1. Introduction

UAVs are widely used in many fields today. A UAV can carry out tasks without human intervention in agriculture, transportation, observation, and control. However, the flight times of UAVs are generally limited depending on the battery capacity [

1]. The usage time of UAVs is increased by wirelessly charging [

2]. Wireless charging eliminates human intervention by making the UAV autonomous [

3].

Various WPT methods have been developed for wireless charging of UAVs. The most common methods are microwave, laser, capacitive, and inductive coupling [

2]. The laser and microwave methods are suitable for far-field wireless charging [

4]. However, it is costly and difficult to control. Additionally, this method creates a high electromagnetic field level that can damage UAVs. The capacitive coupling WPT system transfers energy through the electric field between two metal plates or electrodes [

5]. In capacitively coupled WPT, the operating frequency is generally in the MHz band as the plate size decreases as the frequency increases. There are a few applications for capacitive coupling wireless charging of UAVs at an operating frequency of 500 kHz–1 MHz [

6,

7]. However, since the switching losses of the semiconductor elements, the skin effect and proximity effect are high in this frequency band, the end-to-end efficiency of the system is low. Inductive coupling is the most efficient and reliable method for near-field wireless charging [

8]. An inductive coupling WPT system transfers energy between two coils via magnetic coupling. It is generally the most preferred solution for charging UAVs [

2]. In particular, its most important features are that it frees the UAV from manual charging with wires, offers freedom of landing and taking off, can charge independently of environmental conditions, and has high efficiency and high reliability.

In studies for wireless charging of UAVs using inductive coupling, coil and control designs play an important role. Control design of WPT is essential to achieve maximum efficiency according to the change of circuit parameters. UAVs have various controller design needs such as controlling the landing position [

9], tracking maximum power [

10], achieving optimal efficiency [

11], and stabilizing the output power [

12]. Coil design affects important performance characteristics such as misalignment tolerance, power transfer efficiency, electromagnetic scattering, and heat dissipation. The positions of the coils relative to each other affect the magnetic coupling. The magnetic coupling of the receiver and transmitter coils is maximum when angularly and positionally aligned [

13]. As the alignment deteriorates, the magnetic coupling decreases. The positioning error rate of UAVs may increase in environments where GPS signals are weak, such as buildings, forests, and indoors [

14]. Positional errors in the UAV landing increase the misalignment of the receiver and transmitter coils. For this reason, many WPT system designs in the literature have been designed to operate within a tolerable misalignment tolerance [

6,

15].

Various coil designs have been proposed in the literature for the wireless charging of UAVs. Some of these designs are planar spiral coils, coils with ferrite cores, vertical receiver coils, and multiplanar coils. Stationary, dynamic, or hybrid-mode wireless charging systems are designed [

16].

Planar spiral coil designs can be circular, square, rectangular, hexagonal, or polygonal. The transmitter coil is placed on the ground or a platform. The receiver coil is located on the body or feet of the UAVs [

17]. These designs are cheap, simple, lightweight, and easy to design. However, misalignment tolerance is low, electromagnetic interference is high, and drag force is high.

In coil designs with ferrite cores, ferrite cores are used in transmitter, receiver, or both coils to increase magnetic coupling. If the ferrite cores are placed on the receiver, the weight of the UAV increases. Therefore, it is generally preferred to use ferrite cores only in the transmitter coil [

18]. By using ferrite cores, power transfer efficiency and magnetic coupling are increased, and electromagnetic scattering is reduced. However, ferrite cores increase the weight and cost. Ferrite core position optimisation studies have been carried out to reduce the ferrite core volume and weight [

18]. However, determining the optimum positions of ferrite cores complicates the coil design. Additionally, in coil designs with ferrite cores, the misalignment tolerance is low because the optimum position is disrupted in case of misalignment.

Multi-channel coil designs use multiple micro transmitter and receiver resonators on the body of UAVs [

19,

20]. These designs increase misalignment tolerance and power transfer efficiency. However, more than one driver circuit must be used in these designs. This situation increases cost and control complexity.

The receiver coils are placed perpendicular to the transmitter in designs with vertical receivers. Vertical planar receiver coils are placed on the UAV legs, and horizontal planar spiral transmitter coils are placed on the ground. The vertical receiver coil can be placed on one leg [

21]. However, it creates instability in the UAV. Receiver coils placed on two legs do not create instability in the UAV [

22]. A planar spiral DD or DDD coil is used in the transmitter, depending on whether one or two vertical receiver coils are carried in the UAV’s legs [

21,

22]. Vertical receiver coils on the UAV legs can be spiral [

23] or helical [

21]. When the misalignment problem of these designs is examined, the misalignment tolerance is higher in the axis parallel to the legs and lower in the perpendicular axis. Misalignment in both axes is the worst case, and the tolerance for misalignment is the lowest in this case [

23]. These systems can operate efficiently with a precise GPS or landing guidance system.

UAV landing guidance system reduces the misalignment error between the receiver and transmitter for the WPT system. The landing guidance system can be implemented with image processing [

24] or mechanical guidance [

25] tools. It is used to solve the misalignment problem caused by GPS errors. It is usually accomplished by sliding the UAV over the transmitter or folding it. Static UAV guidance systems are generally provided with inclined transmitter surfaces. It is simple and inexpensive. However, the position cannot be precisely controlled with them because they provide open-loop control. Dynamic position guidance designs are more costly and complex to control because they use motor, driver, and sensor systems. However, it has a more precise position control than static position guidance.

In this paper, a novel folding coil design is proposed for the wireless charging of UAVs. The proposed coil design is based on the planar spiral coil design with vertical receiver and horizontal transmitter. Five planar spiral coils are used in this coil design, two vertical and three horizontal. By folding the coil groups at the edges of the transmitter coil, the position of the UAV is directed in the axis with low misalignment tolerance, and the misalignment tolerance in the other axis is further increased. The number of windings, cable length, weight, and magnetic scattering of the receiver are reduced with the proposed folding coil design. It has high charging efficiency, low copper loss, and high misalignment tolerance. The performance of the proposed coil design is examined using simulations and experiments for 100 W output power at 138.1 kHz frequency. The coil design was performed in Ansys Maxwell 3D (Ansys Electronics version 2017). Circuit analyses and co-simulations were carried out using Ansys Simplorer (Ansys Electronics version 2017). According to the experimental results, the proposed WPT system achieved 97.66% efficiency in the aligned condition. It was wirelessly charged with 85.48% efficiency up to 10 cm misalignment distance.

The rest of this paper is organised as follows:

Section 2 presents the WPT theory and the folding coil design method for UAVs. The numerical results are analysed and examined in

Section 3. Comparison with the other studies is given in

Section 4. The conclusions of the study are summarised in

Section 5.

2. Folding WPT System Design for UAV

Charging UAV batteries via WPT eliminates the requirement for physical links. A UAV can become autonomous with WPT. UAVs can, thus, autonomously travel longer distances this way. Among near-field WPT techniques, IPT is the most suitable method for UAVs. In IPT, the magnetic coupling between coils accomplishes the energy transfer between the transmitter and receiver. In addition, compensation is made by connecting capacitors to the coils to ensure maximum efficiency. In this study, Series-Serial (SS) topology was selected as the compensation topology because SS topology has a simple structure, high efficiency at low load resistance (4 ohm–10 ohm), low equivalent impedance, and high transmittable power [

26]. The equivalent circuit of IPT with SS topology is shown in

Figure 1.

Where

V1 is the supply voltage, I

1 is the input current, and I

2 is the output current. L

1 and L

2 are the self-inductances of the transmitter and receiver coils, respectively. C

1 and C

2 are the compensation capacitances of the transmitter and receiver, respectively. R

1 and R

2 are the internal resistance of the transmitter and receiver resonators, respectively. L

m is the mutual inductance between the transmitter and receiver coils. R

L is the load resistance. Equivalent impedance (Z

Eq) and efficiency (η) values for the SS topology are presented in Equations (1) and (2), respectively [

23].

where ω is the angular frequency. At the resonance frequency, the imaginary impedance of the inductor and capacitor are balanced, and the equivalent impedance has only the real impedance [

27]. Efficiency at the resonance frequency is given in Equation (3).

The efficiency of IPT is affected by frequency, load, mutual inductance, and internal resistance when resonance occurs. Among the factors that affect WPT system efficiency, the most is mutual inductance. It depends on the position of the coils relative to each other, and its value decreases as they move away from each other or become out of alignment. In the IPT, mutual inductance should keep above the critical mutual inductance for efficient WPT. The minimum mutual inductance at which wireless power transfer can be achieved with maximum efficiency is the critical mutual inductance. When the mutual inductance drops below this value, the efficiency drops radically. In the WPT using SS topology, critical mutual inductance is calculated by Equation (4) [

28].

Here, R is the sum of the internal resistances of the capacitor and coils. Lmcritical is the critical mutual inductance. Critical mutual inductance depends on natural resonance frequency, load resistance, and internal resistance of the resonators. If the mutual inductance is higher than the critical mutual inductance, WPT operates at maximum efficiency. In this case, increasing the mutual inductance does not change the efficiency, but the resonance frequency moves away from the natural resonance frequency. If the mutual inductance is below the critical mutual inductance, the efficiency is below the optimum efficiency and the resonance frequency is equal to the natural resonance frequency. In this case, the decrease in mutual inductance rapidly reduces the efficiency.

