1. Introduction

Multirotor Unmanned Aerial Vehicles (UAVs) have revolutionized the field of aerial technology by introducing versatility and agility. These dynamic aircraft have been seamlessly integrated into our society and made remarkable advancements across numerous domains. They have transformed the fields of aerial photography, videography, search and rescue operations, infrastructure inspection, agricultural monitoring, delivery logistics, urban transportation, and environmental surveillance [

1,

2].

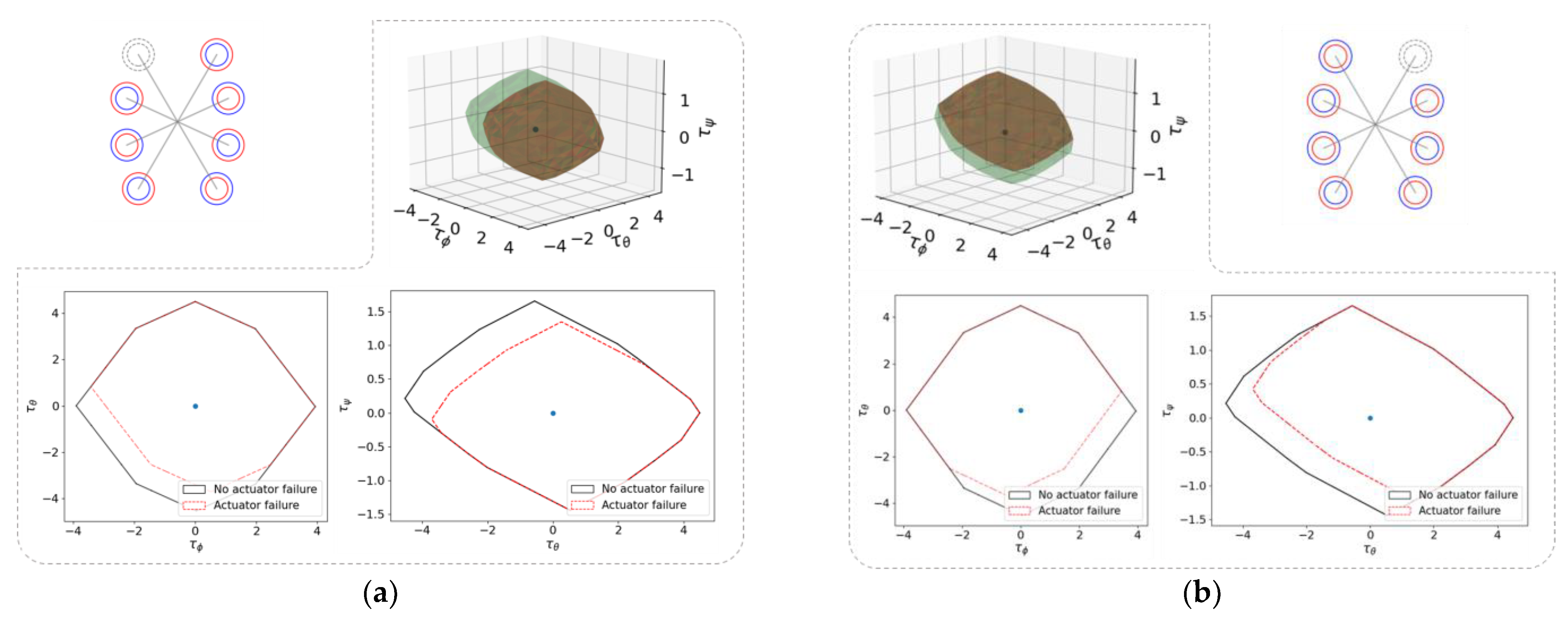

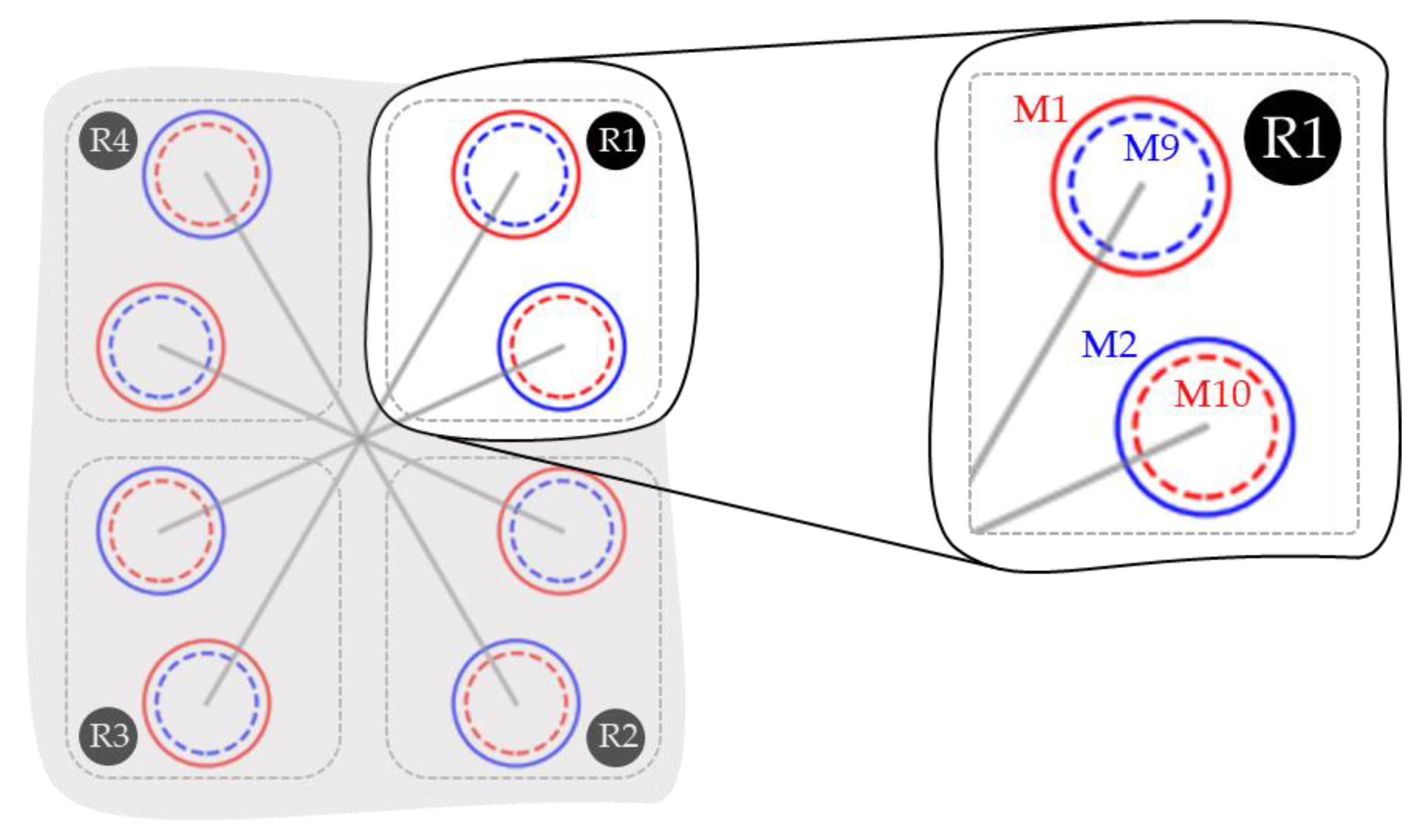

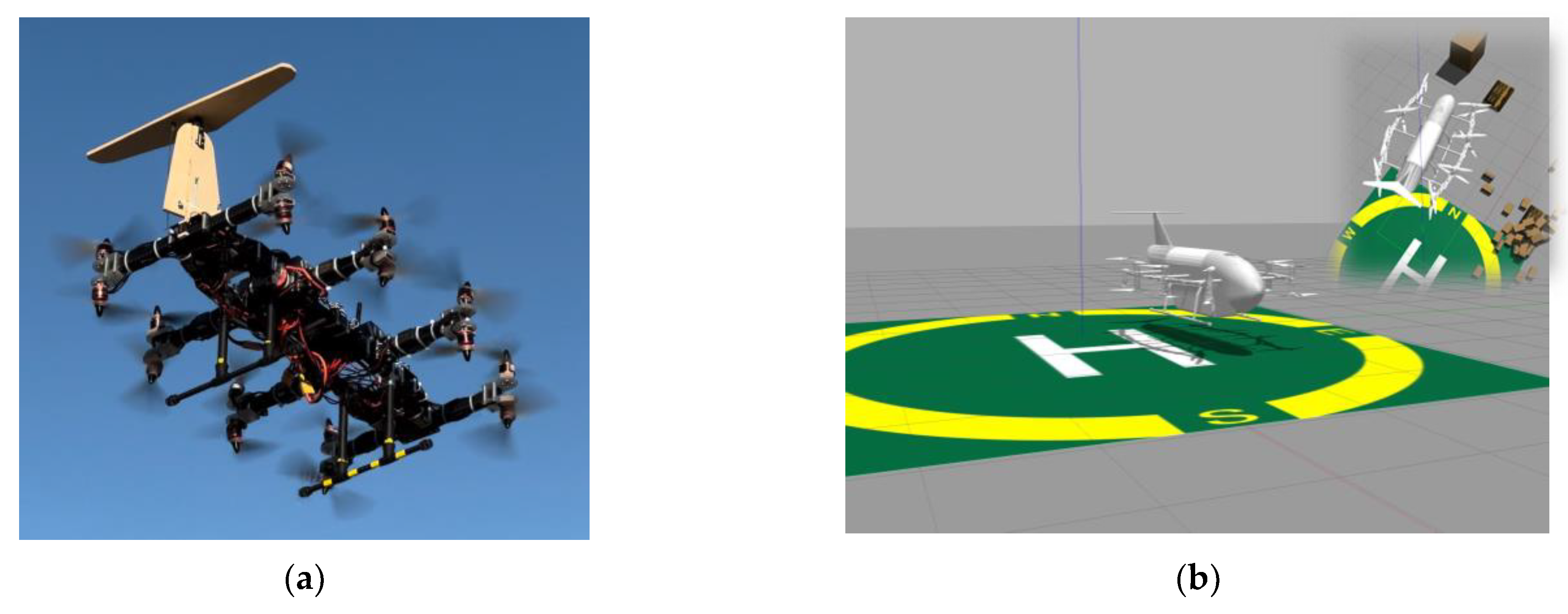

Multirotor UAVs belong to a category of unmanned aerial vehicles that are powered by multiple rotors, usually in the form of propellers. These UAVs consist of a central body or frame with three or more symmetrically placed rotor arms, with each arm supporting one or two motors and propellers, as depicted in

