Data-Driven Digital Twins for Technical Building Services Operation in Factories: A Cooling Tower Case Study

Abstract

1. Introduction

2. Background

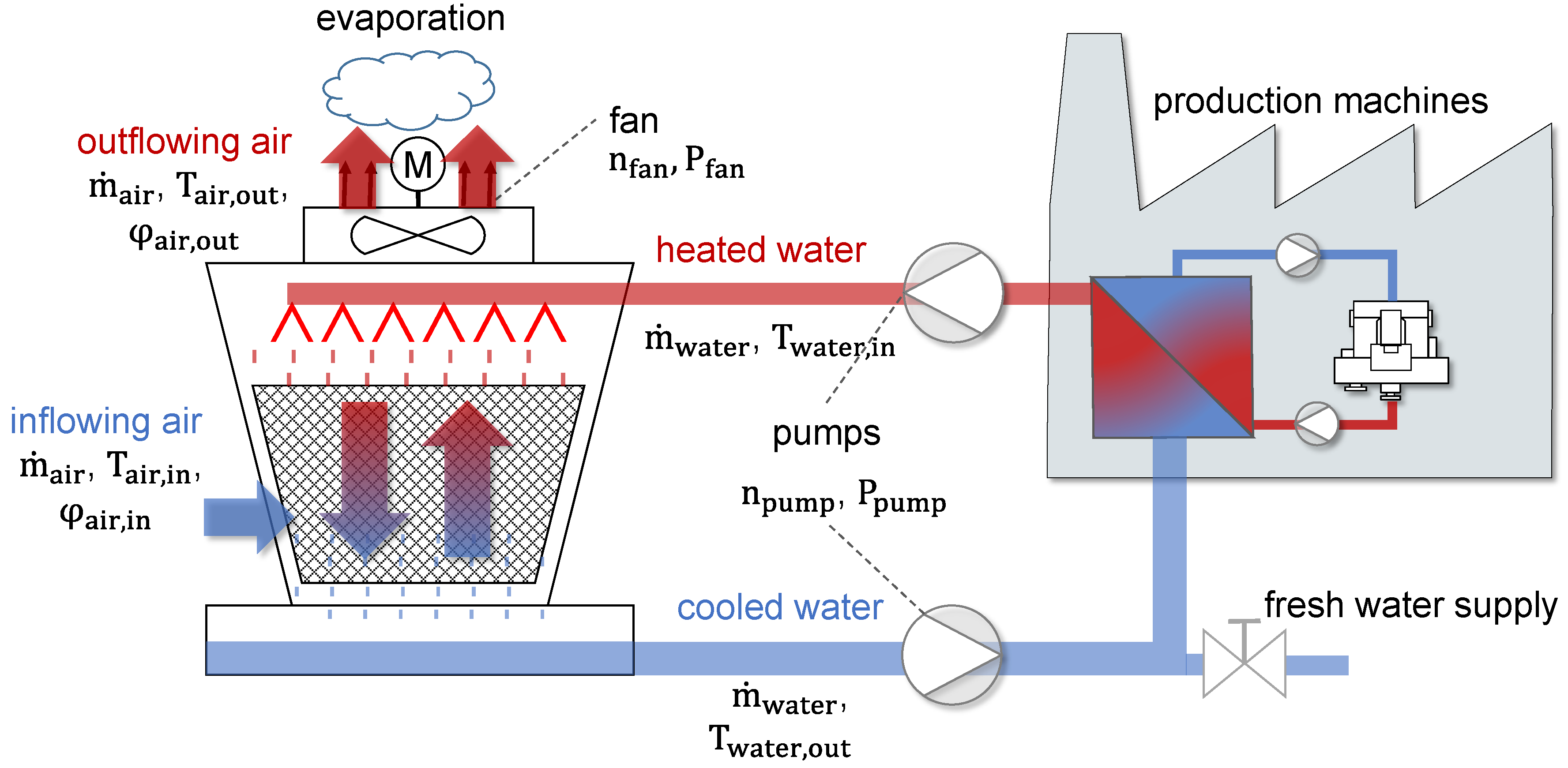

2.1. Industrial Cooling Towers

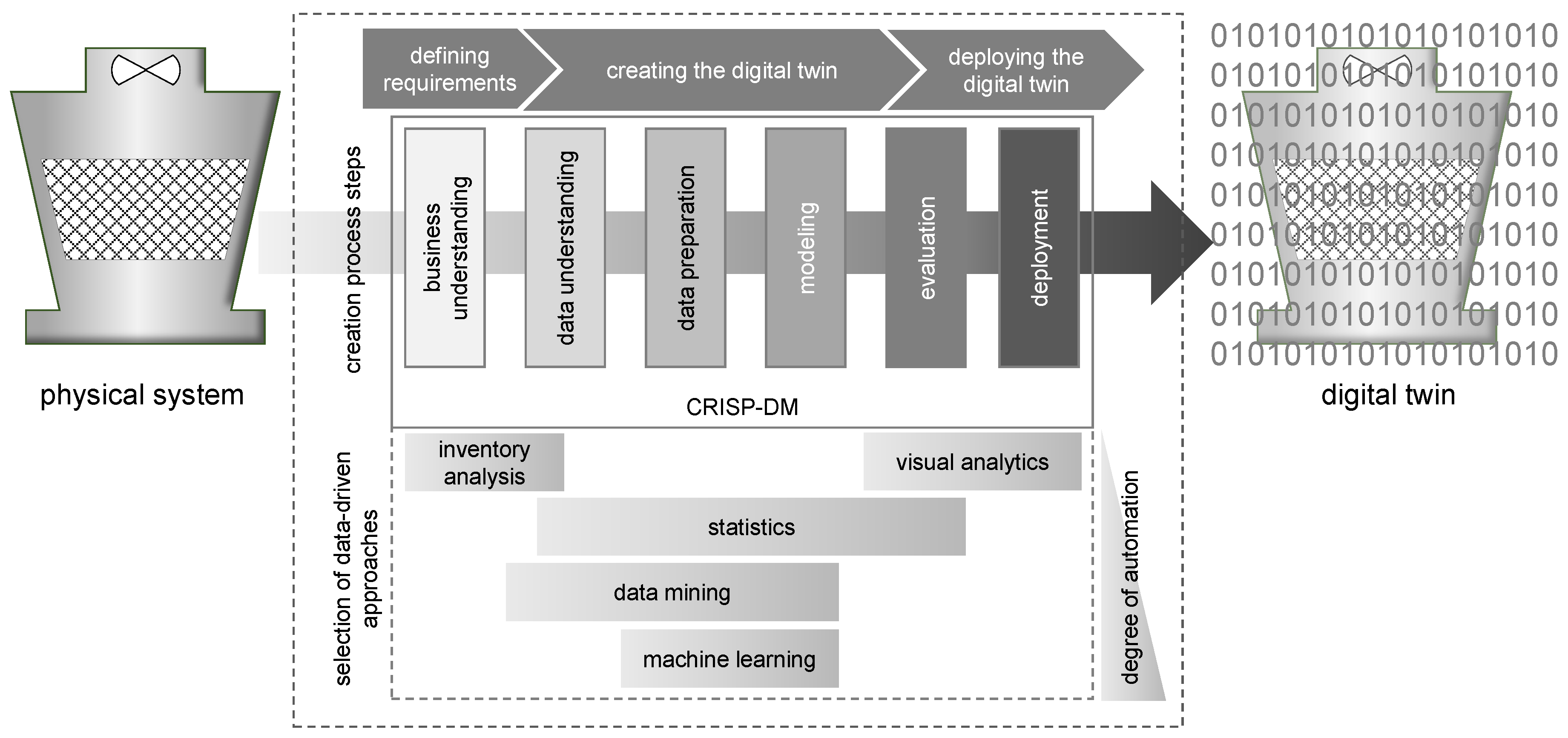

2.2. Data-Driven Approaches to Create Digital Twins in Factories

2.3. Data-Driven Approaches for Cooling Tower Systems

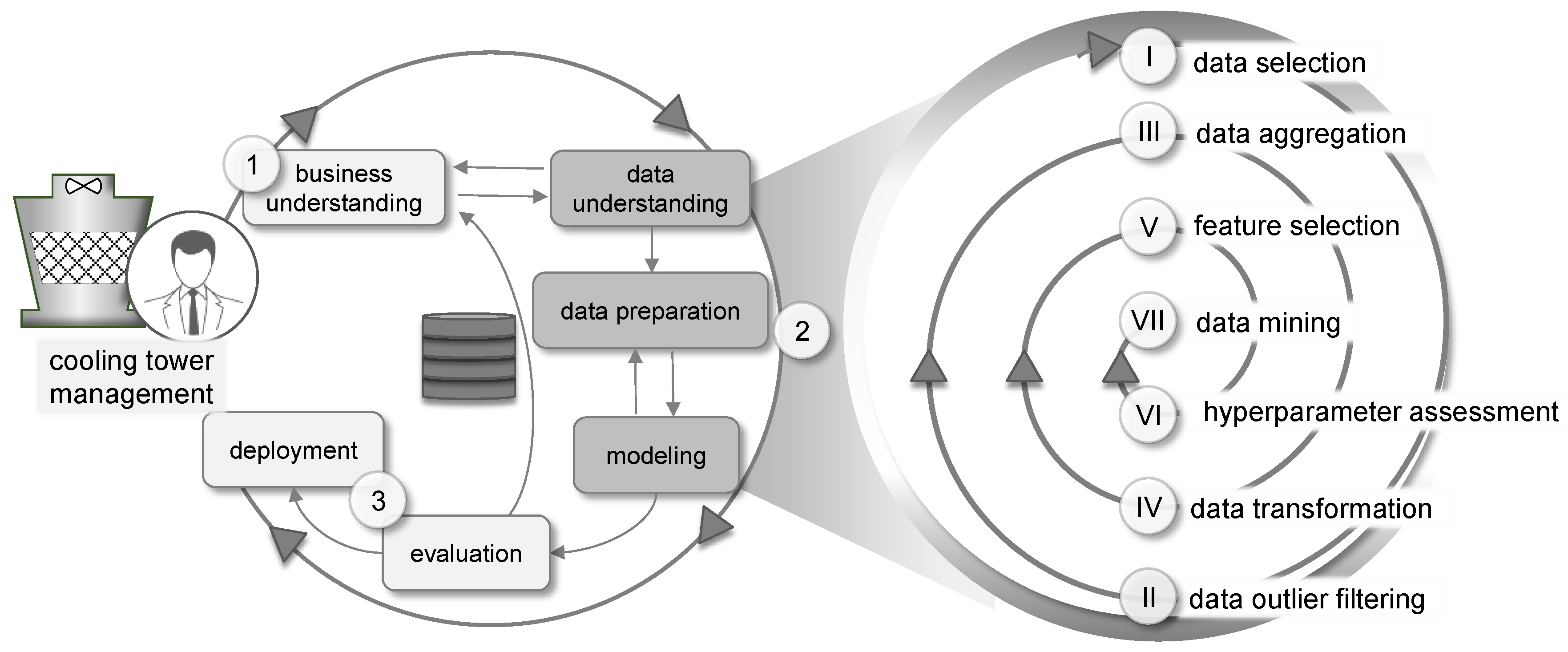

3. A Workflow to Create Digital Twins for Technical Building Services Operation

3.1. Business Understanding (Phase 1)

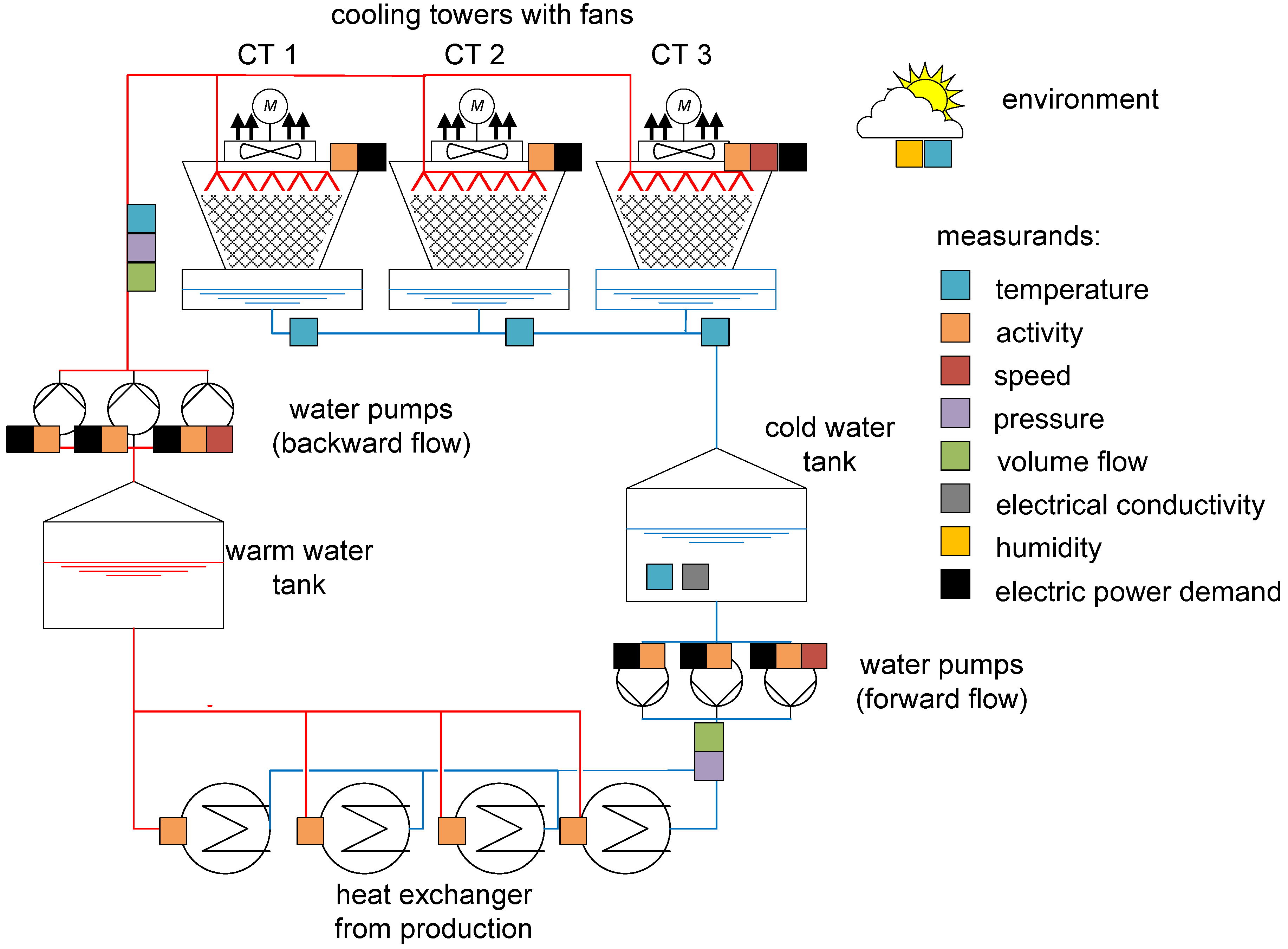

3.1.1. Technical Analysis of the Cooling Tower System

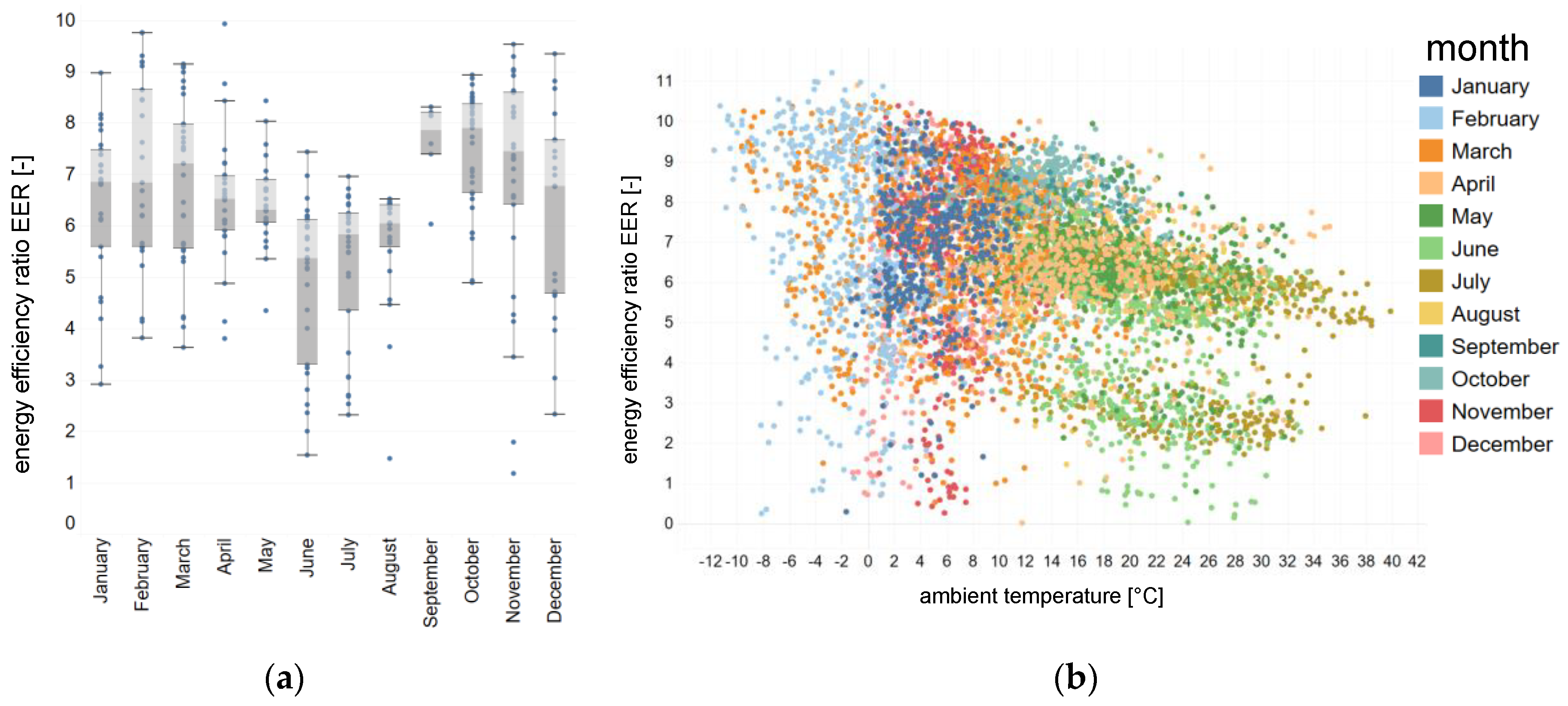

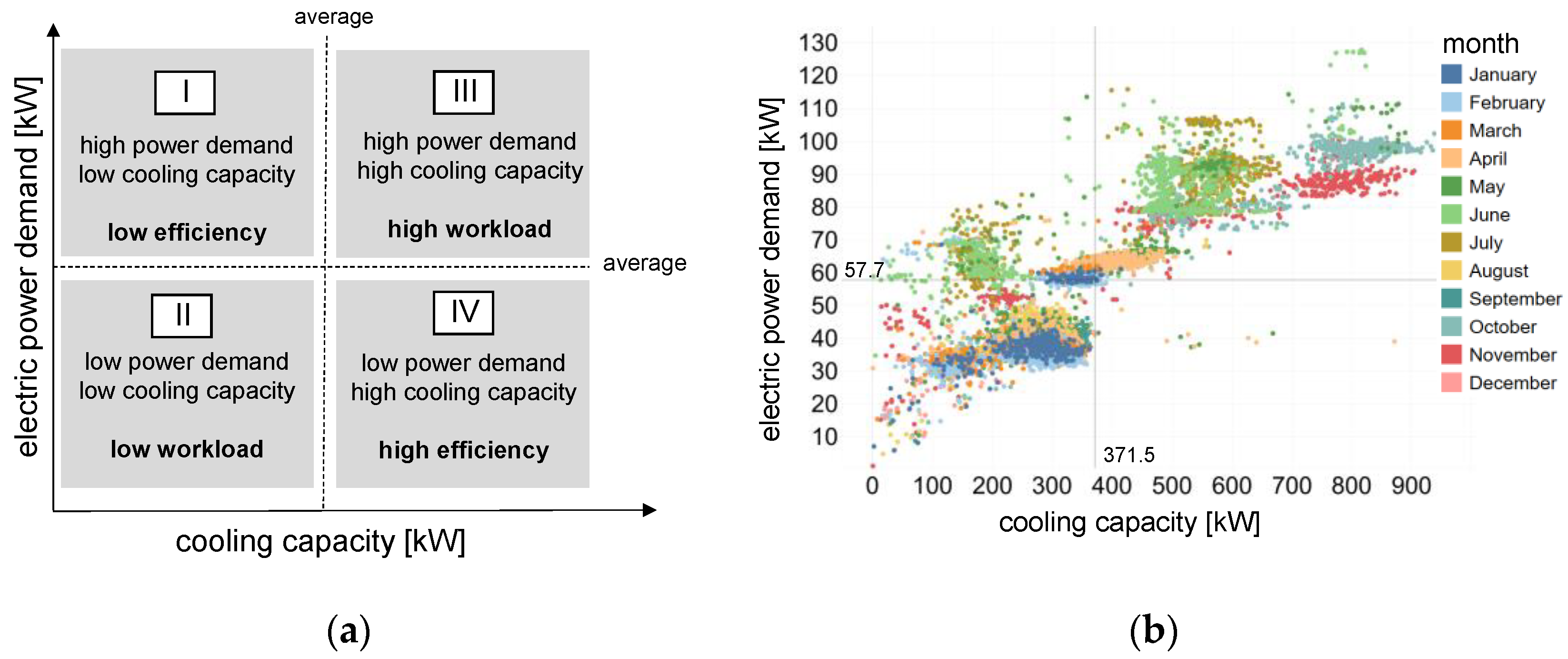

3.1.2. System and Business Analysis

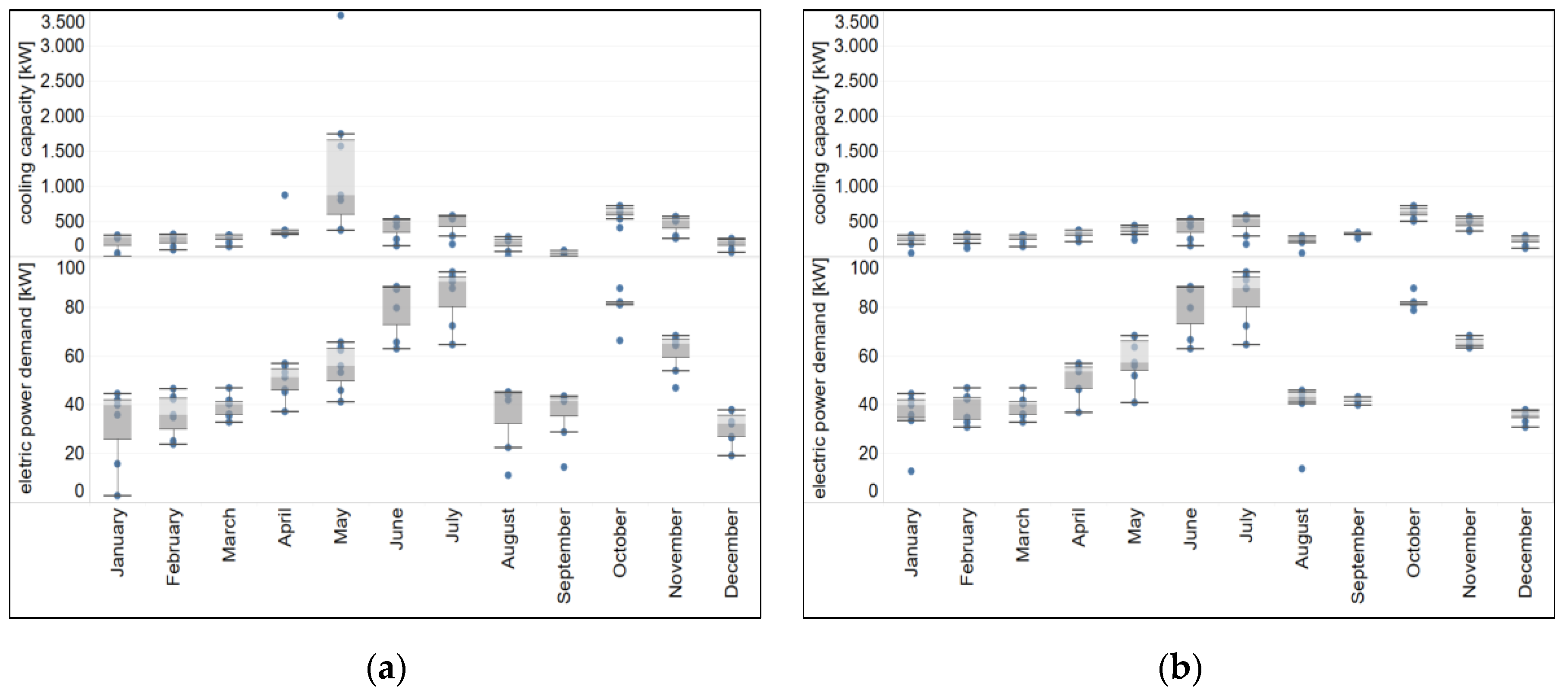

- High electric power demand, low cooling capacity (category I): The EER during these times is low. For the presented use case, such inefficiencies occur intermittently in almost every month of the year, but particularly frequent during May, June and July.

- Low electric power demand, low cooling capacity (category II): The EER is in an acceptable range, whereas the workload of the CT system is comparatively low. On the one hand, these stages are mainly detected during winter season, when low ambient air temperatures increase the natural cooling effect (compare Equation (1)). This means, the CT system already achieves a sufficient cooling capacity with relatively low additional power demands. On the other hand, this portfolio category includes days in August and May, which are typically related with holiday season, and thus, reduced cooling demand from production system.

- High electric power demand, high cooling capacity (category III): High workload is linked to high power demands, yet acceptable EER ranges. High workload occurs particularly during the warm summer season, e.g., June and July. Furthermore, October and November show overall the highest workload of the year, which could indicate high production capacities.

- Low electric power demand, high cooling capacity (category IV): With high EER, those states are the most desirable for CT system operation. However, there are only few samples in April and May in this category.

