Thermal Management for Unmanned Aerial Vehicle Payloads: Mechanisms, Systems, and Applications

Abstract

1. Introduction

2. Brief Overview of Temperature Control Systems for Drone Components

2.1. Advanced Insulation and Cooling Systems for High- and Low-Temperature Environments

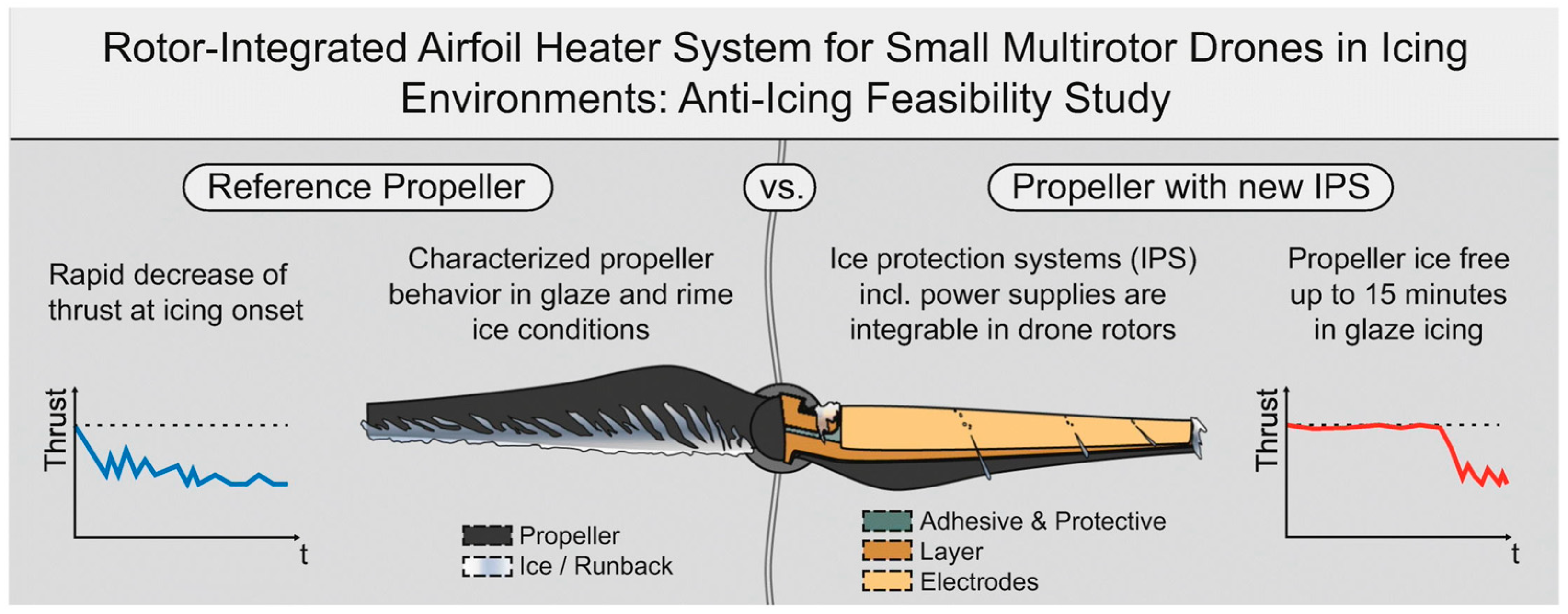

2.2. Anti-Icing Technologies for Rotor Blades

3. Temperature Control Mechanisms for Drone Payloads

3.1. Passive Control

3.2. Active Control

3.2.1. Active Cooling

3.2.2. Active Heating

4. Case Studies of Temperature-Sensitive Payloads Carried by UAVs

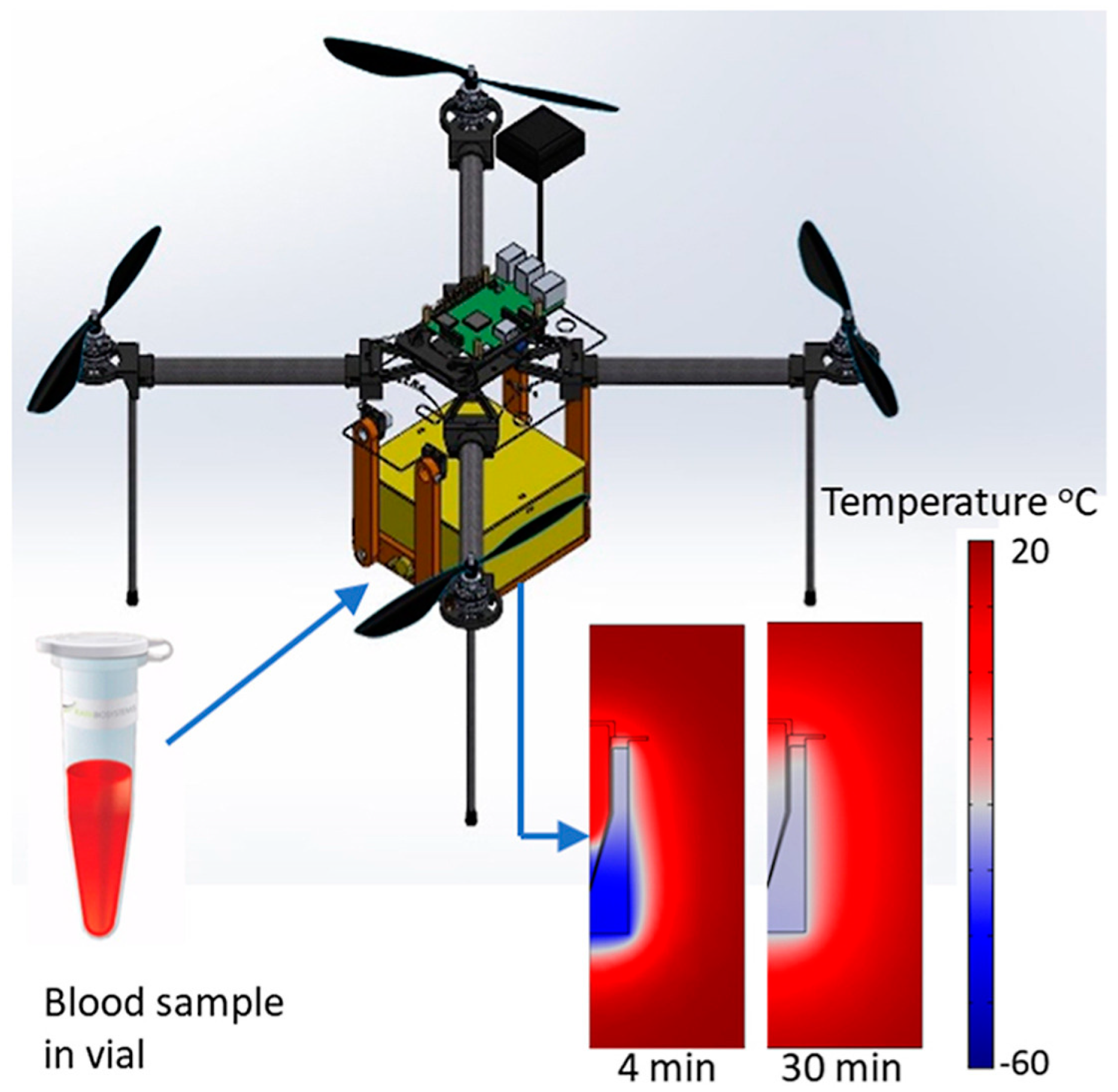

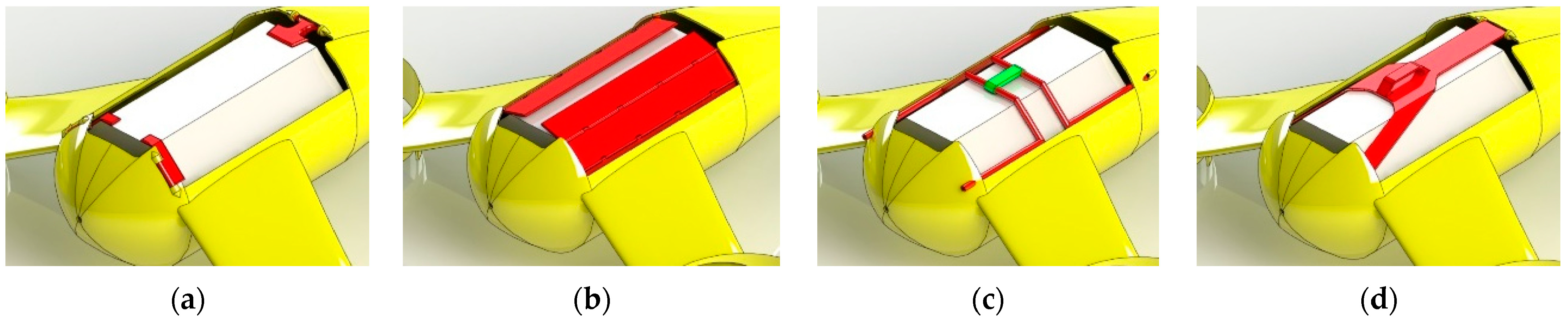

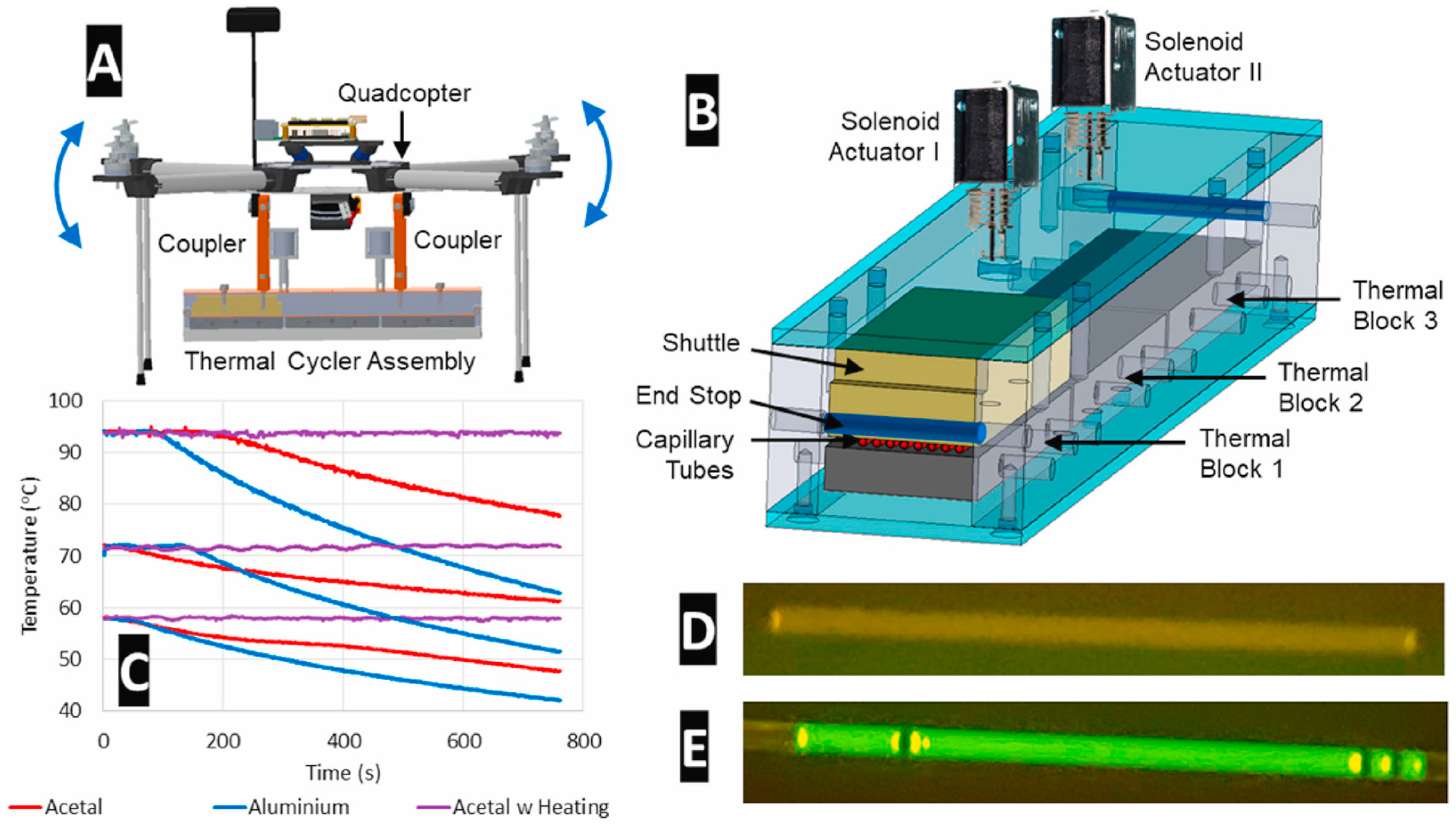

4.1. Blood

4.2. Vaccines

4.3. Organs

4.4. Medicines

4.5. Environmental Samples

5. Current Commercial Solutions

A Note on the Connection Between Academic Research and Commercial Solutions

6. Patents on Thermal Management for UAV Applications

6.1. Temperature Control of Payloads

6.2. Temperature Control of Drone Components

7. Challenges and Limitations

7.1. Regulatory Challenges

7.2. Payload Capacity Constraints: Thrust and Battery Limitations

7.3. Flight Range Challenges

7.4. Temperature Control Challenges

7.5. Battery Limitations

7.6. Environmental Impacts

7.7. Payload Safety from Overheating and Freezing Risks

8. Research Gaps, Future Trends and Directions

8.1. Gaps in State-of-the-Art

- Energy Consumption and Power Constraints: Active cooling and heating systems, particularly thermoelectric (Peltier) devices and resistive (Joule) heating elements, are essential for precise temperature regulation. However, these systems impose a substantial energy burden on the UAV. The extra power consumption not only reduces flight endurance but also necessitates larger battery capacities, which add weight and further compromise the payload-to-power balance. This trade-off between maintaining tight temperature control and sustaining efficient flight performance remains a major challenge.

- Added Weight and Payload Integration: The integration of thermal management systems introduces a significant weight penalty. While passive systems (using phase change materials and high-performance insulation) offer energy-efficient control, their added mass can reduce payload capacity and negatively affect the drone’s flight dynamics. Similarly, the integration of active cooling components increases not only the overall weight but also the design complexity, particularly when striving to maintain aerodynamic efficiency and operational stability. The current state-of-the-art has yet to fully overcome the implications of added weight on the overall UAV system performance.

- Heat Dissipation Efficiency and Insulation Performance: Although recent advances in insulation materials, such as aerogels and expanded polystyrene, have improved thermal resistance, achieving effective heat dissipation remains challenging. Enhanced insulation can minimize unwanted heat transfer but may also impede the efficient removal of accumulated thermal energy, especially under extreme or rapidly changing environmental conditions. This represents a critical gap where a delicate balance must be struck between insulating effectiveness and the ability to actively dissipate heat.

- Control and System Complexity: The evolution toward hybrid systems that merge passive insulation with active thermal control introduces significant system complexity. Current feedback control mechanisms, although promising, often struggle to dynamically adjust to the fluctuating thermal loads encountered during flight. The sophistication required to continuously manage such multi-modal systems, with demands for precision and reliability, poses substantial technical and manufacturing challenges. Achieving this balance is important, as overly complex systems may reduce overall reliability and complicate maintenance.