Figure 1. The propulsion system, which comprises the propeller, motor, and ESC (Electronic Speed Controller), is responsible for generating the required thrust to lift and propel the UAV in the air. The propeller, which is a rotating blade, generates airflow, while the motor supplies mechanical power to rotate the propeller. The ESC controls the motor’s speed and direction. Together, these components collaborate to deliver the necessary force for the UAV’s vertical lift and control, allowing it to hover, take off vertically, and maneuver with remarkable agility. [

3].

Nevertheless, the propulsion system used by multirotor UAVs is susceptible to unforeseen malfunctions during operation caused by various factors, encompassing mechanical issues, electrical problems, and environmental conditions. Instances of motor failures can stem from factors like overheating, mechanical wear, manufacturing defects, or electrical abnormalities, resulting in reduced thrust or complete operational breakdown [

4]. Failures in Electronic Speed Controllers (ESCs) can be ascribed to electrical or communication problems, overheating, or component failures. Disruptions in the power distribution system, such as faulty wiring, loose connections, or inadequate power supply, can also compromise the functionality of the propulsion system [

5]. Moreover, propeller-related complications, including imbalance, cracks, or detachment, can lead to diminished efficiency, vibrations, or even total propeller failure. Environmental elements, like adverse weather conditions, debris, water infiltration, or damage caused by foreign objects, further contribute to motor, ESC, and propeller failures or performance degradation. These faults can result in degraded performance, loss of control, or complete system failure, ultimately leading to service interruptions, decreased efficiency, and weakened reliability [

6].

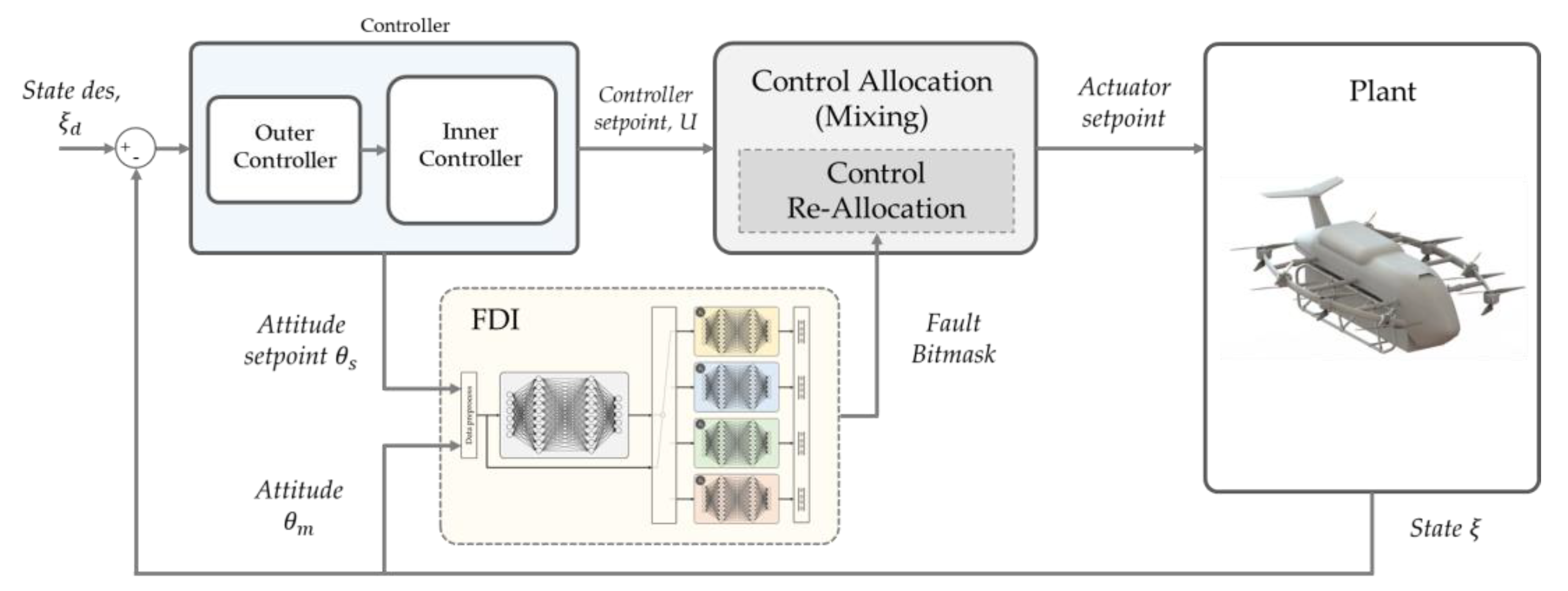

In contrast, researchers have proposed the Actuator Fault Tolerant System (AFTS) as a solution to mitigate the negative impact of actuator failure in redundant multirotor UAVs, enabling them to continue their mission or perform emergency landings. The AFTS consists of two key components: the Actuator Fault Detection and Isolation (FDI) system and the Actuator Fault Management (FM) system [

7,

8,

9]. The FDI system actively monitors the actuators, continuously detecting any abnormal behavior or malfunctions that may occur [

10]. On the other hand, the FM system is designed to effectively handle the recovery process to maintain flight stability and control. It compensates for the failed actuator by leveraging redundancy and redistributing control commands to the operational actuators, ensuring optimal utilization of the healthy actuators. Additionally, proper redundancy management can prevent adverse effects and potential risks, such as limited maneuverability, reduced disturbance rejection, torque imbalance, increased stress on the system, higher failure rates, or additional failures in motor ESCs, wires, and propellers, ultimately extending the flight time [

11].

Nevertheless, the incorporation of redundant actuators into the system presents both advantages and drawbacks. On one hand, it enhances actuator fault tolerance by providing backup options, and it enables the UAV to carry a larger payload. However, it also introduces challenges in accurately detecting and isolating the location of a failed actuator. Therefore, it is crucial to design an effective Fault Detection and Isolation (FDI) system that can handle the increased complexity arising from higher levels of redundancy. This approach allows the Actuator Fault Management (FM) system to remove the failed actuator from the system and optimize the redistribution of control based on the specific scenario of actuator failure.

Numerous researchers have proposed diverse approaches to address actuator Fault Detection and Isolation (FDI) in UAVs, which fall into distinct categories, such as residual-based methods, analytical redundancy, signal processing, and machine learning/data-driven methods [

12]. Residual-based methods involve monitoring the difference or residual between the expected behavior of the UAV and the actual measurements obtained via sensors. By comparing these residuals with pre-determined thresholds or employing statistical techniques, deviations caused by actuator faults can be detected. In contrast, analytical redundancy relies on using mathematical models and system dynamics to identify defects [

13]. This technique compares the UAV’s predicted behavior, as determined using the model, with the actual behavior observed from the sensors. Any disparities between the predicted and observed values can indicate actuator faults. Analytical redundancy techniques may involve using Kalman filters [

14] and observer-based approaches [

15]. Signal processing methods focus on analyzing sensor measurements to detect and isolate actuator faults [

16]. These techniques employ frequency analysis, wavelet transforms, or statistical signal processing methods to identify abnormal patterns or characteristics in the sensor data. Unusual or unexpected variations in sensor signals can indicate the presence of actuator faults. However, some of these methods are ineffective in real-world applications due to system parameter variations during operation and unknown disturbances, which can result in false alarms.

