Towards a Generic Framework for the Performance Evaluation of Manufacturing Strategy: An Innovative Approach

Abstract

:1. Introduction and Related Research

2. System Dynamics and Its Application for Modelling and Analysis of Manufacturing Systems

Objectives and Outline of the Paper

3. Definition of Terms Used in This Paper

3.1. Machining System

3.2. Machining Strategy

4. Manufacturing System Process Modelling

4.1. Engine Block Machining Process Overview

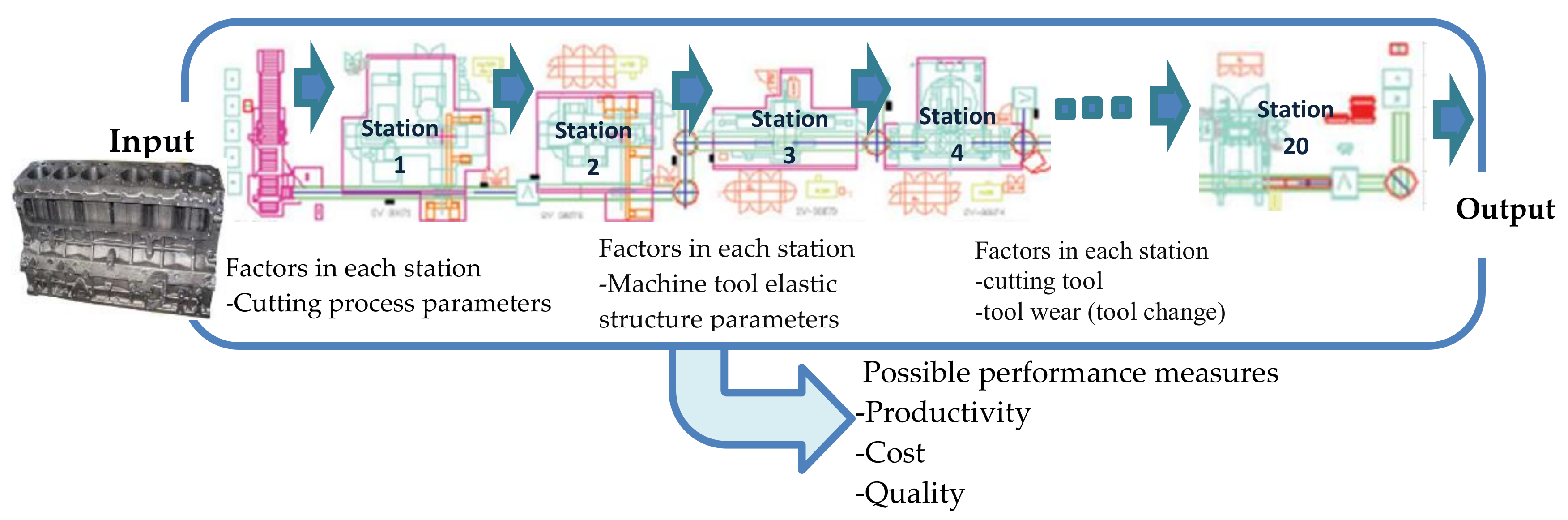

4.1.1. System Level Analysis

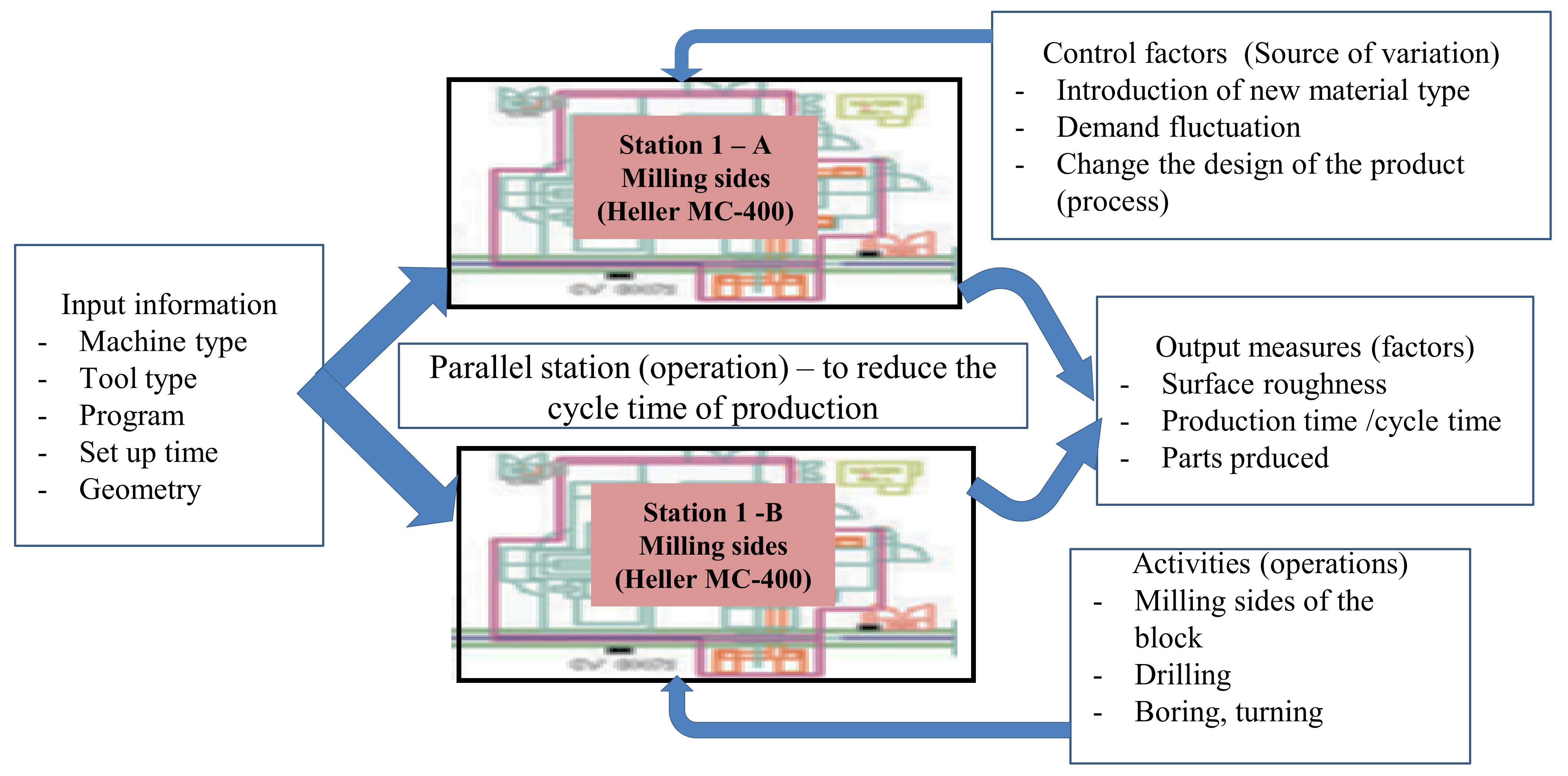

4.1.2. Process Level Analysis

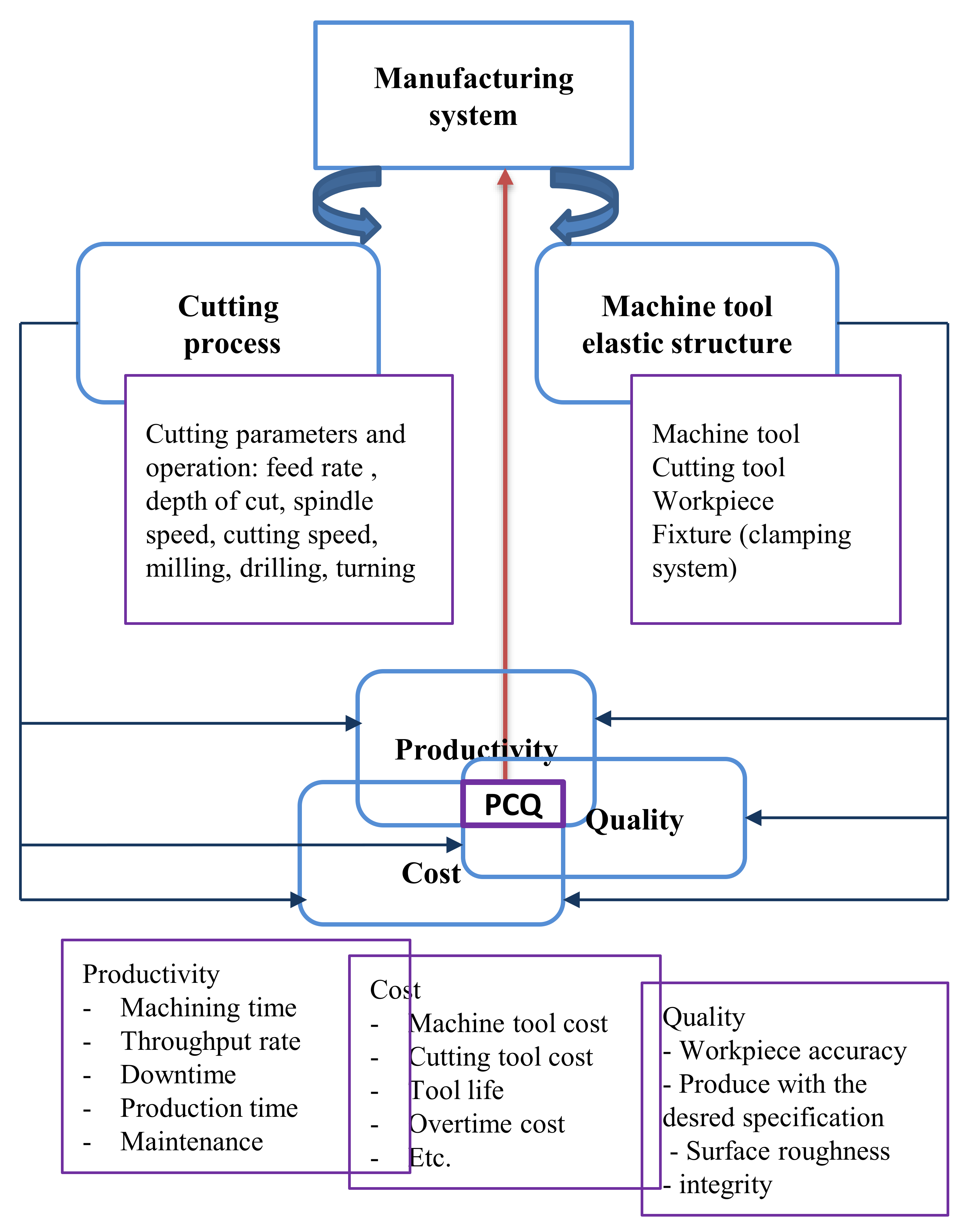