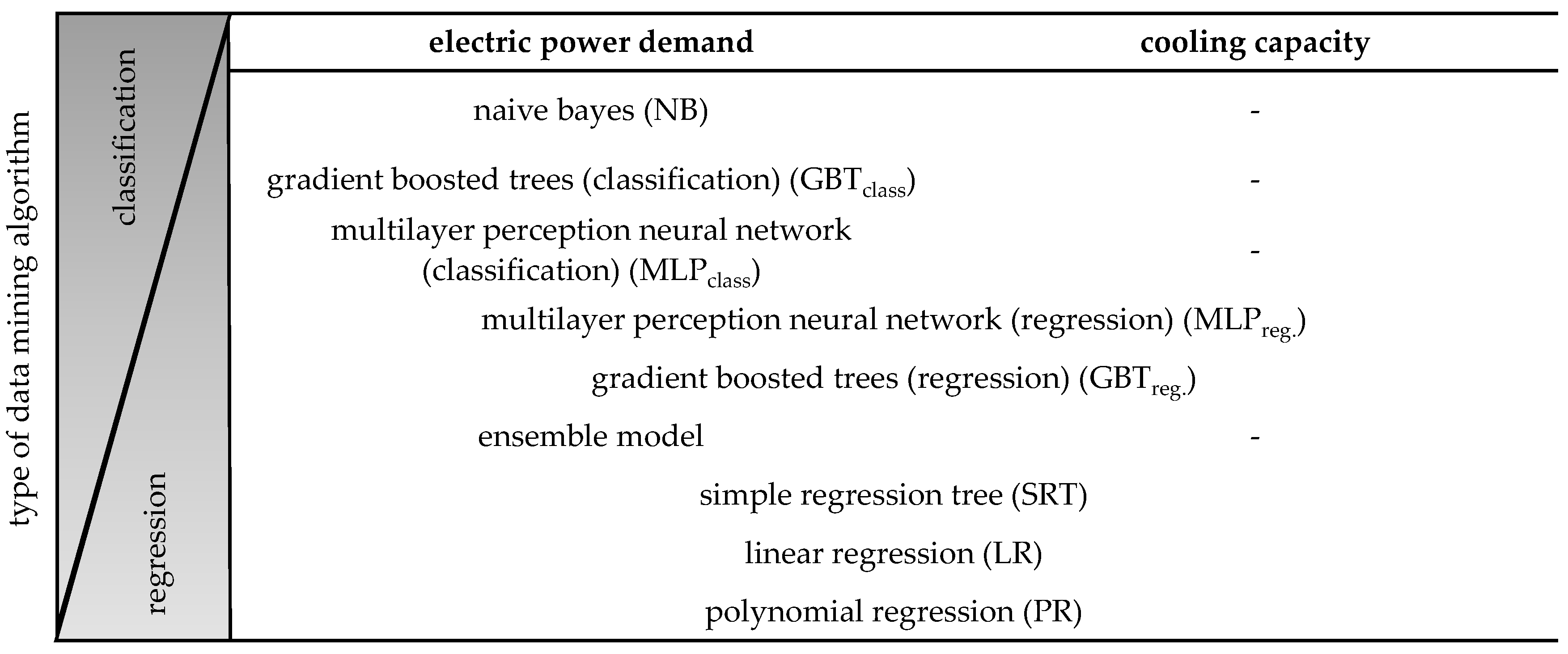

3.2. Creating a Data-Driven Digital Twin—A Data Mining Approach (Phase 2)

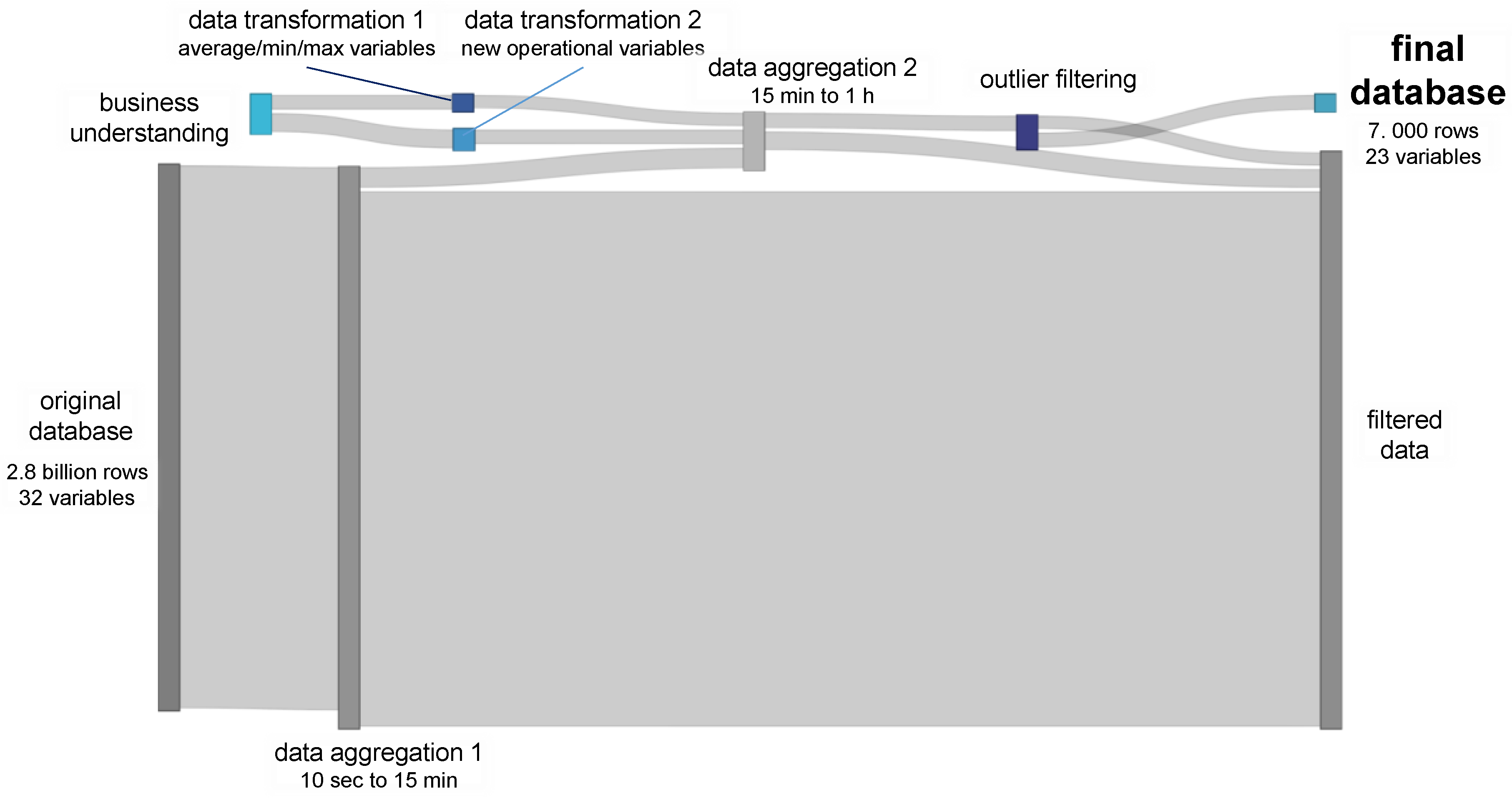

3.2.1. Data Selection and Outlier Filtering

3.2.2. Data Aggregation and Transformation

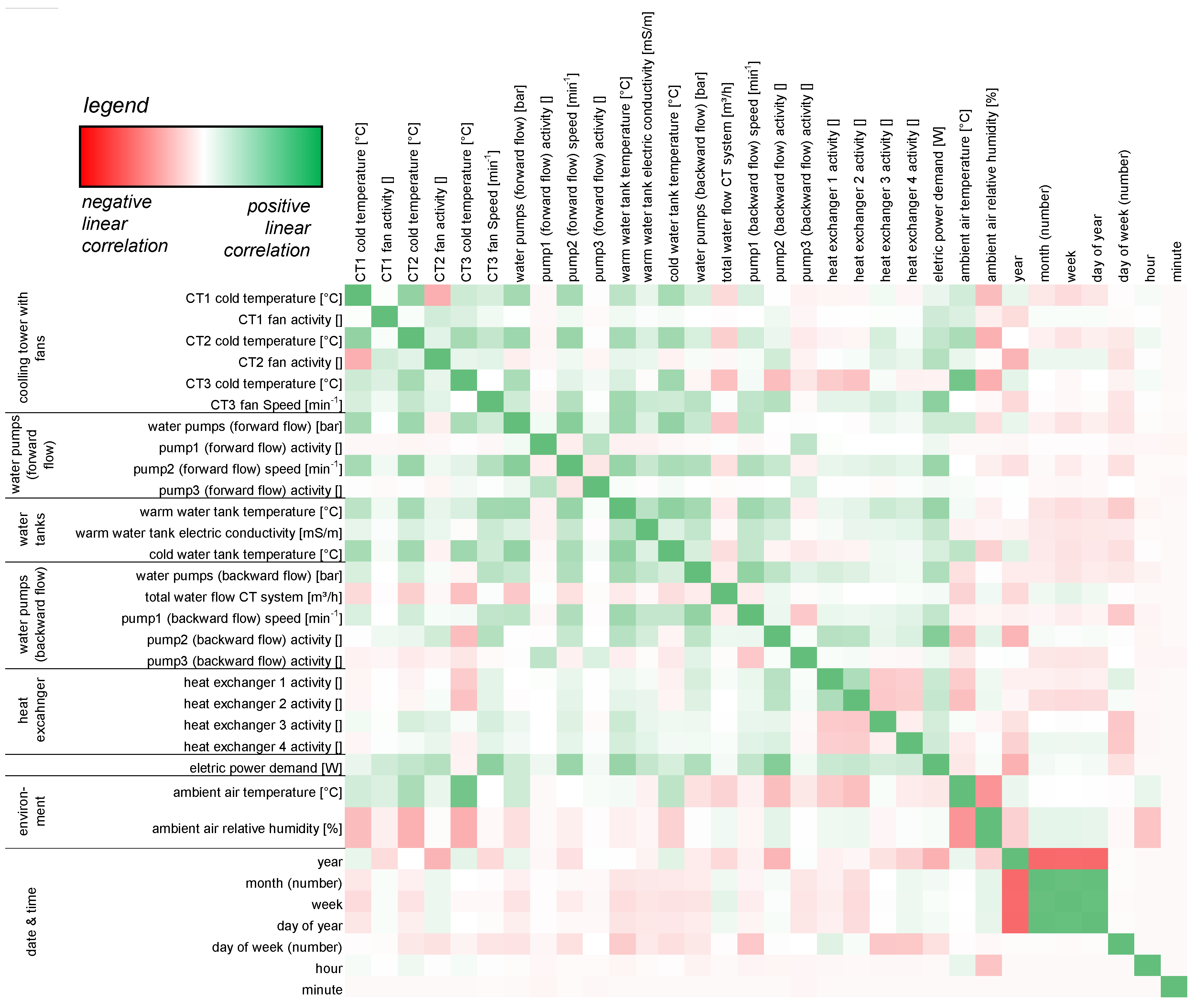

