Aerodynamic Optimization Design of an Orthogonal Octo-Rotor UAV in a Hovering State

Abstract

1. Introduction

2. Theoretical Analysis

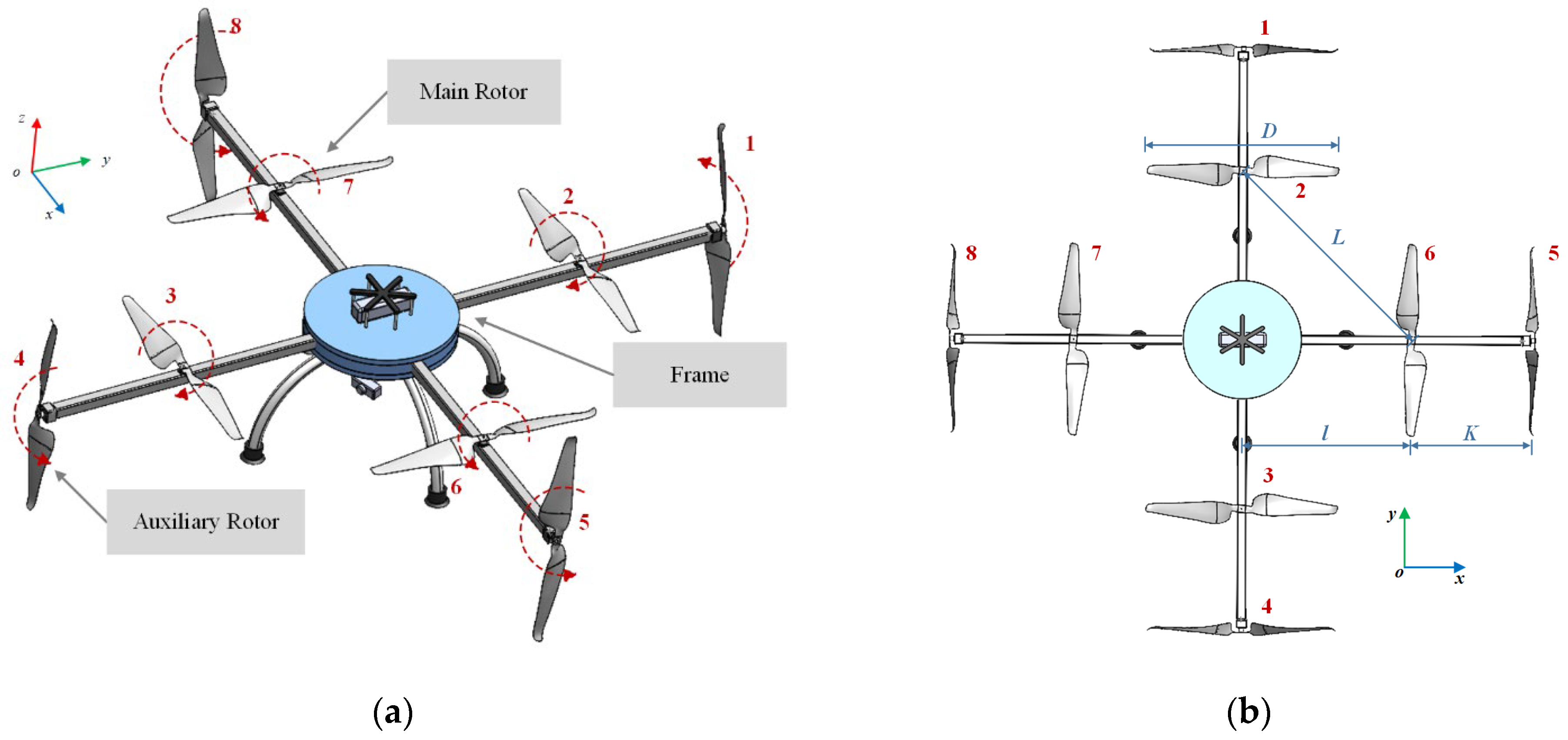

2.1. The Structure of the Orthogonal Octo-Rotor UAV

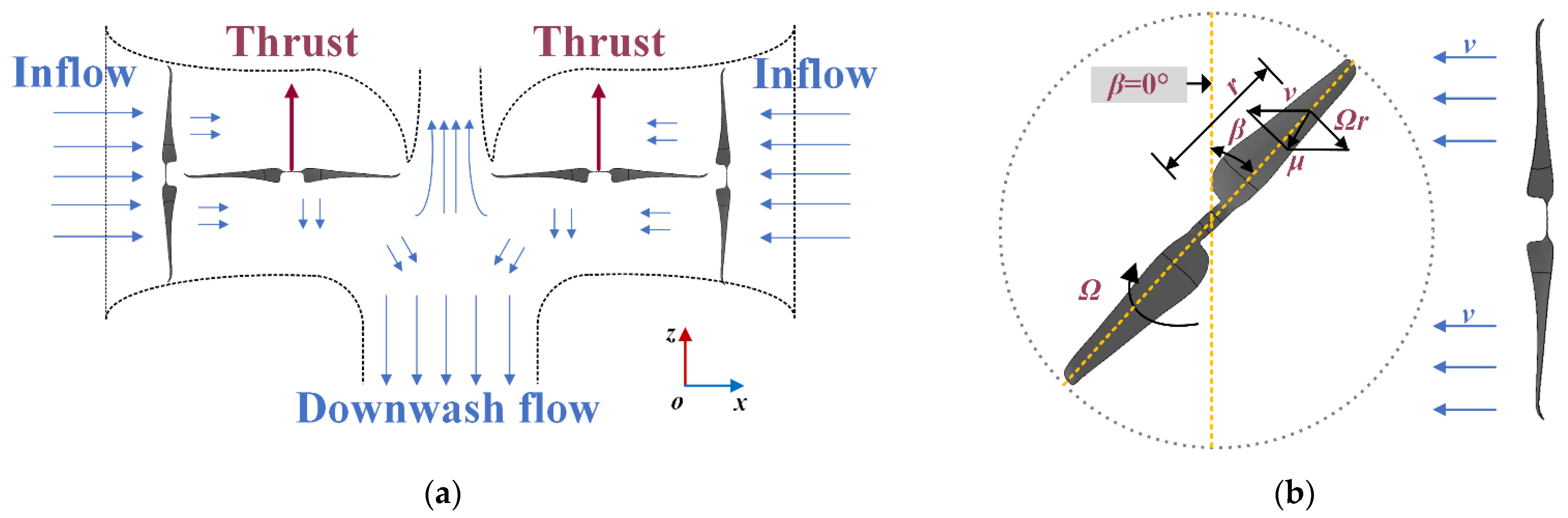

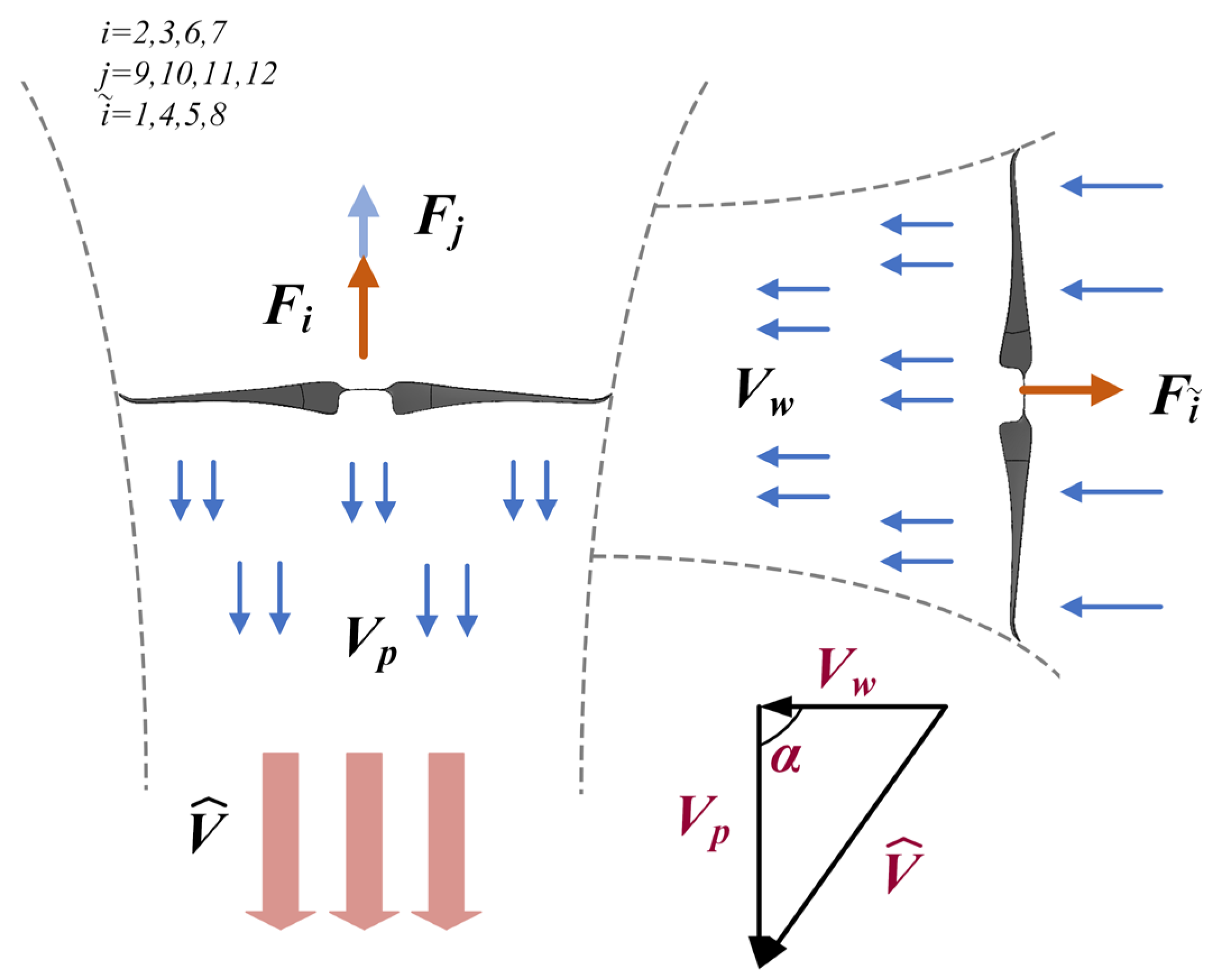

2.2. Force Analysis

2.3. Moment Analysis

2.4. Aerodynamic Parameters

3. Simulations

3.1. Mesh Distribution

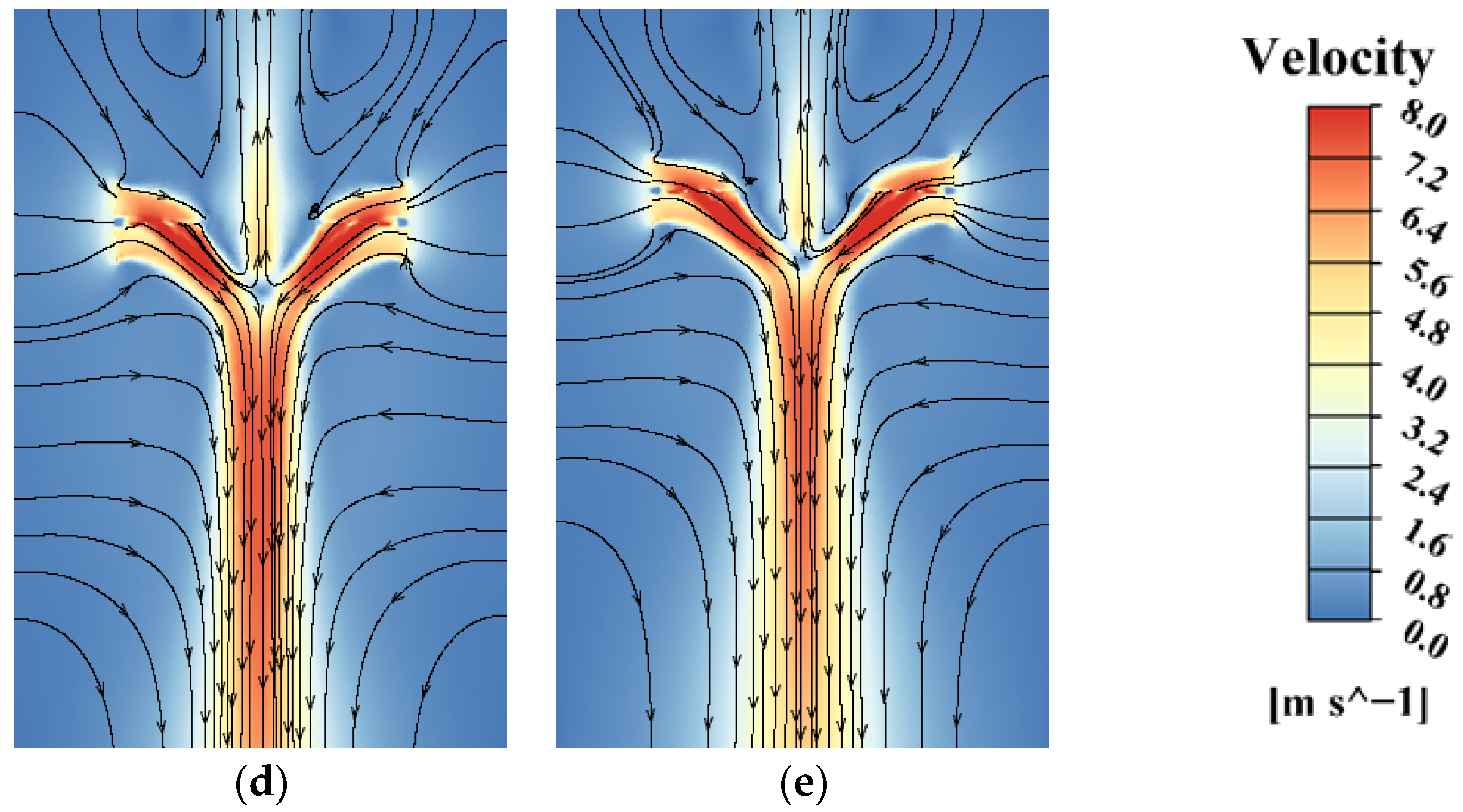

3.2. Simulation Results

4. Experiments

4.1. Experimental Setup

4.2. Experimental Results

5. Conclusions

- 1.

- The outflow of the auxiliary rotors enhanced the thrust increment of the main rotors, with a maximum up to 3.92% at 2000 RPM for i = 