1. Introduction

Unmanned aerial vehicles (UAVs), specifically unmanned aerial spray systems (UASS), are garnering worldwide interest as an application technique for crop protection products, generally referred to as pesticides [

1,

2,

3]. Many terms are used when referring to drones used for agriculture, including UAV, UASS, uncrewed aerial vehicle, unmanned aerial system, and remotely piloted aerial application system (RPAAS), among others. Due to the specific reference to spray systems, the term UASS is given preference in this publication. UASSs demonstrate a use case that will help pave the way for a broader digital-agriculture ecosystem with potential benefits for increasing effectiveness, operational efficiency, and environmental and human safety. Due to the evolving nature and development of the UASS pesticide application technologies, coordination among stakeholder groups will be key to ensuring this technology is introduced safely, efficiently, and effectively in a way that adds value to all.

The Organization for Economic Co-operation and Development Working Party on Pesticides (OECD WPP) was formed in 1992 with one of its goals being to harmonize the data and methods used to test and assess pesticide risks. Following a June 2019 seminar on “Evolving Digital and Mechanical Technologies for Pesticides and Pest Management”, the OECD WPP formed a Drone/UAV Subgroup that, in 2021, published a “state of the knowledge” report on pesticide application using UAVs [

4]. Several recommendations were made in this report, including to “develop and publish a user-friendly summary of best practices (including the essential nature of calibration), pitfalls and a trouble shooting guide (both for generating trials data and applying pesticides in practice), including preliminary recommendations for operational parameters (release height, application volumes, forward speed and spray quality)”. In response to this and a recommendation to identify regulatory knowledge gaps relevant for UASS pesticide application, the pesticide registrant industry formed the Unmanned Aerial Pesticide Application System Task Force (UAPASTF) in summer 2022 to advance global regulatory acceptance and guidance of this technology.

A technical committee within the UAPASTF started working on the Best Management Practices (BMP) draft in March 2022. The first BMP draft was completed by November 2022. In addition to information from many entities also working in the BMP space, including but not limited to CropLife organizations (CropLife International, CropLife America, CropLife Asia), international organizations (FAO, ISO), and government entities (India, Japan, USDA) and associations (NASDARF), this UAPASTF BMP draft incorporated comments by academia experts (Auburn University, Ohio State), pesticide industry experts (UAPASTF company members and others), pesticide application specialists, and drone spraying service providers. This BMP document was then circulated for review at the conference/workshop titled “Applying pesticides by drone”, sponsored by the OECD held on 23–24 May 2023, in York, UK, where the perspectives on drone regulation from policymakers, industry experts, researchers, and stakeholders were obtained for further improvement. In this publication, we provide a synopsis of the various sections considered in the development of a “Best Management Practices” guidance by the UAPASTF when using unmanned aerial spray systems (UASS) for pesticide applications.

This BMP document intends to provide general guidance on best practices for the safe and effective application of pesticides using UASS; while many sections of this BMP are relevant for most pest control applications, the authors of this BMP were predominately focused on uses in agriculture. The information provided is applicable for spraying systems (i.e., nozzle/atomizers attached to a horizontal boom, or nozzle/atomizers located under the rotors) attached to single- and multirotor unmanned aerial vehicles (UAVs) of various payloads and sizes commonly used for the application of crop protection products in liquid form. Larger-payload fixed-wing UASSs are outside of scope of this BMP. Because changes in UASS technology and regulations are happening rapidly, this document is intended to be updated regularly to ensure the guidance and references within stay relevant.

Table 1 provides a high-level overview of the BMPs recommended prior to, during and post application of crop protection (CP) products using a UASS, with more details provided in the sections that follow.

The rest of the manuscript has been arranged as follows. The second section outlines the overview of the regulatory approach in different key geographies globally, followed by the third section comprising general pesticide safety consideration while mixing/handling/spraying crop protection products as well as during cleaning. The fifth, sixth and seventh sections talk about considerations pertinent to drone platforms, efficacy consideration, and off-target movement, respectively.

2. Regulatory Consideration

Typically, there is a local requirement to be certified by multiple government entities to be trained and approved to use UASSs to apply pesticides. The use of UAVs in agriculture is typically separately regulated by national/local departments controlling pesticide use and aviation legislation, respectively, and may require permission and/or approval by all entities before operation along with potentially other information (i.e., description of use, up-to-date product information, and any other potential local requirements). Additionally, and depending on the country, there are cases where UASS pesticide applications are fully incorporated into the regulatory framework, not considered at all, and everywhere between these two ends of the spectrum. Each regulatory approach carries unique challenges and benefits. Some examples, as of May 2025, of country-specific regulations meant for raising awareness and giving examples of different scenarios are provided in

Table 2 and

Figure 1. UASS applicators should seek out their local requirements to determine how UASSs are regulated in their settings.

Given the novelty of UASSs as a method to apply pesticides, some more details of the regulatory approach taken by select countries for the use of pesticides with UASSs is provided with references for further reading. The information provided is accurate as of writing; country and local laws and regulations should be reviewed prior to use for up-to-date information.

2.1. Japan

According to Japan’s national aviation authority, the Japan Civil Aviation Bureau, flying a UASS is legal in Japan subject to certification. Regulations began with a 2015 amendment to the Aviation Law, which established areas and flight rules for UASS aircraft. Before applying pesticides with a UASS in Japan, a request for approval must be sought from the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) at least 10 business days prior to the proposed operation. Additionally, UASSs applying pesticides must comply with specified flying criteria and insurance is recommended but not required. UASS application product registration data requirements can be accessed using the relevant websites [

5,

6].

2.2. Brazil

In Brazil, the application of pesticides with UASSs is regulated. Operators must meet the requirements defined by the National Civil Aviation Agency (ANAC) and by the Ministry of Agriculture, Livestock and Food Supply (MAPA). In addition, pesticide applications must also comply with other legislations, such as pesticide, labor, and environmental legislation. More information can be seen on the Civil Aviation Agency website [

7,

8].

2.3. India

In India, UASS regulations and standard operating procedures (SOPs) are in place and there is wide acceptance of many products and promotion of the technology. UASS regulation for pesticide application covers aspects including flying permissions, distance restrictions, weight classification, UAV registration, safety insurance, piloting certification, operation plan, flight zones, weather conditions, SOPs, and an emergency handling plan. For more information on compliance for using drones in agriculture in India, use the Directorate General of Civil Aviation, Ministry of Civil Aviation: Drone Rules, 2021, under section 14 of the Aircraft Act, 1934 (22 of 1934): Home|Directorate General of Civil Aviation|Government of India [

9]; the Ministry of Agriculture & Farmers Welfare [

10]; provisions under the Sub-Mission on Agriculture Mechanization for Drone Technology Promotion [

11]; the Central Insecticides Board & Registration Committee, Directorate of Plant Protection, Quarantine and Storage, Ministry of Agriculture & Farmers Welfare: Registration requirements of pesticides for Drone application [

12]; and “Interim Approval for Application of Already Approved Pesticide Formulations through Drone” [

13].

