Agricultural Drone-Based Variable-Rate N Application for Regulating Wheat Protein Content

Abstract

1. Introduction

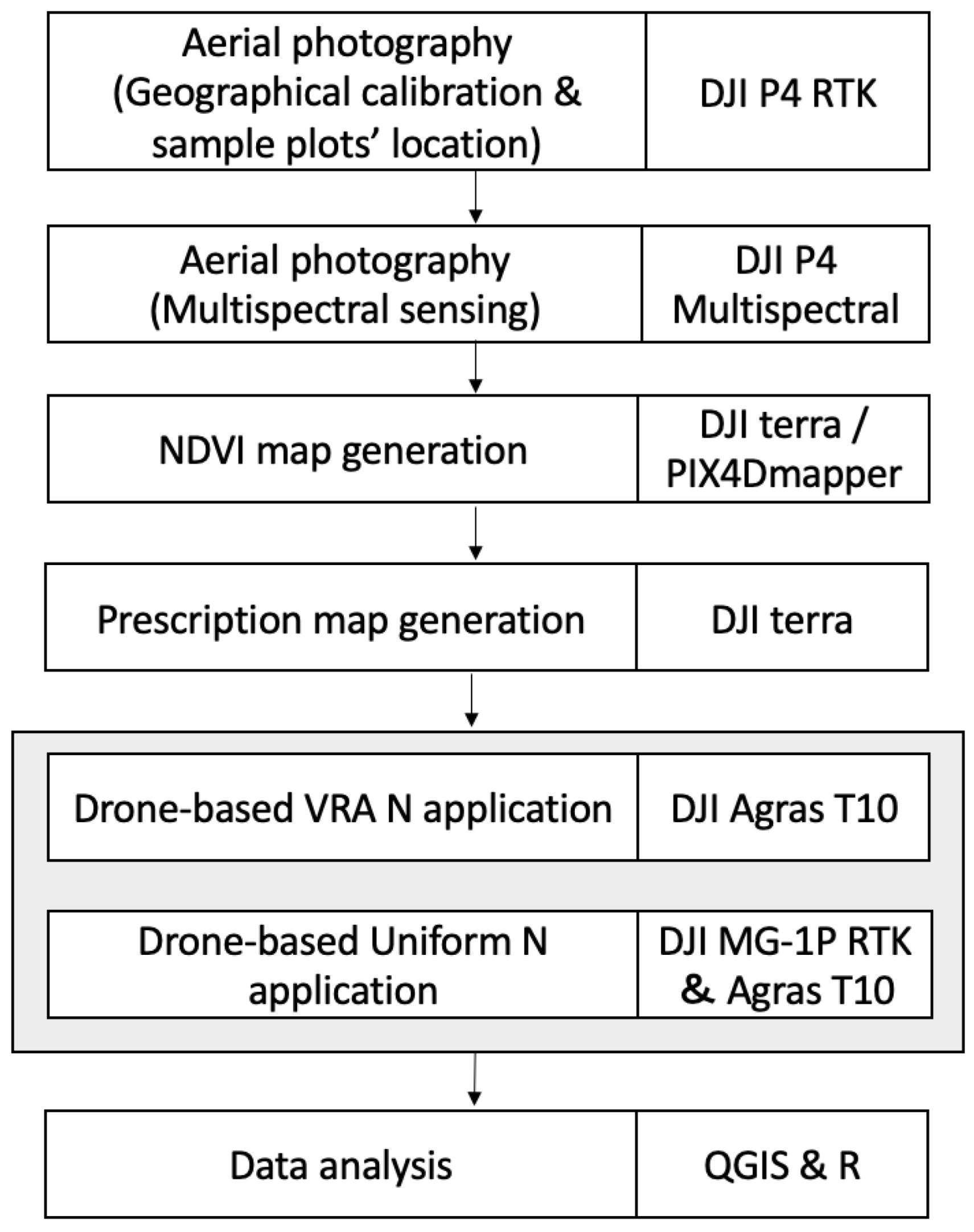