0.55. Furthermore, the reduced rotor interference decreased the power consumption by 5.68%. This improvement was validated by the numerical simulations, where the velocity streamline of the downwash flow between the main rotor and the auxiliary rotor was intact, with symmetry distribution. It is interesting to note that the optimal rotor spacing ratio at i = 0.55 remained a perfect rotor interference, obtaining a thrust increment and the power decrement at the same time. This advantage was related to the orthogonal configuration with the decoupled dynamics that promoted this novel octorotor into a wider class for application compared to the traditional planar octorotors, such as the unique capability to resist wind gusts and a better failure tolerance in extreme conditions.

- 2.

- The hover efficiency at 2000–2300 RPM decreased, with a sudden power increase, and the rotor interference accelerated the movement of the outflow; thereby, the vortex became irregular and unsymmetric. In this case, the orthogonal octorotor was suffering from thrust loss, leading to instabilities.

- 3.

- The orthogonal arrangement not only has decoupled dynamics but also better hover efficiency with an optimal spacing ratio of i = 0.55 at 2000 RPM. The compact structure of the vertical auxiliary rotors allowed the UAV to fly in a narrow space with larger power loading from eight rotors and enhanced the maneuverability and stability of aggressive maneuvers. Further studies will involve the wind effect and more field flight tests in forward flight.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohsan, S.A.H.; Othman, N.Q.H.; Khan, M.A.; Amjad, H.; Żywiołek, J. A Comprehensive Review of Micro UAV Charging Techniques. Micromachines 2022, 13, 977. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.S.A.; Gadsden, S.A.; Wilkerson, S.A. A comprehensive survey of control strategies for autonomous quadrotors. Can. J. Electr. Comput. Eng. 2019, 43, 3–16. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Chen, J.; Fang, C. Altitude control for variable load quadrotor via learning rate based robust sliding mode controller. IEEE Access 2019, 7, 9736–9744. [Google Scholar] [CrossRef]