4.2. Machining Process Parameters

4.3. Manufacturing System Parameters and Performance Indicators

4.4. Scope for Modelling

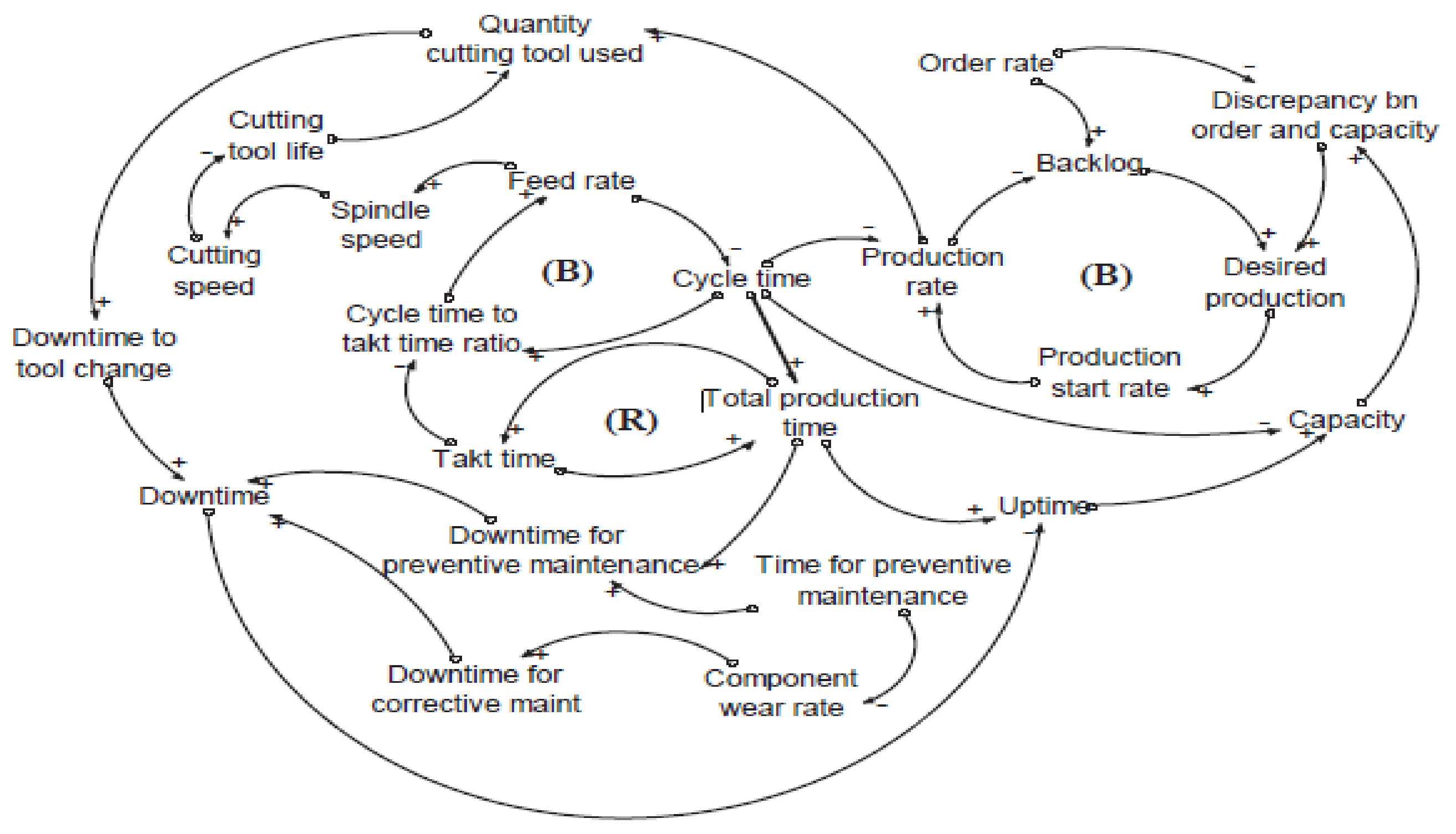

4.5. Causal Loop Diagram

5. Analysis and Discussions

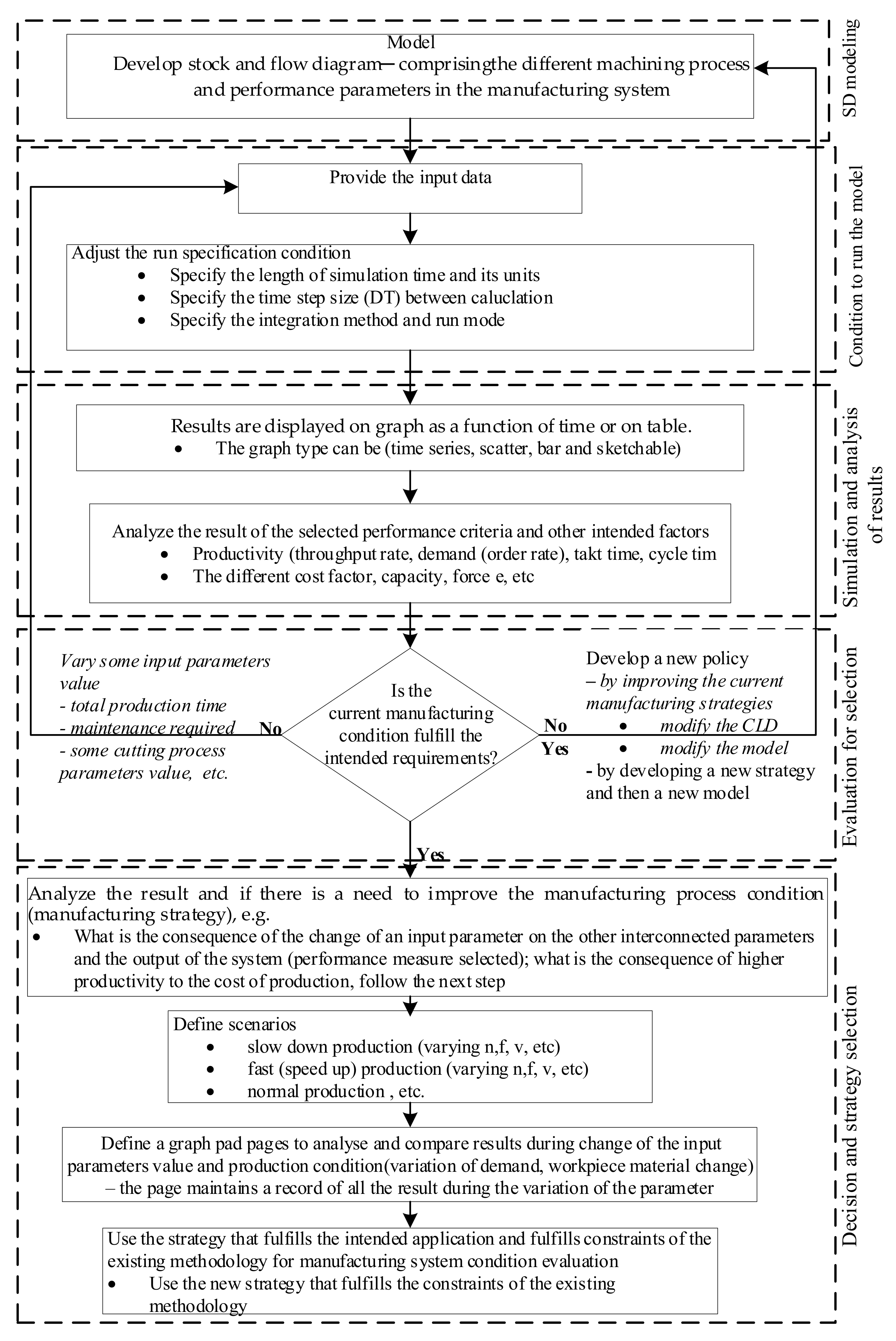

5.1. SD Modelling for Manufacturing System

