A Finite Element Study of Thermo-Mechanical Fields and Their Relation to Friction Conditions in Al1050 Ring Compression Tests

Abstract

:1. Introduction

- Flow stress curves for Al1050 at different temperatures and strain rates are reported.

- Friction coefficients for lubricated and unlubricated contact between the specimen and tools at different temperatures and strain rates are determined.

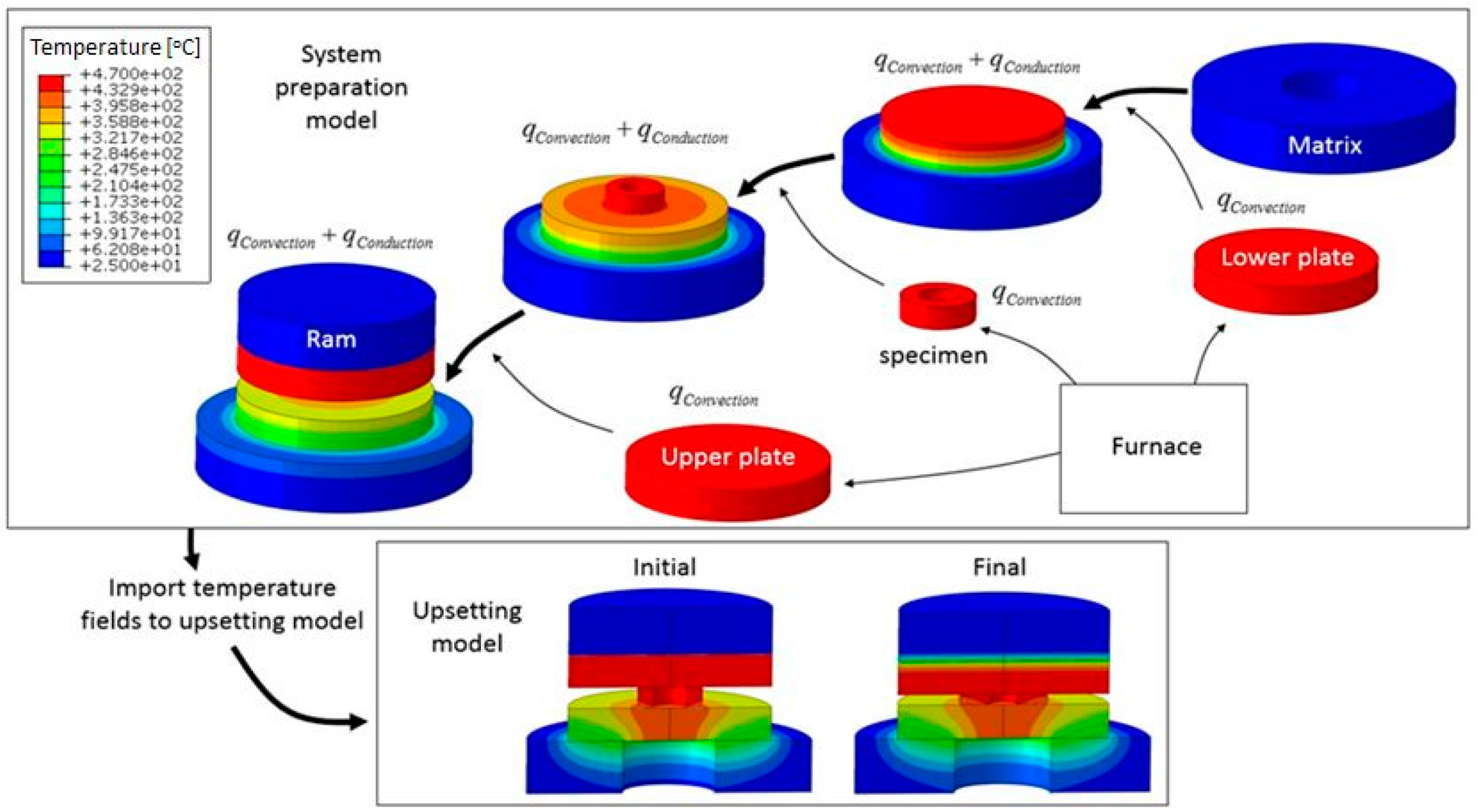

- The heat loss during system RCT preparation is modeled and quantified demonstrating a non-negligible effect on friction and flow stress determination.

- A novel method for validating computed friction values by comparing the neutral radius from the FE model to metallurgical characterization is presented.