Another emerging approach that is gaining traction is the use of Machine Learning (ML) and Data-Driven Approaches, which utilize machine learning techniques to learn the normal behavior of UAV systems and detect deviations caused by actuator faults [

17,

18,

19]. These methods employ supervised or unsupervised learning algorithms trained on historical data to identify patterns or anomalies associated with faulty actuators. Support Vector Machines (SVM) [

20,

21], Artificial Neural Networks (ANN), clustering algorithms [

22], and advanced Deep Neural Network (DNN) learning approaches are encompassed within these techniques. The power of DNN lies in its ability to handle complex and nonlinear relationships between input variables and output predictions, capturing intricate patterns that traditional analytical methods may struggle to model or discover. Furthermore, these approaches excel in learning from large-scale and diverse datasets, automating complex tasks, and streamlining processes that would otherwise require manual effort or extensive rule-based systems [

12]. For time series data classification, such as actuator FDI, recurrent networks, particularly Long–Short-Term Memory (LSTM) networks, prove highly efficient in capturing temporal dependencies within data sequences, surpassing the capabilities of classical RNN structures [

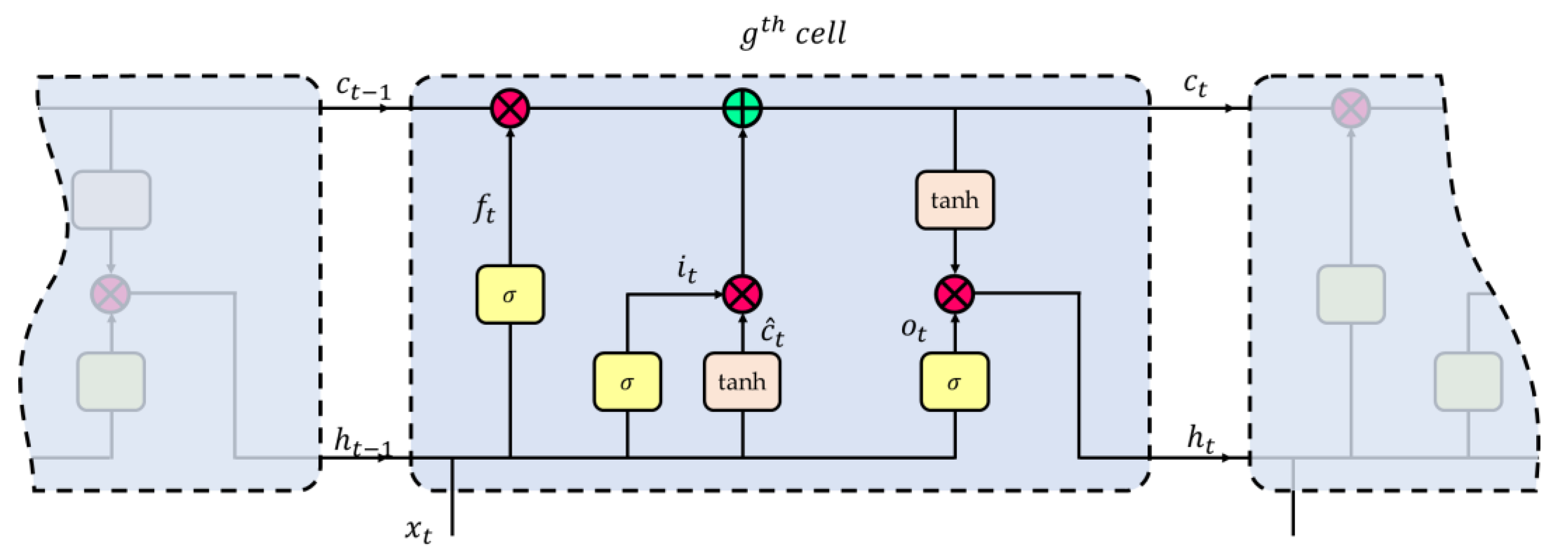

23].