- Mission and Path Planning: Another key gap lies in the need for dedicated mission planning that explicitly accounts for thermal requirements alongside traditional flight parameters. Route selection, altitude, air speed, and overall flight duration can all be optimized to reduce thermal loads and conserve power for active thermal control. In many UAV delivery scenarios, relatively small adjustments in flight path or speed can significantly influence both battery consumption and the internal temperature profile of the payload compartment, especially under conditions with large ambient temperature swings or high wind loads. Integrating thermal considerations into path planning is critical to ensuring efficient power utilization while reliably maintaining target temperatures.

8.2. Future Directions

- Emerging solutions such as AI-enabled smart capsules are enhancing real-time temperature monitoring and climate control for medical payloads, such as vaccines, biologics, and organs [102]. These smart containers can autonomously adjust internal temperatures using feedback from embedded sensors, ensuring the integrity of temperature-sensitive payloads during transit. However, scaling such technologies for large-scale deployments faces significant challenges, including public acceptance of increased drone traffic and regulatory fragmentation across regions, which limits private investments and international operations.

- Advancements in drone power and propulsion systems are central to supporting active thermal management solutions. Hybrid power technologies, including lithium polymer (LiPo) batteries, hydrogen fuel cells, and supercapacitors (SCs), are enabling longer flight durations and higher energy efficiency, addressing the limitations of single-source power systems [103]. These hybrid power sources are particularly crucial for energy-intensive thermal control mechanisms such as Joule heating for warm payloads or Peltier-based cooling systems for vaccines and biologics. Additionally, optimized UAV propulsion systems leveraging these hybrid technologies hold potential for reducing recharge times and extending mission capabilities, which is vital for long-range deliveries of temperature-sensitive payloads. The emergence of solid-state batteries, with their higher energy density and longer lifespan, also offers a potential breakthrough in extending UAV flight durations. AI-driven flight management systems can further enhance autonomous decision-making, allowing drones to dynamically adapt flight paths to avoid hazards and optimize energy consumption.

- Battery thermal management systems (BTMSs) will become increasingly important as drones operate in diverse environmental conditions and carry high-power thermal control systems. Maintaining batteries within their ideal temperature range enhances efficiency, extends battery life, and ensures a continuous power supply for payload temperature regulation [104]. Techniques such as active cooling with heat exchangers, passive insulation with phase change materials, and hybrid liquid–air cooling, commonly used in electric vehicles, are being adapted for UAVs. Integrating BTMS with payload climate control systems will help maintain both battery and cargo temperatures during long flights, expanding the operational range of medical and pharmaceutical deliveries in extreme environments.

