Review of Thrust Vectoring Technology Applications in Unmanned Aerial Vehicles

Abstract

1. Introduction

2. Fundamentals and Mathematical Models

2.1. Mechanical Thrust Vectoring Technology

- (1)

- Definition of a coordinate system

- (2)

- Equations of motion for the centre of mass

- (3)

- Equations of rotation

- (4)

- Model Simplification Explanation

2.2. Fluidic Thrust Vectoring Technology

- (1)

- Equation of conservation of momentum

- (2)

- Thrust and moment generation

- (3)

- Equations of motion for the centre of mass

- (4)

- Equations of rotation

- (5)

- Model Simplification Explanation

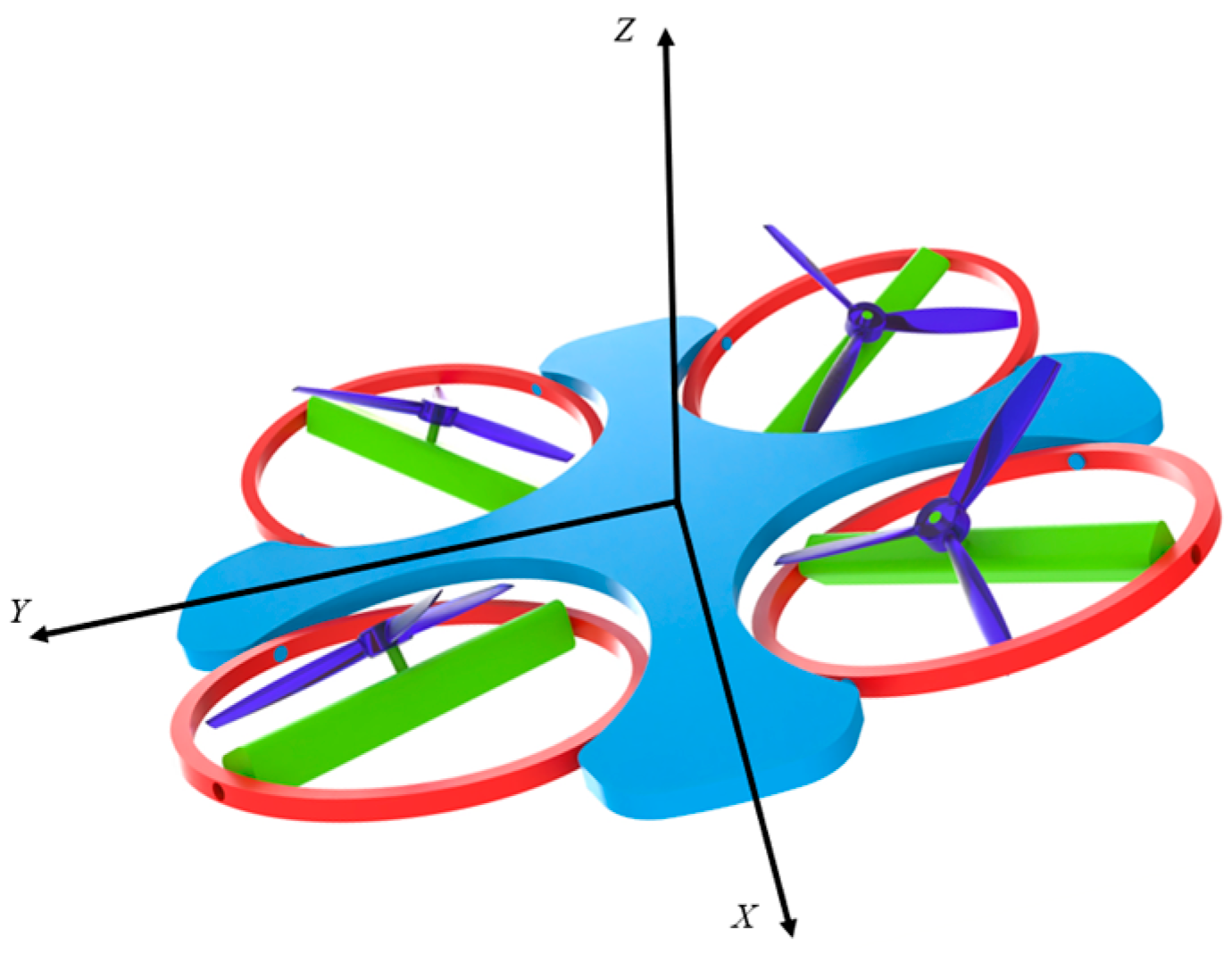

2.3. Multi-Rotor UAV Vector Models

- (1)

- Rotor numbering and position definition (symmetrical cross configuration):

- (2)

- Rotor thrust vector:

- (3)

- dynamical equation

- (4)