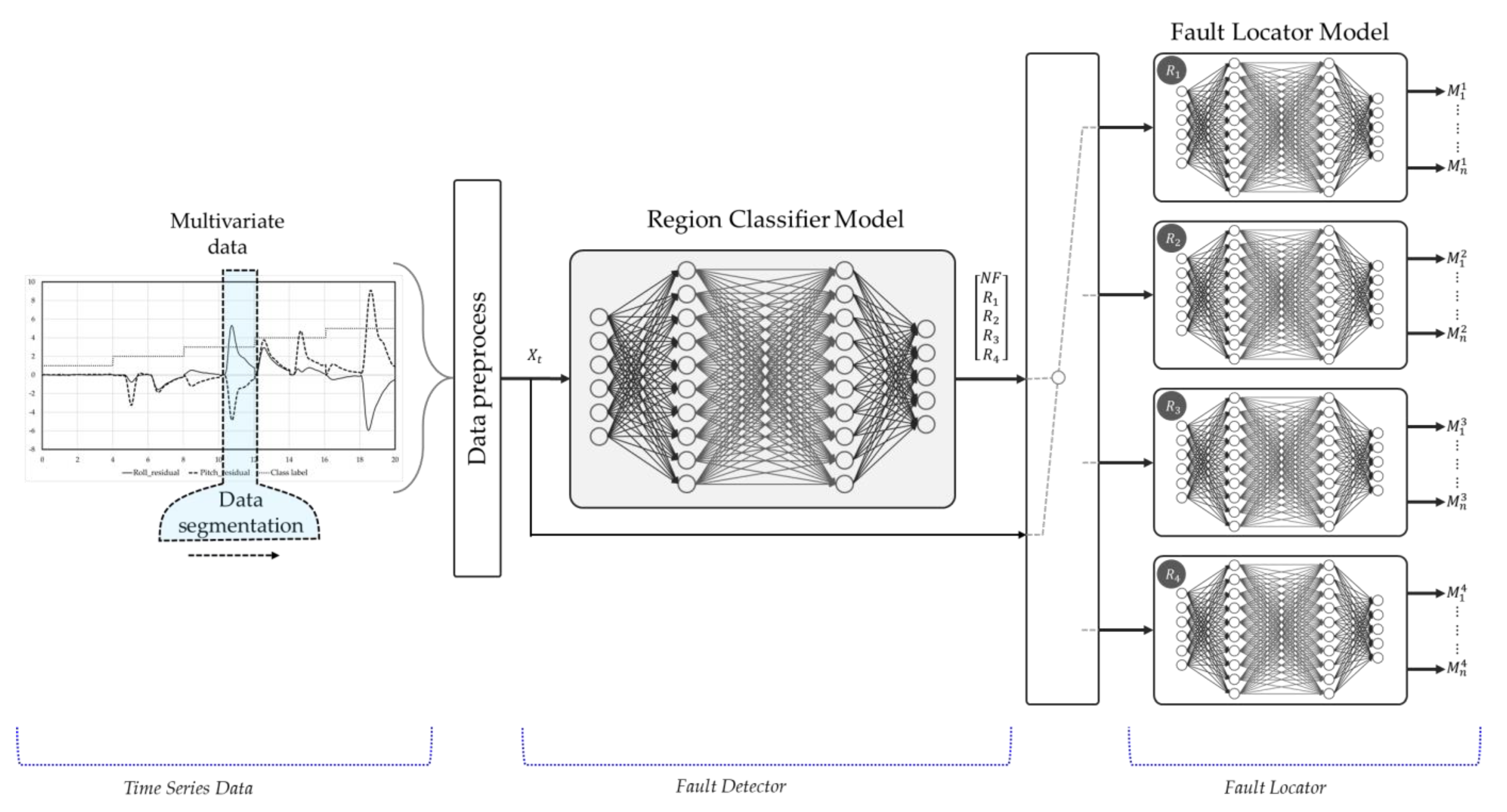

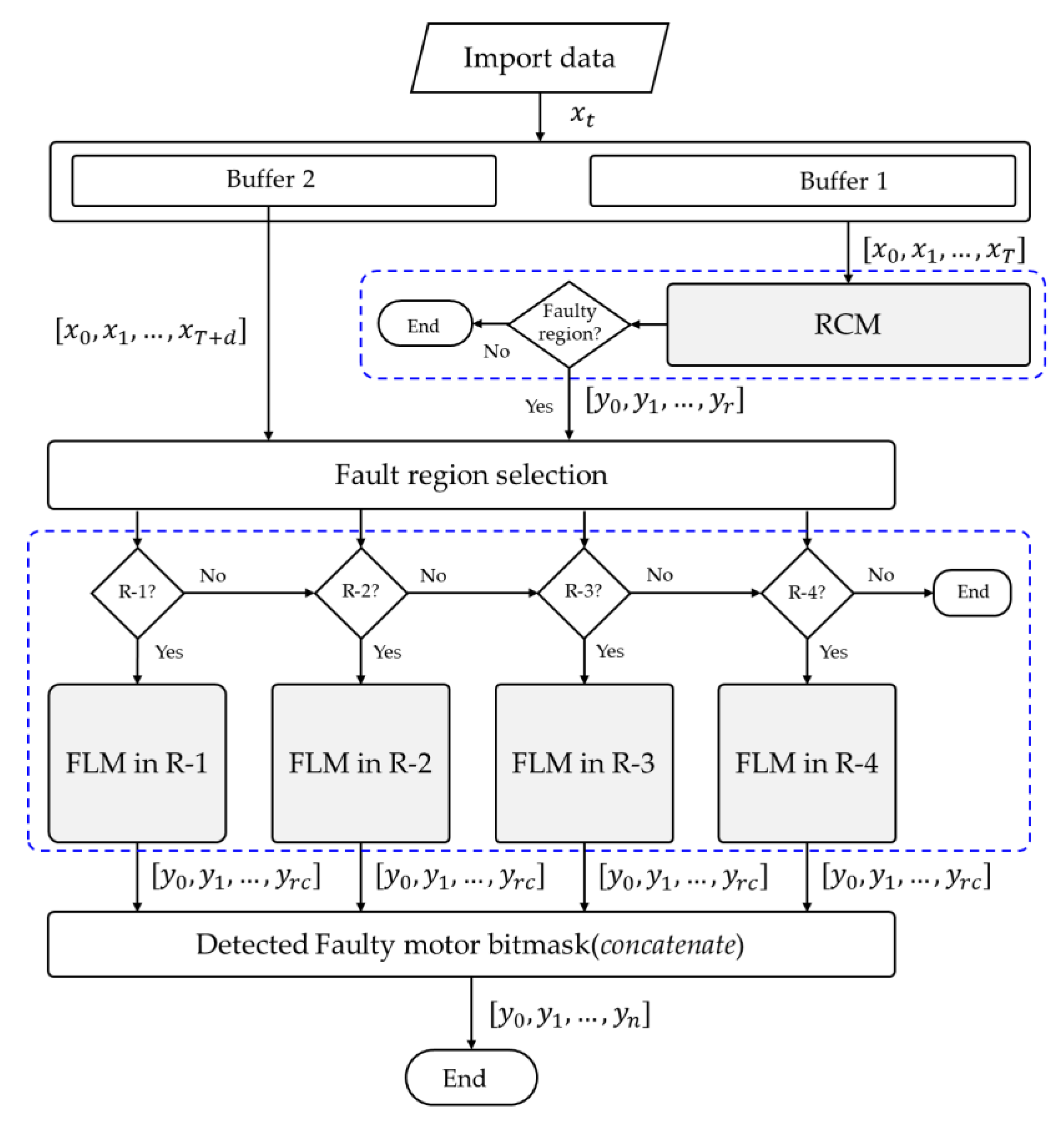

This study introduces a novel approach that utilizes DNNs to detect and isolate faulty actuators in highly redundant multirotor UAVs. The research focuses on a specific configuration that represents a highly redundant multirotor UAV, i.e., a hexadecarotor multirotor cargo drone with sixteen rotors, which is shown in

Figure 1a, as the object of investigation. A cascaded DNN-based FDI framework is proposed, exploiting the capabilities of LSTM networks to capture the complex temporal behavior of the system. The proposed LSTM-based FDI scheme comprises two sections named the Region Classifier Model (RCM), which is designed to detect and identify the region where a fault exists, and the Fault Locator Model (FLM), which is designed to determine the specific failed motor within that suspected region. Rigorous testing and evaluation are conducted using both simulation and real-flight experimental data to validate the resilience and effectiveness of the proposed approach. The results demonstrate the reliability and efficiency of the proposed solution, positioning it as a crucial solution for ensuring the safety and reliability of operations in multirotor UAVs.

The remaining sections of this article are structured as follows.

Section 2 provides a comprehensive review of multirotor UAVs, focusing on the impact of actuator failure and addressing the problem statement. In

Section 3, an overview of DNN and LSTM is presented, along with the proposed scheme. In

Section 4, the process begins with dataset preparation, followed by the presentation of results obtained from training the models and their deployment. Lastly,

Section 5 concludes the article and discusses potential future work.

4. Result and Discussion

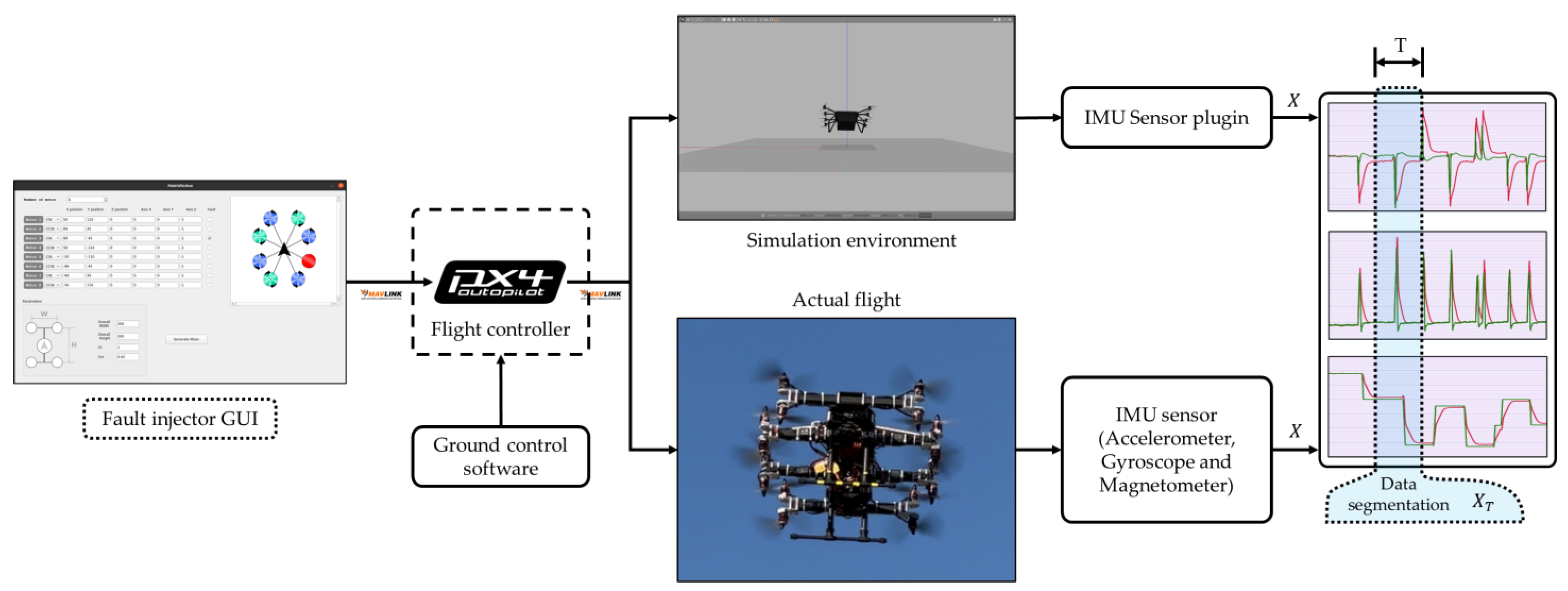

Figure 10 illustrates the research object model, which is known as the hexadecarotor highly redundant multirotor UAV. A prototype of the UAV weighing 5 kg and a CAD model for Gazebo simulation with similar structural properties were both prepared for data generation and testing. To generate a substantial amount of training data for various flight scenarios and fault types, a simulation platform was utilized. However, due to the potential risks associated with intentional stopping in the absence of robust FDI and FM, the amount of data collected from real flight was relatively limited. Nonetheless, the collected data were cured, augmented, and used to test the trained model.

The subsequent section provides a detailed account of the preparation of the data set, as well as the training, testing, and deployment of the models.

4.1. Training Data Collection and Preparation

A critical aspect of ML is the creation of a dataset that is both adequate and of high quality. This process involves ensuring comprehensive coverage of information while minimizing redundancy. Additionally, it is crucial to gather training data that are both informative and representative. Designing an FDI system based on deep learning for multirotor UAVs is a significant challenge, mainly because generating precise flight data in the presence of faulty actuators can be hazardous and impractical during real flights.

To overcome this challenge, we have devised an actuator fault tolerance test environment capable of injecting faults and implementing control reallocation features for both simulated and controlled flight scenarios. This system assumes the presence of a flawless FDI unit and utilizes user input injection commands to generate actuator fault flags

for the FM unit. After a reasonable detection time, the UAV system restructures itself and recovers from the fault. To facilitate the dataset preparation process, the tool facilitates the generation of data for various types of faults by injecting faults into actuators through a provided Graphical User Interface (GUI), as depicted in

Figure 11.

A time series must be converted into samples with input and output components for supervised ML. One common approach to segmentation of time series data is to use sliding windows, which involves dividing elements into fixed-length windows that slide along the time axis. By dividing the time series data into smaller segments, sliding windows can help to capture local patterns and dependencies in the data, and each window is treated as a separate sequence that is fed into LSTM model.

