A Novel Telescopic Aerial Manipulator for Installing and Grasping the Insulator Inspection Robot on Power Lines: Design, Control, and Experiment

Highlights

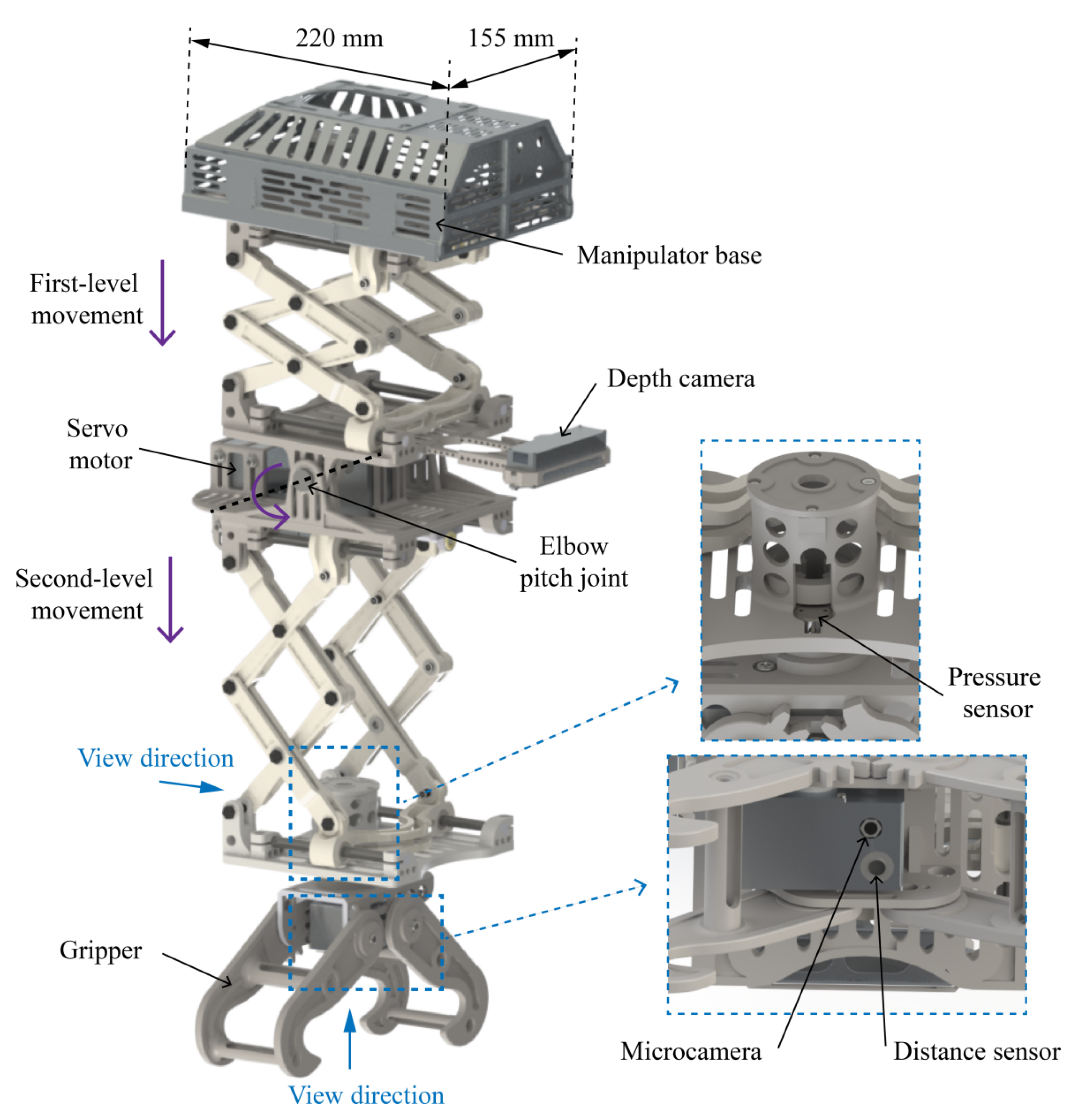

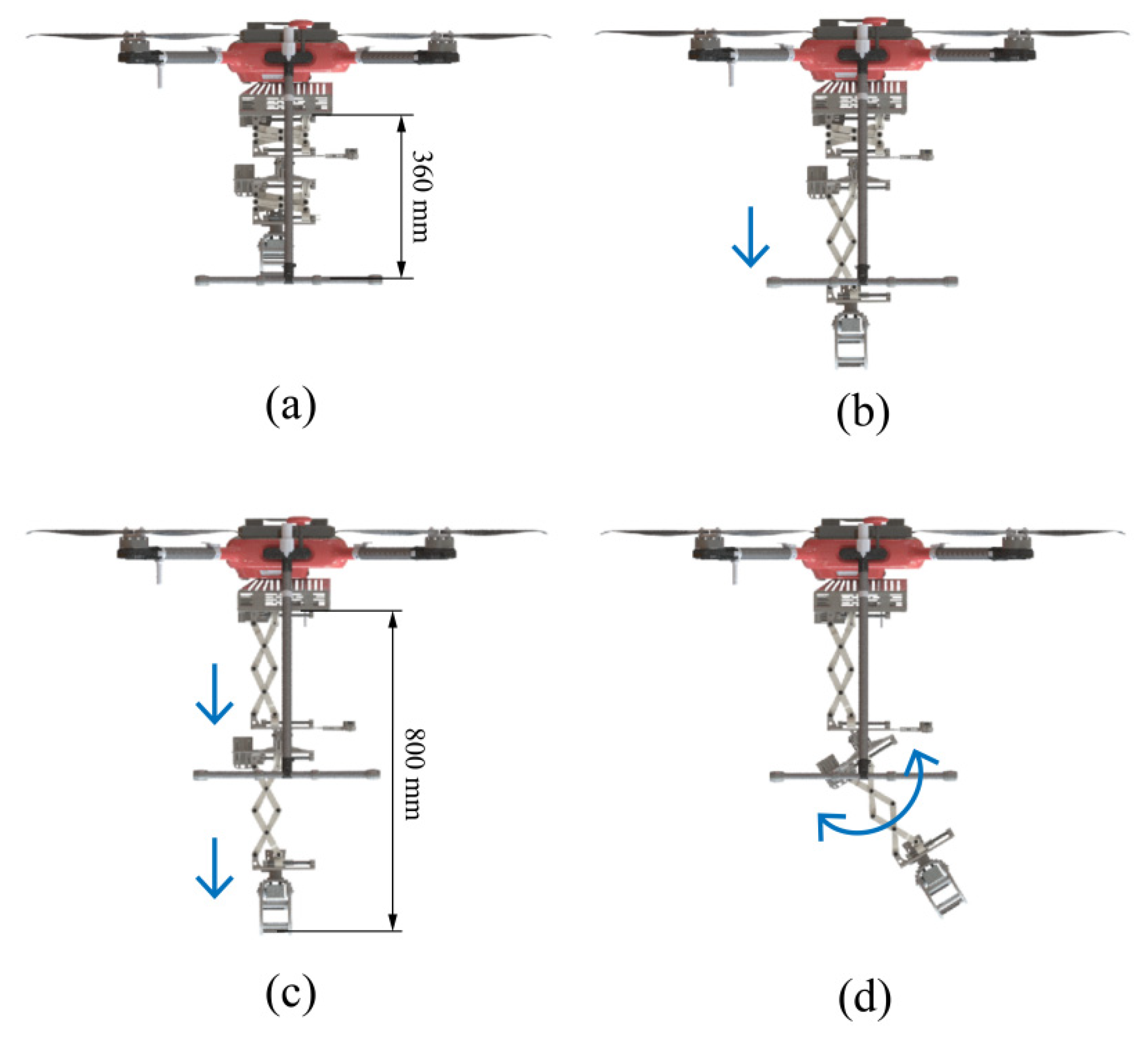

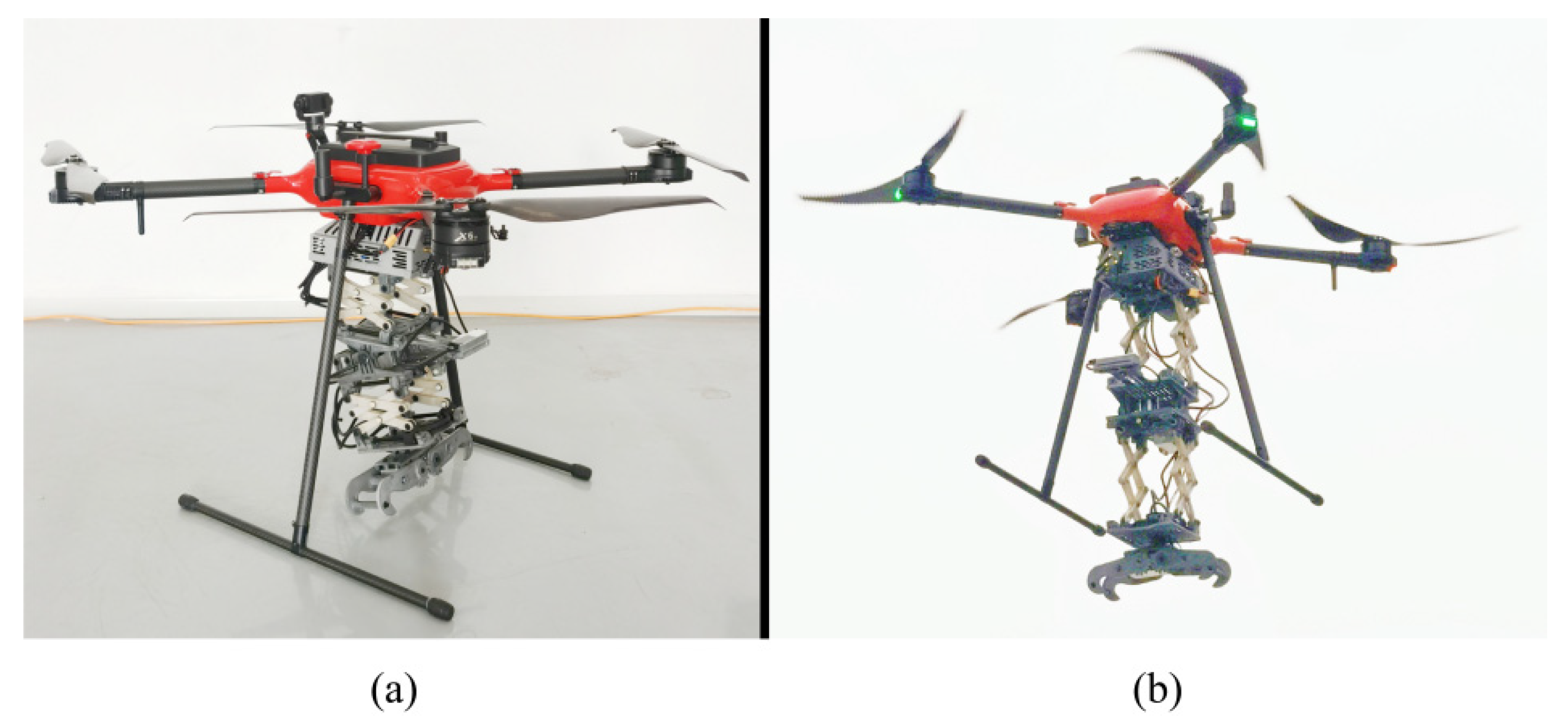

- A novel lightweight telescopic aerial manipulator with three degrees of freedom is developed, incorporating two scissor-linkage mechanisms and a pitch rotation joint, enabling a large operational range (360–800 mm) while maintaining a total mass of only 2.2 kg.

- A hybrid position/force control strategy combined with a robust visual detection and estimation algorithm is proposed, allowing the system to autonomously grasp and install a 3.6 kg insulator inspection robot on power lines under real-world outdoor conditions.

- Various types of performance tests are carried out, and the outdoor operation test is realized for the first time, which effectively promotes the industrial application of aerial manipulators.

- It provides a practical and safer alternative to manual high-altitude work on power lines, potentially reducing operational risks and costs for the maintenance of electrical infrastructure.