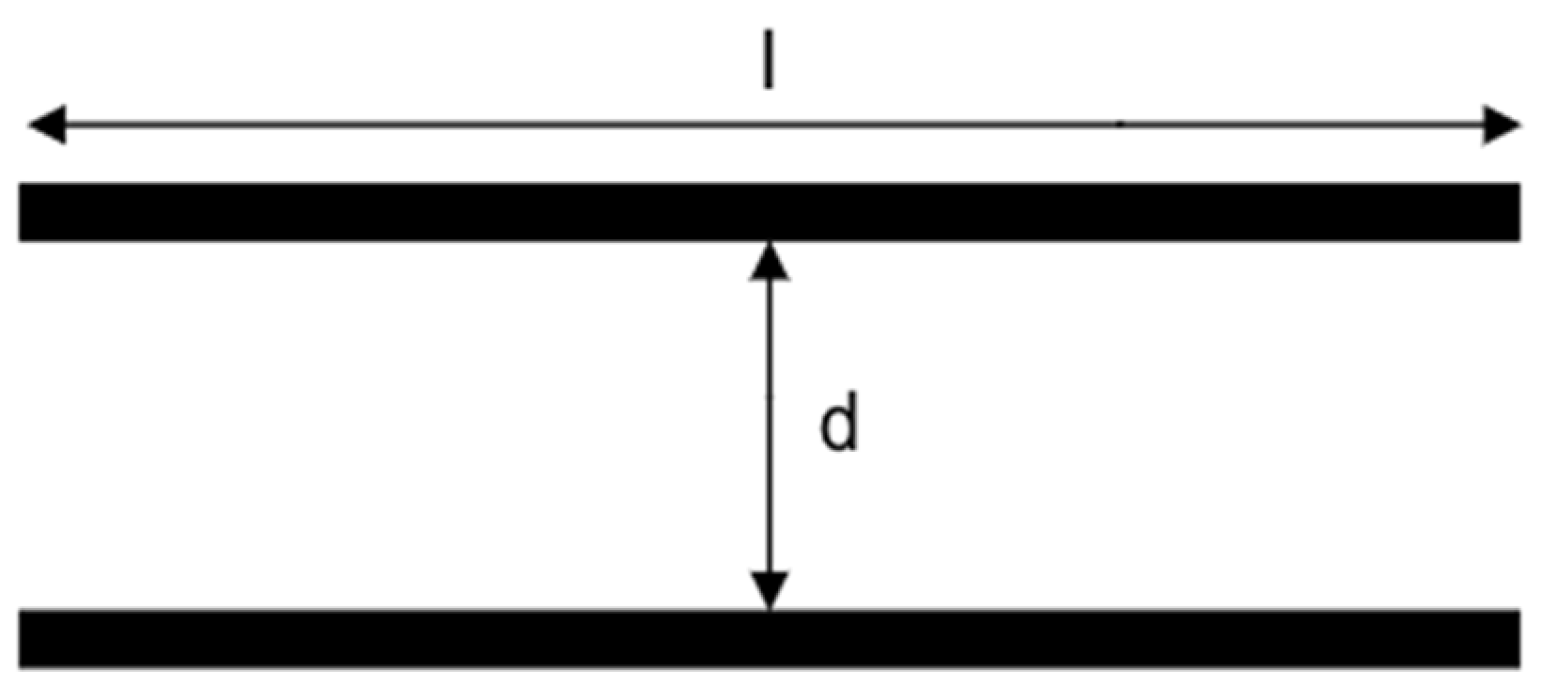

The mutual inductance of two parallel wires of equal length depends on the wire’s length and the distance between the parallel wires. Two parallel wires of equal length are shown in

Figure 2.

Where l is the conductor length and d is the distance between parallel wires. The mutual inductance between two parallel wires of equal length is given in Equation (5) [

29].

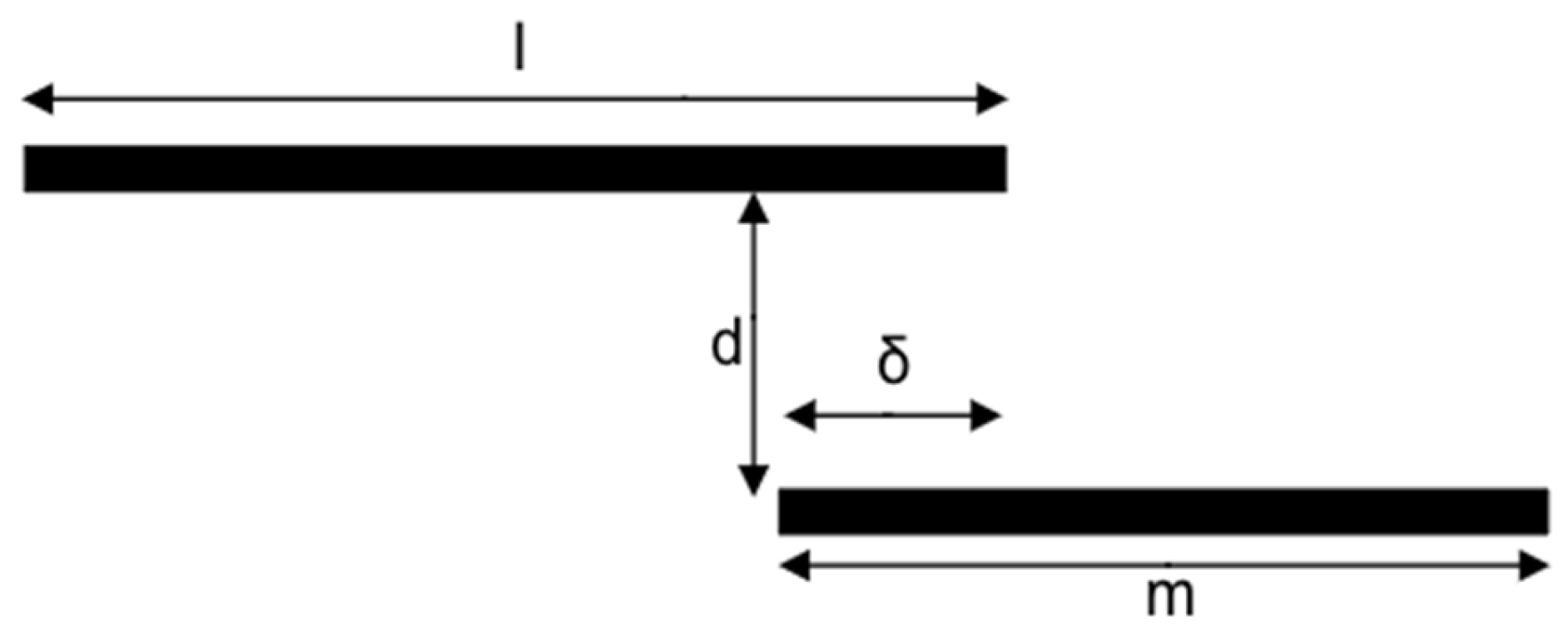

Mutual inductances of unequal parallel wires are found using Equation (5). However, the mutual inductance expression changes depending on the positions of the conductors. Unequal-length parallel conductors may overlap, overlap in some places, or not overlap at all. Mutual inductance between unequal-length parallel conductors is calculated differently during these three cases. In the first case, unequal-length parallel conductors overlapping each other are shown in

Figure 3.

Where m and l are the short and long conductor lengths, respectively. According to the long conductor, p and q are the length differences of the short conductor from left to right. In

Figure 3, the mutual inductance for two unequal-length parallel conductors overlapping each other is given in (6) [

29].