- Model Simplification Explanation

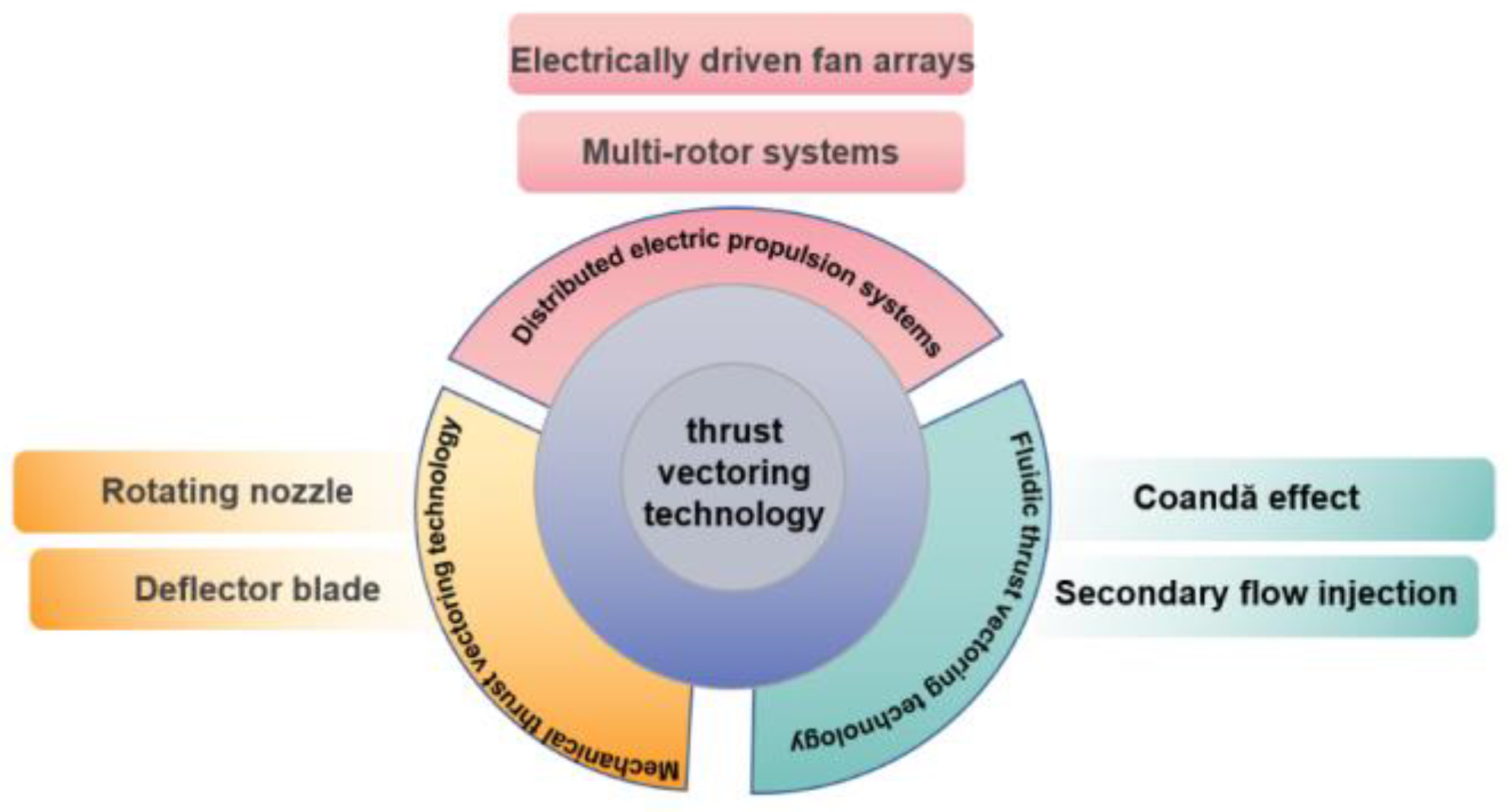

3. Key Technology Systems

3.1. Vector Realisation Technique

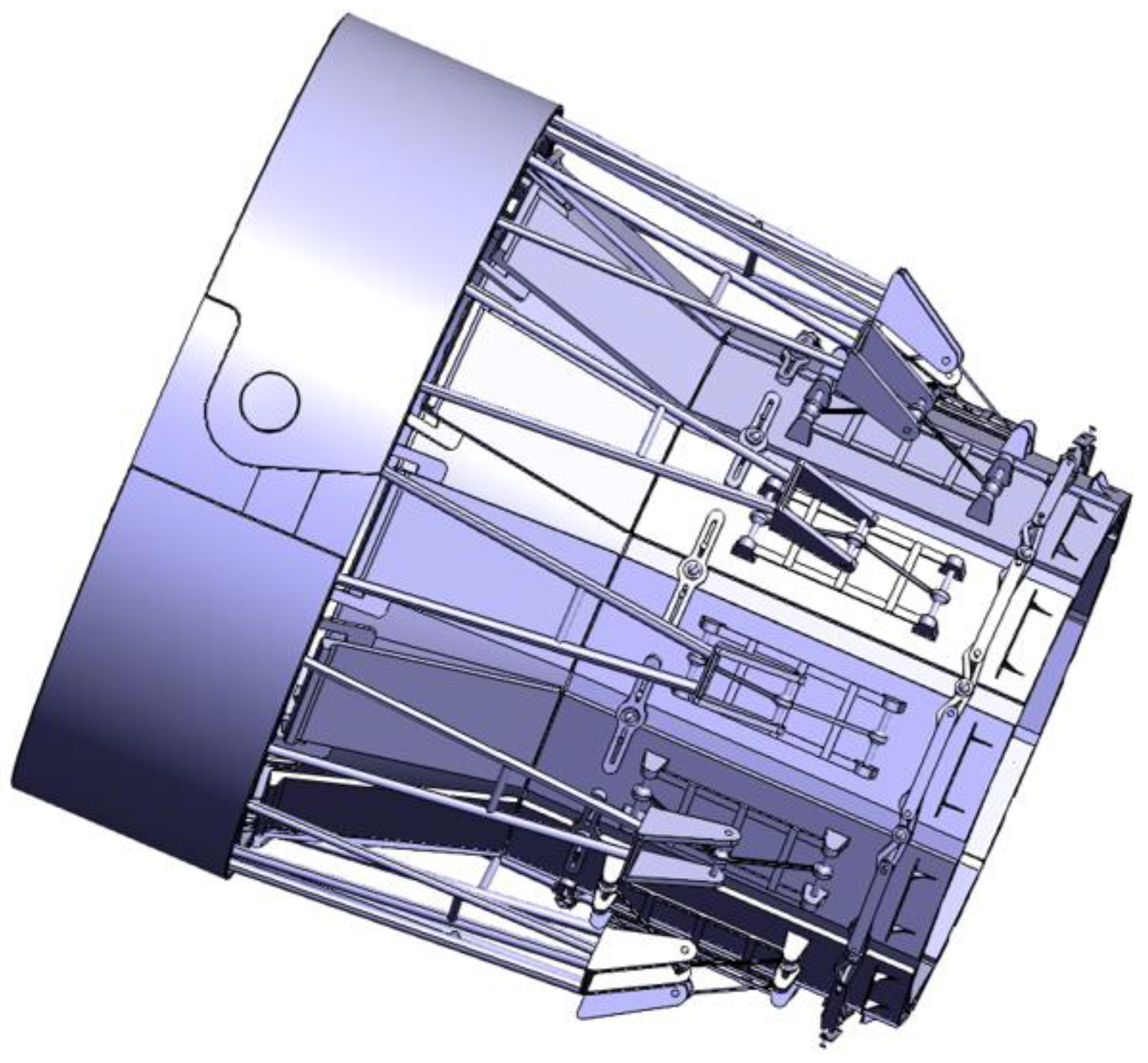

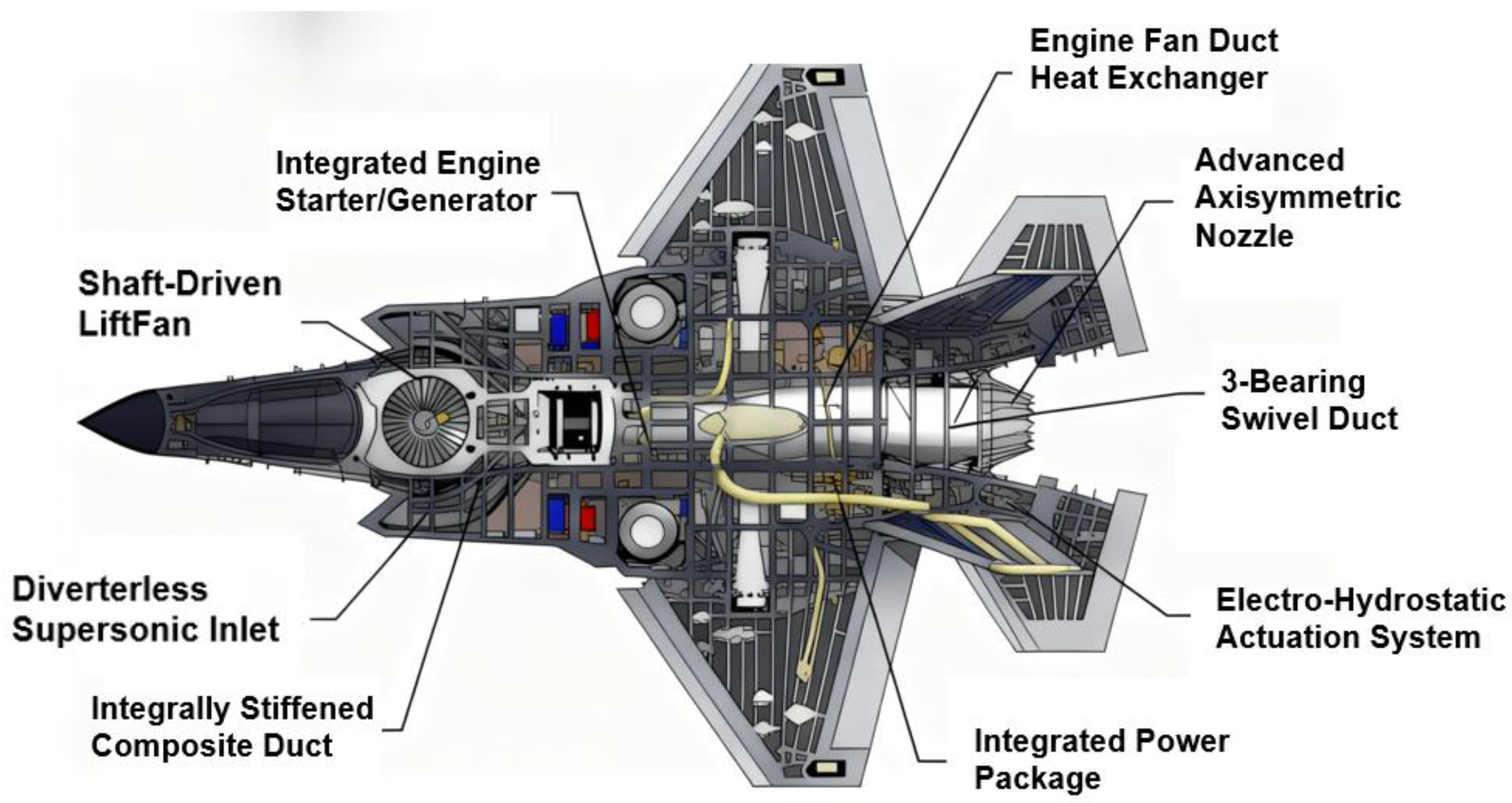

3.1.1. Mechanical Vector System

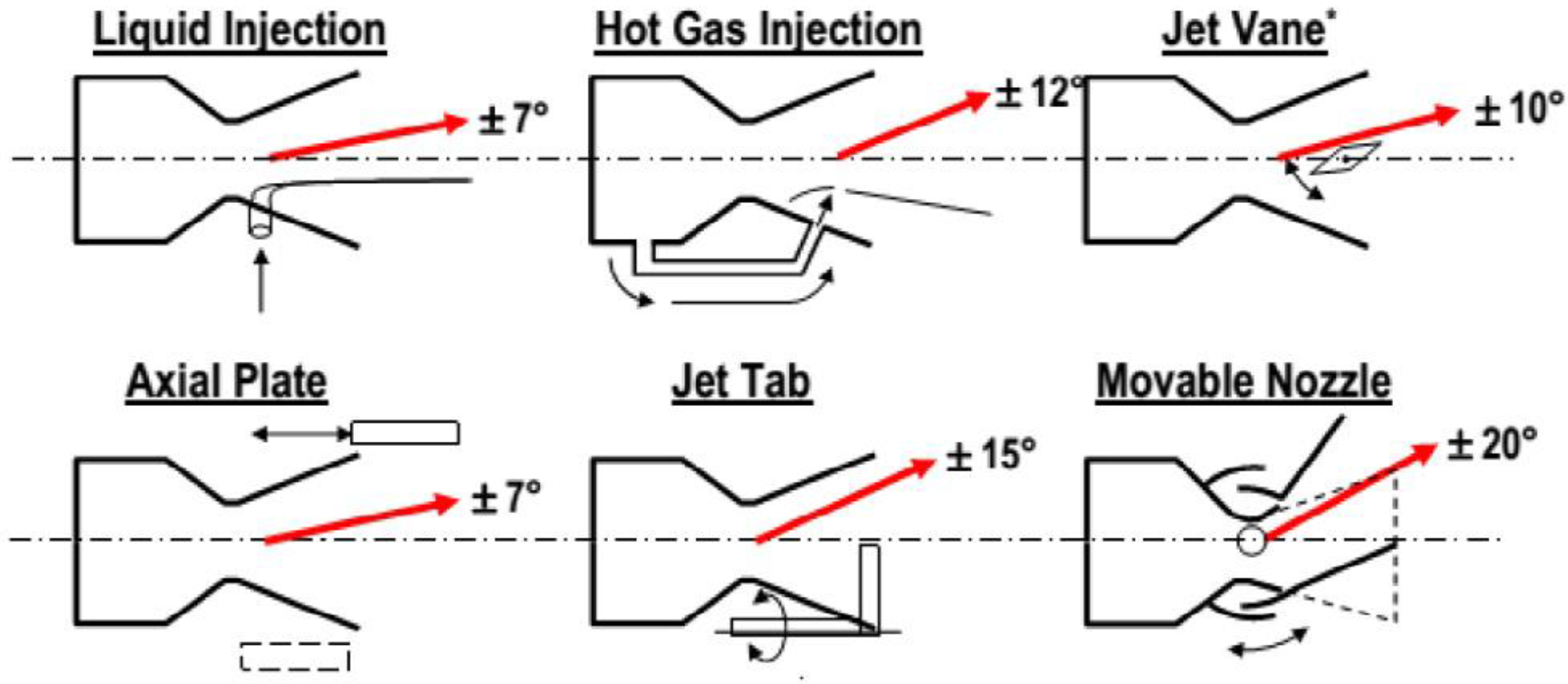

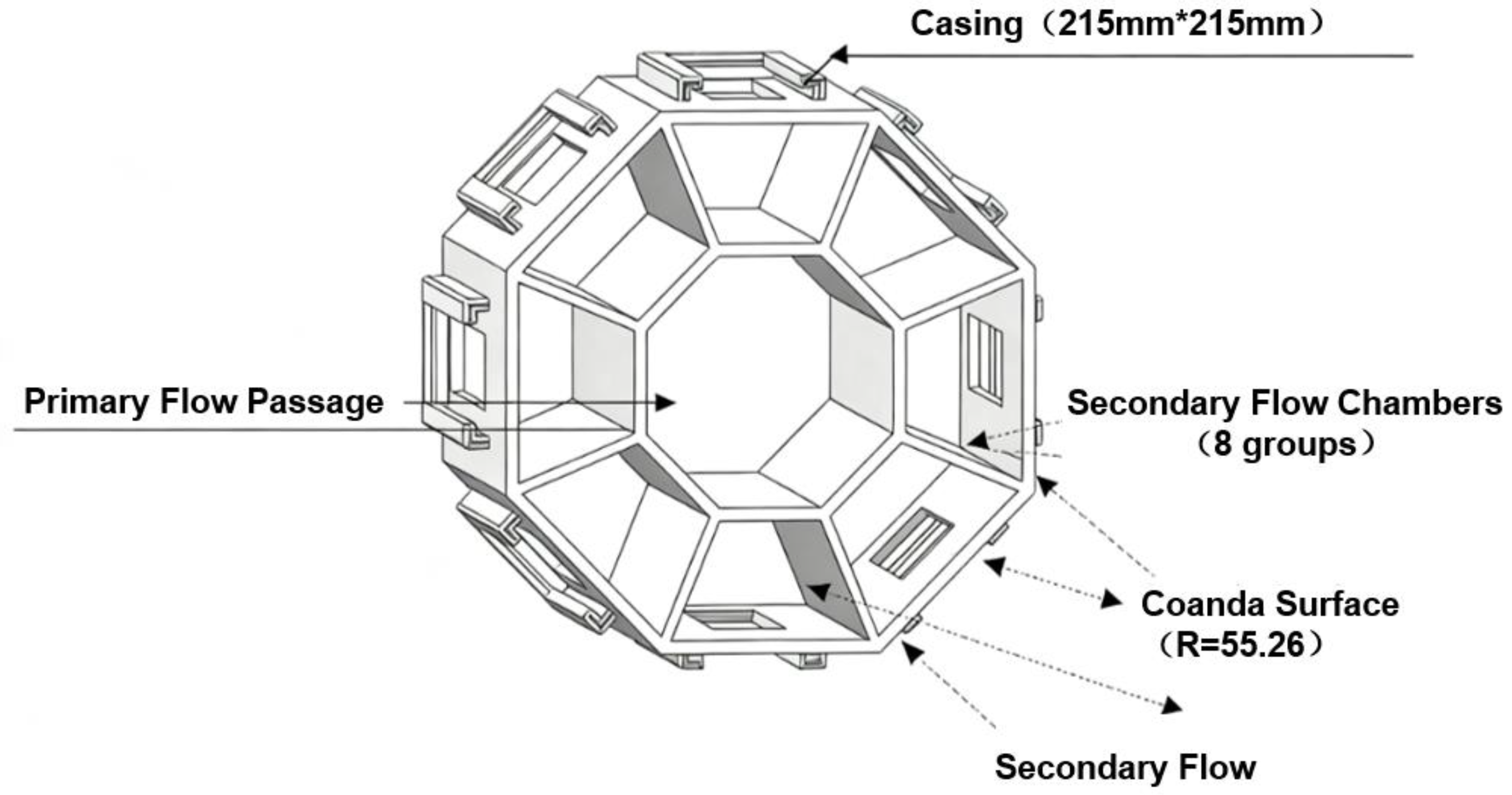

3.1.2. Fluidic Vector System

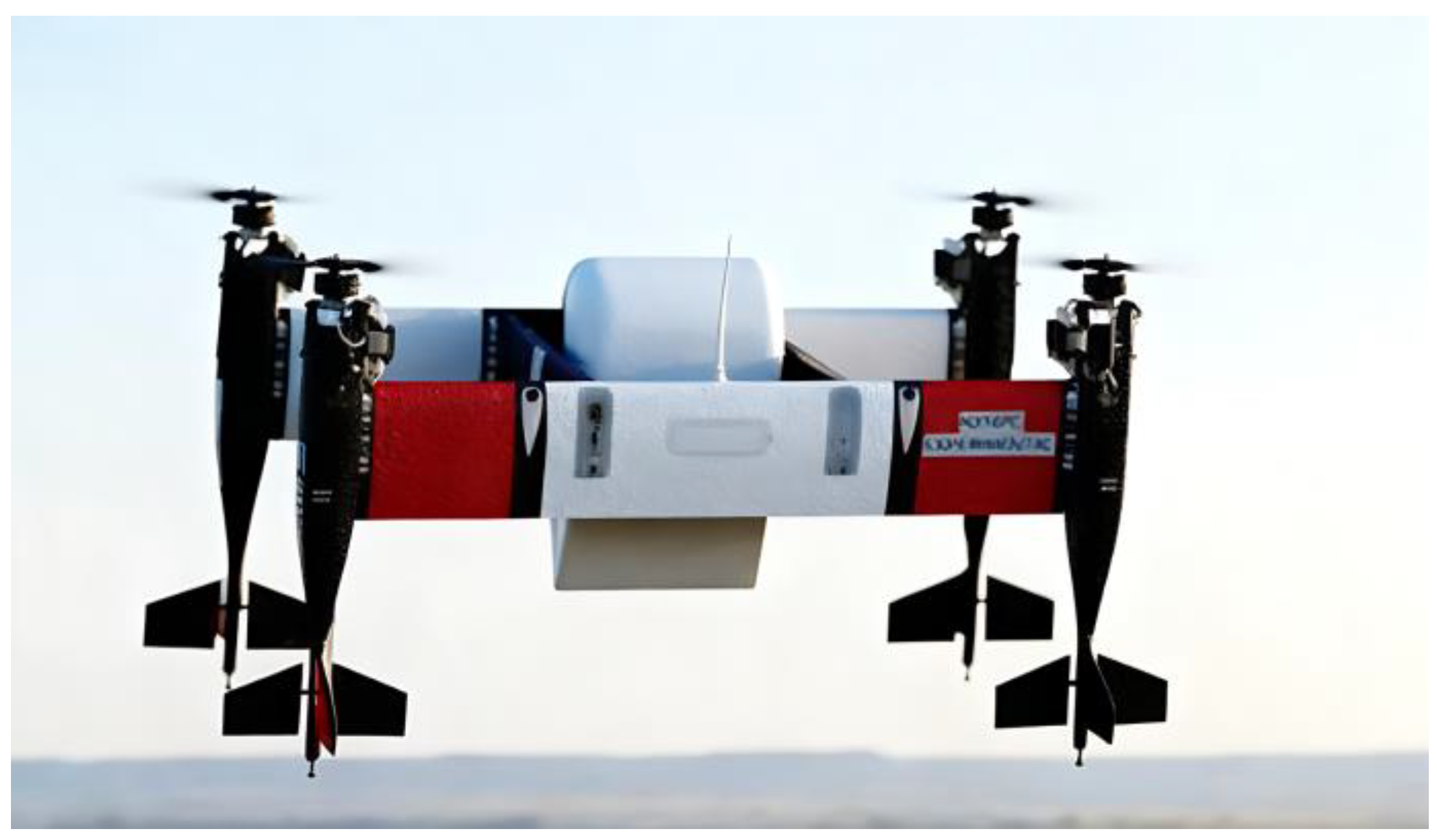

3.1.3. Distributed Electric Propulsion System

3.2. Control Theory and Methods

3.2.1. Active Disturbance Rejection Control (ADRC)

3.2.2. Model Reference Adaptive Control (MRAC)

3.2.3. Backstepping Control

3.2.4. Sliding Mode Control (SMC)

3.3. Path Planning Algorithm

3.3.1. Algorithms Based on Graph Search

- (1)

- Improvement of the A* algorithm

- (2)

- Spatio-temporal Dijkstra algorithm

3.3.2. Bionics-Inspired Algorithm

- (1)

- Chaotic Particle Swarm Optimisation

- (2)

- Adaptive Ant Colony Algorithm

3.3.3. Integration of Related Technologies

- (1)

- A*-PSO convergence architecture

- (2)

- ABC-RRT*

4. Typical Application Case Study

4.1. Applications in the Field of Drones

4.2. Vertical Take-Off and Landing Vehicle Applications

4.3. Speciality Robotics

5. Technical Challenges and Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Longitudinal axis of airframe coordinate system | Lateral axis of airframe coordinate system | ||

| Vertical axis of airframe coordinate system | Position vector of nozzle | ||

| Position vector of control fluid injection point | Position vector of rotor | ||

| Rotor arm length | Distance to obstacle | ||

| Radius of obstacle | Total engine thrust | ||

| Thrust component along -axis | Thrust component along -axis | ||