- The development of active climate control systems for payloads remains a significant research priority [105]. Current solutions rely heavily on passive methods, such as insulated containers, which are unsuitable for payloads requiring precise temperature control, such as biologics, diagnostic samples, and gene therapies. Innovations in miniaturized Peltier cooling modules, nested thermal chambers for ultra-cold storage, and AI-optimized temperature regulation are poised to address these gaps. Additionally, advancements beyond thermal management will play a crucial role in scaling UAV-based medical deliveries. High-precision navigation technologies, such as GPS and GNSS for accurate routing and LIDAR or RADAR for real-time obstacle detection and avoidance, are improving operational safety and reliability. Also, enhanced payload capabilities can enable the transport of diverse and fragile medical materials, from blood samples to entire organs for transplantation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Betti Sorbelli, F. UAV-Based Delivery Systems: A Systematic Review, Current Trends, and Research Challenges. ACM J. Auton. Transport. Syst. 2024, 1, 12:1–12:40. [Google Scholar] [CrossRef]

- Poljak, M.; Šterbenc, A. Use of Drones in Clinical Microbiology and Infectious Diseases: Current Status, Challenges and Barriers. Clin. Microbiol. Infect. 2020, 26, 425–430. [Google Scholar] [CrossRef]

- Zaffran, M.; Vandelaer, J.; Kristensen, D.; Melgaard, B.; Yadav, P.; Antwi-Agyei, K.O.; Lasher, H. The Imperative for Stronger Vaccine Supply and Logistics Systems. Vaccine 2013, 31, B73–B80. [Google Scholar] [CrossRef] [PubMed]

- Eksioglu, S.D.; Proano, R.A.; Kolter, M.; Nurre Pinkley, S. Designing Drone Delivery Networks for Vaccine Supply Chain: A Case Study of Niger. IISE Trans. Healthc. Syst. Eng. 2024, 14, 193–213. [Google Scholar] [CrossRef]

- Enayati, S.; Li, H.; Campbell, J.F.; Pan, D. Multimodal Vaccine Distribution Network Design with Drones. Transp. Sci. 2023, 57, 1069–1095. [Google Scholar] [CrossRef]

- Gunaratne, K.; Thibbotuwawa, A.; Vasegaard, A.E.; Nielsen, P.; Perera, H.N. Unmanned Aerial Vehicle Adaptation to Facilitate Healthcare Supply Chains in Low-Income Countries. Drones 2022, 6, 321. [Google Scholar] [CrossRef]

- Aggarwal, S.; Balaji, S.; Gupta, P.; Mahajan, N.; Nigam, K.; Singh, K.J.; Bhargava, B.; Panda, S. Enhancing Healthcare Access: Drone-Based Delivery of Medicines and Vaccines in Hard-to-Reach Terrains of Northeastern India. Prev. Med. Res. Rev. 2024, 1, 172. [Google Scholar] [CrossRef]

- Griffith, E.F.; Schurer, J.M.; Mawindo, B.; Kwibuka, R.; Turibyarive, T.; Amuguni, J.H. The Use of Drones to Deliver Rift Valley Fever Vaccines in Rwanda: Perceptions and Recommendations. Vaccines 2023, 11, 605. [Google Scholar] [CrossRef]

- Homier, V.; Brouard, D.; Nolan, M.; Roy, M.-A.; Pelletier, P.; McDonald, M.; de Champlain, F.; Khalil, E.; Grou-Boileau, F.; Fleet, R. Drone versus Ground Delivery of Simulated Blood Products to an Urban Trauma Center: The Montreal Medi-Drone Pilot Study. J. Trauma Acute Care Surg. 2021, 90, 515. [Google Scholar] [CrossRef]

- Häusermann, D.; Bodry, S.; Wiesemüller, F.; Miriyev, A.; Siegrist, S.; Fu, F.; Gaan, S.; Koebel, M.M.; Malfait, W.J.; Zhao, S.; et al. FireDrone: Multi-Environment Thermally Agnostic Aerial Robot. Adv. Intell. Syst. 2023, 5, 2300101. [Google Scholar] [CrossRef]

- Xu; Chen; Wang; Zhang; Zhang. Thermal Management Study of UAV Fuel-Environment Control System. In Proceedings of the CSAA/IET International Conference on Aircraft Utility Systems (AUS 2022), Nanching, China, 17–20 August 2022; Volume 2022, pp. 1107–1112. [Google Scholar] [CrossRef]

- Karpen, N.; Diebald, S.; Dezitter, F.; Bonaccurso, E. Propeller-Integrated Airfoil Heater System for Small Multirotor Drones in Icing Environments: Anti-Icing Feasibility Study. Cold Reg. Sci. Technol. 2022, 201, 103616. [Google Scholar] [CrossRef]