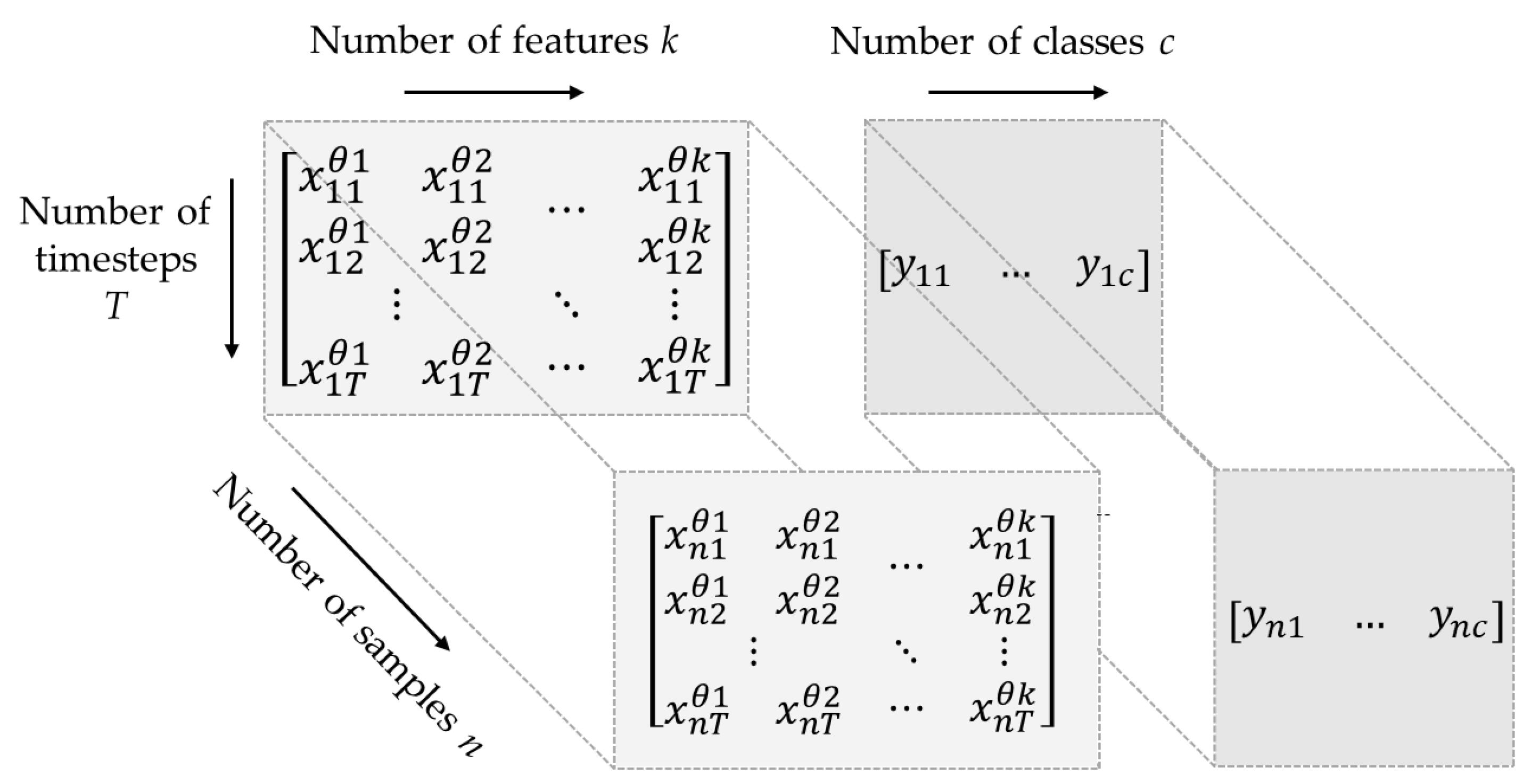

We can define a multivariate time series datum

as a sequence vector

that is made up of real values measured from the sensor or estimated via fusion of different sensors, as defined in

where

n is the number of samples, and

k is the number of features.

Individual sequences were treated as samples and linked to specific classes. Additionally, the collected data comprised multivariate time series data, which entail recording multiple variables at regular time intervals.

Figure 12 presents the overall data structure, depicting the slicing of the multivariate time series data into

n samples, with

k features, with windows of fixed-length

T, along with their corresponding class labels

c.

To train and test our proposed model, we acquired a dataset consisting of both real-time data from sensors installed onto UAVs, including accelerometers, gyroscopes, and magnetometers, and simulation data from sensor plugins were used to capture the UAV’s orientation in a simulated environment. The collected data encompassed roll, pitch, and yaw angles and rates, along with their corresponding setpoints. The data collection process involved various flight scenarios, such as hovering at different heights and mission flights with different vehicle orientations. Furthermore, to enhance the realism of our simulation, we incorporated real-world dynamics and external forces. By augmenting the collected data with random noises, we aimed to emulate the influence of factors like wind gusts and create a comprehensive simulation that closely resembled different flight scenarios. To ensure robustness and prevent overfitting, a diverse and sizable dataset was prepared. This dataset represented a range of complexities and variabilities, as well as a balanced distribution of classes.

For each combination of actuator fault scenarios (four faults per region for four actuators per region) and flight types (eight different scenarios), we recorded 20 s of flight simulation data at a sampling rate of 50 Hz. Subsequently, series data augmentation techniques were applied to enhance the dataset, which involved scaling the collected data. The augmentation process resulted in 2100 samples for the “No fault” class and 2000 samples for each region in the RCM. For the FLM, 600 samples were created for each class per region.

In the final step, we adopted a standard method to assign labels to the prepared data by selecting the majority class within each window as the corresponding label. To transform the categorical variables of the label classes into numerical features for analysis, we employed a widely used technique in ML, which is known as One Hot Encoding. The categorical and numerical representations of the classes can be found in

Table 2 and

Table 3 for their respective models.

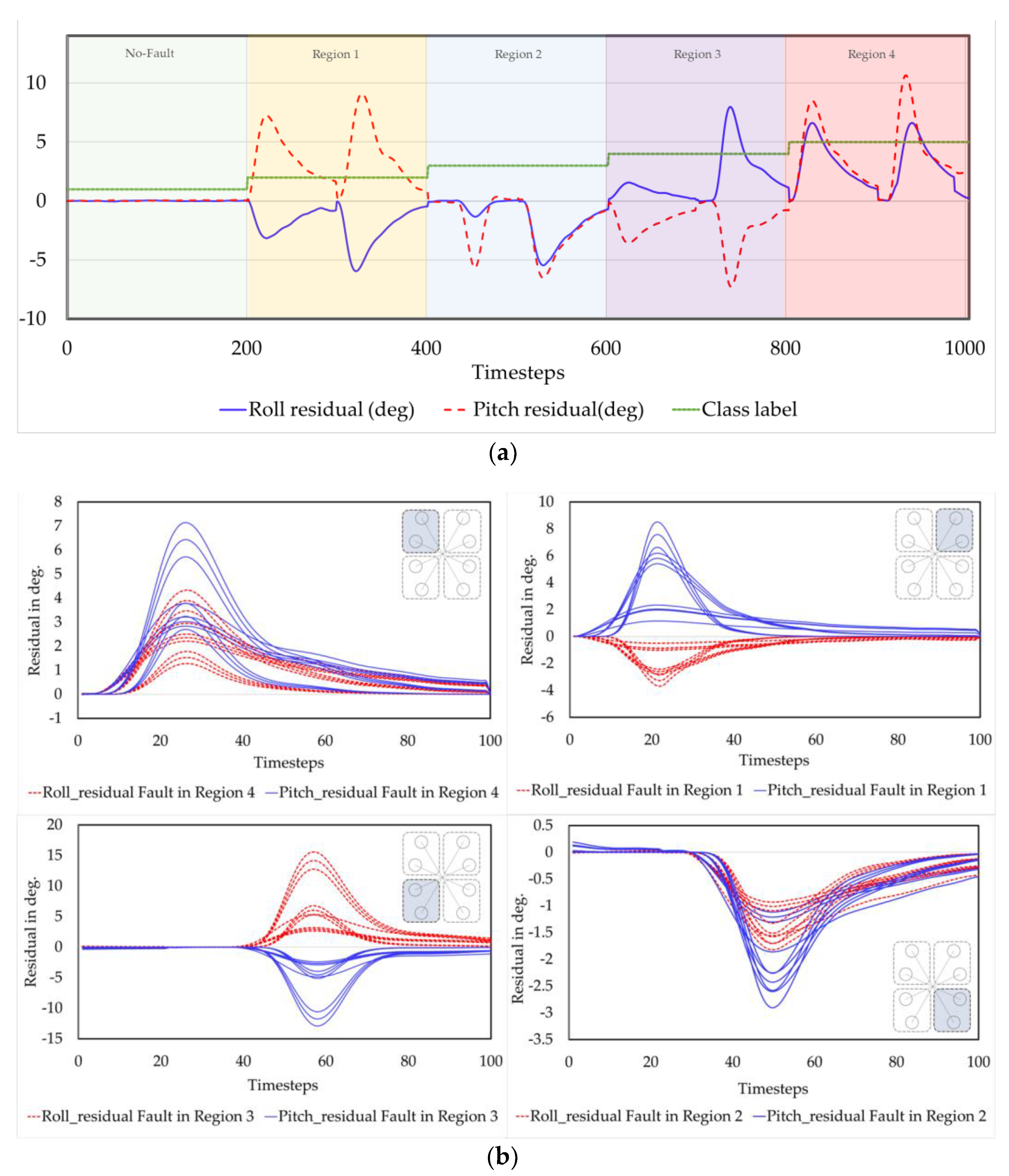

The presented data in

Figure 13 constitute a representative subset selected from the collected and processed dataset. They showcases samples from different classes, along with their corresponding labels, in

Figure 13a, providing a visual representation of the prepared data.

4.2. Faulty Region Classifier Model Result

In

Section 3, we presented the Region Classifier Model, which aimed to detect and classify the region that contained the faulty actuator(s). We also described the approach for dividing a multirotor UAV configuration into regions based on the behavior of attitude residual signs (roll and pitch) when specific actuators fail. The RCM is a multiclass classification model that produces five distinct output classes: “No Fault,” indicating the absence of any failed actuators; “Region1”; “Region2”; “Region3”; and “Region4,” indicating the presence of faults in the system and providing information about the specific fault group. These fault region labels are essential for activating the FLM.

During the training process, we used the following hyperparameters: 100 epochs, a maximum of 50 iterations per epoch, and an initial learning rate of 0.01. The input data had a format array of , in which there were total of 10,100 samples (n), a sequence length of 130 timesteps (T), and 4 features (f), namely roll residual, pitch residual, and their respective rate residuals. The data were partitioned into 70% training data and 30% test data. We employed the “cross entropy” loss function and ‘adam’ as the optimizer for model training. To enhance the learning process, the hyperparameters were fine-tuned through an iterative process of experimentation and evaluation. The training was conducted on MATLAB 2023a using a single CPU.