Abstract

1. Introduction

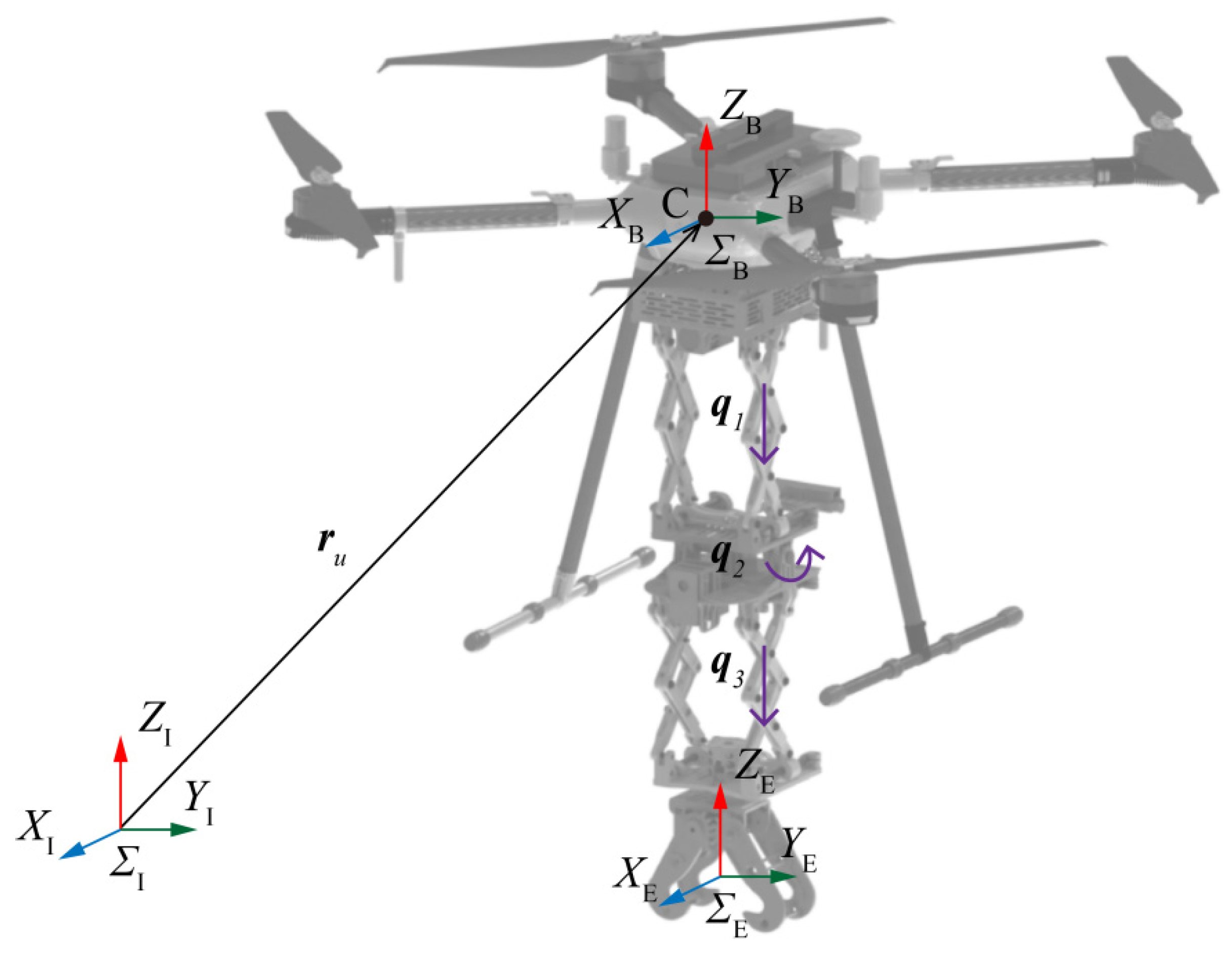

2. Aerial Manipulator System

2.1. Design Considerations

2.2. Telescopic Manipulator Design

2.3. Motors and Materials

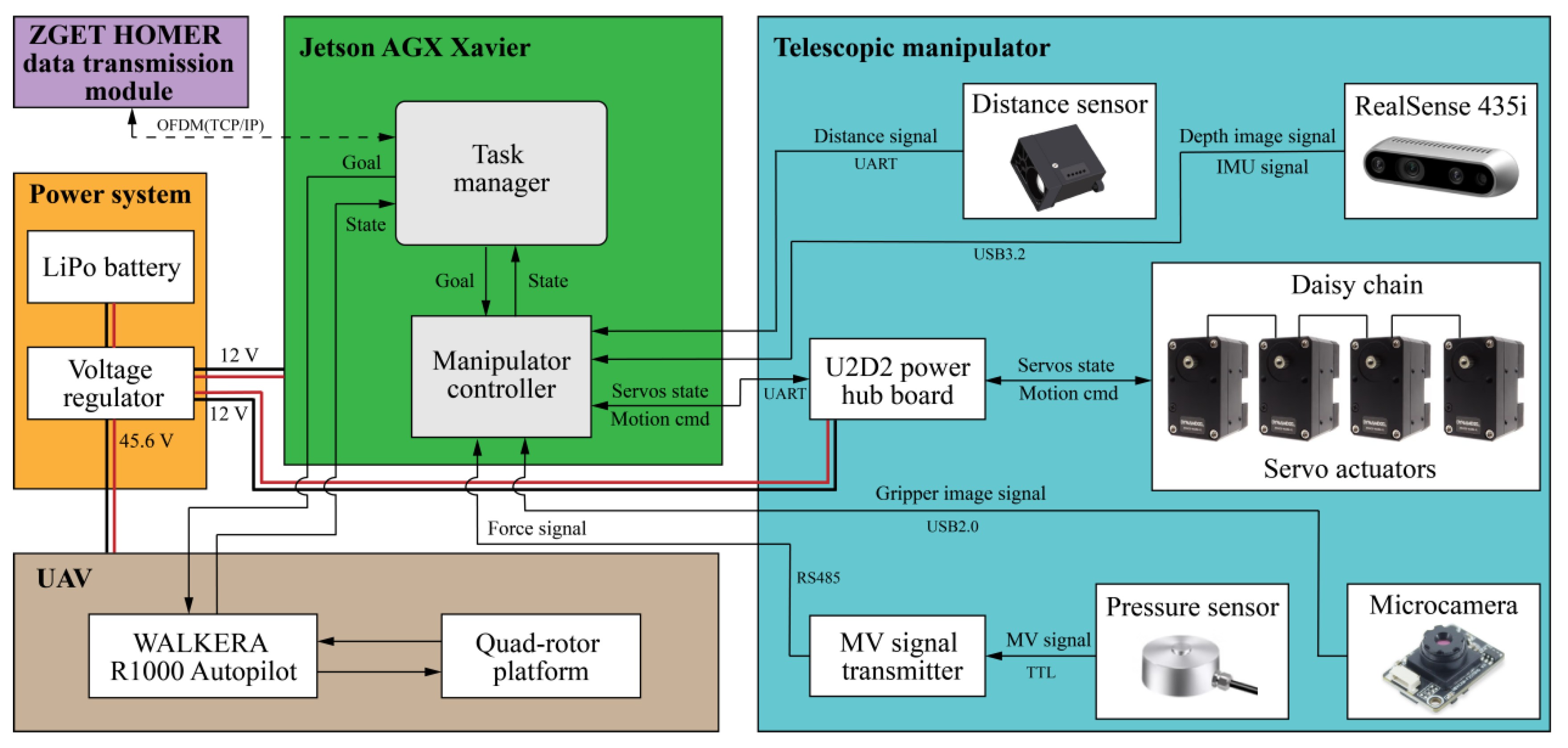

2.4. System Architecture

3. Modeling

3.1. Kinematic Model

3.2. Dynamic Model