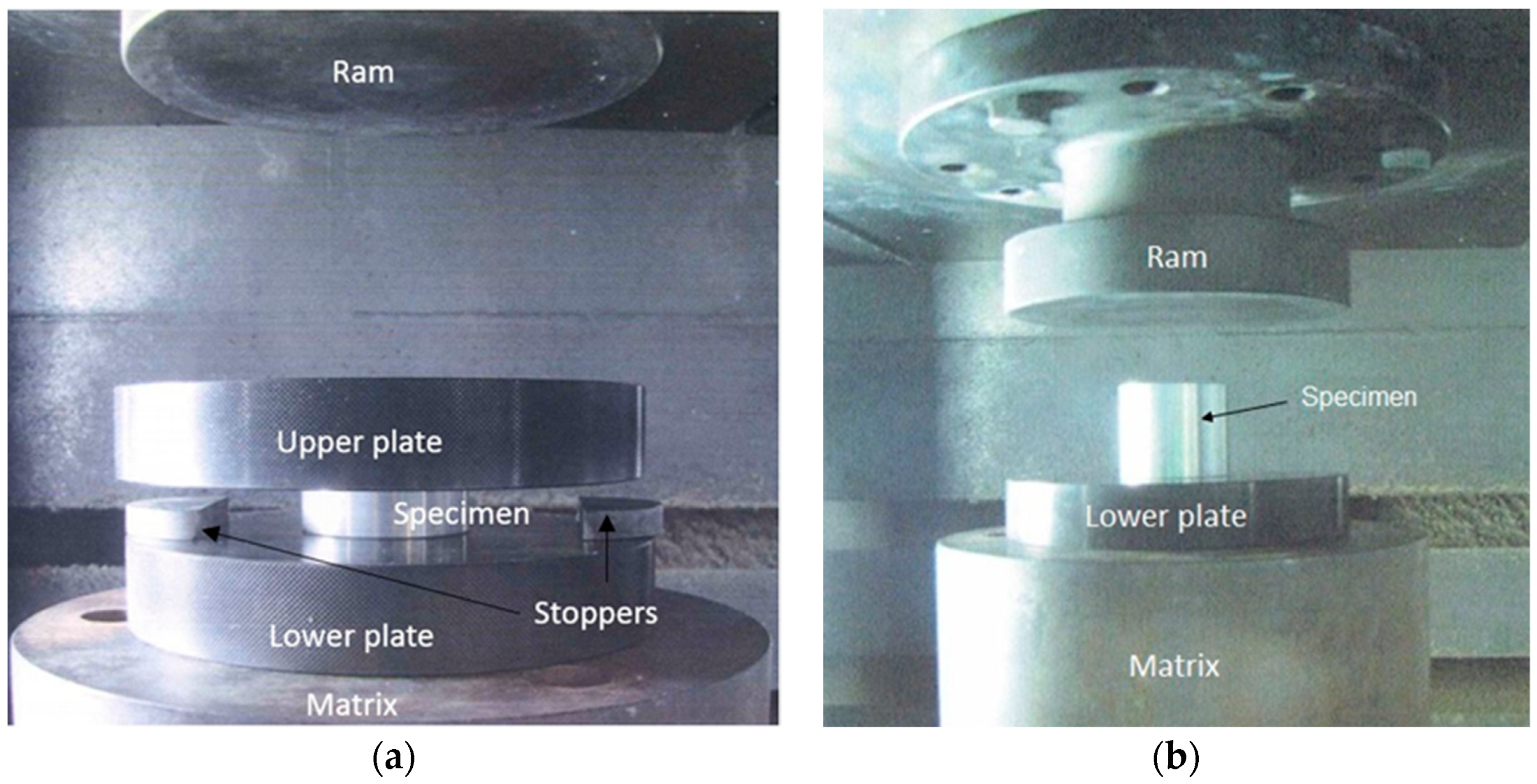

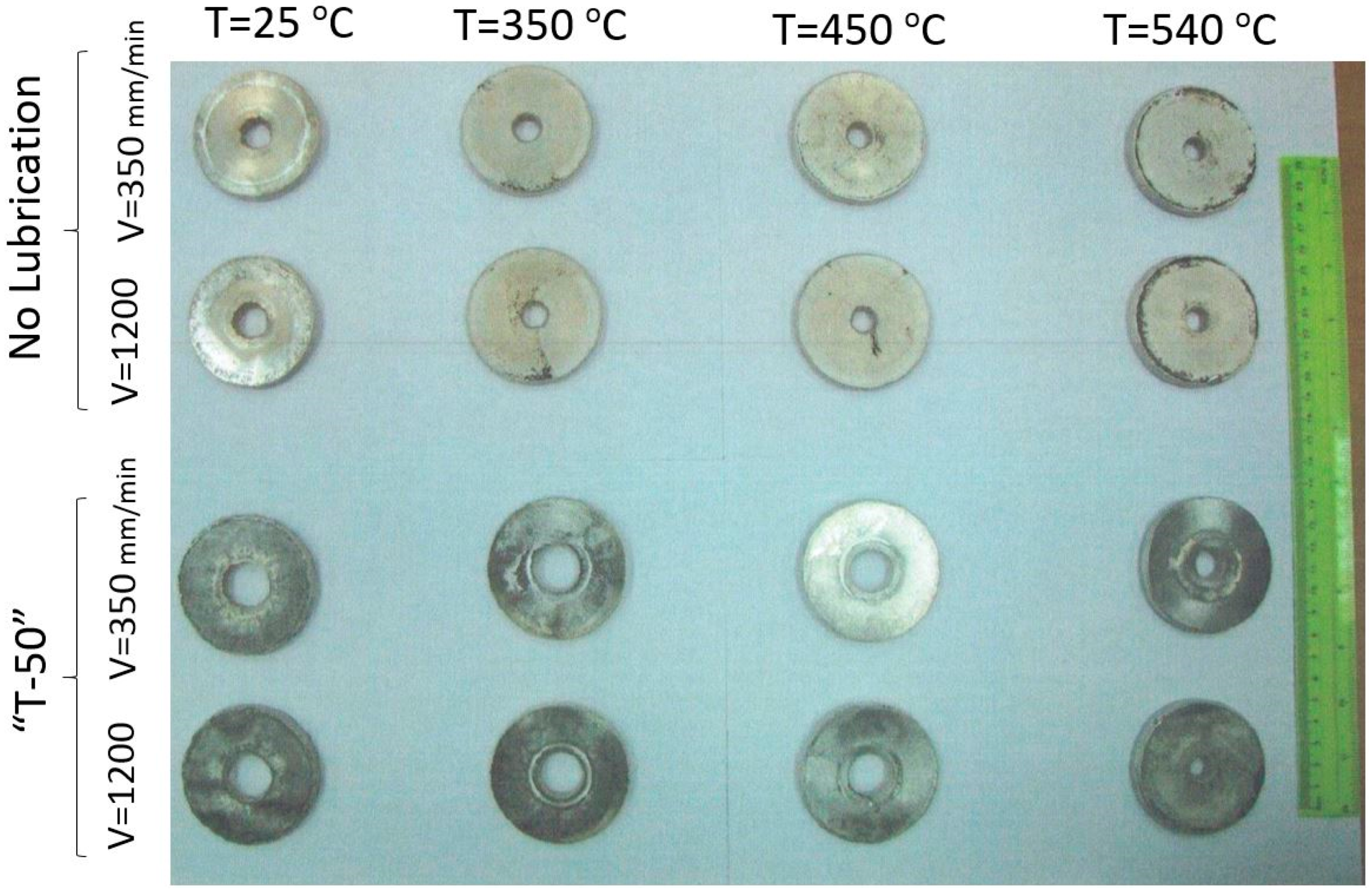

2. Experimental Setup for Al1050 Upsetting Tests

3. Computational Modeling of the Upsetting Tests

3.1 Model Definitions

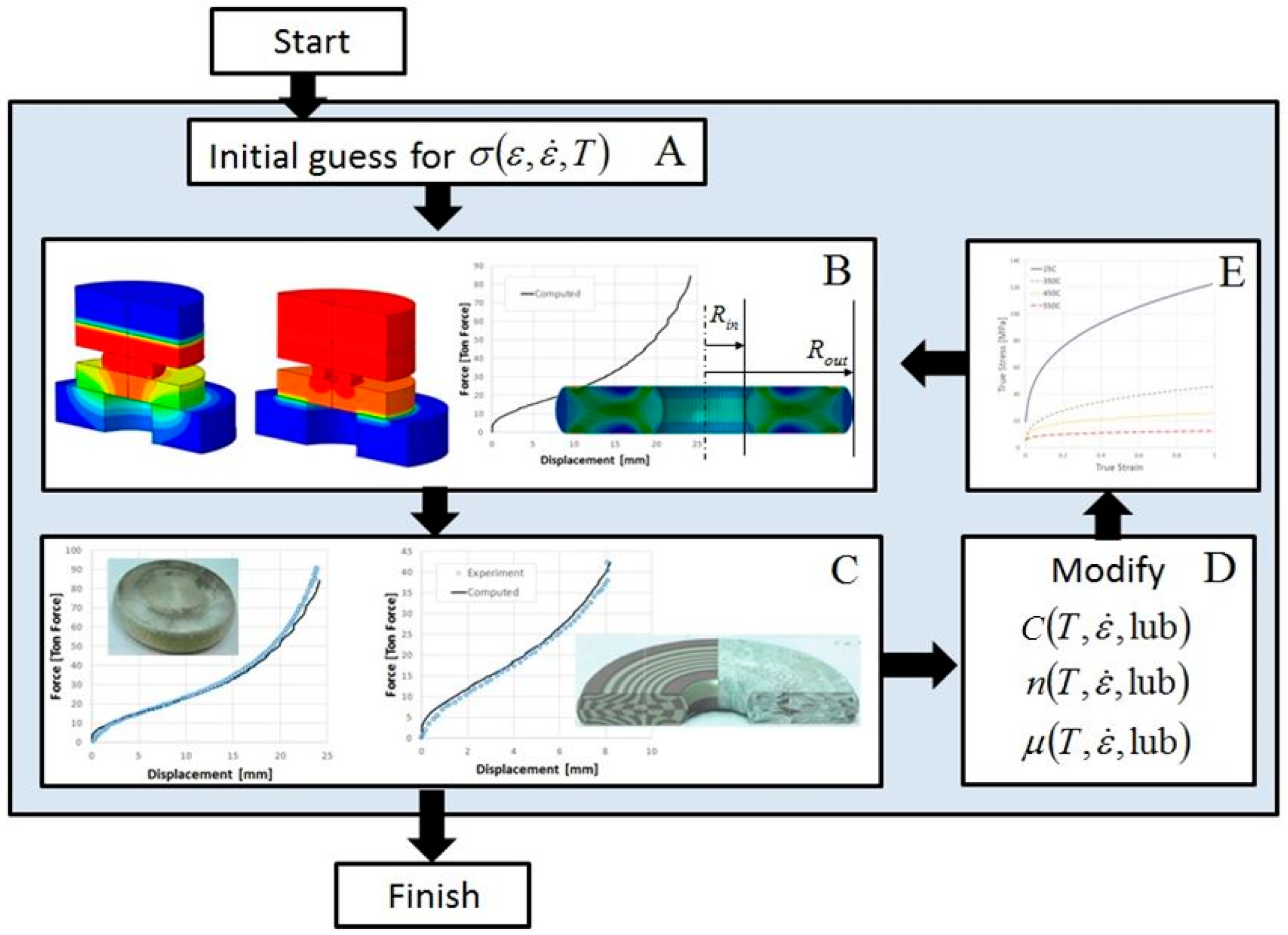

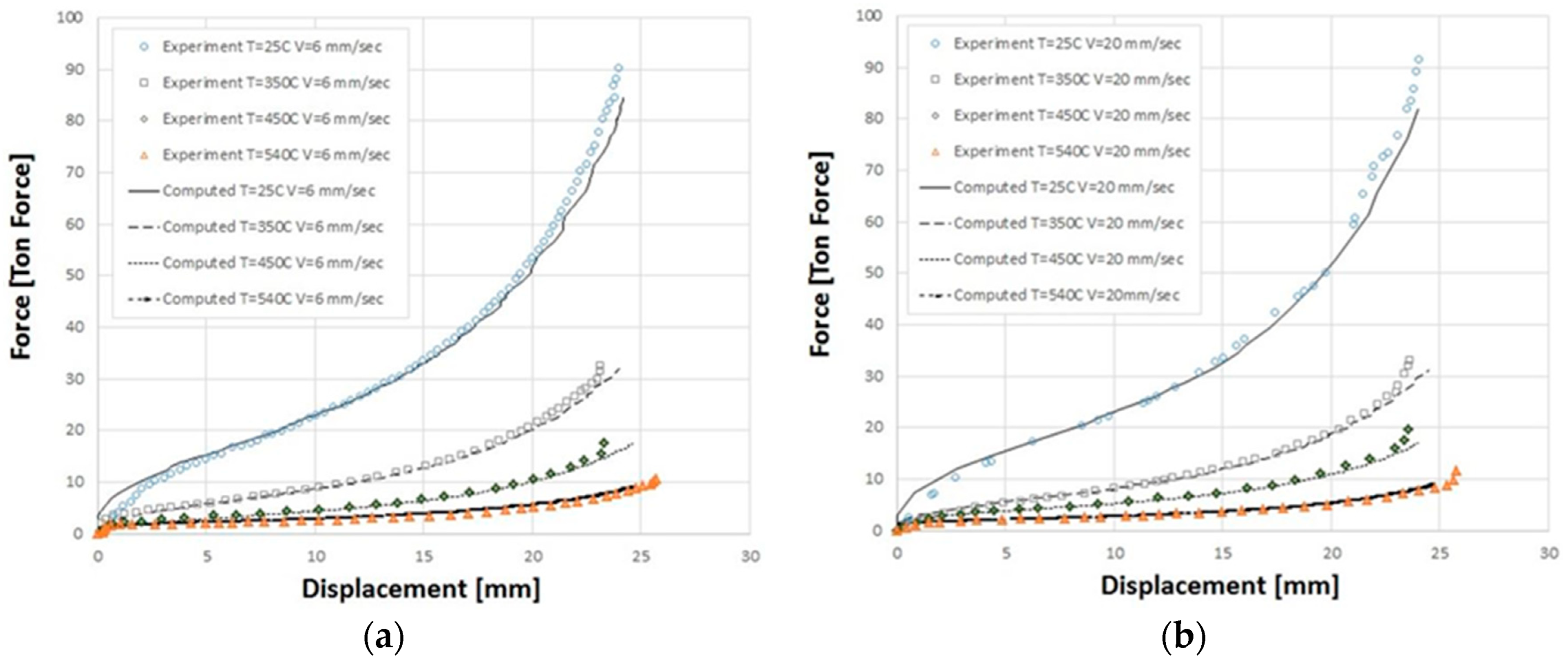

4. Determination of Flow-Stress Manifolds and Friction Conditions

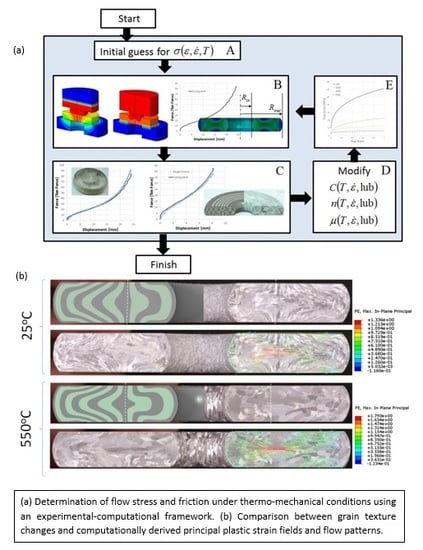

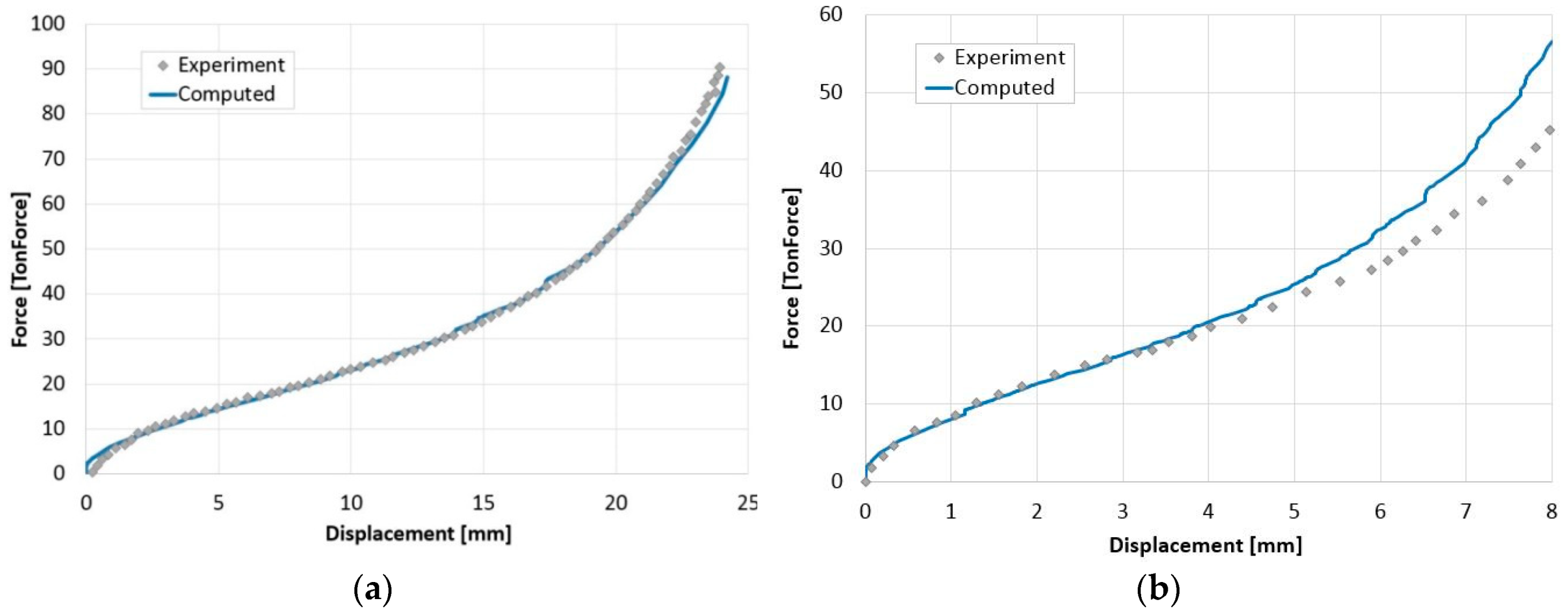

4.1. Iterative Process for Determining Flow Stress Manifolds

4.2. Flow Stress Manifolds for Al1050

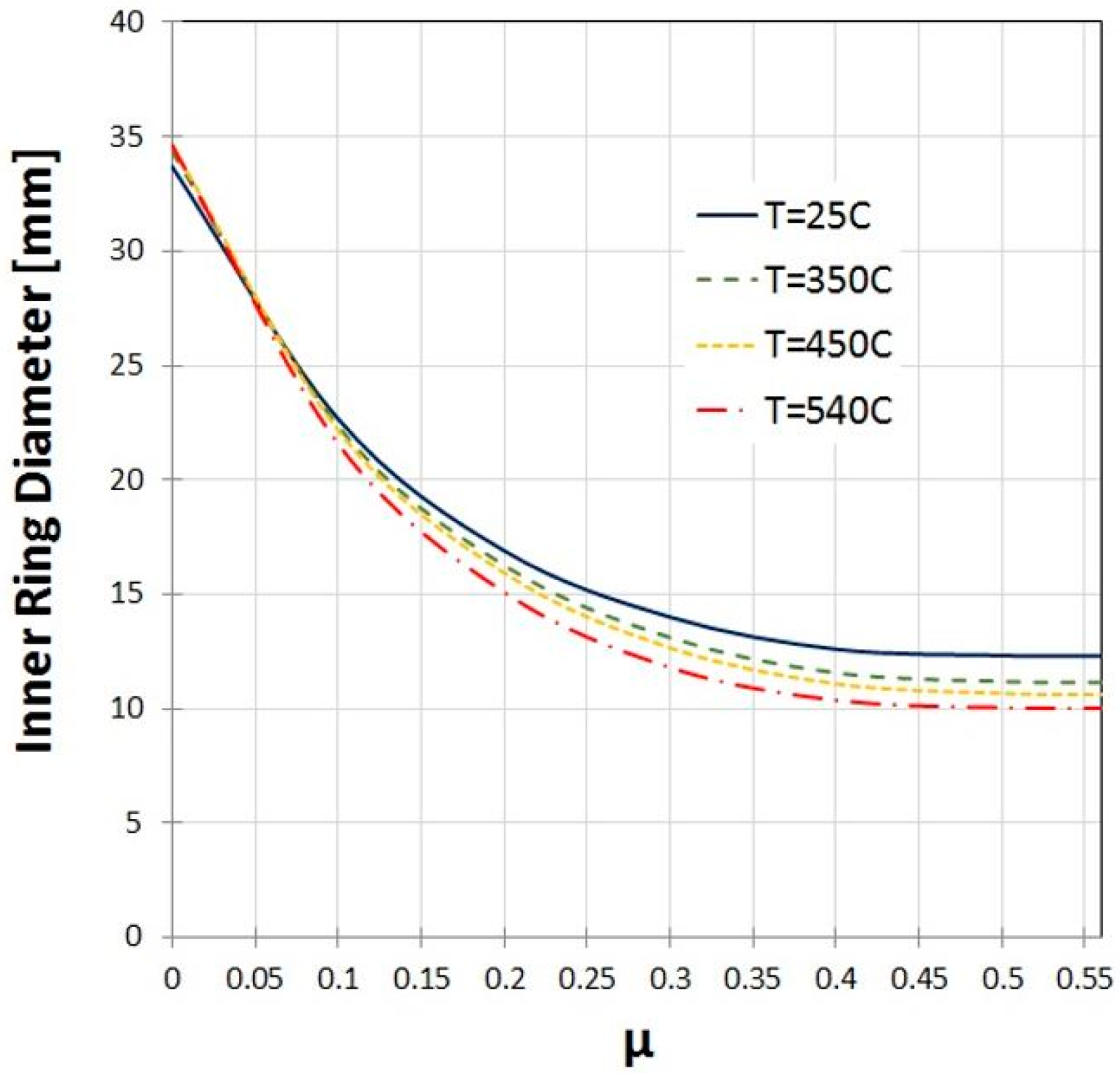

4.3. Determining the Friction Conditions

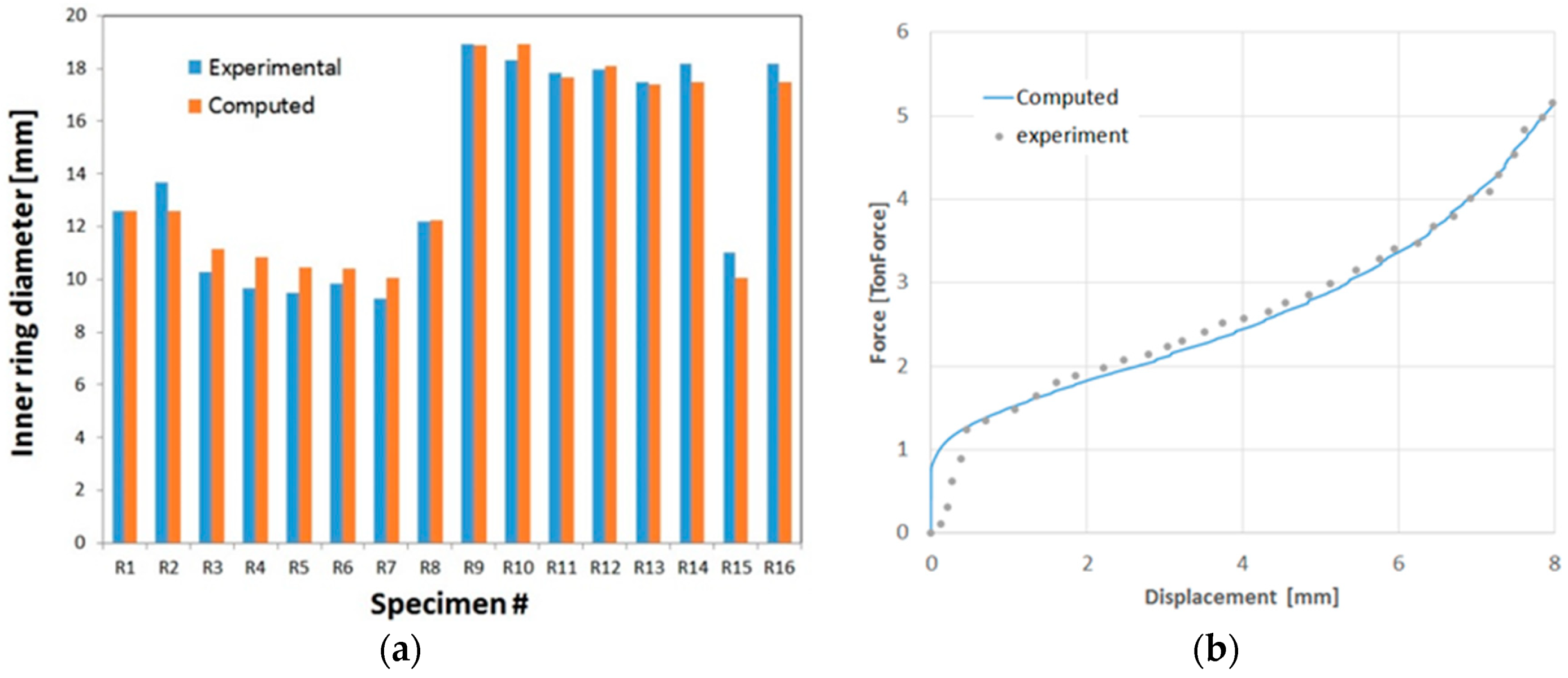

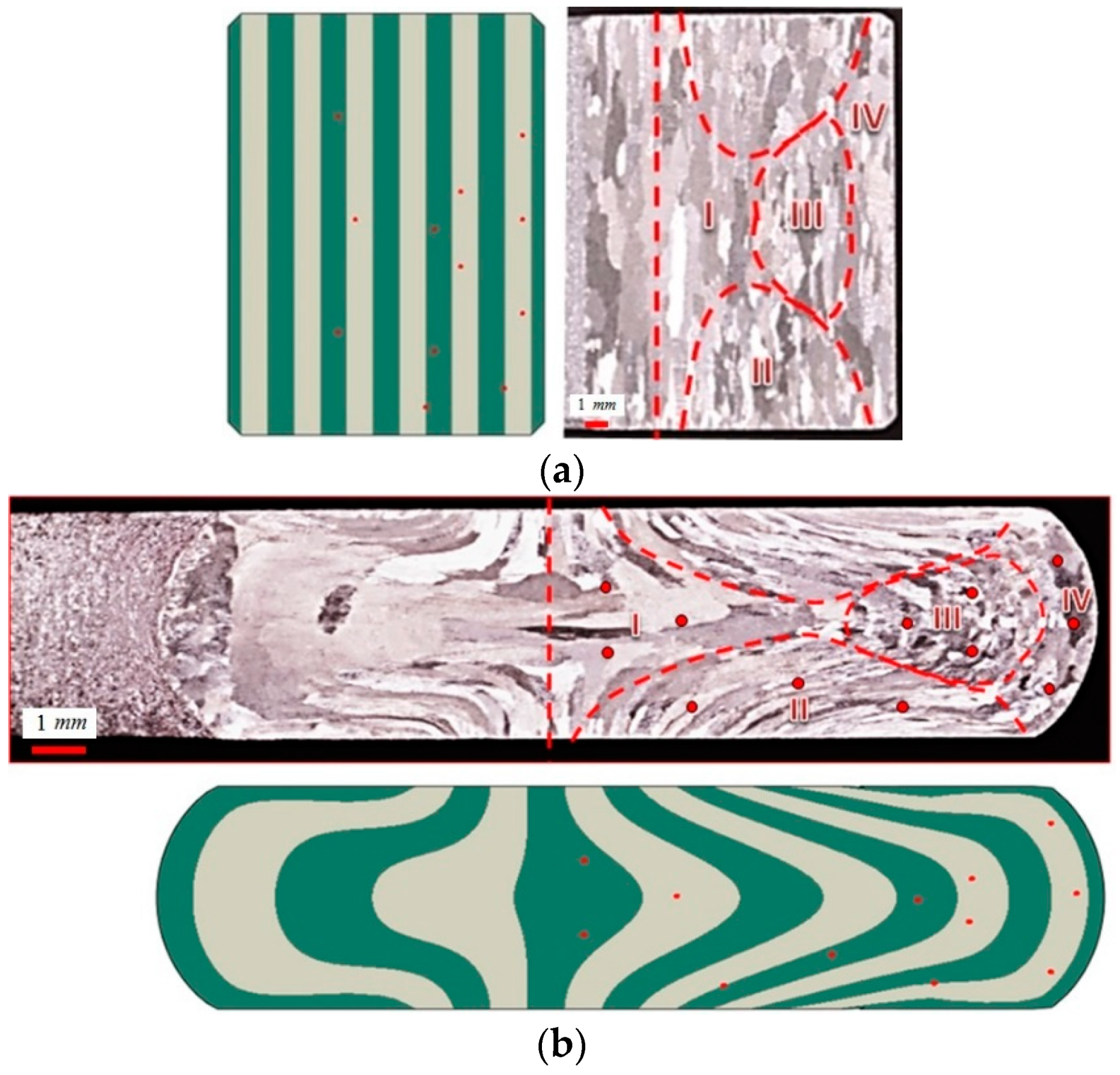

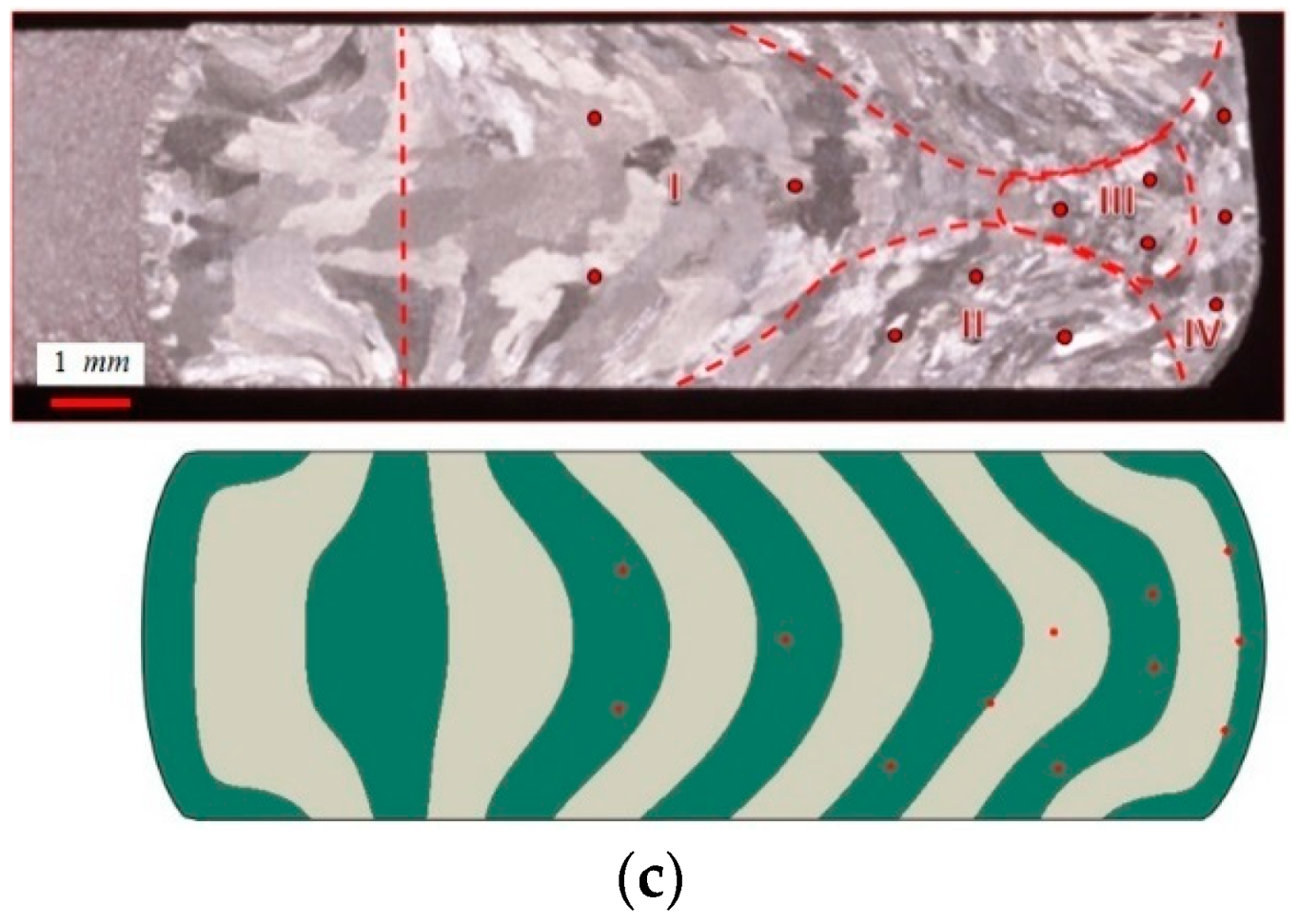

4.4. Validation

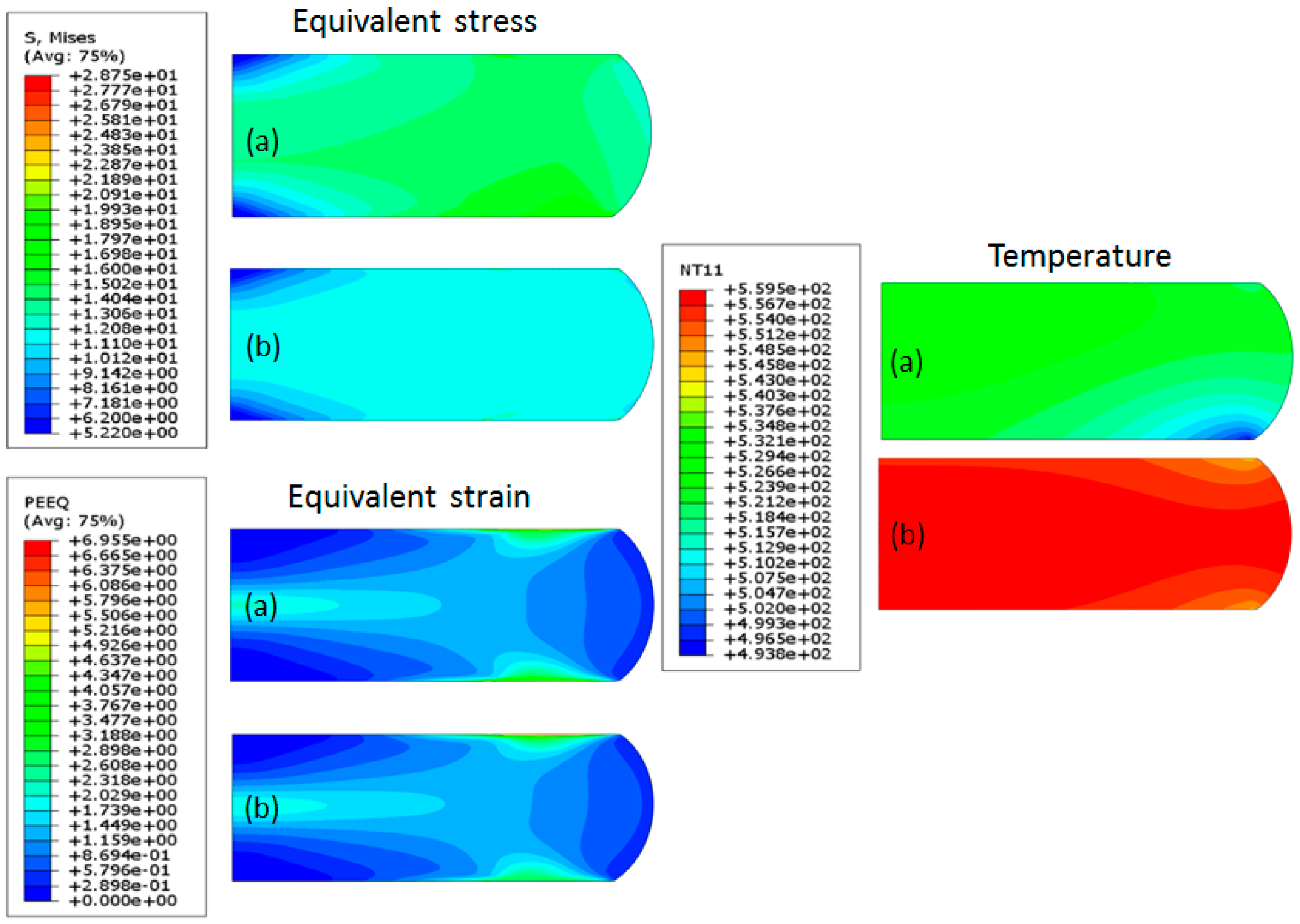

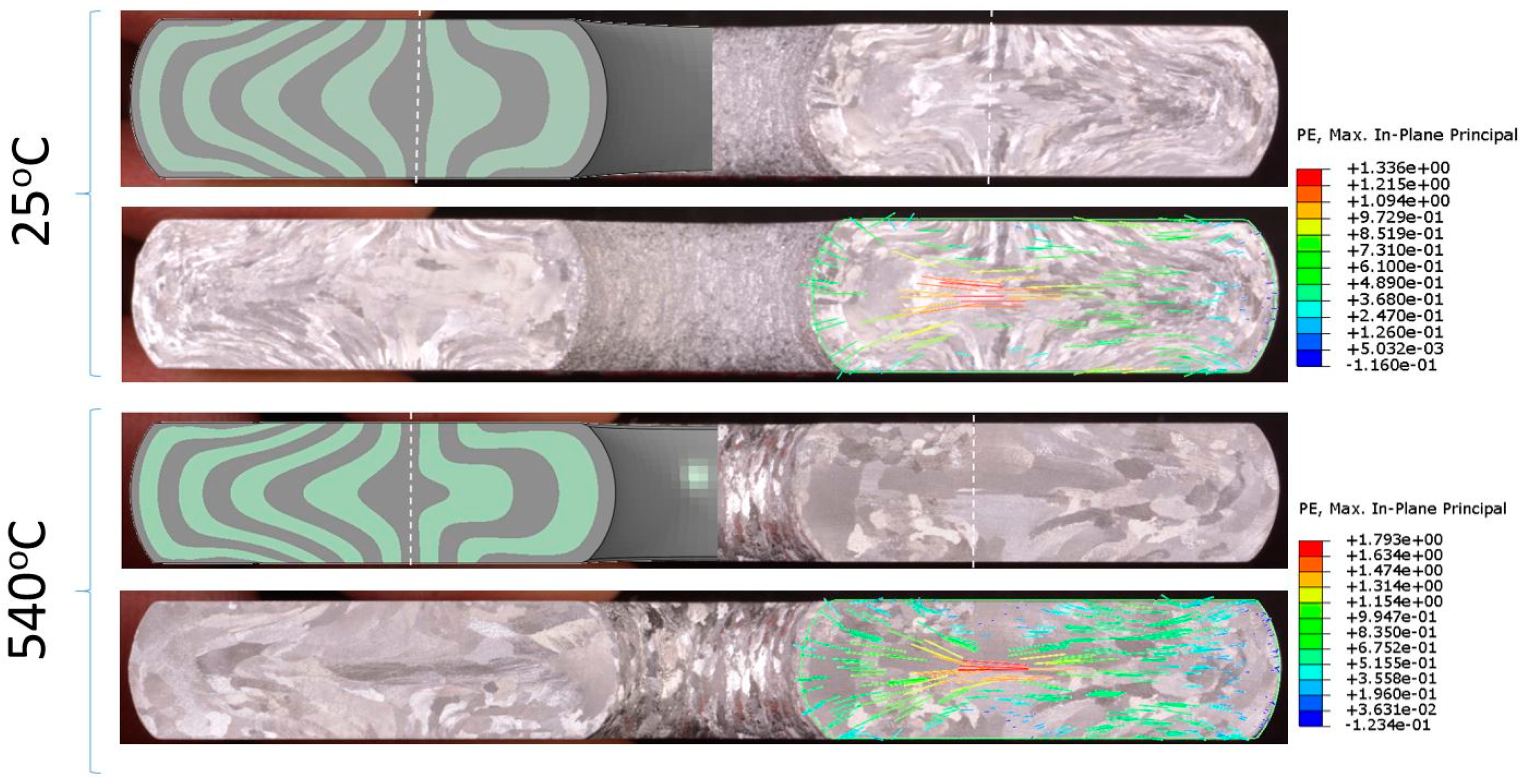

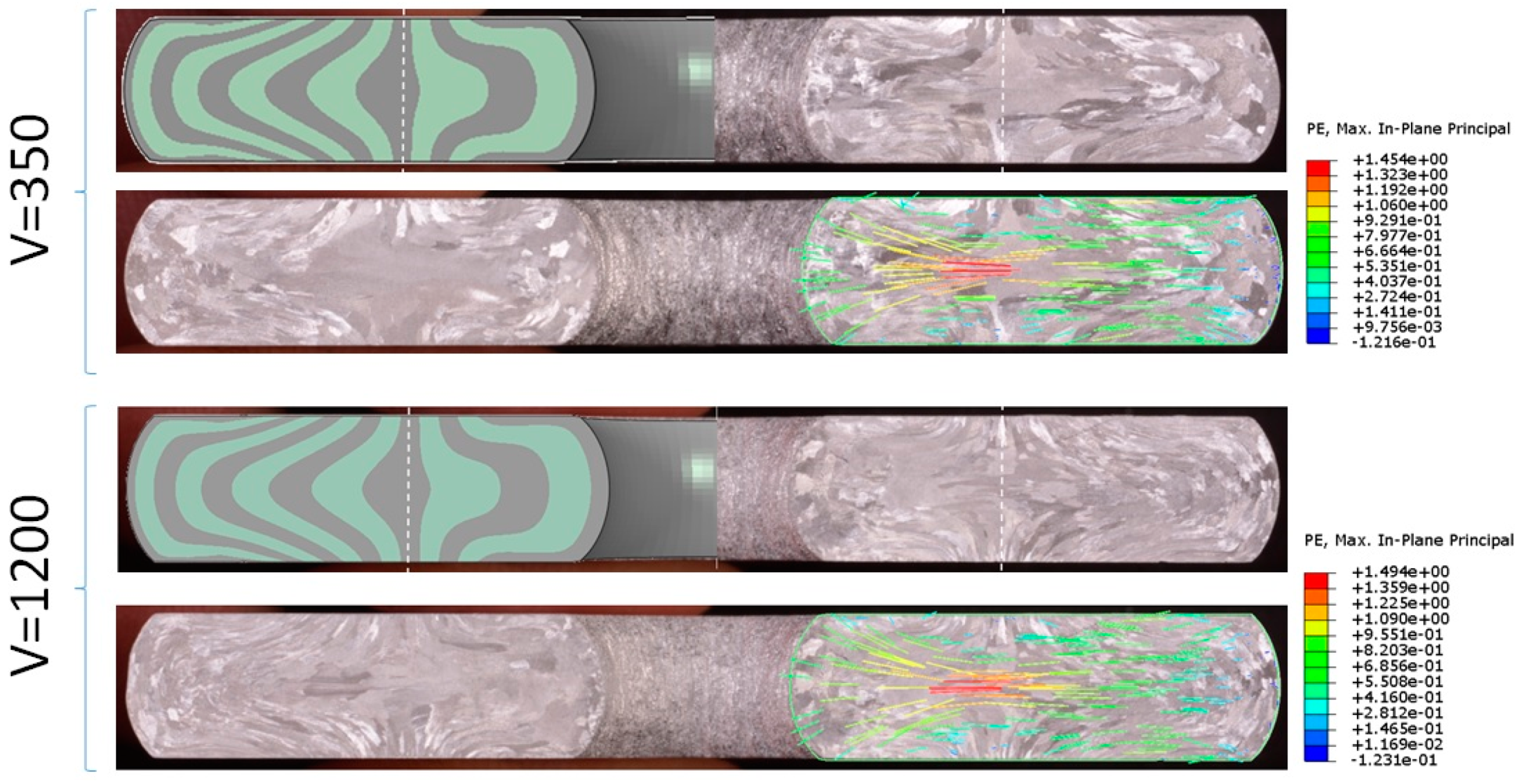

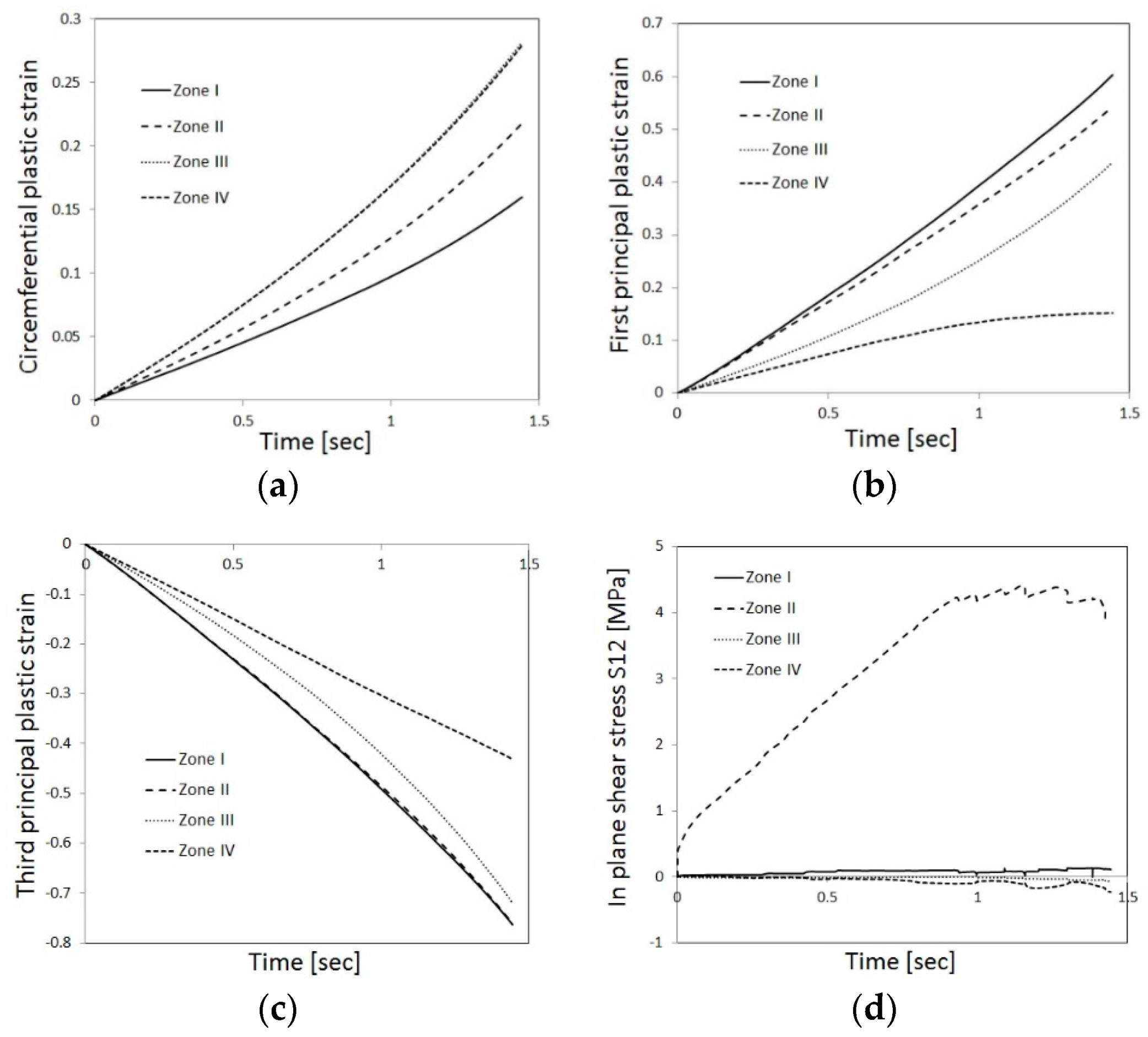

5. Relation Between Friction Induced Texture and Thermo-Mechanical Fields

6. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