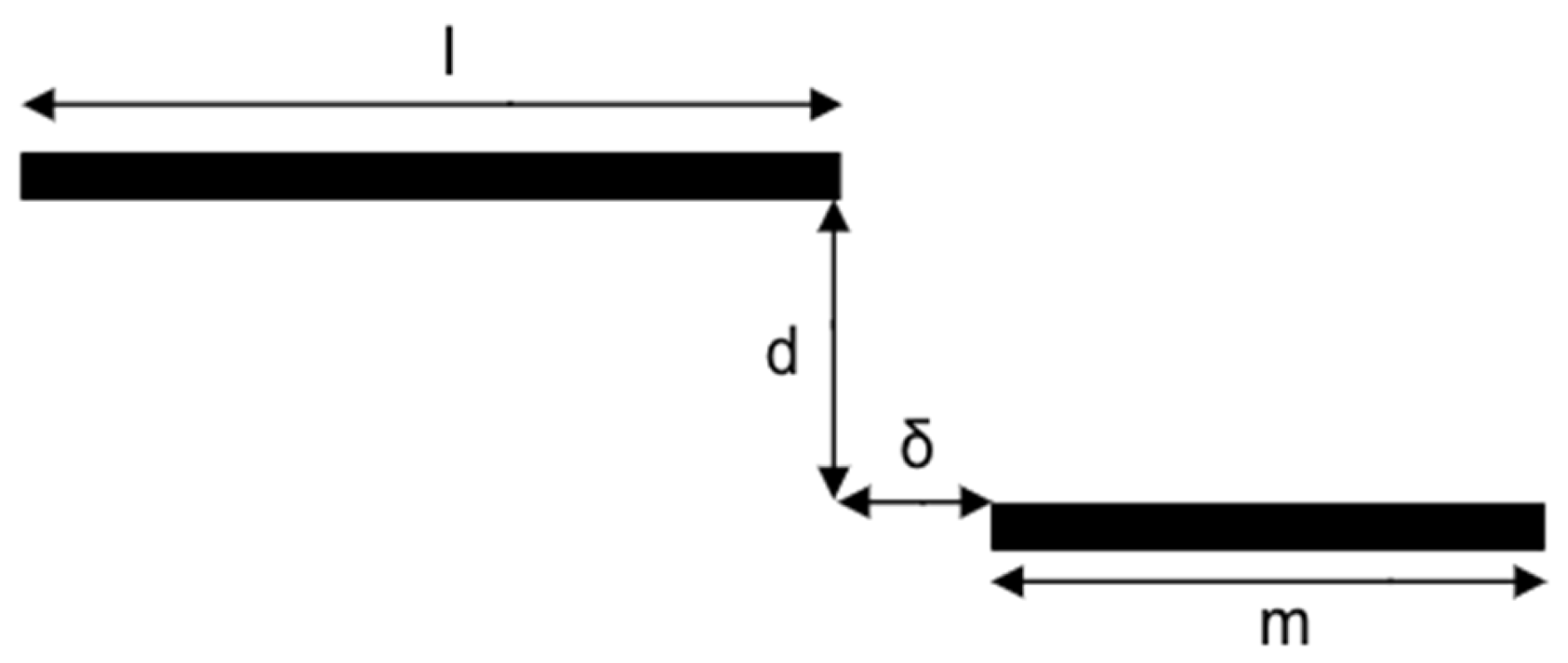

In the second case, unequal-length parallel conductors overlapped in some places are shown in

Figure 4.

Where δ is the length of the overlapping part. In

Figure 4, the mutual inductance for two unequal-length parallel conductors overlapped in some places is given in (7) [

29].

In the third case, unequal-length parallel conductors with no overlap are shown in

Figure 5.

Where δ is the horizontal distance between two conductors. The mutual inductance for two unequal-length parallel conductors with no overlap is given in (8) [

29].

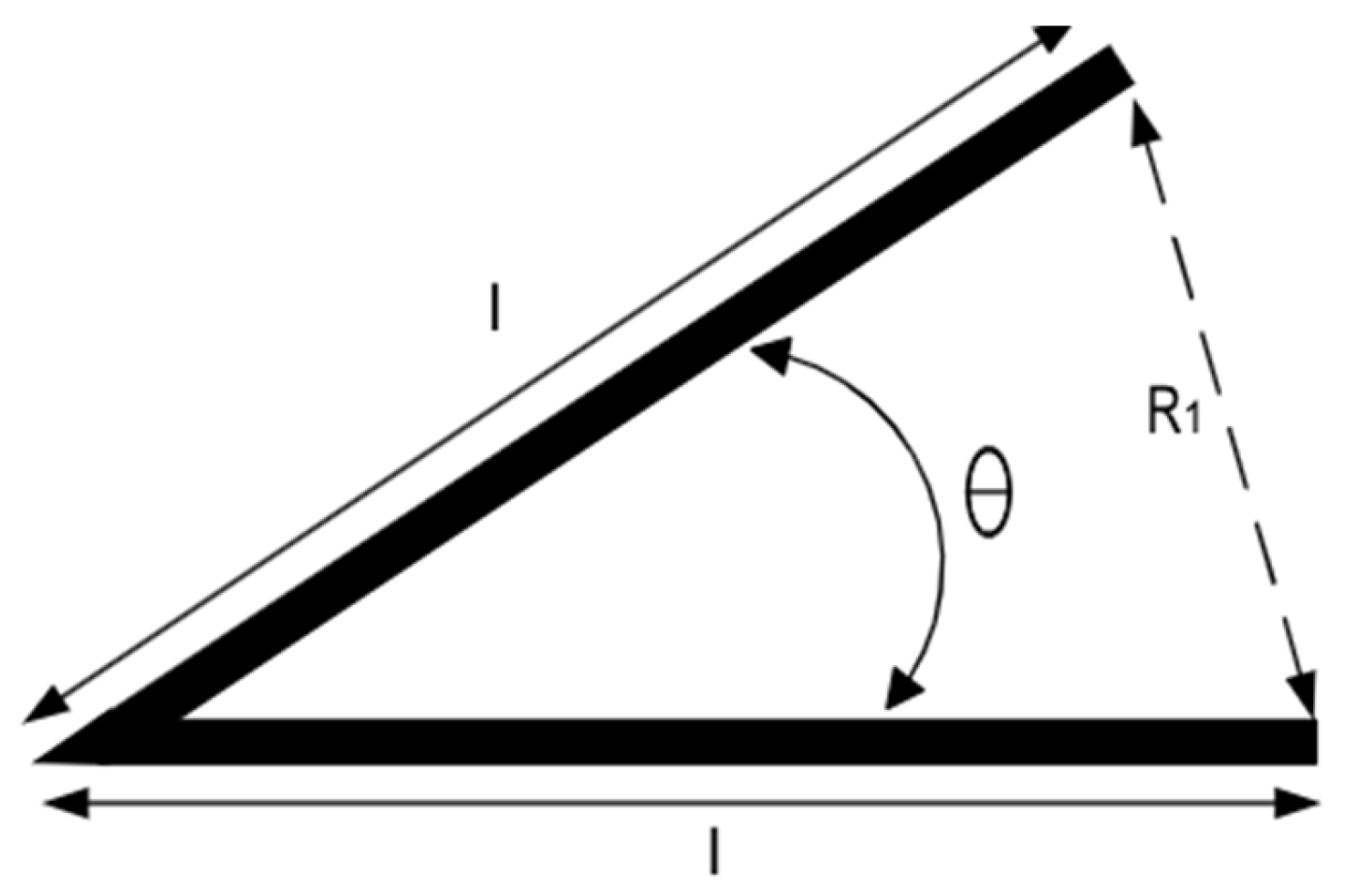

Calculating the mutual inductance of non-parallel conductors is more complicated. Calculation equations vary depending on whether the conductors have the same common end or are independent. Equal length and common end non-parallel wires are shown in

Figure 6.

Where l is the wire length and θ is the angle between the wires. R

1 is the distance between the non-common ends of the wires. The mutual inductance of equal length and common end non-parallel wires is given in (9).