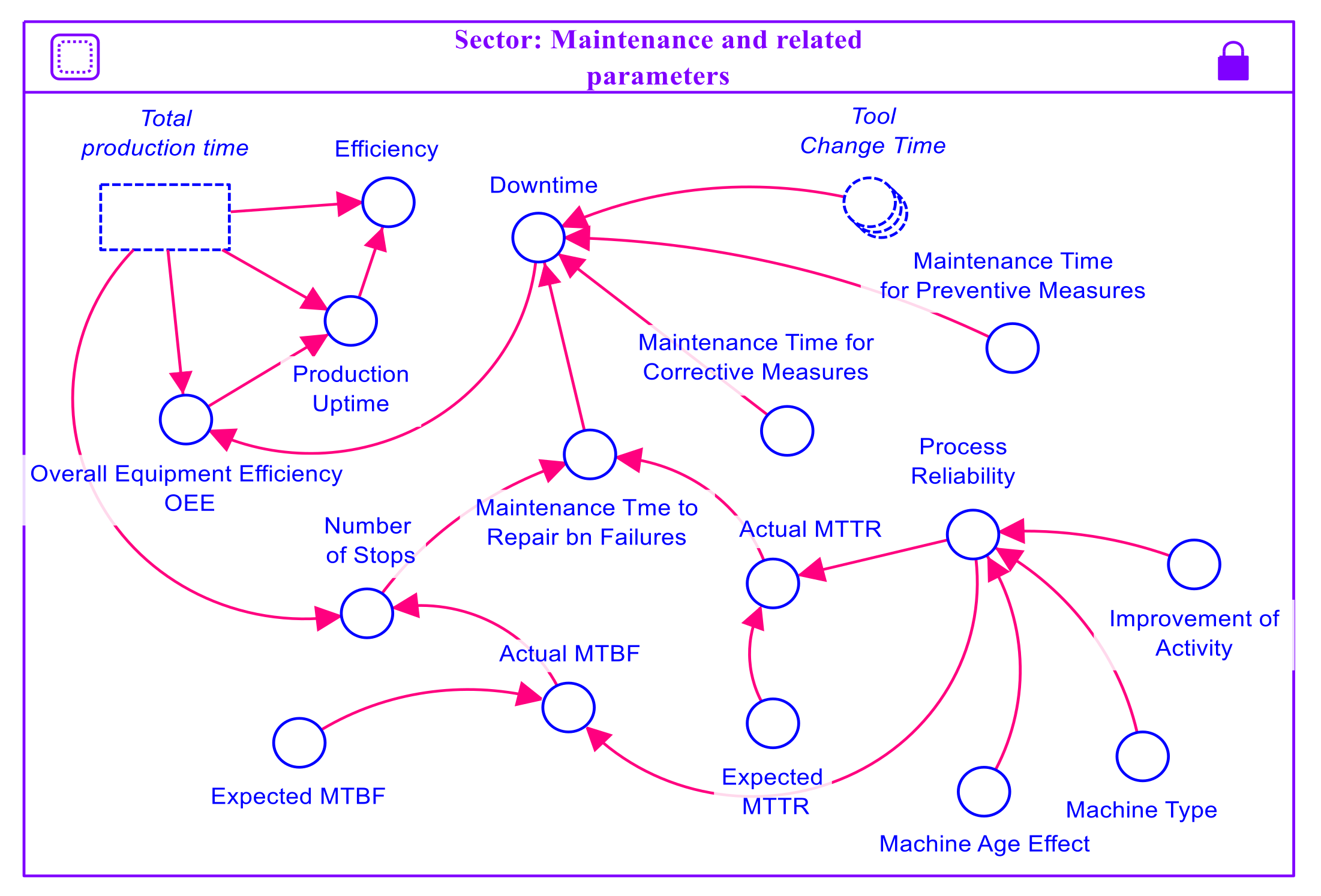

5.2. Representation of Sub-Models/Modules

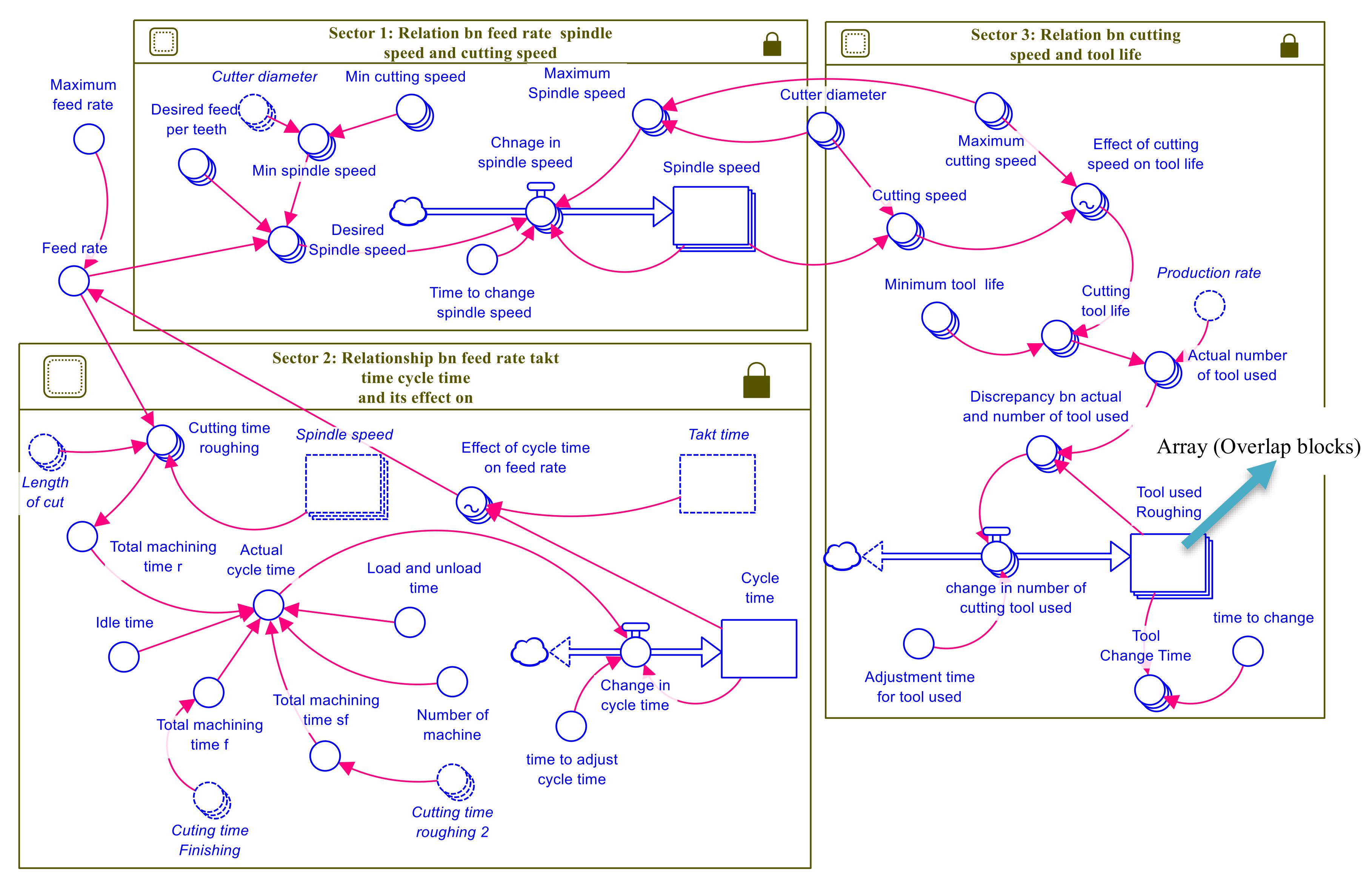

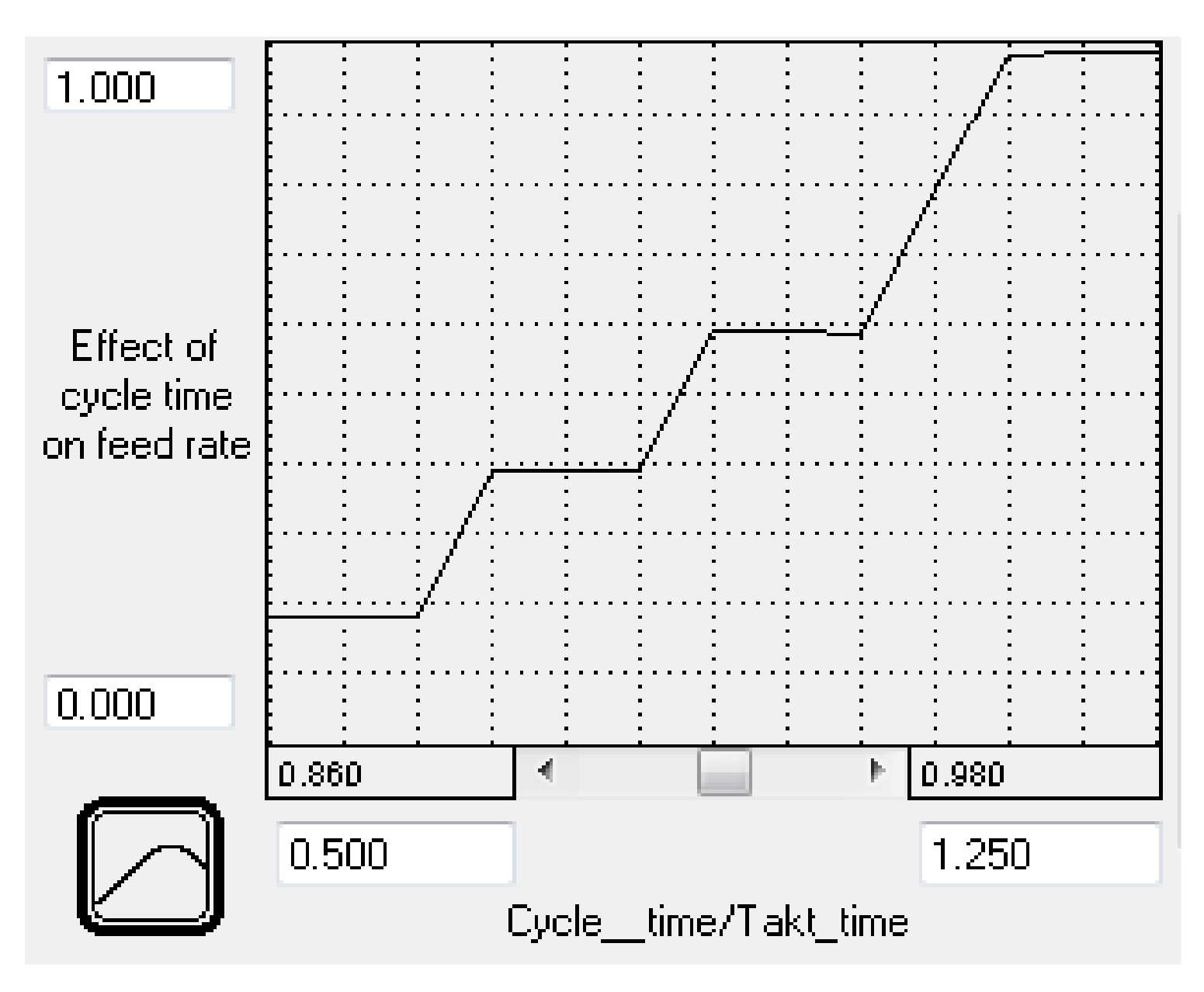

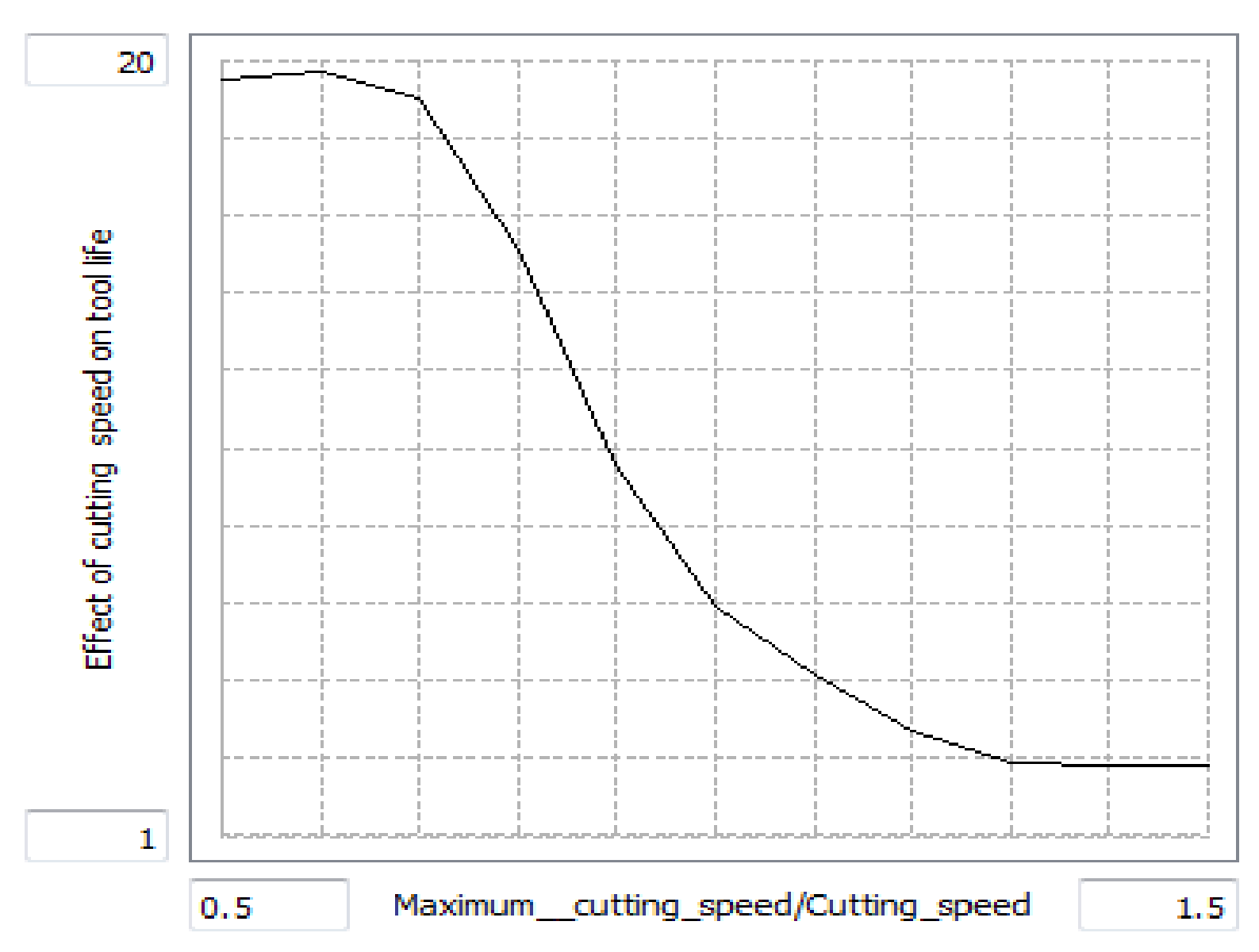

5.2.1. Modelling Machining Process

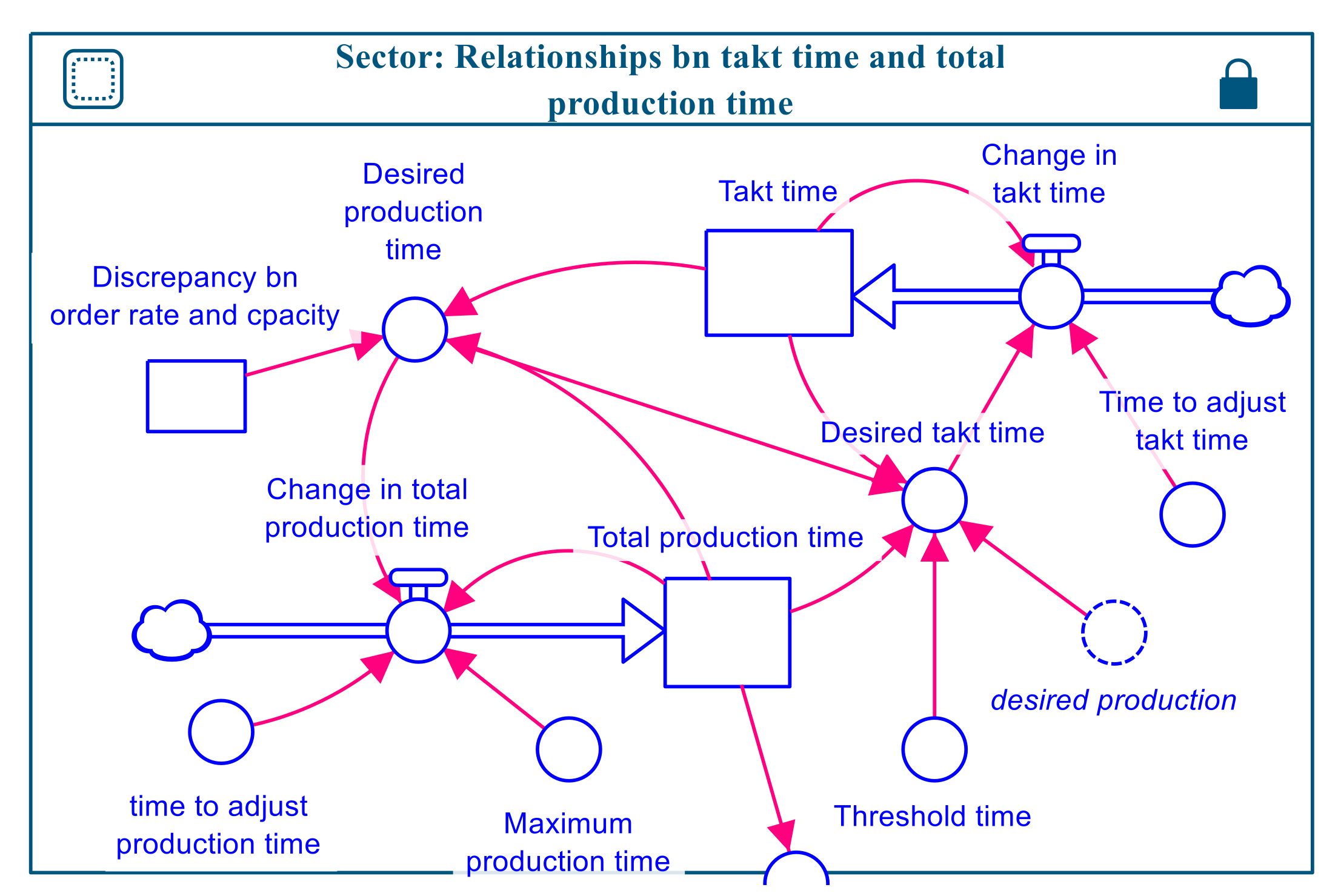

Constant Takt Time

Flexible Takt Time