| Thrust component along Z-axis | Thrust of single rotor | ||

| Total aerodynamic force | Drag | ||

| Lift | Lateral force | ||

| UAV gravity | Total external force | ||

| Additional inertial force | Thrust moment | ||

| Composite disturbance | UAV inertia tensor | ||

| Total pheromone increment | aerodynamic moment | ||

| Longitudinal deflection angle of thrust | Pheromone volatility coefficient | ||

| Lateral deflection angle of thrust | UAV pitch angle | ||

| UAV roll angle | Angle of approach | ||

| Lateral force angle | Vertical deflection angle of control fluid | ||

| Horizontal deflection angle of control fluid | Pitch deflection angle of thrust | ||

| Yaw deflection angle of thrust | Rotor polar angle | ||

| Rotor azimuth angle | Climb angle | ||

| Turn angle | Main fluid velocity vector | ||

| Control fluid velocity vector | Flight speed | ||

| Weight coefficient | Weight coefficient of heuristic function | ||

| Exponential coefficient of heuristic function | |||

| ADRC | Active Disturbance Rejection Control | ABC | Artificial Bee Colony Algorithm |

| CAAC | Civil Aviation Administration of China | DEP | Distributed Electric Propulsion |

| EASA | European Union Aviation Safety Agency | ESO | Extended State Observer |

| FTSMC | Finite-Time Sliding Mode Controller | LESO | Linear Extended State Observer |

| MRAC | Model Reference Adaptive Control | MEMS | Micro-Electro-Mechanical Systems |

| NLSEF | Nonlinear State Error Feedback | PID | Proportional-Integral-Derivative Control |

| PTESO | Predefined Time Extended State Observer | RRT* | Rapidly-exploring Random Tree Star |

| SMC | Sliding Mode Control | STOL | Short Take-Off and Landing |