2.4. China

In China, according to China’s Ministry of Agriculture and Rural Affairs, and Civil Aviation Administration of China (CAAC), flying a UASS for application purposes is supported. In 2017, CAAC released the Regulations on the Administration of Real-name Registration of Civil Uncrewed Aerial Vehicles, applying to civil UAVs with a maximum takeoff weight of no less than 250 g. According to these regulations, UAV manufacturers should register all product information on the system; UASS owners are required to register their names and product information on the system and put the registration labels on their UASS. In 2021, the Certification and Accreditation Administration of the PRC adopted special provisions to promote voluntary certification, which aims to enhance the quality of plant protection UASSs by conducting assessments on their safety and performance together with supervision and inspection of factories. On 1 January 2024, the “Regulations on the Management of Unmanned Aircraft System” was officially implemented, which set out very preferential provisions for agricultural drones. UASSs applying pesticides must comply with specified flying criteria and receive training and licenses from agricultural drone manufacturers [

14].

2.5. USA

Though there is no official EPA policy for UASSs applying pesticides at this time, in the interim, the EPA notes that applications using UASSs follow the label for that registered use as well as any additional state requirements (including states not allowing the use of UASSs for pesticide application). States may also have additional requirements to comply with local laws and regulations, for example, where there is an additional reporting requirement in general for pesticide applications (such as in California) or additional requirements for drone operators (like in Ohio [

15]). The association of American Pest Control Officials is coordinating discussions among states [

16]. Additionally, the operational aspects of the application equipment itself must be followed per FAA requirements; see [

17,

18].

2.6. European Union

According to the 2009/128 Directive on sustainable use of pesticides (the “SUD Directive”), ‘aerial spraying’ is defined in the EU as application of pesticides from an aircraft (plane or helicopter). It was interpreted that the definition allows the use of other types of aircraft (other than plane and helicopter), including drones. In that case, Article 9 of the SUD Directive regarding aerial spraying applies, as well as other general requirements. Any derogations granted are monitored to ensure compliance with the specified conditions of use. In some EU member states, approval from the pertinent aviation authority may also be required. The granting of derogations in special cases is legally possible in the majority of Member States; however, the area on which aerial application of plant protection products takes place is low and is generally declining. The Commission Delegated Regulation (EU) 2019/9452 of 12 March 2019 on unmanned aircraft systems and on third-country operators of unmanned aircraft systems also applies for the design and manufacture of unmanned aircraft systems.

3. General Pesticide Safety Considerations

General recommendations for safe and compliant pesticide use are provided and, for the most part, do not differ from safety considerations when using any other pesticide application method. One area that is not directly paralleled in other application scenarios is the interaction between the operator and the UAV itself. This is an active field of development where job steps and consistency of the workflow are still being understood for broad BMPs to be developed. These activities include filling the UASS, changing batteries, adjusting and performing minor repairs to the equipment, manually moving the UASS (including transportation to and from the field site, where gloves should be considered if the drone has pesticide residue on it), cleanup, and general awareness of machinery components like electricity and propellers that could pose a risk to safety. In cases where batteries are cooled in a water tank, it is important to consider residual pesticide spray being on the batteries from the prior flight and thus in the cooling tank. This water should be disposed of as instructed for pesticide-contaminated water. An example from the United States of the process to mix/load and apply pesticides with a UASS and a comparison to current methods are provided below.

3.1. Initial Mixing and Loading

A common practice with mechanized sprayers in certain regions is the use of nurse tanks. Nurse tanks are large-volume containers of spray solution mixed on-site for the purpose of filling and refilling spray equipment. Because UASS spray tanks do not currently have the capacity for agitation, the use of a nurse tank can ensure that the product(s) in the tank mix are properly dissolved or suspended prior to being added to the UASS tank and proper agitation is maintained where necessary. When mixing in the nurse tank or UASS tank, the first interaction would be with concentrated product. When loading from the nurse tank into the UASS tank, the handler would potentially come into contact with the diluted spray solution. Wearing labeled PPE, such as gloves and a full layer of clothing, is vital. Pesticide applications with UASS can occur in remote areas and an appropriate “fixed” location for pesticide mixing may not always be available. It is important to conduct the mixing/loading steps in a location away from ditches and water sources to avoid contaminating surface or groundwater.

3.2. Spraying

After the product is mixed and loaded into the UASS, the product is ready to be applied. Unlike manned aerial application systems, this process typically takes place from a distance. The operator and others crew members should maintain a safe distance from the drone of at least 6 m (about 20 ft). After choosing an appropriate position for take-off and landing, the certified UASS operator would deploy the UASS to the proper altitude and proceed to the application site. While spraying, the operator and visual observers must keep a visual line of sight with the UASS unit. The operator and bystanders should attempt to remain upwind of the application site; if there is a risk of being downwind of the UASS spray zone, suitable protective measures (e.g., additional PPE) may be required.

3.3. Subsequent Mixing and Loading

After the UASS senses depletion of payload and automatically returns to the filling station/area, the UASS is ready to be refilled from the nurse tank. Multiple sets of batteries are also used, so newly charged batteries are replaced while depleted sets are being charged. This process could occur many times in a single day and will depend on the size and efficiency of the drone platform and the spray operation. It is important to ensure if there is any handling of pesticides or handling of equipment that has potential pesticide residues, such as the batteries, that gloves are worn and that gloved hands do not touch transfer residues to new surfaces (like the drone controller screens). This depends on the optimal workflow for the operation and can be accomplished by either donning and removing gloves at the right moment or having different people perform these tasks.

3.4. Cleaning, Maintenance, and Handling

After each use, the application equipment must be cleaned and residues removed internally (i.e., spray tank) and externally due to the possibility of residues remaining both within and on the outside of the drone. At the end of each day’s spraying, the spraying system should be flushed through with a suitable cleaning agent: either water and detergent for water-based sprays or suitable solvent for oil-based sprays. Cleaning a UASS after use would be similar to cleaning a backpack and other small tank sprayers and typically would follow a triple-rinse procedure. Cleaning and maintenance of spray nozzle/atomizers, pumps, and tubes would be treated similarly to the procedures followed with backpacks and other small-tank application methods. The drone exterior should not be power-washed as water can be forced into electronic parts, causing malfunction. A similar procedure should be applied to the nurse tank to eliminate remnants of the spray solution.