2. Materials and Methods

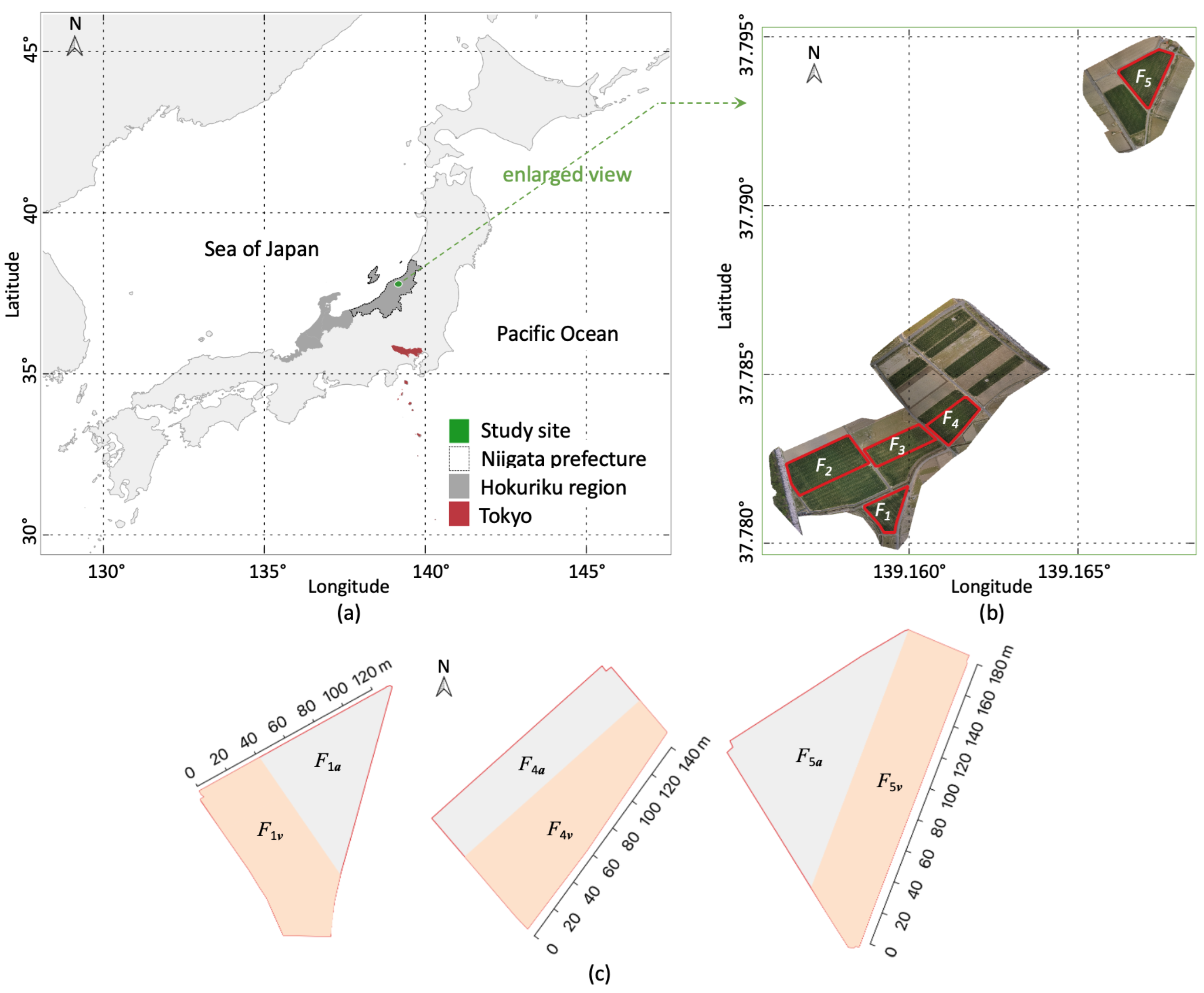

2.1. Study Site

2.2. UAVs for Remote Sensing and Agricultural Drones for N Application

2.3. Data Processing and Field Survey