| TD | Tracking Differentiator | VTOL | Vertical Take-Off and Landing |

| eVTOL | electric Vertical Take-Off and Landing |

References

- Huang, X. The small-drone revolution is coming—Scientists need to ensure it will be safe. Nature 2025, 637, 29–30. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zeng, Q.; Shao, C.; Zhuo, P.; Li, B.; Sun, K. UAV localization method with keypoints on the edges of semantic objects for low-altitude economy. Drones 2024, 9, 14. [Google Scholar] [CrossRef]

- Xu, Y. Research on UAV Control Technology with Thrust Vectoring. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2012. [Google Scholar]

- Chen, J.W.; Chen, K.; Shang, N.N.; Yan, J. Performance analysis of aircraft based on aerodynamic force/thrust vector control. J. Northwestern Polytech. Univ. 2014, 32, 877–881. [Google Scholar]

- Tao, Z.Y.; Li, J.; Cheng, B.Q. Key technology of aircraft propulsion system—Thrust vectoring technology. J. Air Force Eng. Univ. 2000, 2, 86–90. [Google Scholar]

- Afridi, S.; Khan, T.A.; Shah, S.I.A.; Shams, T.A.; Mohiuddin, K.; Kukulka, D.J. Techniques of fluidic thrust vectoring in jet engine nozzles: A review. Energies 2023, 16, 5721. [Google Scholar] [CrossRef]

- Páscoa, J.C.; Dumas, A.; Trancossi, M.; Stewart, P.; Vucinic, D. A review of thrust-vectoring in support of a V/STOL non-moving mechanical propulsion system. Open Eng. 2013, 3, 374–388. [Google Scholar] [CrossRef]

- Rakesh, R.B.; Varghese, S. Fluidic thrust vectoring of engine nozzle. In Proceedings of the International Conference on Modern Research in Aerospace Engineering; Singh, S., Raj, P., Tambe, S., Eds.; Springer Singapore: Singapore, 2018; pp. 43–51. [Google Scholar]