4. Equipment

This section focuses on the spray application components of UASSs. The uniformity/quality of application is critical in achieving the best control possible, which is directly linked to how the equipment is calibrated. Equipment calibration is important to minimize variability, ensure good product deposition, and deliver an optimum dose to effectively control the target pests. At a minimum, calibration should be conducted at the start of the season, prior to starting a new job that requires a different equipment setup (different crop, pest, product, operating conditions, etc.), or when changes or repairs are made (boom configuration changes, nozzle/atomizers replaced, new pump, etc.). These calibration recommendations assume that an airframe inspection has already been conducted according to the UAV manufacturer’s recommendations.

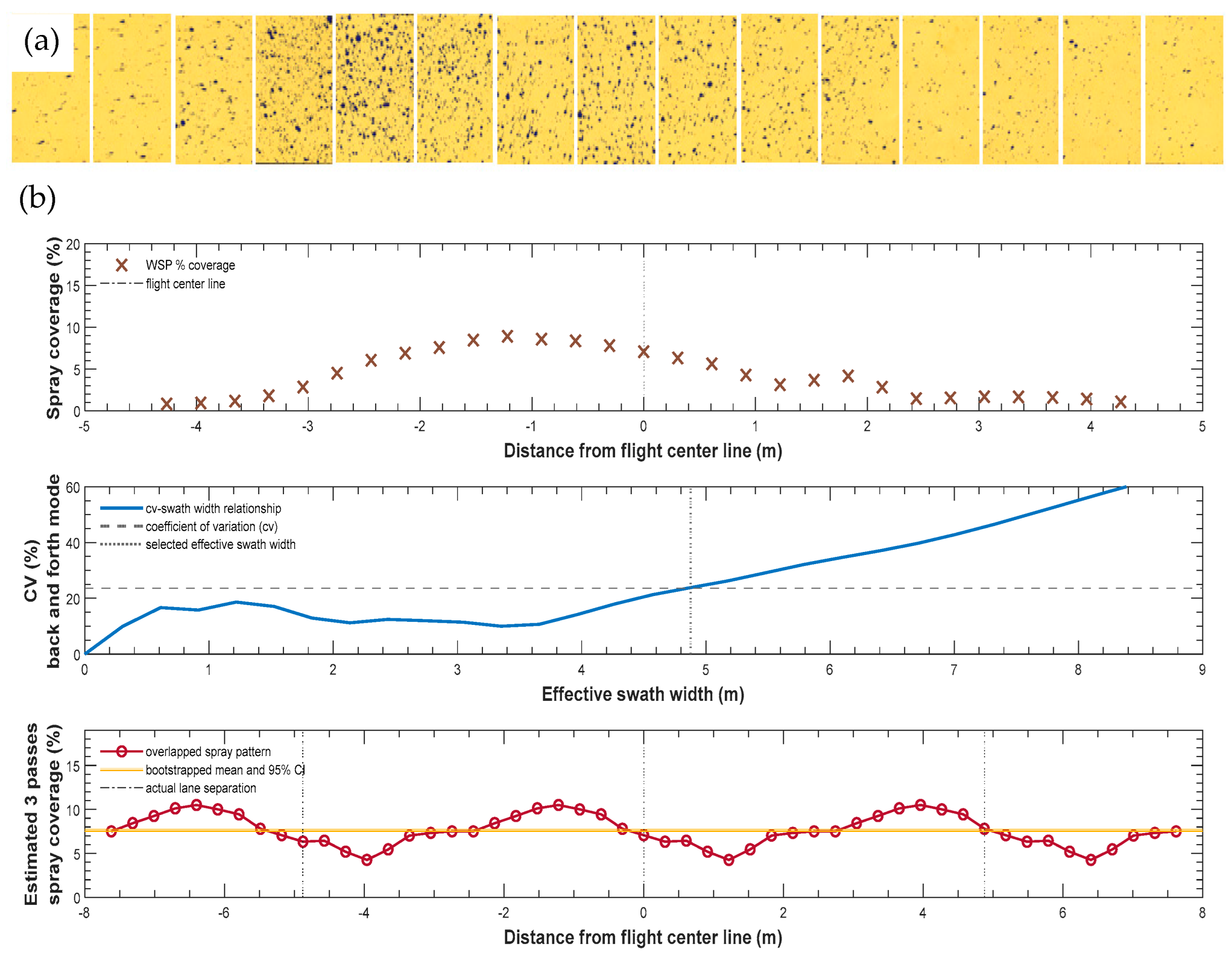

4.1. Effective Swath Width (ESW)

A UASS manufacturer may claim a theoretical swath width, sometimes expressed as a range (e.g., 4 to 9 m). It is important to define the effective swath width (ESW) by measuring spray deposition along the swath and checking for spray distribution variability. Total swath width is defined as the spray footprint of the UASS (the linear distance, perpendicular to the direction of travel that spray deposits during a single spray pass) (see

Figure 2,

Figure 3 and

Figure 4). ESW will be a fraction of the total swath, and an overlap is used to reduce deposition variability. Swath width of a UASS is impacted by several factors, including, but not limited to, the following:

- (1)

Nozzle/atomizer type and use, such as pressure, which determine particle size distribution (see

Figure 2);

- (2)

Nozzle/atomizer position and orientation (under rotor or on a boom, see

Figure 1);

- (3)

Spray release height above the ground or target such as crop;

- (4)

Flight speed;

- (5)

Rotor downwash vortices and aircraft wake (which are affected by the mass of the UASS and speed; see

Figure 2);

- (6)

Environmental conditions;

- (7)

Wind direction and speed.

There are multiple ways to determine ESW; however, this process can be complicated and may require specialized equipment and professional help. One way to calculate ESW is by spraying over media (water-sensitive cards, kromekote paper, mylar cards, paper receipt tape, etc., are some of the most used samplers) distributed across the flight path at known distances (

Figure 4). While water only can produce stains on water-sensitive cards, a dye (FD&C Blue, Rhodamine, Pyaranine, etc.) can be added to the spray to help stain other samplers for better visualization. A digital camera or scanner can be used to capture individual images of the cards alongside computer programs to extract coverage data of individual cards. Mobile/smart phone applications such as DropLeaf, DropScan, Dropflight, and SnapCard are also available to read coverage data. Once the coverage information is obtained and expressed as a function of distance to the centerline, the ESW can be determined by calculating the coefficient of variation (CV) of multiple swaths. Swath characterization has been extensively studied and reported for different application technologies. For more details around effective swath characterization of a UASS, please refer to [

2,

3,

19]. The CV shows the extent of variability in relation to the mean spray coverage in this case. After measurements are collected and coverage is expressed as a function of distance, an ESW is selected and an average coverage (mean) and standard deviation are calculated. CV is calculated by dividing the standard deviation by the average and multiplying by 100. CV is expressed as a percentage (%). Typically, ESW is the largest swath in which the CV is equal to 25–30% or lower. ISO/CD 23117-2 [

20] provides more information on how to determine a UASS’s effective swath, and additional resources can also be found from experts in this field, including but not limited to [

21,

22,

23,

24].