3.3. Instantaneous Contact Force Model

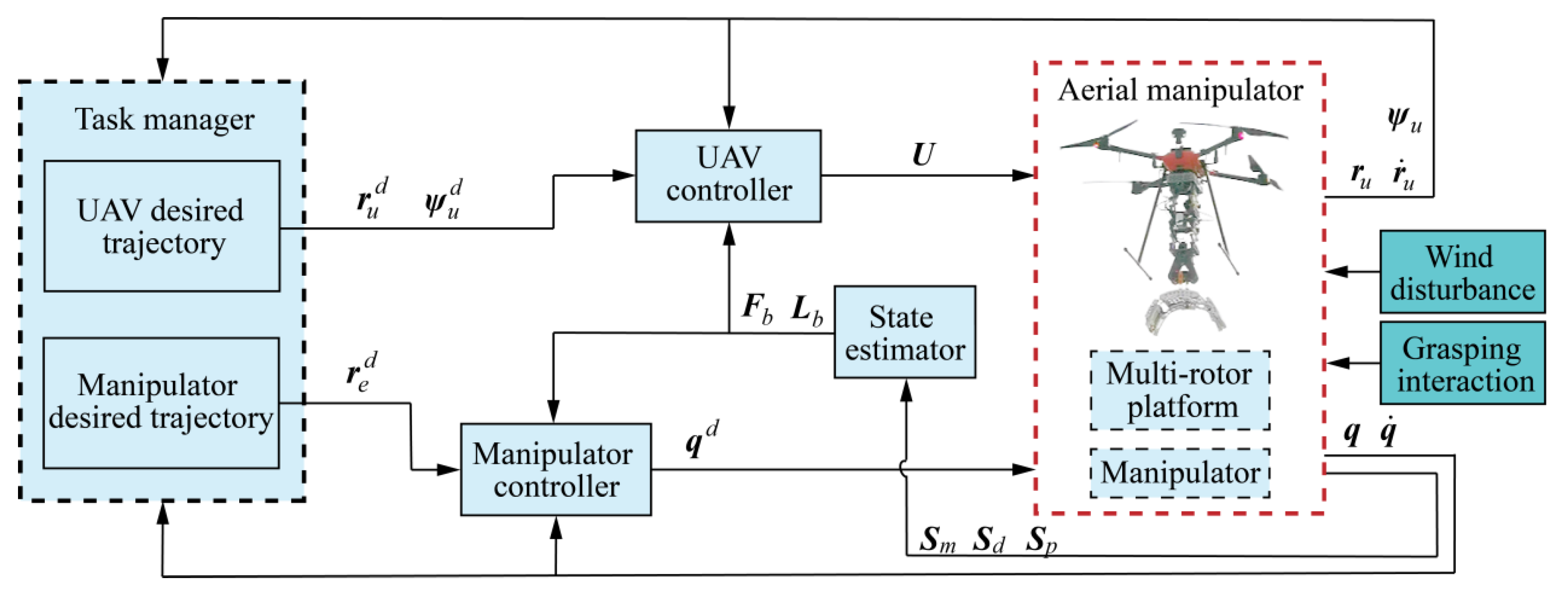

4. Control

4.1. Control Framework

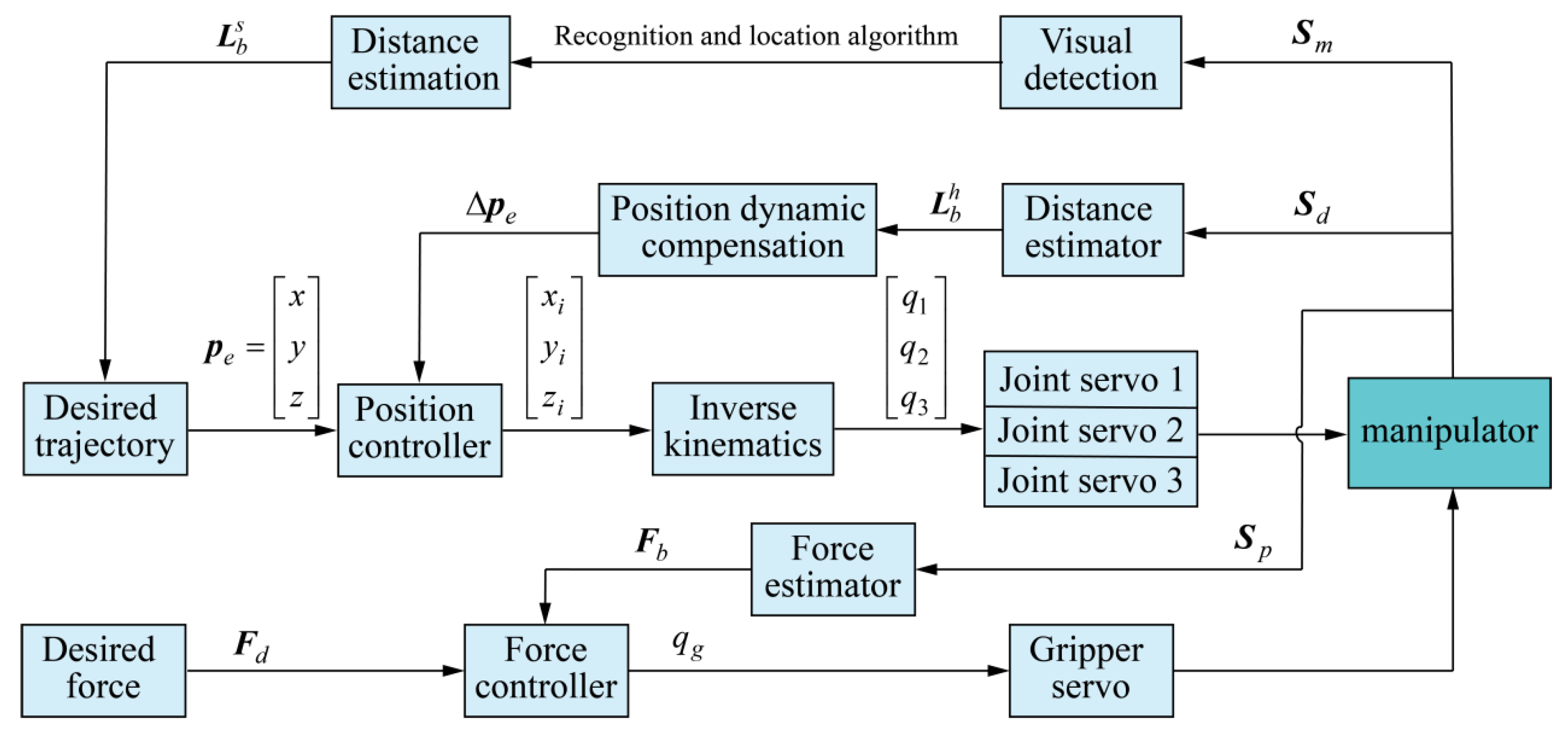

4.2. Manipulator Control

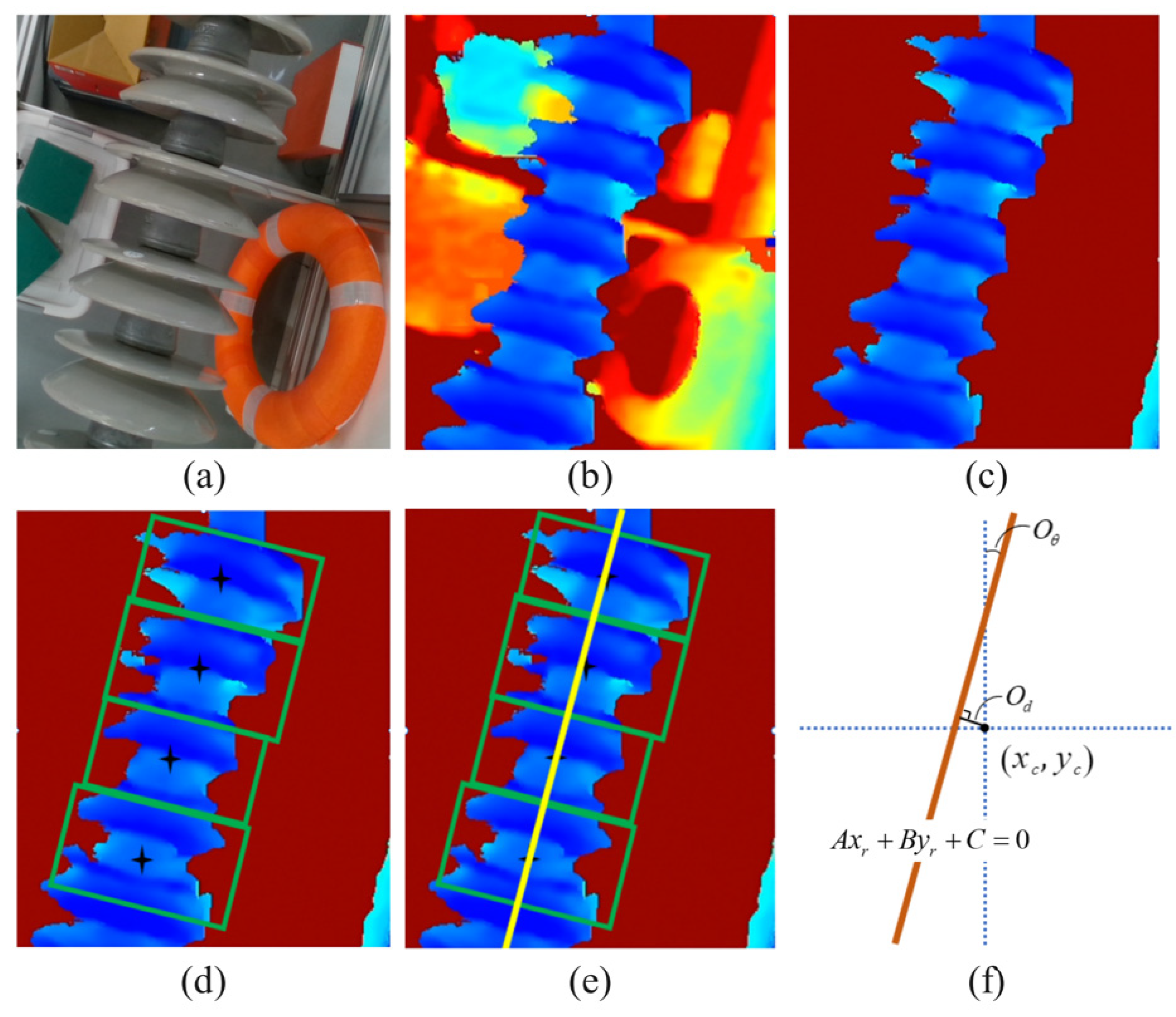

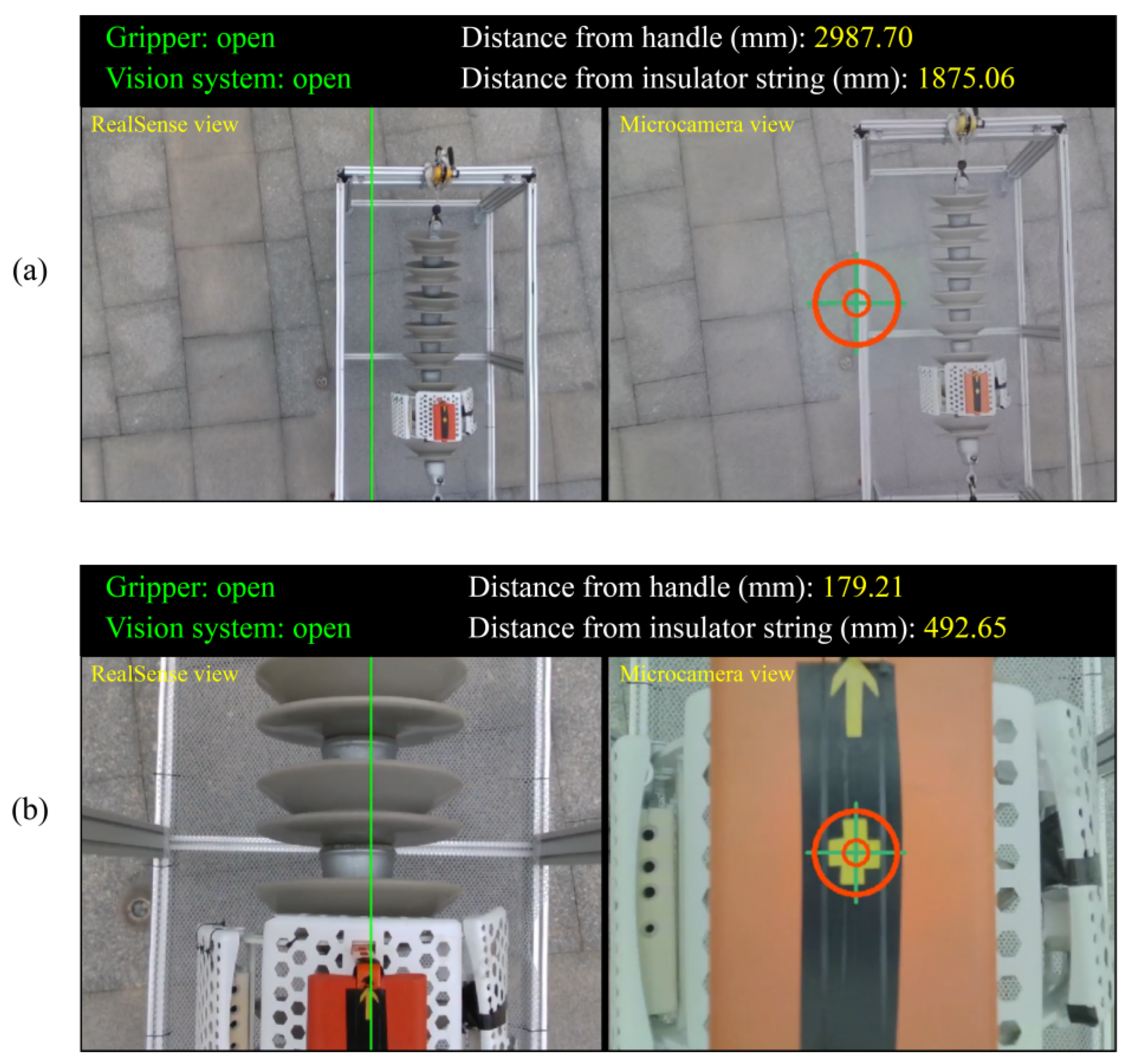

4.3. Visual Detection and Estimation

5. Experimental Results

