–826. [Google Scholar] [CrossRef]

- Takaki, Y.; Aruga, Y.; Kozuka, M.; Sato, T. Effects of pre-aging and natural aging on bake hardening behavior in Al-Mg-Si alloys. Mater. Sci. Forum 2014, 794–796, 1026–1031. [Google Scholar] [CrossRef]

- Zi, Y.; Zeqin, L.; Leyvraz, D.; Banhart, J. Effect of pre-ageing on natural secondary ageing and paint bake hardening in Al–Mg–Si alloys. Materialia 2019, 7, 100413. [Google Scholar] [CrossRef]

- Yang, Z.; Liang, Z.; Leyvraz, D.; Banhart, J. Hardness data related to pre-ageing, natural secondary ageing, and paint bake hardening in Al-Mg-Si alloys. Data Brief 2019, 27, 104494. [Google Scholar] [CrossRef] [PubMed]

- Winter, L.; Hockauf, K.; Scholze, M.; Hellmig, R.J.; Lampke, T. Influence of Pre-Aging on the Artificial Aging Behavior of a 6056 Aluminum Alloy after Conventional Extrusion. Metal 2021, 11, 385. [Google Scholar] [CrossRef]

- Wick, D. Simulation sowie experimentelle Untersuchung von Materialschädigungen bei Umformprozessen. Ph.D. Thesis, Universität Siegen, Siegen, Germany, 2019. [Google Scholar]

- Zottis, J.; Theis Soares Diehl, C.A.; Rocha, A.D.S. Evaluation of experimentally observed asymmetric distributions of hardness, strain and residual stress in cold drawn bars by FEM-simulation. J. Mater. Res. Technol. 2018, 7, 469–478. [Google Scholar] [CrossRef]

- Hsia, S.-Y.; Pan, S.-K.; Chou, Y.-T. Computer Simulation for Flat-die Thread Rolling of Screw. In Proceedings of the International Conference on Innovation, Communication and Engineering, Xiangtan, China, 21 January 2016; pp. 1–5. [Google Scholar]

- Yamada, K.; Sato, T.; Kamio, A. Effects of quenching conditions on two-step aging behavior of Al-Mg-Si alloys. Mater. Sci. Forum 2000, 331, 669–674. [Google Scholar] [CrossRef]

- Suzuki, H.; Kanno, M.; Itoh, G. A consideration of the two-step aging process in an Al-Mg-Si alloy. Aluminium 1981, 57, 628–629. [Google Scholar]

- Dutta, I.; Allen, S.M. A calorimetric study of precipitation in commercial aluminium alloy 6061. J. Mater. Sci. Lett. 1991, 10, 323–326. [Google Scholar] [CrossRef]

- Murayama, M.; Hono, K. Pre-precipitate clusters and precipitation processes in Al–Mg–Si alloys. Acta Mater. 1999, 47, 1537–1548. [Google Scholar] [CrossRef]

- Berndt, N.; Frint, P.; Wagner, M.F.-X. Influence of Extrusion Temperature on the Aging Behavior and Mechanical Properties of an AA6060 Aluminum Alloy. Metal 2018, 8, 51. [Google Scholar] [CrossRef] [Green Version]

| Chemical Composition | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Element | Si | Mg | Cu | Mn | Zn | Fe | Zr | Ti | Cr | Al |

| wt.-% | 1.06 | 0.89 | 0.78 | 0.59 | 0.19 | 0.16 | 0.13 | 0.04 | 0.01 | balance |

| Geometrical and mechanical properties in as-received condition | ||||||||||

| Yield strength Rp0.2 in MPa | Ultimate tensile strength Rm in MPa | Elongation A100mm in % | ||||||||

| 173 ± 1 | 188 ± 2 | 6.3 ± 1.3 | ||||||||

| Processing Step | Processing Route | ||

|---|---|---|---|

| A | B | C | |

| 1 | solution-annealing for 1 h at 530 °C, water-quenching to room temperature | solution-annealing for 1 h at 530 °C, water-quenching to room temperature and naturally aged for 7 d at room temperature | solution-annealing for 1 h at 530 °C, water-quenching to room temperature and pre-aged for 5 h at 80 °C |

| 2 | linear extrusion with φ = 1.2 | ||

| 3 | artificial aging at 120 °C up to 6 h | ||

| 4 | thread-rolling | ||

| Processing Route | Artificial Aging Time in Min | Hardness in HV0.1 | ||

|---|---|---|---|---|

| Prior to Thread Rolling | after Thread Rolling | |||

| Thread Root | Thread Flank | |||

| A (solution-annealed, extruded) | 30 | 143 ± 4 | 171 ± 2 | 168 ± 4 |

| 180 | 152 ± 3 | 172 ± 4 | 172 ± 3 | |

| B (naturally aged, extruded) | 120 | 149 ± 8 | 160 ± 7 | 159 ± 4 |

| 300 | 150 ± 5 | 164 ± 4 | 163 ± 3 | |

| C (pre-aged, extruded) | 120 | 159 ± 4 | 185 ± 4 | 178 ± 3 |

| 300 | 163 ± 5 | 185 ± 2 | 182 ± 4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winter, L.; Hellmig, R.J.; Hockauf, K.; Lampke, T. Influence of Pre-Aging on the Hardness and Formability of a Thread Rolled 6056 Aluminum Alloy after Conventional Extrusion and Artificial Aging. J. Manuf. Mater. Process. 2021, 5, 116. https://doi.org/10.3390/jmmp5040116

Winter L, Hellmig RJ, Hockauf K, Lampke T. Influence of Pre-Aging on the Hardness and Formability of a Thread Rolled 6056 Aluminum Alloy after Conventional Extrusion and Artificial Aging. Journal of Manufacturing and Materials Processing. 2021; 5(4):116. https://doi.org/10.3390/jmmp5040116

Chicago/Turabian StyleWinter, Lisa, Ralph Jörg Hellmig, Kristin Hockauf, and Thomas Lampke. 2021. "Influence of Pre-Aging on the Hardness and Formability of a Thread Rolled 6056 Aluminum Alloy after Conventional Extrusion and Artificial Aging" Journal of Manufacturing and Materials Processing 5, no. 4: 116. https://doi.org/10.3390/jmmp5040116

APA StyleWinter, L., Hellmig, R. J., Hockauf, K., & Lampke, T. (2021). Influence of Pre-Aging on the Hardness and Formability of a Thread Rolled 6056 Aluminum Alloy after Conventional Extrusion and Artificial Aging. Journal of Manufacturing and Materials Processing, 5(4), 116. https://doi.org/10.3390/jmmp5040116