4.2. Spray Coverage

Variability in spray coverage within the swath contributes to a lack of pest control (low/no spray present) or possible crop damage or product wastage (too much spray present). Variability can happen due to several reasons, including but not limited to equipment setup (wrong/faulty nozzle/atomizer used, swath being too wide, speed too slow), bad operational design (flying too high or too low), or weather conditions during operation (strong, variable winds); see

Figure 1. Because the UASSs discussed in this BMP document use rotors that push spray downwards, and the ESW is generally larger than the overall spray equipment width, they may tend to produce sprays that are more variable than sprays produced by other equipment such as a ground sprayer. Therefore, it is critical to understand the factors affecting variability, to calibrate the equipment, and to pay attention to signs that may point to a higher-than-normal variability in spray deposits during the application.

4.3. Component Check

The first step in the calibration process is to conduct a visual scan of the spray components listed below (

Figure 1):

- (1)

Tank: Make sure the tank and screens are clean and free of cracks. Certify that the tank is properly attached to the airframe.

- (2)

Pump: Make sure it is connected properly.

- (3)

Boom: Inspect the integrity of the boom and look for any bends, cracks, loose parts, etc.

- (4)

Hoses: Check the integrity of the hoses before attaching; make sure connections are secured.

- (5)

Nozzle/atomizers: Make sure nozzle/atomizers are in the correct position and securely attached. Make sure they are not worn or damaged and are correctly aligned and normally pointing down.

- (6)

Screens and tips: Check valve spring and diaphragm (if equipped). Make sure screens are the proper size, clean, and undamaged.

- (7)

Rotary atomizers: Some systems use rotary atomizers instead of hydraulic nozzles. If that is the case, make sure the atomizers are clean and components are working.

4.4. Application Parameters Needed for Calibration

The following list contains the required application parameters needed for calibration:

- (1)

Application volume rate (L ha−1 or [gal acre−1]).

- (2)

Nozzle/atomizer selection and droplet size—Check the product label(s) for nozzle/atomizer recommendation. Nozzle/atomizer manufacturers’ catalogs can also help select nozzle/atomizers able to deliver the required application rate and the spray quality (droplet size category). Some UASSs use rotary atomizers, and the operator can select a specific Volume Mean Diameter (VMD) from the spraying software options (e.g., in the range of 60–500 microns).

- (3)

Pump flow rate—Some UASSs have low-capacity pumps which can limit nozzle/atomizer size, ground speed, and consequently application rate. Verify that the pump installed can adequately supply product flow for the application rate required. Most UASSs have control systems that will adjust the flow rate to match speed changes and keep application rate constant.

- (4)

Nozzle/atomizer flow rate—This information should be provided by the nozzle/atomizer manufacturer; measure flow rate as described in the Calibration Section. Certify that all nozzle/atomizers have a similar rate of discharge within ±7% of the theoretical output [

25].

- (5)

Boom setup—Nozzle/atomizer spacing should be consistent on the boom. Boom and nozzle/atomizers should be positioned to avoid spray interference with the UAV frame or components (landing gear, radar sensor, etc.). The optimum boom width requirements in UASSs have not been established as they have been for manned aircrafts. The downwash of multirotor UAVs behaves differently from that of single-rotor UAVs. Maintaining constant flight speed, altitude, and swath width is necessary to achieve a uniform spray pattern.

- (6)

Flight height—Flight height has a direct impact on swath width. Optimum flight height may vary depending on factors such as safety, equipment configuration, environmental conditions, and use pattern. Low-altitude spray (e.g., <1.5 m) will result in a narrower swath and affect overlap. A lower altitude may also change droplet trajectory and coverage due to the interaction of the rotor airflow with the ground (ground effect) and possible vortex bounce. High altitudes (e.g., >3 m) may widen the spray swath, increase in-swath deposition variability, and affect overlap [

3]. Flying too high may also increase the risk of spray drift, reduce coverage, and cause undesired off-target movement to sensitive areas. Maintain optimum flight height during application.

- (7)

Flight speed—UASS measures flight speed through various means such as GPS. When checking speed, fill the spray tank with water to simulate the anticipated payload of the application. Meteorological conditions such as wind direction, wind speed, temperature, humidity, and atmospheric pressure should be recorded. When spraying, maintain a constant flight speed. Never spray while hovering, as this may apply more than the legally labeled dose, or while pulling in or out of a field.

4.5. Calibration

There are three major factors influencing application volume rates, namely ground speed (m s−1, [km h−1, mile h−1]), ESW (m or ft) and nozzle flow rate (L min−1 or gal min−1).

Follow these steps to perform a calibration:

- (1)

Set up the UASS as you would to perform an application (attach/extend booms, connect pumps, etc.).

- (2)

Fill the tank to full capacity with water only.

- (3)

Place the UASS on a location where the nozzle/atomizer pattern can be observed while the rotors are off; turn the pump on at the desired flow rate setting and visually check that the spray pattern is fully established (no obstructions, partial clogging, etc.).

- (4)

Confirm visually that each nozzle/atomizer is providing the expected spray angle and orientation.

- (5)

Using a graduated cylinder or wide-mouth jar for rotary atomizers, collect output from each nozzle/atomizer for 30–60 s while all nozzle/atomizers are spraying. The output (gal/min or l/min) from each nozzle/atomizer should be within ±7% of their theoretical output at the given flow rate or operating pressure [

25]. Larger differences indicate that the nozzle/atomizer is damaged and may need to be replaced. Depending on the position of the nozzle/atomizer, it may also indicate uneven pressure. Large differences in output need to be fixed for uniform spray. Nozzle/atomizer flow rate can also be tested using the procedure described in [

26].

- (6)

Total flow rate volume (FR) will be the sum of measured output by all nozzle/atomizers.

- (7)

Calculate area sprayed per minute (

APM) according to Equation (1).

- (8)

Calculate application rate using Equation (2).

where

AR is the application rate in L ha

−1;

FR is the nozzle flow rate (L min

−1); and

APM is area sprayed per minute (ha min

−1).

- (9)

Verify deposition by making one pass with the UASS using only water or with food-grade dye and verify that coverage and deposition are uniform. The use of water-sensitive paper or other visualization tools is an optional step that can help visualize deposition and detect any other deficiencies. Repeat this step at least three times. Be mindful that flying too close to the ground could cause turbulence and incorrect deposition patterns, especially over hard surfaces such as cement and paved roads.

While it is recognized that calibrating using clean water may not be fully equivalent to using the actual tank mix to be sprayed (due to differences in tank mix solution characteristics), and for safety reasons, calibrating using the actual tank mix may not be possible or recommendable, but water will provide a baseline. Calibrating with the final tank mix will require the proper safety precautions on PPE, drift exposure and disposal of unused material.