- Cui, Z.; Wang, Y.S. Review of research on aircraft thrust vector nozzles. Cruise Missiles 2021, 12, 158–167. [Google Scholar]

- Xu, J.L.; Huang, S.; Pan, R.F.; Zhang, Y.Q. Research on Fluidic Vectoring Nozzle: Recent Developments and Future Trends. Acta Aeronaut. Astronaut. Sin. 2025, 46, 631216. [Google Scholar]

- Fu, J.W.; Wang, C.; Liu, C.; Xu, B.C. Application and requirement analysis of advanced aerodynamic thrust vector control technology. J. Aerosp. Power 2023, 38, 63–66. [Google Scholar]

- Wu, K.; Kim, T.H.; Kim, H.D. Numerical study of fluidic thrust vector control using dual throat nozzle. J. Appl. Fluid Mechanics 2021, 14, 73–87. [Google Scholar]

- Ma, T.; Lu, H.; Li, Q. A systematic review of boundary layer ingestion (BLI) fan: Current status and future perspectives. Prog. Aerosp. Sci. 2025, 154, 101082. [Google Scholar] [CrossRef]

- Albayrak, O.B.; Ersan, Y.; Bagbasi, A.S.; Basaranoglu, A.T.; Arikan, K.B. Design of a Robotic Bicopter. In Proceedings of the 7th International Conference on Control, Mechatronics and Automation (ICCMA), Delft, The Netherlands, 6–8 November 2019; pp. 98–103. [Google Scholar]

- Kara-Mohamed, M.; Zhang, Q.; Yan, X. Design and control of an innovative overactuated thrust vectoring six-DoF quadrotor for extreme and challenging environments. Unmanned Syst. 2025, 13, 345–361. [Google Scholar] [CrossRef]

- Tan, M.; Liu, Y.J. Progress in military UAV power in 2024. J. Aerosp. Power 2025, 40, 24–29. [Google Scholar]

- Xu, Z.R. Research on Integrated Aerodynamic-Acoustic Evaluation Method for Distributed Propulsion Fans. Ph.D. Thesis, Civil Aviation University of China, Tianjin, China, 2023. [Google Scholar]

- Xu, B.; Hu, D.; Feng, L. Dynamic characteristics and application of dual throat fluidic thrust vectoring nozzle. Chin. J. Aeronaut. 2024, 37, 85–99. [Google Scholar] [CrossRef]

- Li, Y.J.; Wu, L.F.; Li, C.W. Modeling and control of micro-aeroengine thrust vectoring system. J. Tsinghua Univ. 2020, 60, 198–205. [Google Scholar]

- Wang, B.H.; Wang, D.B. Control law design for vector thrust fixed-wing UAVs. Mach. Electron. 2019, 37, 57–61. [Google Scholar]

- Wang, J. Research status and development of jet thrust vectoring technology. Sci. Technol. Innov. 2020, 81–83, 85. [Google Scholar]

- Qu, L.X.; Li, Y.; Bai, X.J. Research progress on application verification of fluid thrust vectoring technology. Aeronaut. Sci. Technol. 2020, 31, 64–72. [Google Scholar]

- Sung, H.G.; Heo, J.Y. Fluidic thrust vector control of supersonic jet using coflow injection. J. Propuls. Power 2012, 28, 858–861. [Google Scholar] [CrossRef]

- Chen, W.J.; Pan, Q.Y.; Su, S.D.; Song, Y.Q.; Tang, J.Y.; Xu, Z.J.; Wang, Y.D. Side-by-side dual-rotor UAV system based on improved PID algorithm. Univ. Phys. Exp. 2023, 36, 90–96, 101. [Google Scholar]

- Martinez, R.R.; Paul, H.; Shimonomura, K. Design and control strategies of multirotors with horizontal thrust-vectored propellers. Drones 2025, 9, 145. [Google Scholar] [CrossRef]

- Bai, W.; Xie, Y.P.; Gao, W.M.; Jin, H.; Ren, Z.B.; Pan, B.J. Optimization Method for Exit Area of Vector Nozzle Integrating Thrust Performance and Deflection Efficiency. Patent CN202011125804.6, 19 August 2022. [Google Scholar]

- Meng, X.Z.; Zhao, Z.J.; Zheng, H. Design and verification of axisymmetric vector nozzle for scaled verification aircraft. Mech. Sci. Technol. 2021, 40, 1793–1797. [Google Scholar]

- Si, H.Y.; Bai, Y.K.; Qiu, Y. Numerical calculation study on axisymmetric thrust vector nozzle for UAV. In Proceedings of the 37th Technical Exchange Meeting of the Third Professional Information Network of China Aerospace & the 1st Joint Conference on Aerospace Power, Xi’an, China, 24–25 June 2016; pp. 9+848–856. [Google Scholar]

- Qian, K.; Gao, Z. Icefield Firebird: “Skate” opens a new era for Russian combat UAVs. World Outlook 2007, 23, 48–53. [Google Scholar]

- Das, A.K.; Acharyya, K.; Mankodi, T.K.; Saha, U.K. Fluidic thrust vector control of aerospace vehicles: State-of-the-art review and future prospects. J. Fluids Eng. 2023, 145, 80801. [Google Scholar] [CrossRef]

- Han, J.X. Research on Internal-External Flow Coupling of Fluid Vector Nozzle. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. [Google Scholar]

- Tanveer, A.; Ahmad, S.M. Mathematical modelling and fluidic thrust vectoring control of a delta wing UAV. Aerospace 2023, 10, 563. [Google Scholar] [CrossRef]

- Salehifar, M.; Tahani, M.; Hojaji, M.; Dartoomanian, A. CFD modeling for flow field characterization and performance analysis of HGITVC. Appl. Therm. Eng. 2016, 103, 291–304. [Google Scholar] [CrossRef]

- Huang, J. Overview of Design Technologies for Distributed Electric Propulsion Aircraft. Acta Aeronaut. Astronaut. Sin. 2021, 42, 13–29. [Google Scholar]

- Farokhi, S. Future Propulsion Systems and Energy Sources in Sustainable Aviation, 1st ed.; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar]

- Zhao, X.; Zhou, Z.; Wang, K.; Wang, H.; Li, X. Research on Conceptual Design Method and Propulsive/Aerodynamic Coupling Characteristics of DEP STOL UAV. Drones 2025, 9, 363. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, Z.; Wang, K.L.; Li, X. Research on Overall Design Method of Distributed Electric Propulsion Short Take-Off and Landing Aircraft. Adv. Aeronaut. Sci. Eng. 2025, 1–10. Available online: https://link.cnki.net/urlid/61.1479.V.20250822.1111.004 (accessed on 27 September 2025).

- Wang, H.F. Key technologies and application prospects of fighter thrust vectoring. Acta Aeronaut. Astronaut. Sin. 2020, 41, 20–43. [Google Scholar]

- Cong, Y.H. Flight control of UAV with thrust vectoring. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2009. [Google Scholar]

- Wu, L.; Li, H.; Li, Y.; Li, C. Position tracking control of tailsitter VTOL UAV with bounded thrust-vectoring propulsion system. IEEE Access 2019, 7, 137054–137064. [Google Scholar] [CrossRef]

- Yue, Y.K. Research and application of incremental anti-disturbance control for quadrotor UAVs. Ph.D. Thesis, Xidian University, Xi’an, China, 2020. [Google Scholar]

- Zhu, X.M.; Zhao, S.; Zheng, Y.H. Technical analysis of UAV control law based on active disturbance rejection method. Integr. Circuit Appl. 2023, 40, 324–325. [Google Scholar]

- Liu, J.J.; Sun, M.W.; Chen, Z.Q.; Sun, Q.L. High AOA decoupling control for aircraft based on ADRC. J. Syst. Eng. Electron. 2020, 31, 393–402. [Google Scholar] [CrossRef]

- Li, P.; Lin, Y.; Ji, Y.; Song, Y.; Liu, J. Super-maneuver flight control based on predefined time extended state observer and control allocation. Int. J. Adapt. Control Signal Process. 2025, 39, 664–675. [Google Scholar] [CrossRef]