3. Results

3.1. Prescription Maps and Implementation Results of Agricultural Drone-Based N Application

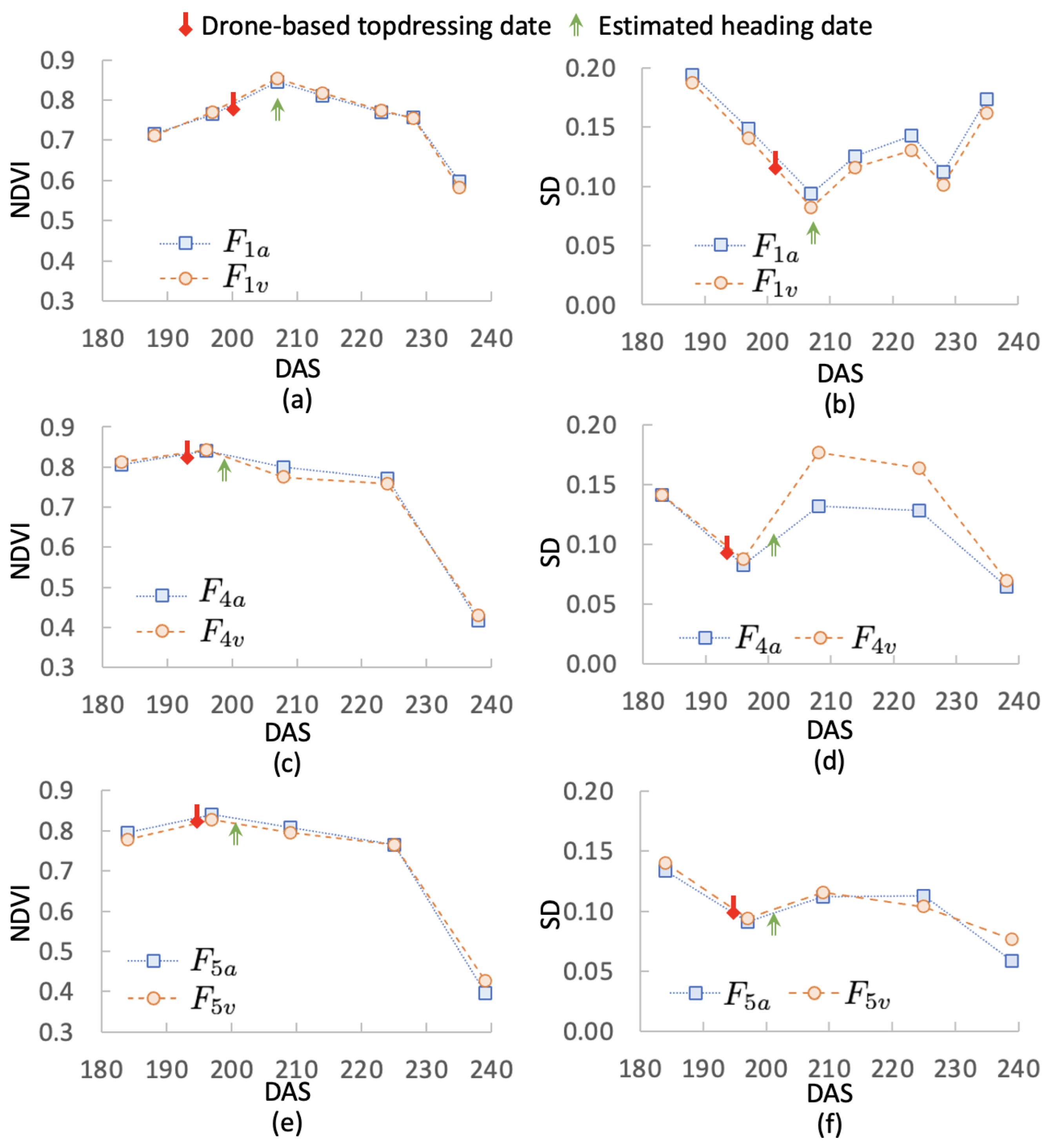