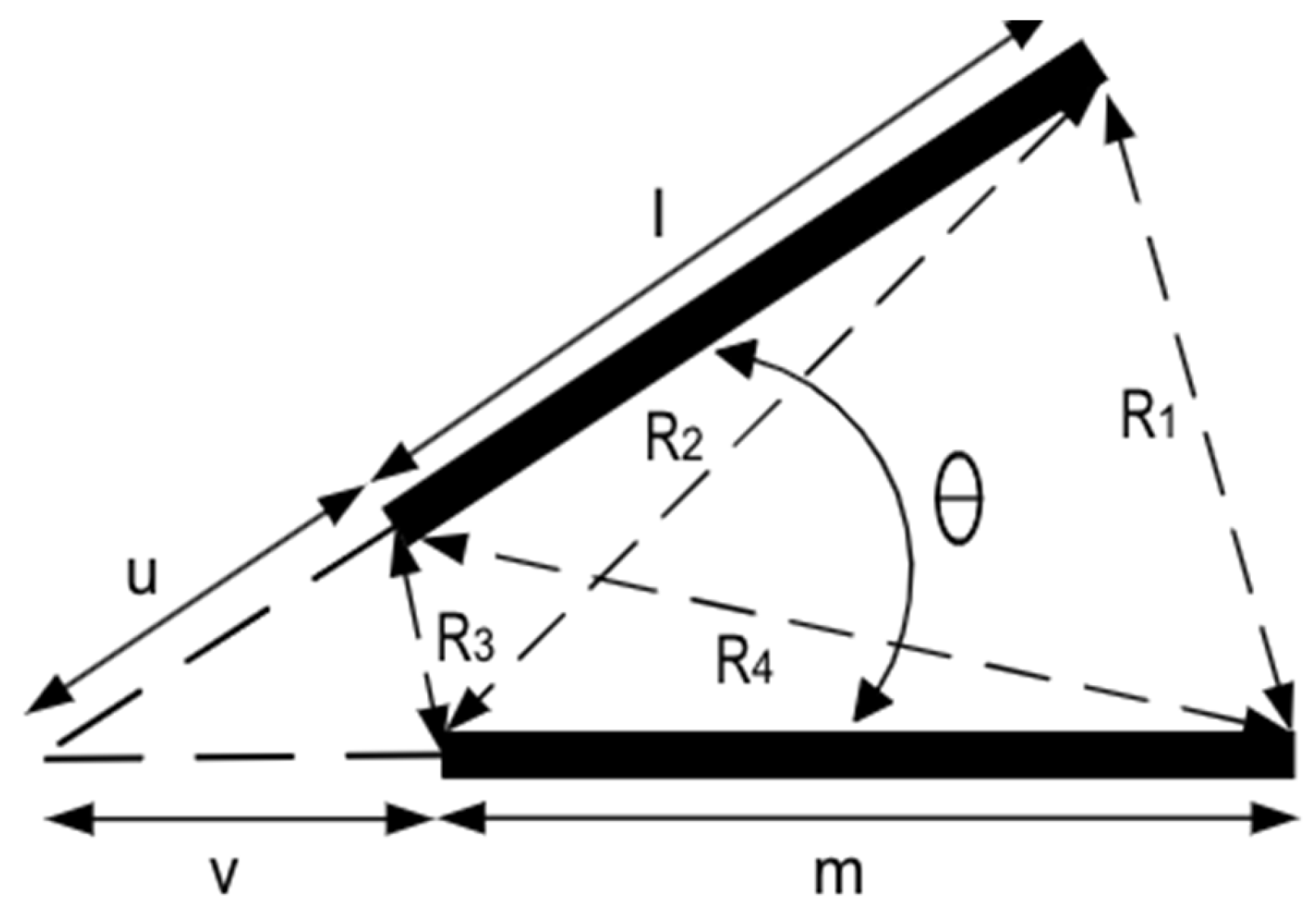

Unequal-length and separated non-parallel wires in the same plane are shown in

Figure 7.

Where l and m are the lengths of non-parallel conductors. u and v are the distance of the intersection point of the lines to the l and m conductors, respectively. R

1 and R

2 are the distance between the far end from the intersection point of the l conductor and the far and near ends of the m conductor from the intersection point, respectively. R

3 and R

4 are the distance between the near end from the intersection point of the l conductor and the near and far ends of the m conductor from the intersection point, respectively. The mutual inductance of unequal length and separated non-parallel wires in the same plane is expressed by (10).

When the coils have more than one conductor, the equivalent mutual inductance of the coils is calculated by the difference between positive and negative mutual inductances as in Equation (11).

L

m+ and L

m− are the sum of the positive and negative mutual inductances, respectively. L

mE is the equivalent mutual inductance between coils. Positive mutual inductance occurs between conductors in the same current direction. Negative mutual inductance occurs between conductors in opposite current directions. Their difference gives the equivalent impedance. In WPT systems, the transmitter and receiver coils should be designed to maximise the mutual inductances. The folding WPT charging station and the UAV are shown in

Figure 8.

The AC grid voltage is converted to DC with a rectifier. DC voltage is changed to the required DC voltage level by the DC/DC converter and applied to the inverter. DC voltage is converted to square wave AC voltage at the desired resonance frequency by the half-bridge inverter. The transmitter resonator of the WPT circuit is fed with the inverter at the resonance frequency. In IPT, energy is transmitted wirelessly to the receiver through the magnetic coupling between the receiver and transmitter coils. The transmitter and receiver coils are the heart of the IPT system. For efficient WPT, the receiver and transmitter coils must be designed to keep the mutual inductance between the receiver and transmitter coils above the critical mutual inductance.

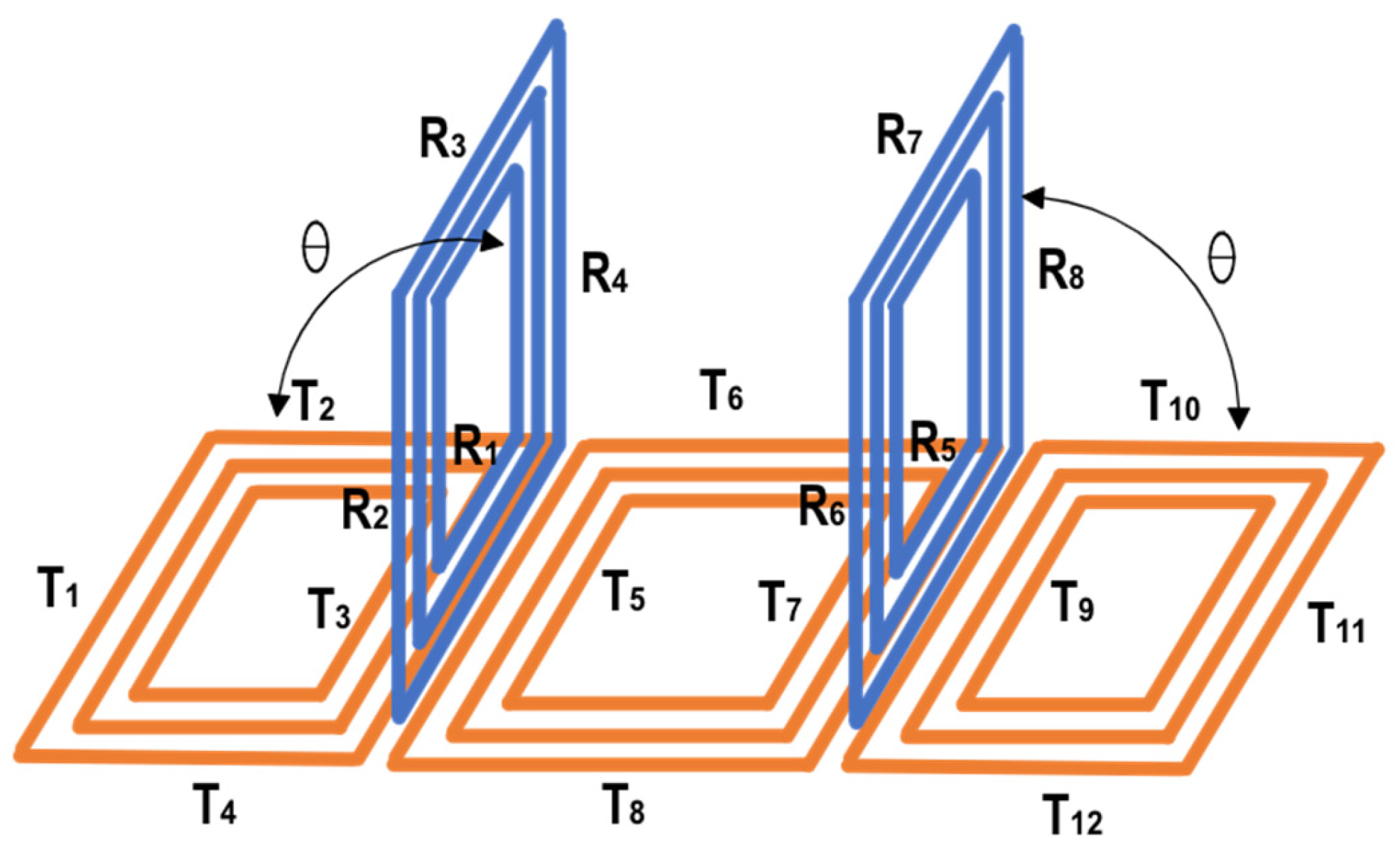

Coil designs for UAV wireless charging can be found in the literature in a variety of forms. Commonly used coil designs are rectangular, square, and circular-shaped planar spiral and helical coils. WPT applications often prefer spiral rectangular coils because of their high coupling, high misalignment tolerance, and ease of production. Generally, these coils are horizontally mounted under the legs of UAVs. However, these coils occupy great space, disrupt the UAV’s aerodynamics, and create intense magnetic exposure and drag force. A spiral rectangular coil mounted vertically on the leg of a UAV is lighter and has less drag force and magnetic field scattering than a horizontal coil. Vertically mounted coils on one leg create instability in the UAVs. As a result, coil designs mounted vertically on two legs are preferred for balance. This WPT design consists of two vertical planar rectangular receiver coils on the legs of the UAV and three horizontal planar rectangular transmitter coils on the ground. This WPT design is shown in

Figure 9.

In this design, the drone legs are directed at the centre conductors of the transmitter. For the classic-cross section coil design, the positive and negative mutual inductance between the conductor groups are given in Equations (12) and (13), respectively.

Maximum mutual inductance is achieved when the bottom conductors of the receiver (R

1 and R

5) overlap the middle conductors of the transmitter (T

3, T

5, T

7, and T

9). However, this coil design cannot fully utilise other conductor groups of the coils. Therefore, other conductors of the coils cannot sufficiently affect the mutual inductance. A novel design is proposed so that other conductor groups of coils also contribute to the positive mutual inductance. In the proposed WPT design, the horizontal transmitter coils on the ground are designed to be foldable and the transmitter and receiver conductors are brought closer to each other. The proposed folding WPT design is shown in

Figure 10.

For the proposed folding coil design, the positive and negative mutual inductance between the conductor groups are given in Equations (14) and (15), respectively.