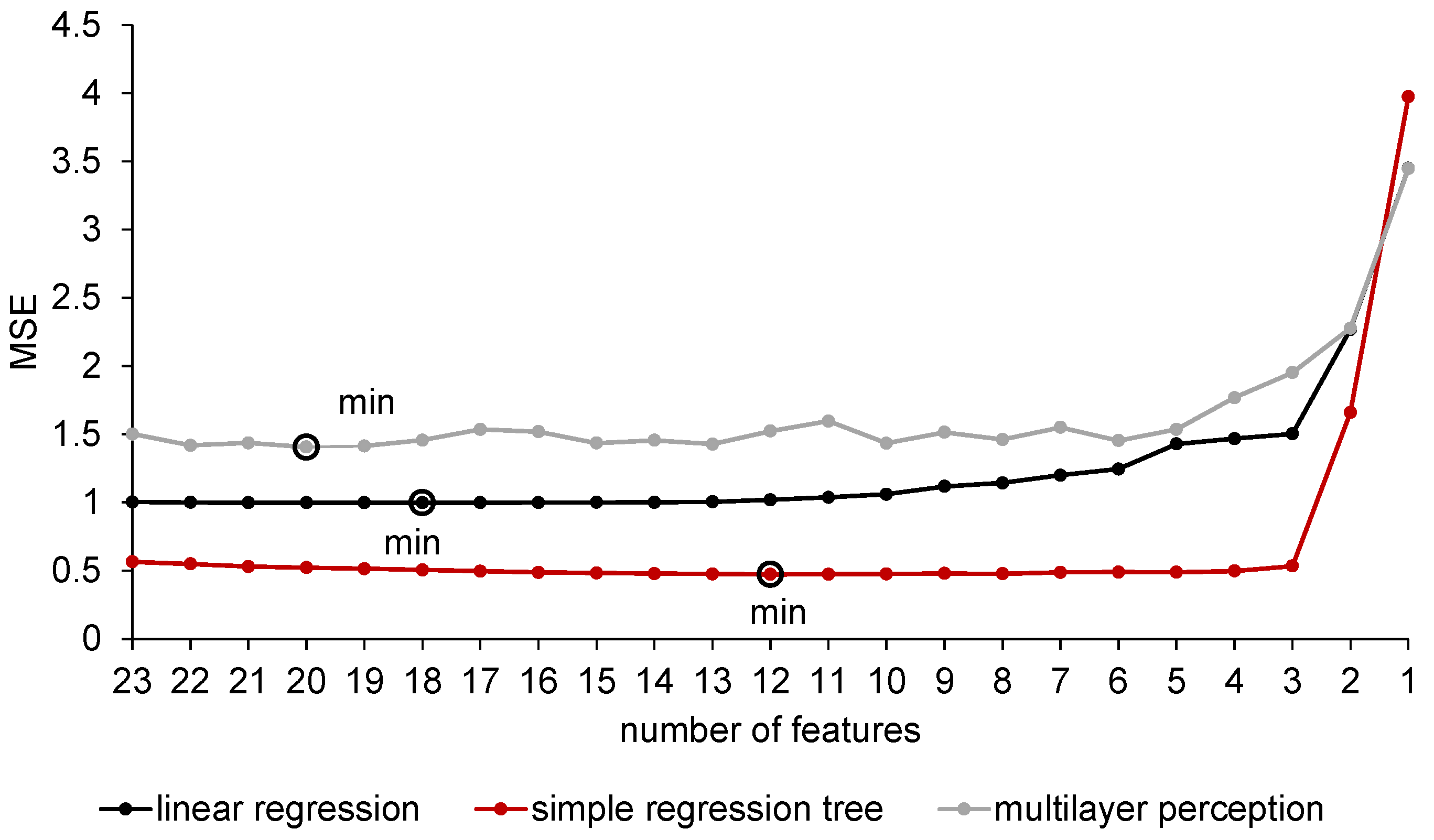

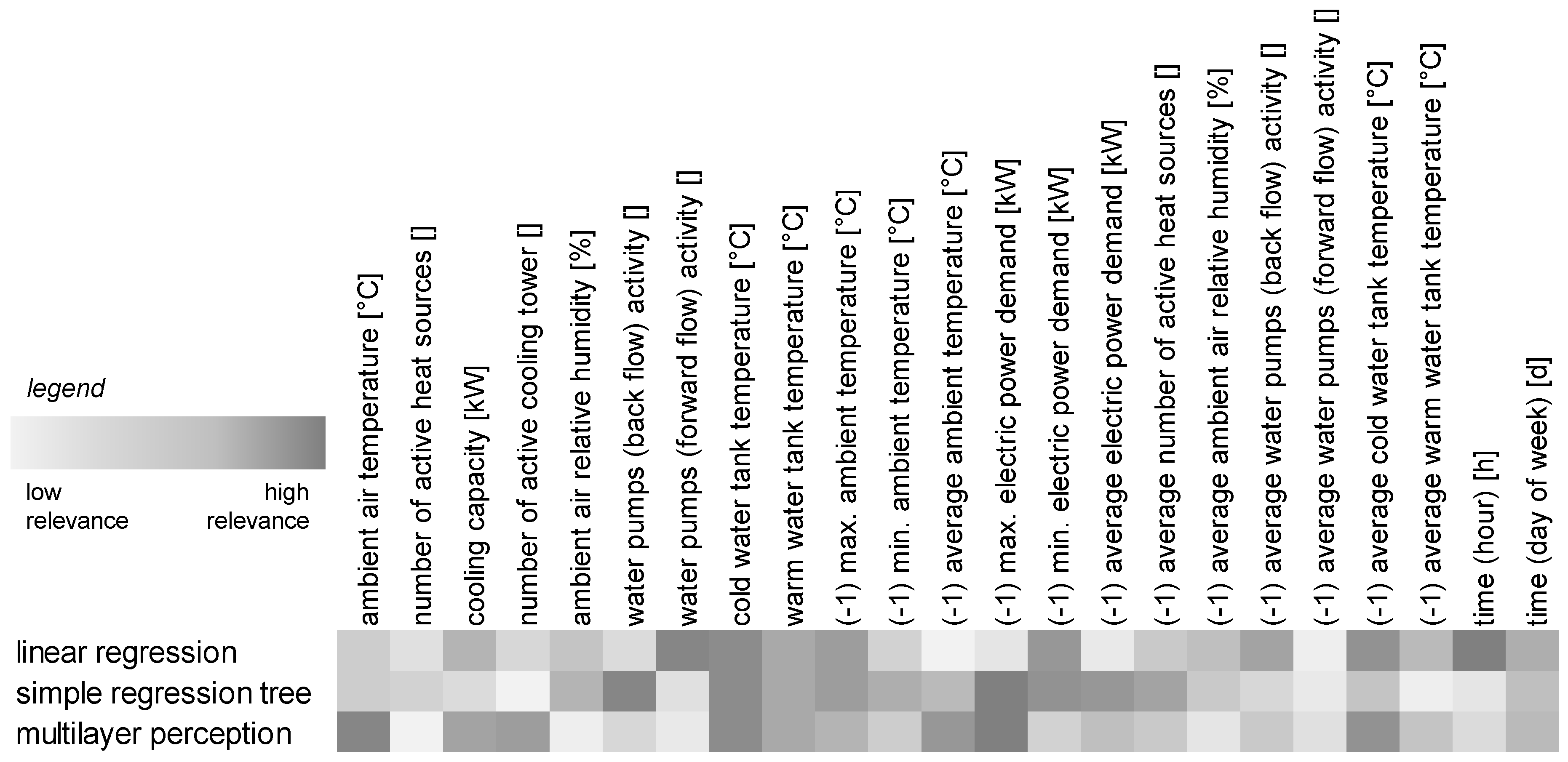

3.2.3. Feature Selection

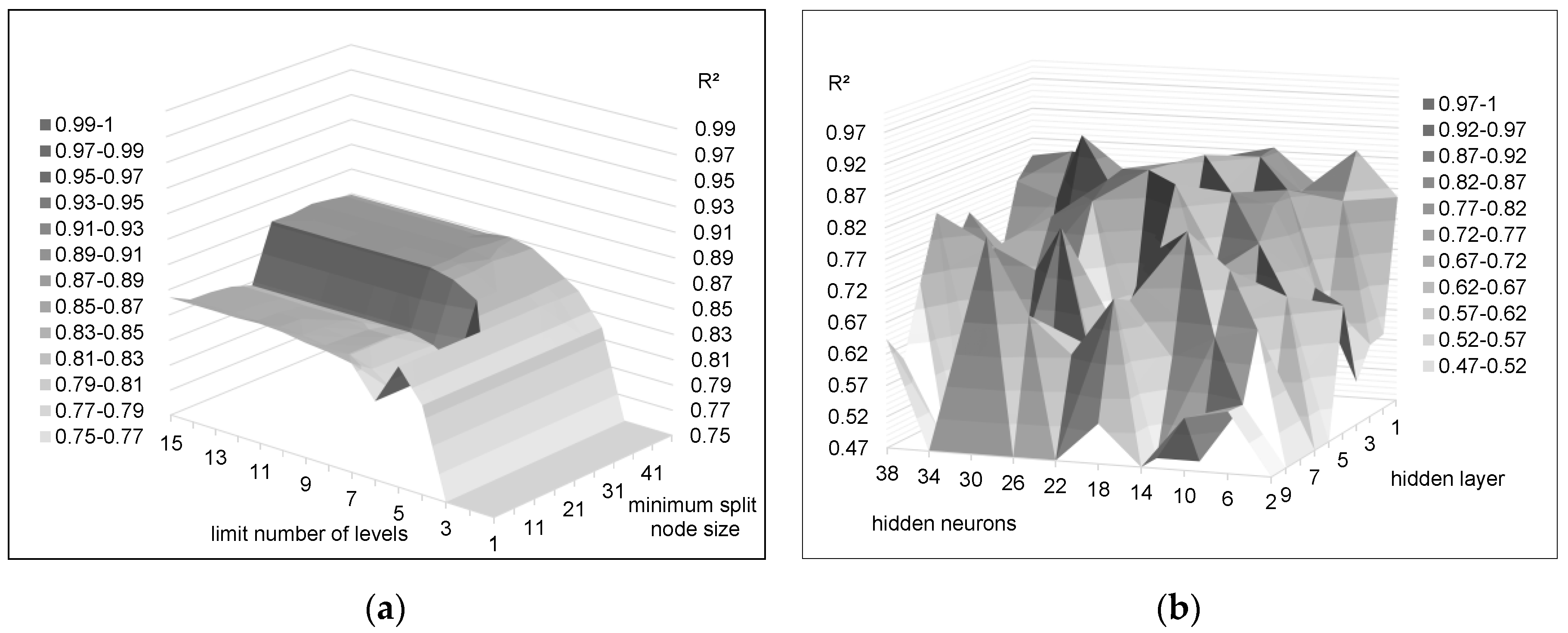

3.2.4. Hyperparameter Assessment

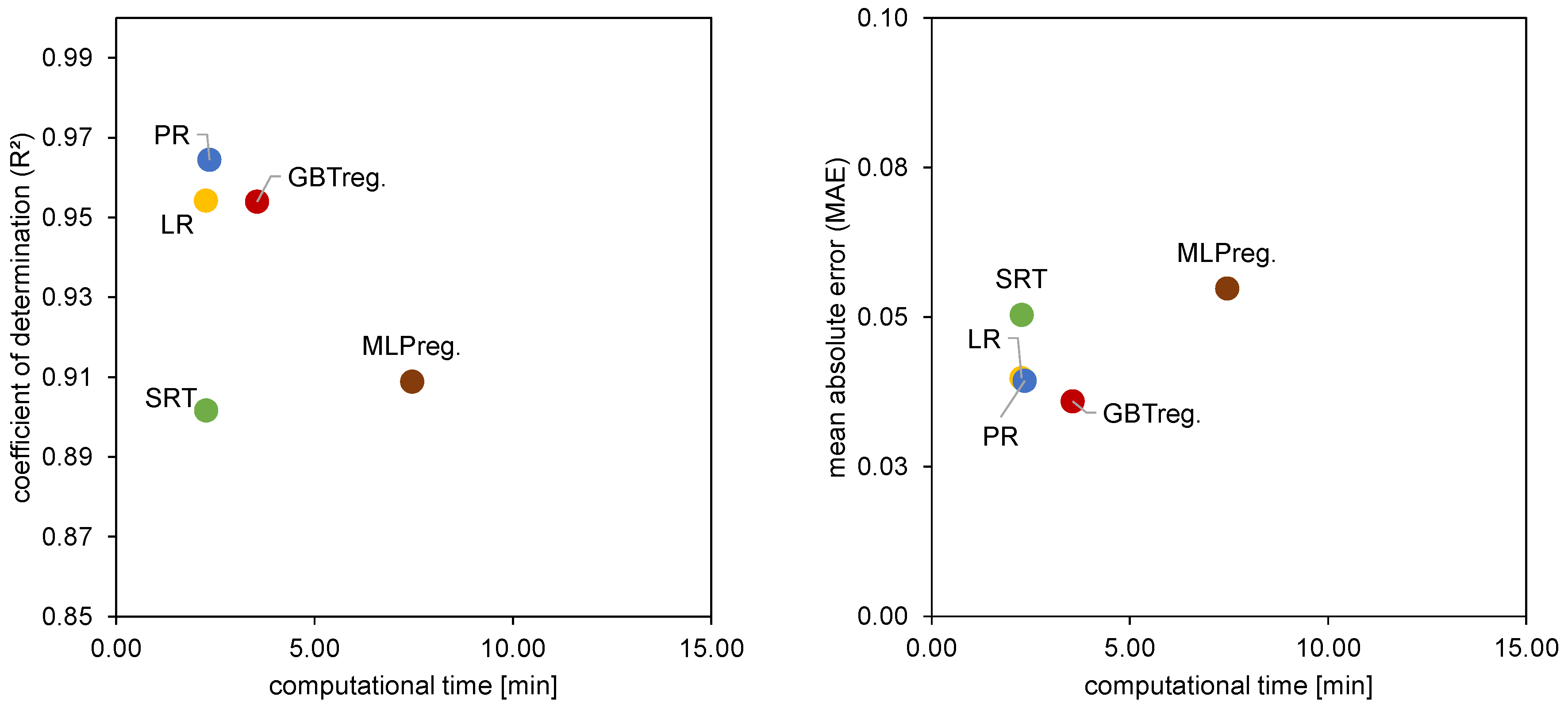

3.3. Evaluation and Deployment of Data Mining Results (Phase 3)