3.2. Effectiveness Analysis of Agricultural Drone-Based N Application

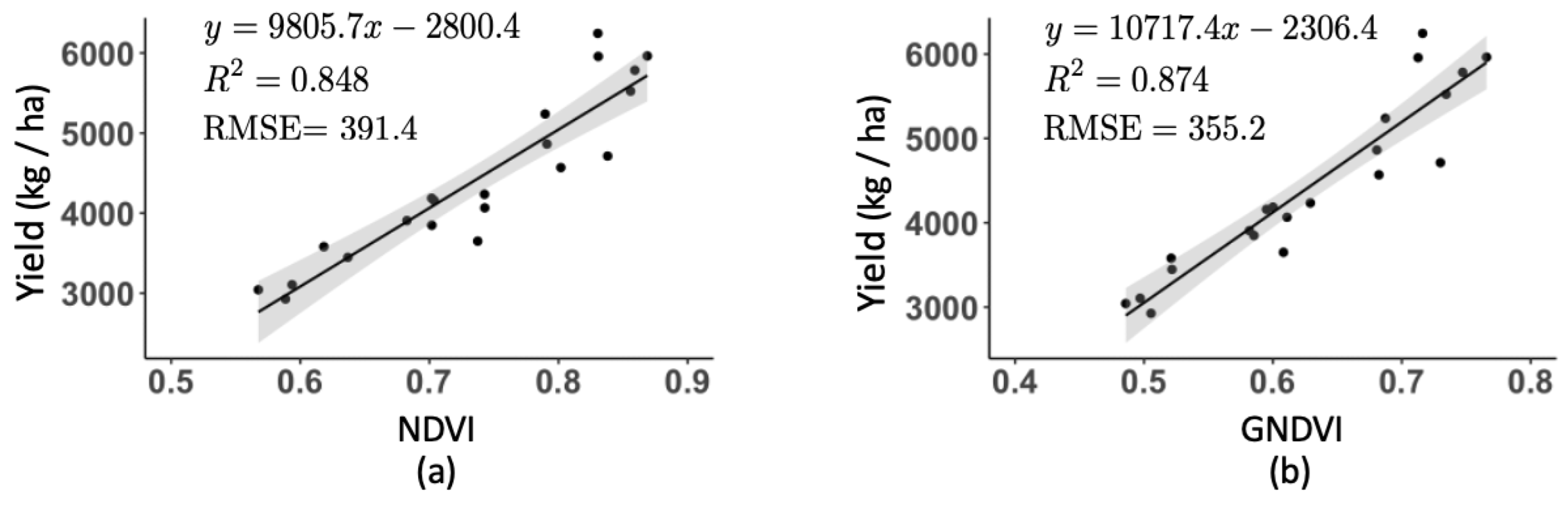

3.3. Correlation Between VIs and Yield

4. Discussion

- (1)