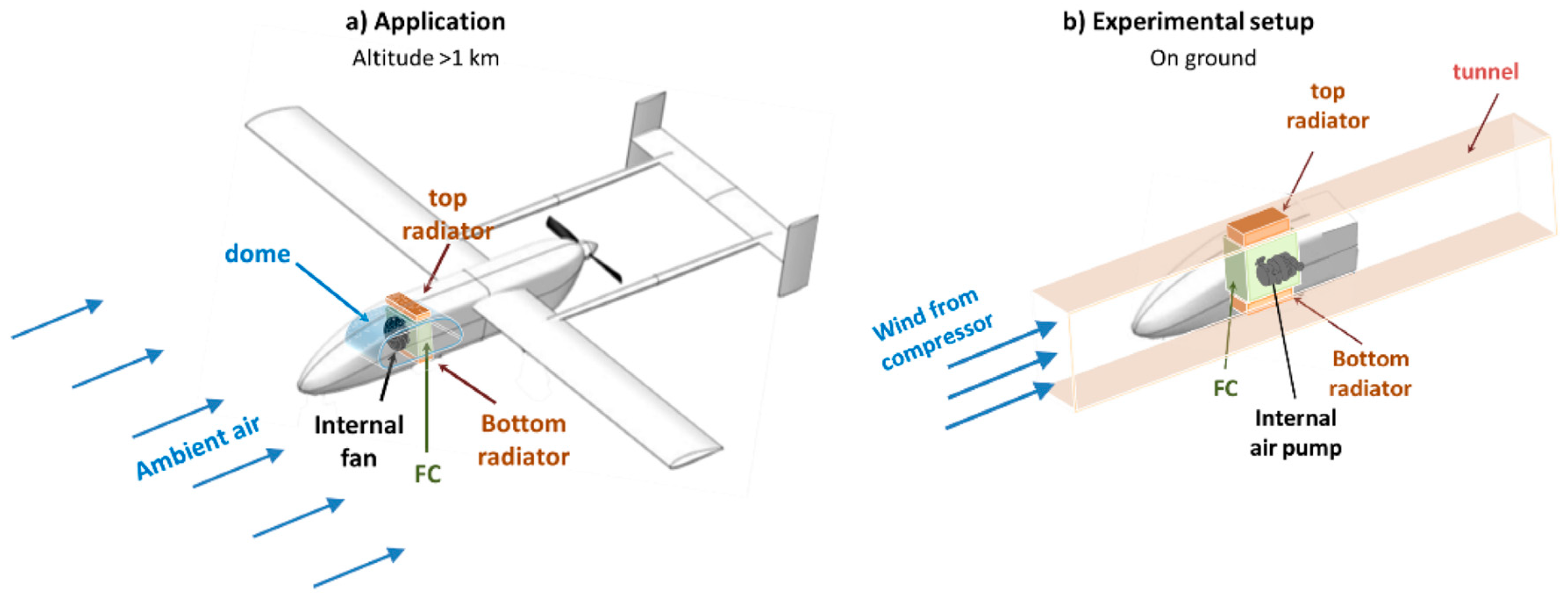

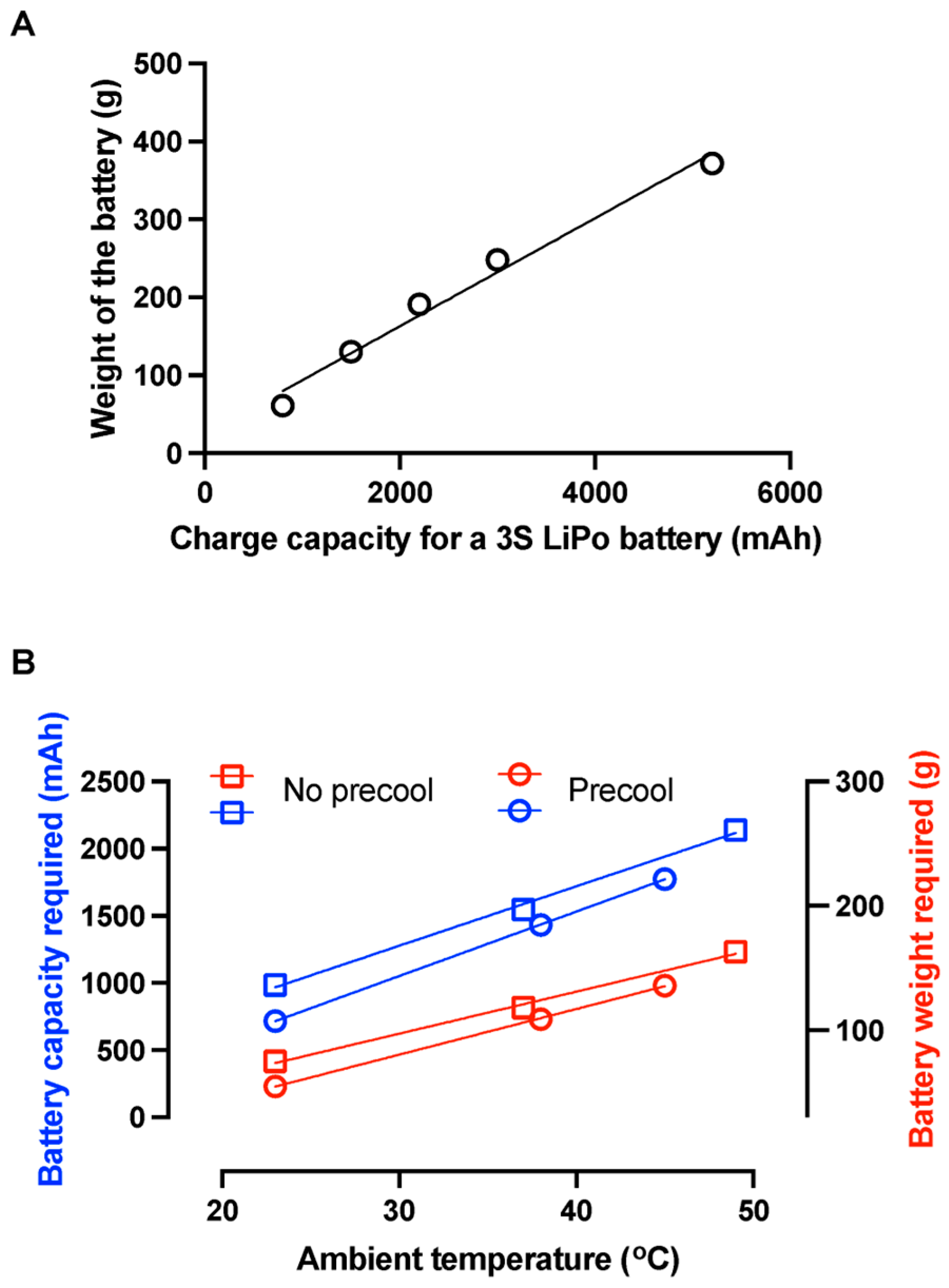

- Pamula, G.; Pamula, L.; Ramachandran, A. Design and Characterization of an Active Cooling System for Temperature-Sensitive Sample Delivery Applications Using Unmanned Aerial Vehicles. Drones 2024, 8, 270. [Google Scholar] [CrossRef]

- Bertran, E.; Sanchez-Cerda, A. On the Tradeoff Between Electrical Power Consumption and Flight Performance in Fixed-Wing UAV Autopilots. IEEE Trans. Veh. Technol. 2016, 65, 8832–8840. [Google Scholar] [CrossRef]

- Bakirci, M. Efficient Air Pollution Mapping in Extensive Regions with Fully Autonomous Unmanned Aerial Vehicles: A Numerical Perspective. Sci. Total Environ. 2024, 909, 168606. [Google Scholar] [CrossRef]

- Hwang, M.; Cha, H.-R.; Jung, S.Y. Practical Endurance Estimation for Minimizing Energy Consumption of Multirotor Unmanned Aerial Vehicles. Energies 2018, 11, 2221. [Google Scholar] [CrossRef]

- Ivanov, K.; Belovski, I.; Aleksandrov, A. Design, Building and Study of a Small-Size Portable Thermoelectric Refrigerator for Vaccines. In Proceedings of the 2021 17th Conference on Electrical Machines, Drives and Power Systems (ELMA), Sofia, Bulgaria, 1–4 July 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Kostin, A.S.; Silin, Y.A. Development of an Insulated Container for the Implementation of the Delivery of Special Cargo Using an Unmanned Aerial System. In Proceedings of the 2022 Wave Electronics and its Application in Information and Telecommunication Systems (WECONF), St. Petersburg, Russia, 30 May–3 June 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Tanda, G. Cooling Solutions for an Electronic Equipment Box Operating on UAV Systems under Transient Conditions. Int. J. Therm. Sci. 2020, 152, 106286. [Google Scholar] [CrossRef]

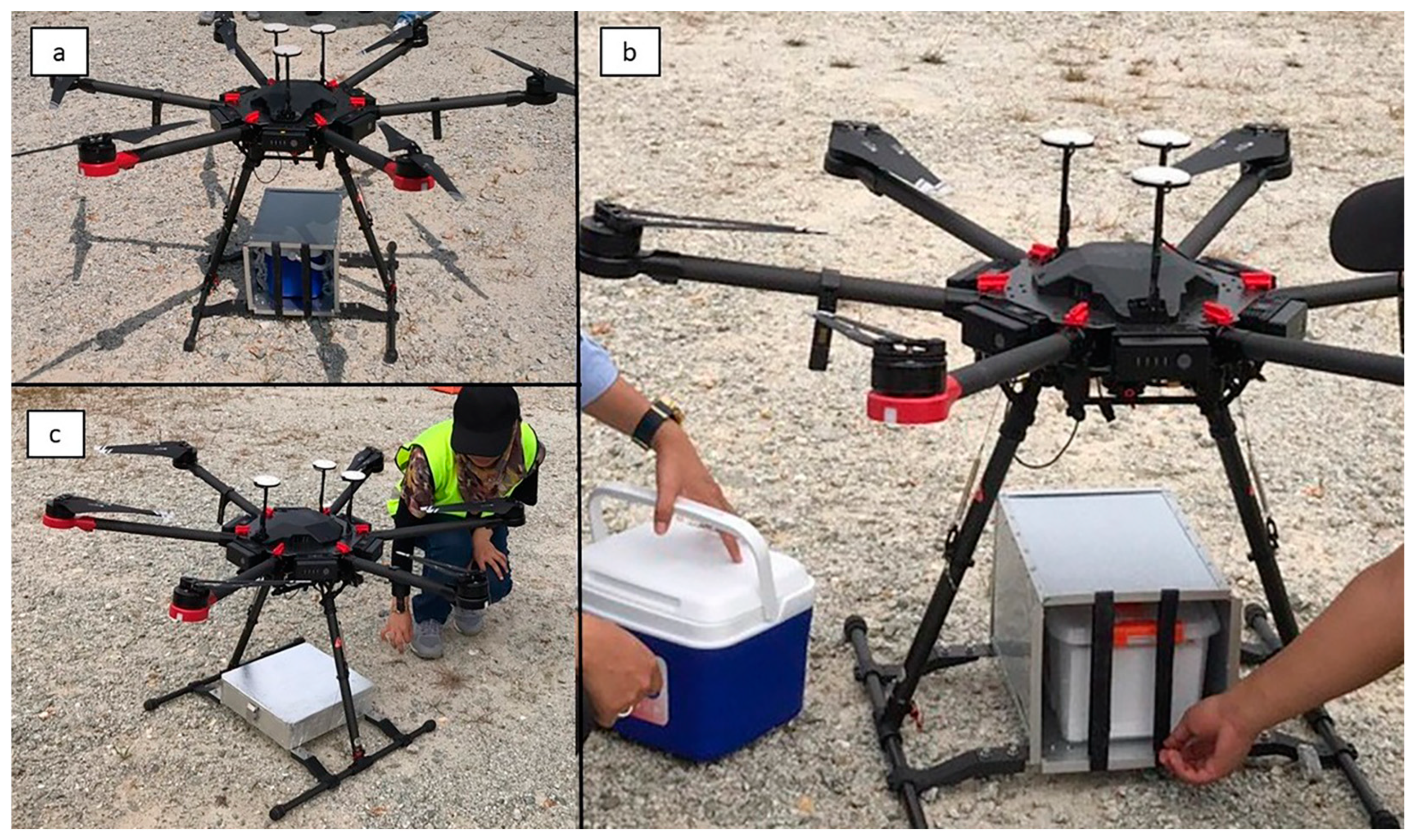

- Ong, J.W.; Abid, H.A.; Minifie, T.; Lin, E.S.; Song, Z.; Katariya, M.; Liew, O.W.; Ng, T.W. Unmanned Aerial Vehicle Transport of Frozen Blood Samples Using Phase Change Materials. Biosyst. Eng. 2022, 221, 30–42. [Google Scholar] [CrossRef]

- Kokate, R.; Virk, A.S.; Park, C.; Mitsingas, C.; Johnson, M.; Kweon, C.-B. Study of Phase Change Thermal Management Architecture for Series-Hybrid Powertrain in Unmanned Aerial Vehicles; SAE Technical Paper 2023-01-0130; SAE International: Detroit, MI, USA, 2023. [Google Scholar] [CrossRef]

- Saponi, M.; Borboni, A.; Adamini, R.; Faglia, R.; Amici, C. Embedded Payload Solutions in UAVs for Medium and Small Package Delivery. Machines 2022, 10, 737. [Google Scholar] [CrossRef]

- Cattin, M.; Jonnalagedda, S.; Makohliso, S.; Schönenberger, K. The Status of Refrigeration Solutions for Last Mile Vaccine Delivery in Low-Income Settings. Vaccine X 2022, 11, 100184. [Google Scholar] [CrossRef]

- Sharma, S.; Dwivedi, V.K.; Pandit, S.N. A Review of Thermoelectric Devices for Cooling Applications. Int. J. Green Energy 2014, 11, 899–909. [Google Scholar] [CrossRef]

- Maity, S.; Aakriti, J.; Manandhar, S.; Anchan, S.B.; Bhat, A.; Shetty, M.U.; Nayak, Y. Emvolio—A Battery Operated Portable Refrigerator Preserves Biochemical and Haematological Integrity of Biological Samples in Preclinical Studies. F1000Res 2022, 11, 223. [Google Scholar] [CrossRef] [PubMed]