5. Efficacy Consideration

A review of available publications comparing the efficacy of selected pesticides applied via UASS versus conventional methods indicates that due to the limited data available, a broad and universal understanding of the relative performance of the technologies could not be established; however, initial limited studies show similar performance in some cases [

26]. Therefore, the transition to using pesticides via UASSs should be made with caution as more information regarding their specific effects may be gathered over time about this new application method. Factors that impact efficacy with other application methods are also relevant to applications with UASSs; some are listed here.

5.1. Target Pest and Crop

Determine if a UASS-based pesticide application is the appropriate method to treat the desired crop, and if so, decide on what type of UASS is appropriate. Choose the application volume rate, nozzle/atomizer type, and other spray parameters such as aircraft height and nozzle/atomizer positions that deliver the product to the target while minimizing off-target movement (drift) [

27,

28]. While for UASS, best practices for minimizing drift are still being developed, there are general guidelines that can be followed such as not flying too high above the target application area, using nozzle/atomizers that give coarser spray quality, not applying during high wind situations, and using a quality, calibrated UASS.

5.2. Pest Control Product Attributes

Ensure the pesticide is allowed to be applied by UASSs per local regulations. Products that are systemic or “local systemic” may work well when using medium to coarse spray quality. This information is available on most herbicide product labels and previously published studies [

28]. Pesticides that have limited plant mobility require good spray coverage, which means fine to medium-size droplets may be needed. Soil applied products, such as herbicides, work well when using coarse or bigger droplets. Adjuvants (including surfactants and drift reducing agents), if allowed on the product label, can help with retention/spreading of droplets, cuticle penetration, reduced evaporation, and drift reduction.

5.3. Tank Mixes, Spray Tank Preparation and Quality, Tank Mixing and Use of Adjuvants and Drift Retardants

Start with a tank, nozzle/atomizers, lines, and booms that are clean and free of previous pesticide deposits before applying to avoid contamination or undesirable pesticide interactions that can cause adverse crop effects/lack of efficacy or impact spray quality. Refer to ISO 22368-1-3 [

29,

30,

31] as publications on cleaning crop protection equipment. Current UASS models are not equipped with an agitation system in the tank. Ensure the solution is well dissolved or dispersed when loading into the tank. Spray within no more than 30 min after loading into the UASS tank. Use of adjuvants and drift retardants may be used to enhance the effectiveness, accuracy and environmental safety of pesticide application using UASS. These can greatly enhance the precision, safety and sustainability of UASS-based pesticide applications. Please consult product label or crop advisors for any recommendations.

6. Environmental Variables and Effects on Off-Target Movement

The interaction of equipment and weather- and atmosphere-related parameters is a key factor in a successful spray application using UASSs. The applicator must be familiar with and follow the product label and local laws, including local restrictions, advisories, and/or statutory mandates around environmental parameters, such as wind or proximity to water, that reduce the potential for off-site exposure to non-target sensitive areas. Wind speed and direction, temperature, relative humidity, and surface temperature inversions greatly influence drift exposure. Below, we discuss these factors and equipment options to consider that maximize on-target spray deposition and minimize drift. ISO/CD 23117-1 [

32] provides more information on precautions to minimize the risk of environmental contamination when using UASSs.

6.1. Wind

Drift potential increases at wind speeds of less than 1.3 m s

−1 (3 miles h

−1 or 5 km h

−1) (due to variable direction and inversion potential) or more than 4.5 m s

−1 (10 miles h

−1 or 16 km h

−1). This information has been provided on pesticide product labels and previously published literature [

33,

34,

35]. However, many factors, including droplet size and application height, determine drift potential at any given wind speed. If high wind speeds are expected, one can compensate with larger droplet size, higher water volume rates where possible and the addition of a drift-reducing agent. Droplets smaller than 150 μm have relatively high drift potential; thus, wind is a key factor to consider when applying pesticides using UASSs. Under high-wind conditions, in addition to utilizing larger droplet size, not spraying directly over the downwind edge of the field, i.e., moving the spray swath upwind (1/2 to full swath offset), can also reduce overall drift potential [

36].

High wind may also alter the flight dynamics of the UASS, so the vehicle (UAV) specifications should also be considered. Since UAVs typically release the spray at altitudes higher than 1.5 m, it is important that wind speeds are measured per international standards at the point of release or as high as possible if standard measurements are not available.