The distances between T1-R3 and T11-R7 are minimised by the foldable design. According to Equations (5) and (6), decreasing the distance between parallel conductors increases the mutual inductance. The proposed method increases the mutual inductance by folding the receiver coils. In the classical design, the connection between some conductors (T2-R4, T4-R2, T12-R6, and T10-R8) perpendicular to each other is zero. The proposed folding method increases the mutual inductance by bringing the angle between the conductors closer to zero. The angle between T2-R4, T4-R2, T12-R6, and T10-R8 are minimized by the foldable design. When the folding angle is brought to 90 degrees, the angle between the conductors becomes 0. According to Equations (9) and (10), the lower the angle between the conductors, the greater the mutual inductance. The desired mutual inductance can be achieved with a lower number of turns and a smaller conductor’s length by the proposed design. In this way, the receiver coil becomes lighter, and internal resistance and magnetic field scattering of the WPT is reduced.

3. Simulation and Experimental Results

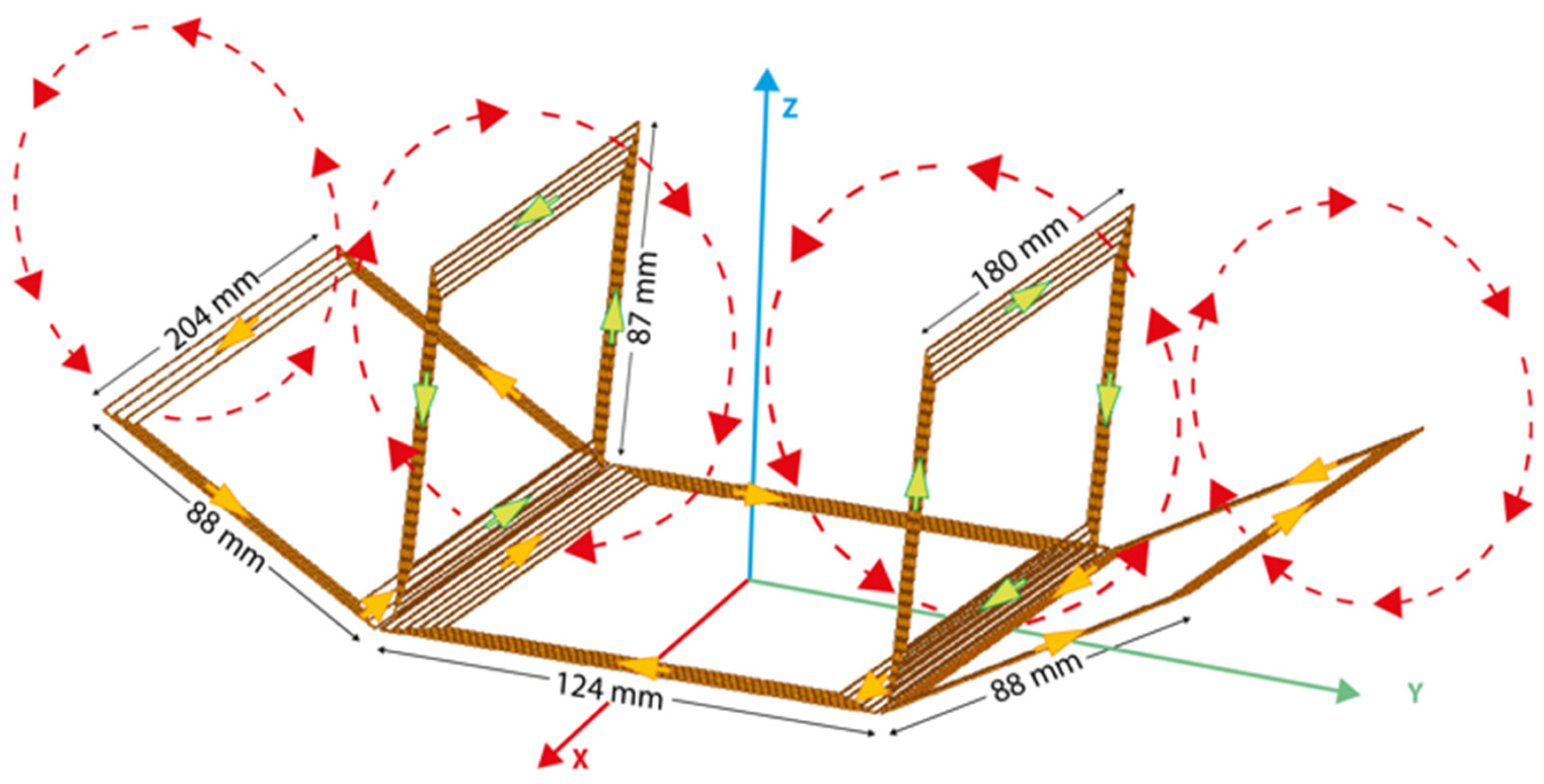

In this study, UAV’s WPT system and coils are designed for 100 watts of charging power. The natural resonance frequency of the WPT system is determined to be 138.1 kHz in accordance with the Qi standard. The proposed folding coil is designed in Maxwell 3D and is shown in

Figure 11 at different folding angles.

The transmitter coil comprises three rectangular planar spiral coils on the same horizontal plane. Each rectangular planar spiral coil in the transmitter is connected to each other by a series connection. The sizes of the right, left, and middle coils in the transmitter are 204 mm–88 mm, 204 mm–88 mm, and 204 mm–124 mm, respectively. The transmitter coil has three turns, a 1 mm wire diameter, and a 0.1 mm spacing between the wires. The receiver coil consists of two rectangular planar spiral coils connected in series to each other in the vertical plane. Receiver coils are 180 mm–87 mm in size, have five turns, a 0.5 mm wire diameter, and a 3 mm spacing between the wires. In this coil design, the transmitter and receiver use 5.39 m and 5.16 m wire, respectively. The inner resistances of the transmitter and receiver coils are measured R1 = 0.109 Ω and R2 = 0.104 Ω, respectively.

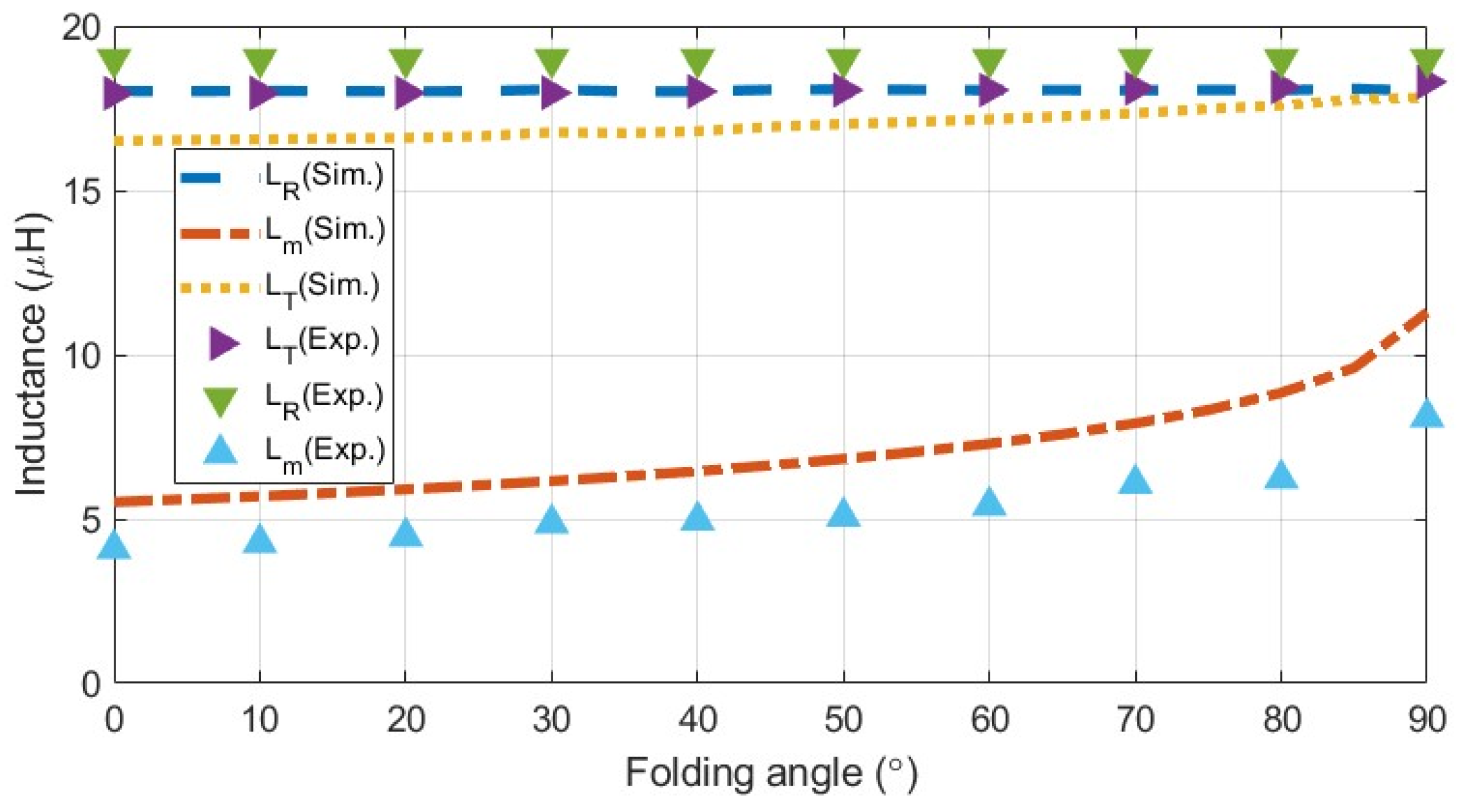

The proposed design was examined for different folding angles and misalignment situations. The self and mutual inductance change graph for different folding angles is shown in

Figure 12.