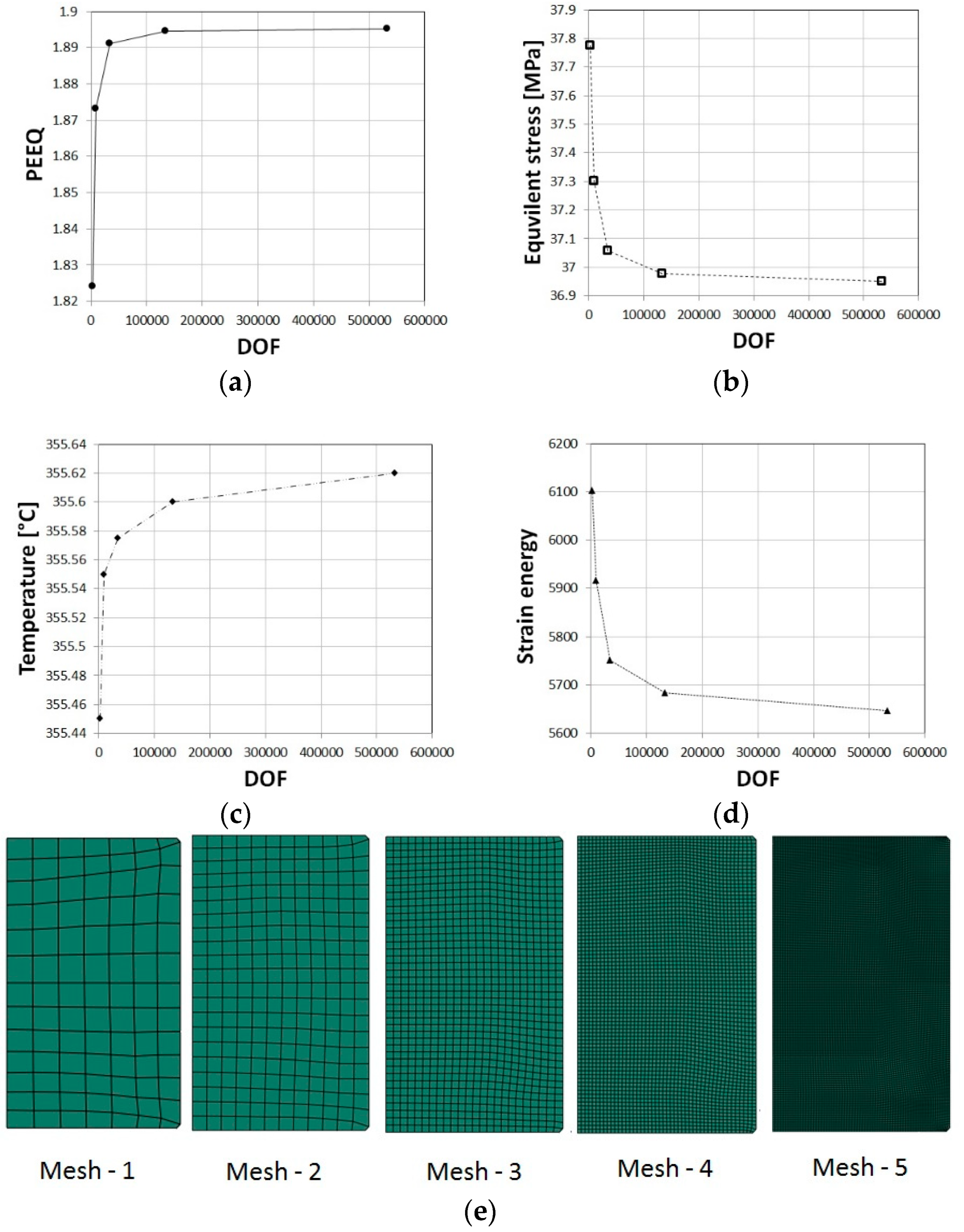

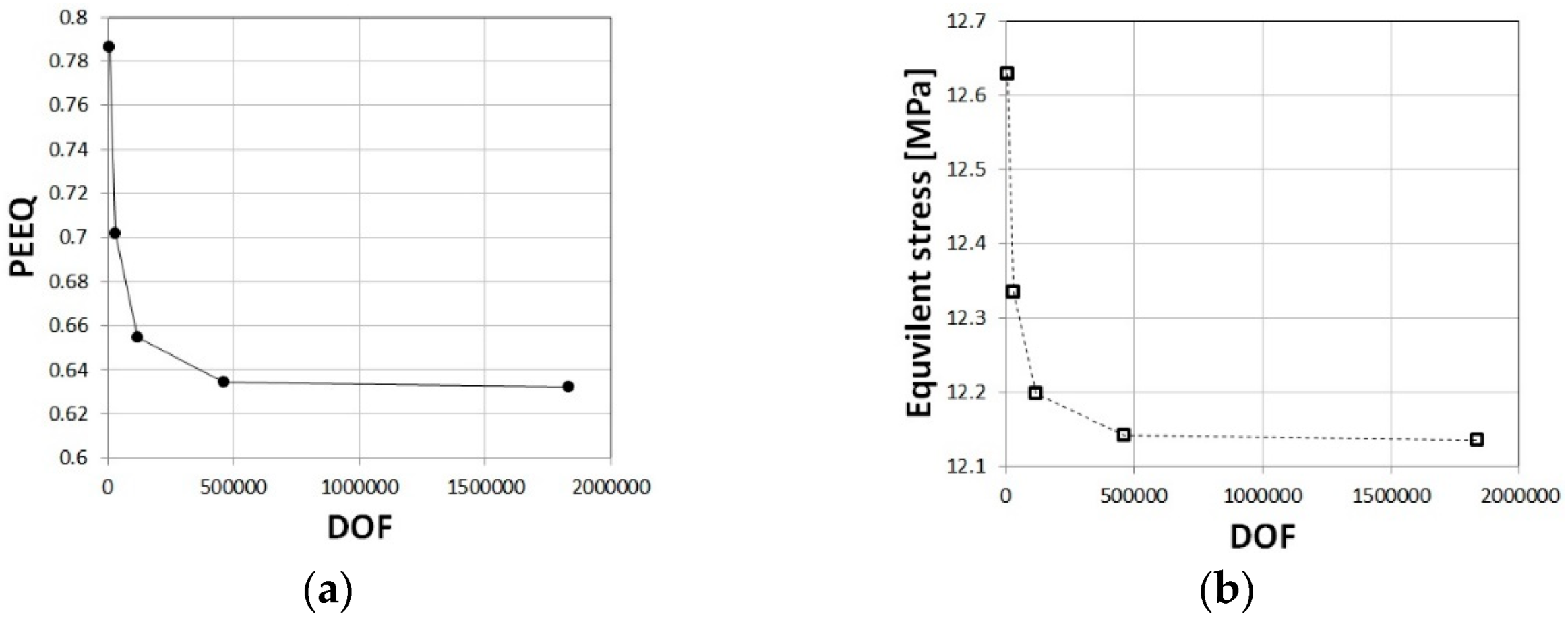

Appendix A. Verification of the Computational Models

References

- Kunogi, M. A new method of cold extrusion. J. Sci. Res. Inst. 1957, 50, 215–246. [Google Scholar] [CrossRef]

- Male, A.T.; Cockroft, M.G. A method of the determination of the coefficient of friction of metals under conditions of bulk plastic deformation. J. Inst. Metals 1964, 93, 38–46. [Google Scholar] [CrossRef]

- Avitzur, B. Metal Forming: Process and Analysis; Robert, E., Ed.; Krieger Publishing Company, Inc.: Huntington, NY, USA, 1968. [Google Scholar]

- Hu, C.; Ou, H.; Zhao, Z. An alternative evaluation method for friction condition in cold forging by ring with boss compression test. J. Mater. Process. Technol. 2015, 30, 18–25. [Google Scholar] [CrossRef]

- Zhu, Y.; Zeng, W.; Ma, X.; Tai, Q.; Li, Z.; Li, X. Determination of the friction factor of Ti-6Al-4V titanium alloy in hot forging by means of ring compression test using FEM. Tribol. Int. 2011, 44, 2074–2080. [Google Scholar] [CrossRef]