- Kuang, M.C.; Zhu, J.H.; Wu, D.G. Tail-sitter vertical takeoff and landing control for thrust vector UAVs. Control Theory Appl. 2015, 32, 1449–1456. [Google Scholar]

- Kuang, M.C. Research on flight control methods for tail-sitter thrust vector UAVs. Ph.D. Thesis, Tsinghua University, Beijing, China, 2017. [Google Scholar]

- Perez, A.; Moncayo, H. Bio-inspired feedback linearized adaptive control for a thrust vectoring free-flyer vehicle. J. Intell. Robot. Syst. 2021, 102, 43. [Google Scholar] [CrossRef]

- Li, B.Q.; Dong, W.H.; Ma, X.S. Backstepping fault-tolerant control for unmanned thrust vector aircraft based on sliding mode observer. J. Northwestern Polytech. Univ. 2018, 36, 978–987. [Google Scholar] [CrossRef]

- Han, D.; Wang, X.L.; Chen, L.; Duan, D.P. Command-filtered backstepping control for a multi-vectored thrust stratospheric airship. Trans. Inst. Meas. Control 2016, 38, 93–104. [Google Scholar] [CrossRef]

- Chen, L.L.; Feng, T.Y.; Lyu, Z.Y.; Wu, Y.H. Finite-time sliding mode attitude control for coaxial tilting rotor UAVs. J. Jilin Univ. 2023, 53, 883–890. [Google Scholar]

- Liu, B.; Gao, Y.; Gao, L.; Zhang, J.; Zhu, Y.; Zhao, J. Research on the control of thrust vectoring turbojet aircraft with uncertainties and input saturation based on fixed-time control. Int. J. Robust Nonlinear Control. 2024, 34, 11282–11311. [Google Scholar] [CrossRef]

- Li, D.; Tong, S.; Yang, H.; Hu, Q. Time-Synchronized Control for Spacecraft Reorientation with Time-Varying Constraints. IEEE/ASME Trans. Mechatron. 2025, 30, 2073–2083. [Google Scholar] [CrossRef]

- Li, J.; Liu, J.; Huangfu, S.; Cao, G.; Yu, D. Leader-follower Formation of Light-weight UAVs with Novel Active Disturbance Rejection Control. Appl. Math. Model. 2023, 117, 577–591. [Google Scholar] [CrossRef]

- Yang, X.; Hu, X.; Ye, H.; Liu, W.; Shen, H. Fraction-order MRAC Method Based Fault Tolerant Control for Plant Protection UAV with Actuator Failure and Uncertainty. Int. J. Control Autom. Syst. 2023, 21, 2623–2633. [Google Scholar] [CrossRef]

- Karahan, M. Robust Backstepping Control of a Quadrotor Unmanned Aerial Vehicle under Colored Noises. Comput. Mater. Contin. 2025, 82, 777–798. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, W.; Deng, Y.; Li, Q.; Deng, Z. Twistor-based Integrated Double Hyperbolic Sliding Mode Control for Time-varying Quadrotor UAV Systems. Appl. Math. Model. 2026, 149, 116309. [Google Scholar] [CrossRef]

- Bai, Z.; Zhou, H.; Wei, J.; Zhou, X.; Ning, Y.; Wang, J. An exploration-enhanced hybrid algorithm based on regularity evolution for multi-objective multi-UAV 3-D path planning. Complex Intell. Syst. 2025, 11, 225. [Google Scholar] [CrossRef]

- Duong, T.T.N.; Bui, D.N.; Phung, M.D. Navigation variable-based multi-objective particle swarm optimization for UAV path planning with kinematic constraints. Neural Comput. Appl. 2025, 37, 5683–5697. [Google Scholar] [CrossRef]

- Hu, M.Z.; Li, X.G.; Ren, Z.Y.; Zeng, S. 3D path planning for UAVs using improved heuristic function-based A* algorithm. Acta Armamentarii 2024, 45, 302–307. [Google Scholar]

- Qu, H.W. UAV safe path planning method with improved A* algorithm in base station environment. Comput. Telecommun. 2024, 45–49. [Google Scholar]

- Zhang, B.; Cai, X.F.; Li, G.Q.; Li, X.M.; Peng, M.J.; Yang, M. A Modified A* Algorithm for Path Planning in the Radioactive Environment of Nuclear Facilities. Ann. Nucl. Energy 2025, 214, 111233. [Google Scholar] [CrossRef]

- Huang, Y.H.; Yu, Y.N. Research on conflict-avoidance shortest path planning based on improved Dijkstra algorithm. Comput. Mod. 2022, 20–24. [Google Scholar]

- Geng, Z.X.; Guang, X.; Chen, J.Y.; Guo, Y.X. Urban UAV path planning based on chaotic particle swarm optimization algorithm. J. Xihua Univ. 2024, 43, 1–7. [Google Scholar]

- Wang, Y.X.; Na, M.X. Scheduling and route planning for forests rescue: Applications with a novel ant colony optimization algorithm. Eng. Appl. Artif. Intell. 2025, 155, 111042. [Google Scholar] [CrossRef]

- Tang, F.; Li, K.; Xu, F.; Han, L.; Zhang, H.; Yang, Z. Optimal ant colony algorithm for UAV airborne LiDAR route planning in densely vegetated areas. J. Appl. Remote Sens. 2023, 17, 46506. [Google Scholar] [CrossRef]

- Guo, K.; Li, M.L.; Lei, Y.F.; Hu, J.W.; Zhao, C.H.; Xu, Z.; Pan, Q.; Xu, G. Research on UAV penetration trajectory planning technology based on improved A* algorithm and WAPSO algorithm. Unmanned Syst. Technol. 2023, 6, 22–31. [Google Scholar]

- Jayarajan, N.; Ganesan, T.; Naganathan, A. Optimal trajectories for UAV three-dimensional path planning using a hybrid ABC-RRT* algorithm. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2025, 239, 930–943. [Google Scholar] [CrossRef]

- Sharma, A.; Shoval, S.; Sharma, A.; Pandey, J.K. Path Planning for Multiple Targets Interception by the Swarm of UAVs Based on Swarm Intelligence Algorithms: A Review. IETE Tech. Rev. 2022, 39, 675–697. [Google Scholar] [CrossRef]

- Meng, W.; Zhang, X.; Zhou, L.; Guo, H.; Hu, X. Advances in UAV Path Planning: A Comprehensive Review of Methods, Challenges, and Future Directions. Drones 2025, 9, 376. [Google Scholar] [CrossRef]

- Kaur, M.; Kaur, A.; Singh, P. UAV Swarm Clustering and Trajectory Planning: A Taxonomy, Systematic Review, Current Trends and Research Challenges. Comput. Electr. Eng. 2025, 128, 110697. [Google Scholar] [CrossRef]

- Poudel, S.; Arafat, M.Y.; Moh, S. Bio-Inspired Optimization-Based Path Planning Algorithms in Unmanned Aerial Vehicles: A Survey. Sensors 2023, 23, 3051. [Google Scholar] [CrossRef]

- Ma, Z.Q.; Dong, W.H.; Xie, W.J.; Shao, P.J. Design and modeling of hexarotor UAV with omnidirectional thrust vectoring. Flight Dyn. 2016, 34, 32–36. [Google Scholar]

- Yao, Q.H.; Wang, S.M.; Yang, G.C.; Bai, X.T.; Li, M.Y.; Wang, Y.S. High-speed airflow thrust vectoring nozzle based on Coanda effect. J. Sun Yat-Sen Univ. 2025, 64, 265–274. [Google Scholar]

- Martinez, R.R.; Paul, H.; Shimonomura, K. Aerial torsional work utilizing a multirotor UAV with add-on thrust vectoring device. Drones 2023, 7, 551. [Google Scholar] [CrossRef]

- Yu, Z.; Zhang, J.; Wang, X. Thrust vectoring control of a novel tilt-rotor UAV based on backstepping sliding model method. Sensors 2023, 23, 574. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Wu, X.; Song, H.Q.; Tang, M.X. Research progress on lift systems for vertical/short take-off and landing aircraft. Aeroengine 2024, 50, 13–22. [Google Scholar]