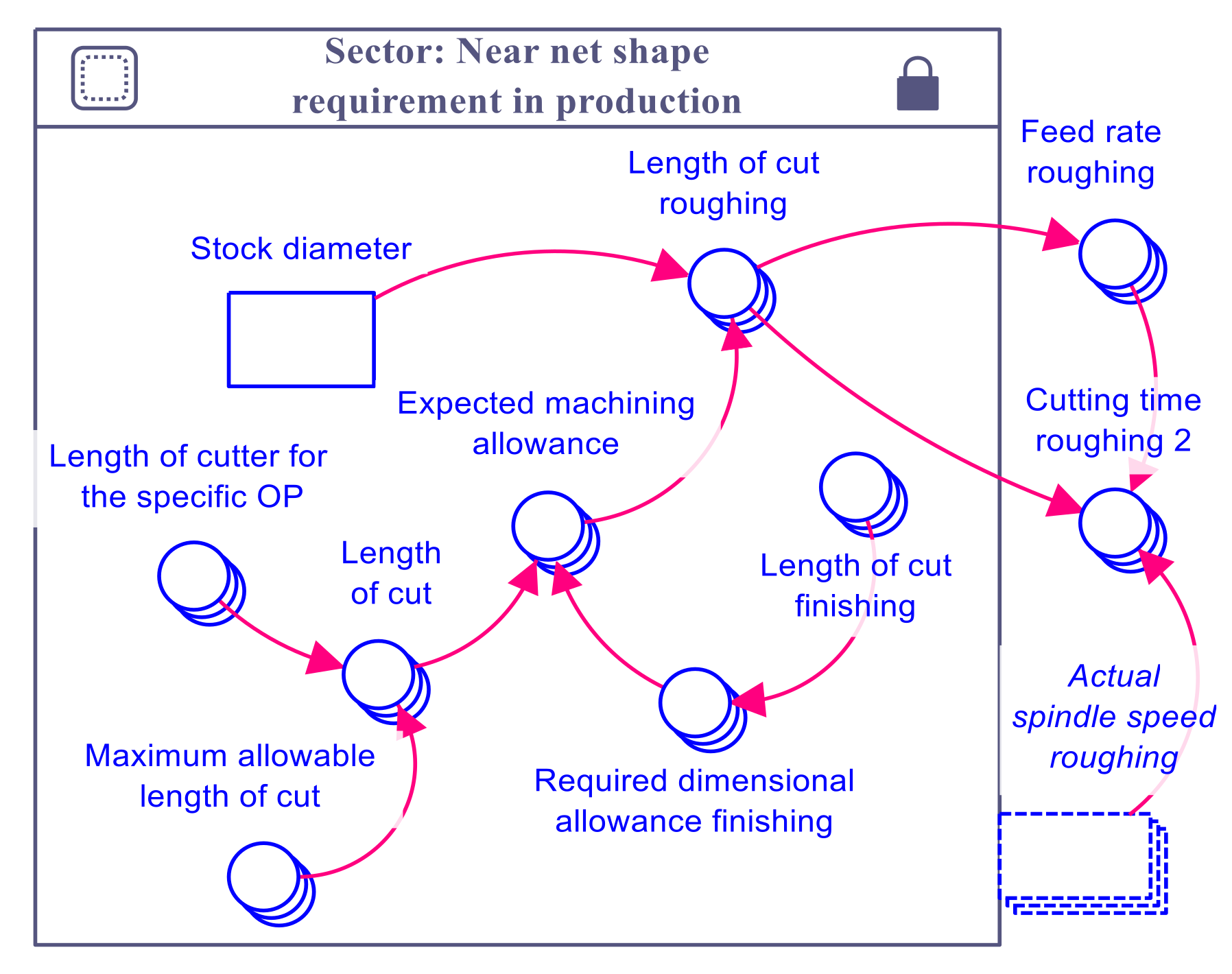

5.2.2. Near-Net Shape Production Modelling

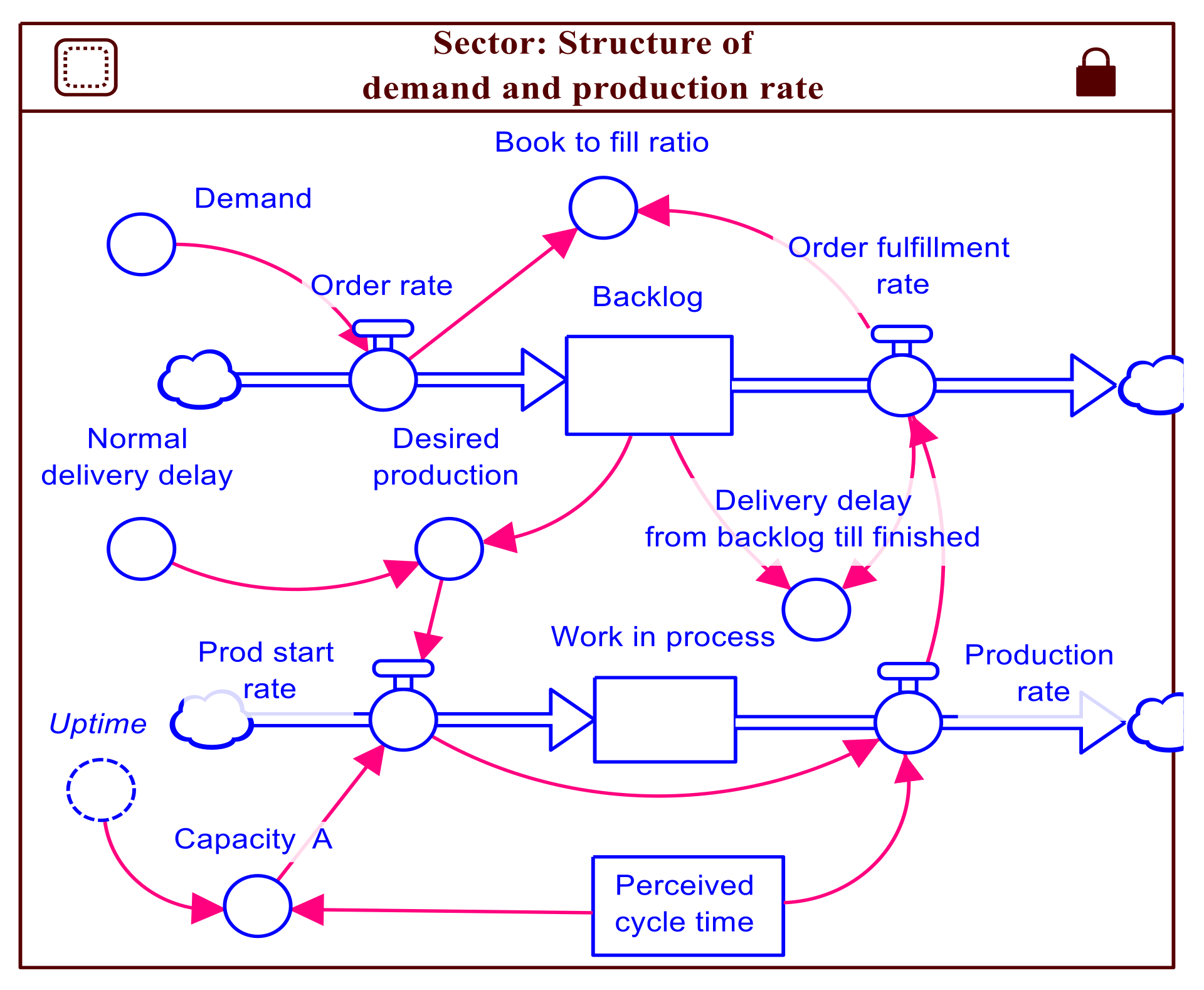

5.2.3. Modelling Production System

- It depends directly on the downtime and total production time available, Equation (25)

- It is related to the overall equipment efficiency and total production time, Equation (26)