- Rajesh, E.; SivaPrakash, M. Analysis of friction factor by employing the ring compression test under different lubricants. IJSER 2013, 4, 1163–1171. [Google Scholar]

- Male, A.T.; DePierre, V. The validity of mathematical solutions for determining friction from the ring compression test. J. Lub. Technol. 1970, 92, 389–397. [Google Scholar] [CrossRef]

- Ramesh, B.; Senthilvelan, T. Studies on ring compression test using finite element analysis on sintered Aluminium alloys. Tech. Sci. Press 2012, 7, 167–185. [Google Scholar] [CrossRef]

- Fereshteh-Saniee, F.; Peaeshki, S.M. Simultaneous determination of interfacial friction and flow curves of temperature and rate dependent materials for bulk metal forming processes. Mat. Trans. 2012, 53, 201–208. [Google Scholar] [CrossRef]

- Petrov, P.; Petrov, M.; Vasileva, E.; Dubinchin, A. Research on friction during hot deformation of Al alloys at high strain rate. Int. J. Mater. Form. 2008, 1, 1255–1258. [Google Scholar] [CrossRef]

- Altan, T.; Ngaile, G.; Shen, G. Cold and Hot Forging: Fundamentals and Applications; ASM International: Materials Park, OH, USA, 2005. [Google Scholar]

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method Vol.2: Solid Mechanics; Butterworth Heinmann: Boston, MA, USA, 2000. [Google Scholar]

- Dieter, G.E.; Kuhn, H.A.; Semiatin, L.S. Workability and Process Design; ASM International: Materials Park, OH, USA, 2003. [Google Scholar]

- Dixit, U.S.; Narayanan, R.G. Metal Forming: Technology and Process Modelling; McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Sofuoglu, H. Physical Modelling in FEA of Friction Encountered in Large Deformation Processes. Ph.D. Thesis, Texas Tech University, Lubbock, TX, USA, 1993. [Google Scholar]

- Wu, Y. Study of Interface Friction Reduction Using Laser Microtexture Die Surface in Metal Forming. Ph.D. Thesis, Ohio State University, Columbus, OH, USA, 2008. [Google Scholar]

| Experiment Notation | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 |

|---|---|---|---|---|---|---|---|---|