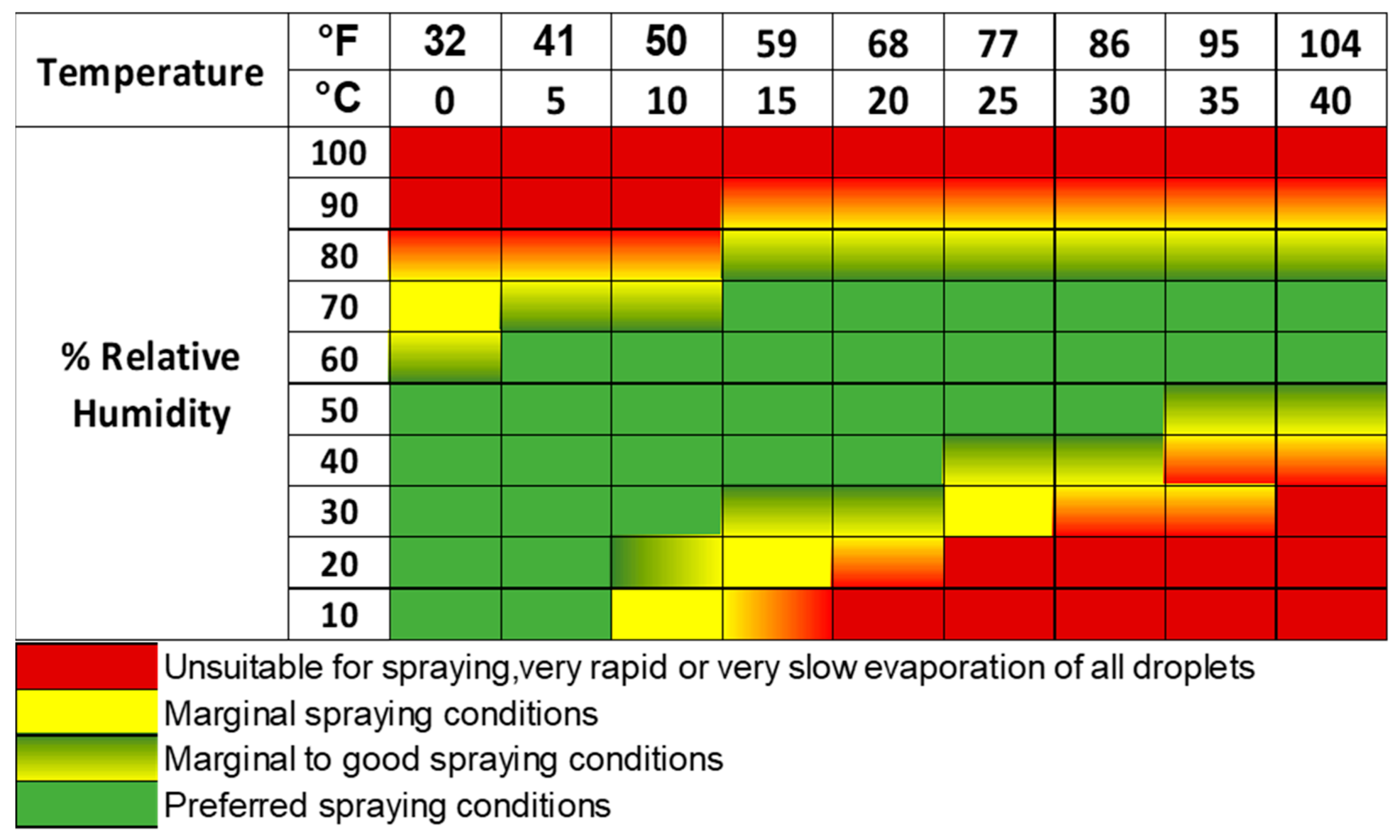

6.2. Hot and Dry Weather Conditions

Applications made at low relative humidity (RH) and in high-temperature conditions have greater risk of increased drift due to increased evaporation, which may lead to poor spray coverage [

37,

38]. This is because as a droplet dries, its size is reduced, making it likely to drift further. Under those conditions, one may increase the droplet size and use higher application volumes (2–5 times more water may be required). See

Figure 5 for guidance on acceptable spray conditions under various temperature and relative humidity combinations.

6.3. Surface Temperature Inversions

Pesticides should not be sprayed when there is a local surface temperature inversion (thermal inversion,

Figure 6) since the potential for off-target movement is high. A temperature inversion occurs when warm air is trapped between cooler air higher in the atmosphere and dense cooler air close to the ground. This typically happens at the end of the day when solar intensity is reduced and can last until sunrise the next day. Surface inversions restrict vertical air mixing, which causes small, suspended spray droplets to remain close to the ground and move laterally in a concentrated cloud and in unpredictable directions [

39,

40].

6.4. Adjusting Spray Parameters to the Environment and Sensitive Areas

Follow the product label instructions carefully to make sure an application can be made that meets any restrictions around drift potential to sensitive non-target areas or organisms. Observe any no-spray buffer zones listed on the label. The user is responsible for knowing and applying any regulatory setbacks and buffer zones above and beyond those included on the label (e.g., stricter provincial/state requirements than Federal requirements). Shut off spray nozzle/atomizers when making row turns. Shut off the boom over irrigation ditches, washes, culverts, and other waterways. When spraying partial swaths, and if possible, shut off nozzle/atomizers that are not aimed at the target. Most commercial UASS platforms have terrain-following capabilities. Make sure to activate the feature when spraying in uneven terrains for effective application and reduced drift.

7. Limitations of UASSs for Pesticide Application

While UASS use for spraying has gained momentum globally in recent times, there are a number of limitations that limit higher adoption rates. The use of UASSs for application of crop protection products started in the Asia–Pacific region (e.g., Japan and China) and was seen as an excellent alternative to traditional backpack sprayers, which were commonly used and well suited for their small land holdings [

41]. Compared to backpacks, UASSs provide advantages like higher field efficiency, reduction in labor, accessing difficult terrain, and minimized exposure risk for the applicator [

3].

As UASS technology evolved, the agricultural industry in other regions of the world (e.g., North America, Latin America, Europe, etc.) also started to show interest in this technology. However, there are differences in these regions that could warrant different benefits, such as crops grown, agronomic practices, and land sizes. When it comes to land sizes, for example, the average farm sizes in the US, Canada, and Brazil are around 178, 273, and 73 ha, respectively, compared to China and Japan, with average farm sizes of 0.6 and 1.2 ha, respectively [

42]. With a relatively smaller effective spray swath (~6–9 m based on manufacturer recommendation) and field efficiency (12–15 ha h

−1), UASSs could take a prohibitively larger amount of time to spray average-sized farms in the USA, Canada and Brazil compared to other conventional application technologies like by airplane or tractor. In addition, limitations with battery power and tank capacity may lead to limited flight time and further reduce the field capacity and operational efficiency for larger farms. Currently, service providers use multiple drones and/or a fleet of batteries (with high-capacity power generators for fast charging) to keep the operation continuous without having to wait. However, this could be cost-prohibitive for growers with relatively larger farms. For larger farms that still intend to use UASSs for application, swarming (involving multiple UAVs to be operated simultaneously by a single pilot) could be a solution and can help with the uptake of this technology in regions with larger farm sizes [

15].

The regulatory landscape in different regions of the world can also be a limiting factor to the widespread adoption of this technology. In the US, Brazil, and Australia, most of the UAV-based applications are conducted under aerial application label guidance and there are no UASS-application-specific guidelines on product labels, which could be problematic for end users needing UAV-specific instructions (

https://aapco.org/wp-content/uploads/2024/12/UAVSummary241104-2.pdf; accessed on 21 March 2025). In the USA and Canada, authorities (Federal Aviation Agency and Transport Canada Civil Aviation) require, in most cases, that the drone pilots must maintain a clear visual line of sight without relying on any visual aid like a pair of binoculars when flying UASSs to apply CP products. Such requirements can also be prohibitive to adoption for large farm sizes.

There are a number of UASS manufacturers (e.g., XAG, DJI, Draganfly, Yamaha, AeroVironment, etc.) who are producing spray drones for application of crop protection products. However, the designs are not consistent and standardized when compared to conventional application technologies. This is likely because the technology is still evolving; however, it can be another potential limitation since application quality can be impacted by design attributes like placement of nozzles relative to the propeller, in-line pressure sensors, and intended nozzle types [

3]. As a result of this and likely other factors, current UASS platforms have more in-swath variability for coverage on the target surface [

2,

3,

43], compared to traditional application methods, which is something UASS manufacturers would need to address. Sub-optimal application quality is a concern for many reasons, including efficacy and pest resistance concerns [

44]. With more complex formulation types being developed by pesticide registrants (e.g., suspension concentrates, capsule suspensions, etc.), there may be a need for an agitation mechanism in UASS spray tanks since such products require continuous agitation while mixing and spraying to keep the active ingredients homogenous in solution. Most of the UAV platforms for pesticide application also lack some critical sensing capabilities like operating pressure and use flow sensors instead to back-calculate. In addition, UASSs typically use a global positioning system (GPS) for navigation and targeted spraying, enabling it to follow a pre-determined flight path for a designated area. At times, issues with GPS such as lost signals could lead to inaccurate flight paths and losing control between the UASS and the remote control. Real-Time Kinematics (RTK)–GPS provides positioning accuracy within cm but comes at an additional cost.