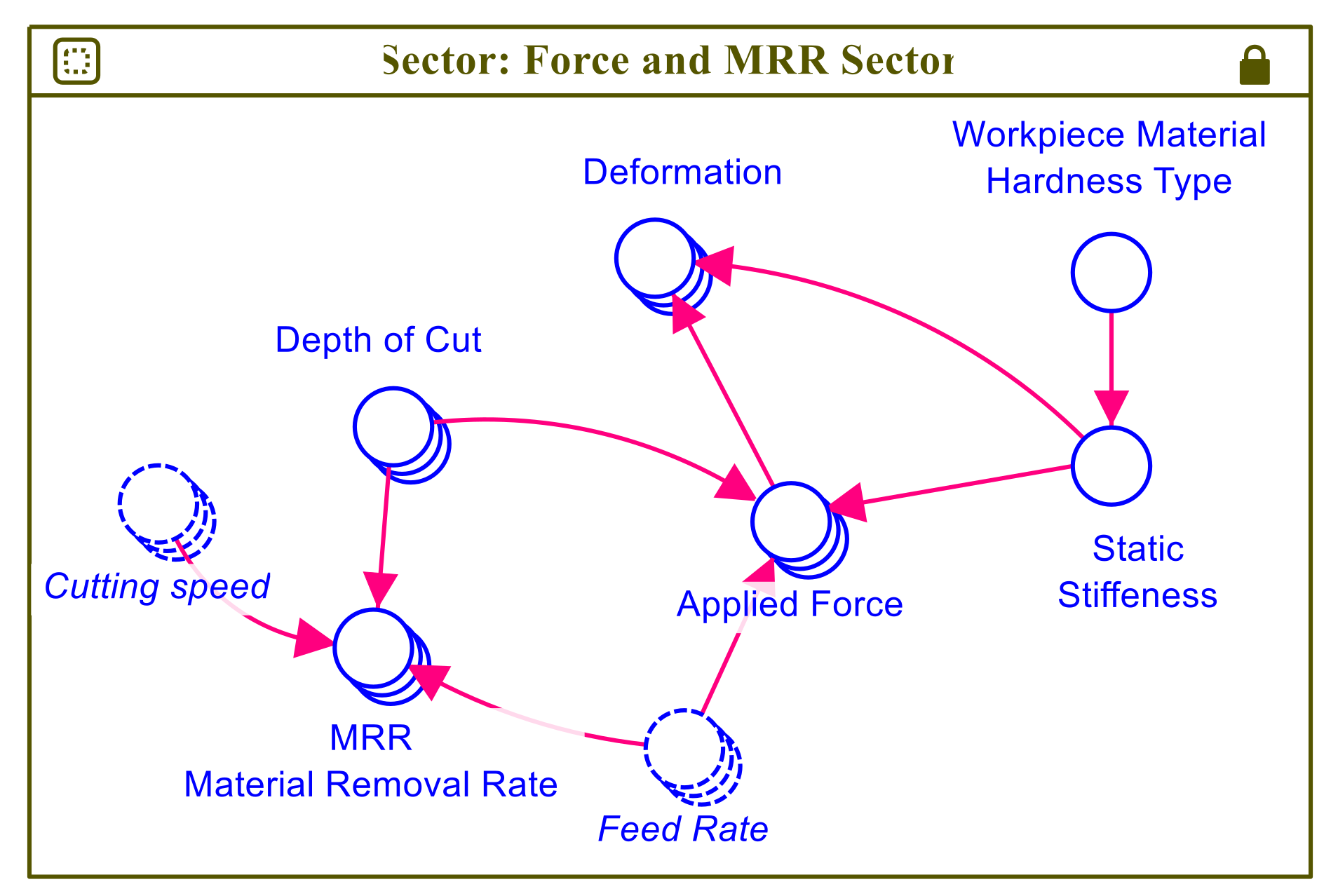

5.2.4. Modelling Cutting Force (MRR)

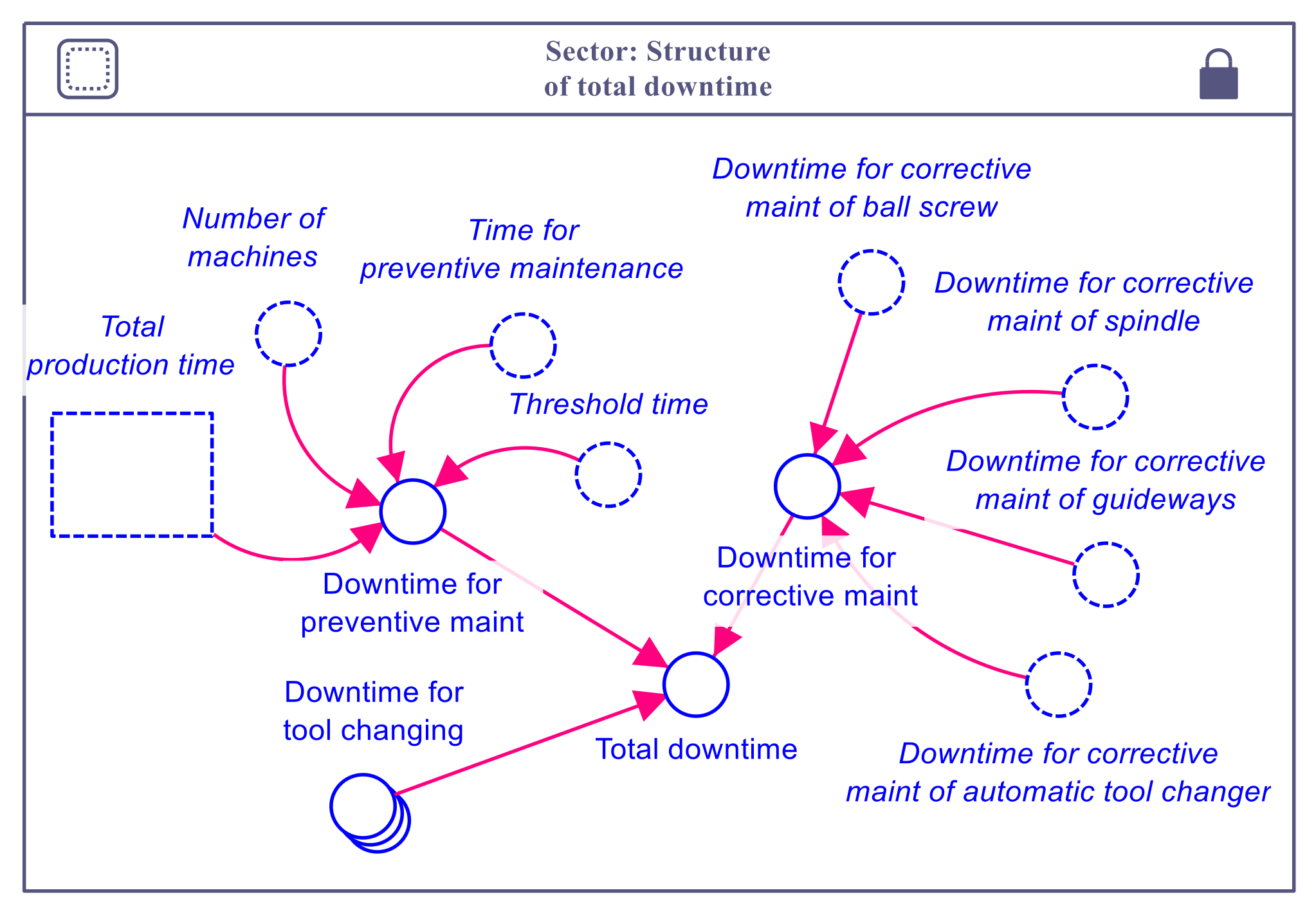

5.2.5. Maintenance

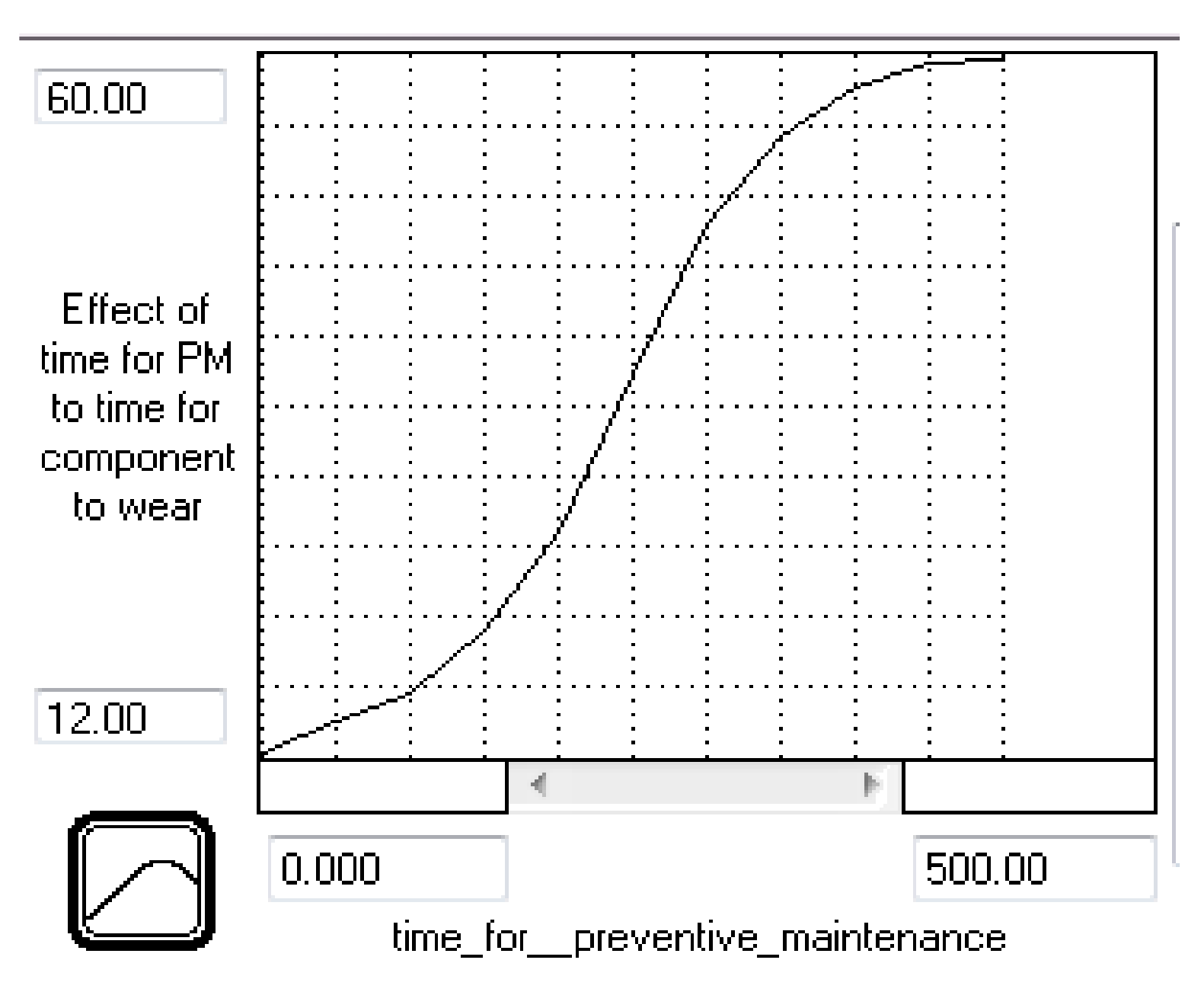

Maintenance Model of the Machine Tool Component

Modelling Maintenance Related to Factors, MTTR and MTBF

- Preventive maintenance requirements must be described. Time needed for inspection and change of wear parts shall be specified.

- Time for tool change must be calculated and include quality check of the first piece after tool change.

- Repairs of major parts/components in the machine and equipment must be described with the calculated time needed.

5.2.6. Cost Model

6. Results

6.1. Analyzed Model’s Results

6.2. General Procedure to Run the Model

6.3. The Behaviour of the System

6.4. Fast and Slow Production/Performance Policy Analysis

7. Conclusions and Recommendation

- A generic model, developed for the performance evaluation of manufacturing systems for specific machining operations which can be used for adapting the production to various market situations. However, modification according to system specifications is required.

- The model could evaluate the relationships between critical parameters in relation to the selected key performance criteria.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| backlog | |

| cycle time | |

| actual cycle time | |

| discrepancy between order rate and capacity | |

| initial cycle time | |

| capacity of machine | |

| demand | |

| stock allowance | |

| depth of cutting /length/diameter for finishing operation | |

| delivery delay | |

| delay | |

| minimum cutting size | |

| actual length/depth of the part to be cut for roughing | |

| maximum capacity cutting tool can cut | |

| maximum allowable depth of material to be removed | |

| depth of cut for semi-finishing operation | |

| expected total depth of the part to be removed | |

| workpiece diameter or length to be cut | |

| delta time | |

| efficiency | |

| effect of cycle time on feed rate | |

| effect of cutting speed on tool life | |

| feed rate | |

| maximum feed rate | |

| desired feed per teeth | |

| finite element method | |

| improvement activity | |

| minimum length of part that can be cut | |

| length of the part to be cut | |

| machining time for roughing operation | |

| machining time for semi-finishing operation | |

| machining time for finishing operation | |

| machine type | |

| machine age effect | |

| actual mean time to repair | |

| actual mean time between failures | |

| expected mean time to repair | |

| expected mean time between failures | |

| total time to repair between failures | |

| material removal rate | |

| meantime to repair | |

| meantime between failures | |

| spindle speed | |

| desired spindle speed | |

| minimum spindle speed | |

| change in spindle speed | |

| maximum spindle speed | |

| initial value of spindle speed | |

| number of machine tools | |

| number of rough passes | |

| number of spindle replaced/maintained | |

| number of stops due to failure | |

| overall equipment efficiency | |

| desired production | |

| desired production demand | |

| production rate | |

| production start rate | |

| spindle replacement rate | |

| R | process reliability |

| system dynamics | |

| machining time | |

| tool life of cutting tool | |

| idle time | |

| time for loading and unloading | |

| time for other activities | |

| tool life | |

| takt time | |

| net available time | |

| change in takt time | |

| takt adjustment time | |

| desired takt time | |

| initial takt time | |

| total production time | |

| threshold time | |

| desired production time | |

| uptime | |

| time to change spindle speed | |

| change in total production time | |

| initial total production time | |

| time to change total production time | |

| downtime | |

| time for spindle to wear | |