- Ma, N.; Meng, J.H.; Luo, J.Q.; Liu, Q.Y. Optimization of Thermal-Fluid-Structure Coupling for Variable-Span Inflatable Wings Considering Case Correlation. Aerosp. Sci. Technol. 2024, 153, 109448. [Google Scholar] [CrossRef]

- Wiegand, C. F-35 air vehicle technology overview. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GE, USA, 25–29 June 2018; 2018. [Google Scholar]

- Di, W.C.; Wei, Z.X.; Liu, Q.Q.; Zhang, J.H.; Xiang, J.W.; Li, D.C.; Tu, Z. Dynamics and Control of Tailless Vectored-Thrust VTOL in Hover-to-Forward Transition. Aerosp. Sci. Technol. 2025, 164, 110385. [Google Scholar] [CrossRef]

- Zhao, Q.F.; Zhou, Z.; Wang, G.C.; Wang, R. Transition performance and transition strategy of a distributed-propulsion-wing VTOL UAV with induced wing configuration. Aerosp. Sci. Technol. 2026, 168(Part B), 110810. [Google Scholar] [CrossRef]

- He, J.C.; Du, F.; Wang, P.H.; Feng, J.J.; Han, S. Aerodynamic Design of a Blended Wing Body VTOL UAV.v. J. Phys. Conf. Ser. 2025, 2965, 012020. [Google Scholar] [CrossRef]

- Khan, S.S.; Akash, A.R.; Maaj, S.; Hassan, M.R.; Rahman, M.A. A novel mechanism design technique to develop a vertical climbing robot with high mobility for flat and spherical surfaces. In Proceedings of the 2nd International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), Dhaka, Bangladesh, 5–7 January 2021; IEEE: Dhaka, Bangladesh, 2021; pp. 303–307. [Google Scholar]

- Han, J.K.; Hui, Z.; Tian, F.B.; Chen, G. Review on bio-inspired flight systems and bionic aerodynamics. Chin. J. Aeronaut. 2021, 34, 170–186. [Google Scholar] [CrossRef]

- Li, D. Biomimetic flapping-wing aircraft: Perfect integration of aerodynamics, flapping motion, and intelligent control—Interview with SONG B F, Distinguished Professor of the Chang Jiang Scholars Program and expert in aircraft design. Aeronaut. Manuf. Technol. 2018, 61, 22–24. [Google Scholar]

- Liu, Y.; Chen, C.; Qian, Z.S. Numerical simulation of stable deceleration and separation characteristics of an integrated life-saving cabin for aerospace vehicles. Acta Aeronaut. Astronaut. Sin. 2020, 41, 137–150. [Google Scholar]

- Lee, S. Multi-scale homogenization of moving interface problems with flux and field jumps. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2011. [Google Scholar]

- Florist, V.; Santhoshkumar, R.; Vamsi, A.; Sajju, V.; Mohan, S.; Kumar, S.; Dhanoop, A.; Venukuttan, C.; Sundaresan, M.K.; Murty, S.V.S.N. Structural integrity of 15-5PH stainless steel flow formed pressure vessel for launch vehicle applications. Procedia Struct. Integr. 2024, 60, 614–630. [Google Scholar] [CrossRef]

- Sun, X.; Li, Z.L.; Zhang, L.; Tian, A.; Chai, W.S.; Jing, T.T. Heat Transfer Augmentation, Endothermic Pyrolysis and Surface Coking of Hydrocarbon Fuel in Manifold Microchannels at a Supercritical Pressure. Int. Commun. Heat Mass Transf. 2025, 161, 108564. [Google Scholar] [CrossRef]

- Cerminara, A.; Nayak, R.; Potts, J.; Tanno, H.; Kloker, M.J.; Saikia, B.; Brehm, C.; Camillo, G.P.; Wagner, A. Transpiration cooling in hypersonic flow and mutual effect on turbulent transition and cooling performance. Phys. Fluids 2025, 37, 26139. [Google Scholar] [CrossRef]

- Li, Z.W.; Zhang, L.; Li, L.; Huang, B.; Yuan, H.T. Analysis of aerodynamic configuration performance characteristics of Starship. Acta Aerodyn. Sin. 2022, 40, 1–14. [Google Scholar]

- Yao, S.B.; Luo, Z.; Sun, Y.H.; Xu, C.Y. Analysis of fluid-structure-thermal coupling dynamic characteristics of axisymmetric thrust vectoring nozzle. In Proceedings of the 19th National Conference on Nonlinear Vibration & 16th National Conference on Nonlinear Dynamics and Motion Stability (NVND2023), Tianjin, China, 17–19 October 2023; pp. 1–235. [Google Scholar]

- Xia, J.; Zhou, Z. The Modeling and Control of a Distributed-Vector-Propulsion UAV with Aero-Propulsion Coupling Effect. Aerospace 2024, 11, 284. [Google Scholar] [CrossRef]

- Erhard, R.M.; Alonso, J.J. A comparison of propeller wake models for distributed electric propulsion and eVTOL aircraft in complex flow conditions. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022; American Institute of Aeronautics and Astronautics: San Diego, CA, USA, 2022. [Google Scholar]

- Weng, L.; Zhang, X.; Yao, T.; Bu, F.; Li, H. A Thrust Cooperative Control Strategy of Multiple Propulsion Motors for Distributed Electric Propulsion Aircraft. World Electr. Veh. J. 2021, 12, 199. [Google Scholar] [CrossRef]

- Wang, X.Y.; Zhang, P.P. Thoughts on the development of eVTOL aircraft and flying cars. Aero Power 2024, 24–28. [Google Scholar]

- Shu, B.W.; Huang, J.T.; Gao, Z.H.; Liu, G.; He, C.J.; Xia, L. Sensitivity analysis of vector performance for two-dimensional shock vector nozzle. Acta Aeronaut. Astronaut. Sin. 2022, 44, 127831. [Google Scholar]

- Bustamante Alarcon, J.M.; Sánchez Marmolejo, J.L.; Manjarrez Muñoz, L.H.; Espinoza Quesada, E.S.; Osorio Cordero, A.; García Carrillo, L.R. Performance Evaluation of an H-VTOL Aircraft with Distributed Electric Propulsion and Ducted-Fans Using MIL Simulation. Machines 2023, 11, 852. [Google Scholar] [CrossRef]

- Xu, L.; Liu, J.S.; Wang, L.L.; Sun, L.S.; Liu, H.L.; Zang, Y.C.; Wang, J.X. Research and application of digital twin virtual reconstruction technology for aerospace machining workshops. Aerosp. Manuf. Technol. 2024, (2), 71–74. [Google Scholar]

- Malone, P.K. Economics of Digital Twins in Aerospace and Defense. In Proceedings of the 2024 International Cost Estimation and Analysis Association (ICEAA) Conference, San Diego, CA, USA, 21–24 May 2024; pp. 1–10. [Google Scholar]

- Hong, H.J.; Han, J.H. Study on revision of aviation safety act for RPAS. Korean J. Air Space Law Policy 2020, 35, 65–93. [Google Scholar] [CrossRef]

- Xiao, Q.; Huang, M.Y. Research on airworthiness certification requirements of EWIS for eVTOL aircraft. Aeronaut. Stand. Qual. 2024, 28, 19–24. [Google Scholar]