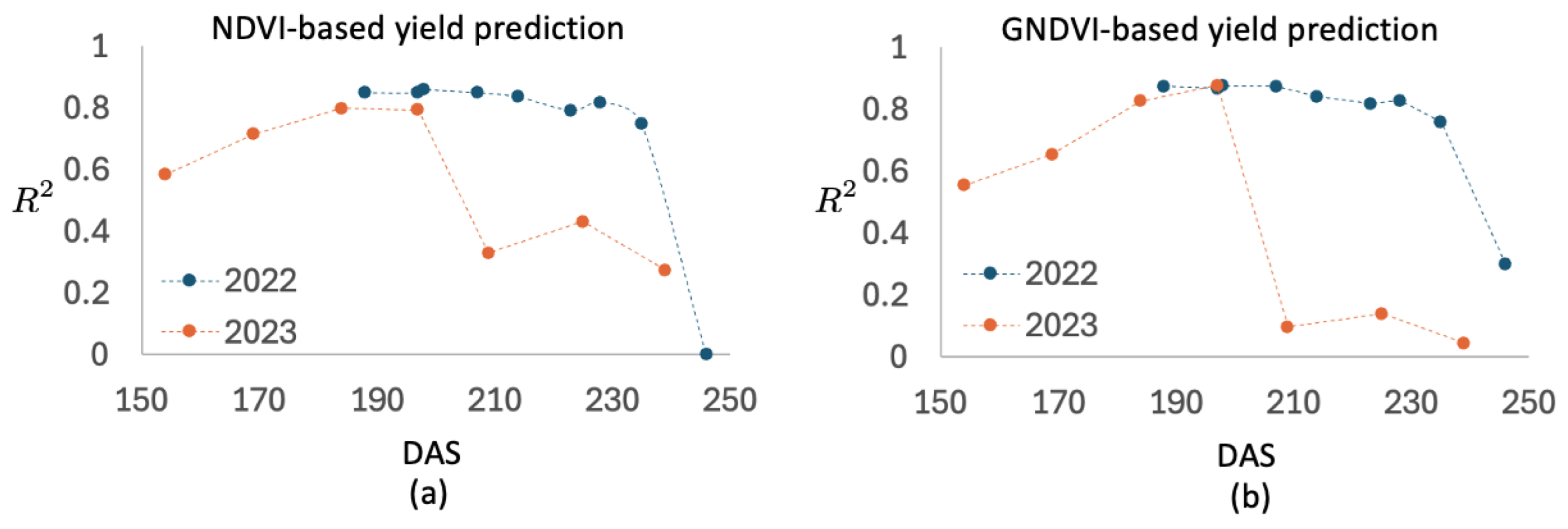

- Decision algorithm for fertilization rates:Building on previous studies [25,26], we adopted an NDVI-based fertilization algorithm. As expected, NDVI measurements taken approximately two weeks before the heading stage predicted yield with high accuracy (Figure 6). Subsequent drone-based nitrogen application was unlikely to have a major impact on wheat growth or yield but primarily influenced the final grain protein content. Wheat plants with higher NDVI values, which reflected better growth conditions, in fact required more nutrients at this stage to ensure higher grain protein content. This suggests that a strategy opposite to our current algorithm—applying more fertilizer in high-NDVI areas and less in low-NDVI areas—could potentially be a more accurate and effective approach. However, this remains a hypothesis and requires further investigation.Additionally, although NDVI and GNDVI showed a strong correlation with yield, they did not exhibit a significant relationship with wheat protein content. Some satellite remote sensing studies have reported that the optimized soil-adjusted vegetation index (OSAVI) is significantly correlated with wheat protein content [27]. However, these indices are not entirely consistent with those derived from UAV-based remote sensing and generally exhibit weaker correlations, making them less suitable for determining fertilization rates.Compared to NDVI, recent studies have indicated that the nitrogen nutrition index (NNI) shows a stronger correlation with grain protein content [28]. Additionally, some researchers have successfully predicted wheat protein content using support vector machine (SVM) algorithms based on four NNIs and five VIs [29]. In our evaluation of other VIs—such as red-edge NDVI (RENDVI), leaf chlorophyll index (LCI), and OSAVI—none showed a significant correlation with grain protein content. Therefore, we suggest that utilizing VIs more strongly correlated with protein content, including those not yet tested, or applying advanced algorithms based on these indices, could lead to a more robust and effective approach to determining fertilization rates.

- (2)

- Number of experimental plots:Due to limitations in manpower and resources, only six VRA experimental plots were included in the 2022 trial. As a result, the observed statistical significance may not be broadly generalizable. To draw more robust and widely applicable conclusions, future trials should include a sufficient and appropriate number of experimental plots.

- (3)

- Deviation between actual and designed application rates:Although we calibrated the agricultural drone’s spreading parameters in advance, we did not conduct a preliminary test application outside the target area before initiating the experiment. Such pre-tests are essential for ensuring high application accuracy. Furthermore, most current agricultural drones lack the capability to automatically adjust the spreading rate during acceleration and deceleration. Consequently, when spreading routes are too short—as was the case in the normal N zone and high N zone in 2022—the agricultural drone frequently operated in transitional speed phases, leading to significant deviations from the target application rate. Therefore, VRA may not be well suited for small experimental plots or fields where spreading paths are only a few meters long.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AGL | Above Ground Level |

| GCP | Ground Control Point |

| DAS | Days After Sowing |

| GNDVI | Green Normalized Difference Vegetation Index |

| GNDVI = (NIR - Green) / (NIR + Green) | |

| NDVI | Normalized Difference Vegetation Index |

| NDVI = (NIR - Red) / (NIR + Red) | |

| NNI | Nitrogen Nutrition Index |

| OSAVI | Optimized Soil Adjusted Vegetation Index |

| OSAVI = 1.16(NIR - Red) / (NIR + Red + 0.16) | |

| RTK | Real-Time Kinematic |

| UAV | Unmanned Aerial Vehicle |

| VI | Vegetation Index |

| VRA | Variable Rate Application |

References

- Bhakta, I.; Phadikar, S.; Majumder, K. State-of-the-art technologies in precision agriculture: A systematic review. J. Sci. Food Agric. 2019, 99, 4878–4888. [Google Scholar] [CrossRef] [PubMed]