| time to replace spindle | |

| time to change spindle | |

| time to change tool | |

| time for corrective maintenance | |

| time for preventive maintenance | |

| time to repair between failures | |

| maximum cutting speed | |

| cutting speed | |

| spindle wear | |

| spindle wear rate | |

| initial spindle wear | |

| spindle wear threshold | |

| work in process | |

| initial work in process | |

| α | exponent in Taylor’s tool life equation |

| & | constant parameters depend on work material, tool material, feed and depth of cut rate, can be obtained either experimentally, statistically or from published data |

| change in cycle time |

References

- Loire, P.; Paris, J.J.; Ward, T.; Weis, C. Comprehensive Analysis of the Evolution of the Automotive Sector in Europe; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- ACEA Pocket Guide 2017–2018. Available online: http://www.acea.be/publications/article/acea-pocket-guide (accessed on 25 February 2018).

- Merchant, M.E. An Interpretive Look at 20th Century Research on Modelling of Machining. In Proceedings of the 1st CIRP International Workshop on Modelling of Machining Operation, Atlanta, GA, USA, 19 May 1998; Volume 2, pp. 157–163. [Google Scholar] [CrossRef]

- Ivester, R.W.; Kennedy, M.; Davies, M.; Stevenson, R.; Thiele, J.; Furness, R.; Athavale, S. Assessment of machining models: Progress report. Mach. Sci. Technol. 2000, 4, 511–538. [Google Scholar] [CrossRef]

- Rao, R.V. Modeling and Optimization of Machining Processes. In Advanced Modeling and Optimization of Manufacturing Processes; Springer Series in Advanced Manufacturing; Springer: London, UK, 2011; Chapter 2. [Google Scholar] [CrossRef]

- Mukherjee, I.; Ray, P.K. A review of optimization techniques in metal cutting processes. Comput. Ind. Eng. 2006, 50, 15–34. [Google Scholar] [CrossRef]

- Tan, F.P.; Creese, R.C. A generalized multi-pass machining model for machining parameter selection in turning. Int. J. Prod. Res. 1995, 33, 1467–1487. [Google Scholar] [CrossRef]

- Röck, S. Hardware in the loop simulation of production systems dynamics. Prod. Eng. Res. Dev. 2011, 5, 329–337. [Google Scholar] [CrossRef]

- Brecher, C.; Esser, M.; Witt, S. Interaction of manufacturing process and machine tool. CIRP Ann. Manuf. Technol. 2009, 58, 588–607. [Google Scholar] [CrossRef]

- Fang, N.; Jawahir, I.S. Analytical prediction of the chip back-flow angle in machining with restricted contact grooved tools. J. Manuf. Sci. Eng. 2003, 125, 210–219. [Google Scholar] [CrossRef]

- Soo, S.L.; Aspinwall, D.K. Developments in modelling of metal cutting processes. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2007, 221, 197–211. [Google Scholar] [CrossRef]

- Mackerle, J. Finite element analysis and simulation of machining: an addendum: A bibliography (1996–2002). Int. J. Mach. Tools Manuf. 2003, 43, 103–114. [Google Scholar] [CrossRef]

- Vaz, M., Jr.; Owen, D.R.J.; Kalhori, V.; Lundblad, M.; Lindgren, L.E. Modelling and simulation of machining processes. Arch. Comput. Methods Eng. 2007, 14, 173–204. [Google Scholar] [CrossRef]

- Teitenberg, T.M.; Bayoumi, A.E.; Yucesan, G. Tool wear modeling through an analytic mechanistic model of milling processes. Wear 1992, 154, 287–304. [Google Scholar] [CrossRef]

- Kannan, S.; Kishawy, H.A.; Deiab, I.M.; Surappa, M.K. Modeling of tool flank wear progression during orthogonal machining of metal matrix composites. Trans. N. Am. Manuf. Res. Inst. SME NAMRC 2005, 33, 605–612. [Google Scholar]

- Yen, Y.C.; Söhner, J.; Weule, H.; Schmidt, J.; Altan, T. Estimation of tool wear of carbide tool in orthogonal cutting using FEM simulation. Mach. Sci. Technol. 2002, 6, 467–486. [Google Scholar] [CrossRef]

- Attanasio, A.; Ceretti, E.; Fiorentino, A.; Cappellini, C.; Giardini, C. Investigation and FEM-based simulation of tool wear in turning operations with uncoated carbide tools. Wear 2010, 269, 344–350. [Google Scholar] [CrossRef]