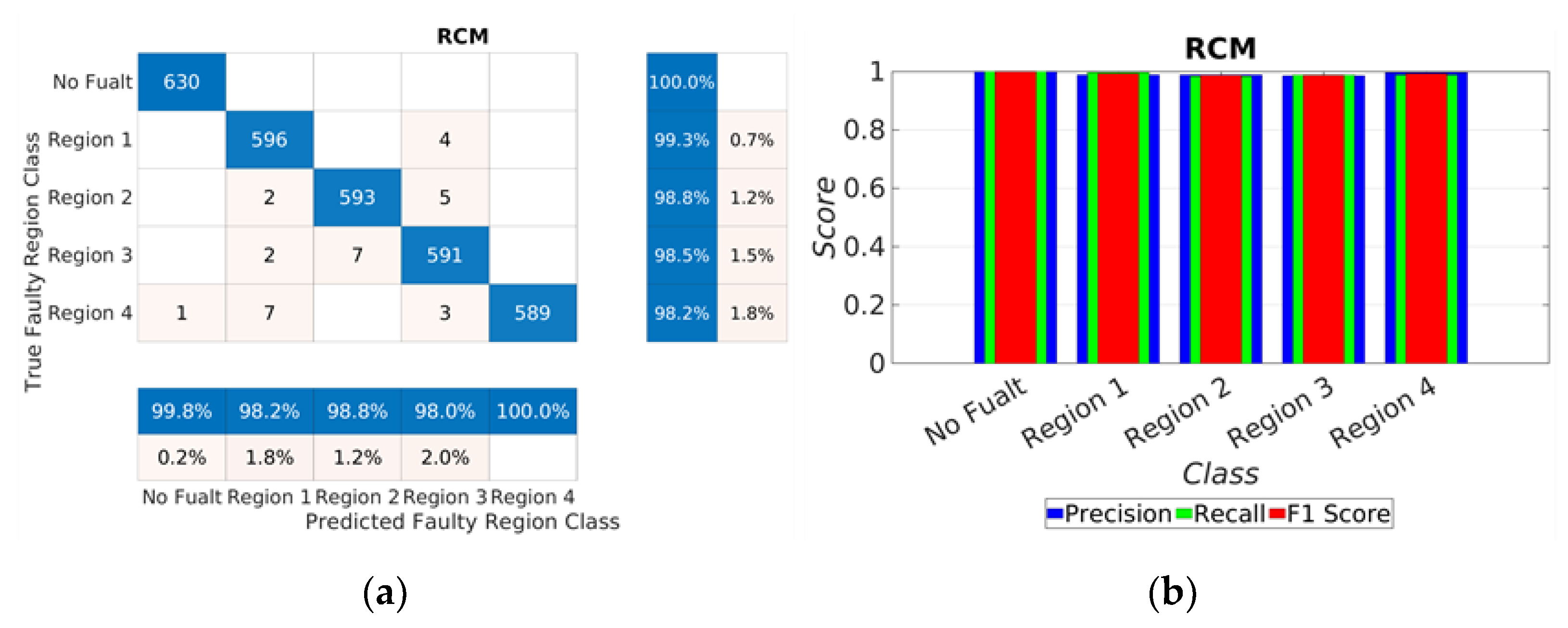

During the training process, an impressive accuracy of 98.97% was attained, and the loss approached zero, after a learning time of 522 min, indicating the model’s strong performance. These results are depicted in the confusion matrix shown in

Figure 14a. Additionally, for a visual representation of the outcome, Precision, Recall, and F1 score metrics were employed, as demonstrated in

Figure 14b. A summary of the performance measures and the number of correctly classified samples can be found in

Table 4.

4.3. Faulty Localization Model Result

In this study, we introduced the FLM as another DNN model. The primary objective of the FLM was to precisely determine the specific source of a fault once the RCM successfully detected the presence of a fault in the system and provided hints regarding the fault group. In the case of our study object, each group consisted of four motors that produced attitudes (roll and pitch) in the same direction. LSTM-based DNN models with identical architectures were separately designed for each region. These models remained inactive until the RCM detected a fault and provided information about the specific region. Once activated, the corresponding FLM outputted the motor ID associated with the detected fault.

During the training process, the FLM model takes the three attitude angles and their respective rate residuals as inputs, along with the corresponding faulty motor class labels that match the input data patterns. Unlike that of RCM, FLM uses a longer sequence to accommodate detection time delay d via RCM. Consequently, the input data had a format array of , having a total of 2400 samples (n), along with a sequence length of 150 timesteps (T+d) and 6 features (f), namely roll residual, pitch residual, yaw residual and their respective rate residuals. For each model training, after a few trial-and-error searches of the hyperparameters to identify the optimized result, the following method was used: 140 epochs, a maximum of 25 iterations per epoch, and a learning rate of 0.0154. Similarly, the data were partitioned into 70% training data and 30% test data. We employed the “cross entropy” loss function and ‘adam’ as the optimizer for model training, and the training was conducted via MATLAB 2023a using a single CPU.