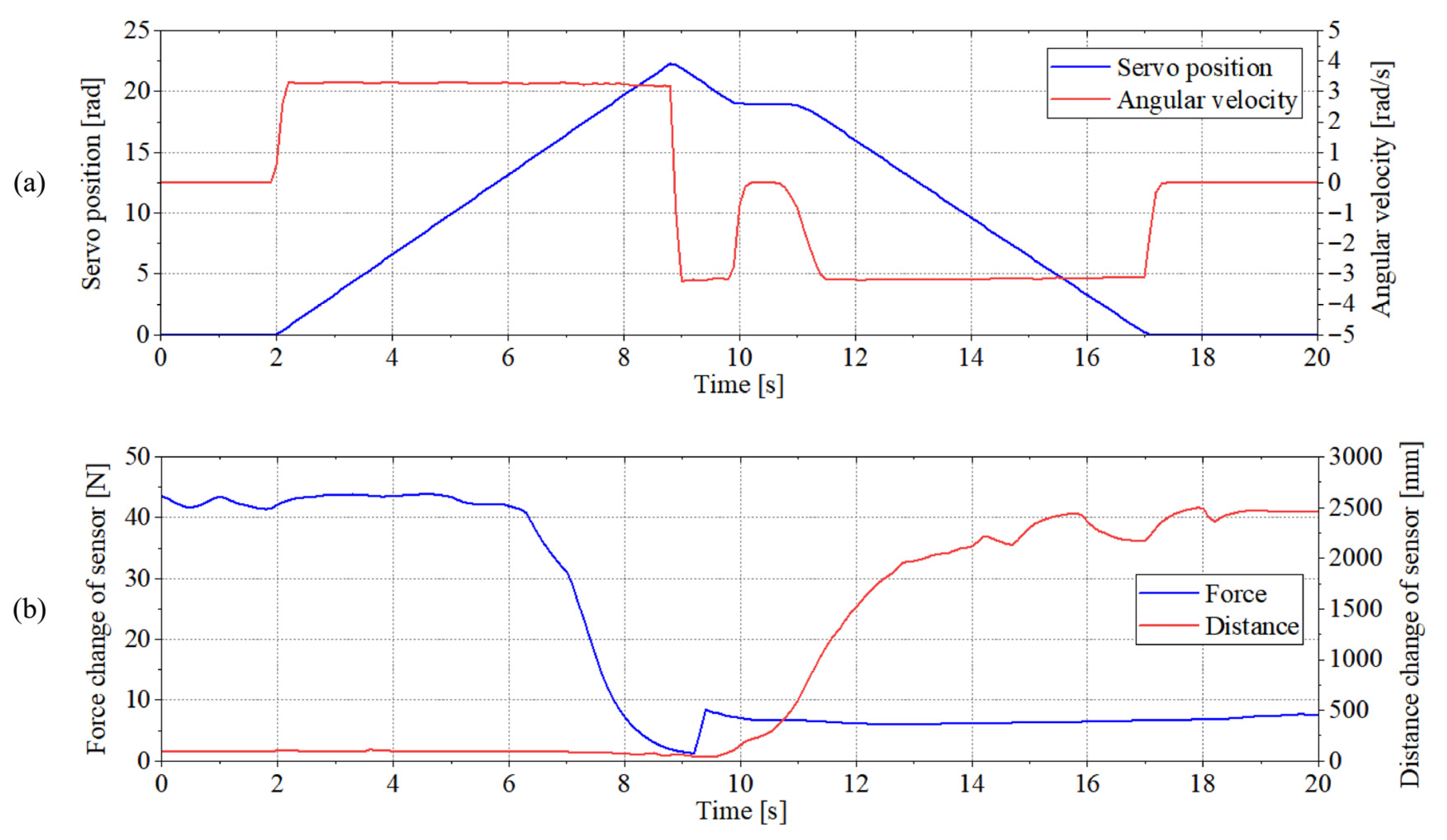

5.1. Lift External Load

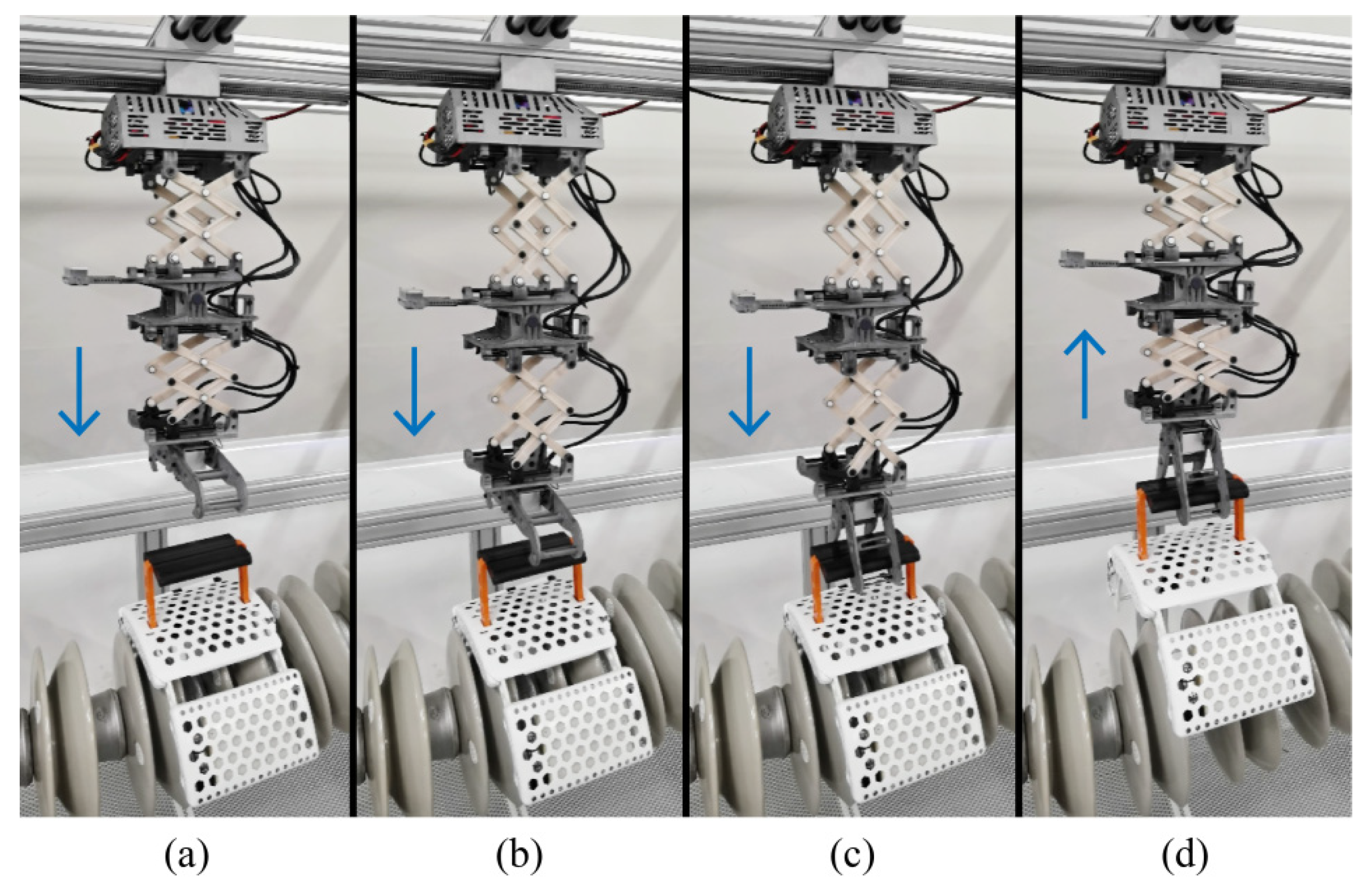

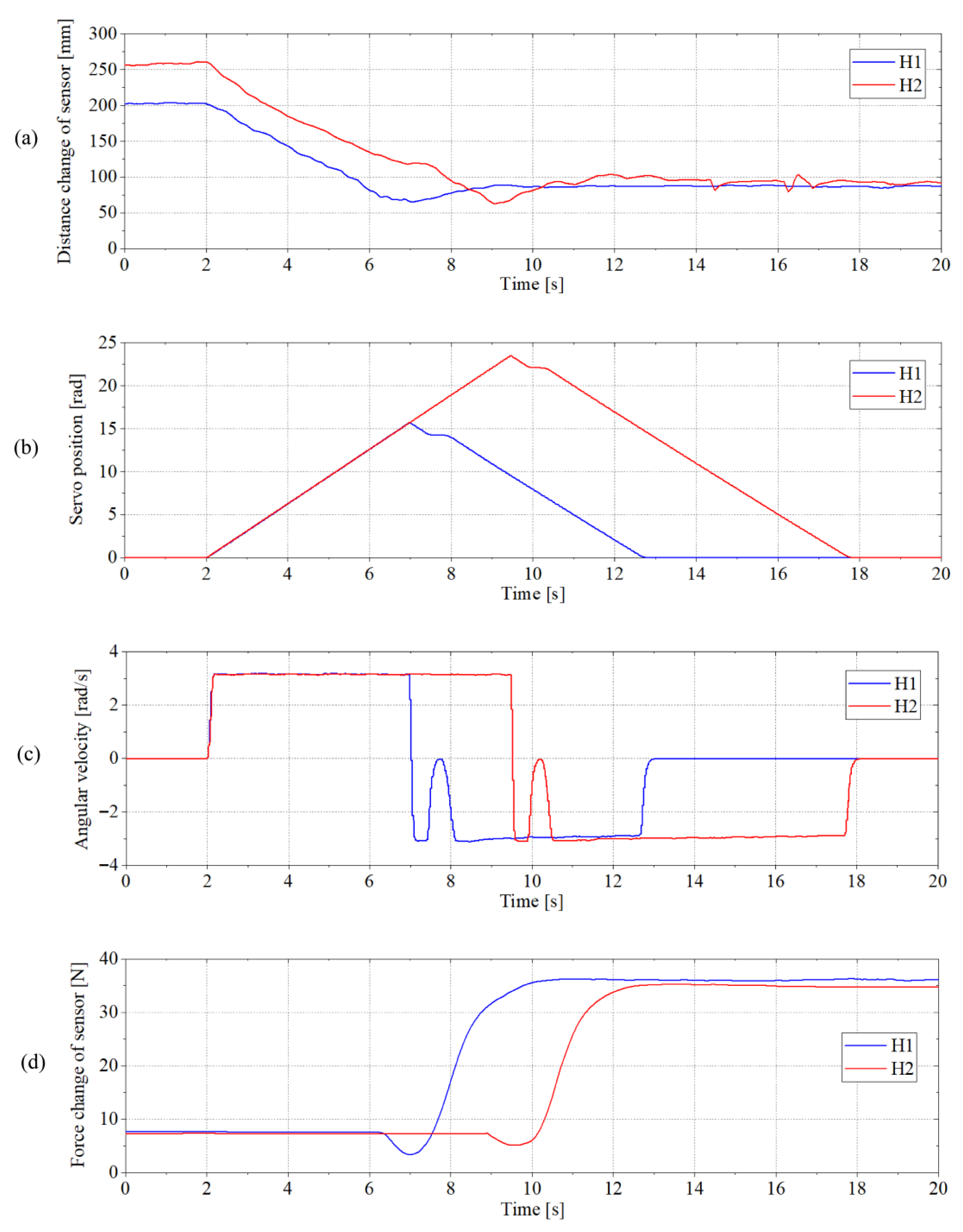

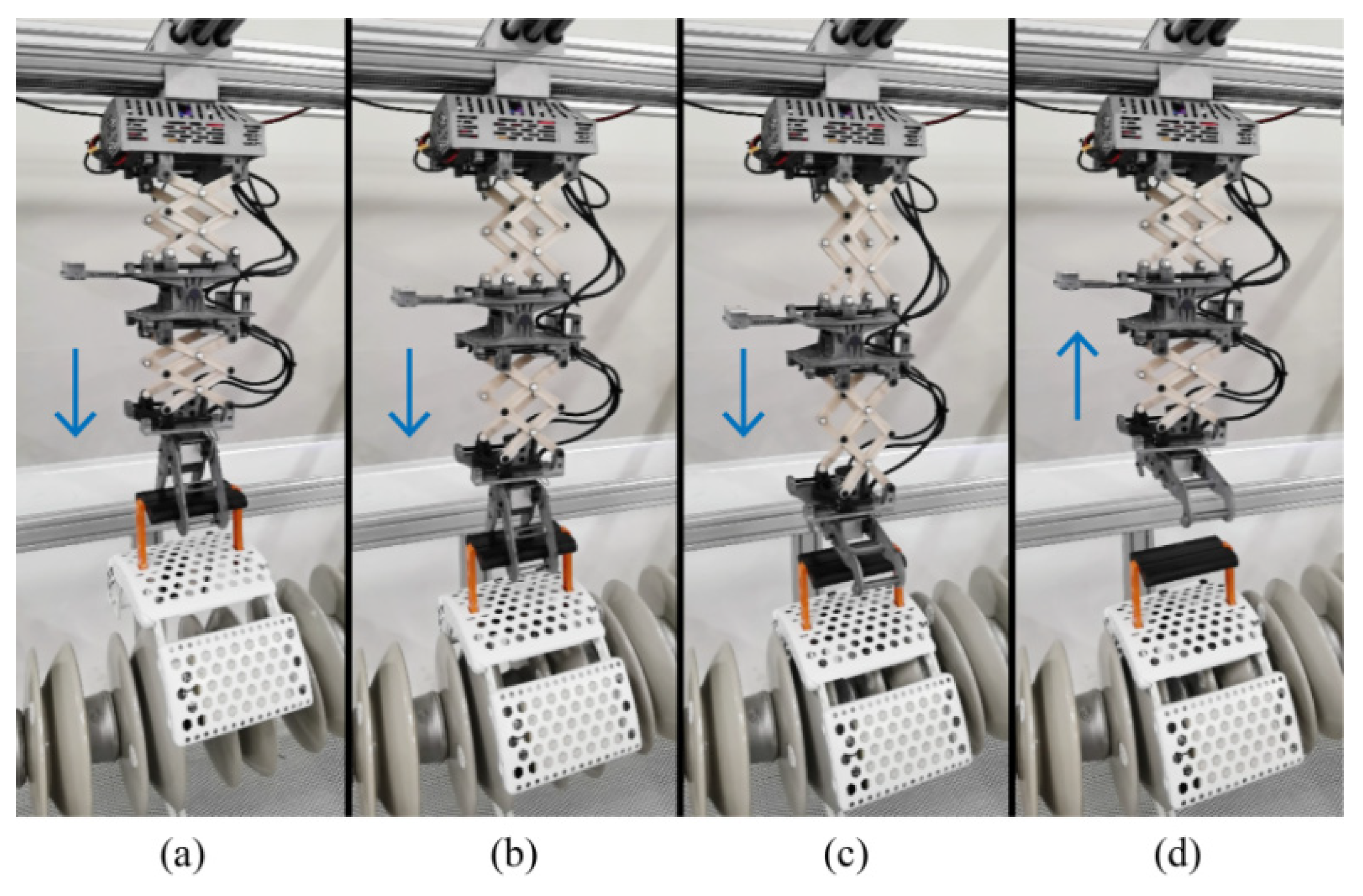

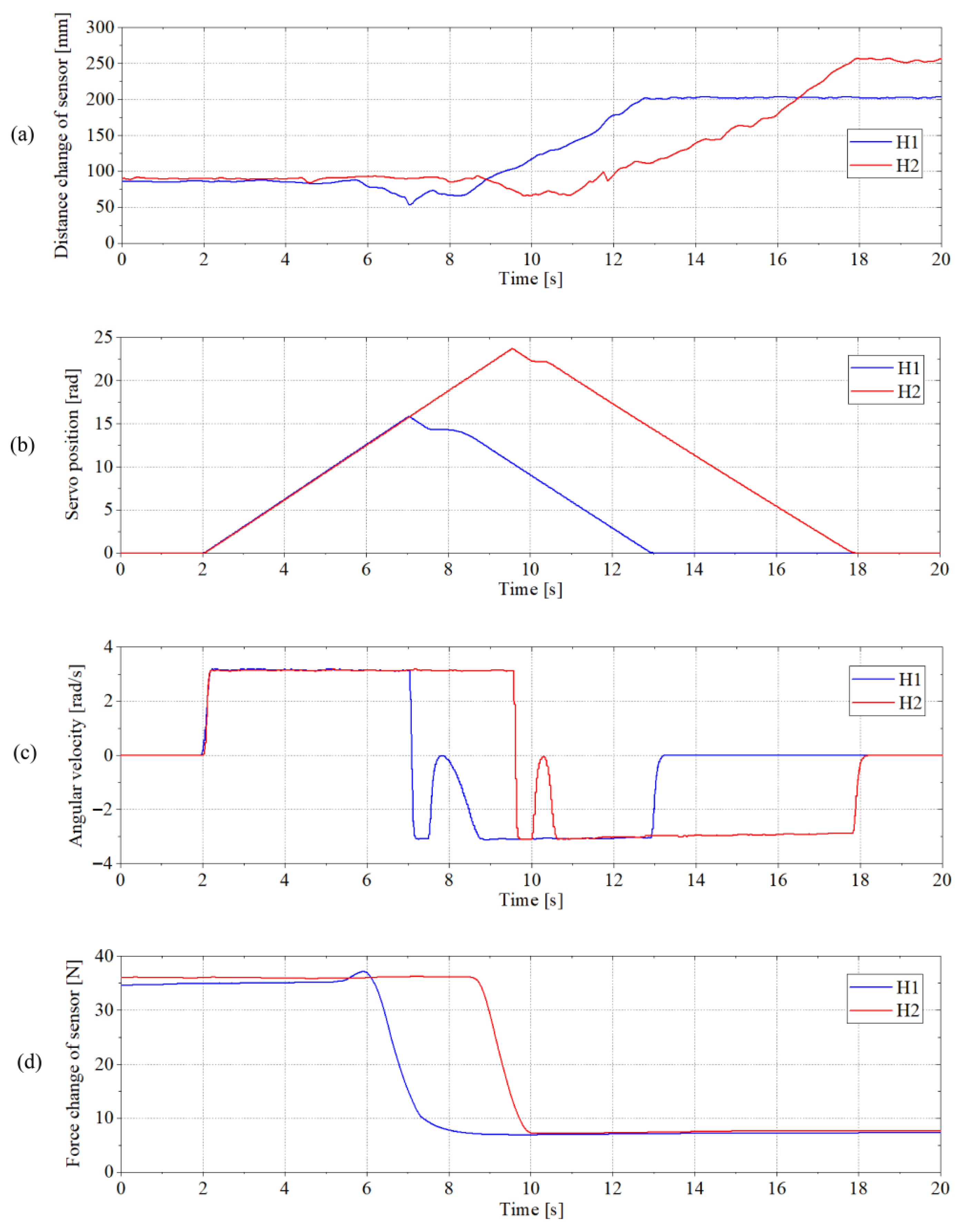

5.2. Grasp and Install Operation Ability

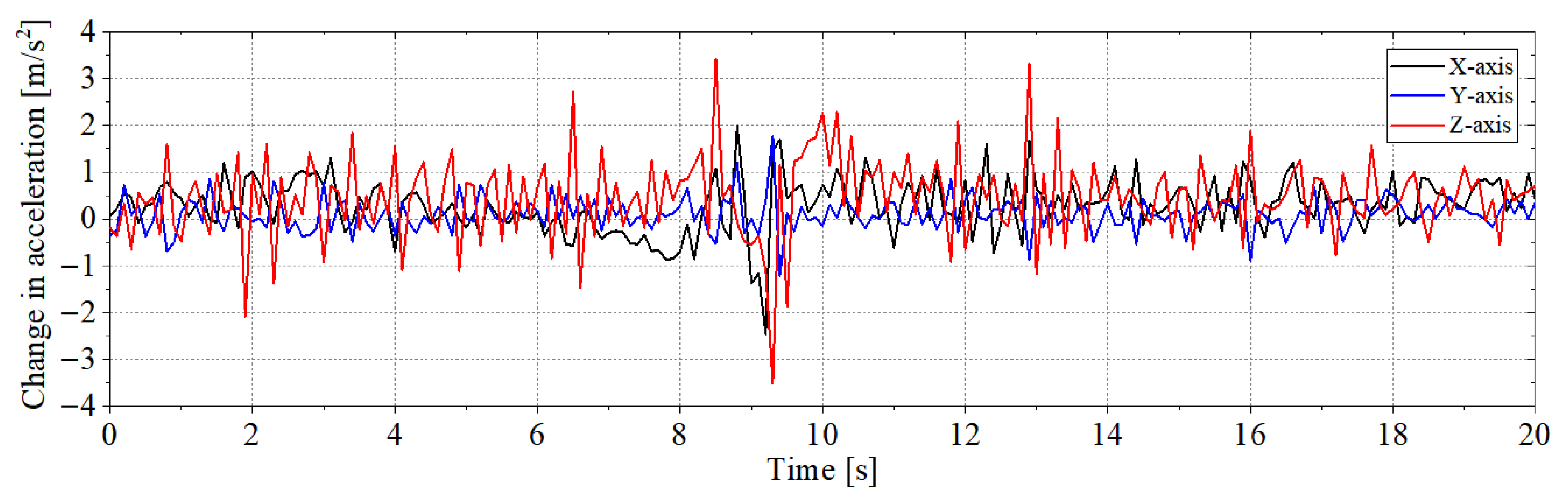

5.3. Outdoor Flight Operation Test

6. Conclusions

- (1)

- The aerial manipulator has three degrees of freedom, including two telescopic scissor mechanisms and one pitch rotation mechanism, and the total mass of the structure is 2.2 kg. The extensible operation range of the manipulator is from 360 mm to 800 mm under the specifically configured arrangement of various types of cameras and sensors in the structure. The kinematic and dynamic models and the instantaneous contact force model are derived based on the designed aerial manipulator, and the hybrid position/force control strategy, as well as the visual detection and estimation algorithm, are designed.