- Özel, T.; Sima, M.; Srivastava, A.K.; Kaftanoglu, B. Investigations on the effects of multi-layered coated inserts in machining Ti–6Al–4V alloy with experiments and finite element simulations. CIRP Ann. Manuf. Technol. 2010, 59, 77–82. [Google Scholar] [CrossRef]

- Ribeiro, J.E.; César, M.B.; Lopes, H. Optimization of machining parameters to improve the surface quality. Procedia Struct. Integr. 2017, 5, 355–362. [Google Scholar] [CrossRef]

- Nalbant, M.; Gökkaya, H.; Sur, G. Application of Taguchi method in the optimization of cutting parameters for surface roughness in turning. Mater. Des. 2007, 28, 1379–1385. [Google Scholar] [CrossRef]

- Hasçahk, A.; Çaydas, U. Optimization of turning parameters for surface roughness and tool life based on the Taguchi method. Int. J. Adv. Manuf. Technol. 2008, 38, 896–903. [Google Scholar] [CrossRef]

- Ribeiro, J.; Lopes, H.; Queijo, L.; Figueiredo, D. Optimization of Cutting Parameters to Minimize the Surface Roughness in the End Milling Process Using the Taguchi Method. Periodica Polytech. Mech. Eng. 2017, 61, 30–35. [Google Scholar] [CrossRef]

- Britz, R.; Ulbrich, H. Lathe: Modeling and Coupling of Process and Structure. In Proceedings of the 1st International Conference on PMI, Hannover, Germany, 3–4 September 2008; pp. 231–238. [Google Scholar]

- Pang, J.S.; Ansari, M.N.M.; Zaroog, O.S.; Ali, M.H.; Sapuan, S.M. Taguchi design optimization of machining parameters on the CNC end milling process of halloysite nanotube with aluminium reinforced epoxy matrix (HNT/Al/Ep) hybrid composite. HBRC J. 2014, 10, 138–144. [Google Scholar] [CrossRef]

- Aurich, J.C.; Biermann, D.; Blum, H.; Brecher, C.; Carstensen, C.; Denkena, B.; Weinert, K. Modelling and simulation of process: Machine interaction in grinding. Prod. Eng. 2009, 3, 111–120. [Google Scholar] [CrossRef]

- Yang, G.; Alkotami, H.; Lei, S. Discrete Element Simulation of Orthogonal Machining of Soda-Lime Glass. J. Manuf. Mat. Process. 2018, 2, 10. [Google Scholar]

- Banks, J.; Carson, J.S.; Nelson, B.L.; Nicol, D.M. Discrete-Event System Simulation; Prentice-Hall: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Mourtzis, D.; Papakostas, N.; Mavrikios, D.; Makris, S.; Alexopoulos, K. The role of simulation in digital manufacturing: applications and outlook. Int. J. Comput. Integr. Manuf. 2015, 28, 3–24. [Google Scholar] [CrossRef]

- Kibira, D.; Shao, D.; Tina Lee, Y. Modeling and simulation analysis types for sustainable manufacturing. In Proceedings of the 10th Performance Metrics for Intelligent Systems Workshop, Baltimore, MD, USA, 28–30 September 2010; pp. 69–76. [Google Scholar]

- Smith, J.S. Survey on the use of simulation for manufacturing system design and operation. J. Manuf. Syst. 2003, 22, 157–171. [Google Scholar] [CrossRef]

- Caggiano, A.; Teti, R. Digital factory technologies for robotic automation and enhanced manufacturing cell design. Cogent Eng. 2018, 5, 1426676. [Google Scholar] [CrossRef]

- Caggiano, A.; Marzano, A.; Teti, R. Sustainability enhancement of a turbine vane manufacturing cell through digital simulation-based design. Energies 2016, 9, 790. [Google Scholar] [CrossRef]

- Oyarbide, A.; Baines, T.S.; Kay, J.M.; Ladbrook, J. Manufacturing systems modelling using system dynamics: Forming a dedicated modelling tool. J. Adv. Manuf. Sys. 2003, 2, 71–87. [Google Scholar] [CrossRef]

- Sterman, J.D. Business Dynamics: Systems Thinking and Modeling for a Complex World; McGraw-Hill Companies: New York, NY, USA, 2000. [Google Scholar]

- Adane, T.F.; Nicolescu, M. System dynamics analysis of energy usage: case studies in automotive manufacturing. Int. J. Manuf. Res. 2014, 9, 131–156. [Google Scholar] [CrossRef]

- Brailsford, S.C.; Lattimer, V.A.; Tarnaras, P.; Turnbull, J.C. Emergency and on-demand health care: modelling a large complex system. J. Oper. Res. Soc. 2004, 55, 34–42. [Google Scholar] [CrossRef]

- Azar, A.T. System dynamics as a useful technique for complex systems. Int. J. Ind. Syst. Eng. 2012, 10, 377–410. [Google Scholar] [CrossRef]

- Adane, T.F.; Nicolescu, M. System dynamics as a decision support system for machine tool selection. J. Mach. Eng. 2016, 16, 102–125. [Google Scholar]

- Hon, K.K.B. Performance and evaluation of manufacturing systems. CIRP Ann. Manuf. Technol. 2005, 54, 139–154. [Google Scholar] [CrossRef]

- Baines, T.S.; Harrison, D.K. An opportunity for system dynamics in manufacturing system modelling. Prod. Plan. Control 1999, 10, 542–552. [Google Scholar] [CrossRef]

- Patel, K.K.; Thanki, S.J. System dynamic modeling and analysis of a single stage single product canban production system. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 2262–2270. [Google Scholar]

- Helo, P.T. Dynamic modelling of surge effect and capacity limitation in supply chains. Int. J. Prod. Res. 2000, 38, 4521–4533. [Google Scholar] [CrossRef]

- Deif, A.M.; ElMaraghy, H.A. Assessing capacity scalability policies in RMS using system dynamics. Int. J. Flex. Manuf. Syst. 2007, 19, 128–150. [Google Scholar] [CrossRef]

- Shooshtarian, C.F. Jones GA System Dynamics Modelling, Simulation and Analysis of Production Line Systems for the Continuous Models of Transfer Lines with Unreliable Machines and Finite Buffers. Available online: http://www.systemdynamics.org/conferences/1998/PROCEED/00094.PDF (accessed on 23 August 2017).

- Aslam, T.; Ng, A.H.; Karlsson, I. Integrating system dynamics and multi-objective optimisation for manufacturing supply chain analysis. Int. J. Manuf. Res. 2014, 9, 27–57. [Google Scholar] [CrossRef]

- Wikner, J.; Towill, D.R.; Naim, M. Smoothing supply chain dynamics. Int. J. Prod. Econ. 1991, 22, 231–248. [Google Scholar] [CrossRef]

- Towill, D.R.; Del Vecchio, A. The application of filter theory to the study of supply chain dynamics. Prod. Plan. Control 1994, 5, 82–96. [Google Scholar] [CrossRef]

- Parnaby, J. Concept of a manufacturing system. Int. J. Prod. Res. 1979, 17, 123–135. [Google Scholar] [CrossRef]

- Byrne, S.J.; Roberts, L. Efficient Parts Supply: Influence of Information Flows. In Proceedings of the International System Dynamics Conference, Production and Operations Management, Scotland, UK, 1–15 July 1994; pp. 1–19. [Google Scholar]

- Nicolescu, C.M. Analysis, Identification and Prediction of Chatter in Turning. Ph.D. Dissertation, Department of Production Engineering, Royal Institute of Technology, Stockholm, Sweden, 1991. [Google Scholar]

- Little, J.D.; Graves, S.C. Little’s law. In Building Intuition; Springer: New York, NY, USA, 2008; pp. 81–100. [Google Scholar]

| Category | Related Parameters (Source of Cost) |

|---|---|

| Capital/Investment cost | Number and type of machine tools |

| Tool cost | Tools used for different operation types |

| Maintenance cost | Cost for corrective maintenance, cost for preventive maintenance, cost from external maintenance worker |

| Spare part cost | Replacement of the worn out part, operator overtime cost |

| Overtime cost | Total production time, threshold |

| Real estate cost | Factory adaption cost and the floor area used by the specific machine type |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adane, T.F.; Nicolescu, M. Towards a Generic Framework for the Performance Evaluation of Manufacturing Strategy: An Innovative Approach. J. Manuf. Mater. Process. 2018, 2, 23. https://doi.org/10.3390/jmmp2020023

Adane TF, Nicolescu M. Towards a Generic Framework for the Performance Evaluation of Manufacturing Strategy: An Innovative Approach. Journal of Manufacturing and Materials Processing. 2018; 2(2):23. https://doi.org/10.3390/jmmp2020023

Chicago/Turabian StyleAdane, Tigist Fetene, and Mihai Nicolescu. 2018. "Towards a Generic Framework for the Performance Evaluation of Manufacturing Strategy: An Innovative Approach" Journal of Manufacturing and Materials Processing 2, no. 2: 23. https://doi.org/10.3390/jmmp2020023

APA StyleAdane, T. F., & Nicolescu, M. (2018). Towards a Generic Framework for the Performance Evaluation of Manufacturing Strategy: An Innovative Approach. Journal of Manufacturing and Materials Processing, 2(2), 23. https://doi.org/10.3390/jmmp2020023