As the folding angle approaches from 0 to 90, the mutual inductance between the receiver and transmitter increases. The highest coupling is at 90 degrees, and the lowest coupling is at 0 degrees. The misalignment tolerance is lower in the axis perpendicular (Y-axis) to the receiver coils [

23]. When the coils are folded at 90 degrees, they are fully aligned on the Y-axis. On the other horizontal axis, the X-axis, alignment may not be fully achieved due to UAV position error. However, the misalignment tolerance is higher on the axis parallel to the receiver (X-axis). The graph of mutual inductance change according to misalignment on the X-axis is shown in

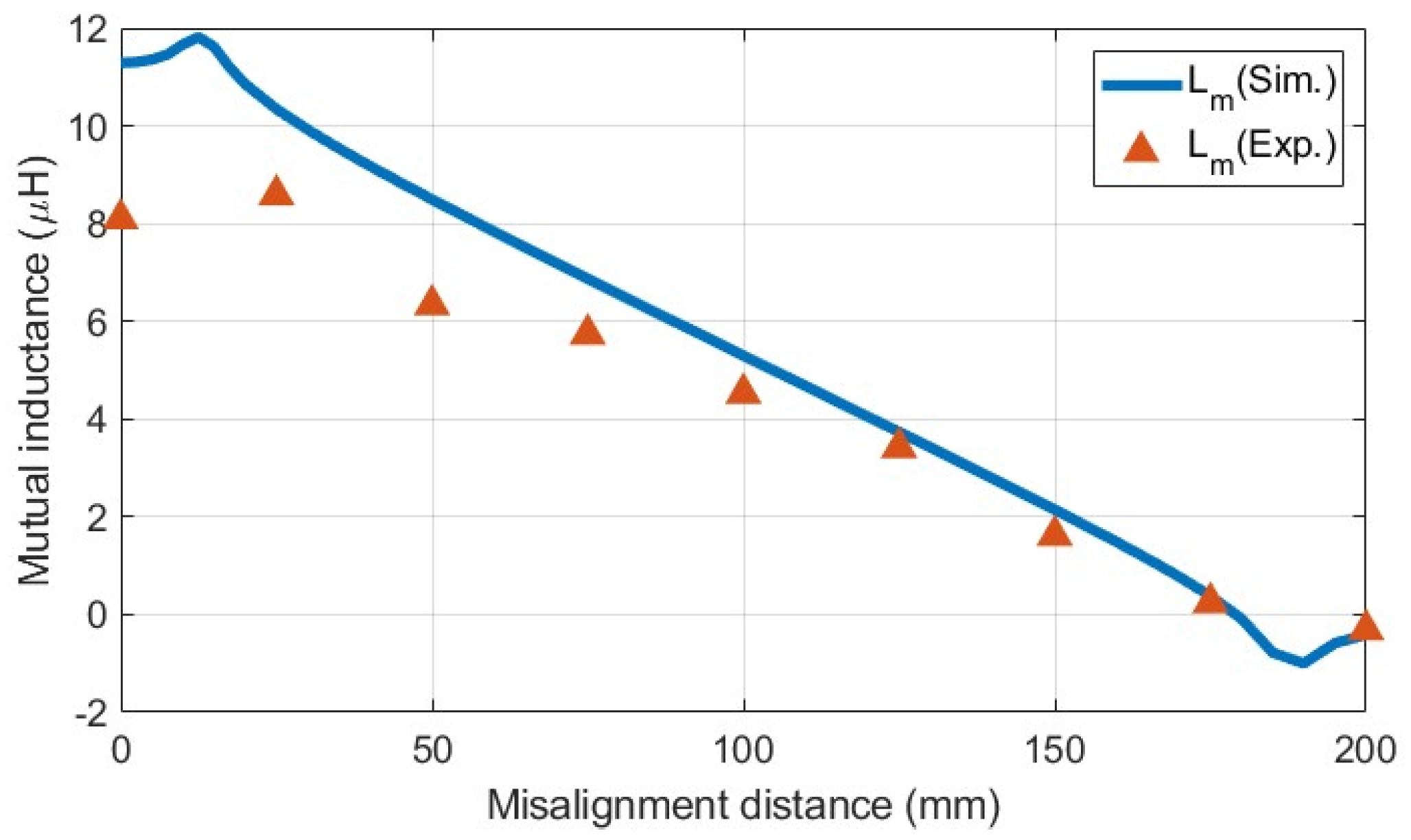

Figure 13.

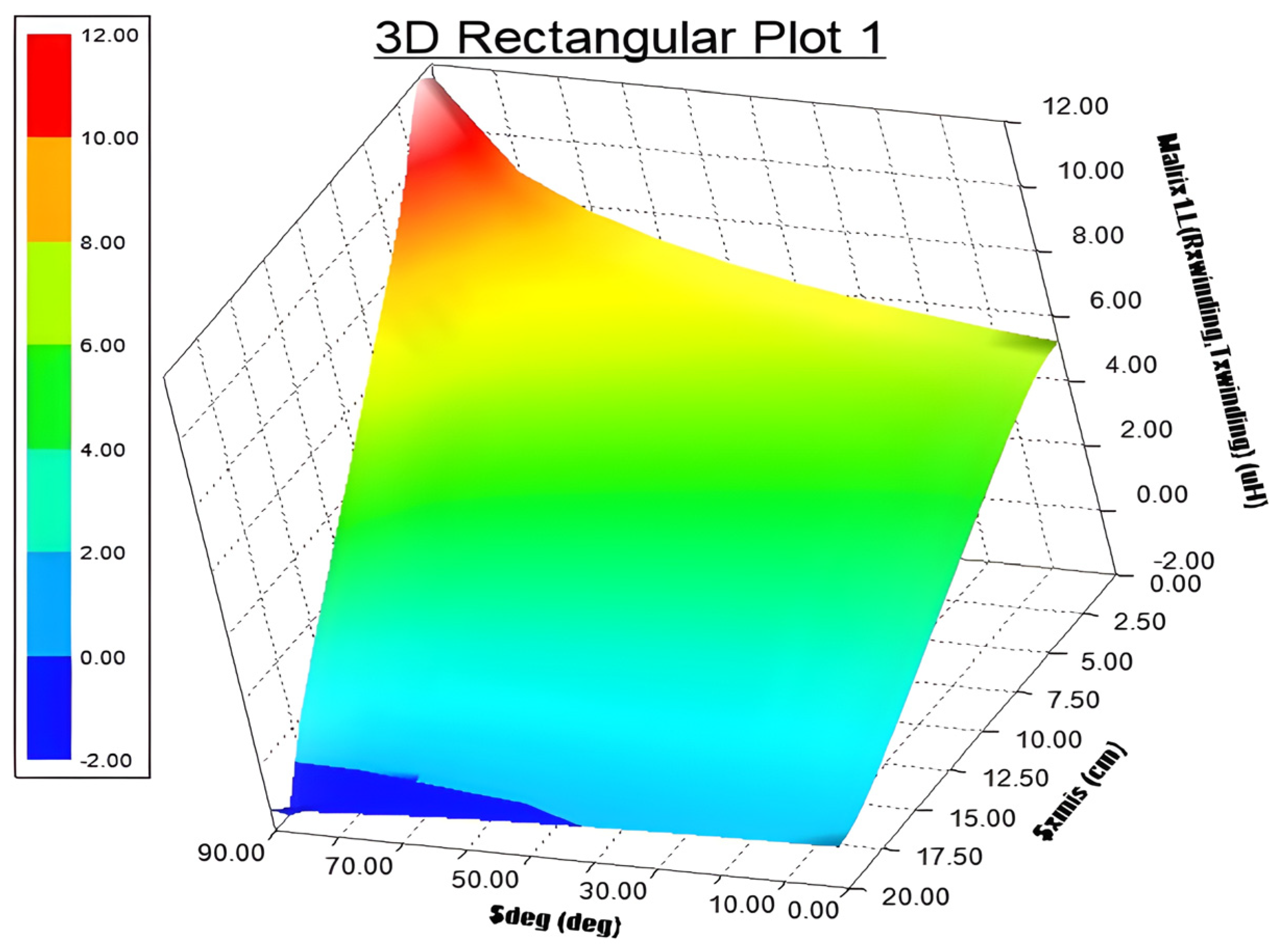

As the misalignment distance increases, the coupling coefficient and the mutual inductance decrease. The mutual inductance in the alignment condition is 11.29 μH. The critical mutual inductance is 4.6 μH by Equation (4). The critical mutual inductance is equal to the mutual inductance at an 11 cm offset for a 90-degree folding angle. Above this misalignment distance, the efficiency of the system decreases. When the folding angle is reduced from 90 degrees, the misalignment tolerance in the X-axis also decreases. To compare the magnetic coupling of the foldable and non-foldable systems, it is necessary to examine the mutual inductance at different folding angles and misalignment distances. The change of mutual inductance according to different folding angles and misalignment distances is shown in

Figure 14.