- Sishodia, R.P.; Ray, R.L.; Singh, S.K. Applications of remote sensing in precision agriculture: A review. Remote Sens. 2020, 12, 3136. [Google Scholar] [CrossRef]

- Savci, S. Investigation of effect of chemical fertilizers on environment. Apcbee Procedia 2012, 1, 287–292. [Google Scholar] [CrossRef]

- Pawase, P.P.; Nalawade, S.M.; Bhanage, G.B.; Walunj, A.A.; Kadam, P.B.; Durgude, A.G.; Patil, M.G. Variable rate fertilizer application technology for nutrient management: A review. Int. J. Agric. Biol. Eng. 2023, 16, 11–19. [Google Scholar] [CrossRef]

- Romano, E.; Bergonzoli, S.; Pecorella, I.; Bisaglia, C.; De Vita, P. Methodology for the definition of durum wheat yield homogeneous zones by using satellite spectral indices. Remote Sens. 2021, 13, 2036. [Google Scholar] [CrossRef]

- Lindblom, J.; Lundström, C.; Ljung, M.; Jonsson, A. Promoting sustainable intensification in precision agriculture: Review of decision support systems development and strategies. Precis. Agric. 2017, 18, 309–331. [Google Scholar] [CrossRef]

- Campos, J.; Gallart, M.; Llop, J.; Ortega, P.; Salcedo, R.; Gil, E. On-farm evaluation of prescription map-based variable rate application of pesticides in vineyards. Agronomy 2020, 10, 102. [Google Scholar] [CrossRef]

- Garcia-Ruiz, F.; Campos, J.; Llop-Casamada, J.; Gil, E. Assessment of map based variable rate strategies for copper reduction in hedge vineyards. Comput. Electron. Agric. 2023, 207, 107753. [Google Scholar] [CrossRef]

- Chen, P.; Xu, W.; Zhan, Y.; Yang, W.; Wang, J.; Lan, Y. Evaluation of cotton defoliation rate and establishment of spray prescription map using remote sensing imagery. Remote Sens. 2022, 14, 4206. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, B.; Zhao, D.; Shan, C.; Wang, G.; Song, C.; Chen, P.; Lan, Y. Prediction of cotton FPAR and construction of defoliation spraying prescription map based on multi-source UAV images. Comput. Electron. Agric. 2024, 220, 108897. [Google Scholar] [CrossRef]

- Li, X.; Liang, Z.; Yang, G.; Lin, T.; Liu, B. Assessing the Severity of Verticillium Wilt in Cotton Fields and Constructing Pesticide Application Prescription Maps Using Unmanned Aerial Vehicle (UAV) Multispectral Images. Drones 2024, 8, 176. [Google Scholar] [CrossRef]

- Castaldi, F.; Pelosi, F.; Pascucci, S.; Casa, R. Assessing the potential of images from unmanned aerial vehicles (UAV) to support herbicide patch spraying in maize. Precis. Agric. 2017, 18, 76–94. [Google Scholar] [CrossRef]

- Yi, L.; Lan, Y.; Kong, H.; Kong, F.; Huang, H.; Han, X. Exploring the potential of UAV imagery for variable rate spraying in cotton defoliation application. Int. J. Precis. Agric. Aviat. 2019, 2, 42–45. [Google Scholar] [CrossRef]

- Song, C.; Zhou, Z.; Zang, Y.; Zhao, L.; Yang, W.; Luo, X.; Jiang, R.; Ming, R.; Zang, Y.; Zi, L.; et al. Variable-rate control system for UAV-based granular fertilizer spreader. Comput. Electron. Agric. 2021, 180, 105832. [Google Scholar] [CrossRef]

- Yu, Z.; Islam, S.; She, M.; Diepeveen, D.; Zhang, Y.; Tang, G.; Zhang, J.; Juhasz, A.; Yang, R.; Ma, W. Wheat grain protein accumulation and polymerization mechanisms driven by nitrogen fertilization. Plant J. 2018, 96, 1160–1177. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, W.; Krienke, B.; Cao, Q.; Zhu, Y.; Cao, W.; Liu, X. In-season variable rate nitrogen recommendation for wheat precision production supported by fixed-wing UAV imagery. Precis. Agric. 2022, 23, 830–853. [Google Scholar] [CrossRef]