UASSs can be beneficial for targeted application (e.g., spot spraying) of pesticides. For example, machine learning algorithms have been used for target pest detection [

45] and can be utilized during spray application using UASSs. However, existing environmental conditions (e.g., ambient wind speed and direction) can prohibit the spray flux to be deposited on the target. This is because the UASS applies the spray at a height of >3 m above the target and, even under the recommended wind speed, can move the spray off-target. To achieve this, there has to be a way (e.g., real-time weather feedback from a weather station) by which the UASS can correct its position based on ambient wind conditions to be able to effectively spray the target. This can also play an important role in deciding to carry out a swath offset while making the last pass along the edge of the treatment area.

Overall, there are opportunities for more technological developments for UASS, including but not limited to payload, flight time, battery technology and charging, flight control and navigation, and application quality hardware components. In addition, this technology would be enabled by fit-for-purpose regulatory frameworks to be more user-friendly and to fully take advantage of the benefits of the technology. Finally, training on how to best use this technology is a limiting factor; documents such as the best practices presented here should help new and more experienced users improve their knowledge on this technology.

8. Conclusions

Application of crop protection products using UAVs has been gaining momentum recently, with large variability in equipment type and product concentration in the drone tank, which is mostly higher than that of conventional spraying. This variability may lead to challenges to effective spraying, safe operation and environmental protection. Therefore, Best Management Practices (BMPs) are critical for spraying crop protection products with UAVs to ensure efficiency, safety, and environmental protection. Proper planning, including selecting the right product (dosage, application volume, etc.), adjusting operational (flight height, speed, etc.) and application attributes (e.g., droplet size) and considering weather conditions, helps to maximize coverage while minimizing drift and unintended exposure. BMPs also ensure compliance with regional regulations, protect pollinators and water sources, and enhance application accuracy through calibrated equipment and flight patterns. By following BMPs, drone operators can improve pest control effectiveness while reducing risks to human health and the environment.

Author Contributions

Conceptualization, H.P., R.B., S.H., N.N., P.L., G.W. and R.S.; writing—original draft preparation, H.P., R.B., E.L. and S.H.; writing—review and editing, H.P., R.B., S.H., E.L., N.N., T.G., M.B., R.H., B.K., P.L., M.O., G.W. and R.S.; visualization, H.P., R.B. and S.H; supervision, H.P., R.B. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study received no external funding.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

The study was completed on behalf of the global Unmanned Aerial Pesticide Application Spray Task Force (UAPASTF). The authors would like to acknowledge all the global experts who reviewed the manuscript and provided constructive feedback.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Chen, H.; Lan, Y.; Fritz, B.K.; Hoffman, W.C.; Liu, S. Review of agricultural spraying technologies for plant protection using unmanned aerial vehicle (UAV). Int. J. Agric. Biol. Eng. 2021, 14, 38–49. [Google Scholar] [CrossRef]

- Li, X.; Giles, D.K.; Niederholzer, F.J.; Andaloro, J.T.; Lang, E.B.; Watson, L.J. Evaluation of an unmanned aerial vehicle as a new method of pesticide application for almond crop protection. Pest Manag. Sci. 2021, 77, 527–537. [Google Scholar] [CrossRef] [PubMed]

- Sinha, R.; Johnson, J.; Power, K.; Moodie, A.; Warhurst, E.; Barbosa, R. Understanding Spray Attributes of Commercial UAAS as Impacted by Operational and Design Parameters. Drones 2022, 6, 281. [Google Scholar] [CrossRef]

- OECD. Report on the State of the Knowledge—Literature Review on Unmanned Aerial Spray Systems in Agriculture; OECD Series on Pesticide, No. 105; OECD Publishing: Paris, France, 2021. [Google Scholar]

- Data Requirements for Registration of Agricultural Chemicals. Available online: http://www.acis.famic.go.jp/eng/shinsei/6278_2nd_e.pdf (accessed on 23 March 2025).

- Chief of Agricultural Products Safety Management Section, Bureau of Consumption and Safety, Ministry of Agriculture, Forestry and Fisheries (農林水産省消費·安全局農産安全管理課長) (Director, Agricultural Products Safety Management Division, Consumer Affairs and Safety Bureau, Ministry of Agriculture, Forestry and Fisheries—Translated from Japanese). Available online: https://www.maff.go.jp/j/nouyaku/n_touroku/attach/pdf/index-38.pdf (accessed on 23 March 2023).

- Requisitos Gerais Para Aeronaves Não Tripuladas de Uso Civil. Available online: https://www.anac.gov.br/assuntos/legislacao/legislacao-1/rbha-e-rbac/rbac/rbac-e-94 (accessed on 23 March 2023).

- Diário Oficial da União. Available online: https://in.gov.br/en/web/dou/-/portaria-mapa-n-298-de-22-de-setembro-de-2021-347039095 (accessed on 23 March 2023).

- Drone Rules 2021. Available online: https://www.dgca.gov.in/digigov-portal/jsp/dgca/homePage/viewPDF.jsp?page=InventoryList/headerblock/drones/Drone%20Rules%202021.pdf (accessed on 23 March 2023).

- Standard Operating Procedure (SOP) for Use of Drone Application with Pesticides for Crop Protection and for Spraying Soil & Crop Nutrients in Agricultural, Forestry, Non-Cropped Areas, Etc. Available online: https://fmttibudni.gov.in/files/SOP_Drone_Application_English_cdr.pdf (accessed on 23 March 2023).

- Sub-Mission on Agricultural Mechanization. Available online: https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1985470 (accessed on 23 March 2023).

- Guidelines for Registration Requirements of Pesticide for Drone Application. Available online: https://croplifeindia.org/wp-content/uploads/2024/01/Drone-Guidlines-Efficacy-Final.pdf (accessed on 23 March 2023).

- Interim Approval for Application of Already Approved Pesticide Formulations through Drone-reg. Available online: https://croplifeindia.org/wp-content/uploads/2024/05/Public-Notice-dated-25.04.2024-for-Extension-of-Interim-Approval-for-Application-of-Existing-Approved-Formulations-through-Drones.pdf (accessed on 23 March 2023).

- Interim Regulations on the Management of Unmanned Aircraft Flights. State Council Documents. Chinese Government Website (Translated from Chinese). Available online: https://www.gov.cn/zhengce/content/202306/content_6888799.htm (accessed on 23 March 2023).

- Drones for Spraying Pesticides—Opportunities and Challenges. Available online: https://ohioline.osu.edu/factsheet/fabe-540 (accessed on 23 March 2023).

- Association of American Pesticide Control Officials. Available online: https://aapco.org/2015/07/01/technology-workgroup/ (accessed on 23 March 2023).