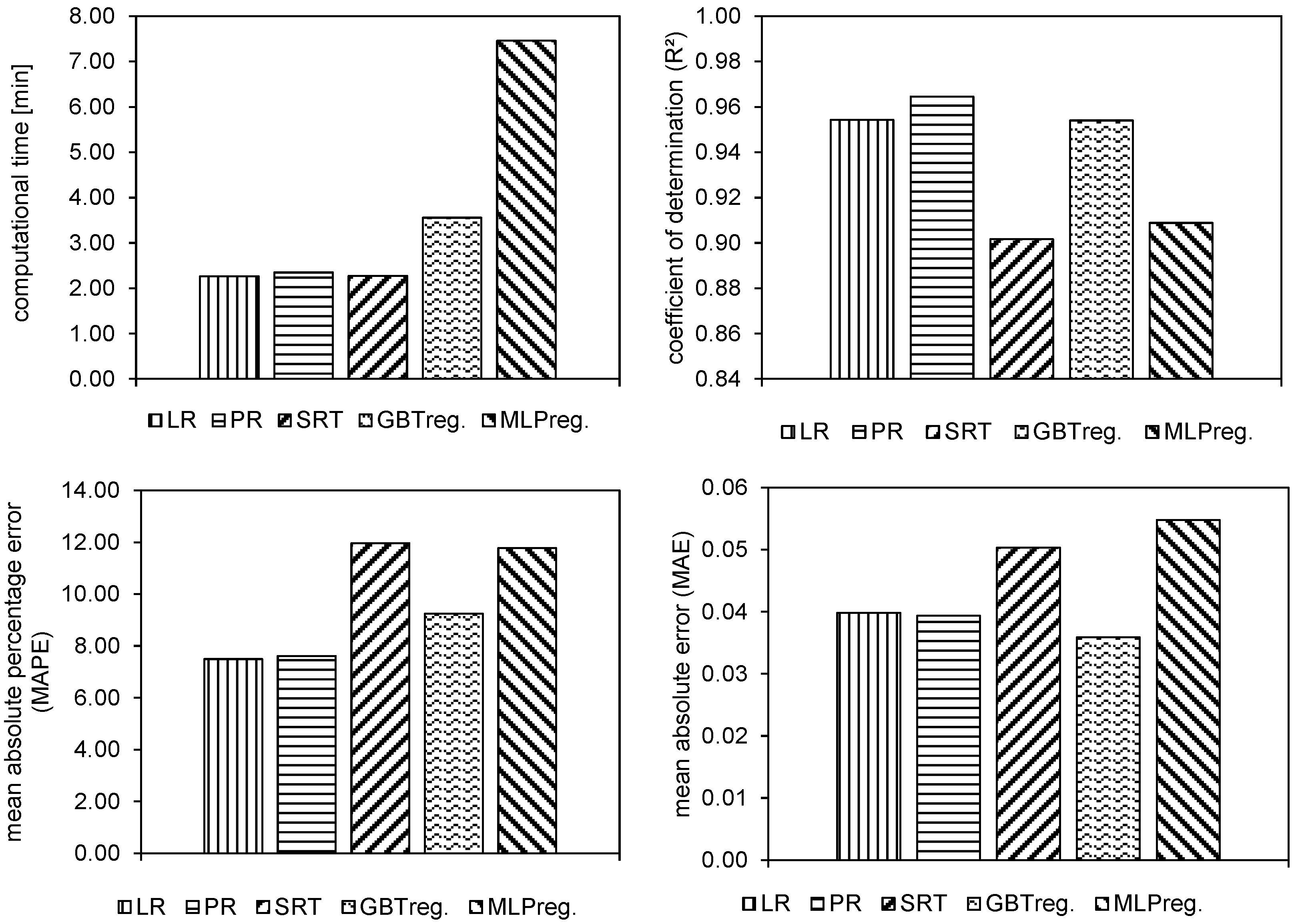

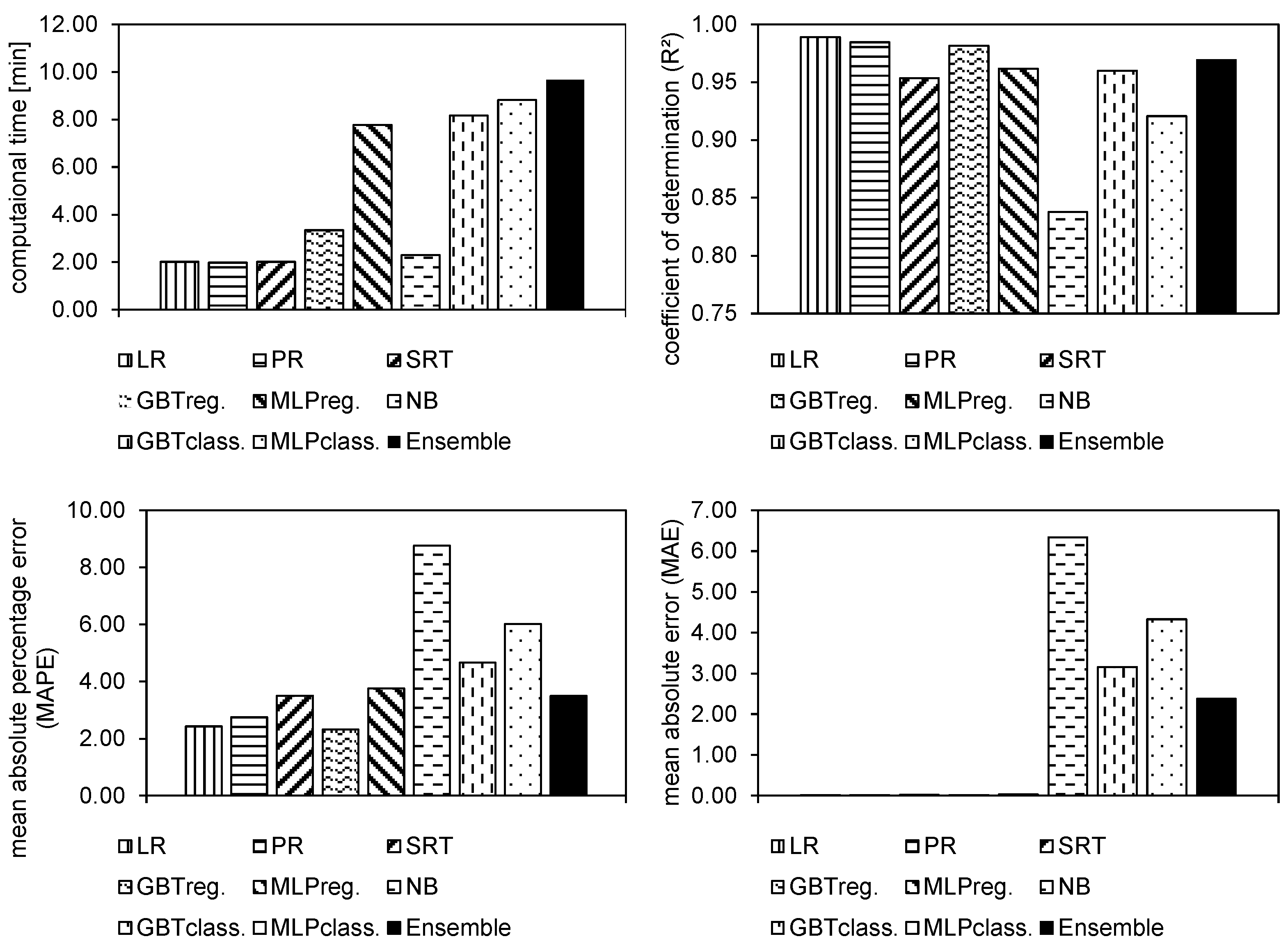

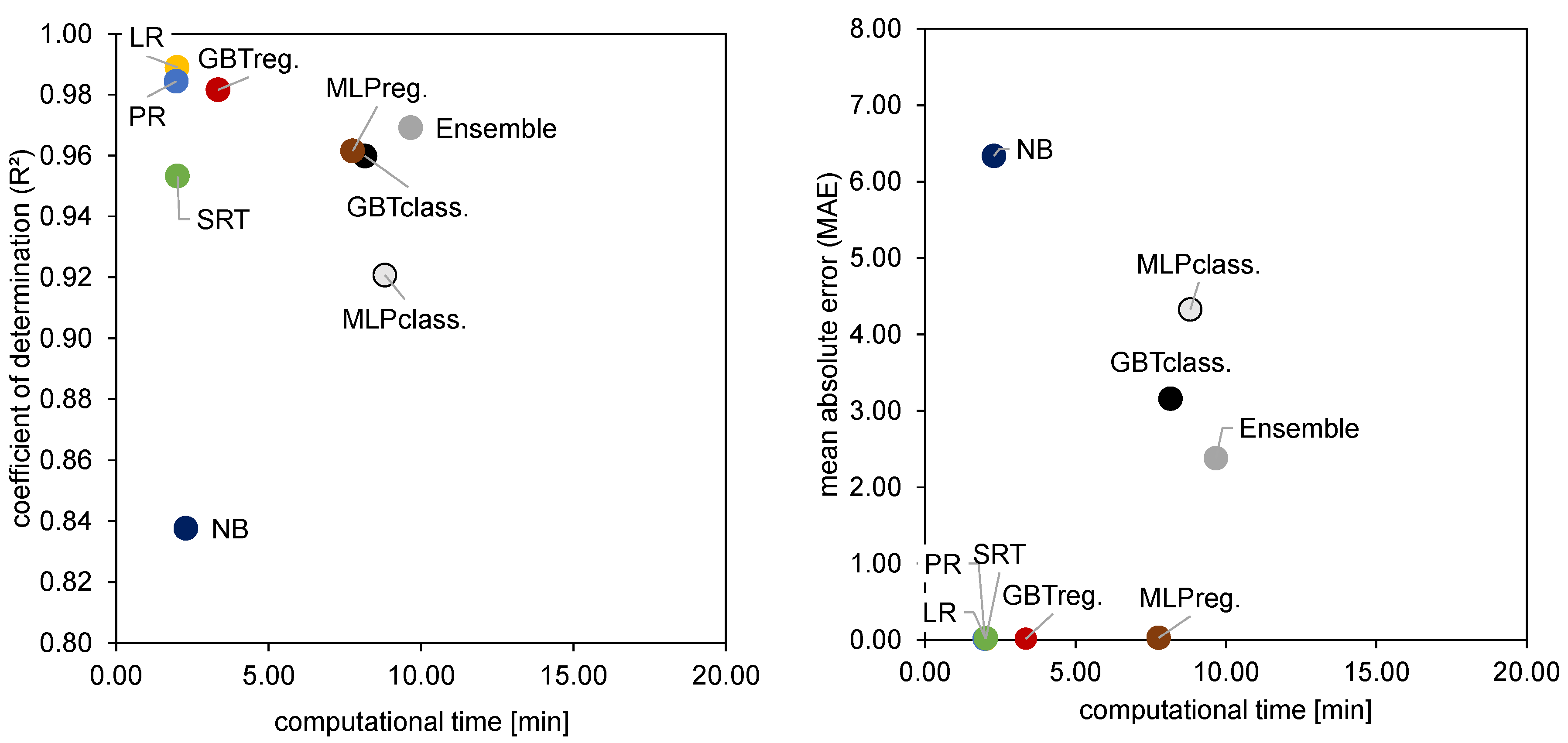

3.3.1. Prediction of Cooling Capacity

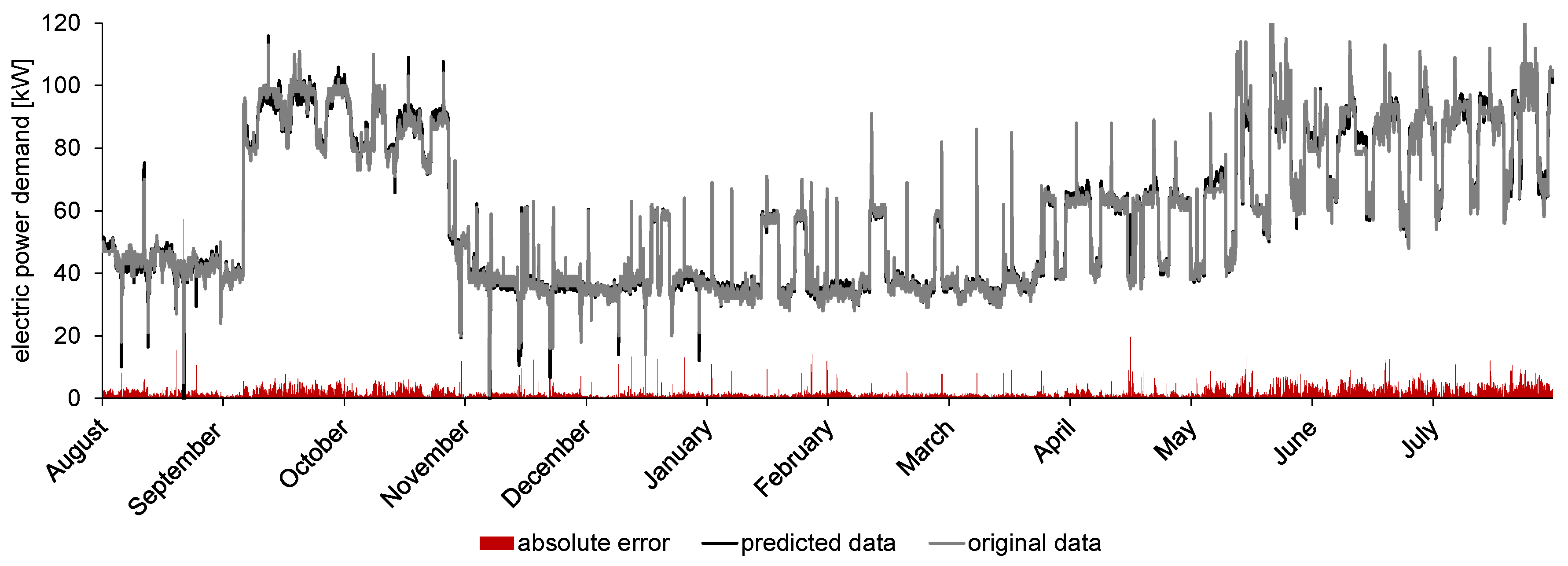

3.3.2. Prediction of Electric Power Demand

3.3.3. Discussion

4. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Herrmann, C.; Schmidt, C.; Kurle, D.; Blume, S.; Thiede, S. Sustainability in manufacturing and factories of the future. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 283–292. [Google Scholar] [CrossRef]