- Benmoussa, A.; Gamboa, P.V. Effect of Control Parameters on Hybrid Electric Propulsion UAV Performance for Various Flight Conditions: Parametric Study. Appl. Mech. 2023, 4, 493–513. [Google Scholar] [CrossRef]

- Lee, S.; Kwon, Y. Development of Drone Cargo Bay with Real-Time Temperature Control. Drone Cargo Bay with Real-Time Temperature Control. World J. Eng. Technol. 2019, 07, 612–621. [Google Scholar] [CrossRef]

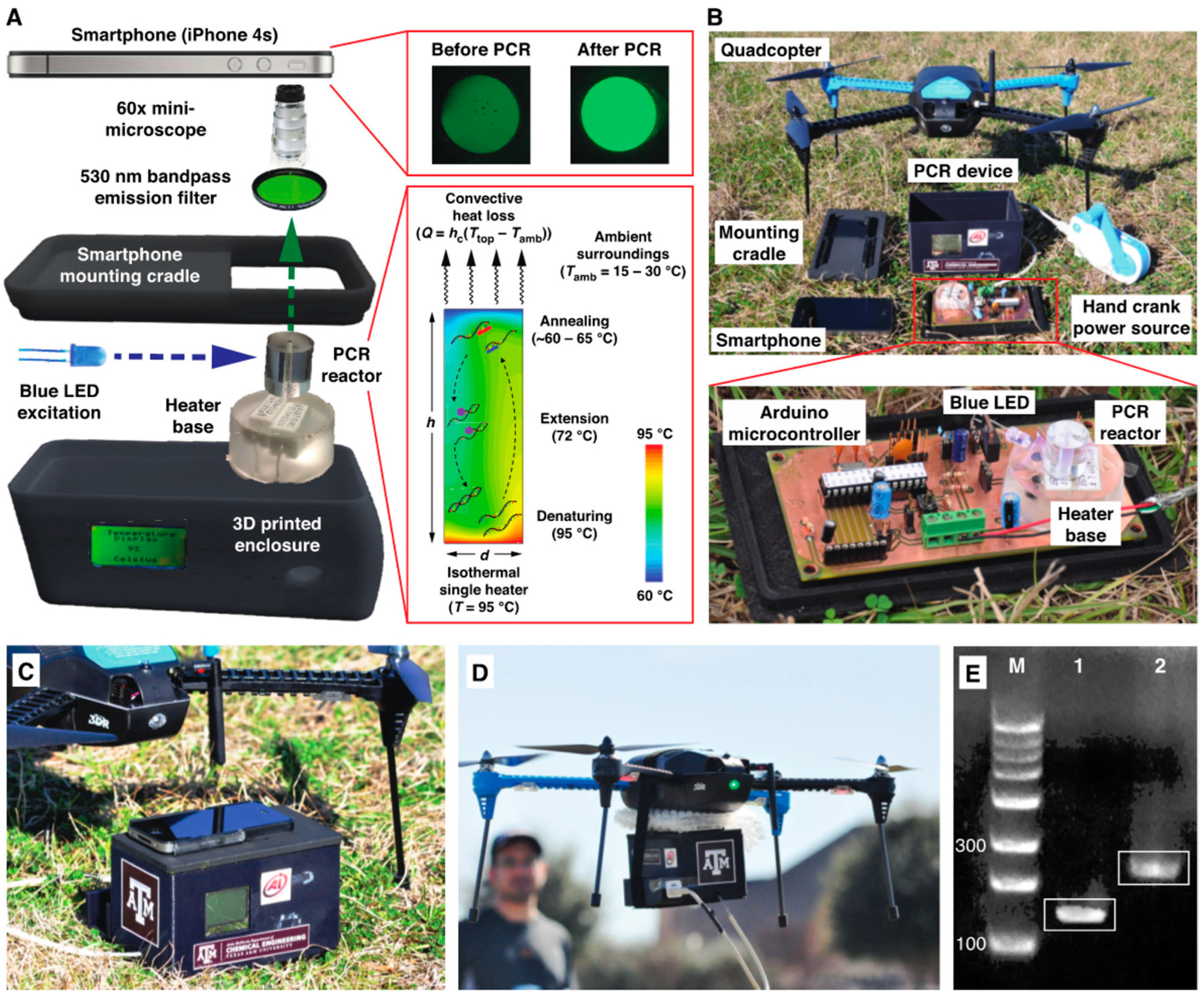

- Abid, H.A.; Minifie, T.; Ong, J.W.; Lin, E.S.; Song, Z.; Liew, O.W.; Ng, T.W. Inflight Polymerase Chain Reaction of Samples with Drones. Anal. Biochem. 2021, 616, 114098. [Google Scholar] [CrossRef]

- Priye, A.; Wong, S.; Bi, Y.; Carpio, M.; Chang, J.; Coen, M.; Cope, D.; Harris, J.; Johnson, J.; Keller, A.; et al. Lab-on-a-Drone: Toward Pinpoint Deployment of Smartphone-Enabled Nucleic Acid-Based Diagnostics for Mobile Health Care. Anal. Chem. 2016, 88, 4651–4660. [Google Scholar] [CrossRef]

- De Silvestri, S.; Capasso, P.J.; Gargiulo, A.; Molinari, S.; Sanna, A. Challenges for the Routine Application of Drones in Healthcare: A Scoping Review. Drones 2023, 7, 685. [Google Scholar] [CrossRef]

- Geronel, R.S.; Begnini, G.R.; Botez, R.M.; Bueno, D.D. An Overview on the Use of Unmanned Aerial Vehicles for Medical Product Transportation: Flight Dynamics and Vibration Issues. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 349. [Google Scholar] [CrossRef]

- Kitchen, S.; Adcock, D.M.; Dauer, R.; Kristoffersen, A.-H.; Lippi, G.; Mackie, I.; Marlar, R.A.; Nair, S. International Council for Standardization in Haematology (ICSH) Recommendations for Processing of Blood Samples for Coagulation Testing. Int. J. Lab. Hematol. 2021, 43, 1272–1283. [Google Scholar] [CrossRef]

- Pierre, C.; Wiencek, J. Sample Delivery to the Clinical Lab Neither Heat Nor Snow Nor Gravitational Force. Available online: https://myadlm.org/cln/articles/2021/june/sample-delivery-to-the-clinical-lab-neither-heat-nor-snow-nor-gravitational-force (accessed on 28 December 2024).

- Dhote, J.; Limbourg, S. Designing Unmanned Aerial Vehicle Networks for Biological Material Transportation—The Case of Brussels. Comput. Ind. Eng. 2020, 148, 106652. [Google Scholar] [CrossRef]

- Yakushiji, F.; Yakushiji, K.; Murata, M.; Hiroi, N.; Takeda, K.; Fujita, H. The Quality of Blood Is Not Affected by Drone Transport: An Evidential Study of the Unmanned Aerial Vehicle Conveyance of Transfusion Material in Japan. Drones 2020, 4, 4. [Google Scholar] [CrossRef]

- Zailani, M.A.H.; Raja Sabudin, R.Z.A.; Ismail, A.; Abd Rahman, R.; Mohd Saiboon, I.; Sabri, S.I.; Seong, C.K.; Mail, J.; Md Jamal, S.; Beng, G.K.; et al. Influence of Drone Carriage Material on Maintenance of Storage Temperature and Quality of Blood Samples during Transportation in an Equatorial Climate. PLoS ONE 2022, 17, e0269866. [Google Scholar] [CrossRef] [PubMed]

- Niglio, F.; Comite, P.; Cannas, A.; Pirri, A.; Tortora, G. Preliminary Clinical Validation of a Drone-Based Delivery System in Urban Scenarios Using a Smart Capsule for Blood. Drones 2022, 6, 195. [Google Scholar] [CrossRef]

- Liu, R.; Pitruzzello, G.; Rosa, M.; Battisti, A.; Cerri, C.; Tortora, G. Towards an Innovative Sensor in Smart Capsule for Aerial Drones for Blood and Blood Component Delivery. Micromachines 2022, 13, 1664. [Google Scholar] [CrossRef]

- King, J. Drone Compatible Medical Transportation Pod Design, Development and Testing. Available online: https://www.cit.ie/contentfiles/seanf/James%20King%20MediPod%20Essay.pdf (accessed on 5 April 2025).

- Maity, N.M. Lightweight Thermal Insulation Systems in Medical Delivery Drones. In Proceedings of the 2021 IEEE Aerospace Conference (50100), Big Sky, MT, USA, 6–13 March 2021; pp. 1–7. [Google Scholar] [CrossRef]

- Amukele, T.K.; Sokoll, L.J.; Pepper, D.; Howard, D.P.; Street, J. Can Unmanned Aerial Systems (Drones) Be Used for the Routine Transport of Chemistry, Hematology, and Coagulation Laboratory Specimens? PLoS ONE 2015, 10, e0134020. [Google Scholar] [CrossRef]

- Amukele, T.K.; Hernandez, J.; Snozek, C.L.; Wyatt, R.G.; Douglas, M.; Amini, R.; Street, J. Drone Transport of Chemistry and Hematology Samples Over Long Distances. Am. J. Clin. Pathol. 2017, 148, 427–435. [Google Scholar] [CrossRef] [PubMed]

- Amukele, T.; Ness, P.M.; Tobian, A.A.R.; Boyd, J.; Street, J. Drone Transportation of Blood Products. Transfusion 2017, 57, 582–588. [Google Scholar] [CrossRef] [PubMed]

- Peltier, G.C.; Meledeo, M.A. The Impact of Delivery by a Fixed-Wing, Sling-Launched Unmanned Aerial Vehicle on the Hematologic Function of Whole Blood. J. Trauma Acute Care Surg 2023, 95, S152–S156. [Google Scholar] [CrossRef]

- CDC. HANDLE WITH CARE: Protect Your Vaccine, Protect Your Patients, 2024. Available online: https://www.cdc.gov/vaccines/hcp/storage-handling/resources.html (accessed on 28 December 2024).