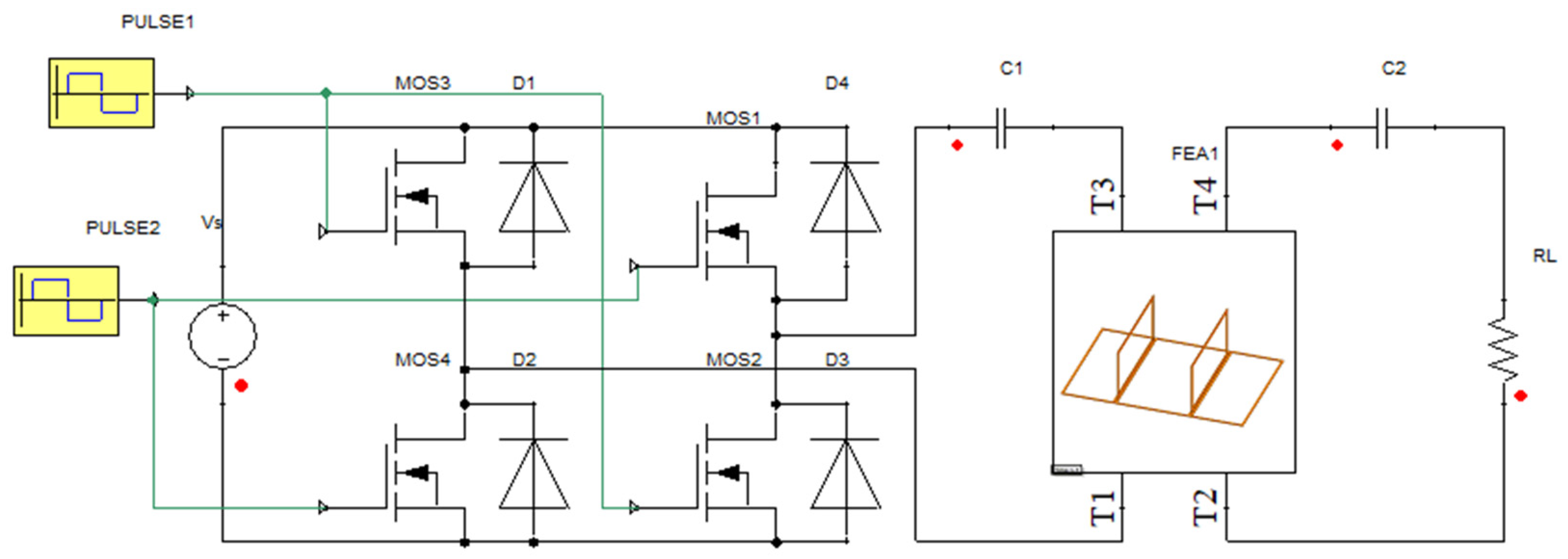

The WPT circuit was analysed using Ansys Simplorer. Ansys Simplorer was used to co-simulate with proposed coils designed in Maxwell 3D. The co-simulation circuit of the WPT system is shown in

Figure 15.

Load resistance (R

L) is determined as 4 ohms. In the proposed coil design, the transmitter self-inductance varies depending on the folding angle. The transmitter’s self-inductance was 17.8 μH at a 90-degree folding angle. The receiver’s self-inductance measured 18.1 μH. Receiver and transmitter resonance capacitors were calculated as 72.65 nF. Simulation results for the aligned and critical misalignment cases at the 90-degree folded WPT system are given in

Table 1.

fr is the resonance frequency. Vin and Vout are input and output rms voltages, respectively. Pin and Pout are the input and output power, respectively. Iin, and Iout are the input and output currents, respectively. VCT and VCR are the voltage stress of transmitter and receiver resonance capacitors, respectively. Until the mutual inductance value falls below the critical value due to misalignment, this design operates efficiently. This proposed design achieves 95% efficiency up to 11 cm misalignment.

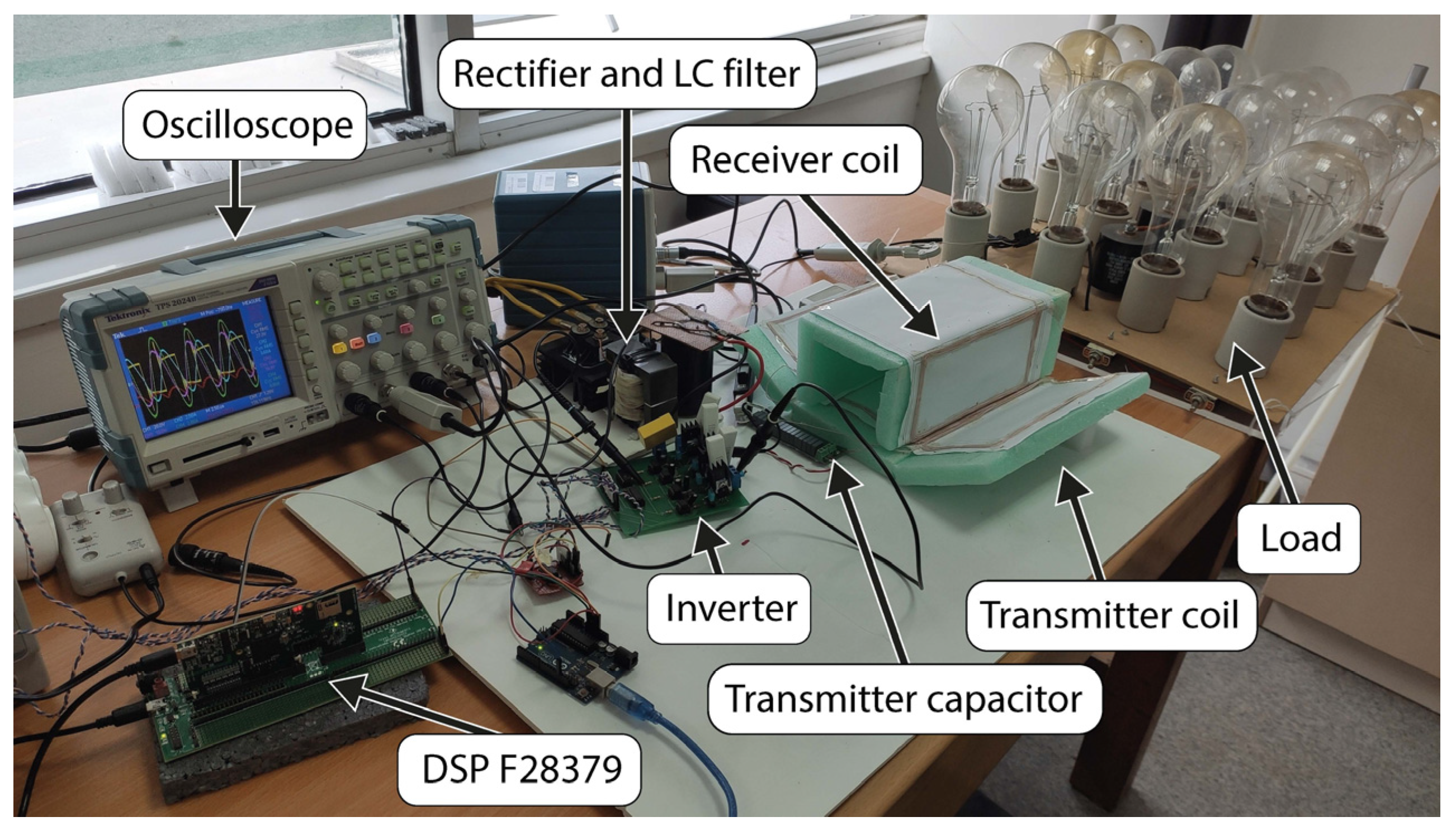

The experimental setup of the proposed foldable wireless charging system is shown in

Figure 16.