- Certificated Remote Pilots Including Commercial Operators. Available online: https://www.faa.gov/uas/commercial_operators (accessed on 23 March 2023).

- Dispensing Chemicals and Agricultural Products (Part 137) with UAS. Available online: https://www.faa.gov/uas/advanced_operations/dispensing_chemicals (accessed on 23 March 2023).

- Liu, Y.; Yao, W.; Guo, S.; Yan, H.; Yu, Z.; Meng, S.; Chen, D.; Chen, C. Determination of the effective swath of a plant protection UAV adapted to mist nozzles in mountain Nangguo pear orchards. Front Plant Sci. 2024, 15, 1336580. [Google Scholar] [CrossRef] [PubMed]

- ISO/CD 23117-2; Agricultural and Forestry Machinery—Unmanned Aerial Spraying Systems—Part 2: Test Methods to Assess the Horizontal Transverse Spray Deposition. ISO: Geneva, Switzerland, 2024.

- How to Calibrate a Drone. Available online: https://sprayers101.com/calibrate-drone/ (accessed on 23 March 2023).

- Better Field Studies. Available online: https://www.betterfieldstudies.com/swath-gobbler (accessed on 23 March 2023).

- Measurement and Analysis Methods for Determination of Effective Swath Width from Unmanned Aerial Vehicles. Available online: https://store.astm.org/stp162720190132.html (accessed on 23 March 2023).

- Calculation of Swath Width and Swath Displacement for Uncrewed Aerial Spray Systems. Available online: https://elibrary.asabe.org/abstract.asp?aid=54009&t=2&redir=&redirType= (accessed on 23 March 2023).

- ISO 16119-2; Agricultural and Forestry Machinery—Environmental Requirements for Sprayers—Part 2: Horizontal Boom Sprayers. ISO: Geneva, Switzerland, 2018.

- ISO 5682-1; Equipment for Crop Protection—Spraying Equipment—Part 1: Test Methods for Sprayer Nozzles. ISO: Geneva, Switzerland, 2017.

- Li, X.; Giles, D.K.; Andaloro, J.T.; Long, R.; Lang, E.B.; Watson, L.J.; Qandah, I. Comparison of UAV and fixed-wing aerial application for alfalfa insect pest control: Evaluating efficacy, residues, and spray quality. Pest Manag. Sci. 2021, 77, 4980–4992. [Google Scholar] [CrossRef] [PubMed]

- Butts, T.R.; Samples, C.A.; Franca, L.X.; Dodds, D.M.; Reynolds, D.B.; Adams, J.A.; Zollinger, R.K.; Howatt, K.A.; Fritz, B.K.; Hoffman, W.C.; et al. Spray droplet size and carrier volume effect on dicamba and glufosinate efficacy. Pest. Manag. Sci. 2018, 74, 2020–2029. [Google Scholar] [CrossRef] [PubMed]

- ISO 22368-1; Crop protection Equipment—Test Methods for the Evaluation of Cleaning Systems—Part 1: Internal Cleaning of Complete Sprayers. ISO: Geneva, Switzerland, 2004.

- ISO 22368-2; Crop Protection Equipment—Test Methods for the Evaluation of Cleaning Systems—Part 2: External Cleaning of Sprayers. ISO: Geneva, Switzerland, 2004.

- ISO 22368-3; Crop Protection Equipment—Test Methods for the Evaluation of Cleaning Systems—Part 3: Internal Cleaning of Tank. ISO: Geneva, Switzerland, 2004.

- ISO/CD 23117-1; Agricultural and Forestry Machinery—Unmanned Aerial Spraying Systems—Part 1: Environmental Requirements. ISO: Geneva, Switzerland, 2023.

- About Temperature Inversions. Available online: https://mrcc.purdue.edu/climate_watch/special_topics/tempinversion/about-temperature-inversions (accessed on 2 April 2025).

- Pesticide Application Consideration with Spray Drones. University of Georgia Extension. Available online: https://site.extension.uga.edu/turnerab/2023/07/pesticide-application-considerations-with-spray-drones-simer-virk-and-steve-li/ (accessed on 2 April 2025).

- Grant, S.; Perine, J.; Abi-Akbar, F.; Lane, T.; Kent, B.; Mohler, C.; Scott, C.; Ritter, A. A Wind-Tunnel Assessment of Parameters That May Impact Spray Drift during UAV Pesticide Application. Drones 2022, 6, 204. [Google Scholar] [CrossRef]

- Grisso, R.; Hipkins, P.; Askew, S.; Hipkins, L.; McCall, D. Nozzles: Selection and Sizing. Virginia Cooperative Extension, Publication 443-032. Available online: https://vtpp.ento.vt.edu/content/dam/vtpp_ento_vt_edu/publications/NozzlesSelectionAndSizing.pdf (accessed on 20 March 2025).

- Martin, D.E. Challenges and Opportunities for Spray Drones in Agriculture. Available online: https://www.planthealthexchange.org/cotton/Documents/GROW-COT-12-24-488.pdf (accessed on 2 April 2025).

- Pesticide Drift. Factors Affecting Pesticide Drift. Kentucky Pesticide Education Program. Available online: https://www.uky.edu/Ag/Entomology/PSEP/pdfs/65drift.pdf (accessed on 2 April 2025).

- Wolf, T. Spraying Weather. Available online: https://www.uky.edu/Ag/Entomology/PSEP/pdfs/65drift.pdf (accessed on 2 April 2025).

- Basol, T. Be on the Watch for Temperature Inversions. Available online: https://crops.extension.iastate.edu/post/be-watch-temperature-inversions (accessed on 2 April 2025).

- Hiremath, C.; Khatri, N.; Jagtap, M.P. Comparative studies of knapsack, boom and drone sprayers for weed management in soybean (Glycine max L.). Environ. Res. 2024, 240, 117480. [Google Scholar] [CrossRef] [PubMed]

- Fram Size and Productivity. Our Worls in Data. Available online: https://ourworldindata.org/farm-size#:~:text=Most%20of%20the%20world’s%20farmers,than%20two%20hectares%20in%20size (accessed on 9 April 2025).

- Deveau, J. RPAS Coverage and Drift in Field Corn. Available online: https://sprayers101.com/drone_corn/ (accessed on 9 April 2025).

- Norsworthy, J.K.; Varanasi, V.K.; Bagavathainnan, M.; Brabham, C. Recurrent Selection with Sub-Lethal Doses of Mesotrione Reduces Sensitivity in Amaranthus palmeri. Plants 2021, 10, 1293. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Yu, F.; Zhang, Q.; Wang, M.; Yu, J.; Tan, Y. Advancements of UAV and Deep Learning Technologies for Weed Management in Farmland. Agronomy 2024, 14, 494. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).