- Iscold, P.; Pereira, G.A.S.; Torres, L.A.B. Development of a Hand-Launched Small UAV for Ground Reconnaissance. IEEE Trans. Aerosp. Electron. Syst. 2010, 46, 335–348. [Google Scholar] [CrossRef]

- Mellinger, D.; Michael, N.; Kumar, V. Trajectory generation and control for precise aggressive maneuvers with quadrotors. Int. J. Robot. Res. 2012, 31, 664–674. [Google Scholar] [CrossRef]

- Ryll, M.; Bulthoff, H.H.; Giordano, P.R. Modeling and control of a quadrotor UAV with tilting propellers. In Proceedings of the IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 4606–4613. [Google Scholar] [CrossRef]

- Elfeky, M.; Elshafei, M.; Saif, A.W.A.; Al-Malki, M.F. Quadrotor helicopter with tilting rotors: Modeling and simulation. In Proceedings of the 2013 World Congress on Computer and Information Technology (WCCIT), Sousse, Tunisia, 22 June 2013. [Google Scholar] [CrossRef]

- Lei, Y.; Wang, H.D. Aerodynamic Performance of a Quadrotor MAV Considering the Horizontal Wind. IEEE Access 2020, 8, 109421–109428. [Google Scholar] [CrossRef]

- Barcelos, D.; Kolaei, A.; Bramesfeld, G. Aerodynamic Interactions of Quadrotor Configurations. J. Aircr. 2020, 57, 1074–1090. [Google Scholar] [CrossRef]

- Asher, P.K.; Deviparameswari, K.; Feonsa Antonitta, B.; Meenakshi, S.; Vijayanandh, R.; Senthil Kumar, M. Comparative Aerodynamic Performance Analysis on Modified UAV’s Propeller by Using CFD; Springer: Singapore, 2021; Volume 2, pp. 969–980. [Google Scholar] [CrossRef]

- Misiorowski, M.; Gandhi, F.; Oberai, A.A. Computational Study on Rotor Interactional Effects for a Quadcopter in Edgewise Flight. AIAA J. 2019, 57, 5309–5319. [Google Scholar] [CrossRef]

- Ganesan, S.; Esakki, B. Computational fluid dynamic analysis of an unmanned amphibious aerial vehicle for drag reduction. Int. J. Intell. Unmanned Syst. 2020, 8, 187–200. [Google Scholar] [CrossRef]

- Lopez, O.D.; Escobar, J.A.; Pérez, A.M. Computational Study of the Wake of a Quadcopter Propeller in Hover. In Proceedings of the 23rd AIAA Computational Fluid Dynamics Conference, Denver, CO, USA, 5 June 2017. [Google Scholar] [CrossRef]

- Wang, Z.; Henricks, Q.; Zhuang, M.; Pandey, A.; Sutkowy, M.; Harter, B.; McCrink, M.; Gregory, J. Impact of Rotor–Airframe Orientation on the Aerodynamic and Aeroacoustic Characteristics of Small Unmanned Aerial Systems. Drones 2019, 3, 56. [Google Scholar] [CrossRef]

- Salazar, S.; Romero, H.; Lozano, R.; Castillo, P. Modeling and Real-Time Stabilization of an Aircraft Having Eight Rotors. J. Intell. Robot. Syst. 2008, 54, 455–470. [Google Scholar] [CrossRef]

- Frankenberg, F.V.; Nokleby, S. Disturbance Rejection in Multi-Rotor Unmanned Aerial Vehicles Using a Novel Rotor Geometry. In Proceedings of the International Conference of Control, Dynamic Systems, and Robotics, Toronto, ON, Canada, 8 June 2017. [Google Scholar] [CrossRef]

- Guo, Y.Y.; Zhang, Y.M. A novel robust attitude control for quadrotor aircraft subject to actuator faults and wind gusts. IEEE/CAA J. Autom. Sin. 2018, 5, 292–300. [Google Scholar] [CrossRef]

- Wang, H.; Sun, W.; Zhao, C.; Zhang, S.; Han, J. Dynamic Modeling and Control for Tilt-Rotor UAV Based on 3D Flow Field Transient CFD. Drones 2022, 6, 338. [Google Scholar] [CrossRef]