In the experimental set-up, incandescent lamps are used as R

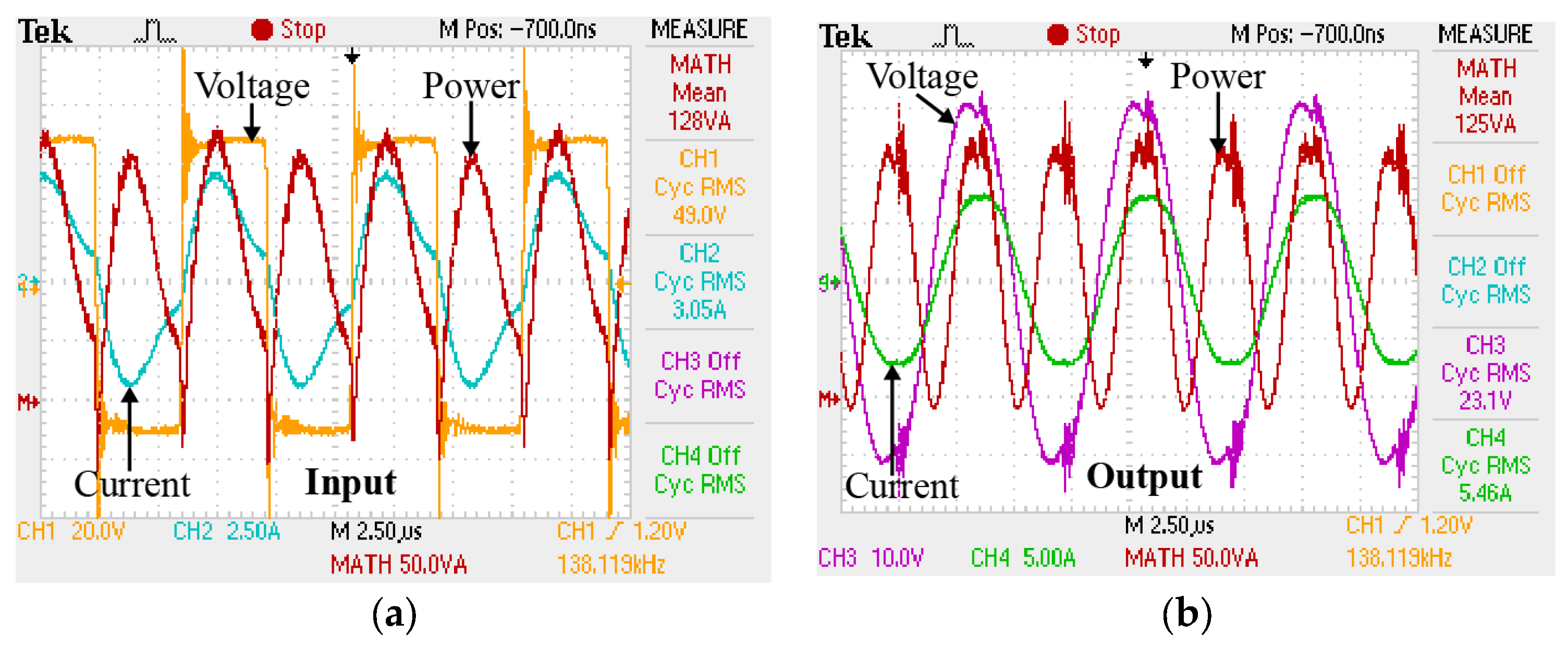

Load. The inverter was controlled with DSP F28379 (Texas Instruments, Dallas, TX, USA). The 40 AWG Litz wires (Imaj Litz Teli, Istanbul, Turkey) are used in the receiver and transmitter windings to reduce AC resistance. Experimental results were obtained using the Tektronix TPS2024B oscilloscope (Tektronix, Beaverton, OR, USA). The experimental results of the output voltage, current, and power of the inverter and load for the folding angle of 90 are shown in

Figure 17.

The details of the experimental results for the folding angle of 0 to 90 are shown in

Table 2.

As the folding angle increases, the mutual inductance and equivalent impedance increase. Increasing the equivalent impedance increases the supply voltage and reduces the input current for the constant output power. Transferring the same power with a lower input current reduces the copper loss in the transmitter resonator. As a result, efficiency increases as the folding angle increases. The wireless charging system has been tested at various misalignment distances. The experimental results of the output voltage, current, and power of the inverter and load for 10 cm misalignment at the 90-degree folding angle are shown in

Figure 18. The experimental results for the misalignment are shown in

Table 3.

As the misalignment distance increases, the equivalent impedance and efficiency decrease due to the decrease in mutual inductance. Efficiency decreases more dramatically below critical mutual inductance. In this study, over 85% efficiency was achieved up to 10 cm misalignment at a 90-degree folding angle. If there is a misalignment of more than 10 cm, the magnetic coupling between the receiver and transmitter becomes very weak, the input current increases extremely, and the efficiency drops to unacceptable levels.

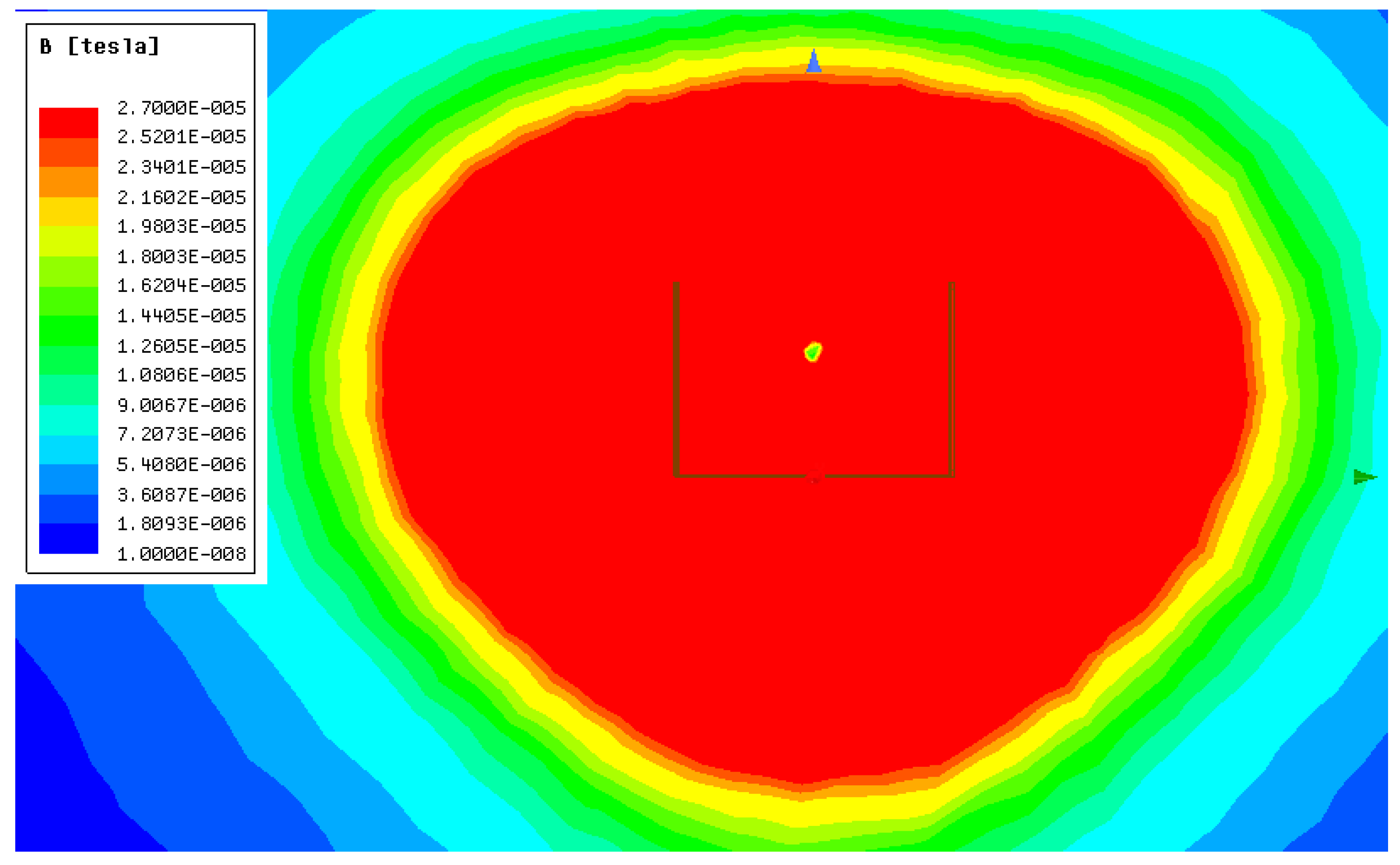

The WPT systems create electromagnetic interference on the UAV and into the environment. It is important to determine the safe distance between the electronic components of the UAV and the human. Safe areas for humans are determined by determining the distances below the limit value according to IEEE and ICNIRP standards [

30,

31]. The electronic components on the UAV must be determined according to the exposure limits of these components. These limits are determined by the manufacturer of the components. If the limits are exceeded, voltage and current may be induced on the conductors of these components, interference may occur, and the functions of the sensors may weaken or malfunction and may cause components to heat up or be destroyed. Electromagnetic interference is below the limit value above the safe distance. The electromagnetic scattering of the proposed design was examined using Ansys Maxwell 3D. The proposed design’s magnetic flux density is shown in

Figure 19.

The magnetic flux density exposure limit for IEEE and ICNIRP for 138.1 kHz is 27 μT [

30,

31]. The magnetic flux density dropped below 27 μT when 6.5 cm, 12 cm, and 8.9 cm were moved away from the transmitter on the X-axis, Y-axis, and Z-axis, respectively. It is recommended to turn off the WPT system when a person or living thing approaches closer than these distances.