- (2)

- Through various types of tests, the load lifting performance of the designed aerial manipulator and the operation performance for grasping and installation of the target device are quantitatively analyzed. In the real outdoor flight operation of the aerial manipulator on the 3.6 kg target, the system can accurately complete the automatic grasp and installation of the target, and the flight platform has no significant impact phenomenon during the operation. It shows that the designed aerial manipulator has the ability to complete the corresponding operation tasks outdoors.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmed, F.; Mohanta, J.C.; Keshari, A. Power transmission line inspections: Methods, challenges, current status and usage of unmanned Aerial systems. J. Intell. Robot. Syst. 2024, 110, 54. [Google Scholar] [CrossRef]

- Seki, H.; Nakayama, S.; Uenishi, K.; Tsuji, T.; Hikizu, M.; Makino, Y.; Kanda, Y. Development of assistive robotic arm for power line maintenance. Precis. Eng. 2021, 67, 69–76. [Google Scholar] [CrossRef]

- Li, X.; Shang, D.; Li, F.; Chen, R. The climbing performance analysis of a robot for power line inspection with retractable double serial manipulators. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 4946–4961. [Google Scholar] [CrossRef]

- Ollero, A.; Suarez, A.; Marredo, J.M.; Cioffi, G.; Penicka, R.; Vasiljevic, G.; Viguria, A. Application of intelligent aerial robots to the inspection and maintenance of electrical power lines. In Robotics and Automation Solutions for Inspection and Maintenance in Critical Infrastructures; Now Publishers: Delft, The Netherlands, 2024; pp. 178–201. [Google Scholar]

- Cacace, J.; Orozco-Soto, S.M.; Suarez, A.; Caballero, A.; Orsag, M.; Bogdan, S.; Ollero, A. Safe Local Aerial Manipulation for the Installation of Devices on Power Lines: AERIAL-CORE First Year Results and Designs. Appl. Sci. 2021, 11, 6220. [Google Scholar] [CrossRef]

- Stuhne, D.; Hoang, V.D.; Vasiljevic, G.; Bogdan, S.; Kovacic, Z.; Ollero, A.; Ebeid, E.S.M. Design of a Wireless Drone Recharging Station and a Special Robot End Effector for Installation on a Power Line. IEEE Access 2022, 10, 88719–88737. [Google Scholar] [CrossRef]

- Kutia, J.R.; Stol, K.A.; Xu, W. Aerial manipulator interactions with trees for canopy sampling. IEEE/ASME Trans. Mechatron. 2018, 23, 1740–1749. [Google Scholar] [CrossRef]

- Samadikhoshkho, Z.; Lipsett, M.G. Visual Servoing for Aerial Vegetation Sampling Systems. Drones 2024, 8, 605. [Google Scholar] [CrossRef]

- Hamaza, S.; Georgilas, I.; Fernandez, M.; Sanchez, P.; Richardson, T.; Heredia, G.; Ollero, A. Sensor installation and retrieval operations using an unmanned aerial manipulator. IEEE Robot. Autom. Lett. 2019, 4, 2793–2800. [Google Scholar] [CrossRef]

- Ivanovic, A.; Markovic, L.; Car, M.; Duvnjak, I.; Orsag, M. Towards Autonomous Bridge Inspection: Sensor Mounting Using Aerial Manipulators. Appl. Sci. 2021, 11, 8279. [Google Scholar] [CrossRef]

- Suarez, A.; Caballero, A.; Garofano, A.; Sanchez-Cuevas, P.J.; Heredia, G.; Ollero, A. Aerial manipulator with rolling base for inspection of pipe arrays. IEEE Access 2020, 8, 162516–162532. [Google Scholar] [CrossRef]

- Meng, X.; He, Y.; Han, J. Survey on aerial manipulator: System, modeling, and control. Robotica 2020, 38, 1288–1317. [Google Scholar] [CrossRef]

- Tognon, M.; Chávez, H.A.T.; Gasparin, E.; Sablé, Q.; Bicego, D.; Mallet, A.; Franchi, A. A truly-redundant aerial manipulator system with application to push-and-slide inspection in industrial plants. IEEE Robot. Autom. Lett. 2019, 4, 1846–1851. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Chen, Z.; Guo, K.; Yu, X.; Zhang, Y.; Guo, L. A compact aerial manipulator: Design and control for dexterous operations. J. Intell. Robot. Syst. 2024, 110, 66. [Google Scholar] [CrossRef]

- Yang, P.; Wang, H.; Liu, Z.; Dong, Z.; Zhang, L. Development of an Anthropomorphic and Dexterous Dual-Arm System for Aerial Cooperative Bimanual Manipulation. Machines 2022, 10, 273. [Google Scholar] [CrossRef]

- Trujillo, M.A.; Martínez-de Dios, J.R.; Martín, C.; Viguria, A.; Ollero, A. Novel aerial manipulator for accurate and robust industrial NDT contact inspection: A new tool for the oil and gas inspection industry. Sensors 2019, 19, 1305. [Google Scholar] [CrossRef] [PubMed]

- Lobermeier, S.; Moldenhauer, M.; Peter, C.M.; Slominski, L.; Tedesco, R.A.; Ver Meer, M.; Stewart, A.H. Mitigating avian collision with power lines: A proof of concept for installation of line markers via unmanned aerial vehicle. J. Unmanned Veh. Syst. 2015, 3, 252–258. [Google Scholar] [CrossRef]

- Li, L.; Zhang, T.; Zhong, H.; Li, H.; Zhang, H.; Fan, S.; Cao, Y. Autonomous Removing Foreign Objects for Power Transmission Line by Using a Vision-Guided Unmanned Aerial Manipulator. J. Intell. Robot. Syst. 2021, 103, 23. [Google Scholar] [CrossRef]

- Rodriguez-Castaño, A.; Nekoo, S.R.; Romero, H.; Salmoral, R.; Acosta, J.Á.; Ollero, A. Installation of Clip-Type Bird Flight Diverters on High-Voltage Power Lines with Aerial Manipulation Robot: Prototype and Testbed Experimentation. Appl. Sci. 2021, 11, 7427. [Google Scholar] [CrossRef]

- Perez-Jimenez, M.; Montes-Grova, M.A.; Ramon-Soria, P.; Arrue, B.C.; Ollero, A. POSITRON: Lightweight active positioning compliant joints robotic arm in power lines inspection. In Proceedings of the 2020 International Conference on Unmanned Aircraft Systems (ICUAS), Athens, Greece, 1–4 September 2020; pp. 729–736. [Google Scholar]

- Suarez, A.; Salmoral, R.; Zarco-Periñan, P.J.; Ollero, A. Experimental evaluation of aerial manipulation robot in contact with 15 kV power line: Shielded and long reach configurations. IEEE Access 2021, 9, 94573–94585. [Google Scholar] [CrossRef]

- Suarez, A.; Real, F.; Vega, V.M.; Heredia, G.; Rodriguez-Castano, A.; Ollero, A. Compliant bimanual aerial manipulation: Standard and long reach configurations. IEEE Access 2020, 8, 88844–88865. [Google Scholar] [CrossRef]

- Suarez, A.; Salmoral, R.; Garofano-Soldado, A.; Heredia, G.; Ollero, A. Aerial device delivery for power line inspection and maintenance. In Proceedings of the 2022 International Conference on Unmanned Aircraft Systems (ICUAS), Dubrovnik, Croatia, 21–24 June 2022; pp. 30–38. [Google Scholar]

- Suarez, A.; Romero, H.; Salmoral, R.; Acosta, J.A.; Zambrano, J.; Ollero, A. Experimental Evaluation of Aerial Manipulation Robot for the Installation of Clip Type Bird Diverters: Outdoor Flight Tests. In Proceedings of the 2021 Aerial Robotic Systems Physically Interacting with the Environment (AIRPHARO), Biograd na Moru, Croatia, 4–5 October 2021; pp. 1–7. [Google Scholar]

- Armengol, I.; Suarez, A.; Heredia, G.; Ollero, A. Design, Integration and Testing of Compliant Gripper for the Installation of Helical Bird Diverters on Power Lines. In Proceedings of the 2021 Aerial Robotic Systems Physically Interacting with the Environment (AIRPHARO), Biograd na Moru, Croatia, 4–5 October 2021; pp. 1–8. [Google Scholar]

- Muñoz-Gómez, A.M.; Marredo-Píriz, J.M.; Ballestín-Fuertes, J. A Novel Charging Station on Overhead Power Lines for Autonomous Unmanned Drones. Appl. Sci. 2023, 13, 10175. [Google Scholar] [CrossRef]

- Muñoz-Gómez, A.M.; Marredo-Píriz, J.M.; Ballestín-Fuertes, J.; Sanz-Osorio, J.F. A Novel Unmanned Aerial System for Power Line Inspection and Maintenance Operations. In Proceedings of the 2024 International Conference on Unmanned Aircraft Systems (ICUAS), Chania, Greece, 4–7 June 2024; pp. 602–609. [Google Scholar]