| Specimen temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Pressing plates temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Ram and matrix temp [°C] | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Ram velocity [mm/min] | 350 | 1200 | 350 | 1200 | 350 | 1200 | 350 | 1200 |

| Experiment Notation | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 |

| Specimen temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Pressing plates temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Ram and matrix temp [°C] | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Ram velocity [mm/min] | 350 | 1200 | 350 | 1200 | 350 | 1200 | 350 | 1200 |

| Experiment Notation | R9 | R10 | R11 | R12 | R13 | R14 | R15 | R16 |

| Specimen temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Pressing plates temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Ram and matrix temp [°C] | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Ram velocity [mm/min] | 350 | 1200 | 350 | 1200 | 350 | 1200 | 350 | 1200 |

| Specimen Temp [°C] | 25 | 350 | 450 | 540 |

| Flow stress [MPa] |

| Experiment Notation | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 |

| Specimen temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Ram velocity [mm/min] | 350 | 1200 | 350 | 1200 | 350 | 1200 | 350 | 1200 |

| Lubriction | none | none | none | none | none | none | none | none |

| 0.4 | 0.4 | >0.45 | >0.45 | >0.45 | >0.45 | >0.45 | >0.45 | |

| Experiment Notation | R9 | R10 | R11 | R12 | R13 | R14 | R15 | R16 |

| Specimen temp [°C] | 25 | 25 | 350 | 350 | 450 | 450 | 540 | 540 |

| Ram velocity [mm/min] | 350 | 1200 | 350 | 1200 | 350 | 1200 | 350 | 1200 |

| Lubriction | T-50 | T-50 | T-50 | T-50 | T-50 | T-50 | T-50 | T-50 |

| 0.15 | 0.15 | 0.17 | 0.16 | 0.17 | 0.16 | 0.28 | >0.45 |

| Experiment | Computed [mm] | Measured [mm] | Relative Error [%] |

|---|---|---|---|

| R2 | 15.52 | 15.05 | 3.12 |

| R8 | 17.10 | 16.92 | 1.06 |

| R5 | 16.24 | 16.53 | 1.75 |

| R13 | 15.68 | 15.10 | 3.84 |

| R3 | 16.60 | 16.49 | 0.67 |