- Kural, A.; Leveque, N.; Welch, C.; Wolanski, P. Design of an ion thruster movable grid thrust vectoring system. Acta Astronaut 2004, 55, 421–432. [Google Scholar] [CrossRef]

| Thrust Vectoring Technology | Weight | Thrust Efficiency | Response Time | Complexity | Cost | Technology Maturity | Advantages | Disadvantage |

|---|---|---|---|---|---|---|---|---|

| Mechanical Thrust Vectoring Technology | Heavy | High | Medium | High | High | High | Suitable for high-speed aircraft (such as fighter jets), with minimal thrust loss, optimised stealth performance, fully validated technology, and flexible flow regulation range. | Reliance on mechanical transmission structures necessitates extended maintenance intervals, imposes stringent demands on the structural integrity of the chassis, requires substantial installation space, and demonstrates limited adaptability in low-speed scenarios. |

| Jet thrust vectoring technology | Light | Medium | Quick | Medium | Medium | Medium | No complex mechanical transmission components, lightweight, suitable for small to medium-sized platforms. Certain types (such as fluid-operated) present low modification difficulty and offer distinct advantages in response speed. | Airflow deflection readily leads to thrust loss and energy dissipation; requires additional components, resulting in increased structural complexity and weight, thereby reducing system reliability; entails higher fuel consumption; at low speeds, reduced airflow velocity diminishes vector control effectiveness and adversely affects low-speed manoeuvrability. |

| Distributed electric propulsion | Medium | Medium | Medium | Mid-to-high | Mid-to-high | Medium | Capable of vertical take-off and landing, with low noise levels suited to urban environments (such as eVTOLs). Multi-motor coordination enhances flight safety, making it suitable for low-altitude, low-speed aircraft. | Battery endurance is limited, multi-motor coordinated control presents significant challenges, ducting and wing surface structures impact range, high-altitude environmental adaptability is weak, and multi-rotor configurations are prone to aerodynamic interference. |

| Control Method | Applicable Scenarios | Advantages | Disadvantages |

|---|---|---|---|

| ADRC [53] | Strongly nonlinear systems under multi-source disturbances (such as unmanned aerial vehicle flight at high angles of attack) | 1. Real-time disturbance estimation and compensation achieved via the Expanded State Observer (ESO), offering robust performance; 2. The enhanced PTESO converges within a predetermined timeframe with minimal estimation error; 3. Supports independent multi-channel control, accommodating thrust vector nozzle constraints. | 1. The convergence speed and accuracy of traditional Linear Expansion State Observers (LESOs) are constrained by bandwidth parameters; 2. Actuator constraints are not explicitly handled, necessitating additional optimisation. |

| MRAC [54] | System parameter perturbations, sudden disturbance scenarios (such as thruster failures, sudden load changes, etc.) | 1. The introduction of a model reference adaptive layer enables rapid compensation for sudden disturbances; 2. Performance in hardware-in-the-loop testing shows significant improvement over traditional PID control; 3. High global performance index. | 1. The fundamental MRAC exhibits insufficient robustness against strong nonlinearities and high-frequency disturbances; 2. It necessitates the design of complex feedback linearisation and immunity-inspired mechanisms, resulting in relatively high algorithmic complexity. |

| Backstepping [55] | Fault-tolerant control of nonlinear systems, multi-variable coupled scenarios (such as rudder failure) | 1. A systematic design methodology adapted to highly non-linear dynamics; 2. Fault identification achievable through integrated cascaded observers; 3. Enhanced wind disturbance resistance and robustness following the incorporation of command filtering techniques. | 1. Traditional backstepping control is susceptible to high-frequency dynamics and requires additional suppression; 2. In fault scenarios, inertial parameters must be updated in real time, entailing significant computational overhead. |

| SMC [56] | System uncertainty, actuator saturation constraint scenarios | 1. Finite-time convergence characteristics with rapid response; 2. Strong interference resistance and insensitivity to parameter perturbations; 3. Integrated anti-saturation auxiliary system capable of handling thrust saturation and wind disturbances. | 1. Traditional SMC suffers from chattering issues, necessitating optimisation of the sliding mode surface design; 2. Fixed sliding mode parameters exhibit poor adaptability under time-varying parameter scenarios. |

| Indicator | Traditional A* Algorithm | Improved A* Algorithm | Lift Rate |

|---|---|---|---|

| Path length (complex environment) | 24.38 m | 26.14 m | +7.2% |

| Search node (complex environment) | 143 | 97 | −32.2% |

| Number of touchdowns (complex environment) | 6 | 0 | −100% |

| Number of route points (after optimisation) | 23 | 6 | −73.9% |

| Total steering angle (after optimisation) | 225° | 180° | −20.0% |

| Algorithm Category | Algorithm Name | Applicable Scenarios | Advantages | Disadvantages |

|---|---|---|---|---|

| Graph search-based algorithm | Improvement of the A* algorithm [68] | In complex three-dimensional environments for unmanned aerial vehicles (such as areas with dense base stations or low-altitude scenarios with numerous obstacles), both safety and real-time performance must be prioritised. | 1. Optimises the heuristic function to enhance search efficiency and reduce redundant path points; 2. Introduces an obstacle distance penalty mechanism to mitigate collision risks; 3. Path smoothness and navigation efficiency are relatively favourable. | 1. Path length may increase slightly in complex environments; 2. Heuristic function weighting factors require scenario-specific tuning, with general applicability yet to be enhanced. |

| Spatio-temporal Dijkstra algorithm [69] | Multi-UAV collaborative missions (such as swarm operations and multi-task conflict avoidance) require conflict-free path planning. | 1. Overcomes the limitation of traditional algorithms that output only a single shortest path, enabling the recording of multiple predecessor nodes; 2. Integrates a time window model to achieve conflict-free multi-vehicle path planning; 3. Supports task prioritisation to enhance overall planning efficiency. | 1. Static time window design exhibits insufficient adaptability to dynamic obstacles; 2. Computational complexity increases linearly with the number of nodes. | |

| Bionics-inspired algorithms | Chaotic Particle Swarm Optimisation [70] | In complex three-dimensional urban environments (such as densely built-up areas), global search and avoidance of local optima are required. | 1. Incorporating chaotic sequences enhances global search capabilities and reduces the probability of becoming trapped in local optima; 2. The fitness function can integrate multiple objectives (such as economic benefit, height, and obstacle avoidance); 3. Iterative convergence speed is superior to that of traditional particle swarm optimisation. | 1. The number of particles and iteration count require careful balancing, as computational costs are relatively high; 2. Paths may fluctuate in highly dynamic environments. |

| Adaptive Ant Colony Algorithm [71] | Areas of dense vegetation and complex terrain (such as in LiDAR surveying) require paths with low vegetation coverage. | 1. Dynamically updates pheromone evaporation coefficients to enhance convergence speed; 2. Optimises path length planning to improve task execution efficiency (e.g., LiDAR ground point acquisition efficiency); 3. Path nodes feature low vegetation coverage, enabling adaptation to complex terrain. | 1. The initial distribution of pheromones significantly impacts algorithm performance; 2. Deadlock is prone to occur in densely obstructed environments, necessitating additional obstacle avoidance strategies. | |

| Integration of relevant technologies | A*-PSO convergence architecture [66] | Complex battlefield environments (such as penetrating radar threat zones) require low probability of detection and short flight paths. | 1. Combining A*’s discrete path generation capability with PSO’s trajectory optimisation capability yields superior path performance; 2. Reduces environmental threats (such as radar detection probability), thereby enhancing mission success rates; 3. Significantly reduces runtime compared to single algorithms. | 1. The parameter coordination between A* and PSO requires meticulous fine-tuning; 2. During dynamic threat updates, the efficiency of re-planning needs improvement. |

| ABC-RRT* [67] | Complex battlefield environments (such as penetrating radar threat zones) require low probability of detection and short flight paths. | 1. Combines the global exploration capabilities of the Artificial Bee Colony (ABC) algorithm with the path optimisation features of RRT*, achieving superior path length; 2. Significantly reduces convergence iterations and simulation time while maintaining high stability; 3. Suitable for real-time obstacle avoidance requirements in dynamic environments. | 1. Under high-density obstacles, random sampling of RRT* may result in local path redundancy; 2. The algorithm exhibits high fusion complexity, leading to significant engineering implementation challenges. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Cui, B.; Zhang, H. Review of Thrust Vectoring Technology Applications in Unmanned Aerial Vehicles. Drones 2025, 9, 689. https://doi.org/10.3390/drones9100689

Luo Y, Cui B, Zhang H. Review of Thrust Vectoring Technology Applications in Unmanned Aerial Vehicles. Drones. 2025; 9(10):689. https://doi.org/10.3390/drones9100689

Chicago/Turabian StyleLuo, Yifan, Bo Cui, and Hongye Zhang. 2025. "Review of Thrust Vectoring Technology Applications in Unmanned Aerial Vehicles" Drones 9, no. 10: 689. https://doi.org/10.3390/drones9100689

APA StyleLuo, Y., Cui, B., & Zhang, H. (2025). Review of Thrust Vectoring Technology Applications in Unmanned Aerial Vehicles. Drones, 9(10), 689. https://doi.org/10.3390/drones9100689