- Blount, W. Temperature Controlled Transport of Vaccines by Drone In Developing Countries, Georgia Institute of Technology, 2018. Available online: http://hdl.handle.net/1853/59653 (accessed on 22 December 2024).

- Gee, M.; Lopez, H.; Magana, V. SkyPort: Payload: Medical Cooler for the Skyport UAV. Mechanical Engineering. Bachelor’s Senior Thesis, Santa Clara University, Santa Clara, CA, USA, 2015. [Google Scholar]

- D’Alessandro, D.; Meyer, D.; Pham, S.; Stukov, Y.; Jacobs, J.; Vidic, A.; Zuckermann, A. Determination of the Optimal Temperature for Organ Preservation through Analysis of the Guardian Registry. J. Heart Lung Transplant. 2024, 43, S156–S157. [Google Scholar] [CrossRef]

- Sankaran, V.; Alagumariappan, P.; Esakki, B.; Choi, J.; Hameed, M.T.K.S.; Pittu, P.S.K.R. Devising an Internet of Things-Based Healthcare Medical Container for the Transportation of Organs and Healthcare Products Using Unmanned Aerial Vehicles. Eng. Proc. 2023, 58, 16. [Google Scholar] [CrossRef]

- Scalea, J.R.; Restaino, S.; Scassero, M.; Blankenship, G.; Bartlett, S.T.; Wereley, N. An Initial Investigation of Unmanned Aircraft Systems (UAS) and Real-Time Organ Status Measurement for Transporting Human Organs. IEEE J. Transl. Eng. Health Med. 2018, 6, 1–7. [Google Scholar] [CrossRef]

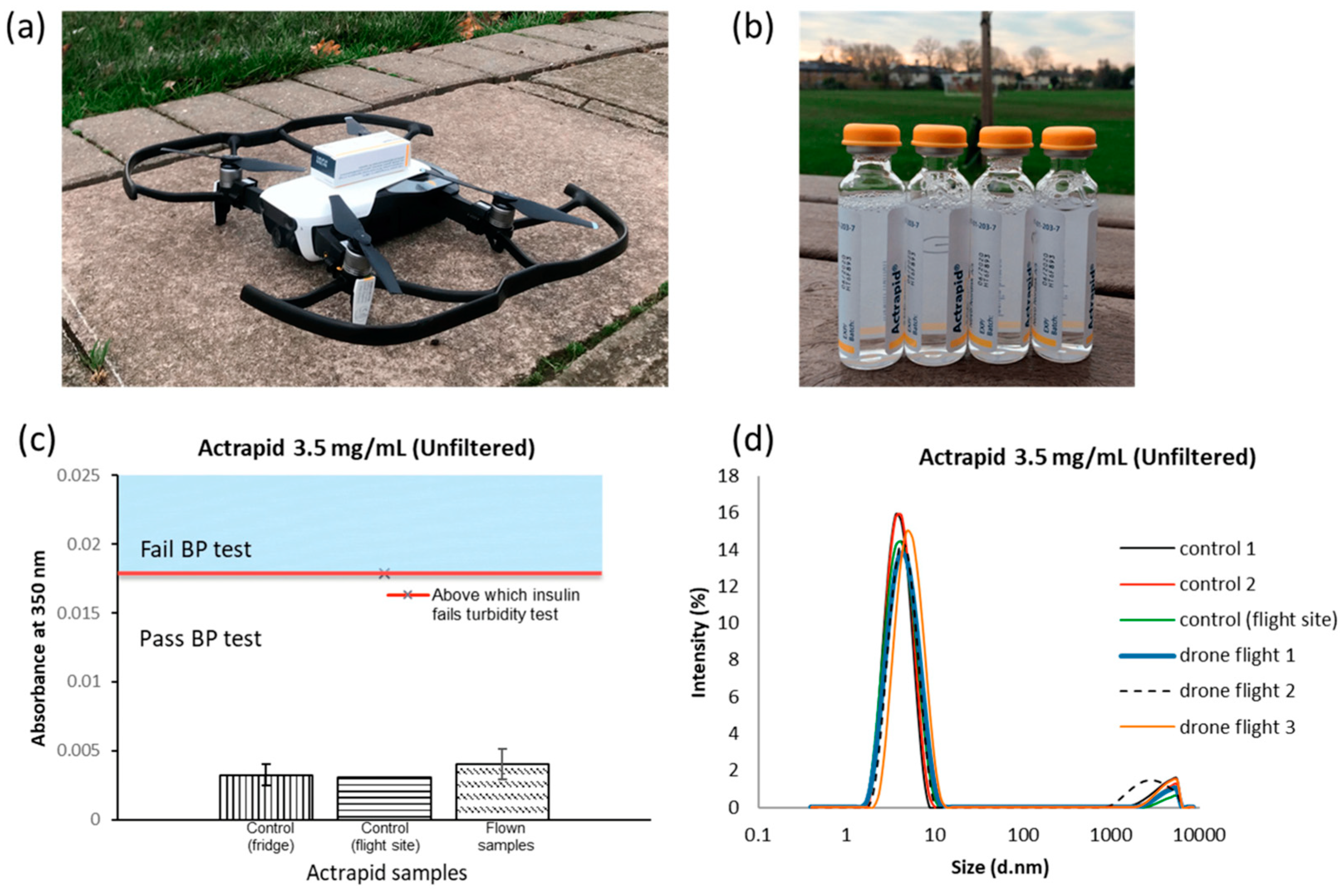

- Hii, M.; Courtney, P.; Royall, P. An Evaluation of the Delivery of Medicines Using Drones. Drones 2019, 3, 52. [Google Scholar] [CrossRef]

- Theobald, K.; Zhu, W.; Waters, T.; Cherrett, T.; Oakey, A.; Royall, P.G. Stability of Medicines Transported by Cargo Drones: Investigating the Effects of Vibration from Multi-Stage Flight. Drones 2023, 7, 658. [Google Scholar] [CrossRef]

- Carlson, D.F.; Pasma, J.; Jacobsen, M.E.; Hansen, M.H.; Thomsen, S.; Lillethorup, J.P.; Tirsgaard, F.S.; Flytkjær, A.; Melvad, C.; Laufer, K.; et al. Retrieval of Ice Samples Using the Ice Drone. Front. Earth Sci. 2019, 7, 287. [Google Scholar] [CrossRef]

- Mohsan, S.A.H.; Khan, M.A.; Noor, F.; Ullah, I.; Alsharif, M.H. Towards the Unmanned Aerial Vehicles (UAVs): A Comprehensive Review. Drones 2022, 6, 147. [Google Scholar] [CrossRef]

- SkyDrop Grounds Its Fleet. sUAS News. Available online: https://www.suasnews.com/2024/02/skydrop-grounds-its-fleet/ (accessed on 24 December 2024).

- Thomsen, S. Drone Delivery Startup Swoop Aero Lands in Liquidation. Startup Daily. Available online: https://www.startupdaily.net/topic/business/drone-delivery-startup-swoop-aero-lands-in-liquidation/ (accessed on 24 December 2024).

- Twilley, N. There Will be Cooler Ways of Keeping Food Fresh—The Boston Globe. BostonGlobe.com. Available online: https://www.bostonglobe.com/2024/11/30/opinion/refrigeration-cold-chain-climate-impact/ (accessed on 23 December 2024).

- Perry, P.; Laszlo, Z.; Parker, S.; Goldsberry, N.; Wade, B.; Wyrobek, K.; Boomgaard, B.; Li, Z.; Blaser, S. Unmanned Aircraft System with Swappable Components. US10988253B2, 27 April 2021. Available online: https://patents.google.com/patent/US10988253B2 (accessed on 24 December 2024).

- Fullerton, L. Domino’s Drone Delivers Hot Pizza in Less Than 30 min. The Drum. Available online: https://www.thedrum.com/news/2016/09/05/dominos-drone-delivers-hot-pizza-less-30-minutes (accessed on 23 December 2024).

- Dave, P. Amazon’s Delivery Drones Won’t Fly in Arizona’s Summer Heat. Wired. Available online: https://www.wired.com/story/amazon-delivery-drones-heat-grounded-summer/ (accessed on 23 December 2024).

- Sopper, C.; Woodworth, A. Inflatable Packaging for Use With UAV. US20190047707A1, 14 February 2019. Available online: https://patents.google.com/patent/US20190047707A1 (accessed on 23 December 2024).

- Payloads. Matternet.com. Available online: https://www.matternet.com/our-system-payloads (accessed on 24 December 2024).

- Raptopoulos, A.; Resmini, P.; Baruchin, I.; Ruiz, L.; Weldon, D.; Byars, J.; O’Sullivan, J.; Wu, A.; Tsai, D.; Novak, M. Ground Station for Unmanned Aerial Vehicles. US20210276735A1, 9 September 2021. Available online: https://patents.google.com/patent/US20210276735A1 (accessed on 24 December 2024).