- Pu, Z.; Xiong, Y.; Wang, H.; Yan, B.; Wu, T.; Zheng, L.; Yin, P. Design and construction of a new insulator detection robot for application in 500 kV strings: Electric field analysis and field testing. Electr. Power Syst. Res. 2019, 173, 48–55. [Google Scholar] [CrossRef]

- Souza, B.J.; Stefenon, S.F.; Singh, G.; Freire, R.Z. Hybrid-YOLO for classification of insulators defects in transmission lines based on UAV. Int. J. Electr. Power Energy Syst. 2023, 148, 108982. [Google Scholar] [CrossRef]

- Dong, S.; Pan, X.; Wang, H.; Du, T.; Zhu, S. A new link-legged insulator inspection robot. Electr. Power Syst. Res. 2022, 213, 108741. [Google Scholar] [CrossRef]

- Jiang, W.; Yan, Y.; Zhang, A.; Yu, L.; Zuo, G.; Li, H.J.; Chen, W. Live maintenance robot for high-voltage transmission lines. Ind. Robot Int. J. Robot. Res. Appl. 2019, 46, 711–718. [Google Scholar] [CrossRef]

- Yang, L.; Fan, J.; Liu, Y.; Li, E.; Peng, J.; Liang, Z. A review on state-of-the-art power line inspection techniques. IEEE Trans. Instrum. Meas. 2020, 69, 9350–9365. [Google Scholar] [CrossRef]

- Ahmed, M.D.F.; Mohanta, J.C.; Sanyal, A. Inspection and identification of transmission line insulator breakdown based on deep learning using aerial images. Electr. Power Syst. Res. 2022, 211, 108199. [Google Scholar] [CrossRef]

- Corso, M.P.; Stefenon, S.F.; Singh, G.; Matsuo, M.V.; Perez, F.L.; Leithardt, V.R.Q. Evaluation of visible contamination on power grid insulators using convolutional neural networks. Electr. Eng. 2023, 105, 3881–3894. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Q.; Chu, L.; Zhou, Y.; Xu, C. Real-time detection and spatial localization of insulators for UAV inspection based on binocular stereo vision. Remote Sens. 2021, 13, 230. [Google Scholar] [CrossRef]

- Rahman, E.U.; Zhang, Y.; Ahmad, S.; Ahmad, H.I.; Jobaer, S. Autonomous vision-based primary distribution systems porcelain insulators inspection using UAVs. Sensors 2021, 21, 974. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, L.; Yi, Y.; Shen, X.; Zhang, Z. Research on the UAV Intelligent Inspection System to Monitor and Prevent Abnormal Heat of Composite Insulators for 500 kV Transmission System. In Proceedings of the 2019 IEEE 3rd Conference on Energy Internet and Energy System Integration (EI2), Changsha, China, 8–10 November 2019; pp. 2236–2240. [Google Scholar]

- Lopez Lopez, R.; Batista Sanchez, M.J.; Perez Jimenez, M.; Arrue, B.C.; Ollero, A. Autonomous UAV System for Cleaning Insulators in Power Line Inspection and Maintenance. Sensors 2021, 21, 8488. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Li, J.; Ai, Y.; Mao, D.; Zou, J.; Wu, Y. Research on resistance detection robot for UHV tension insulator string. J. Phys. Conf. Ser. 2024, 2728, 012049. [Google Scholar] [CrossRef]

- Huang, X.; Xie, Y.W.; Ma, C.; Tan, J.; Qiu, D.; Wu, Y.; Fang, S. Design and application of insulator detection robot system for UHVDC transmission line. Int. J. Mech. Eng. Appl. 2019, 4, 106–110. [Google Scholar] [CrossRef]

- Yuan, H.; Yuan, B.; Wang, H.; Song, Y. Mechanical Design of a Metamorphic Robot for High-voltage Transmission Line Insulator Detection. In Proceedings of the 2021 IEEE International Conference on Robotics and Biomimetics (ROBIO), Sanya, China, 27–31 December 2021; pp. 1916–1922. [Google Scholar]

- Zengin, A.T.; Erdemir, G.; Akinci, T.C.; Seker, S. Measurement of power line sagging using sensor data of a power line inspection robot. IEEE Access 2020, 8, 99198–99204. [Google Scholar] [CrossRef]

- Boukabou, I.; Kaabouch, N. Electric and magnetic fields analysis of the safety distance for UAV inspection around extra-high voltage transmission lines. Drones 2024, 8, 47. [Google Scholar] [CrossRef]

- Jiang, W.; Zou, D.; Zhou, X.; Zuo, G.; Ye, G.C.; Li, H.J. Research on key technologies of multi-task-oriented live maintenance robots for Ultra High Voltage multi-split transmission lines. Ind. Robot Int. J. Robot. Res. Appl. 2021, 48, 17–28. [Google Scholar] [CrossRef]

- Shruthi, C.M.; Sudheer, A.P.; Joy, M.L. Dual arm electrical transmission line robot: Motion through straight and jumper cable. Automatika 2019, 60, 207–226. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics: Modelling, Planning and Control; Springer: London, UK, 2010. [Google Scholar]

- Aydemir, M.; Arıkan, K.B. Evaluation of the disturbance rejection performance of an aerial manipulator. J. Intell. Robot. Syst. 2020, 97, 451–469. [Google Scholar] [CrossRef]

- Xu, W.; Cao, L.; Zhong, C. Review of Aerial Manipulator and its Control. Int. J. Robot. Control Syst. 2021, 1, 308–325. [Google Scholar]

- Mavrakis, N.; Stolkin, R. Estimation and exploitation of objects’ inertial parameters in robotic grasping and manipulation: A survey. Robot. Auton. Syst. 2020, 124, 103374. [Google Scholar] [CrossRef]

- Kanellakis, C.; Nikolakopoulos, G. Guidance for autonomous aerial manipulator using stereo vision. J. Intell. Robot. Syst. 2020, 100, 1545–1557. [Google Scholar] [CrossRef]

- Ramon-Soria, P.; Arrue, B.C.; Ollero, A. Grasp planning and visual servoing for an outdoors aerial dual manipulator. Engineering 2020, 6, 77–88. [Google Scholar] [CrossRef]

- Chen, C.; Zheng, Z.; Xu, T.; Guo, S.; Feng, S.; Yao, W.; Lan, Y. YOLO-Based UAV Technology: A Review of the Research and Its Applications. Drones 2023, 7, 190. [Google Scholar] [CrossRef]

- Jawaharlalnehru, A.; Sambandham, T.; Sekar, V.; Ravikumar, D.; Loganathan, V.; Kannadasan, R.; Alzamil, Z.S. Target object detection from Unmanned Aerial Vehicle (UAV) images based on improved YOLO algorithm. Electronics 2022, 11, 2343. [Google Scholar] [CrossRef]

- Ye, T.; Qin, W.; Zhao, Z.; Gao, X.; Deng, X.; Ouyang, Y. Real-Time Object Detection Network in UAV-Vision Based on CNN and Transformer. IEEE Trans. Instrum. Meas. 2023, 72, 2505713. [Google Scholar] [CrossRef]

- Suarez, A.; Vega, V.M.; Fernandez, M.; Heredia, G.; Ollero, A. Benchmarks for aerial manipulation. IEEE Robot. Autom. Lett. 2020, 5, 2650–2657. [Google Scholar] [CrossRef]

- Jia, H.; Bai, S.; Chirarattananon, P. Aerial manipulation via modular quadrotors with passively foldable airframes. IEEE/ASME Trans. Mechatron. 2023, 28, 1930–1938. [Google Scholar] [CrossRef]

| Telescopic Manipulator | UAV | ||

|---|---|---|---|

| Weight | 2.2 kg | Weight | 7.8 kg |

| Lift external load | Exceed 4 kg | Propellers | 24 × 7.9 inch |

| Max. joint speed | 276°/s | LiPo battery | 12S, 14,000 mAh |

| Elbow rotation | (−10°, 35°) | Width × height | 1140 mm × 531 mm |

| Min./max. length | 360/800 mm | Max. take-off weight | 15.8 kg |

| Servo models | Telescopic mechanisms: XM540-W270-R Elbow: XM430-W350-R Gripper: XM430-W350-R | Max. flight time | 54.5 min (no-load) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, P.; Wang, H.; Huang, X.; Gu, J.; Deng, T.; Yuan, Z. A Novel Telescopic Aerial Manipulator for Installing and Grasping the Insulator Inspection Robot on Power Lines: Design, Control, and Experiment. Drones 2025, 9, 741. https://doi.org/10.3390/drones9110741

Yang P, Wang H, Huang X, Gu J, Deng T, Yuan Z. A Novel Telescopic Aerial Manipulator for Installing and Grasping the Insulator Inspection Robot on Power Lines: Design, Control, and Experiment. Drones. 2025; 9(11):741. https://doi.org/10.3390/drones9110741

Chicago/Turabian StyleYang, Peng, Hao Wang, Xiuwei Huang, Jiawei Gu, Tao Deng, and Zonghui Yuan. 2025. "A Novel Telescopic Aerial Manipulator for Installing and Grasping the Insulator Inspection Robot on Power Lines: Design, Control, and Experiment" Drones 9, no. 11: 741. https://doi.org/10.3390/drones9110741

APA StyleYang, P., Wang, H., Huang, X., Gu, J., Deng, T., & Yuan, Z. (2025). A Novel Telescopic Aerial Manipulator for Installing and Grasping the Insulator Inspection Robot on Power Lines: Design, Control, and Experiment. Drones, 9(11), 741. https://doi.org/10.3390/drones9110741