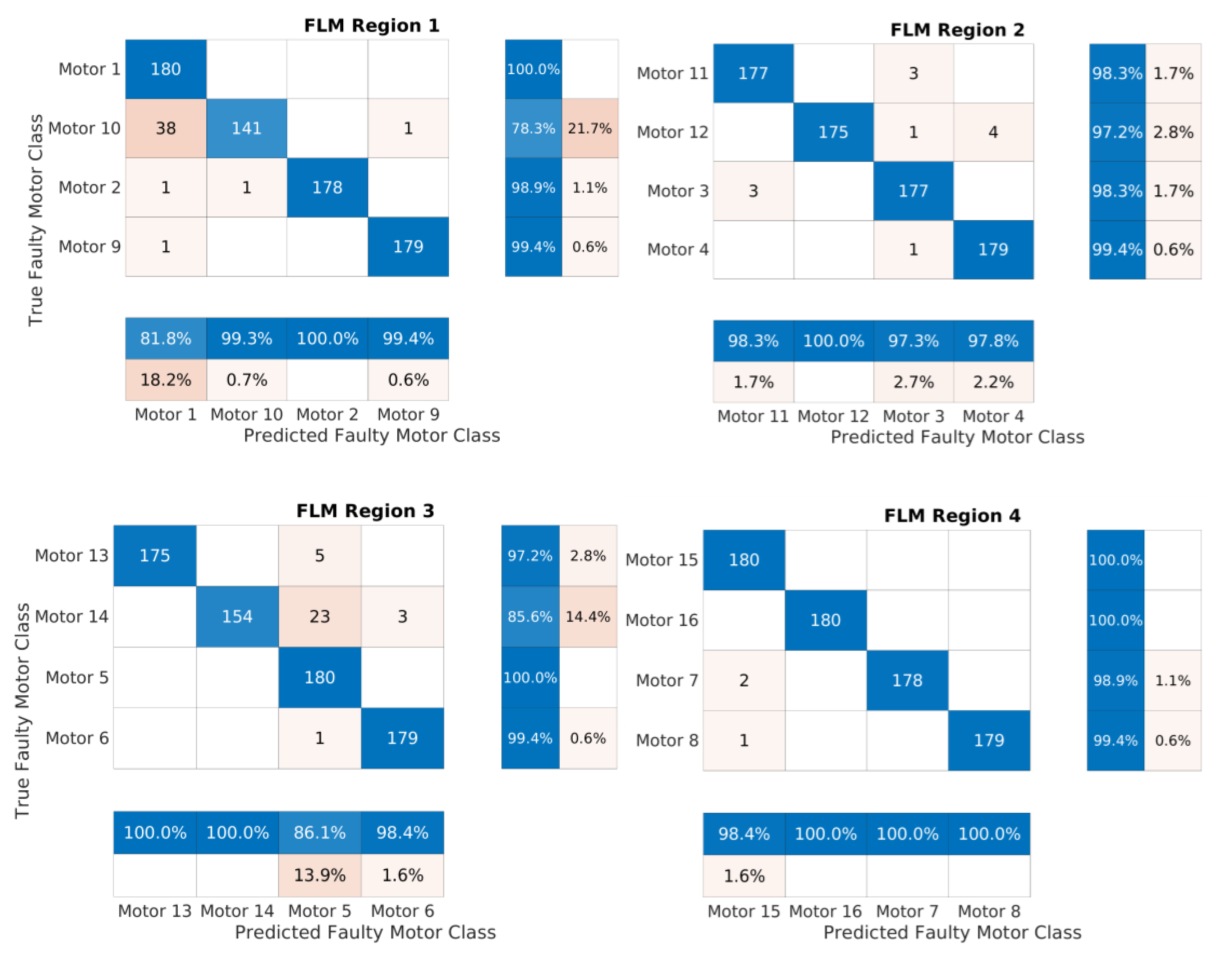

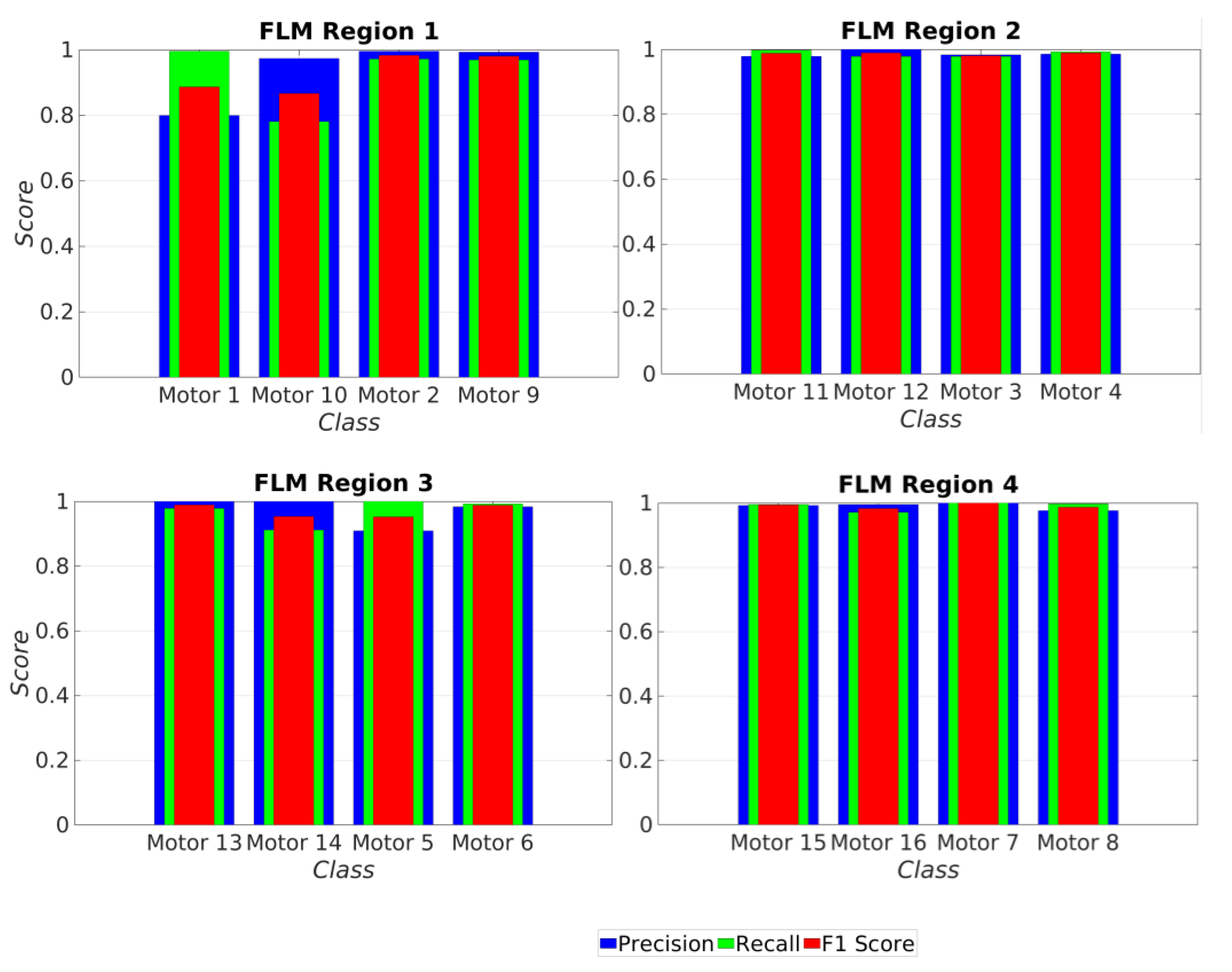

During the training process, impressive accuracy was achieved for each FLM after an average learning time of 368 min. The FLM for region 1 achieved an accuracy of 94.1667%, the FLM for region 2 achieved an accuracy of 98.333%, the FLM for region 3 achieved an accuracy of 95.556%, and the FLM for region 4 achieved an accuracy of 99.107%. Additionally, the loss for each model approached zero, indicating a good convergence during training. In our observation, the reason for identifying these different accuracy rates for each FLM was comes can be attributed to the data preparation process. The results of the training and evaluation process are visualized in the confusion matrix, as shown in

Figure 15. Furthermore, Precision, Recall, and F1 score metrics were employed to assess the performance, as demonstrated in

Figure 16.

A summary of the performance measures, including Accuracy, Precision, Recall, and F1 score, along with the number of correctly classified samples, can be found in

Table 5. These results highlight the effectiveness of the proposed scheme in accurately detecting and locating faulty actuators within the multirotor UAV system.

4.4. Implemetation and Discusion

In this research paper, we employed LSTM-based DNN models to detect and localize actuator faults in highly redundant multirotor UAV systems. The objective was to achieve an accurate fault detection and identification scheme that can be integrated into control system of the UAV to enhance the reliability of the UAV. The trained models exhibited excellent performance in detecting and locating actuator faults within the system. The RCM achieved an impressive accuracy of 98.97%, indicating its effectiveness in identifying the presence of faults in specific regions. Furthermore, the FLM demonstrated even higher accuracy, with an average of 99.107%. This outcome highlights the potential for achieving high accuracy in FLM if appropriate and sufficient training data are provided for the FLM models. Although there may be slight variations in accuracy among the FLM models, overall, the results obtained from the models were highly satisfactory, indicating their effectiveness in fault detection and localization.

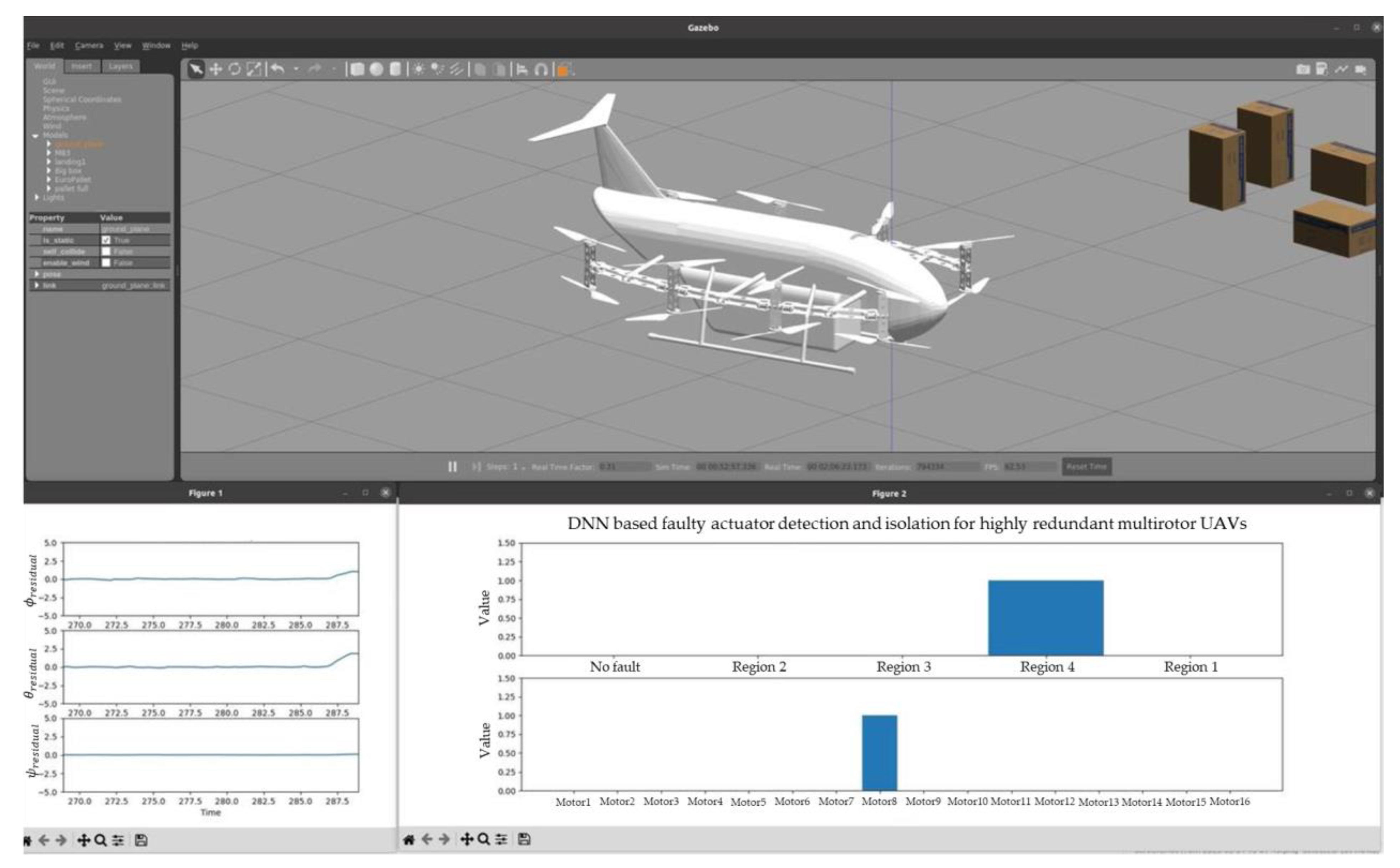

Based on the promising results obtained from the training and evaluation of the proposed scheme, it was integrated into the UAV control system. The integration process involved incorporating the fault detection and localization models into the existing control algorithms and logic. This integration allowed the system to continuously monitor the UAV’s sensor data in real time and identify any potential actuator failures. The implemented scheme was then tested and evaluated using both simulation flights and real flight data logged during actual UAV operations.