- Lee, S. Saving Lives, One Drone Delivery at a Time. DHL Logistics of Things. Available online: https://lot.dhl.com/saving-lives-one-drone-delivery-at-a-time/ (accessed on 24 December 2024).

- Scheer, A.; Dautz, C.; Fischer, L. Consignment Drop-Off at Mobile Transport Units. US20210018922A1, 21 January 2021. Available online: https://patents.google.com/patent/US20210018922A1 (accessed on 24 December 2024).

- Mangelsen, J.; MERCHANT, R. Aerial Delivery Packages. US20220089354A1, 24 March 2022. Available online: https://patents.google.com/patent/US20220089354A1/en#citedBy (accessed on 25 December 2024).

- Pamula, G.; Pamula, L.; Mathur, J.; Pamula, V. Sample Processing Unit (SPU)-Equipped Drone for Transporting and Processing Biological Materials and Method of Using Same. US11965874B2, 23 April 2024. Available online: https://patents.google.com/patent/US11965874B2/ (accessed on 18 December 2024).

- Pamula, G.; Pamula, L.; Pamula, V. Mini Freezer-Equipped Drone for Transporting Biological Materials and Method of Using Same. US20230331405A1, 19 October 2023. Available online: https://patents.google.com/patent/US20230331405A1/ (accessed on 18 December 2024).

- Gentry, N.K. Temperature-Controlled Payload Container. US10207804B1, 19 February 2019. Available online: https://patents.google.com/patent/US10207804B1 (accessed on 22 December 2024).

- Jonghyun Kim, Youngbae Jeon, KooMoon Jung. Heating and cooling devices of drones. KR101778883B1, 14 September 2017. Available online: https://patents.google.com/patent/KR101778883B1/en (accessed on 22 December 2024).

- Cantrell, R.; Winkle, D. Temperature-Controlled UAV Storage System. US10639956B2, 5 May 2020. Available online: https://patents.google.com/patent/US10639956B2/ (accessed on 22 December 2024).

- Skiba, B.; Witzke, T.; Solomon, C.; Skiba, J. Organ and Fluid Preservation and Transportation Container and Docking System. US20220174943A1, 9 June 2022. Available online: https://patents.google.com/patent/US20220174943A1 (accessed on 22 December 2024).

- Ghoshal, U.; Noska, B.L. Nested Freezers for Storage and Transportation of Covid Vaccine. US20220163242A1, 26 May 2022. Available online: https://patents.google.com/patent/US20220163242A1 (accessed on 22 December 2024).

- Kang, K.K.; Jang, J.I.; Park, H.M.; Lee, J.S. Drone with Cooling Function. KR102285303B1, 4 August 2021. Available online: https://patents.google.com/patent/KR102285303B1/en (accessed on 22 December 2024).

- De, M.D. Gemodificeerde Koelcontainer Voor Gekoeld Transport via Gemotoriseerd Transport Waaronder een Drone en/of Een Motorfiets. BE1026942B1, 28 July 2020. Available online: https://patents.google.com/patent/BE1026942B1 (accessed on 23 December 2024).

- Tortora, G.R.; Cannas, A. Drone Structure for the Transport of Temperature-Controlled Material. US11257385B2, 22 February 2022. Available online: https://patents.google.com/patent/US11257385B2 (accessed on 22 December 2024).

- Lepek, H.; COHEN, D.E. System and Method for Automated Cooling Storage Transport and Release of Beneficial Insects. US20230389514A1, 7 December 2023. Available online: https://patents.google.com/patent/US20230389514A1 (accessed on 23 December 2024).

- Meredith, J.S.; Burleson, T.J.; Caldwell, K.D.; Mattingly, T. Pizza Cooking Delivery Drone. US20190202557A1, 4 July 2019. Available online: https://patents.google.com/patent/US20190202557A1 (accessed on 23 December 2024).

- Winkle, D.C.; Wilkinson, B.W.; Mattingly, T.D. Systems and Methods for Delivering Perishable Items. US10240846B2, 26 March 2019. Available online: https://patents.google.com/patent/US10240846B2 (accessed on 24 December 2024).

- Pargoe, B.T. Systems, Devices, and/or Methods for Managing Drone Deliveries. US10210475B2, 19 February 2019. Available online: https://patents.google.com/patent/US10210475B2 (accessed on 23 December 2024).

- Tremblay, S.; Bharucha, E. Multifunctional Motorized Box and Landing Pad for Automatic Drone Package Delivery. US10377507B2, 13 August 2019. Available online: https://patents.google.com/patent/US10377507B2 (accessed on 23 December 2024).

- Haskin, M.; Legrand, L.L., III; RAN, U. Unmanned Aerial Vehicle Payload Delivery. US9650136B1, 16 May 2017. Available online: https://patents.google.com/patent/US9650136B1 (accessed on 22 December 2024).

- Wang, P.; Rosales, J.L.; Chiriac, V.A. Multi-Rotor Aerial Drone with Thermal Energy Harvesting. US20190061970A1, 28 February 2019. Available online: https://patents.google.com/patent/US20190061970A1 (accessed on 22 December 2024).

- Flowers, J.B. Vehicle with Vibration Isolated Electronics. US11054193B2, 6 July 2021. Available online: https://patents.google.com/patent/US11054193B2 (accessed on 23 December 2024).

- Prager, A.; Gu, K. Delivery of Temperature-Sensitive Items. US11410114B2, 9 August 2022. Available online: https://patents.google.com/patent/US11410114B2 (accessed on 22 December 2024).

- Twyford, E.; Qiu, I.; Juma, J. Air Scoop Solar Shield for UAV. US12110139B2, 8 October 2024. Available online: https://patents.google.com/patent/US12110139B2 (accessed on 23 December 2024).

- Nubbe, M. Active Thermal Control of UAV Energy Storage Units. US12119472B2, 15 October 2024. Available online: https://patents.google.com/patent/US12119472B2 (accessed on 23 December 2024).

- Khattar, P. System and Method for Preconditioning Batteries of Unmanned Aerial Vehicles. US11654794B1, 23 May 2023. Available online: https://patents.google.com/patent/US11654794B1 (accessed on 24 December 2024).

- Gil, J.; Ganesh, B.; Ramsager, T. Drone Delivery Platform to Facilitate Delivery of Parcels by Unmanned Aerial Vehicles. US10993569B2, 4 May 2021. Available online: https://patents.google.com/patent/US10993569B2 (accessed on 24 December 2024).

- Zakhvatkin, L.; Schechter, A.; Buri, E.; Avrahami, I. Edge Cooling of a Fuel Cell during Aerial Missions by Ambient Air. Micromachines 2021, 12, 1432. [Google Scholar] [CrossRef]

- Cornew, T.M.; Kabir, M.H.; Monti, B.S. Docking Station for an Aerial Drone. US20240343426A1, 17 October 2024. [Google Scholar]

- Quadrat, Q.; Chaperon, C.; Seydoux, H. Drone Including Advance Means for Compensating the Bias of the Inertial Unit as a Function of the Temperature. US10191080B2, 29 January 2019. [Google Scholar]

- Technical Instructions for the Safe Transport of Dangerous Goods by Air (Doc 9284). Available online: https://www.icao.int/safety/DangerousGoods/Pages/Doc9284-Technical-Instructions.aspx (accessed on 27 December 2024).

- Guidance on Regulations for the Transport of Infectious Substances, 2023–2024. Available online: https://www.who.int/publications/i/item/789240089525 (accessed on 27 December 2024).

- Good Distribution Practice|European Medicines Agency (EMA). Available online: https://www.ema.europa.eu/en/human-regulatory-overview/post-authorisation/compliance-post-authorisation/good-distribution-practice (accessed on 27 December 2024).

- Perishable Cargo Regulations (PCR). Available online: https://www.iata.org/en/publications/manuals/perishable-cargo-regulations/ (accessed on 27 December 2024).