- Posselt, G. Towards Energy Transparent Factories; Herrmann, C., Kara, S., Eds.; Springer International Publishing: Braunschweig, Germany, 2016; ISBN 978-3-319-20868-8. [Google Scholar]

- Stoldt, J.; Trapp, T.U.; Toussaint, S.; Süße, M.; Schlegel, A.; Putz, M. Planning for Digitalisation in SMEs using Tools of the Digital Factory. Procedia CIRP 2018, 72, 179–184. [Google Scholar] [CrossRef]

- Fayyad, U.; Piatetsky-Shapiro, G.; Smyth, P. The KDD process for extracting useful knowledge from volumes of data. Commun. ACM 1996, 39, 27–34. [Google Scholar] [CrossRef]

- Fayyad, U.; Piatetsky-Shapiro, G.; Smyth, P. From Data Mining to Knowledge Discovery in Databases. AI Mag. 1996, 17, 37–54. [Google Scholar] [CrossRef]

- Bagheri, B.; Yang, S.; Kao, H.A.; Lee, J. Cyber-physical systems architecture for self-aware machines in industry 4.0 environment. IFAC-PapersOnLine 2015, 28, 1622–1627. [Google Scholar] [CrossRef]

- Ji, W.; Wang, L. Big data analytics based fault prediction for shop floor scheduling. J. Manuf. Syst. 2017, 43, 187–194. [Google Scholar] [CrossRef]

- Lee, J.; Ardakani, H.D.; Yang, S.; Bagheri, B. Industrial Big Data Analytics and Cyber-physical Systems for Future Maintenance & Service Innovation. Procedia CIRP 2015, 38, 3–7. [Google Scholar] [CrossRef]

- Winters, P.; Adae, I.; Silipo, R. Anomaly Detection in Predictive Maintenance. In Anomaly Detection with Time Series Analysis; KNIME: Zurich, Switzerland, 2014; pp. 3–9. [Google Scholar]

- Lau, H.C.W.; Cheng, E.N.M.; Lee, C.K.M.; Ho, G.T.S. A fuzzy logic approach to forecast energy consumption change in a manufacturing system. Expert Syst. Appl. 2008, 34, 1813–1824. [Google Scholar] [CrossRef]

- Walther, J.; Spanier, D.; Panten, N.; Abele, E. Very short-term load forecasting on factory level—A machine learning approach. Procedia CIRP 2019, 80, 705–710. [Google Scholar] [CrossRef]

- Zhang, Y.; Tao, F.; Chen, K.; Sun, H.; Cheng, Y. Data and knowledge mining with big data towards smart production. J. Ind. Inf. Integr. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Okorie, O.; Salonitis, K.; Charnley, F.; Turner, C. A Systems Dynamics Enabled Real-Time Efficiency for Fuel Cell Data-Driven Remanufacturing. J. Manuf. Mater. Process. 2018, 2, 77. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann. Manuf. Technol. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Gutowski, T.G.; Allwood, J.M.; Herrmann, C.; Sahni, S. A Global Assessment of Manufacturing: Economic Development, Energy Use, Carbon Emissions, and the Potential for Energy Efficiency and Materials Recycling. Annu. Rev. Environ. Resour. 2013, 38, 81–106. [Google Scholar] [CrossRef]

- Thiede, S. Energy Efficiency in Manufacturing Systems; Herrmann, C., Kara, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 9783642259135. [Google Scholar]

- Müller, E.; Engelmann, J.; Löffler, T.; Strauch, J. (Eds.) Energieeffiziente Fabriken Planen und Betreiben; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 9788578110796. [Google Scholar]

- Rebhahn, E. Energiehandbuch—Gewinnung, Wandlung und Nutzung von Energie, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2002; ISBN 9783-6426-25183. [Google Scholar]

- Hesselbach, J.; Herrmann, C.; Detzer, R.; Martin, L.; Thiede, S.; Lüdemann, B. Energy Efficiency through optimized coordination of production and technical building services. In Proceedings of the Conference Proceedings LCE2008—15th CIRP International Conference on Life Cycle Engineering, Sydney, Australia, 17–19 March 2008; Volume 15, pp. 624–628. [Google Scholar]

- Schulze, C.; Thiede, S.; Thiede, B.; Kurle, D.; Blume, S.; Herrmann, C. Cooling tower management in manufacturing companies: A cyber- physical system approach. J. Clean. Prod. 2019, 211, 428–441. [Google Scholar] [CrossRef]

- Hesselbach, J. Energie- und Klimaeffiziente Produktion; Springer Vieweg: Wiesbaden, Germany, 2012; ISBN 9783834804488. [Google Scholar]

- Wischhusen, D.I.S.; Lüdemann, I.B.; Schmitz, I.G. Economical Analysis of Complex Heating and Cooling Systems with the Simulation Tool HKSim. In Proceedings of the 3rd International Modelica Conference, Linköping, Sweden, 3–4 November 2003. [Google Scholar]

- VDI Open Recooler Systems—Securing Hygienically Sound Operation of Evaporative Cooling Systems (VDI Cooling Tower Code of Practice); VDI-Gesellschaft Bauen und Gebäudetechnik: Düsseldorf, Germany, 2017.

- Kloppers, J.C.; Kroger, D.G. Cooling tower performance evaluation: Merkel, poppe, and e-NTU methods of analysis. J. Eng. Gas Turbines Power Trans. ASME 2005, 127, 1–7. [Google Scholar] [CrossRef]

- Schulze, C.; Raabe, B.; Herrmann, C.; Thiede, S. Environmental Impacts of Cooling Tower Operations—The Influence of Regional Conditions on Energy and Water Demands. In Proceedings of the Procedia CIRP 25th Conference on Life Cycle Engineering, Copenhagen, Denmark, 30 April–2 May 2018; Volume 69, pp. 277–282. [Google Scholar]

- VDI Gesellschaft Verfahrenstechnik und Chemieingenieurwesen. VDI-Wärmeatlas, 11th ed.; Springer: Berlin/Heidelbarg, Germany, 2013; ISBN 978-3-642-19980-6. [Google Scholar]

- Thiede, S.; Kurle, D.; Herrmann, C. The water-energy nexus in manufacturing systems: Framework and systematic improvement approach. CIRP Ann. Manuf. Technol. 2017, 66, 49–52. [Google Scholar] [CrossRef]

- Eurovent Certita Certification SAS Energy Efficiency Labels. Available online: https://www.eurovent-certification.com/en/energy-efficiency-labels (accessed on 4 April 2020).

- Lambach, S.; Lohmann, S.; Adam, M. Jahres-Energieeffizienz von Kühlgeräten zur Klimatisierung—Vergleich von Normberechnung und Jahressimulationen. KI Kälte-Luft-Klimatech. 2018, 5, 50–55. [Google Scholar]

- Beier, J.; Neef, B.; Thiede, S.; Herrmann, C. Integrating on-site renewable electricity generation into a manufacturing system with intermittent battery storage from electric vehicles. Procedia CIRP 2016, 48, 483–488. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Sharif Ullah, A.M.M.; Kubo, A.; Akamatsu, T.; D’Addona, D.M. Machining phenomenon twin construction for industry 4.0: A case of surface roughness. J. Manuf. Mater. Process. 2020, 4, 11. [Google Scholar] [CrossRef]

- Lichtblau, K.; Stich, V.; Bertenrath, R.; Blum, M.; Bleider, M.; Millack, A.; Katharina, S.; Schmitz, E.; Schröter, M. Industrie 4.0-Readiness; IMPULS—Stiftung für den Maschinenbau, den Anlagenbau und die Informationstechnik: Aachen, Germany; Köln, Germany, 2015. [Google Scholar]

- Tao, F.; Zhang, M.; Nee, A.Y.C. (Eds.) Digital Twin Driven Smart Manufacturing; Academic Press: Cambridge, MA, USA, 2019; ISBN 978-0-12-817630-6. [Google Scholar]

- Monostori, L. Cyber-Physical Systems. In CIRP Encyclopedia of Production Engineering; Chatti, S., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–8. ISBN 978-3-642-35950-7. [Google Scholar]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A.Y.C. Digital twin driven prognostics and health management for complex equipment. CIRP Ann. Manuf. Technol. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Armendia, M.; Ghassempouri, M.; Selmi, J.; Berglind, L.; Sossenheimer, J.; Flum, D.; Peysson, F.; Fuertjes, T.; Plakhotnik, D. Twin-Control Evaluation in Industrial Environment: Automotive Case. In Twin-Control; Armendia, M., Ghassempouri, M., Ozturk, E., Peysson, F., Eds.; Springer: Cham, Switzerland, 2019; ISBN 9783030022037. [Google Scholar]

- Uhlemann, T.H.J.; Lehmann, C.; Steinhilper, R. The Digital Twin: Realizing the Cyber-Physical Production System for Industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Wirth, R.; Hipp, J. CRISP-DM: Towards a Standard Process Model for Data Mining. In Proceedings of the 4th International Conference on the Practical Application of Knowledge Discovery and Data Mining (PADD ’00), Manchester, UK, 11–13 April 2000; pp. 29–39. [Google Scholar]

- Chapman, P.; Clinton, J.; Kerber, R.; Khabaza, T.; Reinartz, T.; Shearer, C.; Wirth, R. CRISP-DM 1.0—Step-by-Step Data Mining Guide; SPSS Inc.: Chicago, IL, USA, 2000; ISBN 9780769532677. [Google Scholar]

- Shafique, U.; Qaiser, H. A Comparative Study of Data Mining Process Models (KDD, CRISP-DM and SEMMA). Int. J. Innov. Sci. Res. 2014, 12, 217–222. [Google Scholar]