- Kusaka, H.; Suzuki, N.; Yabe, M.; Kobayashi, H. The snow-shadow effect of Sado Island on Niigata City and the coastal plain. Atmos. Sci. Lett. 2023, 24, e1182. [Google Scholar] [CrossRef]

- Whitaker, A.C.; Sugiyama, H. Seasonal snowpack dynamics and runoff in a cool temperate forest: Lysimeter experiment in Niigata, Japan. Hydrol. Process. 2005, 19, 4179–4200. [Google Scholar] [CrossRef]

- Eito, H.; Murakami, M.; Muroi, C.; Kato, T.; Hayashi, S.; Kuroiwa, H.; Yoshizaki, M. The structure and formation mechanism of transversal cloud bands associated with the Japan-Sea polar-airmass convergence zone. J. Meteorol. Soc. Jpn. 2010, 88, 625–648. [Google Scholar] [CrossRef]

- Tachibana, Y.; Honda, M.; Nishikawa, H.; Kawase, H.; Yamanaka, H.; Hata, D.; Kashino, Y. High moisture confluence in Japan Sea polar air mass convergence zone captured by hourly radiosonde launches from a ship. Sci. Rep. 2022, 12, 21674. [Google Scholar] [CrossRef]

- Shibukawa, H.; Shimazaki, Y.; Seki, M. Impact of Nitrogen Topdressing at Flowering on Grain Protein and Ash content in Wheat Variety ’Yukichikara’ for Bread. Hokuriku Crop Sci. 2018, 53, 16–19. [Google Scholar] [CrossRef]

- Shimazaki, Y. The growth of Wheat Variety ’Natsukogane’ compare with ‘Yukichikara’ in Niigata Prefecture. Hokuriku Crop Sci. 2021, 56, 11–16. [Google Scholar] [CrossRef]

- Shimazaki, Y.; Watanabe, Y. Grain Protein Concentration of Wheat T. aestivum L.)-Can cultivation techniques control the grain protein concentration of wheat? Jpn. J. Crop Sci. 2010, 79, 407–413. [Google Scholar] [CrossRef]

- Shimazaki, Y.; Akasaka, M.; Watanabe, Y.; Ohshita, Y.; Matsuyama, H.; Hirasawa, T. Nitrogen Content of Wheat Plants at Anthesis Affects Grain Protein Content and its Increase in Response to Nitrogen Topdressing at Anthesis. Jpn. J. Crop Sci. 2015, 84, 140–149. [Google Scholar] [CrossRef]

- Wang, K.; Huggins, D.R.; Tao, H. Rapid mapping of winter wheat yield, protein, and nitrogen uptake using remote and proximal sensing. Int. J. Appl. Earth Obs. 2019, 82, 101921. [Google Scholar] [CrossRef]

- Walsh, O.S.; Marshall, J.M.; Nambi, E.; Jackson, C.A.; Ansah, E.O.; Lamichhane, R.; McClintick-Chess, J.; Bautista, F. Wheat Yield and Protein Estimation with Handheld and Unmanned Aerial Vehicle-Mounted Sensors. Agronomy 2023, 13, 207. [Google Scholar] [CrossRef]

- Song, X.; Wang, J.; Huang, W.; Yan, G.; Chang, H. Monitoring spatial variance of winter wheat growth and grain quality under variable-rate fertilization conditions by remote sensing data. Trans. Chin. Soc. Agric. Eng. 2009, 25, 155–162. [Google Scholar]

- Fabbri, C.; Delgado, A.; Guerrini, L.; Napoli, M. Precision nitrogen fertilization strategies for durum wheat: A sustainability evaluation of NNI and NDVI map-based approaches. Eur. J. Agron. 2025, 164, 127502. [Google Scholar] [CrossRef]

- Qu, S.; Li, Z.; Qiu, C.; Yang, G.; Song, X.; Chen, Z.; Liu, C. Remote sensing prediction of winter wheat grain protein content based on nitrogen nutrition index at anthesis stage. Trans. Chin. Soc. Agric. Eng. 2017, 33, 186–193. [Google Scholar]