- Chen, W.; Zou, Y.; Mo, W.; Di, D.; Wang, B.; Wu, M.; Huang, Z.; Hu, B. Onsite Identification and Spatial Distribution of Air Pollutants Using a Drone-Based Solid-Phase Microextraction Array Coupled with Portable Gas Chromatography-Mass Spectrometry via Continuous-Airflow Sampling. Environ. Sci. Technol. 2022, 56, 17100–17107. [Google Scholar] [CrossRef]

- Grandy, J.J.; Galpin, V.; Singh, V.; Pawliszyn, J. Development of a Drone-Based Thin-Film Solid-Phase Microextraction Water Sampler to Facilitate On-Site Screening of Environmental Pollutants. Anal. Chem. 2020, 92, 12917–12924. [Google Scholar] [CrossRef]

- Ouyang, Z.; Nikolaidis, T.; Jafari, S. Integrated Power and Thermal Management Systems for Civil Aircraft: Review, Challenges, and Future Opportunities. Appl. Sci. 2024, 14, 3689. [Google Scholar] [CrossRef]

- Beneitez Ortega, C.; Zimmer, D.; Weber, P. Thermal Analysis of a High-Altitude Solar Platform. CEAS Aeronaut. J. 2023, 14, 243–254. [Google Scholar] [CrossRef]

- Coutinho, M.; Afonso, F.; Souza, A.; Bento, D.; Gandolfi, R.; Barbosa, F.R.; Lau, F.; Suleman, A. A Study on Thermal Management Systems for Hybrid–Electric Aircraft. Aerospace 2023, 10, 745. [Google Scholar] [CrossRef]

- Amicone, D.; Cannas, A.; Marci, A.; Tortora, G. A Smart Capsule Equipped with Artificial Intelligence for Autonomous Delivery of Medical Material through Drones. Appl. Sci. 2021, 11, 7976. [Google Scholar] [CrossRef]

- Saravanakumar, Y.N.; Sultan, M.T.H.; Shahar, F.S.; Giernacki, W.; Łukaszewicz, A.; Nowakowski, M.; Holovatyy, A.; Stępień, S. Power Sources for Unmanned Aerial Vehicles: A State-of-the Art. Appl. Sci. 2023, 13, 11932. [Google Scholar] [CrossRef]

- Buidin, T.I.C.; Mariasiu, F. Battery Thermal Management Systems: Current Status and Design Approach of Cooling Technologies. Energies 2021, 14, 4879. [Google Scholar] [CrossRef]

- Patel, K.; El-Khoury, J.M.; Simundic, A.-M.; Farnsworth, C.W.; Broell, F.; Genzen, J.R.; Amukele, T.K. Evolution of Blood Sample Transportation and Monitoring Technologies. Clin. Chem. 2021, 67, 812–819. [Google Scholar] [CrossRef]

- Medical Drone Delivery Services Usage Increases as Market Expected to Reach $1.9 Billion by 2032; 2024. Available online: https://www.financialnewsmedia.com/medical-drone-delivery-services-usage-increases-as-market-expected-to-reach-1-9-billion-by-2032/ (accessed on 28 December 2024).

| Thermal Management Strategy | Key Technologies/Mechanism | Advantages | Drawbacks/ Limitations | Impact on UAV Operations/ Suitability |

|---|---|---|---|---|

| Passive Thermal Control | • High-performance insulation (e.g., aerogels, EPS) • Phase change materials (PCMs) | • Zero power consumption once preconditioned • Minimal mechanical complexity • Compact design that preserves aerodynamic profile | • Added weight if thicker insulation or high PCM mass is required • Limited control once deployed; temperature maintenance is governed by material phase change properties • May not cover prolonged or extreme fluctuations | • Well-suited for short-duration flights where either payload integrity and/or battery conservation is critical • More effective when flight conditions are predictable (e.g., known ambient temperature ranges) |

| Active Cooling (Thermoelectric Cooling/Peltier Devices) | • Peltier modules with associated heat sinks and fans • Duty-cycled operation for feedback control | • Precise temperature regulation • No moving parts (solid state), which can reduce maintenance • Modular design allows integration into compact payloads | • Low efficiency (~10–15% of input power converted to cooling); the majority of energy is dissipated as waste heat • Increases overall power draw, potentially reducing flight duration by 25–40% • Additional battery capacity, heat sinks, or fans add weight and affect aerodynamics | • Suitable for applications that demand tight temperature control (e.g., medical sample transport) but may be more appropriate for short or mission-critical flights due to power and weight penalties |

| Active Heating (Joule Heating/Resistive Elements) | • Resistive (Joule) heating elements • Integration with feedback control systems (e.g., via microcontrollers) | • Provides rapid, controlled heating • Can efficiently bring payloads to required temperatures in cold conditions • Simple implementation and precise power control with real-time monitoring | • High energy consumption during operation • Adds extra weight from the heating elements and required control electronics • Increased design complexity when integrating with cooling systems in dual-mode setups | • Critical for applications that require raising payload temperatures (e.g., preventing sample freezing during longer flights) but likely to impact flight endurance unless power trade-offs are managed effectively |

| Hybrid Systems (Combined Active-Passive Approaches) | • Insulated containers augmented with PCMs and integrated active components (e.g., TECs or Joule heaters) • IoT-enabled feedback and duty cycling | • Leverage the energy efficiency of passive systems for baseline control while using active components for fine tuning • Flexibility to adjust to varied environmental conditions • Potential to optimize power usage via real-time monitoring | • More complex design and control • Requires balancing the added weight and higher energy consumption from the active components • Optimization is crucial to ensure that power requirements do not excessively curtail flight range | • Can be adapted for both short and moderately long flights • Ideal for missions where both precise thermal regulation and energy efficiency are required, provided that the system design carefully accounts for additional weight and power demands |

| UAV Application | Temperature Environment | Reference(s) |

|---|---|---|

| Payload | ||

| In-flight PCR Diagnostics | Thermal cycling with high-temperature denaturation (~94 °C) and lower temperatures for annealing/extension | [28,29] |

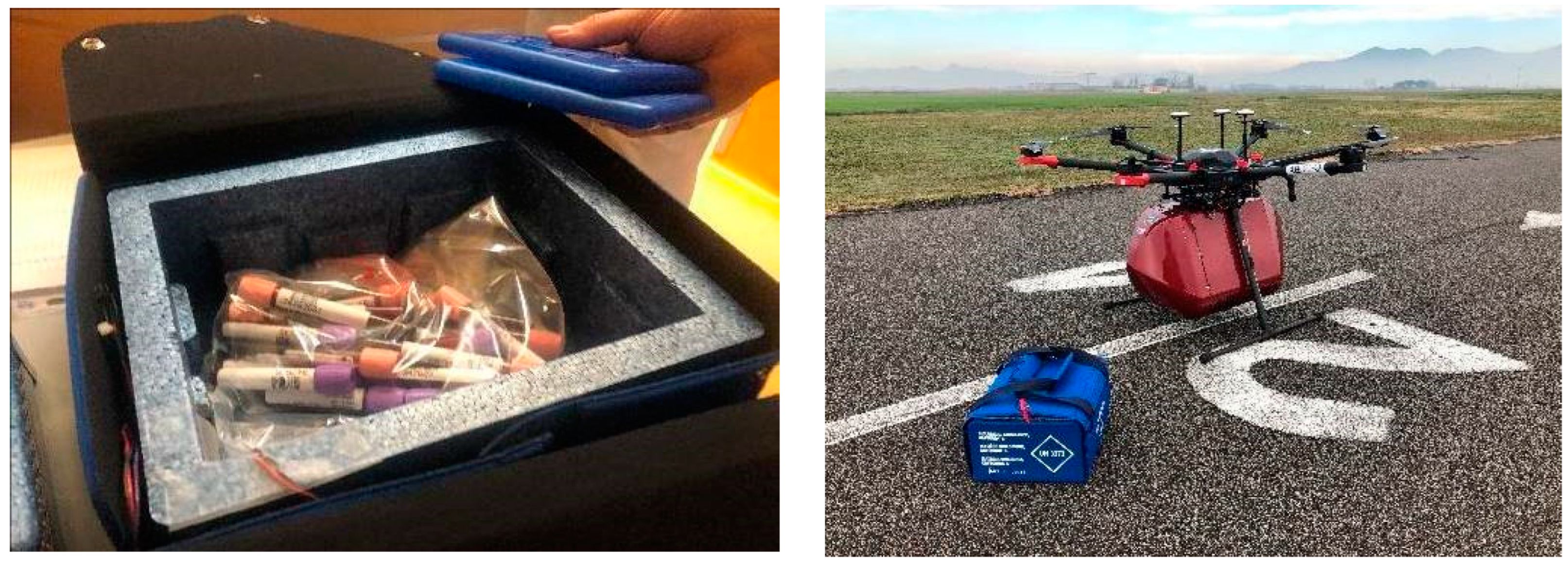

| Blood Sample Transport | Controlled low temperature; includes frozen samples (–20 °C) | [18,20,34,35,36,37,38,41,42,43] |

| Vaccine Delivery | Controlled low temperature (typically 2–8 °C; ultra-cold or frozen for some vaccines) | [46,47] |

| Organ Transport | Controlled low temperature (typically 4–8 °C) | [49,50] |

| Medicinal Products Transport | Controlled low temperature (e.g., for insulin, monoclonal antibodies) | [51,52] |

| Environmental Sample Collection | Temperature-controlled (sub-zero or as required based on sample type) | [53] |

| Drone components | ||

| FireDrone | High temperature (e.g., for wildfire monitoring) | [10] |

| Rotor Blade Anti-Icing | Low temperature (sub-freezing conditions) | [12] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pamula, G.; Ramachandran, A. Thermal Management for Unmanned Aerial Vehicle Payloads: Mechanisms, Systems, and Applications. Drones 2025, 9, 350. https://doi.org/10.3390/drones9050350

Pamula G, Ramachandran A. Thermal Management for Unmanned Aerial Vehicle Payloads: Mechanisms, Systems, and Applications. Drones. 2025; 9(5):350. https://doi.org/10.3390/drones9050350

Chicago/Turabian StylePamula, Ganapathi, and Ashwin Ramachandran. 2025. "Thermal Management for Unmanned Aerial Vehicle Payloads: Mechanisms, Systems, and Applications" Drones 9, no. 5: 350. https://doi.org/10.3390/drones9050350

APA StylePamula, G., & Ramachandran, A. (2025). Thermal Management for Unmanned Aerial Vehicle Payloads: Mechanisms, Systems, and Applications. Drones, 9(5), 350. https://doi.org/10.3390/drones9050350