| R4 | 17.14 | 16.78 | 2.14 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mittelman, B.; Priel, E.; Navi, N.U. A Finite Element Study of Thermo-Mechanical Fields and Their Relation to Friction Conditions in Al1050 Ring Compression Tests. J. Manuf. Mater. Process. 2018, 2, 83. https://doi.org/10.3390/jmmp2040083

Mittelman B, Priel E, Navi NU. A Finite Element Study of Thermo-Mechanical Fields and Their Relation to Friction Conditions in Al1050 Ring Compression Tests. Journal of Manufacturing and Materials Processing. 2018; 2(4):83. https://doi.org/10.3390/jmmp2040083

Chicago/Turabian StyleMittelman, Brigit, Elad Priel, and Nissim U. Navi. 2018. "A Finite Element Study of Thermo-Mechanical Fields and Their Relation to Friction Conditions in Al1050 Ring Compression Tests" Journal of Manufacturing and Materials Processing 2, no. 4: 83. https://doi.org/10.3390/jmmp2040083

APA StyleMittelman, B., Priel, E., & Navi, N. U. (2018). A Finite Element Study of Thermo-Mechanical Fields and Their Relation to Friction Conditions in Al1050 Ring Compression Tests. Journal of Manufacturing and Materials Processing, 2(4), 83. https://doi.org/10.3390/jmmp2040083