- Molina-Solana, M.; Ros, M.; Ruiz, M.D.; Gomez-Romero, J.; Martin-Bautista, M.J. Data Science for Building Energy Management: A review. Renew. Sustain. Energy Rev. 2017, 70, 598–609. [Google Scholar] [CrossRef]

- Decker, K.M.; Focardi, S. Technology Overview: A Report on Data Mining; Swiss Scientific Computing Center: Manno, Switzerland, 1995. [Google Scholar]

- Han, J.; Kamber, M.; Pei, J. Data Mining—Concepts and Techniques, 3rd ed.; Morgan Kaufmann: Waltham, MA, USA, 2011; ISBN 9780123814791. [Google Scholar]

- Clarke, B.; Fokoue, E.; Zhang, H.H. Principles and Theory for Data Mining and Machine Learning; Springer: New York, NY, USA, 2009; ISBN 9780387981345. [Google Scholar]

- Teiwes, H.; Blume, S.; Herrmann, C.; Rössinger, M.; Thiede, S. Energy load profile analysis on machine level. In Proceedings of the Procedia CIRP 25th Conference on Life Cycle Engineering, Copenhagen, Denmark, 30 April–2 May 2018; Volume 69, pp. 271–276. [Google Scholar]

- Anuar, N.; Zakaria, Z. Electricity Load Profile Determination by using Fuzzy C-Means and Probability Neural Network. In Proceedings of the International Conference on Advances in Energy Engineering (ICAEE), Bangkok, Thailand, 27–28 December 2012. Elsevier Ltd. Selection. [Google Scholar]

- Tardioli, G.; Kerrigan, R.; Oates, M.; O’Donnell, J.; Finn, D. Data driven approaches for prediction of building energy consumption at urban level. Energy Procedia 2015, 78, 3378–3383. [Google Scholar] [CrossRef]

- Hosoz, M.; Ertunc, H.M.; Bulgurcu, H. An adaptive neuro-fuzzy inference system model for predicting the performance of a refrigeration system with a cooling tower. Expert Syst. Appl. 2011, 38, 14148–14155. [Google Scholar] [CrossRef]

- Azadeh, M.A.; Sohrabkhani, S. Annual electricity consumption forecasting with Neural Network in high energy consuming industrial sectors of Iran. Proc. IEEE Int. Conf. Ind. Technol. 2006, 49, 2166–2171. [Google Scholar] [CrossRef]

- Chou, J.S.; Hsu, Y.C.; Lin, L.T. Smart meter monitoring and data mining techniques for predicting refrigeration system performance. Expert Syst. Appl. 2014, 41, 2144–2156. [Google Scholar] [CrossRef]

- Fan, C.; Xiao, F.; Wang, S. Development of prediction models for next-day building energy consumption and peak power demand using data mining techniques. Appl. Energy 2014, 127, 1–10. [Google Scholar] [CrossRef]

- Amasyali, K.; El-Gohary, N.M. A review of data-driven building energy consumption prediction studies. Renew. Sustain. Energy Rev. 2018, 81, 1192–1205. [Google Scholar] [CrossRef]

- Ahmad, M.W.; Mourshed, M.; Rezgui, Y. Trees vs Neurons: Comparison between random forest and ANN for high-resolution prediction of building energy consumption. Energy Build. 2017, 147, 77–89. [Google Scholar] [CrossRef]

- Qi, X.; Liu, Z.; Li, D. Numerical simulation of shower cooling tower based on artificial neural network. Energy Convers. Manag. 2008, 49, 724–732. [Google Scholar] [CrossRef]

- Qi, X.; Liu, Y.; Guo, Q.; Yu, S.; Yu, J. Performance prediction of a shower cooling tower using wavelet neural network. Appl. Therm. Eng. 2016, 108, 475–485. [Google Scholar] [CrossRef]

- Pan, T.H.; Shieh, S.S.; Jang, S.S.; Tseng, W.H.; Wu, C.W.; Ou, J.J. Statistical multi-model approach for performance assessment of cooling tower. Energy Convers. Manag. 2011, 52, 1377–1385. [Google Scholar] [CrossRef]

- Gao, Y.; Tumwesigye, E.; Cahill, B.; Menzel, K. Using data mining in optimisation of building energy consumption and thermal comfort management. In Proceedings of the 2nd International Conference on Software Engineering and Data Mining, Chengdu, China, 23–25 June 2010; pp. 434–439. [Google Scholar]

- Patnaik, D.; Marwah, M.; Sharma, R.; Ramakrishnan, N. Sustainable Operation and Management of Data Center Chillers Using Temporal Data Mining. In Proceedings of the 15th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Paris, France, 28 June–1 July 2009; pp. 1305–1314. [Google Scholar] [CrossRef]

- Anuar, N.; Zakaria, Z. Electricity load profile determination by using fuzzy C-means and probability neural network. Energy Procedia 2012, 14, 1861–1869. [Google Scholar] [CrossRef]

- Li, W.; Thiede, S.; Kara, S.; Herrmann, C. A Generic Sankey Tool for Evaluating Energy Value Stream in Manufacturing Systems. Procedia CIRP 2017, 61, 475–480. [Google Scholar] [CrossRef]

- Wang, J.-G.; Shieh, S.-S.; Jang, S.-S.; Wu, C.-W. Discrete model-based operation of cooling tower based on statistical analysis. Energy Convers. Manag. 2013, 73, 226–233. [Google Scholar] [CrossRef]

- Jovanović, R.; Sretenović, A.A.; Živković, B.D. Ensemble of various neural networks for prediction of heating energy consumption. Energy Build. 2015, 94, 189–199. [Google Scholar] [CrossRef]

- Fan, C.; Xiao, F.; Yan, C. A framework for knowledge discovery in massive building automation data and its application in building diagnostics. Autom. Constr. 2015, 50, 81–90. [Google Scholar] [CrossRef]

- Hecht-Nielsen, R. Theory of the Backpropagation Neural Network. Proceedings of International Joint Conference on Neural Networks, Washington, DC, USA, 1989; IEEE: New York, NY, USA, 1989; pp. 593–605. [Google Scholar]

- Rafiq, M.Y.; Bugmann, G.; Easterbrook, D.J. Neural network design for engineering applications. Comput. Struct. 2001, 79, 1541–1552. [Google Scholar] [CrossRef]

- Goebel, M.; Gruenwald, L. A survey of data mining and knowledge discovery software tools. ACM SIGKDD Explor. Newsl. 1999, 1, 20–33. [Google Scholar] [CrossRef]

- Deng, C.; Guo, R.; Liu, C.; Zhong, R.Y.; Xu, X. Data cleansing for energy-saving: A case of Cyber-Physical Machine Tools health monitoring system. Int. J. Prod. Res. 2018, 56, 1000–1015. [Google Scholar] [CrossRef]

- Leys, C.; Ley, C.; Klein, O.; Bernard, P.; Licata, L. Detecting outliers: Do not use standard deviation around the mean, use absolute deviation around the median. J. Exp. Soc. Psychol. 2013, 49, 764–766. [Google Scholar] [CrossRef]

- Rodgers, J.L.; Nicewander, W.A. Thirteen Ways to Look at the Correlation Coefficient. Am. Stat. 1988, 42, 59–66. [Google Scholar] [CrossRef]

| Studies | Data-Driven Algorithms | Use Case | Target KPI | Brief Description | Available Data Set Details | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Artificial Neural Network | Clustering | Fuzzy Association Rules | Support Vector Machine | Linear/Polynomial Regression | Decision Trees | Random Forest | Ensemble | Time Series Analysis | Industry | Buildings | Cooling Performance | Energy Demand | Environmental Conditions | |||

| Abraham et al., 2001 | ● | ● | ● | ● | ● | power demand for the Australian region | 12 months, 15 min. freq. | |||||||||

| Ahmad et al., 2017 | ● | ● | ● | ● | ● | development of an expert system applied on the electric power demand of a hotel in Spain | 10,972 rows, 10 variables | |||||||||

| Amasyali et al., 2016 | ● | ● | ● | ● | power demand of offices considering clouds and number of persons in the building | 60 days, 15 min. freq. | ||||||||||

| Anuar et al., 2012 | ● | ● | ● | ● | ● | electric energy demand of various companies in industry and commerce | 30 min. freq. | |||||||||

| Azadeh et al., 2008 | ● | ● | ● | ● | long-term development of electric energy demand in Iran | 130 rows | ||||||||||

| Fan et al., 2015 | ● | ● | ● | ● | identification of recurring patterns in the power demand of a skyscraper’s TBS | 29,757 rows, 158 variables | ||||||||||

| Fan et al., 2014 | ● | ● | ● | ● | ● | ● | ● | ● | prediction of maximum and total power demand of the cooling tower system for the next day | 34,616 rows, 15 min. freq. | ||||||

| Gao et al., 2010 | ● | ● | ● | ● | ● | identification of operating conditions for comfort air conditioning | 68,000 rows, 7 variables | |||||||||

| Hosoz et al., 2006 | ● | ● | ● | model for the construction of cooling towers to substitute experimental data | 81 rows, 5 variables | |||||||||||

| Jovanovi et al., 2015 | ● | ● | ● | ● | ● | comparison of three different ANNs for a TBS at University | 3 years, 60 min. freq. | |||||||||

| Qi et al., 2006 | ● | ● | ● | model for the construction of cooling towers | 8 variables | |||||||||||

| Qi et al., 2016 | ● | ● | laboratory tests for mapping cooling system behavior using data mining | 400 rows, 7 variables | ||||||||||||

| Tian-Hong Pan et al., 2011 | ● | ● | ● | ● | ● | description of a cooling system with data mining to reduce design effort | 8 months, 1 min. freq. | |||||||||

| Wang et al., 2013 | ● | ● | ● | ● | identification of efficient operating conditions for the cooling system in a steel factory | 60,000 rows, 5 min. freq. | ||||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blume, C.; Blume, S.; Thiede, S.; Herrmann, C. Data-Driven Digital Twins for Technical Building Services Operation in Factories: A Cooling Tower Case Study. J. Manuf. Mater. Process. 2020, 4, 97. https://doi.org/10.3390/jmmp4040097

Blume C, Blume S, Thiede S, Herrmann C. Data-Driven Digital Twins for Technical Building Services Operation in Factories: A Cooling Tower Case Study. Journal of Manufacturing and Materials Processing. 2020; 4(4):97. https://doi.org/10.3390/jmmp4040097

Chicago/Turabian StyleBlume, Christine, Stefan Blume, Sebastian Thiede, and Christoph Herrmann. 2020. "Data-Driven Digital Twins for Technical Building Services Operation in Factories: A Cooling Tower Case Study" Journal of Manufacturing and Materials Processing 4, no. 4: 97. https://doi.org/10.3390/jmmp4040097

APA StyleBlume, C., Blume, S., Thiede, S., & Herrmann, C. (2020). Data-Driven Digital Twins for Technical Building Services Operation in Factories: A Cooling Tower Case Study. Journal of Manufacturing and Materials Processing, 4(4), 97. https://doi.org/10.3390/jmmp4040097