In order to evaluate the performance of the proposed scheme in terms of real-time actuator fault detection and isolation for highly redundant multirotor UAVs, a simulation testing process was conducted prior to hardware deployment. This simulation testing allows a comprehensive assessment of the scheme’s functionality and performance. The simulation testing was performed using the Gazebo simulation software, which provides a powerful platform for simulating UAV dynamics and environments. The selected UAV model, along with its structural parameters, was prepared in the Simulation Description Format (SDF) and a STL file for accurate representation. The control process and fault injection were carried out using the PX4 flight controller software, which provided the necessary control algorithms and interfaces required to complete the simulation. A Python code model was developed to interface with the trained models, including a subscriber to the vehicle state, data formatting for input, the inference section for fault detection and localization using the trained models, and a switching logic between the FLMs based on the output of the RCM. The integrated system was then tested in various scenarios, including hovering and mission flight modes, under both normal (no fault) and faulty conditions.

Furthermore, the scheme was also validated using real flight data logged during UAV operations. This validation process involved analyzing the sensor data collected during actual flight missions and comparing the scheme’s detected and localized faults with overall fault injection history. This real-world validation helped us to assess the scheme’s performance and reliability under practical operating conditions. The successful implementation of the proposed scheme using both simulation flight and real flight operation data demonstrates its potential for practical deployment in UAV systems. By effectively detecting and localizing failed actuators, the scheme contributes to enhancing the safety, reliability, and performance of multirotor UAVs during their operational missions.

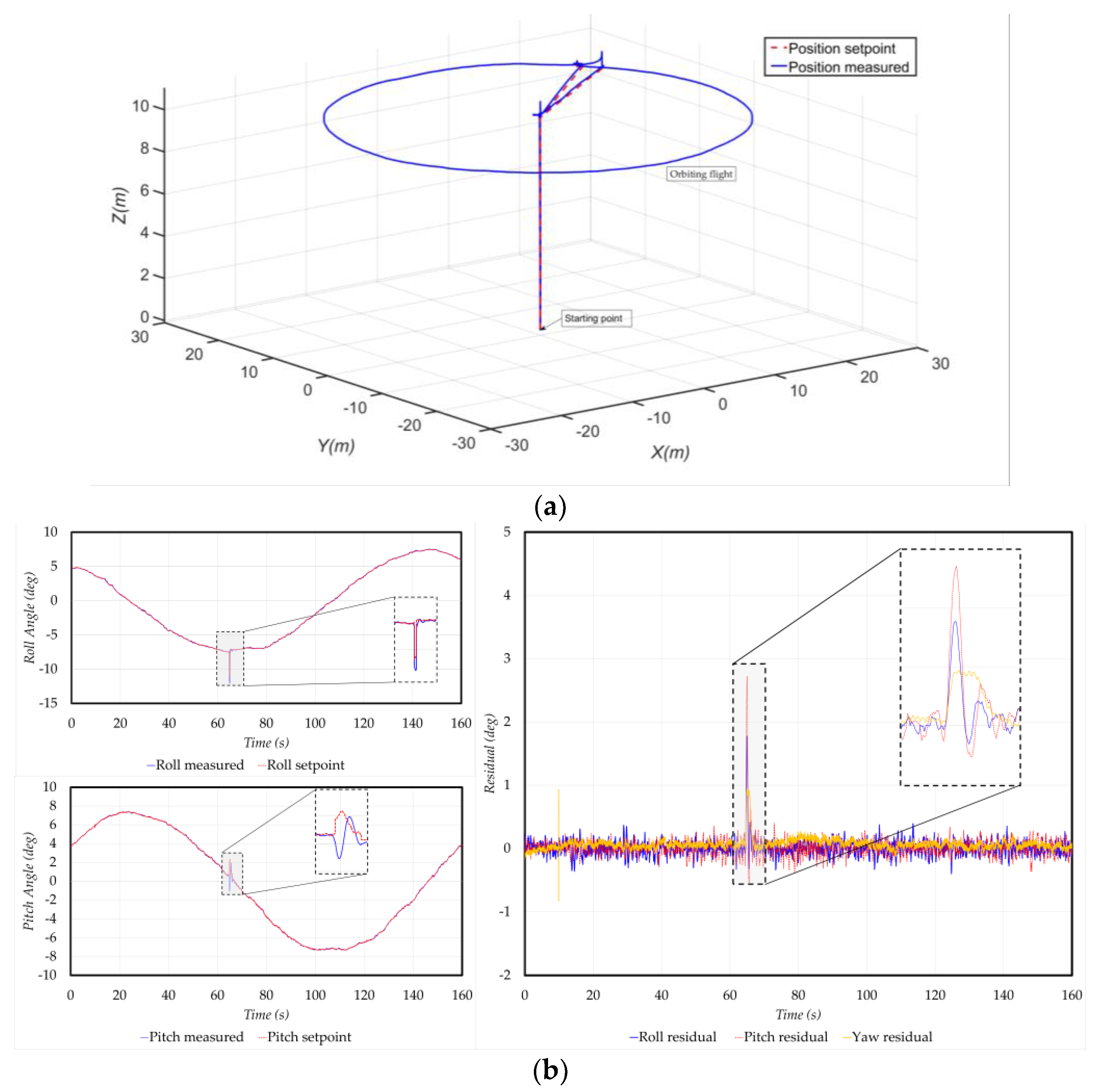

One of the mission flights performed is shown in

Figure 15 and

Figure 16, in which an orbiting flight was given from the ground controller software. The residual of the vehicle’s state, which captured any deviations from the expected behavior, was continuously monitored using the proposed actuator fault identification DNN model. The time series data of residual were passed through a window of 130 timesteps in length for RCM, while for FLM, it was extended to 150 timesteps. The experimental results indicate that the system was operating without any faults from 0 to 63 s, and the proposed scheme correctly outputted “No Fault” during this period. At 63 s, a fault was intentionally injected into motor 8 of the vehicle, causing it to stop functioning. As a result, the residual pattern exhibited a transient change, which is clearly observed in

Figure 17. The proposed scheme successfully identified and categorized the fault by first outputting the “Region 4” flag from the RCM, indicating the region containing the faulty motor. This approach was followed by the FLM outputting the “Motor 8” flag, thus precisely pinpointing the failed motor, as shown in

Figure 17.

These results demonstrate the effectiveness and accuracy of the proposed scheme in detecting and localizing actuator faults in real time during mission flights (

Figure 18). By providing timely and precise fault identification, the scheme enhances the safety and reliability of multirotor UAVs, enabling prompt actions to mitigate the impact of actuator failures and maintain operational integrity.

The experimental showcase video Video S1, which illustrates the integration and real-world implementation of the proposed scheme in the control system of UAVs, is available in the

Supplementary Materials section. The video showcases the practical application of the developed FDI framework, highlighting its effectiveness and performance in detecting and isolating faulty actuators in real-time scenarios. By presenting the integration of the FDI scheme into the UAV’s control system, the video offers visual evidence of its successful implementation and provides additional insight into its practical deployment. The

Supplementary Materials section provides access to the video, enabling readers to observe the scheme in action and gain a deeper understanding of its functionality and potential applications.

5. Conclusions

In conclusion, our work presents a novel DNN–based scheme for effectively detecting and isolating actuator faults in highly redundant multirotor UAVs. The presence of backup in redundant UAVs helps to compensate for unexpected actuator malfunctions. However, identifying and localizing the failed actuator can be challenging. For the FM to optimize compensation, reduce stress on healthy actuators, and minimize power loss, a robust fault detection and locator scheme capable of handling the complexity of redundancy is essential. Our proposed DNN-based scheme addresses these challenges by enhancing the fault tolerance capabilities of multirotor UAVs through improved actuator fault detection and isolation in redundant systems. The scheme focuses on identifying and locating the faulty actuator and facilitating recovery by passing this information to the FM unit. We developed a robust method using a LSTM-based DNN model that utilizes the UAV’s attitude dynamic state for real-time fault detection and classification. We divided the multirotor configuration into four regions based on the vehicle’s attitude dynamics for analysis purposes. The framework consists of two separate models: the RCM and the FLM for each region. The RCM detects fault occurrences and provides high-level identification of the fault source, while the FLM accurately classifies the fault type in the suspected region identified via the RCM. To train the DNN models, we collected time series data containing the attitude dynamics (roll, pitch, and yaw) and their corresponding rates from a developed simulation environment and controlled flight experiments. The data were segmented into windows of length 130 timesteps for RCM and 150 timesteps for each FLM. Through training, we achieved an accuracy of 98.97% for RCM and a maximum accuracy of 99.107% for FLM. The results demonstrate that our models are capable of detecting and locating actuator faults within the system. We presented simulation results for integrating the proposed scheme into the control system, showcasing its effectiveness in monitoring the health of a hexadecarotor redundant multirotor UAV. Overall, the proposed scheme exhibits excellent performance in detecting and locating faulty actuators, irrespective of the configuration’s redundancy level.

The study’s scope is currently restricted to identifying and addressing one actuator failure at a time. In order to enhance performance and make the approach more widely applicable, our future plans involve training the models using larger and higher-quality datasets. These datasets will encompass not only single actuator failures but also combinations of two or more fault types. Moreover, we intend to harness improved computational resources to boost the scheme’s capabilities.