- Lee, H.; Lee, D.J. Rotor interactional effects on aerodynamic and noise characteristics of a small multirotor unmanned aerial vehicle. Phys. Fluids 2020, 32, 47107. [Google Scholar] [CrossRef]

- Prothin, S.; Fernandez Escudero, C.; Doue, N.; Jardin, T. Aerodynamics of MAV rotors in ground and corner effect. Int. J. Micro Air Veh. 2019, 11, 1756829319861596. [Google Scholar] [CrossRef]

- Luo, Y.W.; Ai, T.F.; He, Y.H.; Zhao, Z.Z.; Xu, B.; Qian, Y.P.; Peng, J.; Zhang, Y.J. Aerodynamic analysis on unsteady characteristics of a ducted fan hovering in ceiling effect. Eng. Appl. Comput. Fluid Mech. 2023, 17, 1563–1584. [Google Scholar] [CrossRef]

| Nomenclature | Definitions |

|---|---|

| A | Rotor disk area |

| P | Power consumption |

| R | Rotor radius |

| T | Thrust |

| SST k-ω | Shear Stress Transport k-omega model |

| D | Diameter of the rotor |

| v | Downwash velocity of the auxiliary rotor |

| Ω | Rotor speed |

| β | Azimuth angle of the rotor |

| μ | Downwash velocity of the auxiliary rotor |

| Ψ, θ and Φ | Yaw, pitch, and roll angles |

| PMax and PMin (pa) | Maximum and minimum pressures |

| Thrust coefficients | |

| Power coefficients |

| Parameters | Value Range |

|---|---|

| Rotor diameter (mm) | 400 |

| Rotor speed (RPM) | 1500–2300 |

| Rotor spacing ratio i | 0.55, 0.59, 0.63, 0.67, 0.71, 0.83, 0.90, 0.95 |

| The dimensions of the cylinder(mm) | Height: 6500, Diameter: 4500 |

| The number of grid cells | Approximately 21 million |

| Name | Mesh 1 | Mesh 2 | Mesh 3 | Mesh 4 | Mesh 5 |

|---|---|---|---|---|---|

| No. grids (Million) | 6 | 8 | 16 | 21 | 25 |

| PMax (Pa) | 154.26 | 163.25 | 167.59 | 184.32 | 186.56 |

| Relative error of PMax | 16.4% | 11.0% | 9.2% | 1.7% | - |

| PMin (Pa) | −602.68 | −634.25 | −654.63 | −676.23 | −681.69 |

| Relative error of PMin | 11.4% | 6.9% | 3.7% | 0.8% | - |

| Parameters | Value |

|---|---|

| Rotor diameter (mm) | 400 |

| Number of blades | 2 |

| Weight | 0.015 kg |

| Material of blades | Carbon Fiber |

| Chord length (75% R) | (0.4 − 0.62) × 105 |

| Rotor solidity | 0.128 |

| Rotor speed (RPM) | 1500–2300 |

| Twist | 0 |

| Rotor spacing ratio i | 0.55, 0.59, 0.63, 0.67, 0.71, 0.83, 0.90, 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Y.; Yang, H.; Hu, J.; Li, X.; Qiu, J.; Zhang, Y. Aerodynamic Optimization Design of an Orthogonal Octo-Rotor UAV in a Hovering State. Drones 2025, 9, 257. https://doi.org/10.3390/drones9040257

Lei Y, Yang H, Hu J, Li X, Qiu J, Zhang Y. Aerodynamic Optimization Design of an Orthogonal Octo-Rotor UAV in a Hovering State. Drones. 2025; 9(4):257. https://doi.org/10.3390/drones9040257

Chicago/Turabian StyleLei, Yao, Hengxing Yang, Jifu Hu, Xuan Li, Jiafu Qiu, and Yuanfeng Zhang. 2025. "Aerodynamic Optimization Design of an Orthogonal Octo-Rotor UAV in a Hovering State" Drones 9, no. 4: 257. https://doi.org/10.3390/drones9040257

APA StyleLei, Y., Yang, H., Hu, J., Li, X., Qiu, J., & Zhang, Y. (2025). Aerodynamic Optimization Design of an Orthogonal Octo-Rotor UAV in a Hovering State. Drones, 9(4), 257. https://doi.org/10.3390/drones9040257