- Duan, T.; Chapman, S.; Guo, Y.; Zheng, B. Dynamic monitoring of NDVI in wheat agronomy and breeding trials using an unmanned aerial vehicle. Field Crop. Res. 2017, 210, 71–80. [Google Scholar] [CrossRef]

| Field | F1 | F2 | F3 | F4 | F5 |

|---|---|---|---|---|---|

| Planted area (ha) | 0.95 | 2.32 | 1.24 | 1.09 | 1.45 |

| Basal fertilizer date | 30 September 2021 | 6 October 2022 | |||

| Seeding date | 7 October 2021 | 9 October 2021 | 8 October 2021 | 13 October 2022 | 12 October 2022 |

| Basal fertilizer * | 117 a | 80 b | |||

| Manual N application * @ DAS | 3 c @ 43 | – | – | – | – |

| – | – | – | 39 d @ 144 | 40 d @ 145 | |

| Drone-based | – | – | – | 10 d @ 160 | 10d @ 161 |

| N application * @ DAS | – | – | – | 5 d @ 166 | 5 d @ 168 |

| 60 d @ 201 | 60 d @ 198 | 60 d @ 199 | 60 d @ 194 | 60 d @ 195 | |

| Estimated total N application * | 179 | 177 | 177 | 194 | 195 |

| Estimated heading date (DAS) | 207 | 205 | 206 | 201 | 202 |

| Harvest date (DAS) | 253 | 251 | 252 | 249 | 250 |

| Drone Model | MG-1P | Agras T10 | ||||||

|---|---|---|---|---|---|---|---|---|

| Target field/zone | ||||||||

| Target area percentage (%) | 100 | 100 | 46 | 41 | 54 | 59 | 52 | 48 |

| Treatment | Uniform | VRA | Uniform | |||||

| Weather | Sunny | Sunny | Cloudy | Sunny | Cloudy | Sunny | Cloudy | Cloudy |

| Wind speed (m/s) | - | 2.5 | 1.3 | 4.9 | 3.0 | 3.7 | 4.7 | 7.2 |

| Wind direction | - | WNW | S | NNE | SE | E | NNE | ESE |

| Temperature (dd) | - | 26.2 | 22.8 | 18.1 | 24.7 | 16.1 | 17.5 | 18.8 |

| Working width (m) | 4.0 | 5.0 | ||||||

| Flight speed (km/h) | 15.0 | 14.4 | 10.8 | 10.8 | 10.8 | |||

| Treatment Zone | Designed Fertilization Rate (kg N ha−1) | Actual Fertilization Rate (kg N ha−1) | Ratio to Designed Fertilization Rate |

|---|---|---|---|

| 60 | 58.1 | 96.9% | |

| 60 * | 45.5 | 75.8% | |

| 60 | 61.4 | 102.4% | |

| 60 | 65.1 | 108.5% | |

| 60 | 67.6 | 112.7% | |

| 60 * | 64.3 | 107.2% | |

| 60 | 55.6 | 92.6% | |

| 60 * | 67.5 | 112.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, S.; Shimazaki, Y.; Takahashi, K.; Kato, H.; Fukami, K.; Watanabe, S. Agricultural Drone-Based Variable-Rate N Application for Regulating Wheat Protein Content. Drones 2025, 9, 310. https://doi.org/10.3390/drones9040310

Guan S, Shimazaki Y, Takahashi K, Kato H, Fukami K, Watanabe S. Agricultural Drone-Based Variable-Rate N Application for Regulating Wheat Protein Content. Drones. 2025; 9(4):310. https://doi.org/10.3390/drones9040310

Chicago/Turabian StyleGuan, Senlin, Yumi Shimazaki, Kimiyasu Takahashi, Hitoshi Kato, Koichiro Fukami, and Shuichi Watanabe. 2025. "Agricultural Drone-Based Variable-Rate N Application for Regulating Wheat Protein Content" Drones 9, no. 4: 310. https://doi.org/10.3390/drones9040310

APA StyleGuan, S., Shimazaki, Y., Takahashi, K., Kato, H., Fukami, K., & Watanabe, S. (2025). Agricultural Drone-Based Variable-Rate N Application for Regulating Wheat Protein Content. Drones, 9(4), 310. https://doi.org/10.3390/drones9040310